Abstract

Biomass is an alternative energy source with high potential to contribute to the global energy mix and to countries’ energetic independence. The case of Portugal is particularly relevant, given its biomass availability. Thus, the quantification of woody residual biomass is assumed to be urgent. To achieve the objective of quantifying residual woody biomass, various available data were used, namely the Land Cover and Soil Use Map (COS 2018), from which areas occupied by different categories were selected as being the most relevant. Then, based on coefficients previously established, the amounts of residual woody biomass were determined, namely for maritime pine forests, eucalyptus forests, scrubland, vineyards, olive groves, and orchards. Then, the potential for generating electricity was estimated. It was found that for the hypothetical scenario of the total conversion of the recently closed Pêgo coal power plant to biomass, the available amounts of residual woody biomass in the country would not be sufficient to ensure the operation. On the other hand, if the power plant only worked as a backup unit, the available quantities could ensure its operation and contribute to creating a value chain for residual woody biomass of forest and agricultural origin within a circular economy and sustainable development approach.

1. Introduction

There is an ongoing global search for alternative sources of energy which, in the first phase, was boosted by the growing environmental concerns derived from the use of fossil fuels, but which, in the second phase, became the focus of concern for the pressing need to achieve a higher degree of energy independence [1,2,3]. This situation led to the accelerated development of new processes and technologies in order to satisfy energy needs [4,5]. However, this process, which occurs globally, is felt to exert greater pressure in the more industrialized countries, such as the European Union, North America, Japan, South Korea, and others in South America and the Pacific region [6].

In addition to environmental questions, geostrategic concerns have also contributed to the growing interest in developing viable alternatives that would allow the replacement of traditional sources of fossil origin by others capable of decarbonizing the economy [7,8,9]. Additionally, they would allow countries that do not have fossil energy resources to be less dependent on imports from third countries, which thus gain the ability to influence the economies of these countries according to their interests [10,11,12,13]. The most recent example of this situation is already perceptible in the economy of all European Union countries because of the Ukraine War crisis, with the embargo on energy products from the Russian Federation. However, the economic sanctions imposed practically in unison immediately saw several European Union member states warning of the need for time to implement the embargo measures. They are currently unable to do so due to their significant dependence on Russian natural gas and oil. This situation will undoubtedly accelerate the search for alternatives, which is the first phase, and the urgency of the situation leads countries to seek not just an energy alternative per se but an alternative source of supply. In other words, both natural gas and oil from Russia must be replaced by imports from other countries, such as the US or Qatar. In this way, countries are trying to minimize the effects of a possible lack of energy products. However, from a purely environmental perspective, it does not seem that a reduction in the consumption of fossil fuels is expected, since Russia will also seek alternative destinations for its large production of natural gas and oil, namely selling to China and India. Thus, to make a real contribution to the decarbonization of the economy, and at the same time to achieve greater energy independence from third parties, countries like Portugal must invest heavily in the use of their endogenous resources, and preferably in renewable energy sources.

Portugal, as other countries, made a significant effort to meet the targets for decarbonization, with a solid focus on the use of wind, solar, hydro, and biomass energy [14,15,16,17]. Table 1 presents a summary of the electricity production potential already installed in Portugal.

Table 1.

Balance of electricity production in mainland Portugal in the first four months of 2022 (https://www.apren.pt/pt/energias_renovaveis/producao, accessed on 19 May 2022).

From the results provided by REN (Rede Elétrica Nacional), for the first four months of 2022, 14,677 GWh of electricity were generated in mainland Portugal, of which 59.4% were of renewable origin, 35.46% were of fossil origin, and 5.09% resulted from pumping water in dams, using imported energy. As may be seen, Portugal no longer produces electricity from coal combustion, as both the Sines Power Plant and the Pêgo Power Plant ended their coal production between 2020 and 2021. Portugal continues, however, to depend on natural gas imports to satisfy 35.46% of its electricity needs. This situation corresponds to the energy production of the natural gas thermoelectric plants, as is the case, for example, of the Ribatejo Power Plant, with an installed capacity of 1200 MW, or the Tapada do Outeiro Power Plant, with an installed capacity of 990 MW. Additionally, the numerous natural gas cogeneration units installed in several different industries, mainly in the Northern and Central regions of the country, contributed to the generation of 909 GWh from January to April 2022.

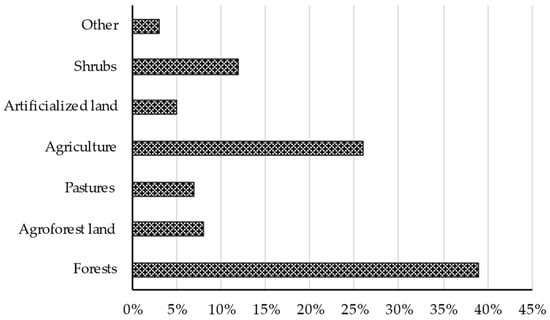

As Portugal is a country with abundant forest resources, the option of using biomass to generate electricity seems straightforward and clear [18,19]. As demonstrated in the last Land Cover and Use Map (COS 2018), published for mainland Portugal (http://www.dgterritorio.gov.pt, accessed on 24 September 2022), forests occupy 39% of the territory. According to the same source of information, the large numbers of land cover and use in mainland Portugal show that 92% of the territory has an agricultural, forestry, and agroforestry occupation; 51% of the territory is occupied by bush and forest; 26% of the territory is occupied by agriculture; 5% of the territory is artificialized. In other words, as can be concluded from the distribution of different types of land cover for mainland Portugal shown in Figure 1, Portugal has a high potential for biomass production.

