Towards the Biobeneficiation of PGMs: Reviewing the Opportunities

Abstract

:1. Introduction

2. Chemical and Mineralogical Composition of PGMs and Their Mineral Associations

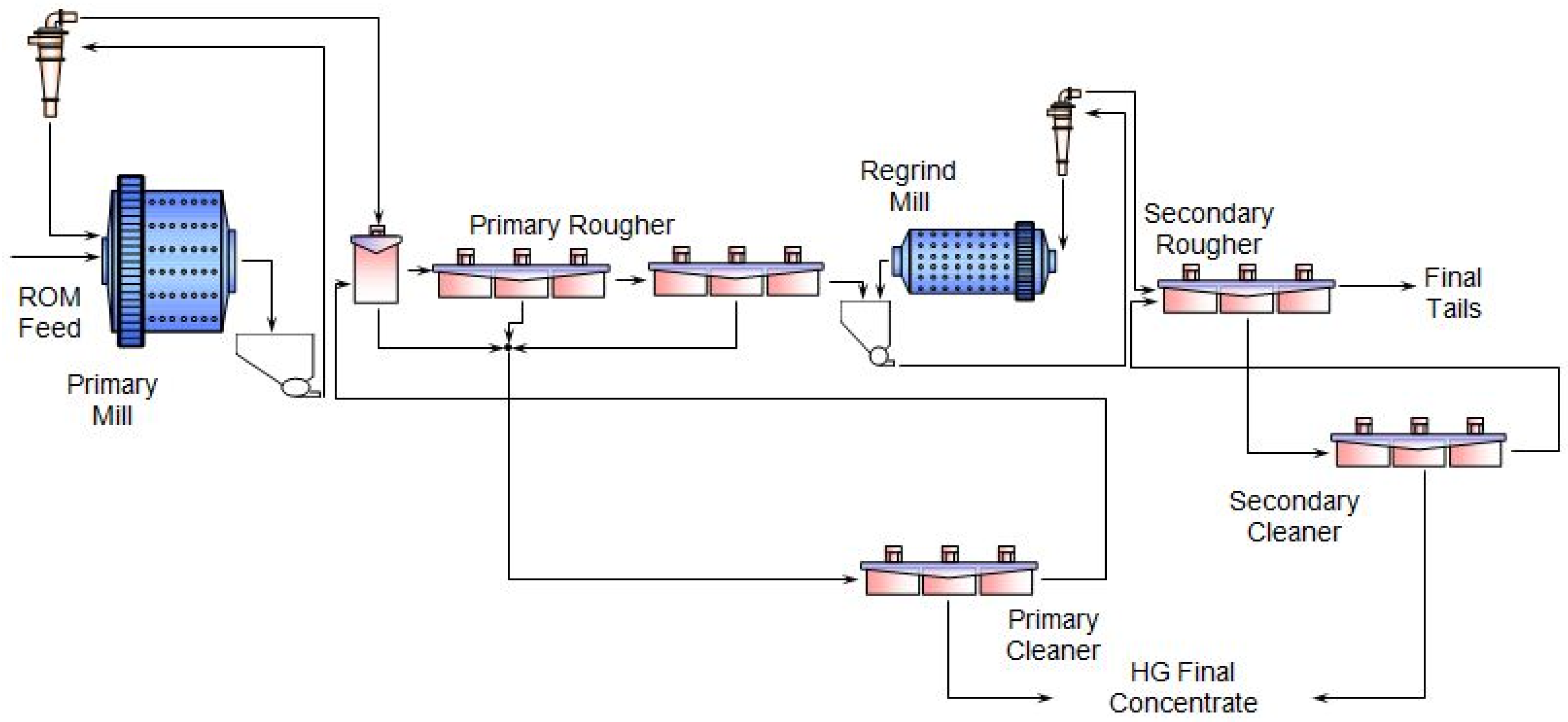

3. Typical Beneficiation Process of PGMs

4. Biobeneficiation of Base Metal Sulphides Associated with PGMs

4.1. Bacillus polymyxa

4.2. Paenibacillus polymyxa

4.3. Mycobacterium phlei

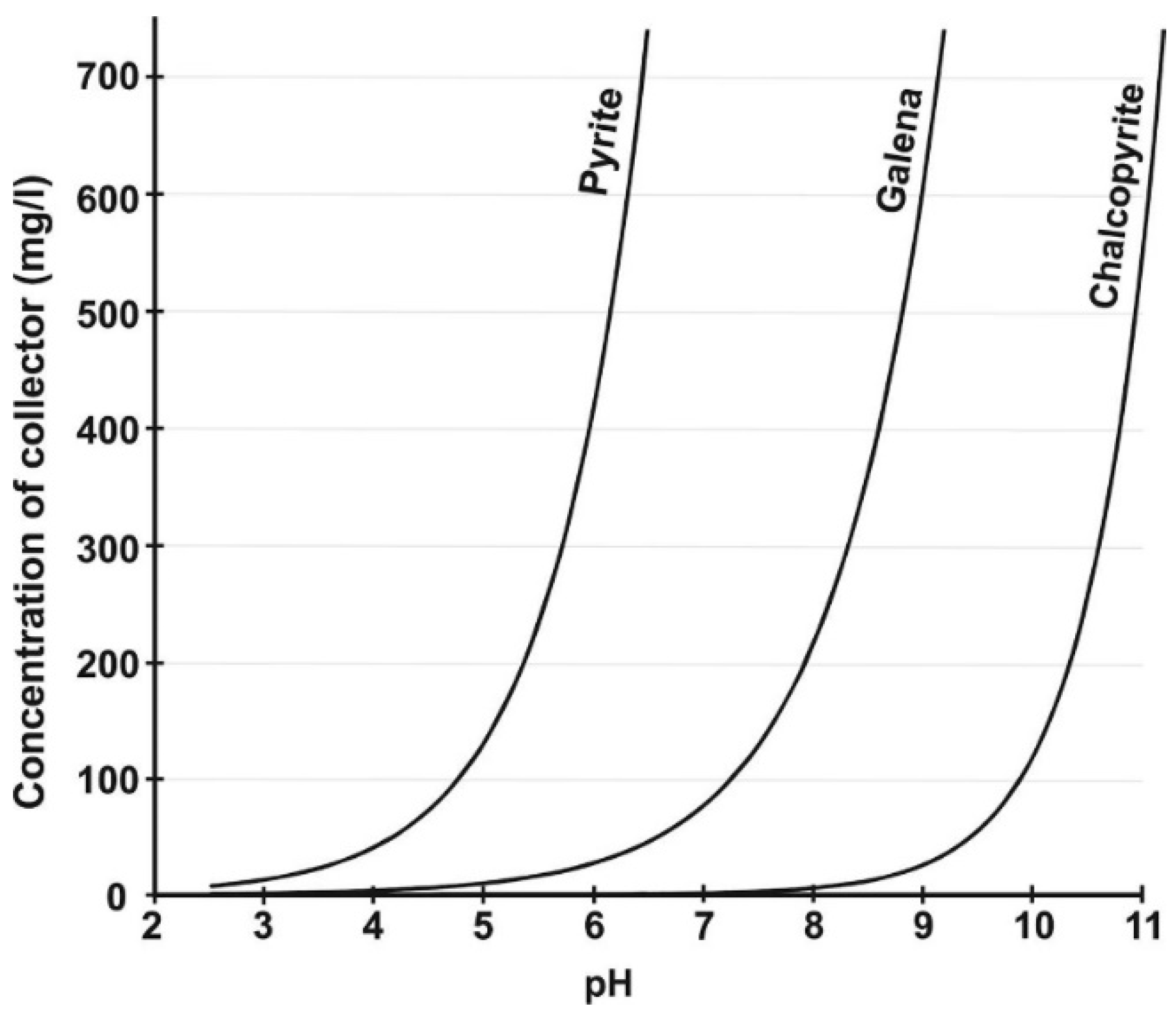

4.4. Acidithiobacillus ferrooxidans

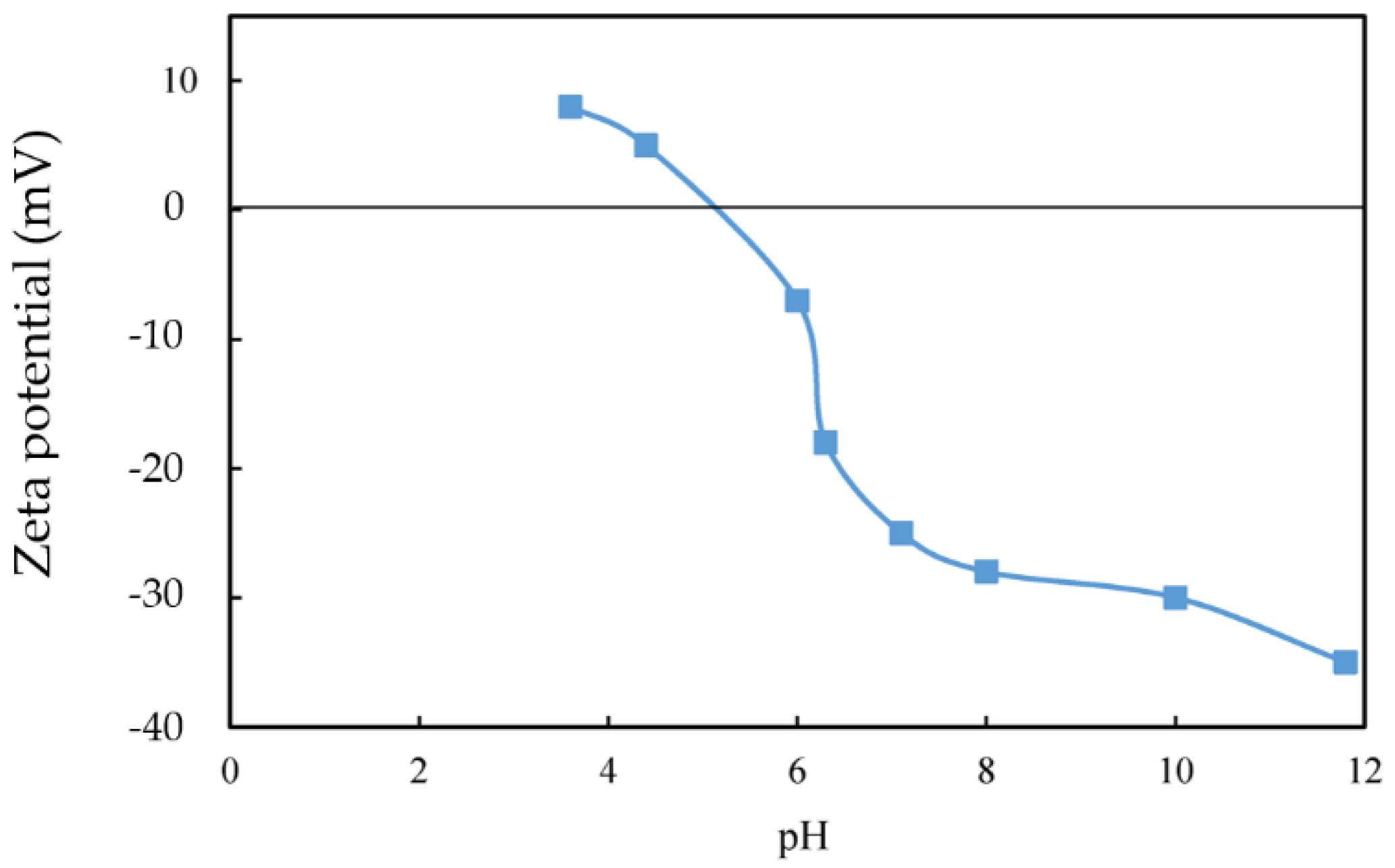

4.5. Acidithiobacillus thiooxidans

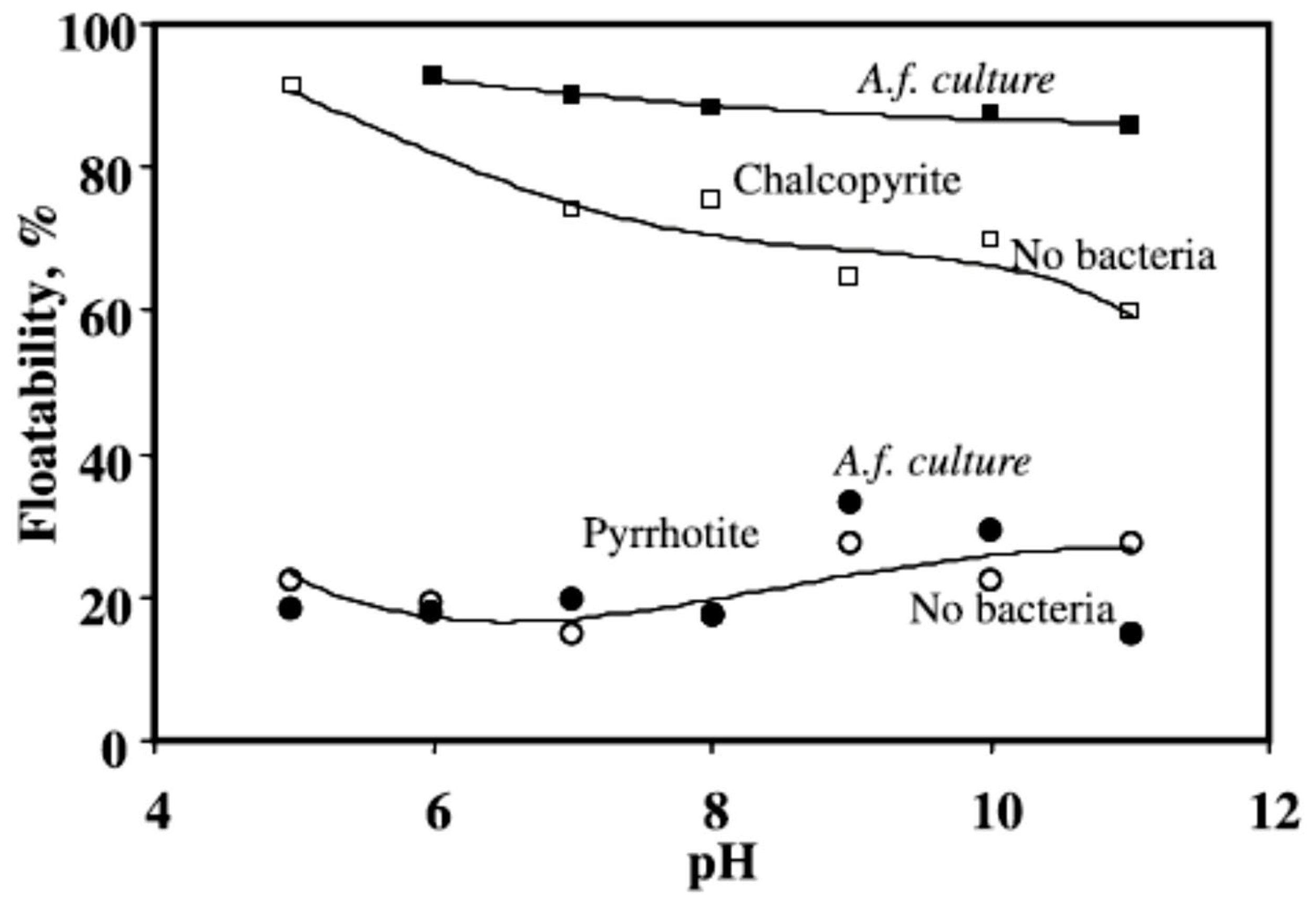

4.6. Leptospirillum ferrooxidans

4.7. Bacillus subtilis

4.8. Bacillus pumilus and Alicyclobacillus ferrooxidans

4.9. Halophilic Bacteria

4.10. Sulphate-Reducing Bacteria

4.11. Mixed Cultures

