Abstract

This paper presents the partial results of a study on obtaining compacted fuel from fine-grained coal fractions and biomass. The aim of the study was to determine the impact of selected parameters of the extrusion process and the applied binder (mechanical durability and density of the products). The fuels were formulated using the extrusion process. Raw materials used in the research were: Fine-grained coal (flotation concentrates), biomass (hydrolytic lignocellulose), and a wide spectrum of organic and mineral binders and their compositions. During the investigations, the variable factors were the following: Extrusion pressure, preparation of the mixtures for extrusion (mixing time and temperature of the mixture), composition of the extruded mixtures (share of fine-grained coal and biomass and type of binder). It was found that it is possible to extrude mechanically durable briquettes from mixtures containing fine-grained coal products and biomass. Under the conditions of the experiment, the most favorable mechanical durability was characterized by briquettes containing in their composition 90% of coal and 6% of biomass (in relation to the dry state). The briquettes with the most favorable physico-mechanical properties were obtained using organic binders—Starch (based on wheat and potato starch) and cellulose derivatives.

1. Introduction

During the heating season, especially in the winter, there is an increase in air pollution which is associated with the burning of fossil fuels in heating devices in the individual heating sector (formation of smog as a result of the so-called low-stack emission). The reason for smog formulation is primarily the combustion of low-quality fuels (flotation concentrates and coal sludges) and the use of low-class chamber boilers with manual dosing of fuel. However, from year to year, there has been an increase in public awareness concerning the phenomenon described, which is mainly related to the intensity of media reports and the dissemination of reports of institutions dealing with the issues of environmental protection and preventive care.

National and European legislation aims to improve air quality by eliminating the combustion of low-quality fuels and energy and ecological inefficient boilers. In Poland in October 2017 there entered into force the Regulation of the Minister of Development and Finance of 1 August 2017 on the requirements for solid fuel boilers [1]. In November of the following year, the Regulation of the Minister of Energy of 27 September 2018 regulated the quality requirements for solid fuels [2], the requirements for fuels introduced to the market and used in households and combustion plants with a nominal thermal power lower than 1 MW. In addition to the abovementioned legal provisions, anti-smog resolutions of individual self-government bodies came into force, which, using the amendment introduced in art. 96 in the Act on Environmental Protection Law [3], regulate types of fuels that cannot be used in individual heating in their area. The quoted legal provisions in practice mean the elimination of flotation concentrates and coal sludges from the market, and consequently, from the primary market of boilers—Devices that do not meet the requirements for class 5 boilers in accordance with standard PN-EN 303-5:2012 [4] (practically: Manual feed boilers).

The elimination of flotation concentrates and coal sludges from the market may cause them to be deposited in the environment and, consequently, affects the loss of their energy potential. In general, flotation is a process widely used in the processing of minerals, including coal [5,6]. This is particularly important for flotation concentrates, which are characterized by relatively good quality parameters, and their only drawback is very fine grain size that results in excessive emission of dust during the combustion. In turn, the withdrawal of manual feed boilers that do not meet the requirements for class 5 boilers according to PN-EN 303-5:2012 [4] will increase the number of automatic boilers used in individual heating, and thus increase the demand for fuel for them (mainly qualified fuels like eco pea coals and culm). Taking into account the emerging market potential resulting from insufficient supply of qualified fuels and, on the other hand, from the irretrievable loss of energy potential of fine-grained coal fractions, it seems necessary to take action towards their use for the production of fuels with appropriate physico-chemical parameters desired for automatic boiler fuels.

