1. Introduction

The field of image analysis is a key area for the implementation of solutions that improve quality within industrial automation processes, where different digital image processing techniques are used [

1]. The use of this technology carries with it a competitive advantage within the companies that use it, being able to have an increase in production, improvement in the quality of the products, and a reduction in production and manufacturing costs [

2].

One of the main lines of image analysis research is the automatic particle recognition process. Automation allows establishing precise and objective forms of control, whereas manual systems are subject to exhaustion and routine on the part of the operator, causing poor or inconsistent control [

3,

4,

5]. Image analysis applications can be found in areas such as PCB (printed circuit boards) fault detection, food, silicon foil, and granulometry, to name a few. However, it should be noted that each analysis is directly associated with the type of application in which it is desired to occupy.

A method designed for face pattern recognition, for example, can hardly be applied to that of printed circuits [

6,

7,

8].

There are two basic conditions that a system must meet to improve the quality of processes: the first case is efficiency, which is related to the least number of false positives and negatives; the second is speed: the idea is that the production process is not affected by the time it takes for the inspection and therefore increases or maintains, at least, the speed of production.

Segmentation is one of the initial stages in the image analysis process; however, its application allows separating and detecting, in a first phase, the regions of interest, which are later classified. Segmentation is commonly considered one of the most complex tasks in image processing [

2,

9]. Research in this area is extensive, but it is specific in relation to the material being analyzed. To have a better control in the crushing process, taking images of the conveyor belts, it is sought to design and implement an algorithm that allows determining all the regions with particles, particularly large particles (20–250 mm), from which their geometric properties can be extracted, through analysis of digital images, and the size distribution of these particles can be determined. The quality in the detection of particles is a fundamental point in the construction of a solution, for which it must be quantifiable. To do this, a comparison algorithm must be used that effectively specifies the number of false positives and false negatives found in the detection of particles.

In the development of this research, segmentation strategies such as the use of the Canny method [

10,

11] for edge detection (a comparison study [

12] showed that, among the different types of edge detection algorithms, the Canny filter is the algorithm with the best performance) and the use of the distance transform [

13] to complement watershed segmentation [

14,

15], which has been studied and improved throughout various studies [

16,

17,

18,

19,

20,

21,

22,

23], will be analyzed, in addition to other digital processing techniques for noise reduction such as the median filter, the Gaussian filter, and the average filter, in order to evaluate the developed solution. To develop the watershed, the algorithm proposed in Vincent’s research [

24] is the one with the best quality and performance, and it is also integrated with the MATLAB software. This type of system also presents an opportunity for the implementation of deep learning, as shown in other investigation works [

25].

In Chile, there are many mining deposits in which sensors and analyzers are required to help their production processes. In particular, the crushing and grinding process is where energy consumption requires the greatest attention. An alternative for controlling the process is measuring and analyzing the particle size distribution in the feed, in the same way as for the milling stage, where particle size distribution sensors do not demonstrate sufficient robustness in operation, particularly for large particle sizes (above 20 mm). A large particle size is a consequence of operational problems in the classification stage (screening), i.e., screen rupture, which requires prompt maintenance in order to reduce major problems in downstream stages. The presence of oversized particles may produce equipment plugging or obstruction. This condition limits the operational time availability. This situation motivates the development of particle size analyzers. To carry out this control, it is necessary to stop a part of the production to obtain samples and send them to a laboratory for a granulometric analysis. This, in addition to causing production losses due to stopped time, is not a representative measure due to the volume of transport that the conveyor belts have.

The solution consists of a device together with online image processing software that allows the determination of particle sizes with statistical significance for 2D images from a 3D sample. Alternative technologies based on images, X-ray diffraction, and laser diffraction have been developed for particle size measurement at a range below 50 mm, which is not the required range for primary to tertiary crushing. In addition, commercial devices such as CAMSIZER or QCPIC are for bench-scale applications. A complete review of particle size technologies is described in [

26].

This solution contemplates a set of image analysis processing techniques, separated into independent phases. This makes it possible to analyze and quantify the quality in each phase in such a way that, if an adjustment is required at any point in the process, it is not necessary to modify the entire algorithm; only the variable which controls that phase is altered, allowing a change in the overall result.

2. Materials and Methodology

2.1. Software and Hardware Tools Used

The main software tool used was MATLAB R2008a (The MathWorks, Portola Valley, CA, USA), version 7.6.0.12063a, “Toolbox” (The MathWorks, Portola Valley, CA, USA) for image processing version 6.1, and “Toolbox” for image acquisition 3.1. The operating system used was Microsoft Windows XP (Microsoft, Redmond, Washington, DC, USA) Professional version 5.1.804013 SP3.

Within the laboratory hardware, an Intel Pentium core 2 processor with a 2.2 GHZ clock frequency was included, with 2 GB of DDR3 RAM memory with a 600 MHZ bus. The hard drive was 160 GB with a speed of 7200 RPM SATA.

For taking and testing, an Intel Pentium III processor with a clock frequency of 600 MHz, 128 Mb of RAM, and a 10 GB hard drive was used. The standard USB 1.1 port was used to connect the cameras (IP camera 1024 p, shutter speed 1/2000 s).

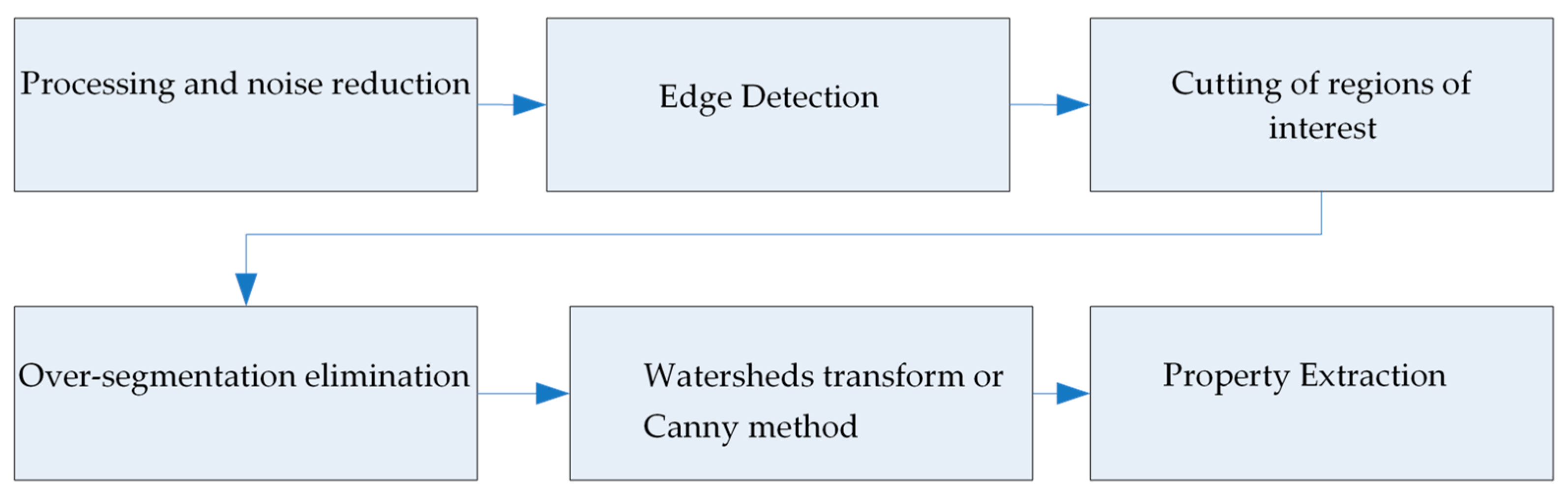

The system is composed of a set of stages, where each of them is analyzed independently, allowing quantifying and analyzing the advantages and disadvantages of its use. In

Figure 1, a general diagram of the proposed segmentation process is presented, without specifically considering the filters to be used in each stage.