Figure 1.

Mapping of land cover classes in mainland Portugal (http://www.dgterritorio.gov.pt, accessed on 24 September 2022).

Nevertheless, what will be the practical contribution from this endogenous resource—forest biomass—to the national energy mix without endangering all other environmental, economic, and social components associated with forest exploitation? This question seems entirely relevant since the Portuguese forest is at the base of the supply of raw materials to critical economic activities, which generated a turnover of EUR 9.8 billion in 2019 (www.ine.pt, accessed on 19 May 2022), with emphasis on the wood, furniture, biomass for energy, cork, and cellulose industries.

In this way, the solution that may be found on the one hand, would not cause any constraint to the supply chains already implemented and installed in Portugal and that serve the economic activities, and on the other hand, would effectively contribute to the national energy mix, which seems to be the sole and exclusive valorization of residual biomass, not only of forest origin but also resulting from agricultural practices. This quantification of biomass does not conflict with the interest of existing economic stakeholders and even allows new business models and value creation, contributing to new ways of generating wealth in rural areas and low-density territories. This valorization of biomass can also be associated with a set of advantages from an environmental point of view, such as reducing the risk of fire caused by the burning of piles and cleaning fires, generally used to eliminate the resulting residual biomass from forest management operations and agricultural practices, namely pruning orchards, vineyards, and olive groves. Thus, the objective of this work was to assess the annual production of residual biomass in the Central region of mainland Portugal and to analyze its use as an alternative to coal-fueled electric energy production. This approach, based on a GIS-supported methodology to estimate the available biomass in the area under study, despite being well-known and largely used in several previous studies, such as those presented, e.g., by Becalli et al. [20], Angelis-Dimakis et al. [21], Yousefi et al. [22], Lozano-Garcia et al. [23], or Famoso et al. [24], just to name a few, can be considered as being a novel approach due to its use as a decision-supporting tool to clarify the assumption assumed in the hypothetical scenario used as a case study.

2. Methodology

To carry out the present work, research and data acquisition were carried out using different sources, namely official (governmental) sources, to obtain the necessary data to carry out the calculations for the estimation of the quantities of biomass woody residue in the region. In this way, the information available from the following sources was used:

- (a)

- Data referring to the Pêgo Power Plant, namely concerning the operation of the power station, logistical process, location, installed equipment, and other data considered relevant for the present study (information available online at http://www.tejoenergia.com/pt/central, accessed on 15 April 2022).

- (b)

- Data on power production in Portugal, by type of source, fuel, and period (information available online at https://www.ren.pt, accessed on 20 April 2022; information available online at https://www.portugalenergia.pt/setor-energetico/bloco-3/, accessed on 20 April 2022; information available online at https://www.apren.pt, accessed on 20 April 2022).

- (c)

- Data referring to land use and soil occupation, which served to calculate the amounts of residual woody biomass available in the analyzed regions (information available online at https://www.dgterritorio.gov.pt/carta-de-uso-e-ocupacao-do-solo-para-2018, accessed on 12 April 2022). According to Caetano and Marcelino [25], COS is a polygons cartography representing homogeneous land use/occupation units supported by aerial photographs (orthophoto maps). A unit of land occupation/use is understood to be an area of land greater than or equal to the defined minimum cartographic unit (1 ha) with a distance between lines greater than or equal to 20 m and whose percentage of a given class of occupation/land use is greater than or equal to 75% of the entire delimited area.

- (d)

- Data for the determination of residual woody biomass estimation coefficients adapted from the “Bioeconomia 2030—Linhas Estratégicas dos Setores de Produção Primária no Contexto do Desenvolvimento da Estratégia Nacional para a Bioeconomia Sustentável 2030” (information available online at https://www.gpp.pt/index.php/noticias/bioeconomia-sustentavel-2030-estudo-para-o-setor-de-producao-primaria-de-produtos-biologicos, accessed on 12 April 2022; information available online at Resolution of the Council of Ministers nr. 163/2017, of 31 June—https://dre.pt/dre/detalhe/resolucao-conselho-ministros/163-2017-114133883—National Plan for the Promotion of Biorefineries, accessed on 12 April 2022; information available online at https://www.icnf.pt/florestas/flestudosdocumentosestatisticasindicadores, accessed on 12 April 2022).

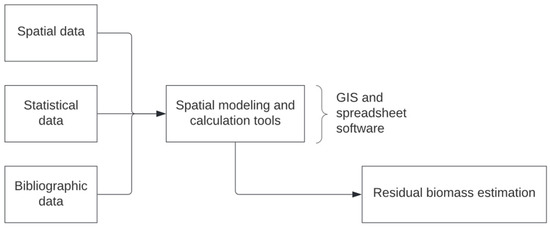

To evaluate each type of land use and soil cover for the selected categories, the QGIS software, version 3.18.1—Zürich (Boston, MA, USA), was used. Estimating the amount of residual woody biomass was performed using Microsoft® Excel software, version 16.60 (Redmond, WA, USA). The data collected from the sources presented above were used according to the methodology summarized in Figure 2.

Figure 2.

Flowchart of the methodology used to quantify residual biomass.