As previously mentioned, flotation concentrates (fine-grained coal products derived from mechanical coal processing plant) are characterized by relatively good properties. Despite their similar physical appearance, they contain much less ash (from 4% to 18%) and sulfur (from 0.21% to 0.8%) than coal sludges (ash and sulfur content respectively: 13–40% and 0.4–1.0%). The calorific value of flotation concentrates is about twice as high as the calorific value of coal sludges and it is in the range from 18 to 25 MJ/kg (for coal sludges is ranging 10–20 MJ/kg) [7]. Due to the very small grain size, flotation concentrates are not suitable for fuel, and legally cannot be used as fuel in individual heating sectors. This material may cause significant difficulties at the stage of its storage, transport, and utilization. One of the methods of processing fine-grained materials (including flotation concentrates) is their compaction, to obtain utility fuels [8,9].

The formation of fine-grained materials can be carried out by pressure and non-pressure methods using a binder or without binder [10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26]. In most cases, coal-based formed fuels require the use of a suitable binder [8,12,15,17,20,21,22,23,24]. Generally, as binders, solid and liquid, mineral or organic substances are used, including carbochemical (i.a. coal tar, coal tar pitch) and petrochemical compounds (i.a. bitumen, wax), polysaccharides (i.a. starches, molasses), polymers (i.a. PVA, PVC), co-polymers dispersion, mineral substances (i.a. lime, clay, bentonite), biomass and others. The choice of the forming method is primarily determined by the properties of the raw material and the required target properties of the final product. The desired product characteristics of the compacted fuel are, above all, adequate mechanical durability and density. Depending on the use of fuel and logistic conditions (e.g., necessity of transport and storage in the open air, exposure to atmospheric factors), some types of formed fuels should also be waterproof [21,22].

Preparation of quality compacted fuels for various types of heating devices is one of the areas of interest of the Institute for Chemical Processing of Coal in Zabrze [19,20,24,25,26]. The paper presents partial results of research on obtaining a compacted fuel from the fine-grained coal fraction and biomass with properties that meet quality requirements for solid fuels (according to the Regulation of the Minister of Energy of 27 September 2018 on quality requirements for solid fuels [2]), dedicated to use in automatic heating boilers to meet the requirements for class 5 (according to PN-EN 303-5:2012 “Heating boilers–Part 5: Heating for solid fuels, hand and automatically stocked, nominal heat output of up to 500 kW-terminology” [4]. The aim of the research was to determine the impact of selected parameters of the extrusion process and the applied binder on usable properties (mechanical durability and density) of the briquettes. The research was carried out as part of the project POIR.04.01.02-00-0038/17 “Development of technology for the production of eco-friendly pellets for individual heating sector based on fine-grained coal grades”—Acronym: EKomPell.

2. Materials and Methods

2.1. Raw Materials

The EKomPell project assumed that the designed fuel would be a composite fuel consisting of fine-grained coal fractions, biomass, and binder. Ultimately, the fuel being developed will be intended for use in domestic heating boilers to meet the requirements for class 5 boilers in accordance with PN-EN 303-5:2012 [4]. The fuel is to be produced in a technological line belonging to an industrial partner (JSW Innowacje S.A.). Fuel after the briquetting process will be subjected to the drying process in a belt dryer, and then packed in bags for convenient storage in a roofed place—A home boiler room.

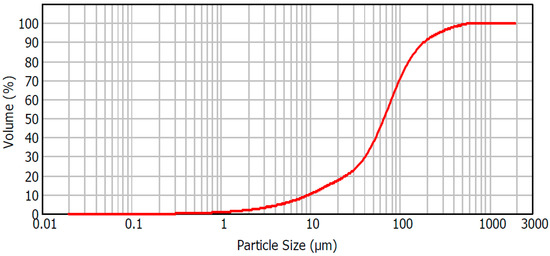

Coal raw material used in the research was a flotation concentrate, originating from one of the national hard coal mines. As the biomass component, hydrolytic lignocellulose was used. The basic physicochemical properties and particle size distribution of the flotation concentrate and biomass are presented in Table 1 and Table 2 and Figure 1. The analytical determinations were made in accordance with the standards and procedures applicable in the IChPW Centre for Laboratory Research, which holds the Accreditation Certificate No. AB081.

Table 1.

Properties of raw materials used.