In addition to analyzing the different strategies for each of the stages, two segmentation methods were developed, used for the process of each of them [

27]. The first was composed by using the Canny method, and the second method used the watershed transform. The difference between the procedures lies in the edge detection method to be used since, in the case of Canny, it is necessary to perform derivative operations to obtain the regions with particles. On the other hand, in the case of the watershed transform, it is necessary to carry out a procedure that eliminates the noise appended to the binary image product of the selected threshold level [

28]. There are different types of noise in an image, such as Gaussian, impulsive, frequency, and multiplicative noise [

29], which makes reduction difficult.

2.2. Processing and Noise Reduction

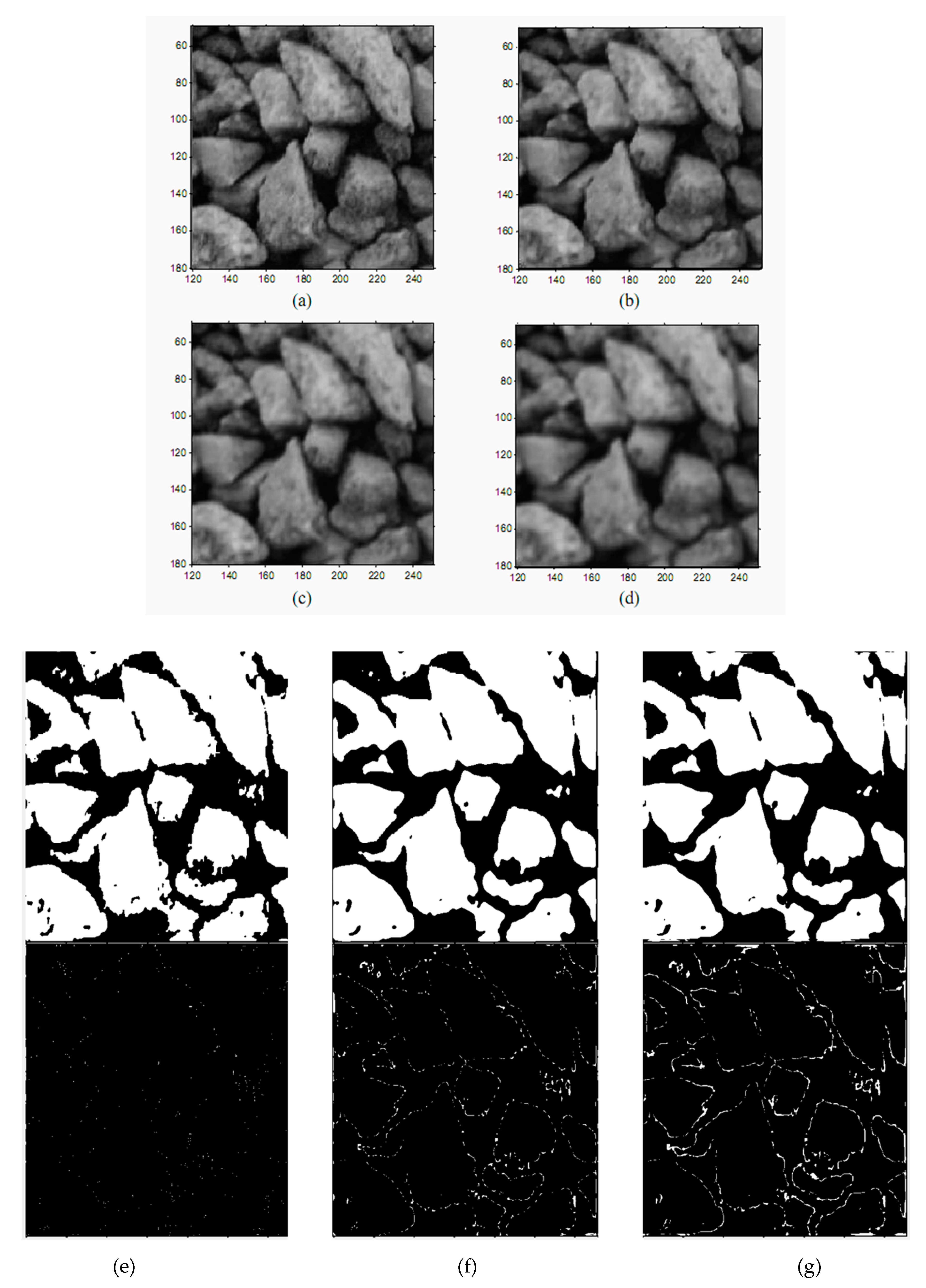

It has been experimentally determined that the median filter [

30] has a better performance compared to the Gaussian filter and the average filter, mainly due to the elimination of a large part of the noise, in addition to preserving the edges of the particles, as seen in

Figure 2.

In

Figure 2b, the median filter is applied, using the original image, shown in

Figure 2a, as the input image, observing that the edges of the structures are not preserved (

Figure 2e). The Gaussian filter is used in

Figure 2c, where the blurring of the particles is combined with the surrounding regions, determining the possible edges of particles (

Figure 2e). Finally, in

Figure 2d, the application of the average filter (9 × 9 window) depicts clear borders. The

Figure 2e–g are binarized images (using Otssu algorithm) from

Figure 2a–c respectively.