Thus, as shown schematically in Figure 2, the different types of spatial and statistical data were collected through the sources described in subparagraphs (c) and (d). In contrast, the bibliographic data were collected through the sources described in subparagraphs (a) and (b), and research on the SCOPUS platform. Subsequently, the spatial and statistical data were processed by spatial modeling and calculation tools to obtain the residual biomass estimation. Six types of biomass sources were selected to estimate the potential for generating residual biomass: orchards, olive groves, vineyards, maritime pine, eucalyptus, and scrubland. Afterwards, the occupied areas for each of these types of land cover were determined and, based on the theoretical indices of residual biomass generation presented in the sources described in paragraph (d) and in the bibliography, the annual production potential of residual biomass per hectare for the Central region of Portugal. The selection of these six biomass sources was based on their relevance in the region, compared to other types of biomass sources, which is considered irrelevant due to the reduced amounts of residual biomass they can generate.

3. Results

3.1. The Pêgo Power Plant

3.1.1. Location

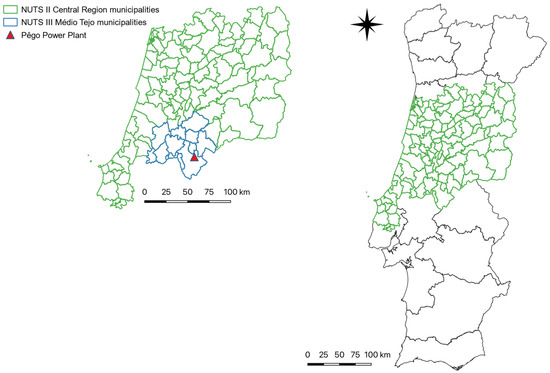

The Pêgo Power Plant is in the parish of Pêgo, in the municipality of Abrantes, in the district of Santarém. The municipality of Abrantes is part of the NUTS III of the Médio Tejo, which also includes the municipalities of Alcanena, Ourém, Torres Novas, Entroncamento, Vila Nova da Barquinha, Constância, Tomar, Ferreira do Zêzere, Sardoal, and Mação, also in the district of Santarém, and the municipalities of Vila de Rei and Sertã, in the district of Castelo Branco. The Pêgo Power Plant has its rail access through a branch built from the Beira Baixa railway line, which allows the connection to the port of Sines, from where coal was supplied during the period of operation of the power plant. Figure 3 shows the location of the Pêgo Power Plant in the national and regional context.

Figure 3.

Location of the Pêgo Power Plant.

3.1.2. Operation of the Coal-Fueled Power Plant

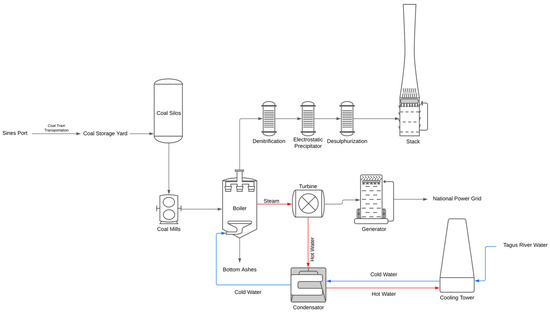

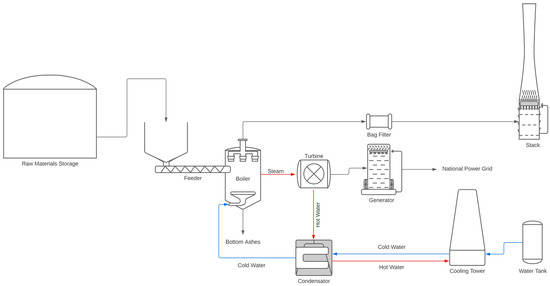

Figure 4 presents the simplified schematic of the power plant operating model.

Figure 4.

Operational flowchart of the Pêgo Power Plant (adapted from https://www.tejoenergia.com/pt/central/, accessed on 20 April 2022).

The process began when the fuel (bituminous and sub-bituminous coal) was received from different origins, namely from Brazil, Colombia, the USA, Venezuela, and South Africa, having entered Portugal through the port of Sines. After unloading the boats, the coal was transported to the Pêgo Power Plant by train. When it arrived, the coal was unloaded and stored in an outdoor park. Subsequently, coal was collected and carried by conveyor belts to the coal silos, from which the mills were fed. In the mills, the coal was dried and crushed. Then, it was injected into the combustion chamber of the boiler. This boiler produced steam that was channeled to the turbine, which is connected to the generator, producing electrical energy. Afterwards, the steam went to the condenser, being recirculated again to restart the process. During the combustion of coal, two types of ash are produced. Bottom ashes are cooled with water and deposited in the ash park. Fly ashes are collected by the dust collectors (filters) and deposited in silos. Flue gases are treated by denitrification (SCR) and desulfurization processes.

3.1.3. Operation of a Biomass-Fueled Power Plant

In the present work it is assumed that it is possible to directly replace coal with biomass in a plant designed for the use of coal. However, although this substitution is possible, the two fuels present significant differences in their properties, which in this substitution may imply alterations, mainly in the handling and pretreatment systems. The main differences are found in the heating value, moisture content, grindability, and density, with these last properties being decisive for the grinding efficiency, which can be the bottleneck of the entire process. In a simplified way, a biomass-fueled power plant can be described according to the scheme presented in Figure 5.

Figure 5.

Operational flowchart of a biomass-fueled power plant.