Table 2.

Particle size distribution of raw materials used.

Figure 1.

Cumulative particle size distribution of coal—Grain size 0–0.5 mm.

The following organic and mineral additives as well as their compositions were used as binding agents (binders):

- solid binders based on wheat starch (S1, S2) and potato starch (S3)

- liquid briquetting binder based on simple and complex carbohydrates (sugars) (M1 i M2)

- solid binder based on cellulose derivatives (C1)

- protein based binders (K1 i G1)

- synthetic, organic polymer binders (LP1 i LP2)

- inorganic binders: quicklime (CaO), hydrated lime (Ca(OH)2), bentonite (BNT) and calcium-aluminum cement (CEM).

2.2. Research Methodology

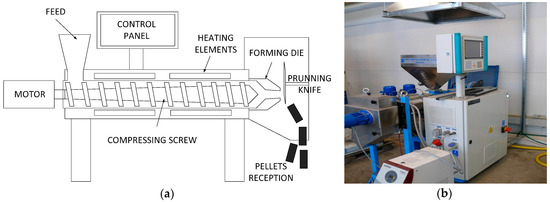

The production of coal-biomass briquettes was carried out in a S45 single-screw extruder from Metalchem (Figure 2). The device makes it possible to produce a cylindrical shaped fuel, so-called briquettes with a given diameter (depending on the extrusion die used)—Figure 3.

Figure 2.

(a) Scheme of the single-screw extruder; (b) general view of the single-screw extruder.

Figure 3.

General view of briquettes produced.

The weighed raw materials were homogenized in a planetary mixer. Based on our previous experience, it was determined that the moisture content in the extruded mixture should be 30 ± 2%—This level of moisture (regulated by the addition of water) enables smooth implementation of the extrusion process. The briquettes produced in the extruder were dried in a chamber drier at 80 °C until the total moisture content was below 5%.

Dried briquettes were subjected to the assessment of basic physico-mechanical parameters, such as: apparent and bulk density, compressive strength, and mechanical durability.

The apparent density (ρapp) was assessed by the quasi-fluid pycnometric method using the GeoPyc 1360 from Micromeritics. Bulk density (ρbulk) was determined as the quotient of the mass of freely poured briquettes in the measuring cylinder to its volume (1000 cm3). To determine the compressive strength (FS), a hydraulic press with a maximum pressure of 5 kN was used—The determination consisted in compressing individual briquettes (the longitudinal section was perpendicular to the pressure force) until they were degraded. The result of the research was the average of 10–12 sample test results.

An important property of briquettes as a fuel is their mechanical strength DU (“The mechanical durability is a measure of the resistance of compressed fuels towards shocks and/or abrasion as a consequence of handling and transportation” [27]). This parameter determines the behavior of fuel during its delivery from the hopper to the chamber of the automatic boiler. Determination of mechanical strength (DU) was carried out using the Pelltest device—The determination was made in accordance with PN-EN ISO 17831-1:2016-02 standard—The strength measure is the percentage share of briquettes that are not degraded under the conditions of the determination [27]. Our previous research showed that the minimum mechanical strength of briquettes (that protects them against excessive degradation during feeding of the heating device and minimizing the emission of dust particles during their combustion) is 85%. This value was adopted as a limit value in assessing the quality of briquettes produced within the project.

During the investigations, the variable factors were the following: extrusion pressure, preparation of the mixture for extrusion (mixing time and temperature of the mixture), composition of the extruded mixture (share of fine-grained coal, biomass, and type of binder).

3. Results and Discussion

3.1. Influence of Extrusion Process Pressure on Briquette Quality

In the extrusion process, it is not possible to directly determine the process pressure value. With the constant properties of the extruded mixture, the pressure can be varied by changing the rotational speed of the screw compressing the mixture, or, by using dies of various internal diameters. The tests carried out for the rotational speed of the compressing screw in the range from 25 to 60 rpm showed that this method was not useful in the conducted tests. At 25 rpm, the efficiency of the process was very low, and the material extruded tended to block the extrusion machine. In turn, briquettes obtained at the screw speed of 60 rpm were characterized by irregular shape (empty caverns) and breaks in their production was also observed. The most stable operation of the extrusion machine was observed at the rotational speed of the compressing screw at a level of approx. 40 rpm.