4.12. Biobeneficiation of Pentlandite

5. Removal of Silicates and Chromites during Biobeneficiation

6. Potential Challenges and Opportunities of PGM Biobeneficiation

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Watson, J.H.P.; Ellwood, D.C. Biomagnetic separation and extraction process for heavy metals from solution. Miner. Eng. 1994, 7, 1017–1028. [Google Scholar] [CrossRef]

- Chandraprabha, M.N.; Natarajan, K.A. Microbially induced mineral beneficiation. Miner. Process. Extr. 2009, 31, 1–29. [Google Scholar] [CrossRef]

- Smith, R.W.; Miettinen, M. Microorganisms in flotation and flocculation: Future technology or laboratory curiosity? Miner. Eng. 2006, 19, 548–553. [Google Scholar] [CrossRef]

- Attia, Y.A.; Elzeky, M.; Ismail, M. Enhanced separation of pyrite from oxidized coal by froth flotation using biosurface modification. Int. J. Miner. Process. 1993, 37, 61–71. [Google Scholar] [CrossRef]

- Hosseini, T.R.; Kolahdoozan, M.; Tabatabaei, Y.S.M.; Oliazadeh, M.; Noaparast, M.; Eslami, A.F.S.A.R.; Manafi, Z.; Alfantazi, A. Bioflotation of Sarcheshmeh copper ore using Thiobacillus ferrooxidans bacteria. Miner. Eng. 2005, 18, 371–374. [Google Scholar] [CrossRef]

- Botero, A.E.C.; Torem, M.L.; de Mesquita, L.M.S. Fundamental studies of Rhodococcus opacus as a biocollector of calcite and magnesite. Miner. Eng. 2007, 20, 1026–1032. [Google Scholar] [CrossRef]

- Santhiya, D.; Subramanian, S.; Natarajan, K.A.; Rao, K.H.; Forssberg, K.S.E. Bio-modulation of galena and sphalerite surfaces using Thiobacillus thiooxidans. Int. J. Miner. Process. 2001, 62, 121–141. [Google Scholar] [CrossRef]