As shown in Figure 5, there are no significant differences between the flowchart presented for the biomass-fueled power plant and the flowchart presented in Figure 4 for the coal-fueled power plant, except for some equipment related to cleaning of gaseous flows, which are related to the composition of fuels. On the other hand, the equipment used for the pre-treatment of fuels, namely for grinding, differs significantly since coal mills cannot grind biomass with the same efficiency, forcing process changes. Additionally, the needs associated with the storage of fuels, mainly after milling, are different since it is recommended to use storage to protect it from weather conditions, while coal does not need to be protected. However, in the hypothetical scenario created for this evaluation, it is assumed that there are no differences between the two types of processing.

3.1.4. Assessment of the Potential for Biomass Consumption in the Hypothetical Scenario of Total Conversion

To estimate the operation of the power plant in a scenario of full use of the installed capacity, the full use of the facility for 24 h and 365 days a year is assumed. However, it is also necessary to include downtime for maintenance or any other type of constraint. In this way, 20 days were included for maintenance stoppages, and an availability of 90% was assumed for the remaining time.

Phours = [(days per year × hours per day) − (maintenance days × hours per day)] × availability = 7452 hr·yr−1

The gross installed power (GIP) is 314 MW in each generator set. As the thermoelectric power station comprises two groups, the gross installed power is 628 MW. Based on this value, it is now possible to determine the gross electricity production, which corresponds to the total amount of electricity produced, if there were no losses or self-consumption.

EP’production = GIP × Phours = 4,679,856 MWh·yr−1

To determine the amount of biomass needed to generate all this energy, residual biomass was assumed, consisting of a random mix composed of several species common in the Middle Tagus region and neighboring regions. This biomass is formed by maritime pine, eucalyptus, woody invasive species (e.g., acacias, robinias, ailanthus), and woody scrub (e.g., broom, heather), as well as residues resulting from the pruning of vines, olive groves, and orchards. Moisture content between 30% and 50% was also assumed for these residual biomasses. In this way, it was possible to assume a low heating value between 8.77 and 10.47 MJ·kg−1.

Thus, from the calculations carried out, it can be inferred that the total conversion of the Pêgo Power Plant to biomass would imply the use and availability of biomass within the range of 5,792,830 to 7,246,229 t·yr−1. However, at least in the years prior to the closure of energy production using coal, the Pêgo Power Plant was no longer operating at its total capacity, instead functioning as a backup unit. In other words, it was a production unit that operated at the request of the grid when it was unable to ensure the capacity to respond to consumption using other sources, namely renewable sources, and natural gas. Casau et al. presented an estimate for coal consumption for the year 2019, of 689,419 tons [26]. If an average low heating value of 22 MJ·kg−1 for the coal used is considered, it will correspond to the potential energy production of 15,167,218,000 MJ·yr−1 (4,213,116 MWh·yr−1), which corresponds to a potential consumption of residual biomass between 1,448,636 and 1,812,093 t·yr−1.

3.2. Quantification of Residual Woody Biomass Potential

The residual biomass production potential of a given region is directly related to the biomass types available and the areas occupied by these biomass sources. In this way, it is possible to estimate the amount of residual biomass generated by a type of source, provided that the coefficients of production/generation of residual biomass for each specific type are known. It is also expected that these coefficients may present a perfect fit for a given region, but they present a poor fit for another. However, for a larger-scale assessment, for example, at the national territory level or even at the level of large regions (NUTS II), the results obtained can offer a valid estimate of the potential for generating residual biomass. Recently, the Planning, Policies, and General Administration Office (GPP), in partnership with the National Institute for Agricultural and Veterinary Research (INIAV), presented the “Strategic Lines of the Primary Production Sectors in the Context of the Development of the National Strategy for the Sustainable Bioeconomy 2030”, wherein in a series of volumes dedicated to different subthemes, they present a characterization of the primary sector in Portugal in a bioeconomy context. In addition to the more general aspects, the framework of public policies for the sector is presented through the systematization of the available information regarding the primary production of biological resources and assets, which includes the potential for the generation of residual woody biomass.

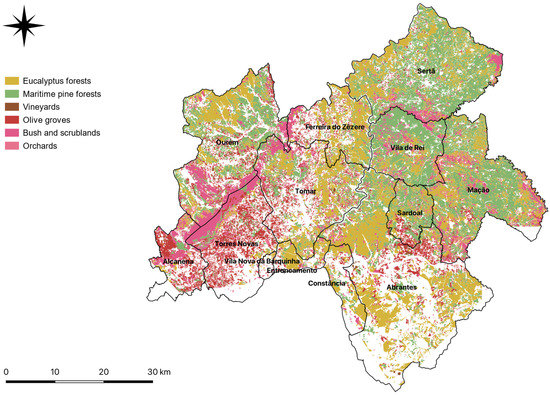

As previously mentioned, the production of residual biomass is directly related to the types of sources available, and the areas occupied by these types of sources. Figure 6 shows, as an example, the different land occupation and use that could potentially generate residual woody biomass for the Central region of mainland Portugal, based on the COS 2018.

Figure 6.

Types of land use and soil cover that could potentially generate residual woody biomass in the Central region of mainland Portugal.

As can be seen from the legend in Figure 6, several types of occupation cover the different parts of land and soil of the region continuously, revealing a potentially high capacity for the generation of residual woody biomass. However, when analyzing in more detail the different types of sources, it appears that, at the outset, there are some types of land occupation and soil cover with a greater capacity to generate biomass than others. Alternatively, even though some types can generate large amounts of residual biomass, a value chain has already been established, and its use or integration into a new value chain can jeopardize an already established economic activity.