3.2. Influence of Mixing Time and Extrusion Process Temperature on Briquettes Quality

In connection with the above, the variable pressure of the process was obtained via the application of extrusion dies with various internal diameters with the constant rotational speed of the compressing screw (40 rpm). The diameter of die has a direct influence on the effective value of the extrusion pressure—The smaller the diameter, the higher the resistance of material flow through the channel of the die, and thus the higher the pressure. The test were conducted with the use of dies with internal diameters of 10, 12, and 14 mm. Extruded blend consisted of 90% dry matter of coal, 6% dry weight of biomass, and 4% dry weight of a binder based on wheat starch (S2). The mixing time of the blend was 5 min, and the temperature of the extrusion process (the mixture undergoing the process) was about 20 °C. The results of tests carried out are presented in Table 3.

Table 3.

Properties of briquettes produced (variable: extrusion process pressure).

For the case, with the increase in the inner diameter of the die (reduction of the pressing pressure), deterioration of the basic physico-mechanical parameters of the briquettes was observed. Despite this, the strength parameters of the briquettes produced were at a high level. The mechanical durability (DU) of briquettes obtained using dies of different diameters was above 90% (in each case).

The investigation of the effect of mixture preparation on briquette quality was carried out for the same mixture as in the tests on the impact of extrusion pressure, i.e. consisting of fine-grained coal, biomass, and binder S2 in the percentage ratio of 90:6:4 of dry matter. In all the tests, a forming element (die) with an internal diameter of 10 mm and a speed of the compressing screw 40 rpm were used.

To investigate the effect of the mixing time of raw materials, the mixing time ranged from 5 to 15 min—The components were mixed at room temperature (about 20 °C). Diversified process temperature was obtained by heating the mixture in the range from approx. 20 °C (ambient temperature) to 60 °C, and the mixing time of the blend was constant and amounted to 5 min. The obtained test results, in the form of the physico-mechanical properties of the produced briquettes are presented in Table 4.

Table 4.

Properties of briquettes produced (variable: mixing time and extrusion process temperature).

Extending the mixing time of raw materials and increasing the temperature of the extruded mixture caused a slight deterioration of the physico-mechanical parameters of the briquettes produced. The mechanical durability decreased by 2% for 15 min. mixing time, and decreased by 1% for a process temperature of 60 °C. However, in all cases the value of the mechanical durability was maintained at a higher level than the assumed threshold value and exceeded 90% in each case.

3.3. Influence of Coal and Biomass Raw Material Proportion on Briquette Quality

The type and properties of the basic carbonaceous components of briquettes—Fine-grained coal fractions and biomass—Determine primarily their main utility values including calorific value and ash content. Some of the physical properties of coal and biomass, such as the particle size distribution, shape, brittleness or elasticity of the particles also affect the susceptibility to the formation of stable densified products. Preliminary tests for the production of extruded briquettes without the use of a binder showed the necessity of adding binders in the formula of the fuel. Regardless of the inner diameter of the die used (10, 12, or 14 mm), extrusion of the fine-grained coal itself failed—Too much resistance caused the extruder to block. On the other hand, briquettes obtained from a mixture of fine-grained coal (93.75% of dry matter) and biomass (6.25% of dry matter) were characterized by very low mechanical compressive strength (FS) and mechanical durability (DU), which amounted to 63.5 N and 39.5% respectively.

