Slurry Spreading on a Silt Loam Soil: Influence of Tyre Inflation Pressure, Number of Passages, Machinery Choice and Tillage Method on Physical Soil Quality and Sugar Beet Growth

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Site

2.2. Experimental Design

2.3. Field Measurements

2.4. Laboratory Measurements

2.5. Weather Conditions

2.6. Statistical Analysis

3. Results

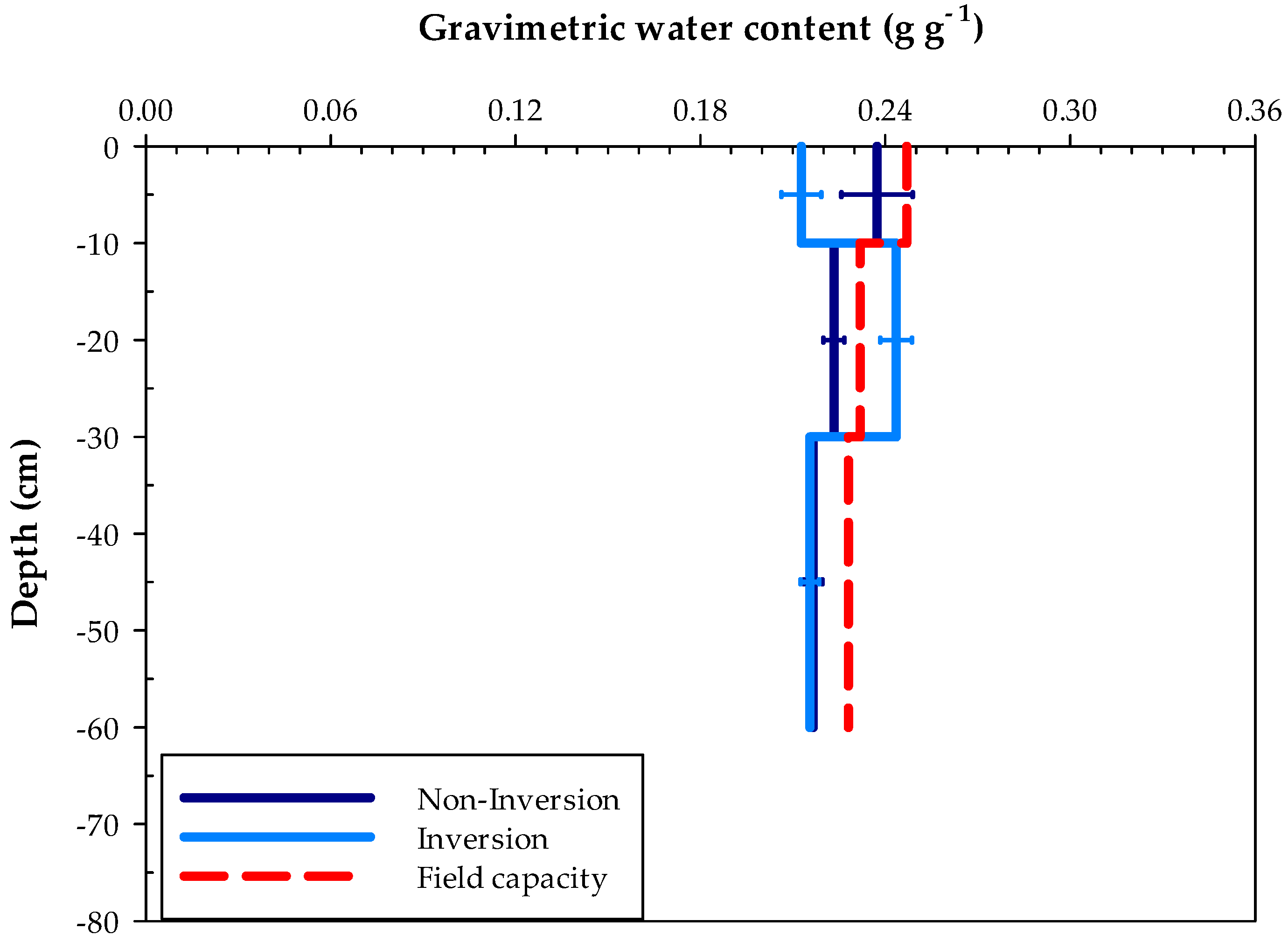

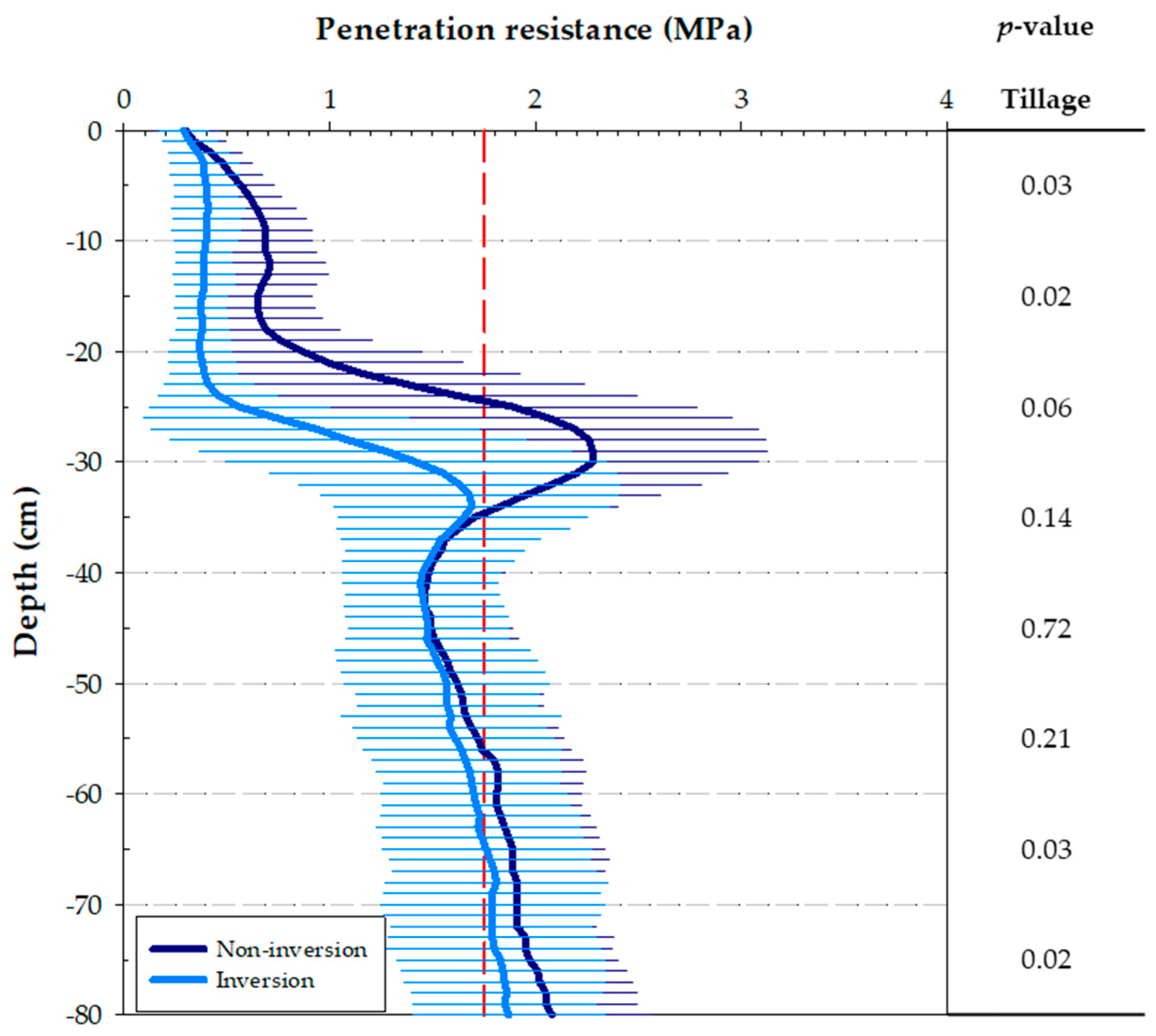

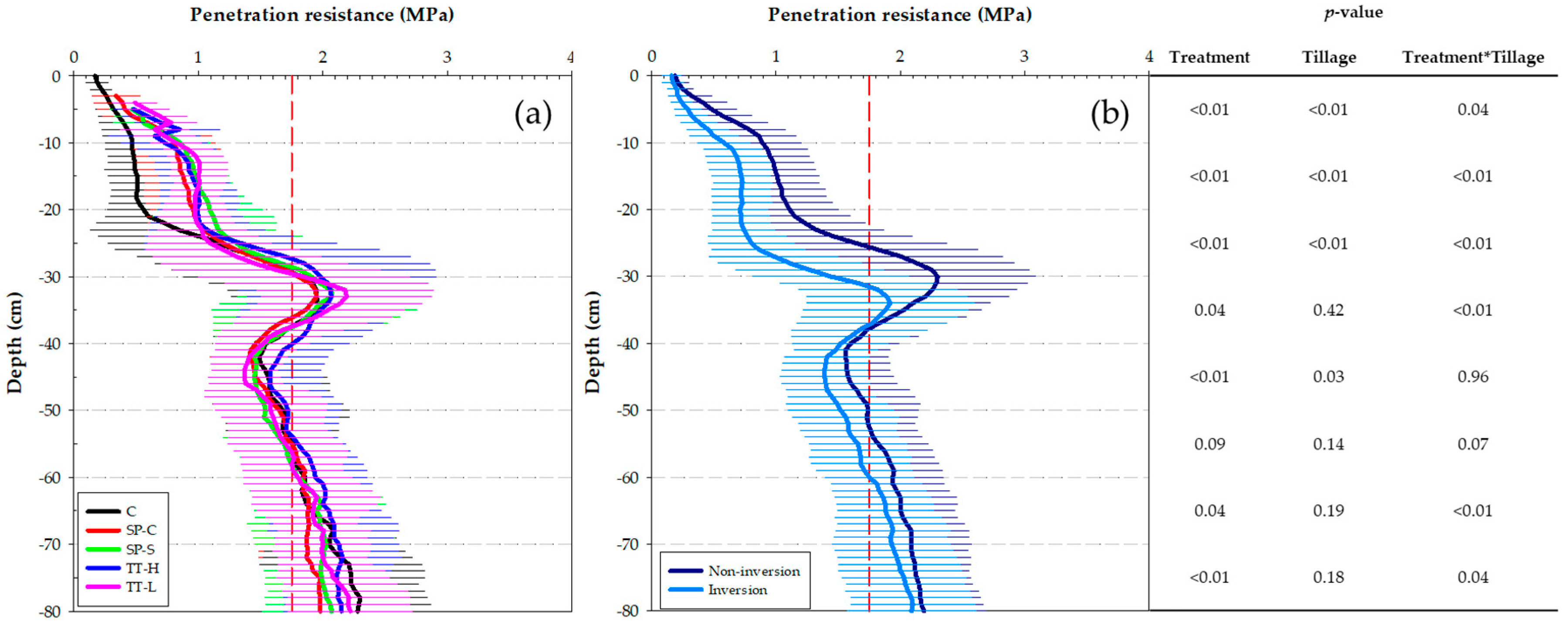

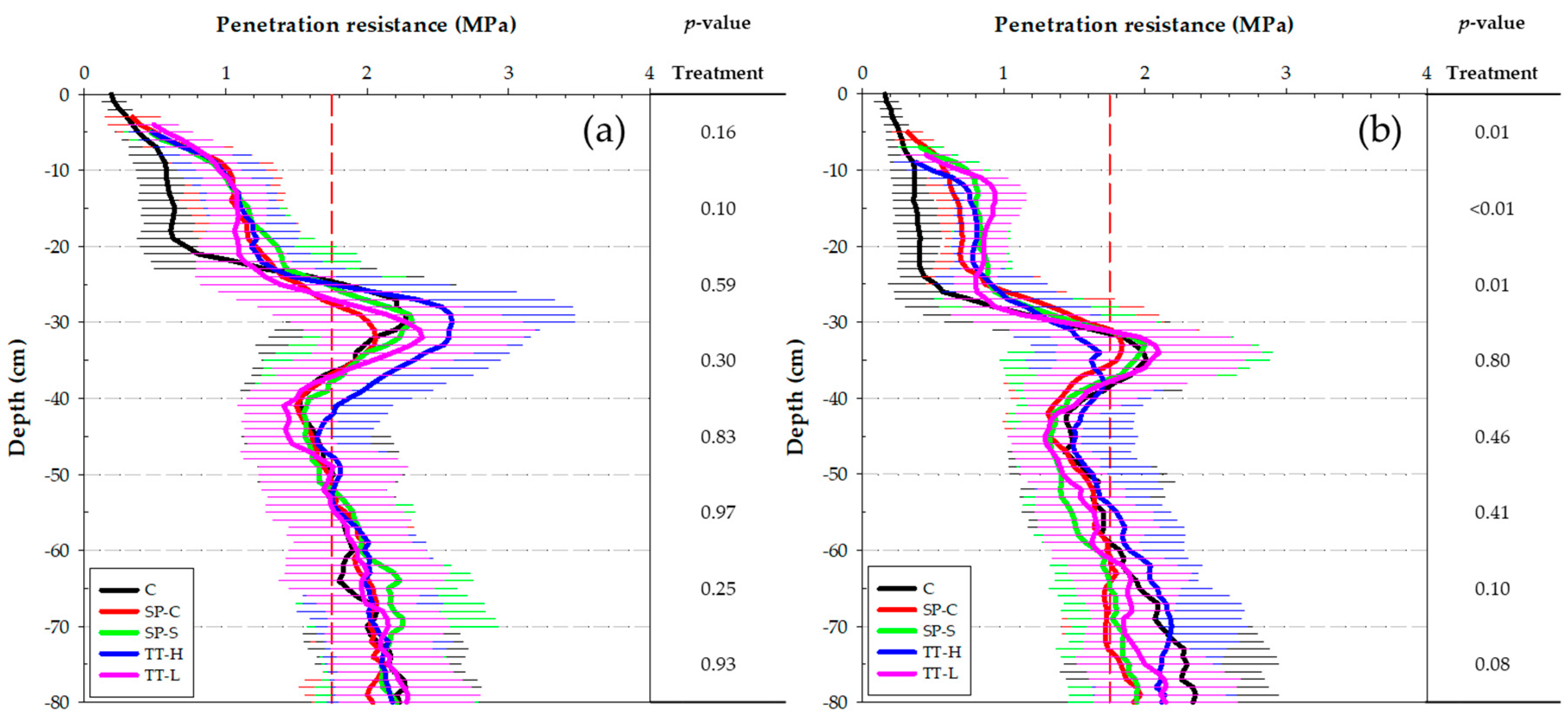

3.1. Field Measurements

3.2. Laboratory Measurements

4. Discussion

4.1. Tyre Inflation Pressure

4.2. Number of Passages

4.3. Machinery Choice

4.4. Tillage Method

5. Conclusions

- (1).

- Lowering the tyre inflation pressure to the recommended level for field traffic had a clear positive effect on the prevention of soil compaction and helped to avoid losses in sugar beet yield. Taking the time to alter the tyre inflation pressure before field traffic, possibly with a central, rapid tyre inflation system, should be a top priority.

- (2).

- The effects of repeated wheeling were less clear, but still observable, for PR and sugar beet yield. Crab steering can be used to prevent soil compaction by limiting the number of passages.

- (3).

- The overall effect of the machinery used remained limited. The heavier self-propelled slurry spreader did not significantly increase the level of soil compactness and reduce sugar beet yield compared to the more common tractor-trailer combination.

- (4).