- Natarajan, K.A.; Deo, N. Role of bacterial interaction and bioreagents in iron ore flotation. Int. J. Miner. Process. 2001, 62, 143–157. [Google Scholar] [CrossRef]

- Pecina-Treviño, E.T.; Ramos-Escobedo, G.T.; Gallegos-Acevedo, P.M.; López-Saucedo, F.J.; Orrantia-Borunda, E. Bioflotation of sulfide minerals with Acidithiobacillus ferrooxidans in relation to copper activation and surface oxidation. Can. J. Microbiol. 2012, 58, 1073–1083. [Google Scholar] [CrossRef]

- Nagaoka, T.; Ohmura, N.; Saiki, H. A novel mineral flotation process using Thiobacillus ferrooxidans. Appl. Environ. 1999, 65, 3588–3593. [Google Scholar] [CrossRef] [Green Version]

- Chandraprabha, M.N.; Natarajan, K.A. Surface chemical and flotation behaviour of chalcopyrite and pyrite in the presence of Acidithiobacillus thiooxidans. Hydrometallurgy 2006, 83, 146–152. [Google Scholar] [CrossRef]

- Sanwani, E.; Chaerun, S.; Mirahati, R.; Wahyuningsih, T. Bioflotation: Bacteria-mineral interaction for eco-friendly and sustainable mineral processing. Procedia Chem. 2016, 19, 666–672. [Google Scholar] [CrossRef] [Green Version]

- Deo, N.; Natarajan, K.A. Interaction of Bacillus polymyxa with some oxide minerals with reference to mineral beneficiation and environmental control. Miner. Eng. 1997, 10, 1339–1354. [Google Scholar] [CrossRef]

- Patra, P.; Natarajan, K.A. Role of mineral specific bacterial proteins in selective flocculation and flotation. Int. J. Miner. Process. 2008, 88, 53–58. [Google Scholar] [CrossRef]

- Vasanthakumar, B.; Ravishankar, H.; Subramanian, S. A novel property of DNA—As a bioflotation reagent in mineral processing. PLoS ONE 2012, 7, e39316. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Behera, S.K.; Mulaba-Bafubiandi, A.F. Microbes assisted mineral flotation a future prospective for mineral processing industries: A review. Miner. Process. Extr. 2017, 38, 96–105. [Google Scholar] [CrossRef]

- Mehrabani, J.V.; Mousavi, S.M.; Noaparast, M. Evaluation of the replacement of NaCN with Acidithiobacillus ferrooxidans in the flotation of high-pyrite, low-grade lead–zinc ore. Sep. Purif. Technol. 2011, 80, 202–208. [Google Scholar] [CrossRef]

- Kolahdoozan, M.; Tabatabaei Yazdi, S.M.; Yen, W.T.; Hosseini Tabatabaei, R.; Shahverdi, A.R.; Oliazadeh, M.; Noaparast, M.; Eslami, A.; Manafi, Z. Bioflotation of the low grade Sarcheshmeh copper sulfide. Trans. Indian Inst. Met. 2004, 57, 485–490. [Google Scholar]

- Raichur, A.M.; Misra, M.; Bukka, K.; Smith, R.W. Flocculation and flotation of coal by adhesion of hydrophobic Mycobacterium phlei. Colloids Surf. B Biointerfaces 1996, 8, 13–24. [Google Scholar] [CrossRef]

- Marhual, N.P.; Pradhan, N.; Kar, R.N.; Sukla, L.B.; Mishra, B.K. Differential bioleaching of copper by mesophilic and moderately thermophilic acidophilic consortium enriched from same copper mine water sample. Bioresour. Technol. 2008, 99, 8331–8336. [Google Scholar] [CrossRef]

- Buswell, A.M.; Bradshaw, D.J.; Harris, P.J.; Ekmekci, Z. The use of electrochemical measurements in the flotation of a platinum group minerals (PGM) bearing ore. Miner. Eng. 2002, 15, 395–404. [Google Scholar] [CrossRef]

- Buswell, A.M.; Nicol, M.J. Some aspects of the electrochemistry of the flotation of pyrrhotite. J. Appl. Electrochem. 2002, 32, 1321–1329. [Google Scholar] [CrossRef]

- Kim, G.; Park, K.; Choi, J.; Gomez-Flores, A.; Han, Y.; Choi, S.Q.; Kim, H. Bioflotation of malachite using different growth phases of Rhodococcus opacus: Effect of bacterial shape on detachment by shear flow. Int. J. Miner. Process. 2015, 143, 98–104. [Google Scholar] [CrossRef]

- Cramer, L.A. What is your PGM concentrate worth. In Proceedings of the Third International Platinum Conference, Platinum in Transformation, Southern African Institute of Mining and Metallurgy, Sun City, South Africa, 6–9 October 2008; pp. 387–394. [Google Scholar]

- Corin, K.C.; McFadzean, B.J.; Shackleton, N.J.; O’Connor, C.T. Challenges Related to the Processing of Fines in the Recovery of Platinum Group Minerals (PGMs). Minerals 2021, 11, 533. [Google Scholar] [CrossRef]

- Scoon, R.N.; Teigler, B. Platinum-group element mineralization in the critical zone of the western Bushveld Complex; I, Sulfide poor-chromitites below the UG-2. Econ. Geol. 1994, 89, 1094–1121. [Google Scholar] [CrossRef]

- Naldrett, A.J.; Naldrett, A.L. Magmatic Sulfide Deposits: Geology, Geochemistry and Exploration; Springer Science & Business Media: Berlin, Germany, 2004. [Google Scholar]

- Junge, M.; Oberthür, T.; Melcher, F. Cryptic variation of chromite chemistry, platinum group element and platinum group mineral distribution in the UG-2 chromitite: An example from the Karee Mine, western Bushveld Complex, South Africa. Econ. Geol. 2014, 109, 795–810. [Google Scholar] [CrossRef]