The tests aimed at determining the effect of the coal-biomass mixture on the quality of briquettes were carried out in analogy to previous research series. The mixture components (fine-grained coal, biomass and binder) were mixed at room temperature in a planetary mixer and then the mixture was extruded through the die having an inner diameter of 10 mm. In order to eliminate the influence of the type and amount of the binder on the quality of the briquettes produced, in each test the S2 starch binder in an amount of 4% of the dry mass of the mixture was used. A variable factor in the conducted tests were the mass shares of coal and biomass, where the minimum share of coal in the mixture was set at 85% (in accordance with the applicable legislative provisions—The Regulation of the Minister of Energy of 27 September 2018 on quality requirements for solid fuels [2]). Table 5 presents the results obtained.

Table 5.

Properties of briquettes produced (variable: Coal and biomass raw material proportion).

Briquettes with the most favorable physico-mechanical parameters consisted of 90% of fine-grained coal. The briquettes made from the rest of mixtures were characterized by slightly worse, but also satisfactory physico-mechanical properties.

3.4. Influence of Binder Type on Briquette Quality

One of the most important factors affecting the mechanical properties of extruded briquettes is the type and amount of binders used. The binders used in this series of tests were the substances listed in Section 2.1. Taking into account the results of previous research, the following basic mixture composition (% of dry matter) was assumed: fine-grained coal material—90, biomass feedstock—6, binder—4. The procedure and parameters of the extrusion process were analogous to the process described in the previous subsection. The results of the tests are presented in Table 6.

Table 6.

Properties of briquettes produced (variable: Binder type).

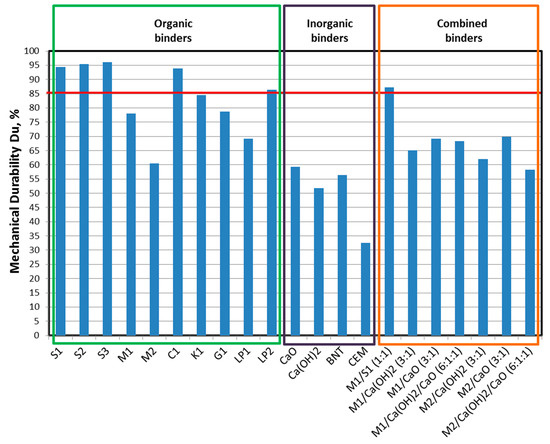

Figure 4 presents the effect of the type of binder on the mechanical durability (DU) of briquettes produced. The red line indicates the minimum mechanical durability that should be characterized by the briquettes produced. As of results from the obtained data, the binder used in the process exerts a significant influence on the properties of briquettes, especially on their mechanical durability. The briquettes with the most favorable physico-mechanical properties, in particular the mechanical durability DU, were obtained using organic binders while the use of inorganic binders did not give a satisfactory result. The best results were obtained using binders based on wheat and potato starch (S1, S2, and S3). The briquettes produced with these binders were characterized by very high mechanical durability—94.4%, 95.4%, and 96.0% respectively. Very high durable briquettes (DU = 93.9%) were also obtained for briquettes consisting of C1 binder based on cellulose derivatives. Of all the tested binders, the minimum strength criterion was also obtained for the polymeric binder LP2 and the combined binder M1/S1 (1:1). Practically all briquettes made with the use of other binders were characterized by mechanical durability significantly lower than the minimum assumed threshold (DU = 85%). Lime is often used as an additive to other binders to improve the strength of briquettes produced [12,15,21,22]. In our cases, addition of lime (both quicklime and hydrated lime, added separately) to the M1 binder caused deterioration of compressive strength and mechanical durability while for M2 binder a slight improvement was observed. The simultaneous addition of a mixture of quicklime and hydrated lime caused deterioration of the briquette properties for both M1 as well as M2 binders. Deniz [21], while on examining the effect of the addition of lime to the co-polymer binder, a decrease in the strength of the briquettes was noted. However, the addition of a mixture of molasses and lime resulted in improved strength. The effect was better as the molasses to lime ratio increased.

Figure 4.

Influence of binder type on mechanical durability of briquettes.