- Experimental traffic after inversion tillage caused more soil compaction than after non-inversion tillage and it also led to a decreasing effectiveness of reducing tyre inflation pressure as a prevention strategy. The tillage method did not have any overall influence on sugar beet yield. Entering the field with heavy farming machinery when the topsoil has a low bearing capacity should be avoided.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Status of the World’s Soil Resources; FAO: Rome, Italy, 2015; ISBN 9789251090046. [Google Scholar]

- Håkansson, I.; Reeder, R.C. Subsoil Compaction by Vehicles with High Axle Load—Extent, Persistence and Crop Response. Soil Tillage Res. 1994, 29, 277–304. [Google Scholar] [CrossRef]

- Soane, B.D.; Blackwell, P.S.; Dickson, J.W.; Painter, D.J. Compaction by Agricultural Vehicles: A Review I. Soil and Wheel Characteristics. Soil Tillage Res. 1980, 1, 207–237. [Google Scholar] [CrossRef]

- Horn, R.; Taubner, H.; Wuttke, M.; Baumgartl, T. Soil Physical Properties Related to Soil Structure. Soil Tillage Res. 1994, 30, 187–216. [Google Scholar] [CrossRef]

- Hartge, K.H.; Horn, R. Essential Soil Physics; Schweizerbart Science Publisher: Stuttgart, Germany, 2016. [Google Scholar]

- Keller, T.; Sandin, M.; Colombi, T.; Horn, R.; Or, D. Historical Increase in Agricultural Machinery Weights Enhanced Soil Stress Levels and Adversely Affected Soil Functioning. Soil Tillage Res. 2019, 194, 104293. [Google Scholar] [CrossRef]

- Oldeman, L.R.; Hakkeling, R.T.; Sombroek, W.G. World Map of the Status of Human-Induced Soil Degradation: An Explanatory Note; ISRIC: Wageningen, The Netherlands, 1991. [Google Scholar]

