Mechanism Study and Tendency Judgement of Rockburst in Deep-Buried Underground Engineering

Abstract

:1. Introduction

2. Project Overview

2.1. Engineering Background

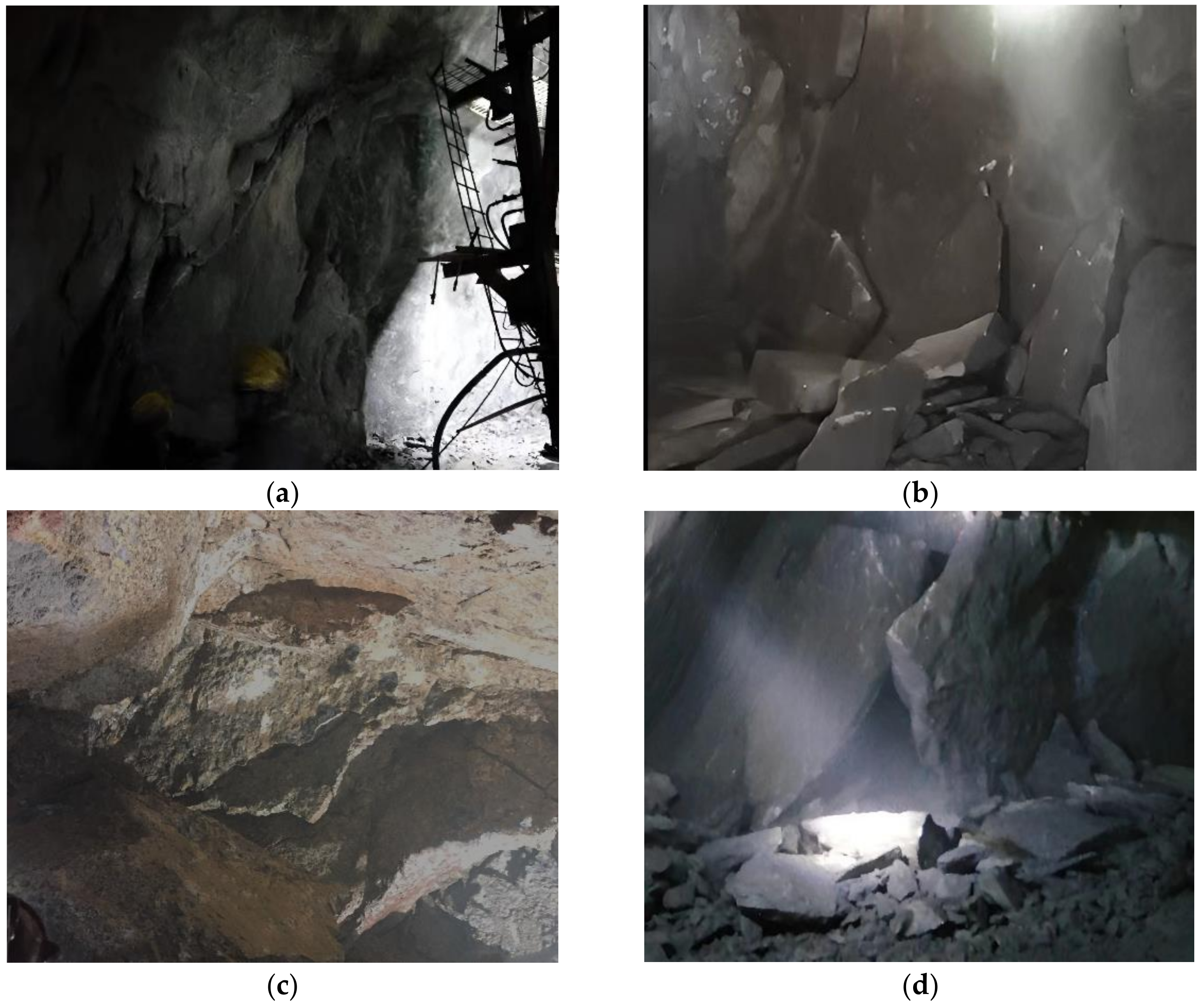

2.2. Rockburst Characteristics

2.3. In Situ Stress Measurement

3. Rock Properties and Rockburst Mechanism

3.1. Experimental Study of In Situ Rocks

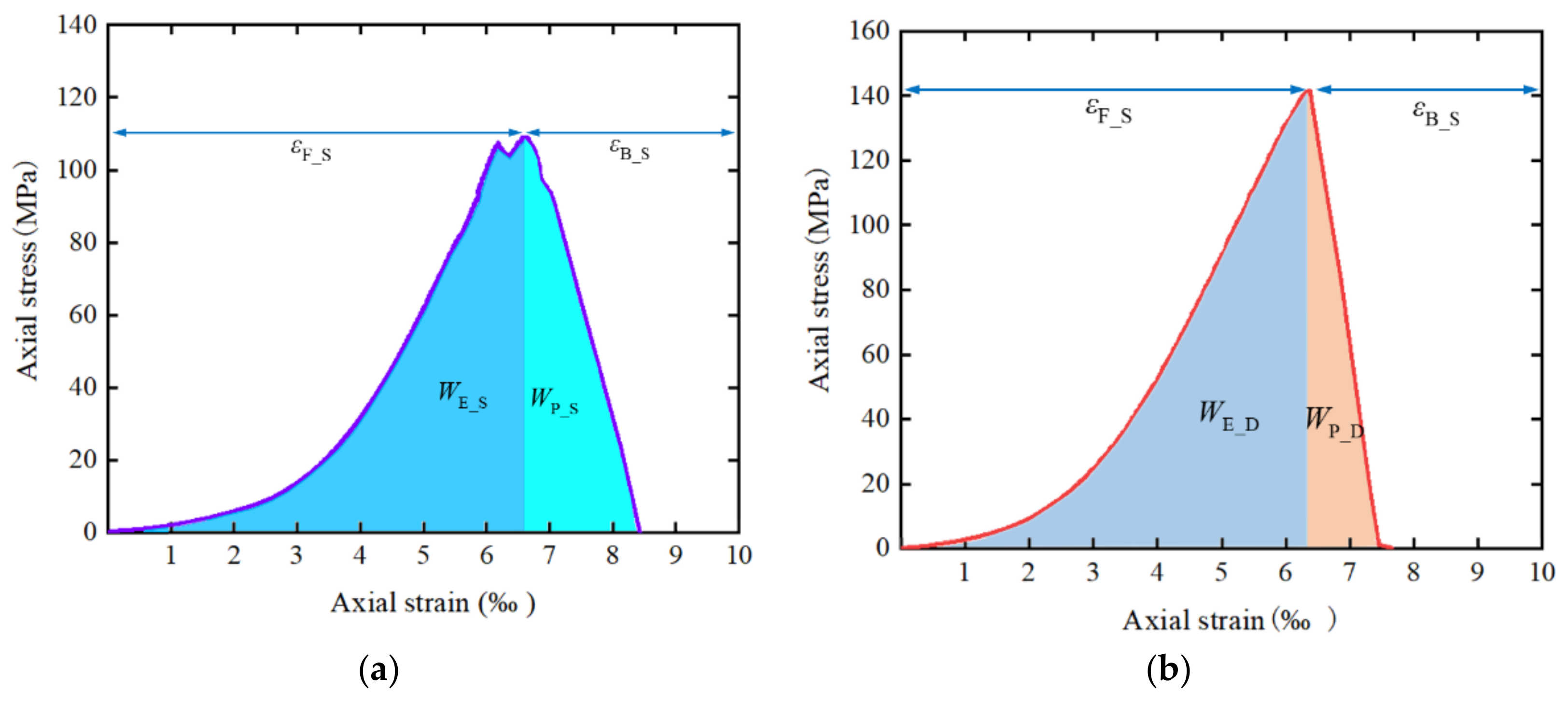

3.1.1. Whole Process Test of Rock Deformation and Failure

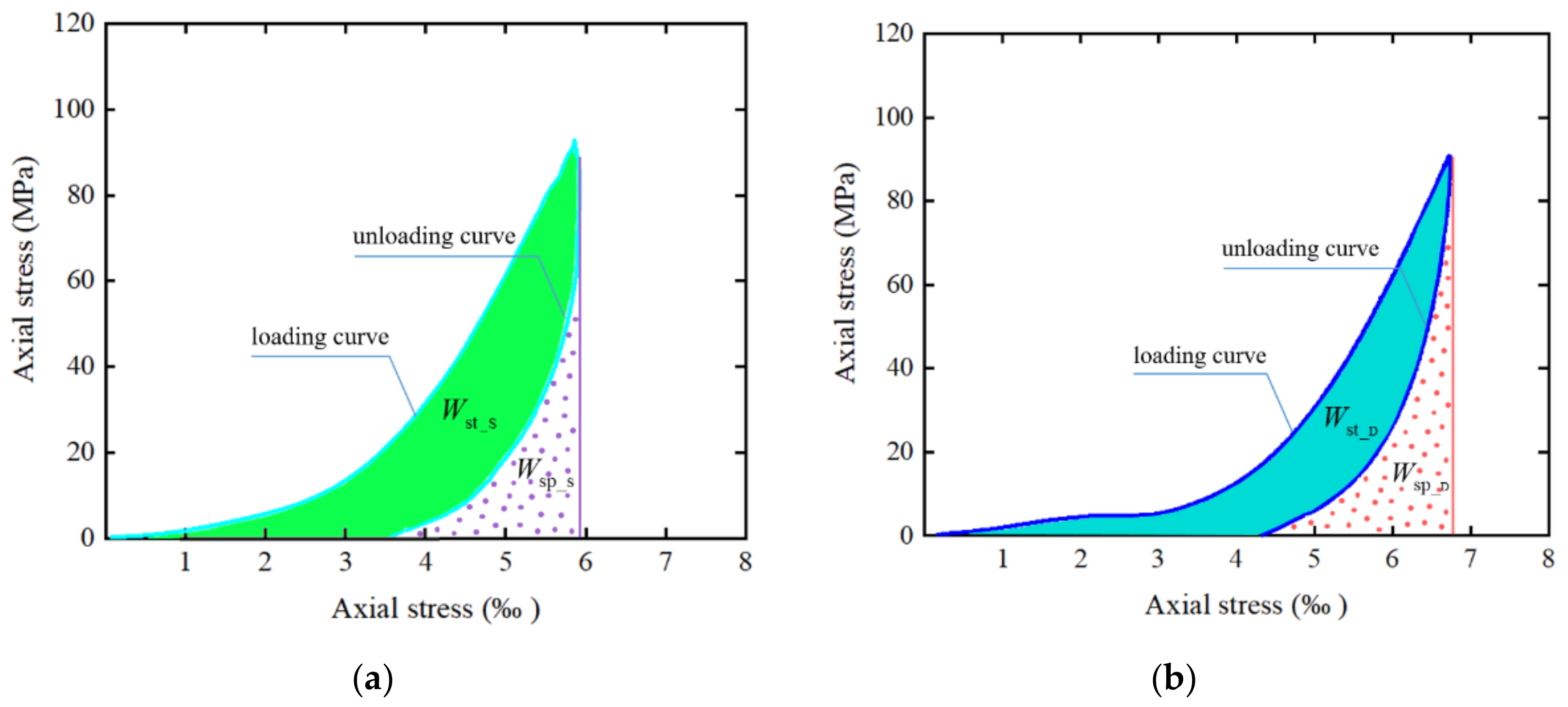

3.1.2. Uniaxial Loading and Unloading Test

3.2. Microscopic Mechanism Analysis of Rockburst

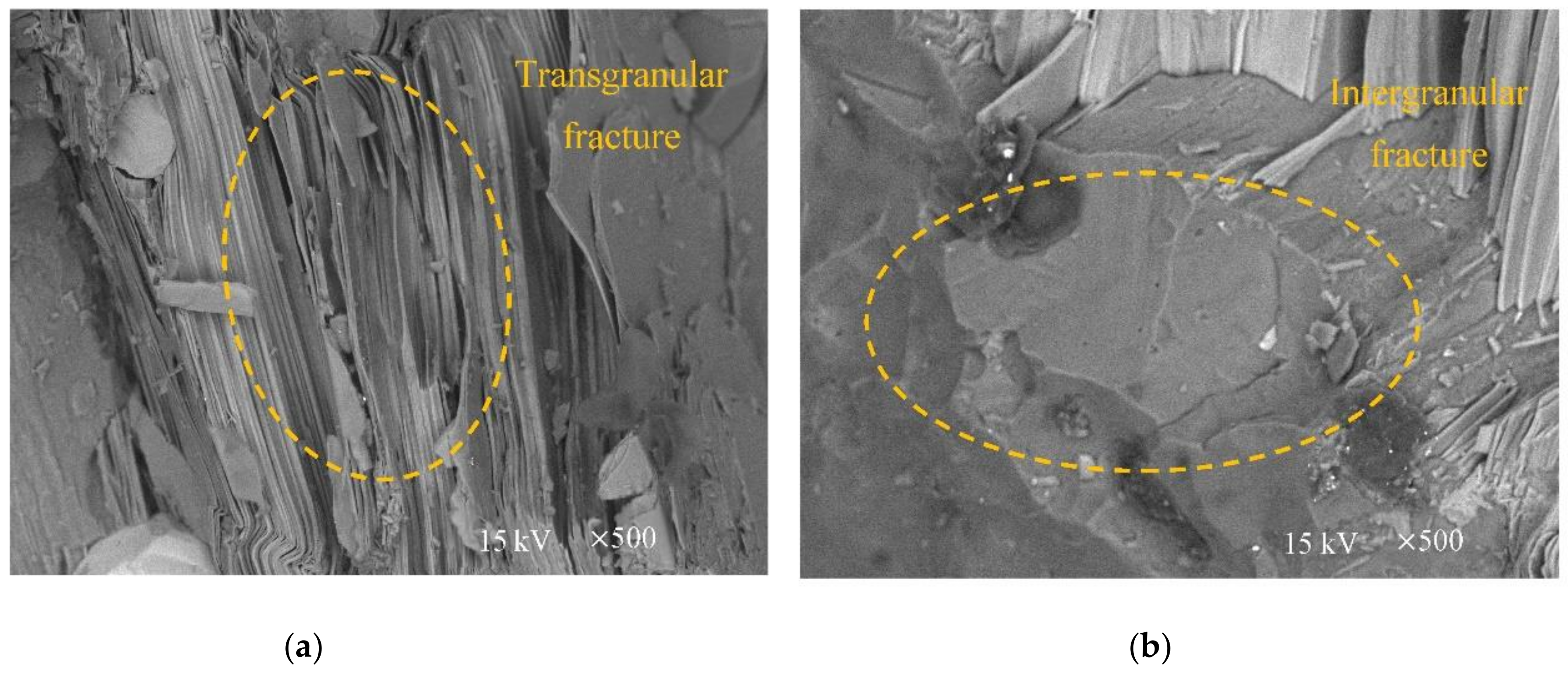

3.2.1. Analysis of Fracture Topography

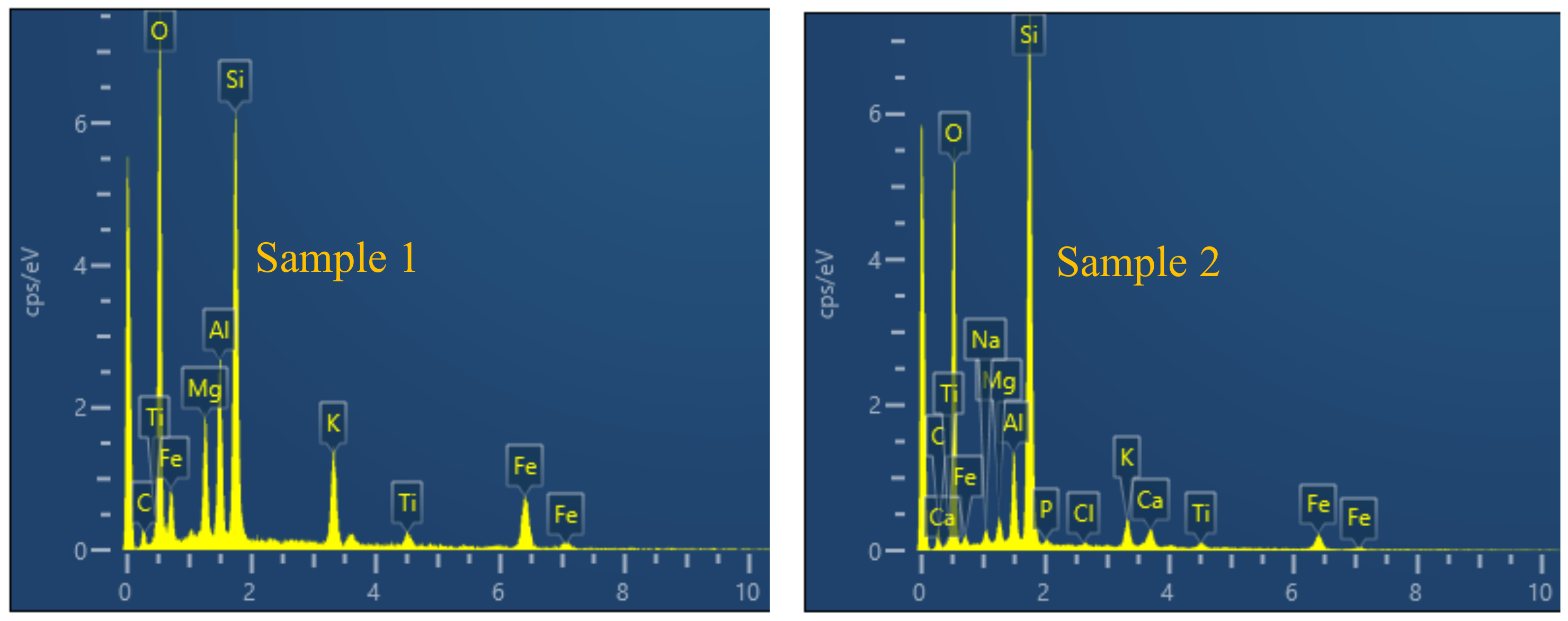

3.2.2. Mechanism Study Based on Microscopic Components

4. Comprehensive Judgment of Rockburst Tendency

4.1. Analysis of Rockburst Tendency