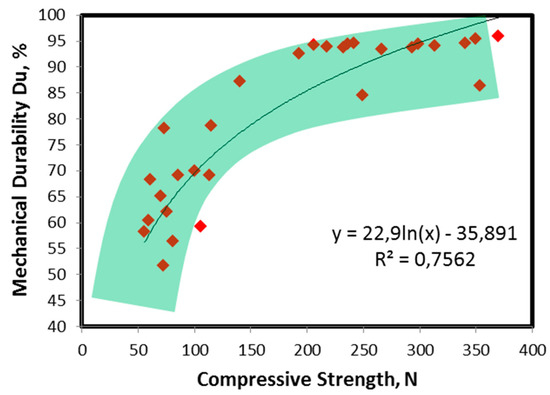

The value of mechanical durability (DU) has a quite strong correlation with the compressive strength (FS) value of the briquettes produced. It was observed that this relationship is logarithmic (Figure 5).

Figure 5.

Relation between mechanical durability and compressive strength.

In the case of briquettes with a relatively low compressive strength (FS approx. 50–125 N), a significant increase in DU is observed along with an increase in FS. After exceeding a certain FS value (approx. 125–150 N), the increase in DU is not so significant. The obtained logarithmic regression equation shows that the minimum compressive strength corresponded to the mechanical durability (when DU = 85%, Fs = 196 N).

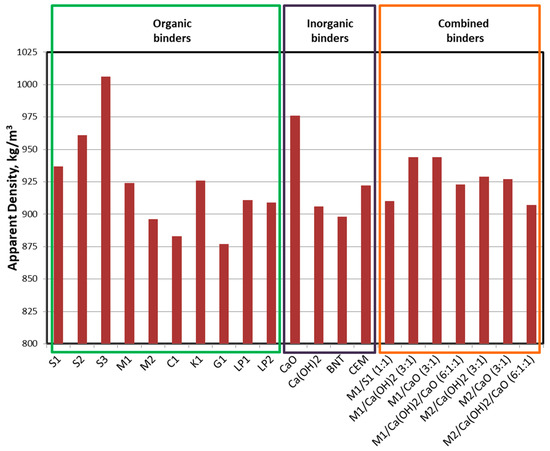

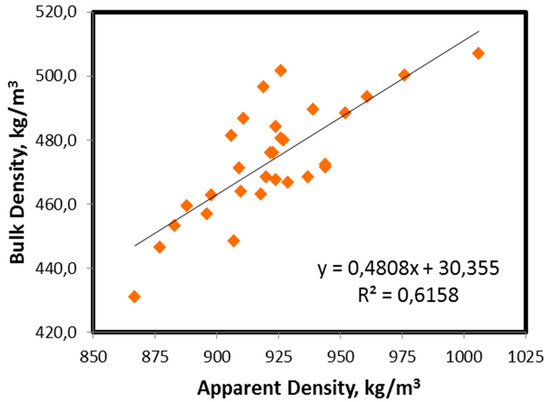

The applied type of binder also affects the apparent density of the briquettes. It should be noted that the differences in density may be caused by both the change in rheological properties of the extruded mixture (affecting the mass transfer resistance), the change in the average actual/apparent density of the mixture (differences in density of organic and mineral substances), and the different behavior of additives during the process of crosslinking and drying. Generally, all of the briquettes produced were characterized by an apparent density of 875–950 kg/m3 (Figure 6). There was no significant effect of the density of briquettes on their mechanical durability DU. However, as expected, a significant correlation was found between the apparent density of briquettes and their bulk density (Figure 7).

Figure 6.

Influence of binder type on apparent density of briquettes.

Figure 7.

Relation between apparent density and bulk density of briquettes.