2.3. Edge Detection

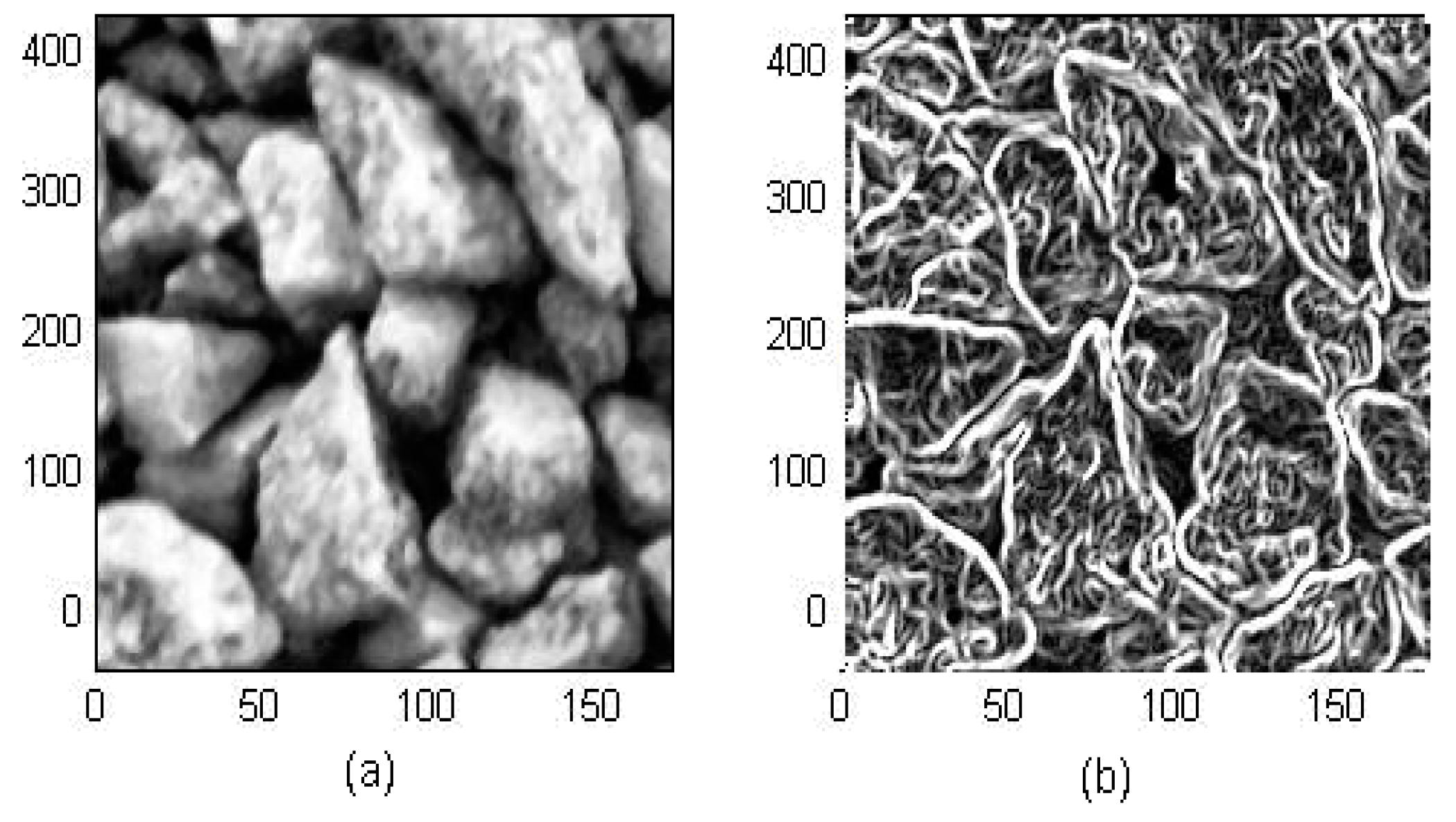

2.3.1. Sobel Operator

The Sobel operator is a discrete differential that calculates an approximation to the gradient of the intensity function of an image. As it can be seen in

Figure 3b, applying the Sobel operator to

Figure 3a is not sufficient for edge detection. While it denotes easily visible edges more vividly, it also shows edges that are the result of noise, drift, and the irregular shape of the image. With the help of the minimum elimination operation together with the Sobel function, it is possible to eliminate areas where hypothetical particles will not be found.

2.3.2. Canny Operator

The Canny method more accurately detects the edges of structures because it is less sensitive to noise since it uses a Gaussian filter to reduce it. However, it generates many open edges, which is why it is necessary to carry out the dilation, filling, and erosion process. Before applying the Canny operator on the image, unnecessary areas were eliminated by multiplying the binarization of the original image. With the discretized image of

Figure 4a and with the 16 discrete values shown in

Figure 4b, the result is

Figure 4c, which allows the Canny operator to help find the edges of the particles. This results in

Figure 4d, where an improvement in the detection of the edges is appreciated, in comparison to the Gaussian filter and Otssu binarization (

Figure 2g), as well as a decrease in false edges or those introduced by noise.