Through the data previously presented by the GPP, it is possible to quantify the residual woody biomass existing in Portugal, which is summarized in Table 2.

Table 2.

Annual quantity of residual woody biomass available in mainland Portugal.

As mentioned, not all biomass sources contribute in the same way, and they do not present the same potential. The study presented by the GPP includes in the category “Pruning Residues” the materials resulting from the pruning of fresh fruit orchards, citrus, subtropical fruits, almond trees, chestnut trees, walnut trees, carob trees, other nuts, olive groves, and vineyards. However, some of these sources occur exclusively in certain regions, as is the case of the carob tree, and others are closely associated with strips of territory due to the climate, as is the case of the almond tree or citrus. Thus, for more regional analysis, the most frequent types of potential generators of residual biomass in the region were selected, as they will undoubtedly contribute most effectively to the overall computation of residual biomass. The same applies to residual forest biomass, with the GPP dividing the species into maritime pine, stone pine, eucalyptus, cork oak, holm oak, oaks, other forest species, herbaceous green residues, and brushwood. In this case, herbaceous green waste was not considered for the present work since it is understood that there are other more efficient ways of recovering this type of waste. Concerning forest species, it is understood that the most relevant are, without a doubt, maritime pine, and eucalyptus, so only these two were considered in this study. Woody scrubland also plays a crucial role, as it occupies large areas from the north to the south of the national territory, which is why it was also included in the assessment. Table 3 presents the quantification results of residual biomass for the six categories defined as being the most relevant for the Central region of mainland Portugal, namely orchards, olive groves, vineyards, maritime pine, eucalyptus, and bushes.

Table 3.

Estimation of residual biomass resulting from pruning, forestry, and woody scrubland management operations in the Central region of mainland Portugal.

As can be seen from the results obtained, the area occupied by sources potentially generating residual biomass corresponds to 59.6% of the territory of the Central region of mainland Portugal. However, the total residual woody biomass estimated for the region, 1,279,495 t·yr−1, corresponds to 82.5% of the total residual woody biomass estimated for the region.

In an approximation to the scale of the surroundings of the Pêgo Power Plant, the estimated potential for generating residual woody biomass of the Médio Tejo subregion (NUTS III) is summarized in Table 4.

Table 4.

Estimation of residual biomass resulting from pruning, forestry, and woody scrubland management operations in the Médio Tejo subregion of mainland Portugal.

The Médio Tejo subregion, which represents 11.9% of the total area of the Central region of mainland Portugal, contributes 13.3% of the total residual woody biomass generated annually.

4. Discussion

The estimates presented point to a high capacity to generate residual woody biomass throughout the territory of mainland Portugal, with emphasis on the Northern and Central regions, although with distinctive differences in characteristics between them, since biomass resulting from the leftovers of pruning dominates the Northern region. By contrast, residual biomass resulting from forest management dominates in the Central region. This situation is easily understandable, given the enormous contribution of the vineyard areas to this region, where some of the most important wine regions of the country are located, namely the Vinho Verde region and the Douro region. Concerning the amount of residual woody biomass generated in the Central region and considering its possible energy recovery in the Pêgo Power Plant, the results obtained require a careful analysis and the assumption of some presuppositions, in particular concerning operating conditions.

Assuming that the direct replacement of coal by residual biomass is possible, the needed amount of biomass for the power plant to operate at its maximum capacity would be 5,800,000 to 7,860,000 t·yr−1. However, a simple comparison with the results obtained in the previous section to estimate the generation capacity of regional woody biomass in mainland Portugal shows that this scenario appears to be impossible to achieve since the total residual woody biomass totals approximately 5,500,000 t·yr−1. In this way, the total conversion of the thermoelectric plant to residual woody biomass would consume the entire amount available at the level of the national mainland, assuming that all of the biomass would be available and accessible, which, as is known, is not expected to be so, given the usual constraints associated with collection, transport, and processing. The adoption of such a measure would result in pressure on the resource, which would lead to a shortage of the resource, and the subsequent rise in the price of fuel. On the other hand, it would create competition with other economic activities already in place, such as among biomass power plants, the wood pellet industry, the wood pellet and briquette industry, and the biomass industry for energy, among others. This pressure on the resource and the increase in prices (which to a certain extent could serve to boost the collection of residual biomass considered less accessible) would lead to an overexploitation of the resource, jeopardizing its sustainability. In addition to these more structural aspects of the model, questions of a more operational nature also arise, namely those of a logistical nature, since, despite the central location of the Pêgo Power Plant in the national territory, it would be necessary to transport the residual biomass over great distances, which in some cases could be more than 300 km. Portugal does not yet have logistical support structures functioning as collection and pre-processing centers for subsequent dispatch; for example, places where residual biomass can dry before being processed for later shipment to the energy recovery destination, optimizing transport as much as possible. These centers would have as their primary function the correction of the main disadvantages associated with residual biomass, which are its low density, heterogeneity, high humidity, and low heating value.

Despite the existing possibility and the fact that the estimated consumption is practically equivalent to the estimated availability (at least in its lower limit), this scenario would make unfeasible an entire existing network of plants dedicated to biomass, which at this moment already totals an installed power of 523.79 MW, as shown in Table 5, corresponding to an annual consumption of residual woody biomass of approximately 1,800,000 t·yr−1.

Table 5.

Biomass power plants in operation in Portugal (adapted from https://florestas.pt, accessed on 12 April 2022).