4. Conclusions

The aim of the research was to determine the influence of the extrusion process parameters and the mixture (including the type of binder used) on the quality parameters of the briquettes produced. On the basis of the conducted research, the following conclusions can be drawn:

(1) The use of the extrusion method allows the production of mechanically durable briquettes from mixtures based on fine-grained coal fractions (e.g., flotation concentrate) and biomass. In the experimental conditions, the best mechanical durability DU (according to PN-EN ISO 17831-1:2016-02) [27] was characterized by briquettes containing in their composition 90% fine-grained coal and 6% biomass (in relation to the dry state).

(2) The briquettes with the most favorable physico-mechanical properties (in particular the mechanical durability DU) were obtained using organic binders—Starch based on wheat and potato starch and binders based on cellulose derivatives.

(3) There was a logarithmic relationship between the mechanical durability DU and compressive strength FS, where the increase in DU with the increase in FS was more noticeable for lower (up to approx. 125 N) ranges of FS.

(4) The apparent density of the briquettes produced was in the range of 875–950 kg/m3, and the bulk density ranged from approx. 431–507 kg/m3. A linear (positive) correlation was observed between these parameters.

Author Contributions

Conceptualization, M.R. and J.R.; methodology, M.R., J.R., and K.I.; formal analysis, M.R.; investigation, A.C. and M.R.; writing—original draft preparation, M.R., J.R., K.I., and A.C.; writing—review and editing, M.R., J.R., and P.F. All authors have read and agreed to the published version of the manuscript.

Funding

The presented results are a part of research carried out under the project POIR.04.01.02-00-0038/17 “Development of technology for the production of eco-friendly pellets for individual heating sector based on fine-grained coal grades”, co-financed from the European Regional Development Fund.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Regulation of the Minister of Development and Finance of 1 August 2017 on requirements for solid fuel boilers. J. Laws 2017. item 1690 (In Polish)

- Regulation of the Minister of Energy of 27 September on the quality requirements for solid fuels. J. Laws 2018. item 1890 (In Polish)

- Act of 10 September 2015 amending the Act - Environmental Protection Law Act. J. Laws 2015. item 1593 (In Polish)

- PN-EN 303-5: 2012. Heating Boilers–Part 5: Heating for Solid Fuels, Hand and Automatically Stocked, Nominal Heat output of up to 500 kW-Terminology; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- Rong, G.; Xia, Y.; Zhang, Y.; Guo, F.; Wang, D.; Zhang, R.; Xing, Y.; Gui, X. Effect of Comminution Methods on Low-Rank Coal Bubble–Particle Attachment/Detachment: Implications for Flotation. Minerals 2019, 9, 452. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, W.; Xu, H.; Zhuo, Q.; Sun, X. Adsorption Behavior of Methyl Laurate and Dodecane on the Sub-Bituminous Coal Surface: Molecular Dynamics Simulation and Experimental Study. Minerals 2019, 9, 30. [Google Scholar] [CrossRef]

- Jelonek, I.; Mirkowski, Z.; Jelonek, Z. The characteristics of floto-concentrate and coal slurries used in central heating stoves as well as the by-products of their combustion. Zesz. Nauk. Inst. Gospod. Surowcami Miner. Energią PAN (Bull. Miner. Energy Econ. Res. Inst. Pol. Acad. Sci.) 2016, 96, 91–104. [Google Scholar]

- Borowski, G.; Hycnar, J.J. Utilization of Fine Coal Waste as a Fuel Briquettes. Int. J. Coal Prep. Util. 2013, 33, 194–204. [Google Scholar] [CrossRef]

- Borowski, G. Pilot tests for utilization of fine coal to fuel briquettes production. Arch. Waste Manag. Environ. Prot. 2013, 15, 9–18. [Google Scholar]

- Klassen, P.V.; Grishaev, I.G. Fundamentals of Granulation Techniques; Khimiya: Moscow, Russia, 1989. (In Russian) [Google Scholar]

- Koch, R.; Noworyta, A. The Mechanical Processes in Chemical Engineering; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1992. (In Polish) [Google Scholar]