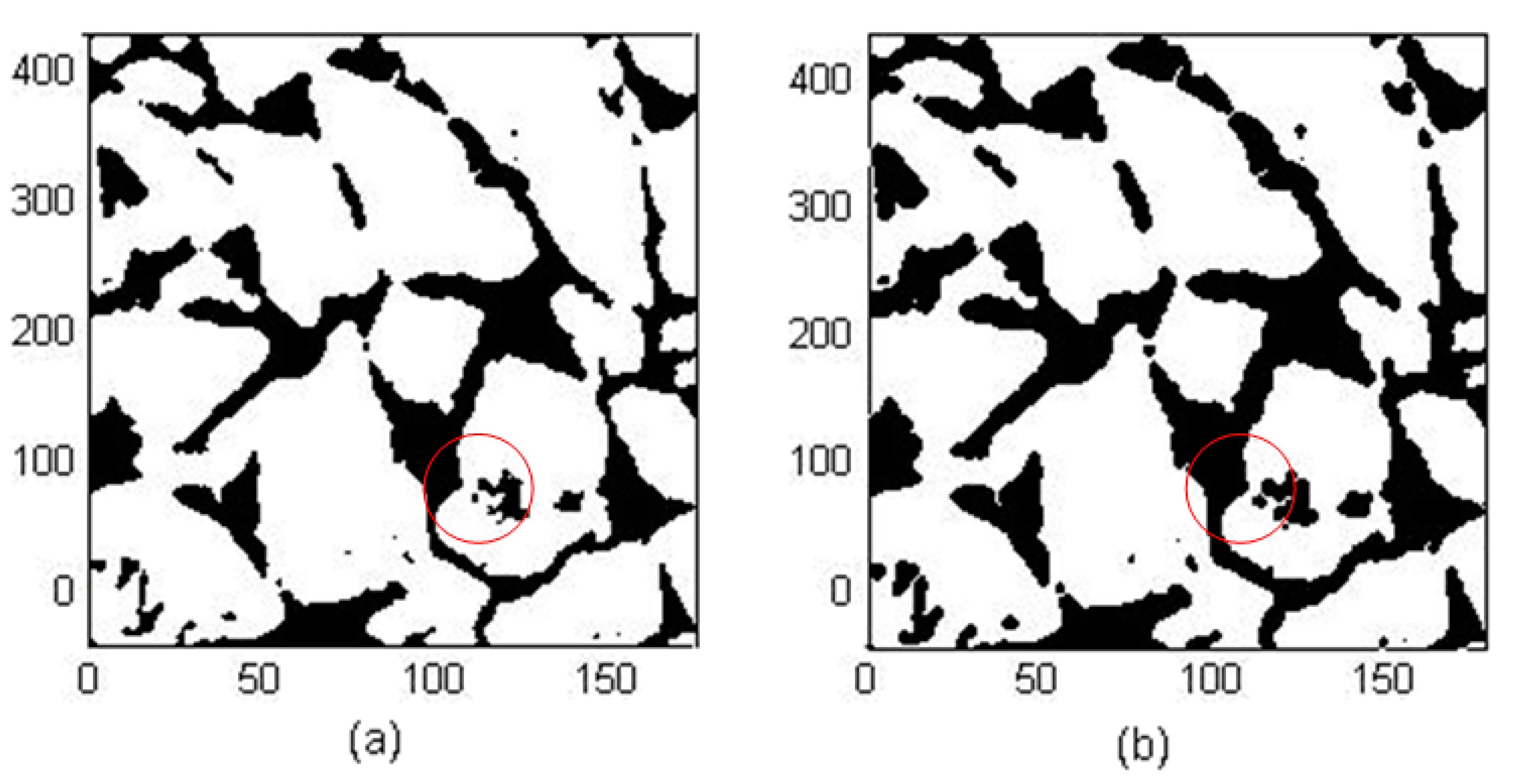

2.4. Cutting of Regions

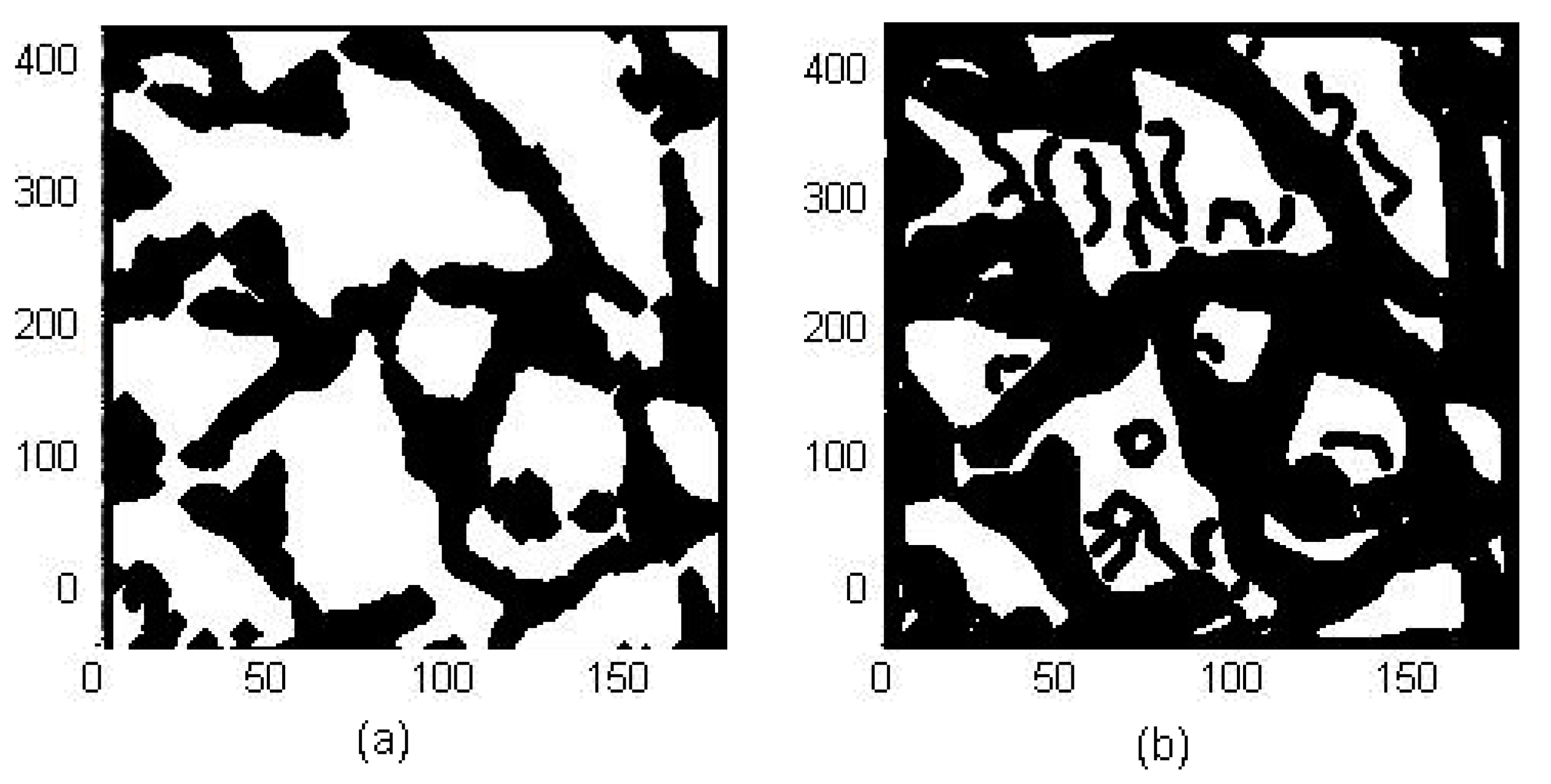

Once the binarization and the detection of the edges have been obtained, the regions of interest are generated, in which it is possible to find hypothetical particles. To do this, the original binarized image shown in

Figure 5a was smoothed, using the opening and closing morphological operators, generating smoother edges, as seen in

Figure 5b. This operation tends to increase the internal details of the threshold regions.

As it can be appreciated in the red circles in

Figure 5, the internal details are exalted for a better fit with the edges. Subsequently, this image was eroded, and the gaps were filled (

Figure 6a), in order to then expand the edges generated by Canny (

Figure 4d) and subtract them from this image, generating regions in which it is possible to find the hypothetical particles, as shown in

Figure 6b.

2.5. Elimination of Over-Segmentation

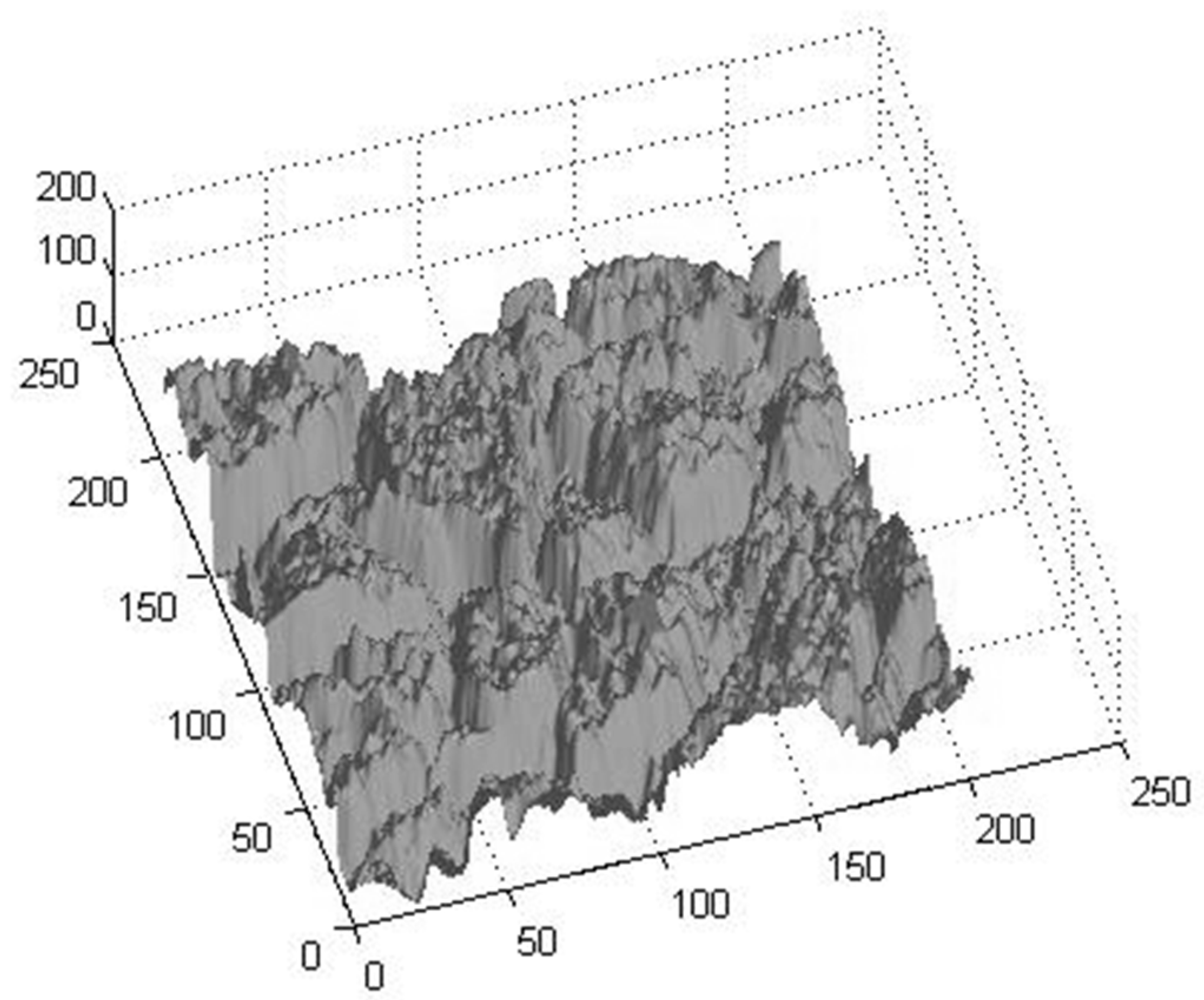

Gray scale images can be transformed into 3D space. In this type of image, each pixel is transformed into a 3D shape using its coordinate (x, y) as the position and its gray level as the elevation. The 3D representation applied to the original image (

Figure 4a) with a gray level between 0 and 255 can be seen in

Figure 7. The areas that represent peaks are the regions where the hypothetical particles can be found, and the valleys or low areas are regions where there is no interest for the meeting of particles. This interpretation can be used to eliminate over-segmentation, since, as seen in the peaks, there are also valleys, but they are clearly areas where it is possible to find a particle.