- Stolte, J.; Tesfai, M.; Øygarden, L.; Kværnø, S.; Keizer, J.; Verheijen, F.; Panagos, P.; Ballabio, C.; Hessel, R. Soil Threats in Europe; European Union: Luxembourg, 2016. [Google Scholar] [CrossRef]

- Brus, D.J.; Van Den Akker, J.J.H. How Serious a Problem Is Subsoil Compaction in the Netherlands? A Survey Based on Probability Sampling. Soil 2018, 4, 37–45. [Google Scholar] [CrossRef] [Green Version]

- Koolen, A.J.; Kuipers, H. Agricultural Soil Mechanics; Springer: New York, NY, USA, 1983; ISBN 978-3-642-69012-9. [Google Scholar]

- Saffih-Hdadi, K.; Défossez, P.; Richard, G.; Cui, Y.J.; Tang, A.M.; Chaplain, V. A Method for Predicting Soil Susceptibility to the Compaction of Surface Layers as a Function of Water Content and Bulk Density. Soil Tillage Res. 2009, 105, 96–103. [Google Scholar] [CrossRef]

- Gut, S.; Chervet, A.; Stettler, M.; Weisskopf, P.; Sturny, W.G.; Lamandé, M.; Schjønning, P.; Keller, T. Seasonal Dynamics in Wheel Load-Carrying Capacity of a Loam Soil in the Swiss Plateau. Soil Use Manag. 2015, 31, 132–141. [Google Scholar] [CrossRef]

- Schjønning, P.; van den Akker, J.J.H.; Keller, T.; Greve, M.H.; Lamandé, M.; Simojoki, A.; Stettler, M.; Arvidsson, J.; Breuning-Madsen, H. Driver-Pressure-State-Impact-Response (DPSIR) Analysis and Risk Assessment for Soil Compaction—A European Perspective. In Advances in Agronomy; Elsevier Inc.: Amsterdam, The Netherlands, 2015; Volume 133, pp. 183–237. ISBN 9780128030523. [Google Scholar]

- STATBEL Landbouwgegevens. Available online: https://statbel.fgov.be/nl/themas/landbouw-visserij/land-en-tuinbouwbedrijven#figures (accessed on 8 October 2021).