As can be seen, of the 23 biomass power plants operating in mainland Portugal, only five are not located in the Central region of the country, namely those in the districts of Viana do Castelo, Braga, and Setúbal, so it can be inferred that the pressure on the resource is exerted more intensely precisely in this region. The 18 biomass power plants located in the region represent an annual biomass demand of 853,961 to 1,018,302 t·yr−1. However, as shown in Table 5, some of the units belong to groups in the pulp and paper industry, so they are energy recovery units that have access to other types of residual biomass, namely black liquor and other residues resulting from the production of paper pulp. In this way, the estimated biomass consumption may be significantly lower in terms of residual biomass needs.

The possibility of using the Pêgo Power Plant in a more conservative scenario, in approximation to the model under which it already operated before its closure, as a backup unit, seems to be more plausible since the estimated amounts for the satisfaction of fuel needs seem to fit much better with the current availability within the region itself. As seen in the estimate presented in Table 3, the potential for generating residual woody biomass in the Central region of Portugal is approximately 1,280,000 t·yr−1. As determined in Section 3.1.3, the fuel requirements for the operation of the power plant (in the lower estimated limit) are approximately 1,450,000 t·yr−1. Given the proximity of the power plant to both Lisbon and the Tagus Valley and Alentejo regions, with, respectively, approximately 715,000 and 1,250,000 t·yr−1 of residual woody biomass, the feasibility of this scenario seems to be much more acceptable, since although requirements exceed the availability of the region, it seems possible to transfer fuel from other nearby regions. In this way, there would be no constraints on the functioning of all other economic activities already in place.

In this scenario and given the availability of biomass in the Médio Tejo subregion, which is approximately 170,000 t·yr−1, it seems possible to create a value chain for residual biomass, which would contribute to the valorization of an endogenous resource until now almost always neglected. It could also contribute to the resumption of the power plant activity and mitigate the negative impacts of the local socioeconomic system, as presented by Casau et al., which could somehow be reversed and/or minimized in this scenario [26]. However, coal-fired power plants, such as the Pêgo Power Plant, do not allow the direct use of residual biomass, as the coal handling system is quite different from those used for handling biomass. Problems in transportation caused by the difference in the density of the materials, problems in grinding due to the difference in the Hardgrove Grindability Index (with the biomass presenting very low values), and problems caused by the differences in the heating value (with the biomass presenting significantly lower values) could be addressed through the production of, for example, torrefied biomass, which would make the use of biomass possible in an efficient manner and without profound changes in the thermoelectric plant. In such a scenario, the residual woody biomass would be subjected to a thermochemical conversion process, which converts the material received into a new material, in which properties such as grindability, heating value, hydrophobicity, and perishability approach the characteristics presented by coal. In this way, the plant could operate in the same way used for coal, avoiding the significant investments necessary to convert the power plant to non-thermally treated biomass. Despite this possibility having already been mentioned in several previous studies, such as those presented by Bergman et al. [27], Tumuluru et al. [28], Li et al. [29], Goldfarb and Liu [30], Panahi et al. [31], and Sher et al. [32], and apparently, as mentioned by Li et al. [33], the use of severe thermochemical conversion processes not being recommended, because they are potentially more difficult to operate with the current state of the art of available technologies, it is a topic that still lacks in-depth investigation relating to its effective application.

Despite all the possibilities currently available for the recovery of residual biomass, and the large-scale solutions seeming, at first sight, more interesting since they allow the concentration of the solution of the problem in a single point, with the inherent advantages related to the economies of scale that can be leveraged, it is also easy to foresee a set of constraints. Collecting different biomass sources associated with territorial dispersion at different times of the year creates a real logistical challenge. The generation potential of each of the biomass sources is also not equal, forcing complex planning to ensure that the power plant has its fuel supply guaranteed. This option of valuing the various biomass sources available in the region in a single location and of great capacity, as is the case of the Pêgo Power Plant, seems to present too many constraints, and it is, therefore, essential to analyze all alternatives to dispose of the amounts of residual biomass sources. Another option that should be considered, although it still needs deep analysis and investigation on its potential, is the valorization of this residual biomass through its use for thermal energy production. This thermal energy production can occur in industrial units, for example, that use steam in their processes, or in the generation of hot air to heat greenhouses, aviaries, or industrial dryers, or even as fuel for heating both domestic and service buildings, such as schools, university residences, nursing homes, hotels, and municipal swimming pools, among others.

5. Conclusions

The demand for renewable energy sources has gained increasing importance in recent years in Portugal, with the emergence of numerous investments aimed at producing energy from different sources. In this way, biomass was identified as an alternative capable of contributing to the diversification of the energy mix and to the decarbonization of the economy and the energy independence of countries. In Portugal, the use of biomass already has a relevant history. However, there is a lack of knowledge of the real potential of its use and availability. As verified in the case study analyzed, the total conversion of a medium-sized coal-fired power plant (628 MW) to biomass would imply a consumption equivalent to the total amount of residual woody biomass generated in mainland Portugal. While the logistical difficulties would already be an obstacle to the viability of this scenario, it would also create competition between different sectors of activity already installed and dependent on the exploitation of the available resource. Thus, the conversion of the Pêgo Power Plant for the exclusive use of biomass, as was assumed in the hypothetical scenario equated to this work, is not an option that can be considered, as there are no sufficient residual biomass resources available. However, using the aforementioned power plant in backup mode to guarantee the base load of the national electricity grid could be a hypothesis to be considered. This option could contribute to provide a solution to the excess of residual biomass generated in the region that is not yet included in the supply chains, but also for the two adjacent regions, namely the Alentejo and Lisboa e Vale do Tejo regions, where significant amounts of residual biomass are also generated, and where there are still no other options for its recovery. Additionally, given the availability of a high amount of residual biomass, it may promote another type of recovery that is not the production of electricity but instead its use in smaller units to produce thermal energy, for example, in industries that use steam in their processes. However, this possibility still needs further investigation.