An image contains multiple local minimum or maximum regions, but only one global minimum and maximum. These maximum and minimum values are used for a morphological reconstruction, segmenting the image through the watershed transform.

To find these minima, the edges found by Sobel (

Figure 8a, from

Figure 3b) were used, and the image segmented by Canny (

Figure 6b) was used as a mask, resulting in

Figure 8b.

2.6. Watershed Transform

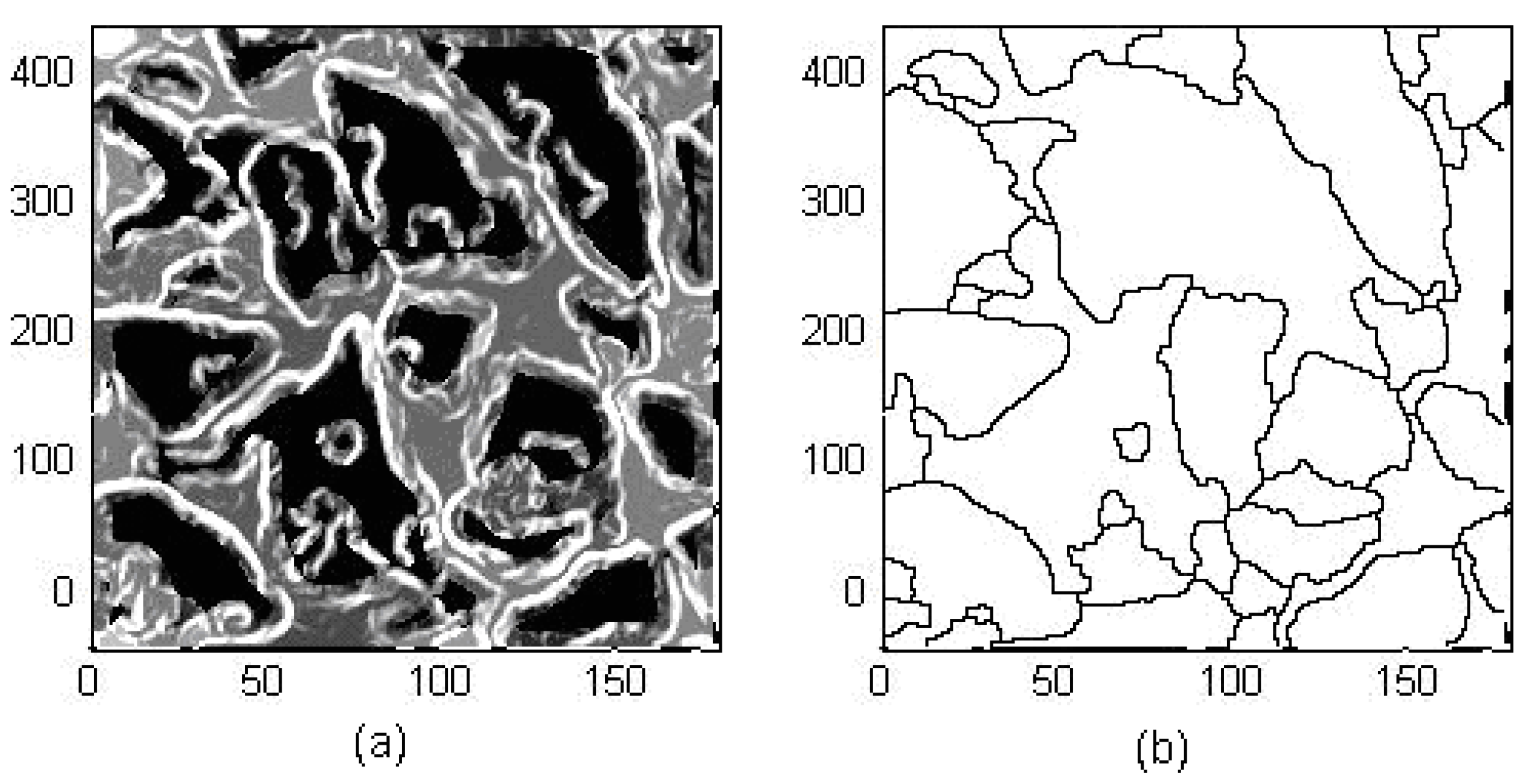

After applying the edge detection and over-segmentation elimination methods, with the search for minima, the watershed transform was applied. To improve the performance of the found regions, one of the advantages of this transform is that it only segments the regions based on the images generated by the previous processes.