- Vermeulen, G.D.; Verwijs, B.R.; van den Akker, J.J.H. Vergelijking van de Bodembelasting Bij Agrarisch Veldwerk in 1980 En 2010; Wageningen University: Wageningen, The Netherlands, 2013; Volume 501. [Google Scholar]

- Alakukku, L. Long-Term Soil Compaction Due to High Axle Load Traffic; Agricultural Research Centre of Finland: Jokioinen, Finland, 1997. [Google Scholar]

- Soane, G.C.; Godwin, R.J.; Marks, M.J.; Spoor, G. Crop and Soil Response to Subsoil Loosening, Deep Incorporation of Phosphorus and Potassium Fertilizer and Subsequent Soil Management on a Range of Soil Types. Part 2: Soil Structural Conditions. Soil Use Manag. 1987, 3, 123–130. [Google Scholar] [CrossRef]

- Sharratt, B.; Voorhees, W.; McIntosh, G.; Lemme, G. Persistence of Soil Structural Modifications along a Historic Wagon Trail. Soil Sci. Soc. Am. J. 1998, 62, 774–777. [Google Scholar] [CrossRef]

- Schäfer-Landefeld, L.; Brandhuber, R.; Fenner, S.; Koch, H.J.; Stockfisch, N. Effects of Agricultural Machinery with High Axle Load on Soil Properties of Normally Managed Fields. Soil Tillage Res. 2004, 75, 75–86. [Google Scholar] [CrossRef]

- Schjønning, P.; Rasmussen, S.T.; Lamandé, M.; Nielsen, J.M.; Christensen, B.B.; Nørgaard, H.; Bak, H.; Nielsen, J.A. Soil Characterization of Experimental Fields Prior to Soil Compaction Experiments; Aarhus University: Tjele, Denmark, 2011. (In Danish) [Google Scholar]

- van den Akker, J.J.H.; Arts, W.B.M.; Koolen, A.J.; Stuiver, H.J. Comparison of Stresses, Compactions and Increase of Penetration Resistances Caused by a Low Ground Pressure Tyre and a Normal Tyre. Soil Tillage Res. 1994, 29, 125–134. [Google Scholar] [CrossRef]

- Arvidsson, J.; Ristic, S. Soil Stress and Compaction Effects for Four Tractor Tyres. J. Terramech. 1996, 33, 223–232. [Google Scholar] [CrossRef]

- Bailey, A.C.; Raper, R.L.; Way, T.R.; Burt, E.C.; Johnson, C.E. Soil Stresses under a Tractor Tire at Various Loads and Inflation Pressures. J. Terramech. 1996, 33, 1–11. [Google Scholar] [CrossRef]

- Arvidsson, J.; Keller, T. Soil Stress as Affected by Wheel Load and Tyre Inflation Pressure. Soil Tillage Res. 2007, 96, 284–291. [Google Scholar] [CrossRef]

- ten Damme, L.; Stettler, M.; Pinet, F.; Vervaet, P.; Keller, T.; Munkholm, L.J.; Lamandé, M. The Contribution of Tyre Evolution to the Reduction of Soil Compaction Risks. Soil Tillage Res. 2019, 194, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Söhne, W. Druckverteilung Im Boden Und Bodenverformung Unter Schlepperreifen. Grundl. Landtech.-Konstr. 1953, 5, 49–63. [Google Scholar]

- Taylor, J.H.; Burt, E.C. Total Axle Load Effects on Soil Compaction. J. Terramech. 1987, 24, 179–186. [Google Scholar] [CrossRef]

- Smith, D.L.O.; Dickson, J.W. Contributions of Vehicle Weight and Ground Pressure to Soil Compaction. J. Agric. Eng. Res. 1990, 46, 13–29. [Google Scholar] [CrossRef]

- Lamandé, M.; Schjønning, P.; Tøgersen, F.A. Mechanical Behaviour of an Undisturbed Soil Subjected to Loadings: Effects of Load and Contact Area. Soil Tillage Res. 2007, 97, 91–106. [Google Scholar] [CrossRef]

- Lamandé, M.; Schjønning, P. Transmission of Vertical Stress in a Real Soil Profile. Part II: Effect of Tyre Size, Inflation Pressure and Wheel Load. Soil Tillage Res. 2011, 114, 71–77. [Google Scholar] [CrossRef]

- Jakobsen, B.F.; Greacen, E.L. Compaction of Sandy Forest Soils by Forwarder Operations. Soil Tillage Res. 1985, 5, 55–70. [Google Scholar] [CrossRef]

- Lipiec, J.; Szustak, A.; Tarkiewicz, S. Soil Compaction: Responses of Soil Physical Properties and Crop Growth. Zesz. Probl. Postep. Nauk Rol.-Pol. Akad. Nauk 1992, 398, 113–117. [Google Scholar]

- Peth, S.; Horn, R. The Mechanical Behavior of Structured and Homogenized Soil under Repeated Loading. J. Plant Nutr. Soil Sci. 2006, 169, 401–410. [Google Scholar] [CrossRef]

- Botta, G.F.; Becerra, A.T.; Tourn, F.B. Effect of the Number of Tractor Passes on Soil Rut Depth and Compaction in Two Tillage Regimes. Soil Tillage Res. 2009, 103, 381–386. [Google Scholar] [CrossRef]

- Naderi-Boldaji, M.; Kazemzadeh, A.; Hemmat, A.; Rostami, S.; Keller, T. Changes in Soil Stress during Repeated Wheeling: A Comparison of Measured and Simulated Values. Soil Res. 2018, 56, 204–214. [Google Scholar] [CrossRef]

- Schjønning, P.; Rasmussen, K.J. Danish Experiments on Subsoil Compaction by Vehicles with High Axle Load. Soil Tillage Res. 1994, 29, 215–228. [Google Scholar] [CrossRef]

- Schjønning, P.; Lamandé, M.; Munkholm, L.J.; Lyngvig, H.S.; Nielsen, J.A. Soil Precompression Stress, Penetration Resistance and Crop Yields in Relation to Differently-Trafficked, Temperate-Region Sandy Loam Soils. Soil Tillage Res. 2016, 163, 298–308. [Google Scholar] [CrossRef]

- Pulido-Moncada, M.; Munkholm, L.J.; Schjønning, P. Wheel Load, Repeated Wheeling, and Traction Effects on Subsoil Compaction in Northern Europe. Soil Tillage Res. 2019, 186, 300–309. [Google Scholar] [CrossRef]

- Seehusen, T.; Riggert, R.; Fleige, H.; Horn, R.; Riley, H. Soil Compaction and Stress Propagation after Different Wheeling Intensities on a Silt Soil in South-East Norway. Acta Agric. Scand. Sect. B Soil Plant Sci. 2019, 69, 343–355. [Google Scholar] [CrossRef]

- ten Damme, L.; Schjønning, P.; Munkholm, L.; Green, O.; Nielsen, S.; Lamandé, M. Soil Structure Response to Field Traffic: Effects of Traction and Repeated Wheeling. Soil Tillage Res. 2021, 213, 105–128. [Google Scholar] [CrossRef]

