Kinetic Modelling of the Removal of Multiple Heavy Metallic Ions from Mine Waste by Natural Zeolite Sorption

Abstract

:1. Introduction

2. Materials and Methods

2.1. Zeolite Sample Material

2.2. Kinetic Experimental Procedure

- single-component system—10 meq/L per metal,(lead [P], copper [C], iron [F], nickel [N], zinc [Z]);

- dual-component system [D]—5.0 meq/L per metal(lead-copper [D-PC], lead-iron [D-PF], lead-nickel [D-PN], lead-zinc [D-PZ],copper-iron [D-CF], copper-nickel [D-CN], iron-zinc [D-FZ], nickel-zinc [D-NZ]);

- triple-component system [T]—3.3 meq/L per metal (lead-copper-iron), and;

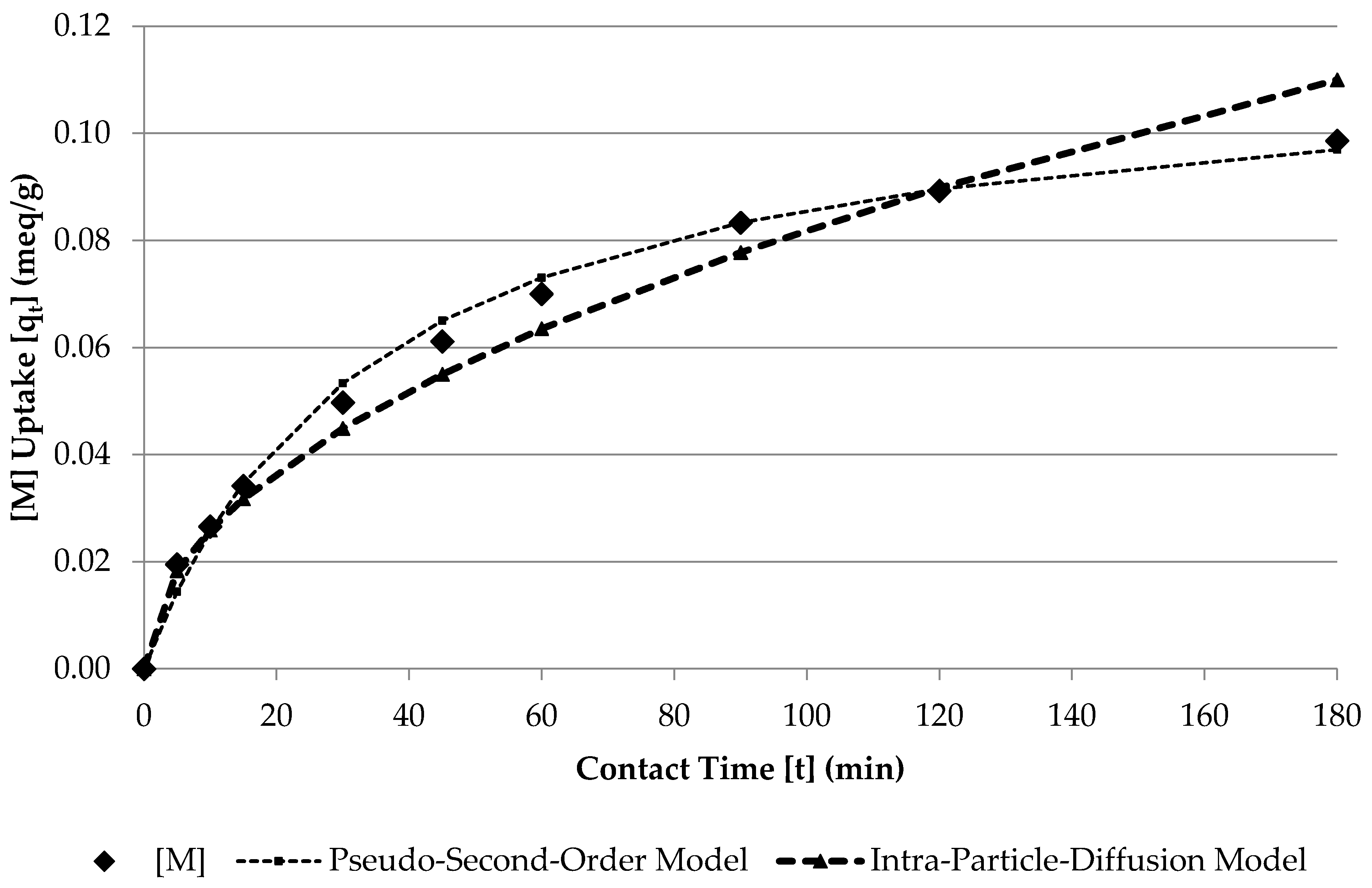

- multi-component system [M]—2.0 meq/L per metal (all five metals).

2.3. Analytical Procedure

2.4. Sorption Kinetics Principles and Model Selection

- Reaction-Type ModelChemisorption—chemical reaction at the sites of the functional ionic groups within the zeolite and focuses on the process as a whole.

- Diffusion-Type Model

- Film Diffusion—diffusion of counterions in the adherent layer surrounding the zeolite (between the external solution and crystal surface).

- Intra-Particle Diffusion—diffusion of counterions in the solute within the zeolite pores and/or along the pore walls.

- Mass Action—sorption or desorption between the active sites and the sorbate material.