- Hycnar, J.J.; Borowski, G. Methods of Increasing the Calorific Value of Fine Coal Waste; Wydawnictwo Politechniki Lubelskiej: Lublin, Poland, 2016. (In Polish) [Google Scholar]

- Peng, J.H.; Bi, H.T.; Lim, C.J.; Sokhansanj, S. Study on Density, Hardness and Moisture Uptake of Torrefied Wood Pellets. Energy Fuels 2013, 27, 967–974. [Google Scholar] [CrossRef]

- Adeleke, A.A.; Odusote, J.K.; Lasode, O.A.; Ikubanni, P.P.; Malathi, M.; Paswan, D. Densification of coal fines and mildly torrefied biomass into composite fuel using different organic binders. Heliyon 2019, 5, e02160. [Google Scholar] [CrossRef]

- Taulbee, D.; Patil, D.B.; Honaker, R.Q.; Parekh, B.K. Briquetting of Coal Fines and Sawdust Part I: Binder and Briquetting-Parameters Evaluations. Int. J. Coal Prep. Util. 2009, 29, 1–22. [Google Scholar] [CrossRef]

- Leokaoke, N.T.; Bunt, J.R.; Neomagus, H.W.J.P.; Waanders, F.B.; Strydom, C.A.; Mthombo, T.S. Manufacturing and testing of from intertinite-rich low-grade coal fines using various binders. J. South. Afr. Inst. Min. Metall. 2018, 118, 83–88. [Google Scholar] [CrossRef]

- Dzik, T.; Marciniak-Kowalska, J.; Madejska, L. Pressure agglomeration of hard and brown coals. Chemik 2012, 66, 445–452. [Google Scholar]

- Kosturkiewicz, B.; Janewicz, A.; Magdziarz, A. Results of Briquetting and Combustion Process on Binder-Free Coking Coal. Pol. J. Environ. Stud. 2014, 23, 1385–1389. [Google Scholar]

- Robak, J.; Matuszek, K. Alternative fuel design process. In Legal and Technological Aspects in: Innovative and Environmentally Friendly Mineral Processing Systems in the Aspect of Sustainable Development; Klich, A., Koziel, A., Eds.; KOMAG Institute of Mining Technology: Gliwice, Poland, 2009. [Google Scholar]

- Robak, J.; Janusz, M.; Sobolewski, A. Preparation of lignocellulosic waste for combustion process. Chemik 2012, 66, 436–440. [Google Scholar]

- Deniz, V. Production of Water-Resistant Briquettes from a Mixture of an Imported Bituminous Coal and a Turkish Lignite with Copolymer Binder. Int. J. Coal Prep. Util. 2013, 33, 26–35. [Google Scholar] [CrossRef]

- Deniz, V. A new binder in production of water-resistant briquettes from bituminous coals: Co-polymer binder. Energy Sources A Recovery Util. Environ. Eff. 2016, 38, 1068–1074. [Google Scholar] [CrossRef]

- Zhang, G.; Sun, Y.; Xu, Y. Review of briquette binders and briquetting mechanism. Renew. Sustain. Energy Rev. 2018, 82, 477–487. [Google Scholar] [CrossRef]

- Rejdak, M.; Winkler, R.; Supernok, K.; Ignasiak, K. Pelletizing tests of waste anthracite dust. Inż. Ekolog. 2016, 49, 100–106. [Google Scholar] [CrossRef][Green Version]

- Rejdak, M.; Czardybon, A.; Ignasiak, K.; Sobolewski, A.; Robak, J. Compaction Studies of Torrefied Willow. J. Ecol. Eng. 2017, 18, 183–192. [Google Scholar] [CrossRef]

- Supernok, K.; Robak, J.; Ignasiak, K.; Szul, M. Preparation of granules made of fine-grained coal fractions for gasification process. Inż. Ekolog. 2018, 19, 1–13. [Google Scholar] [CrossRef]

- PN-EN ISO 17831-1: 2016-02. Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).