- Horn, R.; Lebert, M. Soil Compactability and Compressibility. In Soil Compaction in Crop Production; Soane, B.D., van Ouwerkerk, C., Eds.; Elsevier Science B.V.: Amsterdam, The Netherlands, 1994; pp. 45–69. ISBN 9780444882868. [Google Scholar]

- Blanco-Canqui, H.; Shaver, T.M.; Lindquist, J.L.; Shapiro, C.A.; Elmore, R.W.; Francis, C.A.; Hergert, G.W. Cover Crops and Ecosystem Services: Insights from Studies in Temperate Soils. Agron. J. 2015, 107, 2449–2474. [Google Scholar] [CrossRef] [Green Version]

- Horn, R. Auswirkung Unterschiedlicher Bodenbearbeitung Auf Die Mechanische Belastbarkeit von Ackerböden. Z. Für Pflanz. Und Bodenkd. 1986, 149, 9–18, (In German with English Summary). [Google Scholar] [CrossRef]

- Horn, R. Time Dependence of Soil Mechanical Properties and Pore Functions for Arable Soils. Soil Sci. Soc. Am. J. 2004, 68, 1131–1137. [Google Scholar] [CrossRef]

- Wiermann, C.; Werner, D.; Horn, R.; Rostek, J.; Werner, B. Stress/Strain Processes in a Structured Unsaturated Silty Loam Luvisol under Different Tillage Treatments in Germany. Soil Tillage Res. 2000, 53, 117–128. [Google Scholar] [CrossRef]

- Lamandé, M.; Schjønning, P. Transmission of Vertical Stress in a Real Soil Profile. Part I: Site Description, Evaluation of the Söhne Model, and the Effect of Topsoil Tillage. Soil Tillage Res. 2011, 114, 57–70. [Google Scholar] [CrossRef]

- Fröhlich, O.K. Druckverteilung Im Baugrunde (Pressure Distribution in Foundation Soils); Springer: Vienna, Austria, 1934. [Google Scholar]

- Lassen, P.; Lamandé, M.; Stettler, M.; Keller, T.; Jørgensen, M.S.; Lilja, H. Terranimo®—A Soil Compaction Model with Internationally Compatible Input Options. In Proceedings of the EFITA-WCCA-CIGR Conference “Sustainable Agriculture through ICT Innovation”, Torino, Italy, 24–27 June 2013. [Google Scholar]

- Lipiec, J.; Simota, C. Role of Soil and Climate Factors in Influencing Crop Responses to Soil Compaction in Central and Eastern Europe. In Soil Compaction in Crop Production; Soane, B.D., van Ouwerkerk, C., Eds.; Elsevier: Amsterdam, The Netherlands, 1994; pp. 365–389. ISBN 9780444882868. [Google Scholar]

- Håkansson, I.; Lipiec, J. A Review of the Usefulness of Relative Bulk Density Values in Studies of Soil Structure and Compaction. Soil Tillage Res. 2000, 53, 71–85. [Google Scholar] [CrossRef]

- Arvidsson, J.; Håkansson, I. Response of Different Crops to Soil Compaction-Short-Term Effects in Swedish Field Experiments. Soil Tillage Res. 2014, 138, 56–63. [Google Scholar] [CrossRef]

- Glinski, J.; Lipiec, J. Soil Physical Conditions and Plant Roots; CRC Press: Boca Raton, FL, USA, 1990; ISBN 9781315897608. [Google Scholar]

- Birkás, M.; Gyuricza, C. INCO-Copernicus Concerted Action on ‘Expertiences with the Impact of Subsoil Compaction on Soil Nutrition, Crop Growth and Environment and Ways to Prevent Subsoil Compaction’; Gödöllö, Hungary, 2001. [Google Scholar]

- Lipiec, J.; Medvedev, V.V.; Birkas, M.; Dumitru, E.; Lyndina, T.E.; Rousseva, S.; Fulajtár, E. Effect of Soil Compaction on Root Growth and Crop Yield in Central and Eastern Europe. Int. Agrophys. 2003, 17, 61–69. [Google Scholar]

- Arvidsson, J.; Bölenius, E.; Maria, K.; Cavalieri, V. Effects of Compaction during Drilling on Yield of Sugar Beet (Beta vulgaris L.). Eur. J. Agron. 2012, 39, 44–51. [Google Scholar] [CrossRef]

- Gemtos, T.A.; Lellis, T. Effects of Soil Compaction, Water and Organic Matter Contents on Emergence and Initial Plant Growth of Cotton and Sugar Beet. J. Agric. Eng. Res. 1997, 66, 121–134. [Google Scholar] [CrossRef]

- Hebblethwaite, P.D.; McGowan, M. The Effects of Soil Compaction on the Emergence, Growth and Yield of Sugar Beet and Peas. J. Sci. Food Agric. 1980, 31, 1131–1142. [Google Scholar] [CrossRef]

- Brereton, J.C.; McGowan, M.; Dawkins, T.C.K. The Relative Sensitivity of Spring Barley, Spring Field Beans and Sugar Beet Crops to Soil Compaction. F. Crop. Res. 1986, 13, 223–237. [Google Scholar] [CrossRef]

- Pabin, J.; Sienkiewicz, J.; Włdek, S. Effect of Loosening and Compacting on Soil Physical Properties and Sugar Beet Yield. Soil Tillage Res. 1991, 19, 345–350. [Google Scholar] [CrossRef]

- Marinello, F.; Pezzuolo, A.; Cillis, D.; Chiumenti, A.; Sartori, L. Traffic Effects on Soil Compaction and Sugar Beet (Beta vulgaris L.) Taproot Quality Parameters. Spanish J. Agric. Res. 2017, 15, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Arvidsson, J. Subsoil Compaction Caused by Heavy Sugarbeet Harvesters in Southern Sweden: I. Soil Physical Properties and Crop Yield in Six Field Experiments. Soil Tillage Res. 2001, 60, 67–78. [Google Scholar] [CrossRef]

- Koch, H.-J.; Heuer, H.; Tomanova, O.; Bernwar, M. Cumulative Effect of Annually Repeated Passes of Heavy Agricultural Machinery on Soil Structural Properties and Sugar Beet Yield under Two Tillage Systems. Soil Tillage Res. 2008, 101, 69–77. [Google Scholar] [CrossRef]

- Dondeyne, S.; Vanierschot, L.; Langohr, R.; Van Ranst, E.; Deckers, J.A. The Soil Map of the Flemish Region Converted to the 3rd Edition of the World Reference Base for Soil Resources; Vlaamse Overheid—Departement Leefmilieu, Natuur & Energie, 2014. [Google Scholar] [CrossRef]