- Junge, M.; Oberthür, T.; Osbahr, I. Gutter, Platinum-group elements and minerals in the lower and middle group chromitites of the western Bushveld Complex, South Africa. Miner. Depos. 2016, 51, 841–852. [Google Scholar] [CrossRef]

- Barnes, S.J.; Pagé, P.; Prichard, H.M.; Zientek, M.L.; Fisher, P.C. Chalcophile and platinum-group element distribution in the Ultramafic series of the Stillwater Complex, MT, USA—Implications for processes enriching chromite layers in Os, Ir, Ru, and Rh. Miner. Depos. 2016, 51, 25–47. [Google Scholar] [CrossRef]

- Kinloch, E.D. Regional trends in the platinum-group mineralogy of the critical zone of the Bushveld Complex, South Africa. Econ. Geol. 1982, 77, 1328–1347. [Google Scholar] [CrossRef]

- Oberthür, T.; Weiser, T.W.; Gast, L.; Kojonen, K. Geochemistry and mineralogy of platinum-group elements at Hartley Platinum Mine, Zimbabwe. Miner. Depos. 2003, 38, 327–343. [Google Scholar] [CrossRef]

- Holwell, D.A.; Boyce, A.J.; McDonald, I. Sulfur isotope variations within the Platreef Ni-Cu-PGE deposit: Genetic implications for the origin of sulfide mineralization. Econ. Geol. 2007, 102, 1091–1110. [Google Scholar] [CrossRef]

- Osbahr, I.; Klemd, R.; Oberthür, T.; Brätz, H.; Schouwstra, R. Platinum-group element distribution in base-metal sulfides of the Merensky Reef from the eastern and western Bushveld Complex, South Africa. Miner. Depos. 2013, 48, 211–232. [Google Scholar] [CrossRef]

- Junge, M.; Wirth, R.; Oberthür, T.; Melcher, F.; Schreiber, A. Mineralogical siting of platinum-group elements in pentlandite from the Bushveld Complex, South Africa. Miner. Depos. 2015, 50, 41–54. [Google Scholar] [CrossRef] [Green Version]

- Junge, M.; Oberthür, T.; Kraemer, D.; Melcher, F.; Piña, R.; Derrey, I.T.; Manyeruke, T.; Strauss, H. Distribution of platinum-group elements in pristine and near-surface oxidized Platreef ore and the variation along strike, northern Bushveld Complex, South Africa. Miner. Depos. 2019, 54, 885–912. [Google Scholar] [CrossRef]

- Seymour, R.J.; O’Farrelly, J.I.; Potter, L.C. Platinum-group metals. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley and Sons: New York, NY, USA, 2000. [Google Scholar]

- Schouwstra, R.P.; Kinloch, E.D.; Lee, C.A. A short geological review of the Bushveld Complex. Platin. Met. Rev. 2000, 44, 33–39. [Google Scholar]

- Lee, C.A. A review of mineralization in the Bushveld Complex and some other layered intrusions. Dev. Petrol. 1996, 15, 103–145. [Google Scholar]

- Crabtree, E.H.; Vincent, J.D. The early days of froth flotation. In Froth Flotation—50th Anniversary; AIMME: New York, NY, USA, 1962; pp. 39–54. [Google Scholar]

- Engelbrecht, J. Potential Changes in the Physical Beneficiation Processes That Can Improve the Recovery Grade or Costs for the Platinum Group Metals. In Proceedings of the Fifth International Platinum Conference: A Catalyst for Change, Sun City, South Africa, 18–20 September 2012. [Google Scholar]

- Filippov, L.O.; Filippova, I.V.; Severov, V.V. The use of collectors mixture in the reverse cationic flotation of magnetite ore: The role of Fe-bearing silicates. Miner. Eng. 2010, 23, 91–98. [Google Scholar] [CrossRef]

- Wark, I.W.; Cox, A.B. Principles of flotation, III. Trans. AIME 1934, 112, 267–301. [Google Scholar]

- Sharma, P.K.; Rao, K.H. Role of a heterotrophic Paenibacillus polymyxa bacteria in the bioflotation of some sulfide minerals. Mining Metall. Explor. 1999, 16, 35–41. [Google Scholar] [CrossRef]

- Wills, B.A.; Naier-Munn, T. Froth Flotation. In Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, 7th ed.; Elsevier Science and Technology Books: Amsterdam, The Netherlands, 2013; pp. 267–352. [Google Scholar]

- Sheni, N.; Corin, K.; Wiese, J. Considering the effect of pulp chemistry during flotation on froth stability. Miner. Eng. 2018, 116, 15–23. [Google Scholar] [CrossRef] [Green Version]

- Pearse, M.J. An overview of the use of chemical reagents in mineral processing. Miner. Eng. 2005, 18, 139–149. [Google Scholar] [CrossRef]

- Klassen, V.I.; Mokrousov, V.A. An Introduction to the Theory of Flotation; Butterworth: Oxford, UK, 1963. [Google Scholar]

- Bulatovic, S.M. Handbook of Flotation Reagents: Chemistry, Theory and Practice: Volume 1: Flotation of Sulfide Ores; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Patra, P.; Natarajan, K.A. Microbially-induced flocculation and flotation for pyrite separation from oxide gangue minerals. Miner. Eng. 2003, 16, 965–973. [Google Scholar] [CrossRef]

- Patra, P.; Natarajan, K.A. Microbially enhanced removal of pyrite and chalcopyrite from oxide gangue minerals with reference to desulfurization of tailings. Mining Metall. Explor. 2004, 21, 169–178. [Google Scholar] [CrossRef]

- Santhiya, D.; Subramanian, S.; Natarajan, K.A. Surface chemical studies on sphalerite and galena using extracellular polysaccharides isolated from Bacillus polymyxa. J. Colloid Interface Sci. 2002, 256, 237–248. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P.K.; Rao, K.H. Adhesion of Paenibacillus polymyxa on chalcopyrite and pyrite: Surface thermodynamics and extended DLVO theory. Colloids Surf. B Biointerfaces 2003, 29, 21–38. [Google Scholar] [CrossRef]