4.2. Prediction of Rockburst Grade

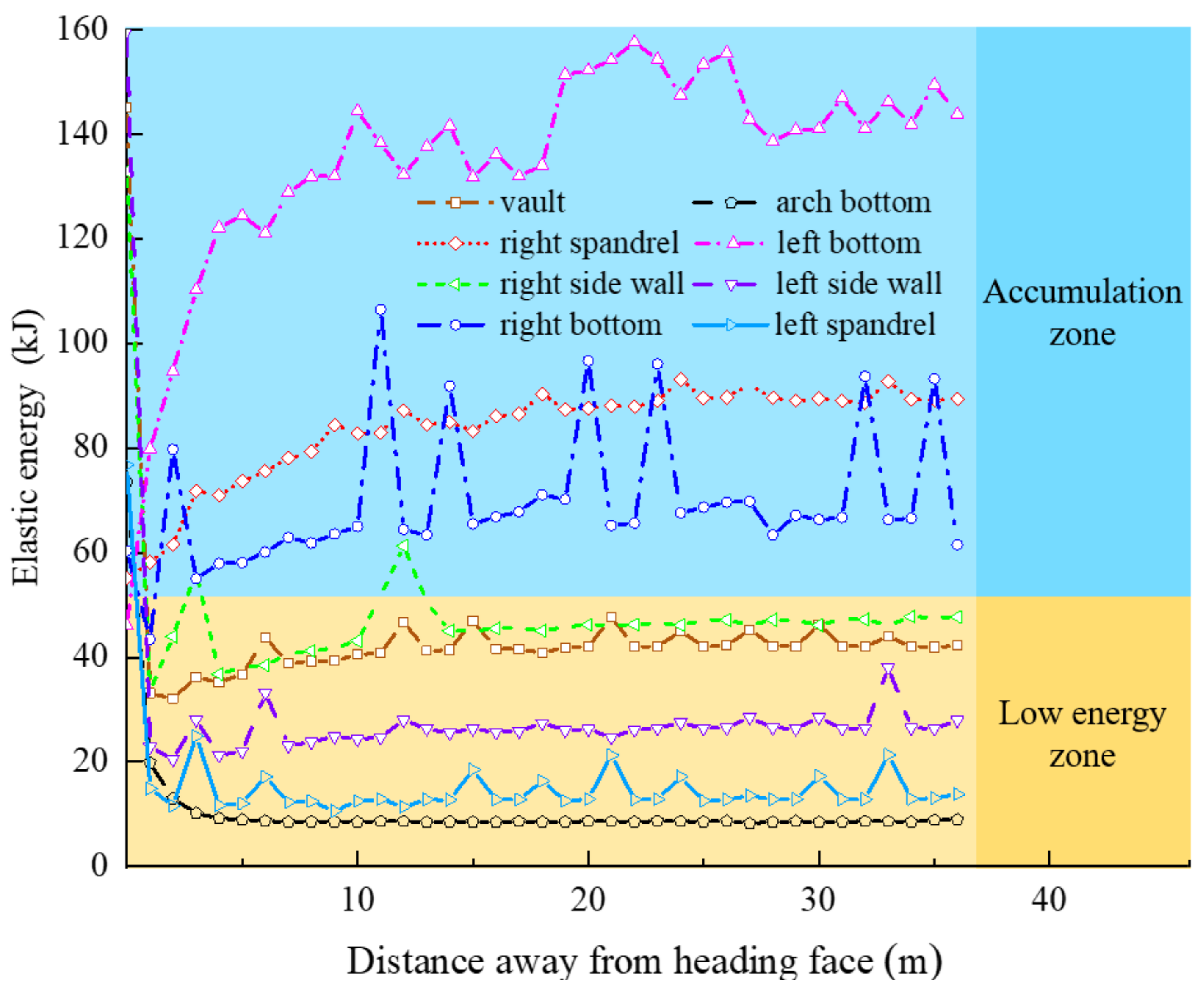

5. Simulation Analysis Based on Energy Accumulation Theory

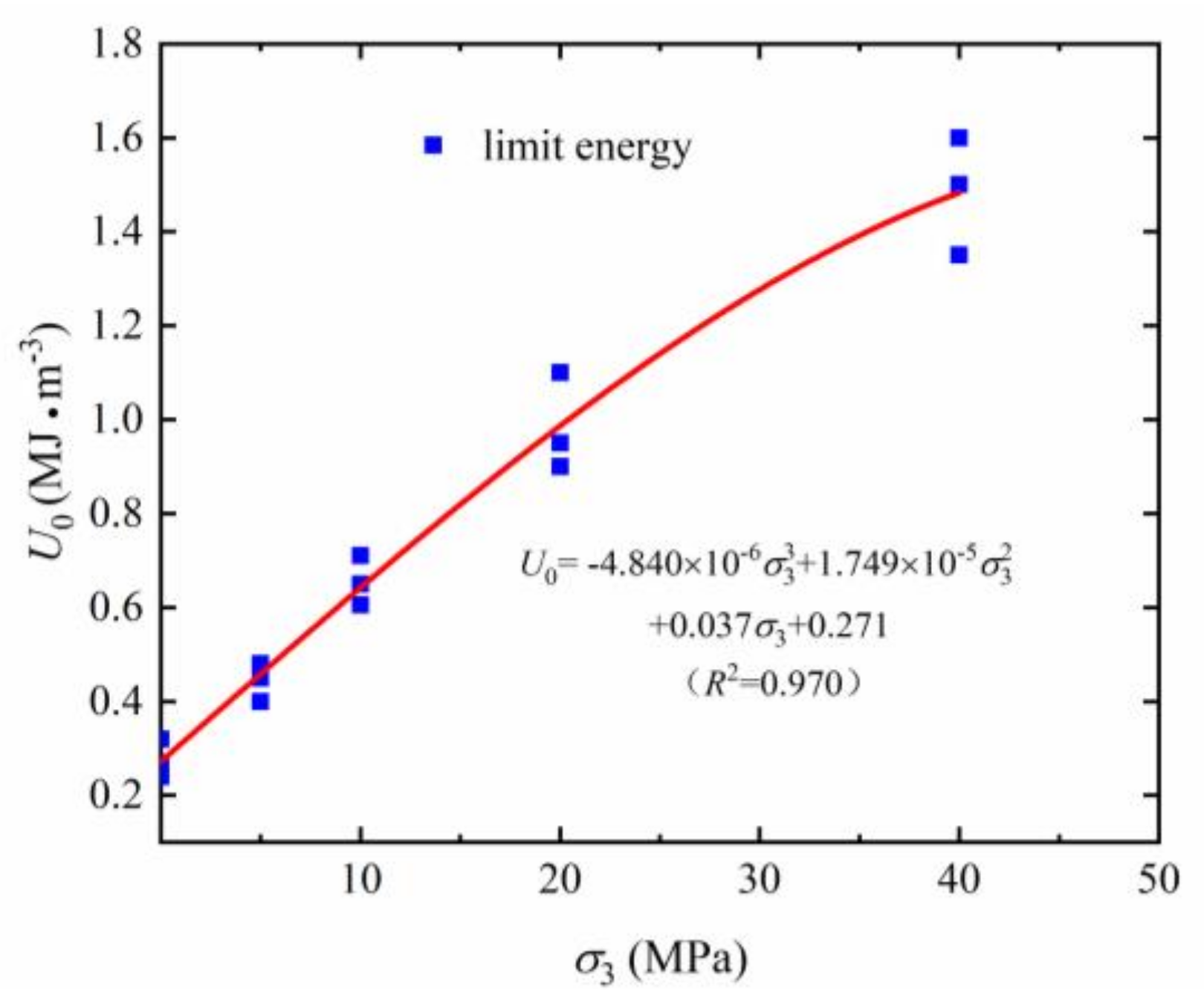

5.1. Rockburst Criterion Based on Limit Energy

5.2. Numerical Simulation Analysis

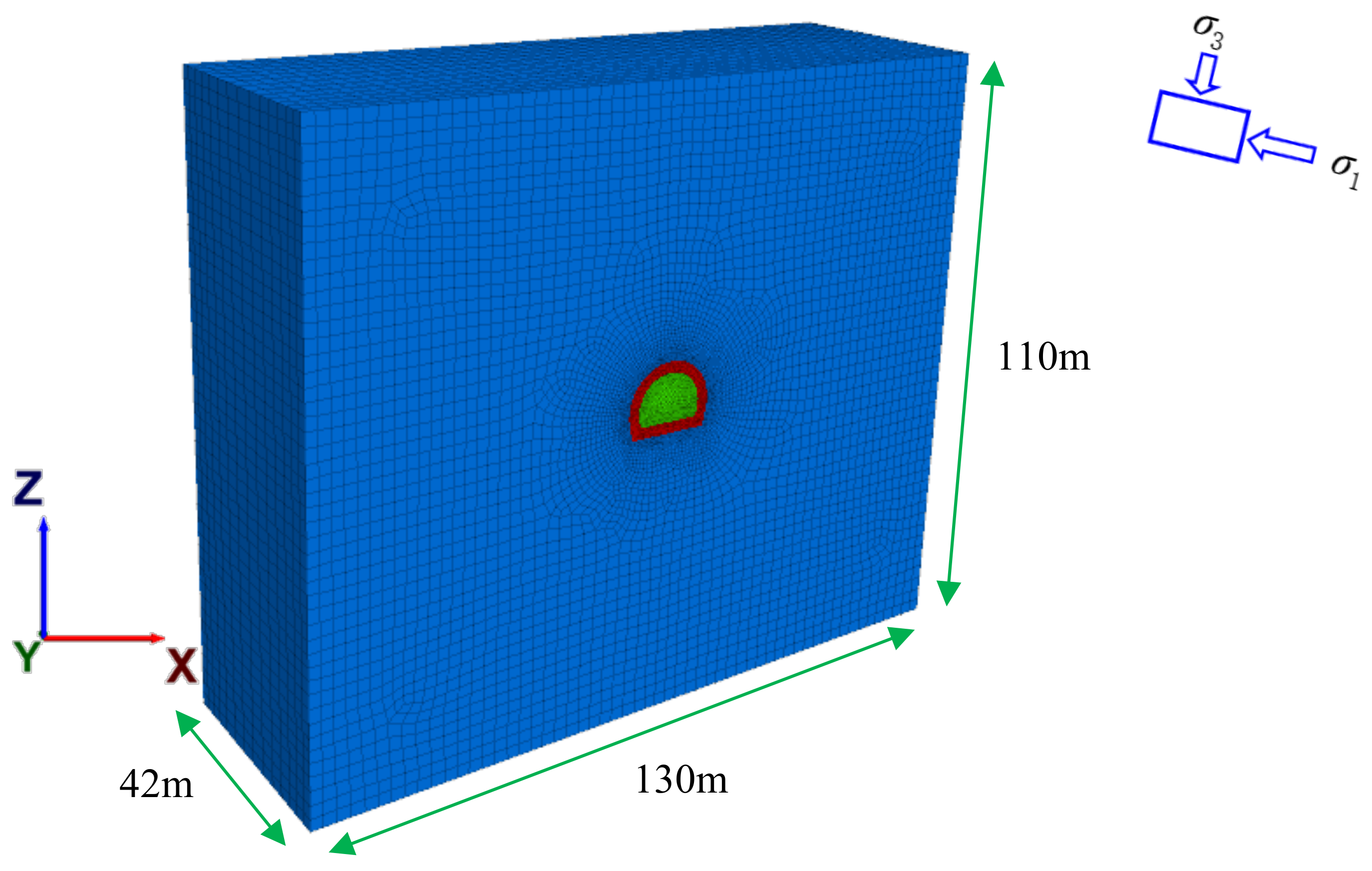

5.2.1. Modeling and Calculation

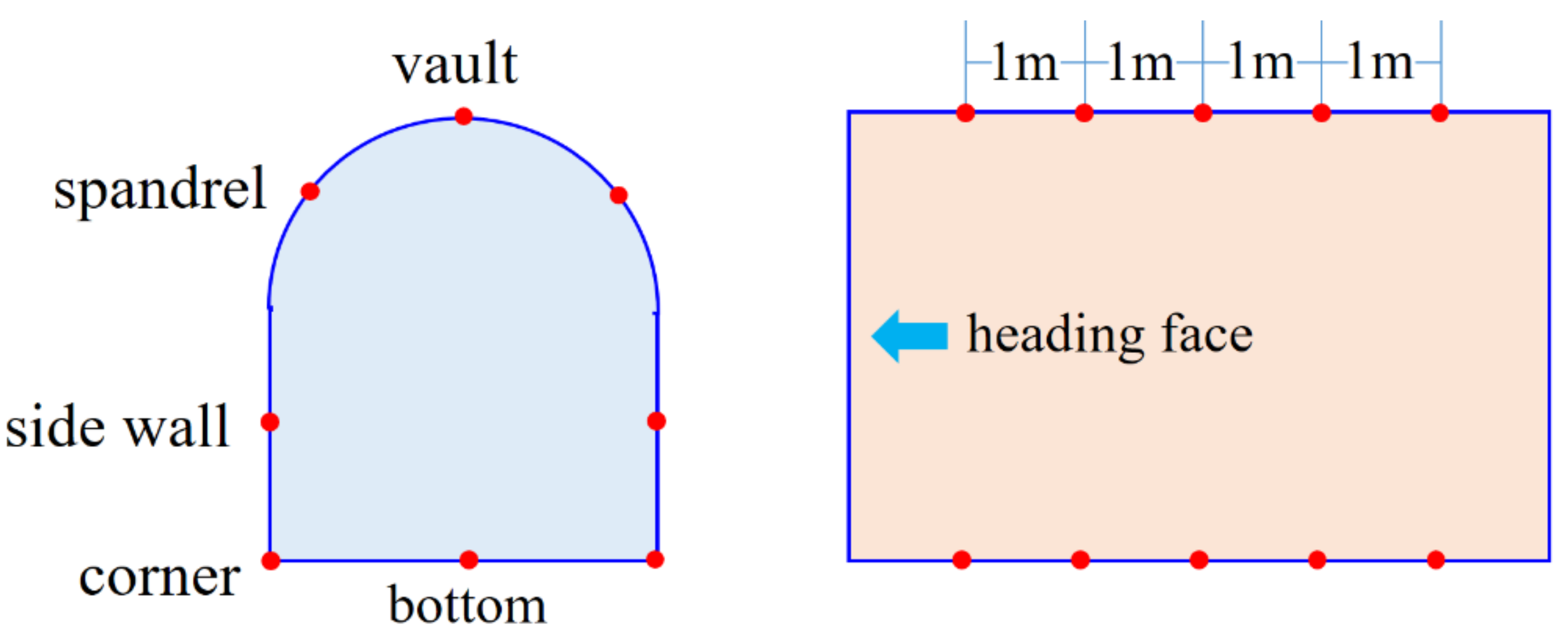

5.2.2. Analysis of Calculation Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, C.; Cao, C.; Liu, Y.; Li, C.; Lu, H. Experimental investigation on synergetic prediction of rockburst using the dominant-frequency entropy of acoustic emission. Nat. Hazards 2021, 108, 3253–3270. [Google Scholar] [CrossRef]

- Du, H.; Song, D.; Chen, Z.; Guo, Z. Experimental study of the influence of structural planes on the mechanical properties of sandstone specimens under cyclic dynamic disturbance. Energy Sci. Eng. 2020, 8, 4043–4063. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, J.; Peng, S.; Yan, F.; Ni, G. Experimental Analysis of the Dynamic Effects of Coal–Gas Outburst and a Protean Contraction and Expansion Flow Model. Nat. Resour. Res. 2010, 29, 1617–1637. [Google Scholar] [CrossRef]

- Du, H.; Song, D. Investigation of failure prediction of open-pit coal mine landslides containing complex geological structures using the inverse velocity method. Nat. Hazards 2022, 111, 2819–2854. [Google Scholar]

- Aki, K. Generation and propagation of G waves from the Niigata Earthquake of June 16, 1964. Part 2. Estimation of earthquake movement, released energy, and stress-strain drop from the G wave spectrum. Bull. Earthq. Res. Inst. 1966, 44, 73–88. [Google Scholar]

- Wang, H.; Li, Z.; Song, D.; He, X.; Aleksei, S.; Majid, K. An Intelligent Rockburst Prediction Model Based on Scorecard Methodology. Minerals 2019, 9, 1294. [Google Scholar] [CrossRef]

- Feng, X.; Xiao, Y.; Feng, G.; Yao, Z.; Chen, B.; Yang, C.; Su, G. Study on the development process of rockbursts. Chin. J. Rock Mech. Eng. 2019, 38, 649–673. [Google Scholar]

- Zhang, C.; Liu, N.; Chu, W.; Ni, S. Inducement mechanism and case analysis of tectonic rockburst in Jinping II deep buried tunnel. Chin. J. Rock Mech. Eng. 2015, 34, 2242–2250. [Google Scholar]

- Han, X.; Liang, X.; Ye, F.; Wang, X.; Chen, Z. Statistics and construction methods for deep TBM tunnels with high geostress: A case study of Qinling Tunnel in Hanjiang-Weihe River Diversion Project. Eng. Fail. Anal. 2022, 138, 106301. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, D.; Wang, Z.; Zhao, D.; Tian, H. Research on the Method and Model for Calculating Impact Load in the Rockburst Tunnel. Minerals 2022, 12, 13. [Google Scholar] [CrossRef]