2.4.1. Reaction-Type Models

Pseudo-First-Order Rate Equation

Pseudo-Second-Order Rate Equation

Elovich’s Equation

2.4.2. Diffusion-Type Models

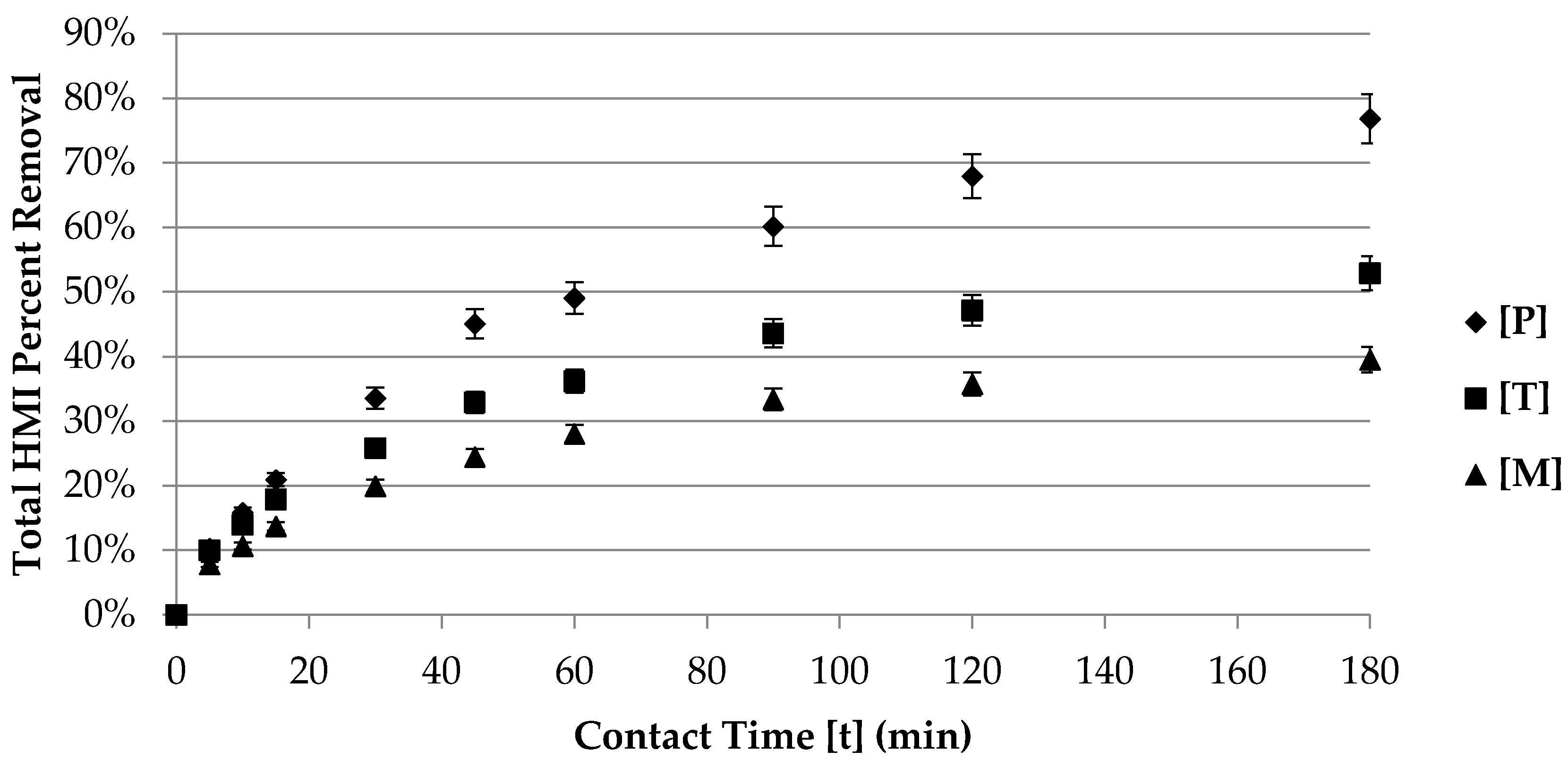

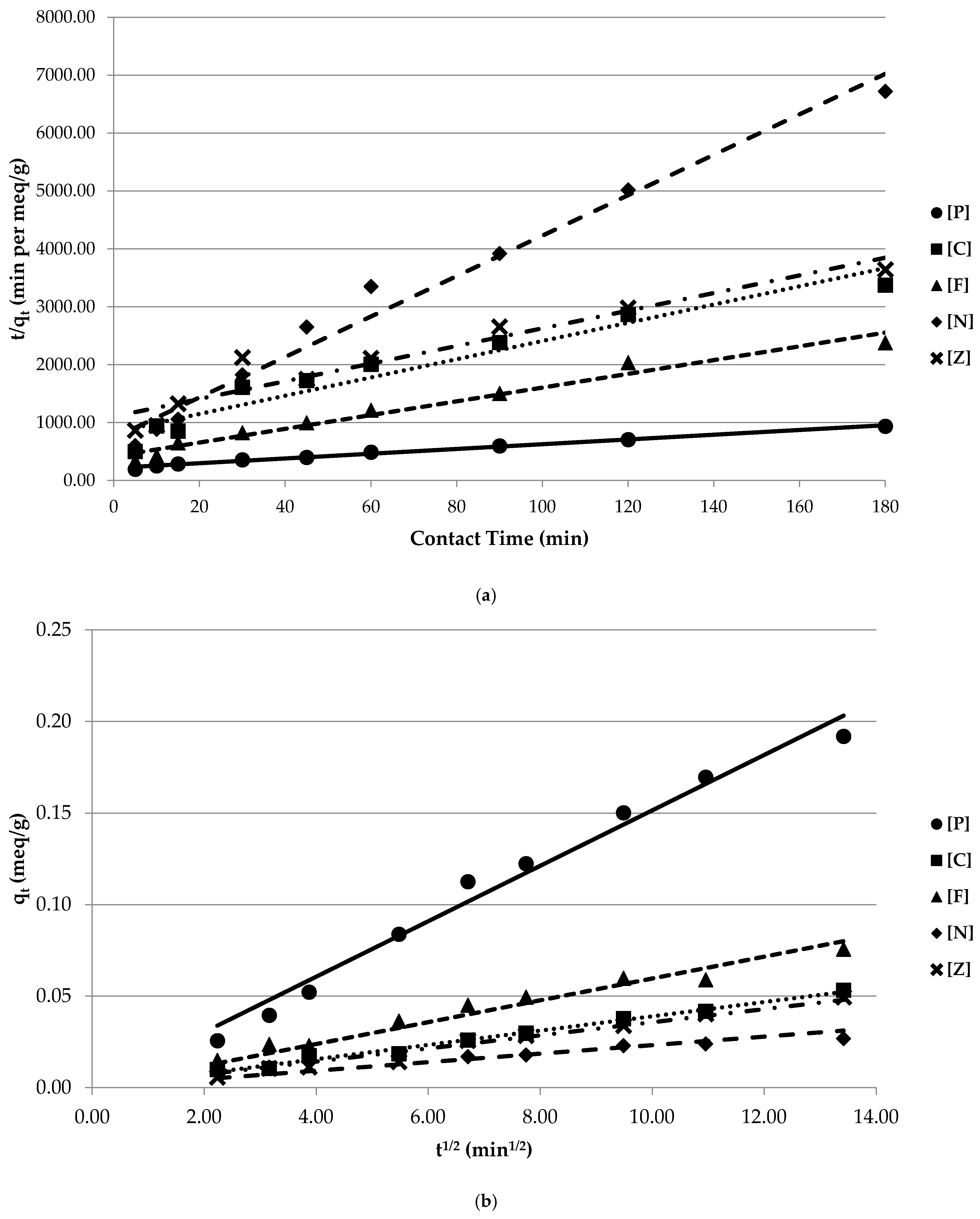

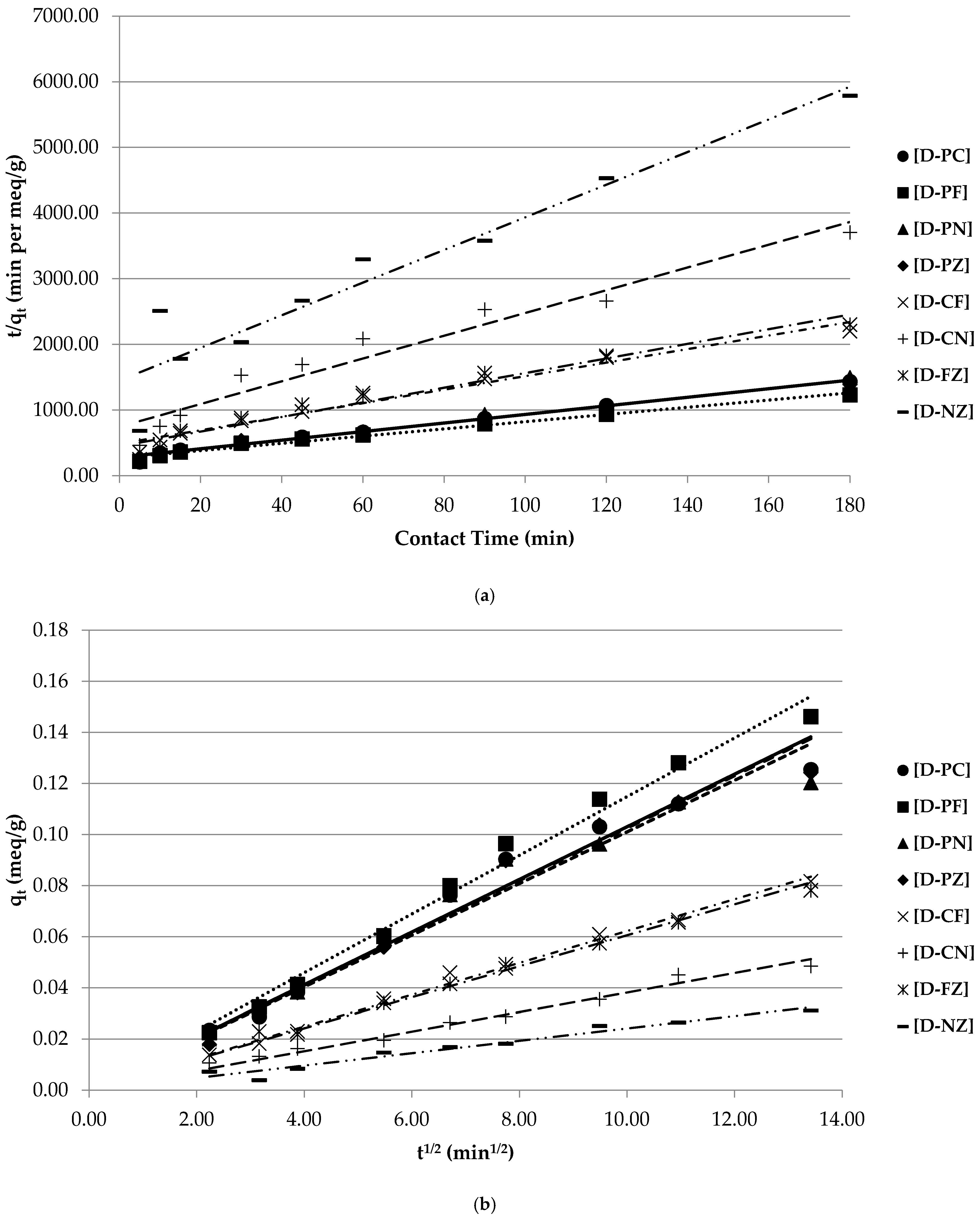

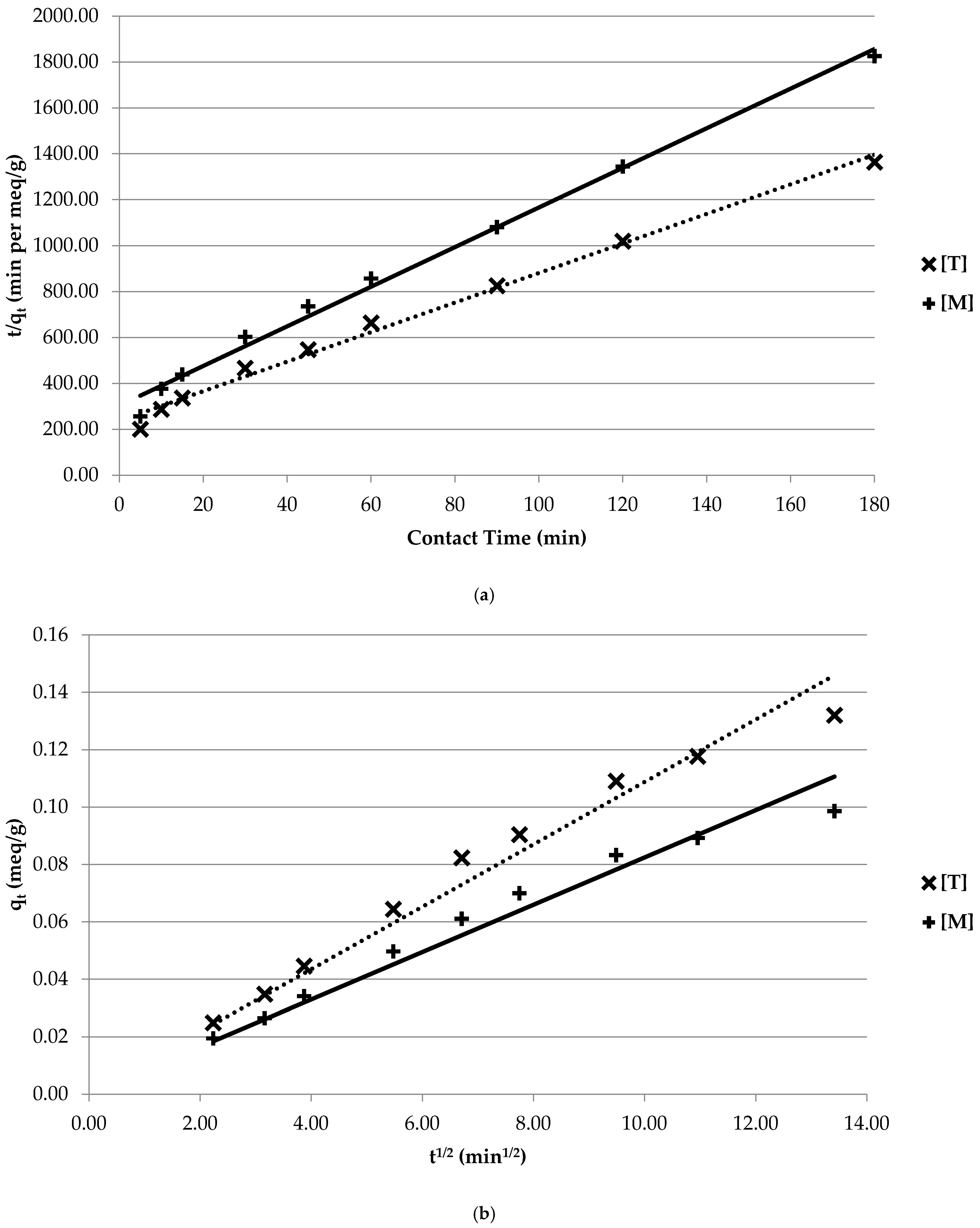

3. Results and Discussion

3.1. Acidity Levels

3.2. Heavy Metallic Ion Levels