Author Contributions

Conceptualization, M.C., J.C.O.M., M.F.D., and L.J.R.N.; methodology, J.C.O.M., M.F.D., and L.J.R.N.; validation, M.C., J.C.O.M., M.F.D., and L.J.R.N.; formal analysis, M.C., J.C.O.M., M.F.D., and L.J.R.N.; investigation, M.C., J.C.O.M., M.F.D., and L.J.R.N.; resources, J.C.O.M., M.F.D., and L.J.R.N.; data curation, M.C., J.C.O.M., M.F.D., and L.J.R.N.; writing—original draft preparation, M.C., M.F.D., and L.J.R.N.; writing—review and editing, J.C.O.M., M.F.D., and L.J.R.N.; visualization, M.C., J.C.O.M., M.F.D., and L.J.R.N.; supervision, M.F.D. and L.J.R.N.; project administration, J.C.O.M., M.F.D., and L.J.R.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the FCT—Fundação para a Ciência e Tecnologia/MCTES, through national funds and, when applicable, co-financed by the FEDER, under the new partnership agreement PT2020, grant number PCIF/GVB/0083/2019. L.J.R.N. was supported by proMetheus—Research Unit on Energy, Materials and Environment for Sustainability—UIDP/05975/2020, funded by national funds through FCT—Fundação para a Ciência e Tecnologia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available upon request from the corresponding author.

Acknowledgments

The authors would like to thank the GPP—Office of Planning, Policies, and General Administration of the Ministry of Agriculture and Food of the Government of Portugal, and in particular Clara Lopes, for providing essential data for the realization of this research work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Armaroli, N.; Balzani, V. The Future of Energy Supply: Challenges and Opportunities. Angew. Chem. Int. Ed. 2007, 46, 52–66. [Google Scholar] [CrossRef] [PubMed]

- Mikulčić, H.; Baleta, J.; Klemeš, J.J.; Wang, X. Energy transition and the role of system integration of the energy, water and environmental systems. J. Clean. Prod. 2021, 292, 126027. [Google Scholar] [CrossRef]

- Chen, W.-M.; Kim, H.; Yamaguchi, H. Renewable energy in eastern Asia: Renewable energy policy review and comparative SWOT analysis for promoting renewable energy in Japan, South Korea, and Taiwan. Energy Policy 2014, 74, 319–329. [Google Scholar] [CrossRef]

- Unruh, G.C. Escaping carbon lock-in. Energy Policy 2002, 30, 317–325. [Google Scholar] [CrossRef]

- Chow, J.; Kopp, R.J.; Portney, P.R. Energy Resources and Global Development. Science 2003, 302, 1528–1531. [Google Scholar] [CrossRef]

- Martens, J.A.; Bogaerts, A.; De Kimpe, N.; Jacobs, P.A.; Marin, G.B.; Rabaey, K.; Saeys, M.; Verhelst, S. The Chemical Route to a Carbon Dioxide Neutral World. ChemSusChem 2016, 10, 1039–1055. [Google Scholar] [CrossRef]

- Lange, M.; Cummins, V. Managing stakeholder perception and engagement for marine energy transitions in a decarbonising world. Renew. Sustain. Energy Rev. 2021, 152, 111740. [Google Scholar] [CrossRef]

- Simionescu, M.; Păuna, C.B.; Diaconescu, T. Renewable Energy and Economic Performance in the Context of the European Green Deal. Energies 2020, 13, 6440. [Google Scholar] [CrossRef]

- Grubler, A.; Wilson, C.; Bento, N.; Boza-Kiss, B.; Krey, V.; McCollum, D.L.; Rao, N.D.; Riahi, K.; Rogelj, J.; De Stercke, S. A low energy demand scenario for meeting the 1.5 C target and sustainable development goals without negative emission technologies. Nature energy 2018, 3, 515–527. [Google Scholar] [CrossRef]

- Inderwildi, O.; Zhang, C.; Wang, X.; Kraft, M. The impact of intelligent cyber-physical systems on the decarbonization of energy. Energy Environ. Sci. 2020, 13, 744–771. [Google Scholar] [CrossRef]

- Niles, K.; Lloyd, B. Small Island Developing States (SIDS) & energy aid: Impacts on the energy sector in the Caribbean and Pacific. Energy Sustain. Dev. 2013, 17, 521–530. [Google Scholar] [CrossRef]

- Bazilian, M.; Onyeji, I. Fossil fuel subsidy removal and inadequate public power supply: Implications for businesses. Energy Policy 2012, 45, 1–5. [Google Scholar] [CrossRef]

- Van Schaik, L.; Schunz, S. Explaining EU activism and impact in global climate politics: Is the Union a norm-or interest-driven actor? JCMS J. Common Mark. Stud. 2012, 50, 169–186. [Google Scholar] [CrossRef]

- Di Silvestre, M.L.; Favuzza, S.; Sanseverino, E.R.; Zizzo, G. How Decarbonization, Digitalization and Decentralization are changing key power infrastructures. Renew. Sustain. Energy Rev. 2018, 93, 483–498. [Google Scholar] [CrossRef]