- He, M.; Xia, H.; Jia, H.; Jia, X.; Gong, W.; Zhao, F.; Liang, K. Studies on classification, criteria and control of rockbursts. J. Rock Mech. Geotech. Eng. 2012, 4, 97–114. [Google Scholar] [CrossRef]

- Miao, S.; Cai, M.; Guo, Q.; Huang, Z. Rockburst prediction based on in-situ stress and energy accumulation theory. Int. J. Rock Mech. Min. Sci. 2016, 83, 86–94. [Google Scholar] [CrossRef]

- Gu, M.; He, F.; Chen, C. Study on Rockburst in Qingling Tunnel. Chin. J. Rock Mech. Eng. 2002, 21, 1324–1329. [Google Scholar]

- Li, T.; Meng, L.; Wang, L. High Geostress Tunnel Stability and Rockburst and Large Deformation Disaster Prevention; Science Press: Beijing, China, 2016. [Google Scholar]

- Shan, Z.; Peng, Y. Management of Rock Bursts during Excavation of the Deep Tunnels in Jinping II Hydropower Station. Bull. Eng. Geol. Environ. 2010, 69, 353–363. [Google Scholar] [CrossRef]

- Xu, L. Research on the experimental rock mechanics of rockburst under unloading condition. J. Chongqing Jiaotong Univ. 2003, 22, 1–4. [Google Scholar]

- Zhao, X.; Wang, J.; Cai, M.; Su, G. Influence of Intermediate Principal Stress on the Strainburst Characteristics of Beishan Granite with Consideration of End Effect. Rock Mech. Rock Eng. 2021, 54, 4771–4791. [Google Scholar] [CrossRef]

- Ma, T.; Tang, C.; Tang, S.; Kuang, L.; Yu, Q.; Kong, D.; Xu, Z. Rockburst mechanism and prediction based on microseismic monitoring. Int. J. Rock Mech. Min. Sci. 2018, 110, 177–188. [Google Scholar] [CrossRef]

- Wang, J.; Chen, G.; Xiao, Y.; Li, S.; Chen, Y.; Qiao, Z. Effect of structural planes on rockburst distribution: Case study of a deep tunnel in Southwest China. Eng. Geol. 2021, 292, 106250. [Google Scholar] [CrossRef]