- Misra, M.; Smith, R.W.; Dubel, J.; Chen, S. Selective flocculation of fine coal with hydrophobic Mycobacterium phlei. Mining Metall. Explor. 1993, 10, 20–23. [Google Scholar] [CrossRef]

- Raichur, A.M.; Misra, M.; Smith, R.W. Differential adhesion of hydrophobic bacteria onto coal and associated minerals. Coal Prep. 1995, 16, 51–63. [Google Scholar] [CrossRef]

- Chandraprabha, M.N.; Natarajan, K.A.; Modak, J.M. Selective separation of pyrite and chalcopyrite by biomodulation. Colloids Surf. B Biointerfaces 2004, 37, 93–100. [Google Scholar] [CrossRef]

- Dwyer, R.; Bruckard, W.J.; Rea, S.; Holmes, R.J. Bioflotation and bioflocculation review: Microorganisms relevant for mineral beneficiation. Miner. Process. Extr. 2012, 121, 65–71. [Google Scholar] [CrossRef]

- Atkins, A.S.; Bridgwood, E.W.; Davis, A.J.; Pooley, F.D. A study of the suppression of pyritic sulphur in coal froth flotation by Thiobacillus ferrooxidans. Coal Prep. 1987, 5, 1–13. [Google Scholar] [CrossRef]

- Blake II, R.C.; Sasaki, K.; Ohmura, N. Does aporusticyanin mediate the adhesion of Thiobacillus ferrooxidans to pyrite? Hydrometallurgy 2001, 59, 357–372. [Google Scholar] [CrossRef]

- Misra, M.; Chen, S. The effect of growth medium of Thiobacillus ferrooxidans on pyrite and galena flotation. Miner. Eng. 1996, 9, 157–168. [Google Scholar] [CrossRef]

- Natrajan, K.A. Biotechnology for metal extraction, mineral beneficiation and environmental control. In Proceedings of the International Seminar on Mineral Processing Technology and Indo-Korean Workshop on Resource Recycling (MPT-2006), Chennai, India, 8–10 March 2006; Volume 1, pp. 68–81. [Google Scholar]

- Mehrabani, J.V.; Noaparast, M.; Mousavi, S.M.; Dehghan, R.; Rasooli, E.; Hajizadeh, H. Depression of pyrite in the flotation of high pyrite low-grade lead–zinc ore using Acidithiobacillus ferrooxidans. Miner. Eng. 2010, 23, 10–16. [Google Scholar] [CrossRef]

- Vilinska, A.; Rao, K.H. Leptosririllum ferrooxidans-sulfide mineral interactions with reference to bioflotation and bioflocculation. Trans. Nonferrous Met. Soc. China 2008, 18, 1403–1409. [Google Scholar] [CrossRef]

- Natarajan, K.A.; Das, A. Surface chemical studies on ‘Acidithiobacillus’ group of bacteria with reference to mineral flocculation. Int. J. Miner. Process 2003, 72, 189–198. [Google Scholar] [CrossRef]

- Abramov, A.; Avdohin, V.M. Oxidation of Sulfide Minerals in Benefication Processes; Gordon and Breach Science Publishers: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Leja, J. Collector Mechanism, I. Thiol collectors in sulfide minerals. In Surface Chemistry of Froth Flotation, 2nd ed.; Rao, S.R., Ed.; Springer: Boston, MA, USA, 2004; Volume 1, pp. 479–526. [Google Scholar]

- San Martín, F.; Kracht, W.; Vargas, T. Biodepression of pyrite using Acidithiobacillus ferrooxidans in seawater. Miner. Eng. 2018, 117, 127–131. [Google Scholar] [CrossRef]

- San Martín, F.; Kracht, W.; Vargas, T.; Rudolph, M. Mechanisms of pyrite biodepression with Acidithiobacillus ferrooxidans in seawater flotation. Miner. Eng. 2020, 145, 106067. [Google Scholar] [CrossRef]

- Muzenda, E.; Afolabi, A.S.; Abdulkareem, A.S.; Ntuli, F. Effect of pH on the Recovery and grade of base metal sulphides (PGMs) by flotation. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 19–21 October 2011; Volume 2, p. 2. [Google Scholar]

- La Vars, S.M.; Newton, K.; Quinton, J.S.; Cheng, P.Y.; Wei, D.H.; Chan, Y.L.; Harmer, S.L. Surface chemical characterisation of pyrite exposed to Acidithiobacillus ferrooxidans and associated extracellular polymeric substances. Minerals 2018, 8, 132. [Google Scholar] [CrossRef] [Green Version]

- Jefferson, K.K. What drives bacteria to produce a biofilm? FEMS Microbiol. Lett. 2004, 236, 163–173. [Google Scholar] [CrossRef]

- Das, A.; Modak, J.M.; Natarajan, K.A. Surface chemical studies of Thiobacillus ferrooxidans with reference to copper tolerance. Antonie Van Leeuwenhoek 1998, 73, 215–222. [Google Scholar] [CrossRef] [PubMed]

- Bleeze, B.; Zhao, J.; Harmer, S.L. Selective attachment of Leptospirillum ferrooxidans for separation of chalcopyrite and pyrite through bio-flotation. Minerals 2018, 8, 86. [Google Scholar] [CrossRef] [Green Version]

- Harneit, K.; Göksel, A.; Kock, D.; Klock, J.H.; Gehrke, T.; Sand, W. Adhesion to metal sulfide surfaces by cells of Acidithiobacillus ferrooxidans, Acidithiobacillus thiooxidans and Leptospirillum ferrooxidans. Hydrometallurgy 2006, 83, 245–254. [Google Scholar] [CrossRef]

- He, Z.G.; Yang, Y.P.; Shan, Z.H.O.U.; Hu, Y.H.; Zhong, H. Effect of pyrite, elemental sulfur and ferrous ions on EPS production by metal sulfide bioleaching microbes. Trans. Nonferrous Met. Soc. China 2014, 24, 1171–1178. [Google Scholar] [CrossRef]