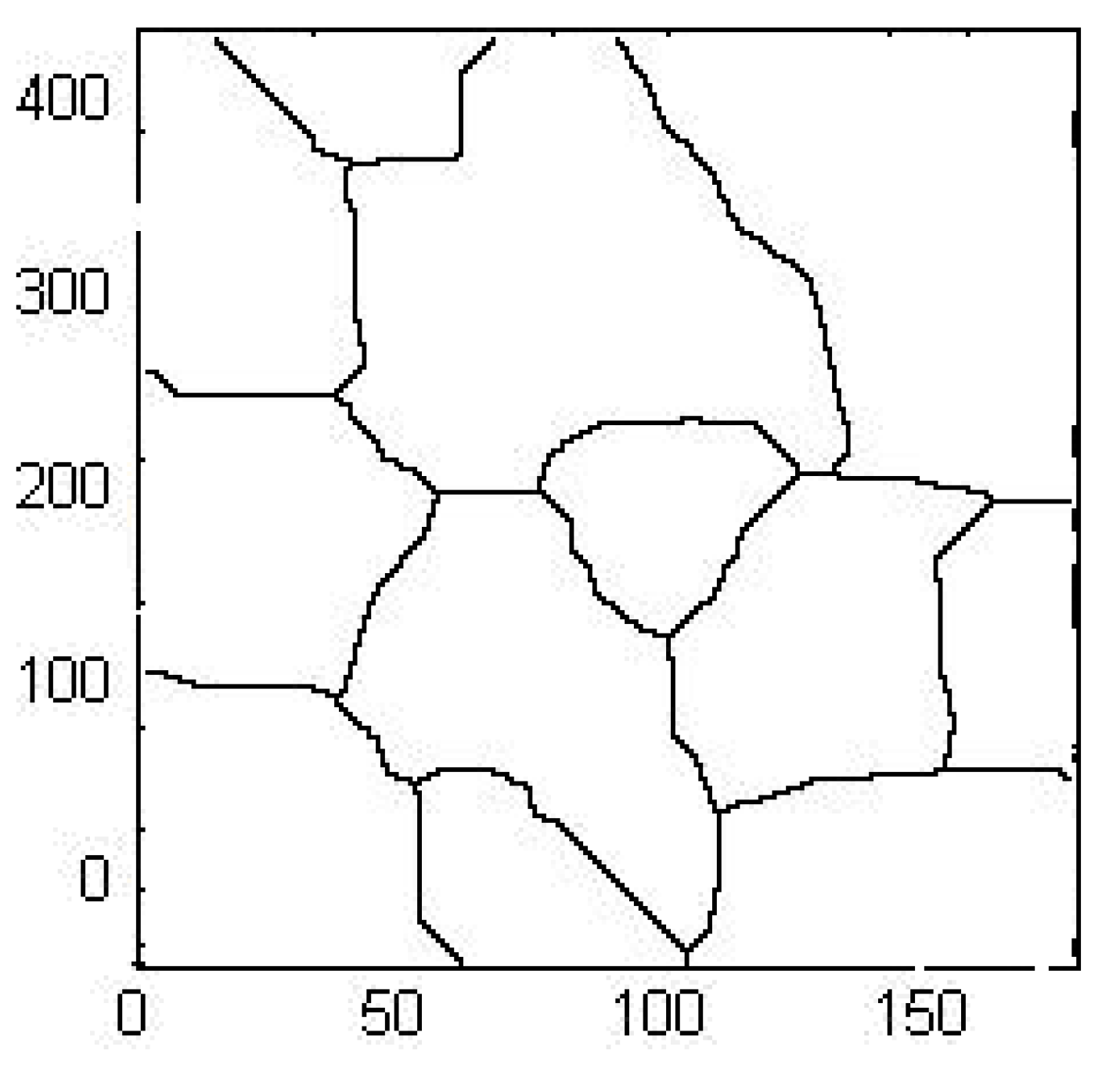

The watershed transform generates regions which are the limits or edges of the “floods” that it affects. A clear example can be seen in

Figure 9b, where the transform is applied to

Figure 9a, from

Figure 8b.

As it can be seen in

Figure 9b, there is already a first approximation of hypothetical particles. However, it is still necessary to determine, in a better way, the shapes of the regions. For this purpose, the resulting image was complemented (

Figure 9b), and the previous segmented image was subtracted (

Figure 6a), generating new regions with a closer approximation to the hypothetical particles to be characterized, as shown in

Figure 10b.

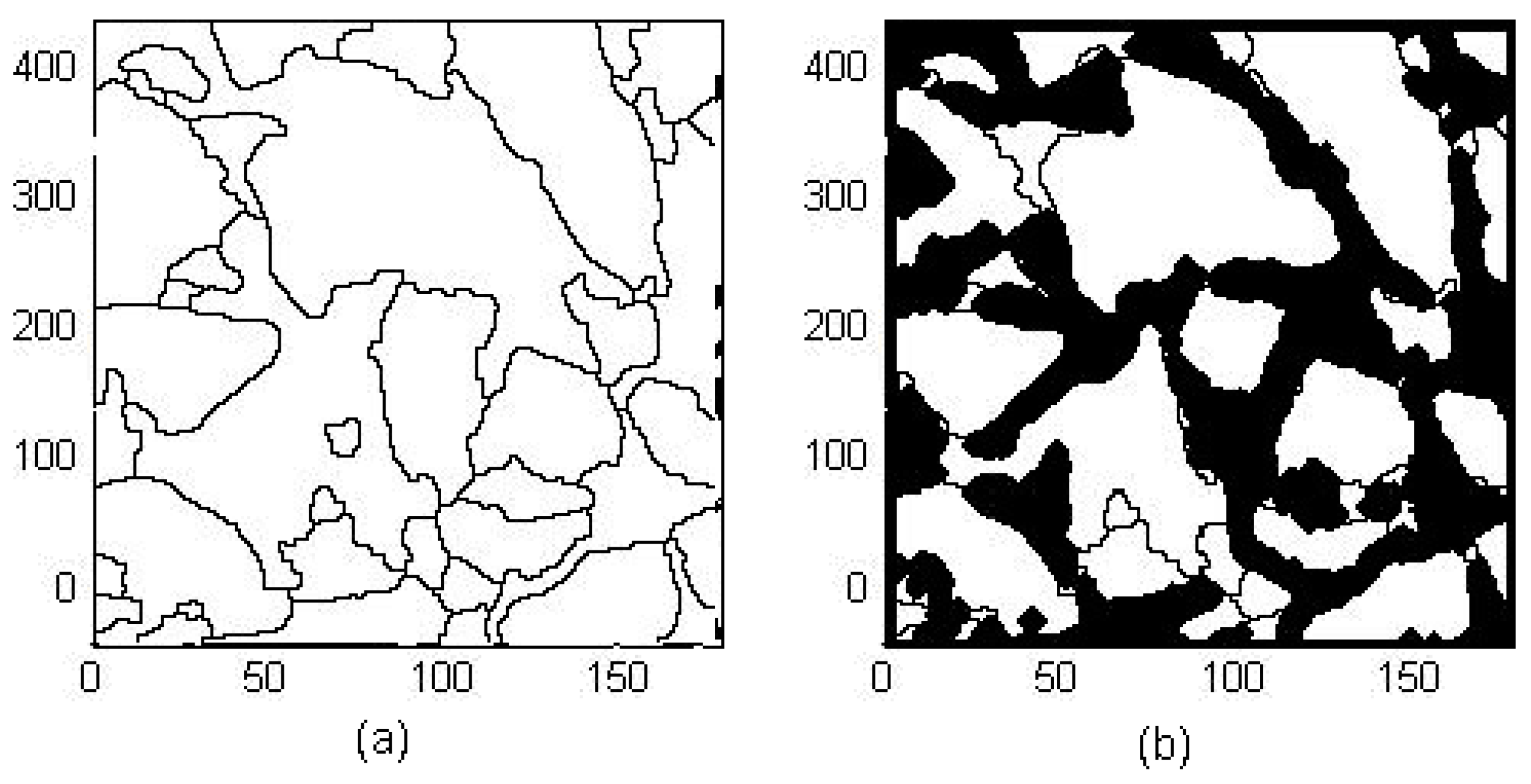

In order to further refine the segmentation process, the watershed transform was applied to the maxima found in the image resulting from the subtraction (

Figure 10b), in order to know, with a wide margin, the probable regions where a possible hypothetical particle can be found, as seen in

Figure 11.