- Luo, Z.; Li, J.; Tang, S.; Li, S.; Zhang, L. Numerical Studies on Rockbursts in Tunnels with High In Situ Stresses and Geothermally Rich Areas. Appl. Sci. 2022, 12, 5108. [Google Scholar] [CrossRef]

- Akdag, S.; Karakus, M.; Taheri, A.; Nguyen, G.; He, M. Effects of Thermal Damage on Strain Burst Mechanism for Brittle Rocks Under True-Triaxial Loading Conditions. Rock Mech. Rock Eng. 2018, 51, 1657–1682. [Google Scholar] [CrossRef]

- Li, T.; Pan, H.; Chen, G.; Meng, L. Physical model tests on thermo-mechanical effects in rockbursts around tunnels. Chin. J. Rock Mech. Eng. 2018, 37, 261–273. [Google Scholar]

- He, M.; Miao, J.; Feng, J. Rock burst process of limestone and its acoustic emission characteristics under true-triaxial unloading conditions. Int. J. Rock Mech. Min. Sci. 2010, 47, 286–298. [Google Scholar] [CrossRef]

- Wang, M.; Zhu, Z.; Liu, J. The photoelastic analysis of stress intensity factor for cracks around a tunnel. Appl. Mech. Mater. 2012, 142, 197–200. [Google Scholar] [CrossRef]

- Li, N.; Feng, X.; Jimenez, R. Predicting rock burst hazard with incomplete data using Bayesian networks. Tunn. Undergr. Space Technol. 2017, 61, 61–70. [Google Scholar] [CrossRef]

- Xue, Y.; Bai, C.; Kong, F.; Qiu, D.; Li, L.; Su, M.; Zhao, Y. A two-step comprehensive evaluation model for rockburst prediction based on multiple empirical criteria. Eng. Geol. 2020, 268, 105515. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Mitri, H.S. Evaluation Method of Rockburst: State-of-the-art Literature Review. Tunn. Undergr. Space Technol. 2018, 81, 632–659. [Google Scholar] [CrossRef]

- Qu, H.; Zhang, X.; Zhang, Y.; Chen, S.; Wu, K. Rock Burst in Deep-buried Tunnel Based on Tendency Index. Chin. J. Underg. Space Eng. 2021, 17, 949–955. [Google Scholar]

- Wu, W.; Xie, X.; Hu, Y.; Chen, J.; Ou, Y. Rock burst proneness in Zhazixi Antimony Mine. Min. Metall. Eng. 2017, 37, 21–24. [Google Scholar]

- Zhang, C.; Yu, J.; Chen, J.; Lu, J.; Zhou, H. Evaluation method for poten-tial rockburst in underground engineering. Rock Soil Mech. 2016, 37, 341–349. [Google Scholar] [CrossRef]

- Guo, B.; Dong, W.; Bo, G.; Si, J. Modifying rock burst criteria based on observations in a di-vision tunnel. Eng. Geol. 2017, 216, 153–160. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, Q.; Li, J. Application of fuzzy probability model to prediction of rockburst intensity. Chin. J. Rock Mech. Eng. 2008, 27, 3095–3103. [Google Scholar]

- Yu, H.; Liu, H.; Lu, X.; Liu, H. Prediction method of rockburst proneness based on rough set and genetic algorithm. J. Coal Sci. Eng. 2009, 15, 367–373. [Google Scholar] [CrossRef]

- Wang, Y.; Shang, Y.; Sun, H.; Yan, X. Study of prediction of rockburst intensity based on efficacy coefficient method. Rock Soil Mech. 2010, 31, 529–534. [Google Scholar]

- Li, N.; Jimenez, R. A logistic regression classifier for long-term probabilistic prediction of rock burst hazard. Nat. Hazards 2018, 90, 197–215. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Mitri, H.S. Classification of rockburst in underground projects: Comparison of ten supervised learning methods. J. Comput. Civil Eng. 2016, 30, 04016003. [Google Scholar] [CrossRef]

- Zhou, K.; Lin, Y.; Deng, H.; Li, J.; Liu, C. Prediction of rock burst classification using cloud model with entropy weight. Trans. Nonferrous Met. Soc. China 2016, 26, 1995–2002. [Google Scholar] [CrossRef]

- Wang, J.; Apel, D.B.; Pu, Y.; Hall, R.; Wei, C.; Sepehri, M. Numerical modeling for rockbursts: A state-of-the-art review. J. Rock Mech. Geotech. Eng. 2021, 13, 457–478. [Google Scholar] [CrossRef]

- Hatzor, Y.H.; He, B.; Feng, X. Scaling rockburst hazard using the DDA and GSI methods. Tunn. Undergr. Space Technol. 2017, 70, 343–362. [Google Scholar] [CrossRef]

- Chen, G.; He, M.; Fan, F. Rock burst analysis using DDA numerical simulation. Int. J. Geomech. 2018, 18, 04018001. [Google Scholar] [CrossRef]

- Li, X.; Lan, Y.; Zou, J. A study of rock fractures. J. China U. Min. Technol. 1983, 1, 15–21. [Google Scholar]

- Liu, X.; Lee, C.F. Microfailure mechanism analysis and test study for rock failure surface. Chin. J. Rock Mech. Rock Eng. 1997, 16, 509–513. [Google Scholar]

- Cai, M.; Wang, J.; Wang, S. Analysison energy distribution and prediction of rock burst during deep mining excavation in Linglong Gold Mine. Chin. J. Rock Mech. Rock Eng. 2001, 20, 38–42. [Google Scholar]

- Kidybinski, A. Bursting liability indices of coal. Int. J. Rock Mech. Min. Sci. 1981, 18, 295–304. [Google Scholar] [CrossRef]

- Tang, L.; Wang, W. New rock burst proneness index. Chin. J. Rock Mech. Rock Eng. 2002, 21, 874–878. [Google Scholar]

- Wu, S.; Li, L.; Zhang, X. Rock Mechanics; Higher Education Press: Beijing, China, 2021. [Google Scholar]

- Russenes, B.F. Analyses of Rockburst in Tunnels in Valley Sides (in Norwegian). Ph.D. Thesis, Norwegian Institute of Technology, Trondheim, Norway, 1974. [Google Scholar]

- Barton, N.; Lien, R.; Lunde, J. Engineering classification of rock masses for the design of tunnel support. Rock Mech. 1974, 6, 189–236. [Google Scholar] [CrossRef]

- Solecki, R.; Conant, R.J. Advanced Mechanics of Materials; Oxford University Press: London, UK, 2003. [Google Scholar]