- IUSS Working Group WRB. World Reference Base for Soil Resources 2006, First Update 2007; World Soil Resources Reports No 103; FAO: Rome, Italy, 2007. [Google Scholar]

- Gee, G.W.; Bauder, J.W. Particle-Size Analysis. In Methods of Soil Analysis: Part 1—Physical and Mineralogical Methods (Methods of Soil Analysis); Klute, A., Ed.; American Society of Agronomy/Soil Science Society of America: Madison, WI, USA, 1986; pp. 383–411. [Google Scholar]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger Climate Classification Updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Bengough, A.G.; McKenzie, B.M.; Hallett, P.D.; Valentine, T.A. Root Elongation, Water Stress, and Mechanical Impedance: A Review of Limiting Stresses and Beneficial Root Tip Traits. J. Exp. Bot. 2011, 62, 59–68. [Google Scholar] [CrossRef] [Green Version]

- Cornelis, W.M.; Khlosi, M.; Hartmann, R.; Van Meirvenne, M.; De Vos, B. Comparison of Unimodal Analytical Expressions for the Soil-Water Retention Curve. Soil Sci. Soc. Am. J. 2005, 69, 1902–1911. [Google Scholar] [CrossRef] [Green Version]

- Grover, B.L. Simplified Air Permeameters for Soil in Place1. Soil Sci. Soc. Am. J. 1955, 19, 414. [Google Scholar] [CrossRef]

- Pulido Moncada, M.; Helwig Penning, L.; Timm, L.C.; Gabriels, D.; Cornelis, W.M. Visual Examination of Changes in Soil Structural Quality Due to Land Use. Soil Tillage Res. 2017, 173, 83–91. [Google Scholar] [CrossRef]

- White, R.E. Principles and Practice of Soil Science, 4th ed.; Blackwell Publishing: Oxford, UK, 2006; ISBN 9781118685730. [Google Scholar]

- Reynolds, W.D.; Drury, C.F.; Yang, X.M.; Tan, C.S. Optimal Soil Physical Quality Inferred through Structural Regression and Parameter Interactions. Geoderma 2008, 146, 466–474. [Google Scholar] [CrossRef]

- Grossman, R.B.; Reinsch, T.G. 2.1 Bulk Density and Linear Extensibility. In Methods of Soil Analysis: Part 4—Physical Methods; Dane, J.H., Topp, G.C., Eds.; American Society of Agronomy/Soil Science Society of America: Madison, WI, USA, 2002; pp. 208–228. ISBN 9780891188933. [Google Scholar]

- Goldsmith, W.; Marvin, S.; Fischenich, C. Determining Optimal Degree of Soil Compaction for Balancing Mechanical Stability and Plant, Ecosystem Management and Restoration Research Program; ERDCTN EMRRP-SR-26; United States Army Engineer Research and Development Center: Vicksburg, MS, USA, 2001. [Google Scholar]

- United States Department of Agriculture (USDA). Soil Quality Test Kit Guide. 1999. Available online: https://www.nrcs.usda.gov/wps/portal/nrcs/detail/soils/health/assessment/?cid=nrcs142p2_053873 (accessed on 10 May 2022).

- Hall, D.G.M.; Reeve, M.J.; Thomasson, A.J.; Wright, V.F. Water Retention, Porosity and Density of Field Soils; Rothamsted Experimental Station: Harpenden, UK, 1977. [Google Scholar]

- Verdonck, O.; Penninck, R.; De Boodt, M. The Physical Properties of Different Horticultural Substrates. Acta Hortic. 1984, 150, 155–160. [Google Scholar] [CrossRef]

- Cockroft, B.; Olsson, K.A. Case Study of Soil Quality in South-Eastern Australia: Management of Structure for Roots in Duplex Soils. In Soil Quality for Crop Production and Ecosystem Health; Gregorich, E.G., Carter, M.R., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 1997; Volume 25, pp. 339–350. ISBN 9780080541402. [Google Scholar]

- Doran, J.W.; Mielke, L.N.; Power, J.F. Microbial Activity as Regulated by Soil Waterfilled Pore Space. In Proceedings of the Symposium III-3, Ecology of Soil Microorganisms in the Microhabitat Environments III. Transactions of the 14th International Congress of Soil Science, Kyoto, Japan, August 1990; pp. 94–99. [Google Scholar]

- Fish, A.N.; Koppi, A.J. The Use of a Simple Field Air Permeameter as a Rapid Indicator of Functional Soil Pore Space. Geoderma 1994, 63, 255–264. [Google Scholar] [CrossRef]

- Ball, B.C.; O’Sullivan, M.F.; Hunter, R. Gas Diffusion, Fluid Flow and Derived Pore Continuity Indices in Relation to Vehicle Traffic and Tillage. J. Soil Sci. 1988, 39, 327–339. [Google Scholar] [CrossRef]

- Topp, C.G.; Ferré, P. 3.1 Water Content. In Methods of Soil Analysis, Part 4—Physical Methods; Dane, J.H., Topp, G.C., Eds.; American Society of Agronomy/Soil Science Society of America: Madison, WI, USA, 2002; pp. 255–293. ISBN 978-0-891-18893-3. [Google Scholar]

- Moitzi, G.; Sattler, E.; Wagentristl, H. Effect of Cover Crop, Slurry Application with Different Loads and Tire Inflation Pressures on Tire Track Depth, Soil Penetration Resistance and Maize Yield. Agriculture 2021, 11, 641. [Google Scholar] [CrossRef]

- Spoor, G.; Tijink, F.G.J.; Weisskopf, P. Subsoil Compaction: Risk, Avoidance, Identification and Alleviation. Soil Tillage Res. 2003, 73, 175–182. [Google Scholar] [CrossRef]

- Hillel, D. Environmental Soil Physics: Fundamentals, Applications, and Environmental Considerations; Academic Press: Cambridge, MA, USA, 1998; ISBN 9780080544151. [Google Scholar]

- Colombi, T.; Torres, L.C.; Walter, A.; Keller, T. Feedbacks between Soil Penetration Resistance, Root Architecture and Water Uptake Limit Water Accessibility and Crop Growth—A Vicious Circle. Sci. Total Environ. 2018, 626, 1026–1035. [Google Scholar] [CrossRef]

- Christensen, J.H.; Hewitson, B.; Busuioc, A.; Chen, A.; Gao, X.; Held, R.; Jones, R.; Kolli, R.K.; Kwon, W.K.; Laprise, R.; et al. Observations: Surface and Atmospheric Climate Change. In Climate Change 2007: The Physical Science Basis; Hoskins, B.J., Karl, T.R., Jallow, B., Eds.; Cambridge University Press: Cambridge, UK, 2007; pp. 235–336. ISBN 9780521880091. [Google Scholar]