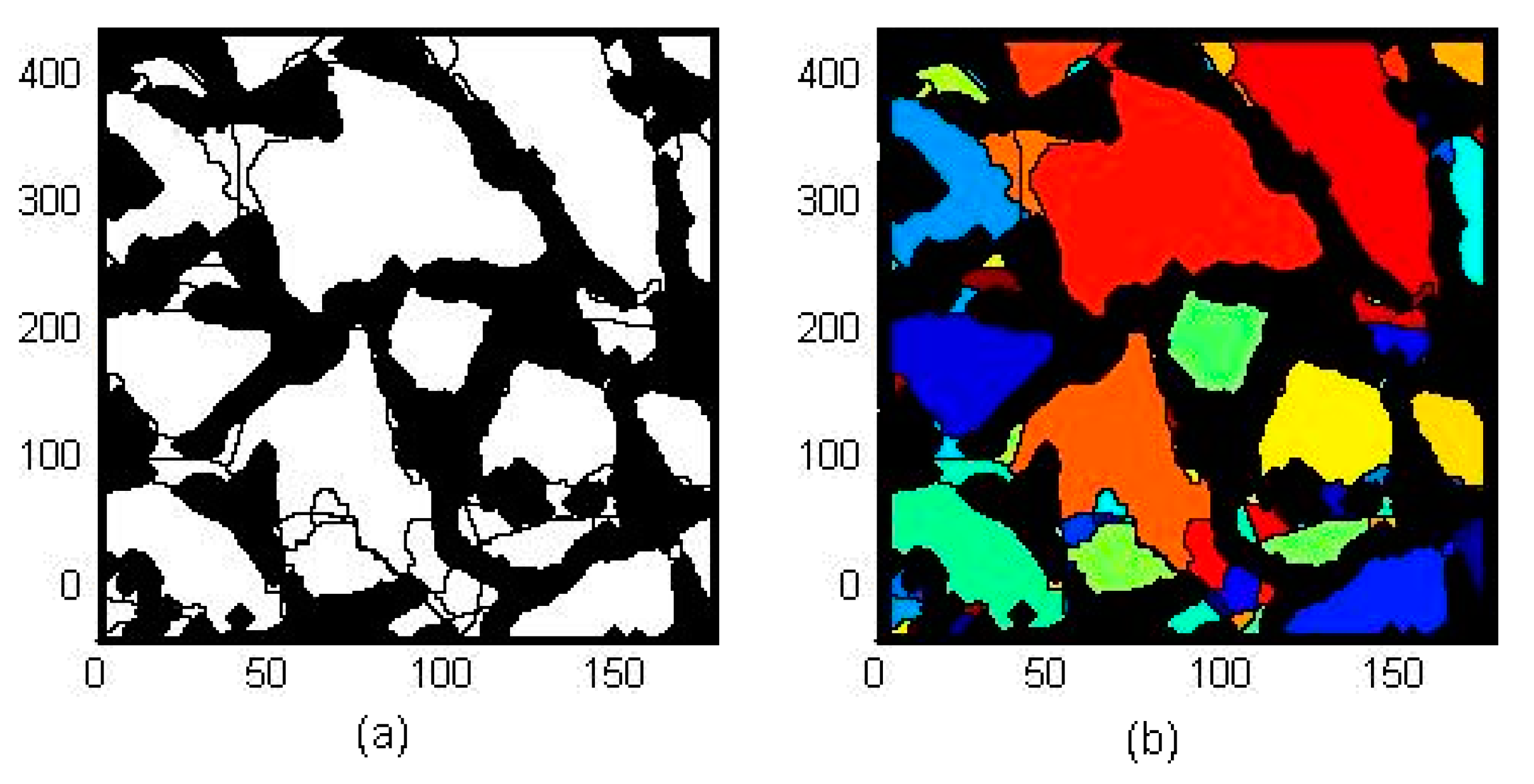

The resulting segmentation was multiplied with the previous resulting image (

Figure 10b), and the final segmentation was generated to process and extract the characteristic properties (

Figure 12a), coloring them for better identification (

Figure 12b).

2.7. Property Extraction

Once each of the hypothetical particle regions was segmented and extracted, we proceeded to extract the characteristic properties of each of these regions. To do this, the “region props” function was used, which was implemented in the Matlab image analysis “Toolbox”. Each of these characteristics returns one or more values that correspond to the measurements carried out, providing the pixels as a reference. In addition, each of these measurements is multiplied by a conversion factor which indicates the measurement to be calculated by the number of pixels.

2.8. Comparison Strategy

A quite complex problem when proposing algorithms that perform image processing is to have a quantitative measurement of their performance, not only in terms of processing time, which can be a relevant factor, but also in terms of the quality of the processing.

In addition, segregation occurs while particles are transported, as a consequence of the conveyor belt vibrations. This phenomenon is well known from plant experience, and it has recently been modeled and studied [

31]. This particle segregation settles down small particle sizes, while larger particles emerge to the surface of the bed, as shown in

Figure 13. This bias in the sampling procedure (2D imaging) oversamples large particles. This bias allows a better characterization of larger particles, which is the main objective of the technology, in order to detect classification failures (screening) and to reduce subsequent operational problems downstream due to particle plunging in the secondary or tertiary crushing stage.

The problem validation is, fundamentally, in having something to compare the performance with, that is, an ideal of the treated image, since, as shown many times, that does not exist unless a person conducts it manually, for example, marking with a specific color in the case of touching objects, as shown in

Figure 13.

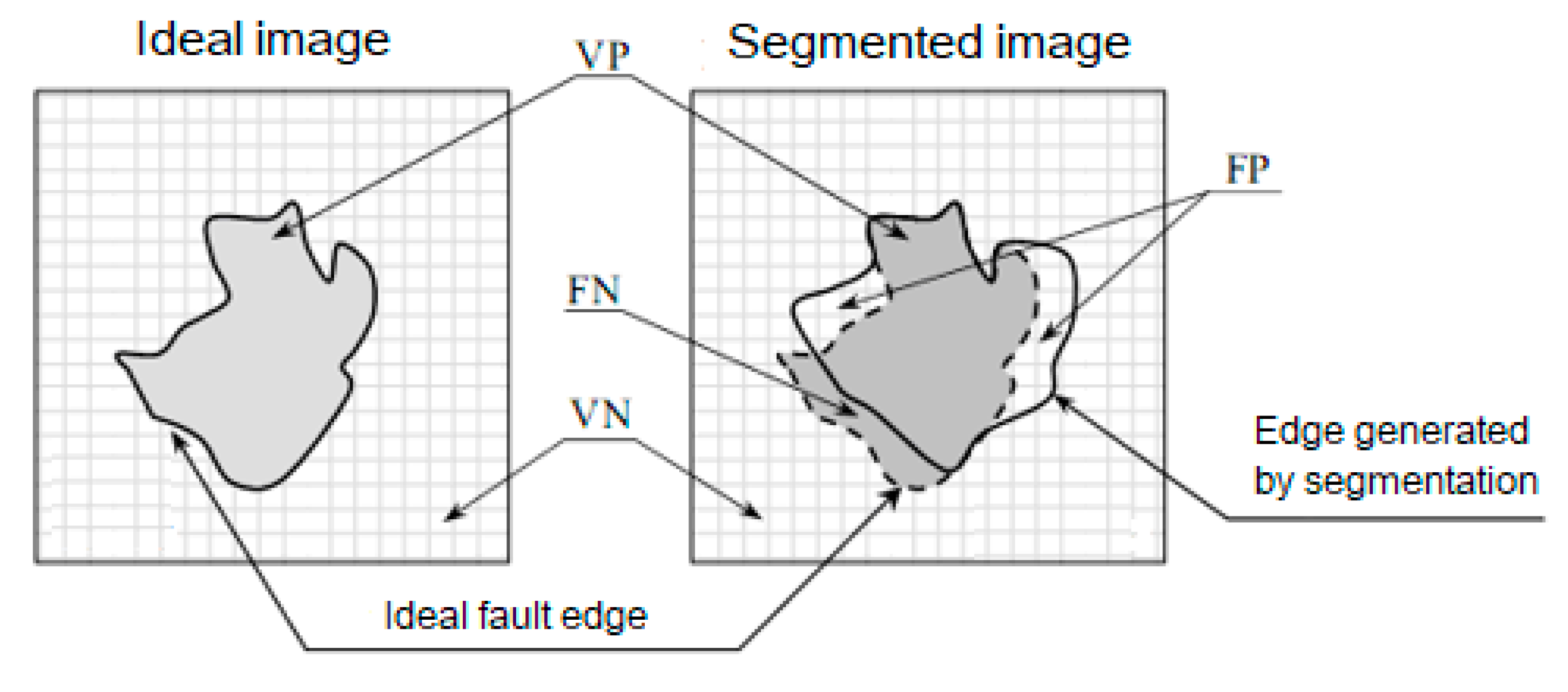

Figure 13 represents the conveyor belt in operation. To evaluate the performance achieved by the segmentation, it is measured by classifying 2 classes of tests that help measure the performance of the system [

30]. These classes are constituted by the set of segmented regions with defects, and those free of defects or that are regular; for this, the “sensitivity” and “1-specificity” tests must be determined.

For each of the comparison cases, it is expected to obtain the following:

FP: False positives. The number of points where a particle was found but it should not have been.

FN: False negatives. The number of points where a particle was not found but it should have been.

VP: True positives. The number of points in successful particles.