- Díaz-López, C.V.; Pecina-Treviño, E.T.; Orrantia-Borunda, E. A study of bioflotation of chalcopyrite and pyrrhotite mixtures in presence of L. ferrooxidans. Can. Metall. Quart. 2012, 51, 118–125. [Google Scholar] [CrossRef]

- Pecina, E.T.; Rodriguez, M.; Castillo, P.; Diaz, V.; Orrantia, E. Effect of Leptospirillum ferrooxidans on the flotation kinetics of sulphide ores. Miner. Eng. 2009, 22, 462–468. [Google Scholar] [CrossRef]

- Sarvamangala, H.; Natarajan, K.A.; Girisha, S.T. Microbially-induced pyrite removal from galena using Bacillus subtilis. Int. J. Miner. Process 2013, 120, 15–21. [Google Scholar] [CrossRef]

- Consuegra, G.L.; Kutschke, S.; Rudolph, M.; Pollmann, K. Halophilic bacteria as potential pyrite bio-depressants in Cu-Mo bioflotation. Miner. Eng. 2020, 145, 106062. [Google Scholar] [CrossRef]

- Govender, Y.; Gericke, M. Extracellular polymeric substances (EPS) from bioleaching systems and its application in bioflotation. Miner. Eng. 2011, 24, 1122–1127. [Google Scholar] [CrossRef]

- Sun, D.S.; Wan, Q.; Zhao, X.P.; Zhang, Q. Metabolites of Bacillus mucilaginous JXF and their desiliconization Effect. J. Min. Metall. Eng. 2008, 28, 52–56. [Google Scholar]

- Štyriaková, I.; Bhatti, T.M.; Bigham, J.M.; Tyriak, I.; Vuorinen, A.; Tuovinen, O.H. Weathering of phlogopite by Bacillus cereus and Acidithiobacillus ferrooxidans. Can. J. Microbiol. 2004, 50, 213–219. [Google Scholar] [CrossRef]

- Sefako, R.; Sibanda, V.; Sekgarametso, K. PGM extraction from oxidized ores using flotation and leaching. J. S. Afr. Inst. Min. Metall. 2019, 119, 929–936. [Google Scholar] [CrossRef]

- Rao, K.H.; Vilinska, A.; Chernyshova, I.V. Minerals bioprocessing: R & D needs in mineral biobeneficiation. Hydrometallurgy 2010, 104, 465–470. [Google Scholar]

| Assay | Merensky | UG2 | Platreef | Hi-Ni Platreef |

|---|---|---|---|---|

| PGM-4E | 200 | 200 | 120 | 30 |

| Pt-% of 4E | 63.5 | 56.7 | 45.1 | 24.0 |

| Pd | 28.1 | 29.4 | 45.7 | 69.3 |

| Rh | 4.4 | 13.0 | 3.2 | 1.3 |

| Au | 4.0 | 0.9 | 6.0 | 5.4 |

| Ir-% of 6E | 0.6 | 1.6 | 1.0 | - |

| Ru | 6.8 | 9.6 | 3.5 | - |

| Base metals (%) | ||||

| Ni | 6.0 | 1.4 | 4.9 | 6.0 |

| Cu | 3.4 | 0.7 | 2.5 | 4.0 |

| Co | 0.15 | 0.05 | 0.2 | 0.07 |

| Cr2O3 (%) | 0.6 | 3.0 | 0.3 | 0.1 |

| S (%) | 15–20 | 4–6 | 10–15 | 15–20 |

| Mineral Name | Merensky Reef | UG2 Reef | Platreef |

|---|---|---|---|

| Vol (%) | |||

| Pyroxene | 55–60 | 15–30 | 30–40 |

| Feldspar | 30–40 | 3–9 | 18 |

| Chromite | 6 | 50–75 | - |

| Talc | <1 | <1 | <1 |

| Serpentine | 2–3 | 1 | 5 |

| Amphibole | 1–2 | <1 | 4 |

| Chlorite | 1–2 | <1 | 4 |

| Mica | <1 | <1 | 1 |

| BMS | <1 | <1 | 2 |

| Other | 1–2 | <1 | 5 |

| Minerals | Merensky Reef | UG2 Reef | Platreef |

|---|---|---|---|

| Vol (%) | |||

| Pentlandite | 35 | 44–52 | 27 |

| Pyrrhotite | 46 | 26–35 | 52 |

| Chalcopyrite | 20 | 21 | 19 |

| Class | Minerals | Merensky Reef | UG2 Reef | Platreef |

|---|---|---|---|---|

| Vol (%) | ||||

| PGM Alloys | Ferro platinum | 40 | 40 | 11–30 |

| Pt Alloy | ||||

| Pd Alloy | ||||

| Electrum (Au) | 2 | 0.2 | 3 | |

| Arsenides | Pt-arsenides | 4 | 0.1–1 | 1–20 |

| Pd-arsenides | ||||

| PGE-sulphur arsenides | 3 | 0.8–7 | 16–35 | |

| PGM sulphides | PtPd-sulphide | 16 | 40–60 | 1–7 |

| Pt-sulphide | ||||

| PtRh-sulphide | ||||

| Tellurides | Pt-tellurides | 35 | 0.5–5 | 20–50 |

| Pd-tellurides | ||||

| Bacteria | PGM Associated Mineral Floated | PGM Associated Mineral Depressed | Bioflotation Conditions and BMS Recovery or Depression | References |

|---|---|---|---|---|

| Bacillus polymyxa | Pyrite | pH—8 (hexamine collector—1 × 10−4 M) bio-conditioning time—15 min, extracellular bacterial protein—50 mg/L, up to 92.2% pyrite depressed | [50] | |

| Paenibacillus polyxyma | Chalcopyrite | Pyrite | particle size—106 + 38 μm, 1 min, air flow rate—13 Lh−1, pH 3–10, 3 × 106 cells mL−1, up to 65% chalcopyrite recovered and up to 70% pyrite depressed | [44,51] |