- Olesen, J.E.; Trnka, M.; Kersebaum, K.C.; Skjelvåg, A.O.; Seguin, B.; Peltonen-Sainio, P.; Rossi, F.; Kozyra, J.; Micale, F. Impacts and Adaptation of European Crop Production Systems to Climate Change. Eur. J. Agron. 2011, 34, 96–112. [Google Scholar] [CrossRef]

- Porter, J.R.; Xie, L.; Challinor, A.J.; Cochrane, K.; Howden, S.M.; Iqbal, M.M.; Lobell, D.B.; Travasso, M.I. Food Security and Food Production Systems. In Climate Change 2014: Impacts, Adaptation, and Vulnerability. Part A: Global and Sectoral Aspects. Contribution of Working Group II to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2014; pp. 485–533. [Google Scholar]

- Tijink, F.G.J. Quantification of Vehicle Running Gear. In Soil Compaction in Crop Production; Soane, B.D., van Ouwerkerk, C., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 1994; Volume 11, pp. 391–415. ISBN 9780444882868. [Google Scholar]

- Ball, B.C. Pore Characteristics of Soils from Two Cultivation Experiments as Shown by Gas Diffusivities and Permeabilities and Air-Filled Porosities. J. Soil Sci. 1982, 32, 483–498. [Google Scholar] [CrossRef]

- Vandergeten, J.; Roisin, C. Ploegloze Teelttechnieken in de Suikerbietenteelt; IRBAB-KBIVB: Tienen, Belgium, 2004; Available online: https://www.irbab-kbivb.be/wp-content/uploads/2015/10/GidsTeelttechnieken.pdf (accessed on 10 May 2022).

- Casamitjana Causa, M.; D’Haene, K.; Usuga, J.C.L.; Gabriels, D.; De Neve, S. Influence of Tillage Systems on Soil Structural Properties. In No-Till Farming: Effects on Soil, Pros and Cons and Potential; Nardali, E.T., Ed.; Nova Science Publishers Inc.: Hauppauge, NY, USA, 2009; Chapter 1; pp. 1–26. ISBN 9781607414025. [Google Scholar]

- Van den Putte, A.; Govers, G.; Diels, J.; Langhans, C.; Clymans, W.; Vanuytrecht, E.; Merckx, R.; Raes, D. Soil Functioning and Conservation Tillage in the Belgian Loam Belt. Soil Tillage Res. 2012, 122, 1–11. [Google Scholar] [CrossRef]

- Jabro, J.D.; Stevens, W.B.; Iversen, W.M.; Evans, R.G. Tillage Depth Effects on Soil Physical Properties, Sugarbeet Yield, and Sugarbeet Quality. Commun. Soil Sci. Plant Anal. 2010, 41, 908–916. [Google Scholar] [CrossRef] [Green Version]

| Depth (cm) | Sand (g kg−1) | Silt (g kg−1) | Clay (g kg−1) | Organic Carbon Content 1 (g kg−1) | Texture Class (USDA) |

|---|---|---|---|---|---|

| 0–30 | 99.0 ± 18.0 | 688.7 ± 51.8 | 212.3 ± 33.9 | 12.1 ± 1.7 | Silt loam |

| 30–60 | 82.2 ± 13.5 | 618.8 ± 68.5 | 299.0 ± 56.4 | - | Silty clay loam |

| Treatment | Axle | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| SP-C | Tyre type | Michelin Mega X BIB 1050/50R32 17A8/172D TL | Michelin Mega X BIB 1050/50R32 17A8/172D TL | - | - |

| Wheel load (103 kg) | 9.405 | 10.375 | - | - | |

| Tyre inflation pressure (kPa) | 220 | 220 | - | - | |

| SP-S | Tyre type | Michelin Mega X BIB 1050/50R32 17A8/172D TL | Michelin Mega X BIB 1050/50R32 17A8/172D TL | - | - |

| Wheel load (103 kg) | 9.405 | 10.375 | |||

| Tyre inflation pressure (kPa) | 220 | 220 | - | - | |

| Tractor | Trailer | ||||

| TT-H | Tyre type | Cultor RD03 540/65 R30 | Cultor RD03 650/65 R42 | Alliance 750/45 R26.5 Flotation radial | Alliance 750/45 R26.5 Flotation radial |

| Wheel load (103 kg) | 1.330 | 4.445 | 5.080 | 5.845 | |

| Tyre inflation pressure (kPa) | 250 | 250 | 450 | 450 | |

| TT-L | Tyre type | Cultor RD03 540/65 R30 | Cultor RD03 650/65 R42 | Alliance 750/45 R26.5 Flotation radial | Alliance 750/45 R26.5 Flotation radial |

| Wheel load (103 kg) | 1.330 | 4.445 | 5.080 | 5.845 | |

| Tyre inflation pressure (kPa) | 60 | 130 | 90 | 140 | |

| Parameter | Threshold Values | References |

|---|---|---|

| Bulk density (g cm−3) | Ideal: <1.30 g cm−3 (silt soil) Restricting root growth: >1.60 g cm−3 Optimum for sugar beet yield: 1.51 g cm−3 | [74,75] [59] |

| Penetration resistance (MPa) | Restricting root growth: >2 MPa Optimum for sugar beet yield: 1.75 MPa | [67] [59] |

| Air capacity (m3 m−3) | Limiting value: 0.10 m3 m−3 | [71] |

| Plant available water capacity (m3 m−3) | Ideal for root growth: ≥0.20 Limiting value: 0.10 m3 m−3 | [71,76,77,78] |

| Relative field capacity (-) | Optimal range: >0.60 & <0.70 | [79] |

| Air permeability (µm2) | Limiting value: 20 µm2 Impermeable: <1 µm2 | [80] [81] |

| Axle | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||||||||

| Wheel Load (kg) | Tyre Contact Area (cm2) | Mean Contact Pressure (kg cm−2) | Wheel Load (kg) | Tyre Contact Area (cm2) | Mean Contact Pressure (kg cm−2) | Wheel Load (kg) | Tyre Contact Area (cm2) | Mean Contact Pressure (kg cm−2) | Wheel Load (kg) | Tyre Contact Area (cm2) | Mean Contact Pressure (kg cm−2) | |

| Treatment | ||||||||||||

| SP-C | 9405 | 7280 | 1.29 | 10,375 | 6160 | 1.68 | - | - | - | - | - | - |

| SP-S | 9405 | 7280 | 1.29 | 10,375 | 6160 | 1.68 | - | - | - | - | - | - |

| TT-H | 1330 | 2026 | 0.66 | 4445 | 3876 | 1.15 | 5080 | 2528 | 2.01 | 5845 | 2814 | 2.08 |

| TT-L | 1330 | 2141 | 0.62 | 4445 | 4350 | 1.02 | 5080 | 3697 | 1.37 | 5845 | 3692 | 1.58 |

| Treatment | Rut Depth (cm) |

|---|---|

| SP-C | 2.3 ± 1.6 - |

| SP-S | 6.4 ± 2.3 a |

| TT-H | 7.5 ± 3.0 b |

| TT-L | 5.8 ± 1.9 a |

| Tillage | |

| Non-inversion | 4.5 ± 2.2 a |

| Inversion | 7.6 ± 2.6 b |

| Statistical analysis | p-value |

| Treatment | <0.01 |

| Tillage | <0.01 |

| Treatment*Tillage | <0.01 |

| Treatment | Fresh Beet Yield (kg ha−1) | Sugar Yield (kg ha−1) | Deformed Beets (%) |