- Capros, P.; Paroussos, L.; Fragkos, P.; Tsani, S.; Boitier, B.; Wagner, F.; Busch, S.; Resch, G.; Blesl, M.; Bollen, J. European decarbonisation pathways under alternative technological and policy choices: A multi-model analysis. Energy Strat. Rev. 2014, 2, 231–245. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Monforti-Ferrario, F.; Banja, M.; Motola, V. Renewable energy policy framework and bioenergy contribution in the European Union—An overview from National Renewable Energy Action Plans and Progress Reports. Renew. Sustain. Energy Rev. 2015, 51, 969–985. [Google Scholar] [CrossRef]

- Fortes, P.; Simoes, S.; Gouveia, J.P.; Seixas, J. Electricity, the silver bullet for the deep decarbonisation of the energy system? Cost-effectiveness analysis for Portugal. Appl. Energy 2019, 237, 292–303. [Google Scholar] [CrossRef]

- Ericsson, K.; Nilsson, L.J. Assessment of the potential biomass supply in Europe using a resource-focused approach. Biomass Bioenergy 2006, 30, 1–15. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Casau, M.; Dias, M.F. Portuguese Wood Pellets Market: Organization, Production and Consumption Analysis. Resources 2021, 10, 130. [Google Scholar] [CrossRef]

- Beccali, M.; Columba, P.; D’Alberti, V.; Franzitta, V. Assessment of bioenergy potential in Sicily: A GIS-based support methodology. Biomass Bioenergy 2009, 33, 79–87. [Google Scholar] [CrossRef]

- Angelis-Dimakis, A.; Biberacher, M.; Dominguez, J.; Fiorese, G.; Gadocha, S.; Gnansounou, E.; Guariso, G.; Kartalidis, A.; Panichelli, L.; Pinedo, I.; et al. Methods and tools to evaluate the availability of renewable energy sources. Renew. Sustain. Energy Rev. 2011, 15, 1182–1200. [Google Scholar] [CrossRef]

- Yousefi, H.; Noorollahi, Y.; Hajinezhad, A.; Alimohammadi, A. GIS-based spatially integrated bioenergy resources assessment in Kurdistan Province-Northwest Iran. Sustain. Energy Technol. Assess. 2017, 23, 11–20. [Google Scholar] [CrossRef]

- Lozano-García, D.F.; Santibañez-Aguilar, J.E.; Lozano, F.J.; Flores-Tlacuahuac, A. GIS-based modeling of residual biomass availability for energy and production in Mexico. Renew. Sustain. Energy Rev. 2020, 120, 109610. [Google Scholar] [CrossRef]

- Famoso, F.; Prestipino, M.; Brusca, S.; Galvagno, A. Designing sustainable bioenergy from residual biomass: Site allocation criteria and energy/exergy performance indicators. Appl. Energy 2020, 274, 115315. [Google Scholar] [CrossRef]

- Caetano, M.; Marcelino, F. Especificações Técnicas da Carta de Uso e Ocupação do Solo (COS) de Portugal Continental Para 2018; Direção Geral do Território: Lisboa, Portugal, 2019; p. 60. [Google Scholar]

- Casau, M.; Cancela, D.C.M.; Matias, J.C.O.; Dias, M.F.; Nunes, L.J.R. Coal to Biomass Conversion as a Path to Sustainability: A Hypothetical Scenario at Pego Power Plant (Abrantes, Portugal). Resources 2021, 10, 84. [Google Scholar] [CrossRef]

- Bergman, P.C.; Boersma, A.; Zwart, R.; Kiel, J. Torrefaction for Biomass Co-Firing in Existing Coal-Fired Power Stations; Energy Research Centre of the Netherlands: Petten, The Netherlands, 2005. [Google Scholar]

- Tumuluru, J.S.; Wright, C.T.; Boardman, R.D.; Yancey, N.A.; Sokhansanj, S. A review on biomass classification and composition, co-firing issues and pretreatment methods. Am. Soc. Agric. Biol. Eng. 2011, 1, 1110458. [Google Scholar] [CrossRef]

- Li, J.; Brzdekiewicz, A.; Yang, W.; Blasiak, W. Co-firing based on biomass torrefaction in a pulverized coal boiler with aim of 100% fuel switching. Appl. Energy 2012, 99, 344–354. [Google Scholar] [CrossRef]

- Goldfarb, J.L.; Liu, C. Impact of blend ratio on the co-firing of a commercial torrefied biomass and coal via analysis of oxidation kinetics. Bioresour. Technol. 2013, 149, 208–215. [Google Scholar] [CrossRef]

- Panahi, A.; Tarakcioglu, M.; Schiemann, M.; Delichatsios, M.; Levendis, Y.A. On the particle sizing of torrefied biomass for co-firing with pulverized coal. Combust. Flame 2018, 194, 72–84. [Google Scholar] [CrossRef]

- Sher, F.; Yaqoob, A.; Saeed, F.; Zhang, S.; Jahan, Z.; Klemeš, J.J. Torrefied biomass fuels as a renewable alternative to coal in co-firing for power generation. Energy 2020, 209, 118444. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Pawlak-Kruczek, H.; Yang, W.; Kruczek, P.; Blasiak, W. Process simulation of co-firing torrefied biomass in a 220MWe coal-fired power plant. Energy Convers. Manag. 2014, 84, 503–511. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).