VN: True negatives. The number of points that are not part of a particle but are correctly detected.

These four parameters were used to conduct the sensitivity test, where its equation is:

Additionally, for the “1-specificity” test, the representative equation is:

The first of the Sn indicators takes the value 1 in the case of recognition of all particle points, and 0 in the case of not recognizing any particle points. This indicator shows if the particles that are being searched were found or not, that is, it provides a measure for the sensitivity of the algorithm that is being measured to the test case that is being applied.

The indicator 1 − Sp takes the value 0 in the case of a perfect recognition of the edge points, varying up to 1 in the case of detecting any false positives correctly. Unlike the first indicator, this shows the relative number of points that failed to be detected as edge points, that is, it shows the precision of an algorithm in the test case that it is measuring.

This way of comparing can be questioned since, as shown many times, an algorithm, in general, tends to partially fail, or, sometimes, it is not totally successful but works badly in parts. In any case, this way of comparing is a practical and repeatable technique.

Figure 14 presents an example of the comparison method used to calculate the variables VP, VN, FP, and FN. In this way, the “sensitivity” and “1-specificity” can be calculated when the values of each pixel of the two images are analyzed, and the comparison can be conducted.

2.9. Industrial testing

During the commercial validation period, an ANALITA sample prototype was installed to analyze the material carried by the conveyor belt E-135 of the secondary and tertiary crushing plant. This belt is the intermediate point between the 2 crushers; therefore, it is an important point of reference on the size and quality of the transported material.

It is worth mentioning that the tests were conducted with an old USB 1.0 data communication standard, which does not provide all the features that its successors bring. However, for test analysis, it is sufficient to see the behavior of the sensor in industrial sites.

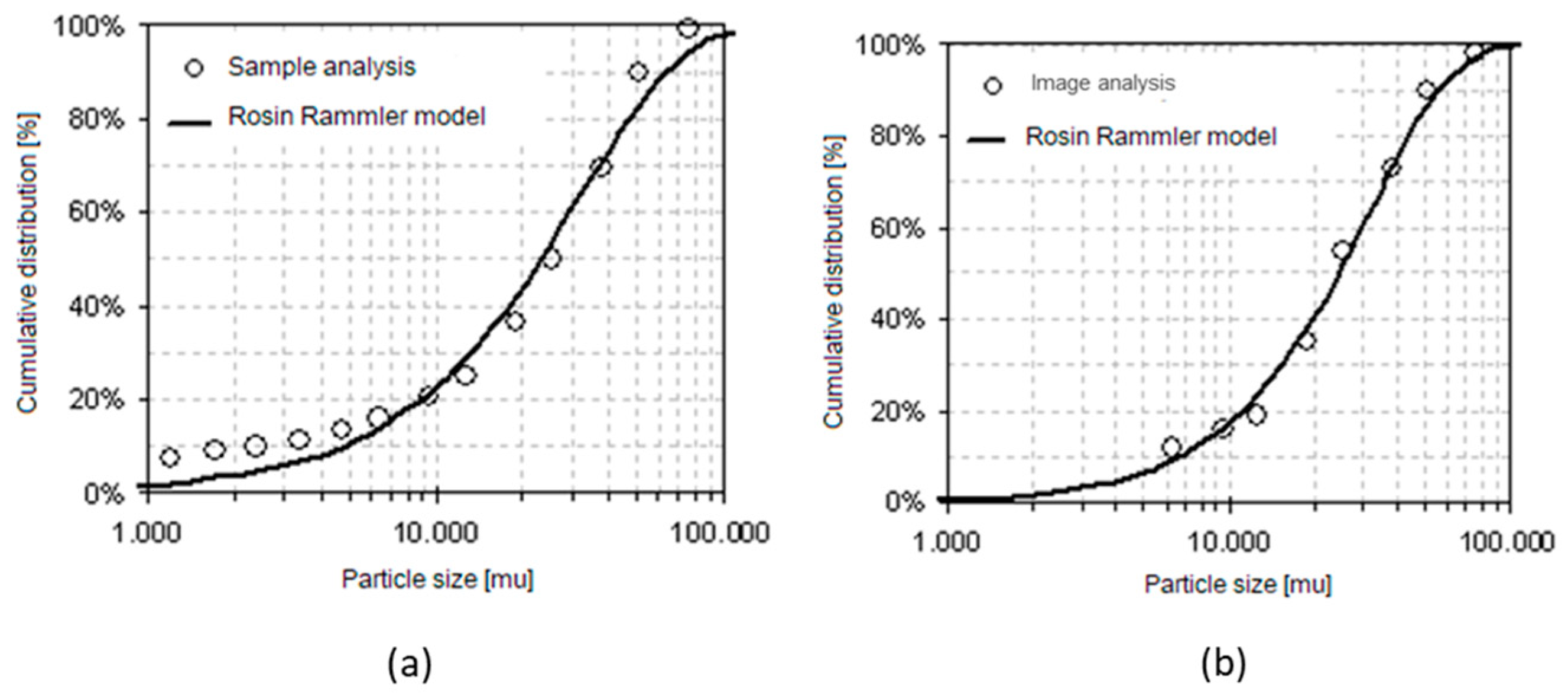

Around 215 samples of photographic images were taken for a period of 30 min, which provided an average material of 300 tons, as seen in

Figure 15, which were analyzed and compared with the curves of the percentage passing by weight of such belt.

The revision of the tests carried out made it possible to formulate the observations detailed in the following points.

2.10. Global Observations of the Test

The tests were compared against the results of historical samples, since, due to the very nature of the mining operation, it was not possible to obtain a real contrast of the same analyzed material (counter-sample).

It should be mentioned that the test methods differ in the way of obtaining the different classes of material, mainly because of the sampling method with Tyler meshes. Although they classify the material according to a diameter established by each type of mesh, its representation of the passing percentage is based on the total weight of the particles, retained by said mesh, contrary to how the classification is conducted by means of image analysis, since this is carried out with respect to the amount that is retained by a certain limit, with the number of total particles. For reasons of the density of the material under study, the results obtained vary according to the margins of this.

To determine the distributions, 2 different classification methods were carried out. First, the characteristic size that defines the ISO standard for granulometric sizes was taken as a reference, and the passing percentages were counted according to the amount under that size with respect to the total amount of particles. For the second method, the percentiles were counted, and the corresponding sizes were derived.

The tests were carried out together with the same conveyor belt, without extracting data from the control room or other PLC (programmable logic controller) control equipment.

4. Conclusions and Future Remarks

A hardware and software system for online measurement of particle size distribution based on image analysis was developed and implemented. This analyzer was created by separating the process into stages, such as image acquisition and enhancement, noise reduction and processing, edge detection, region cutting, over-segmentation elimination, watershed transform application, and property characterization, which were finally used to create the size distribution. The prototype and software demonstrated the technical feasibility of using this system in industry. Tests were carried out that showed that the sensor manages to be a suitable tool for particle size analysis.

With the comparison and performance strategy procedure, it was obtained as a result that the sensitivity, that is, the average amount of particles that the analyzer manages to detect in an image, is 60% of the particle area, and the precision (model fitting) is 5%. The analyzer was validated at a mining company of Chile, where an average error of 4.78% was obtained when the Rosin Rambler model was adjusted. Nevertheless, with the Rosin Rammler modeling method, this error was reduced to 1.61% for a coarse material; therefore, this device can be used to determine size distributions on conveyor belts. In addition to this, the most appropriate algorithms could be established to reduce noise, improve the contour of the particles, and optimize the segmentation time through Matlab software.

This system also presents an opportunity for the use of machine learning or deep learning, which would substantially improve its performance and would have the advantage of not needing such repeated adjustments.