- Chen, W.; Lu, S.; Guo, X.; Qiao, C. Research on unloading confining pressure tests and rockburst criterion based on energy theory. Chin. J. Rock Mech. Eng. 2009, 28, 1530–1540. [Google Scholar]

- Xie, H.; Ju, Y.; LI, L. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles. Chin. J. Rock Mech. Eng. 2005, 24, 3003–3010. [Google Scholar]

| Stress Factors | The Maximal Principal Stress | The Intermediate Principal Stress | The Minimum Principal Stress |

|---|---|---|---|

| Value/MPa | 38.27 | 24.94 | 23.11 |

| Direction | −36.82 | −19.34 | 54.94 |

| Inclination/° | −18 | 71 | −5 |

| Type of Test | Specimen Source | Serial Numble | Specimen Source | Serial Numble |

|---|---|---|---|---|

| Compression test | Entrance section | WLFUS-01-1 | Deep buried section | WLF-UD-02-1 |

| WLF-US-01-2 | WLF-UD-02-2 | |||

| WLF-US-01-3 | WLF-UD-02-3 | |||

| Loading and unloading test | Entrance section | WLF-LS-03-1 | Deep buried section | WLF-LD-04-1 |

| WLF-LS-03-2 | WLF-LD-04-2 | |||

| Brazilian test | Entrance section | WLF-BS-05-1 | Deep buried section | WLF-BD-06-1 |

| WLF-BS-05-2 | WLF-BD-06-2 | |||

| WLF-BS-05-3 | WLF-BD-06-3 |

| Sample Source | Serial Number | Uniaxial Compression Strength (UCS)/MPa | Elasticity Modulus/GPa | Poisson’s Ratio | Failure Mode |

|---|---|---|---|---|---|

| Entrance section | WLF-US-01-1 | 124.38 | 33.12 | 0.21 | tensile |

| WLF-US-01-2 | 92.23 | 26.67 | 0.17 | tensile | |

| WLF-US-01-3 | 102.17 | 29.85 | 0.20 | tensile/shear | |

| mean value | 106.26 | 29.89 | 0.19 | ||

| Deep buried section | WLF-UD-02-1 | 131.74 | 32.55 | 0.21 | tensile |

| WLF-UD-02-2 | 144.62 | 35.36 | 0.23 | tensile | |

| WLF-UD-02-3 | 126.42 | 37.42 | 0.23 | tensile | |

| mean value | 134.26 | 35.11 | 0.22 |

| Chemical Element | Percentage by Weight | Wt/% (Variance) | Atomic Percentage |

|---|---|---|---|

| Fe | 12.29 | 0.42 | 4.57 |

| O | 55.99 | 0.55 | 72.73 |

| Al | 6.13 | 0.19 | 4.72 |

| Si | 14.42 | 0.27 | 10.67 |

| K | 5.28 | 0.17 | 2.80 |

| Mg | 4.61 | 0.18 | 3.94 |

| Ti | 1.30 | 0.15 | 0.56 |

| Chemical Element | Percentage by Weight | Wt/% (Variance) | Atomic Percentage |

|---|---|---|---|

| Fe | 4.74 | 0.21 | 1.67 |

| O | 60.67 | 0.34 | 74.70 |

| Al | 3.93 | 0.10 | 2.87 |

| Si | 23.47 | 0.23 | 16.46 |

| Mg | 1.20 | 0.07 | 0.97 |

| K | 2.18 | 0.08 | 1.10 |

| Ca | 1.62 | 0.08 | 0.80 |

| Na | 0.97 | 0.09 | 0.83 |

| Ti | 0.72 | 0.08 | 0.30 |

| P | 0.31 | 0.05 | 0.20 |

| Cl | 0.19 | 0.04 | 0.10 |

| Sample Source | Serial Number | Analysis of Rockburst Tendency | Prediction of Rockburst Grade | ||||

|---|---|---|---|---|---|---|---|

| Linear Elastic Energy | Energy Impact Index | Energy Storage and Consumption Index | Brittleness Coefficient | Russense Criterion | Barton Criterion | ||

| Entrance section | US-01-1 | heavy | heavy | moderate | moderate | no | no |

| US-01-2 | moderate | heavy | moderate | heavy | no | no | |

| US-01-3 | moderate | no | moderate | moderate | no | no | |

| Deep buried section | UD-02-1 | heavy | heavy | moderate | heavy | heavy | weak |

| UD-02-2 | heavy | heavy | moderate | moderate | heavy | weak | |

| UD-02-3 | heavy | moderate | moderate | heavy | heavy | moderate | |

| Density g/m3 | Bulk Modulus/GPa | Shear Modulus/GPa | Cohesion/MPa | Friction/° | Principal Stress/MPa |

|---|---|---|---|---|---|

| 2.71 | 21.6 | 14.2 | 15 | 48 | 34-25-19 |

| Position | Judgement Level | ||

|---|---|---|---|

| Vault | 0.11 | 0.41 | medium rockburst |

| Right spandrel | 0.14 | 0.52 | heavy rockburst |

| Right side wall | 0.11 | 0.43 | medium rockburst |

| Right arch bottom | 0.12 | 0.47 | medium rockburst |

| arch bottom | 0.04 | 0.14 | no rockburst |

| Left arch bottom | 0.17 | 0.65 | heavy rockburst |

| Left Side wall | 0.08 | 0.33 | weak rockburst |

| Left spandrel | 0.07 | 0.25 | no rockburst |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Gao, Y.; Chen, F.; Cao, Z. Mechanism Study and Tendency Judgement of Rockburst in Deep-Buried Underground Engineering. Minerals 2022, 12, 1241. https://doi.org/10.3390/min12101241

Liu J, Gao Y, Chen F, Cao Z. Mechanism Study and Tendency Judgement of Rockburst in Deep-Buried Underground Engineering. Minerals. 2022; 12(10):1241. https://doi.org/10.3390/min12101241

Chicago/Turabian StyleLiu, Jiazhu, Yongtao Gao, Fan Chen, and Zhensheng Cao. 2022. "Mechanism Study and Tendency Judgement of Rockburst in Deep-Buried Underground Engineering" Minerals 12, no. 10: 1241. https://doi.org/10.3390/min12101241

APA StyleLiu, J., Gao, Y., Chen, F., & Cao, Z. (2022). Mechanism Study and Tendency Judgement of Rockburst in Deep-Buried Underground Engineering. Minerals, 12(10), 1241. https://doi.org/10.3390/min12101241