|---|---|---|---|

| C | 85,919 ± 2355 ab | 17,896 ± 669 b | 40 ± 8 ab |

| SP-C | 86,687 ± 2278 b | 18,048 ± 530 b | 36 ± 13 a |

| SP-S | 84,570 ± 3730 ab | 17,639 ± 775 ab | 43 ± 11 ab |

| TT-H | 83,056 ± 2398 a | 17,246 ± 431 a | 50 ± 7 b |

| TT-L | 84,818 ± 1133 ab | 17,843 ± 474 ab | 40 ± 10 ab |

| Tillage | |||

| Non-inversion | 85,111 ± 2529 n.s. | 17,733 ± 631 n.s. | 42 ± 8 n.s. |

| Inversion | 84,909 ± 2914 n.s. | 17,736 ± 636 n.s. | 41 ± 13 n.s. |

| Statistical analysis | p-value | ||

| Treatment | 0.02 | 0.01 | 0.05 |

| Tillage | 0.66 | 0.90 | 0.82 |

| Treatment*Tillage | 0.09 | 0.09 | 0.30 |

| Bulk Density (g cm−3) | Air Permeability (µm2) | |||||

|---|---|---|---|---|---|---|

| Depth (cm) | 5 | 20 | 45 | 5 | 20 | 45 |

| C | 1.50 ± 0.07 | 1.35 ± 0.15 | 1.52 ± 0.05 | 22.96 ± 18.45 | 109.58 ± 68.92 | 29.42 ± 17.50 |

| n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | |

| SP-C | 1.58 ± 0.04 | 1.50 ± 0.07 | 1.55 ± 0.04 | 0.54 ± 0.71 | 13.27 ± 4.92 | 9.58 ± 9.44 |

| n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | |

| SP-S | 1.56 ± 0.08 | 1.50 ± 0.09 | 1.56 ± 0.04 | 47.99 ± 70.19 | 76.21 ± 54.04 | 33.83 ± 14.08 |

| n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | |

| TT-H | 1.62 ± 0.02 | 1.55 ± 0.05 | 1.56 ± 0.01 | 20.94 ± 29.73 | 11.04 ± 6.12 | 9.42 ± 6.68 |

| n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | |

| TT-L | 1.56 ± 0.04 | 1.42 ± 0.09 | 1.54 ± 0.01 | 48.72 ± 61.39 | 27.27 ± 21.60 | 17.94 ± 14.13 |

| n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | |

| Statistical analysis | p-values | |||||

| Treatment | 0.18 | 0.15 | 0.14 | 0.65 | 0.05 | 0.49 |

| Air Capacity (m3 m−3) | Plant Available Water Capacity (m3 m−3) | Relative Field Capacity (m3 m−3) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Depth (cm) | 5 | 20 | 45 | 5 | 20 | 45 | 5 | 20 | 45 |

| C | 0.04 ± 0.05 | 0.17 ± 0.08 | 0.07 ± 0.03 | 0.23 ± 0.01 | 0.16 ± 0.03 | 0.16 ± 0.02 | 0.90 ± 0.11 | 0.66 ± 0.13 | 0.84 ± 0.08 |

| n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | |

| SP-C | 0.01 ± 0.01 | 0.05 ± 0.04 | 0.05 ± 0.01 | 0.24 ± 0.01 | 0.21 ± 0.02 | 0.17 ± 0.01 | 0.97 ± 0.01 | 0.88 ± 0.07 | 0.87 ± 0.02 |

| n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | |

| SP-S | 0.01 ± 0.01 | 0.08 ± 0.04 | 0.05 ± 0.03 | 0.23 ± 0.01 | 0.20 ± 0.03 | 0.17 ± 0.01 | 0.96 ± 0.02 | 0.83 ± 0.09 | 0.88 ± 0.07 |

| n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | |

| TT-H | 0.01 ± 0.01 | 0.05 ± 0.03 | 0.04 ± 0.01 | 0.22 ± 0.01 | 0.19 ± 0.02 | 0.17 ± 0.01 | 0.98 ± 0.01 | 0.88 ± 0.06 | 0.90 ± 0.03 |

| n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | |

| TT-L | 0.01 ± 0.01 | 0.08 ± 0.05 | 0.07 ± 0.01 | 0.23 ± 0.02 | 0.22 ± 0.02 | 0.16 ± 0.02 | 0.96 ± 0.01 | 0.82 ± 0.09 | 0.83 ± 0.01 |

| n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | |

| Statistical analysis | p-values | ||||||||

| Treatment | 0.34 | 0.07 | 0.47 | 0.14 | 0.08 | 0.95 | 0.40 | 0.06 | 0.41 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanderhasselt, A.; Euben, R.; D’Hose, T.; Cornelis, W. Slurry Spreading on a Silt Loam Soil: Influence of Tyre Inflation Pressure, Number of Passages, Machinery Choice and Tillage Method on Physical Soil Quality and Sugar Beet Growth. Land 2022, 11, 913. https://doi.org/10.3390/land11060913

Vanderhasselt A, Euben R, D’Hose T, Cornelis W. Slurry Spreading on a Silt Loam Soil: Influence of Tyre Inflation Pressure, Number of Passages, Machinery Choice and Tillage Method on Physical Soil Quality and Sugar Beet Growth. Land. 2022; 11(6):913. https://doi.org/10.3390/land11060913

Chicago/Turabian StyleVanderhasselt, Adriaan, Ronald Euben, Tommy D’Hose, and Wim Cornelis. 2022. "Slurry Spreading on a Silt Loam Soil: Influence of Tyre Inflation Pressure, Number of Passages, Machinery Choice and Tillage Method on Physical Soil Quality and Sugar Beet Growth" Land 11, no. 6: 913. https://doi.org/10.3390/land11060913

APA StyleVanderhasselt, A., Euben, R., D’Hose, T., & Cornelis, W. (2022). Slurry Spreading on a Silt Loam Soil: Influence of Tyre Inflation Pressure, Number of Passages, Machinery Choice and Tillage Method on Physical Soil Quality and Sugar Beet Growth. Land, 11(6), 913. https://doi.org/10.3390/land11060913