| Acidithiobacillus ferrooxidans | Chalcopyrite | Pyrite | methyl isobutyl carbinol collector, aeration—100 mL/min Conditioning time—20 min, Flotation time—10 min Cell suspension added to 10 mL KPO4, pH 2–8, 72% to 100% chalcopyrite floated and 77% to 95% pyrite depressed | [4,10,56,57,58,62,64,67,70] |

| Leptospirillum ferrooxidans | Pyrite | Chalcopyrite | potassium isopropyl xanthate collector, preconditioning time (30 min), 2.5 × 108 cells mL−1, pH 4, 67% pyrite recovery and 75% chalcopyrite depression | [63] |

| Leptospirillum ferrooxidans | Chalcopyrite | Pyrrhotite | Conditioning time (10 min), conditioning substrate (thionocarbamate) isopropyl ethyl thionocarbamate collector, nitrogen injected, time (10 min), chalopyrite recovery increased to between 80% and 95%, 30% pyrrhotite depressed | [76] |

| Bacillus subtilis | - | Pyrite | Incubation period (1 h), flotation time (3 min), 79%–94% pyrite depressed | [78] |

| Bacillus pumilus | - | Pyrite | 10% vol/vol inoculum, 25% wt/vol pyrite, 25% pulp density, 150 rpm agitation, 30 °C, varying pH, 14–21 days, (no recoveries reported) contact angle of about 5° | [12] |

| Bacillus pumilus | Pyrite | No information | 10% vol/vol inoculum, 25% wt/vol pyrite, 25% pulp density, 150 rpm agitation, 30 °C, varying pH, 0–14 days, (no recoveries reported) contact angles between 90 and 100° | [12] |

| Alicyclobacillus ferrooxidans | - | Pyrite | 10% vol/vol inoculum, 25% wt/vol pyrite, 25% pulp density, 150 rpm agitation, 30 °C, varying pH, 14 days, (no recoveries reported) contact angle of about 68° | [12] |

| Alicyclobacillus ferrooxidans | Pyrite | No information | 10% vol/vol inoculum, 25% wt/vol pyrite, 25% pulp density, 150 rpm agitation, 30 °C, varying pH, 4–8 days, (no recoveries reported) contact angles between 80 and 85° | [12] |

| Halophilic bacteria (Halomonas boliviensis, Halobacillus sp. and Halomonas sp.) | Chalcopyrite | Pyrite | pH (between 8.02 and 8.14), mineral particle size (100–200 µm), Sodium Isopropyl Xanthate (SIPX), flotation time (5 min), up to 91% chalcopyrite flotation and 90% pyrite depression | [79] |

| Sulphate-reducing bacteria (Desulfovibrio) | - | Chalcopyrite | pH (6–7), H2S gas production (no extraction information provided) | [61] |

| Sulphate-reducing bacteria (Desulfovibrio) | Chalcopyrite | - | Sulphide products formation, no extraction information provided | [61] |

| Mixed bioleaching cultures (A. ferrooxidans, A. thiooxidans and L. ferrooxidans) | Chalcopyrite | Pyrite | Used EPS extracted from chalcopyrite-rich concentrate, pH (4 and 9), sodium isobutyl xanthate, flotation time (20 min), 70 °C, up to 80% chalcopyrite recovered and about 75% pyrite depressed | [80] |

| Bacteria | PGM Minerals Recovered by Flocculation | Flocculation Conditions and Associated Recoveries | Reference |

|---|---|---|---|

| Bacillus polymyxa | Pyrite | pH 3 | [50,51] |

| 20 min, 50 mg/L metabolite-extracted protein | |||

| d50 < 50 μm, 92% pyrite settled | |||

| Mycobacterium phlei | Pyrite (by reverse recovery) | pH (2–11), bacterial concentration (200 ppm), 64% pyrite rejection | [19] |

| Acidithiobacillus ferrooxidans | Pyrite | pH adjusted by NaOH and H2SO4, double distilled water medium, 2 min settling time, 1.8 × 108 cells/mL, pulp density of 1 g/100 mL, various pH, about 98% pyrite settled | [64] |

| Acidithiobacillus thiooxidans | Pyrite | pH adjusted by NaOH and H2SO4, double distilled water medium, 2 min settling time, 1.8 × 108 cells/mL, pulp density of 1 g/100 mL, various pH, about 78%–96% pyrite settled | [64] |

| Leptospirillum ferrooxidans | Chalcopyrite | Solid concentration (2.5 g/L), Particle size (<5 µm), Bacterial concentration (4 × 1010 cells/g), about 100% chalcopyrite settled | [63] |

| Bacillus subtilis | Pyrite | 100 mL cell suspension in 10−3 M KNO3, Sample particle size (5–8 µm), up to 85% pyrite settled | [78] |

| Parameter | Proposed for Bioflotation of PGMs | Used in Conventional Flotation of PGMs |

|---|---|---|

| Grade | <3 g/t | 3–8 g/t [38] |

| Particle size | <50 μm | 38–75 μm [25] |

| Temperature | 30 °C | ~25 °C [83] |

| pH | 8 | 9 [69] |

| Pulp density | 25% (w/v) | 30–35% (w/v) [25,83] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chipise, L.; Ndlovu, S.; Shemi, A. Towards the Biobeneficiation of PGMs: Reviewing the Opportunities. Minerals 2022, 12, 57. https://doi.org/10.3390/min12010057

Chipise L, Ndlovu S, Shemi A. Towards the Biobeneficiation of PGMs: Reviewing the Opportunities. Minerals. 2022; 12(1):57. https://doi.org/10.3390/min12010057

Chicago/Turabian StyleChipise, Liberty, Sehliselo Ndlovu, and Alan Shemi. 2022. "Towards the Biobeneficiation of PGMs: Reviewing the Opportunities" Minerals 12, no. 1: 57. https://doi.org/10.3390/min12010057

APA StyleChipise, L., Ndlovu, S., & Shemi, A. (2022). Towards the Biobeneficiation of PGMs: Reviewing the Opportunities. Minerals, 12(1), 57. https://doi.org/10.3390/min12010057