3.3. Sorption Kinetics

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Motsi, T.; Rowson, N.A.; Simmons, M.J.H. Kinetic studies of the removal of heavy metals from acid mine drainage by natural zeolite. Int. J. Miner. Process. 2011, 101, 42–49. [Google Scholar] [CrossRef]

- Akcil, A.; Koldas, S. Acid Mine Drainage (AMD): Causes, treatment and case studies. J. Clean. Prod. 2006, 14, 1139–1145. [Google Scholar] [CrossRef]

- Erdem, E.; Karapinar, N.; Donat, R. The removal of heavy metal cations by natural zeolites. J. Colloid Interface Sci. 2004, 280, 309–314. [Google Scholar] [CrossRef] [PubMed]

- Sprynskyy, M.; Buszewski, B.; Terzyk, A.P.; Namiesnik, J. Study of the selection mechanism of heavy metal (Pb2+, Cu2+, Ni2+, and Cd2+) adsorption on clinoptilolite. J. Colloid Interface Sci. 2006, 304, 21–28. [Google Scholar] [CrossRef] [PubMed]

- Acheampong, M.A.; Meulepas, R.J.W.; Leans, P.N.L. Removal of heavy metals and cyanide form gold mine wastewater. J. Chem. Technol. Biotechnol. 2010, 85, 590–613. [Google Scholar] [CrossRef]

- Acheampong, M.A. Sustainable Gold Mining Wastewater Treatment by Sorption Using Low-Cost Materials. Ph.D. Thesis, UNESCO-IHE Institute of Water Education, Delft, The Netherlands, 2013. [Google Scholar]

- Nezamzadeh-Ejhieh, A.; Shahanshahi, M. Modification of clinoptilolite nano-particles with hexadecylpyridynium bromide surfactant as an active component of Cr(VI) selective electrode. J. Ind. Eng. Chem. 2013, 19, 2026–2033. [Google Scholar] [CrossRef]

- Muttil, N.; Chau, K.W. Machine learning paradigms for selecting ecologically significant input variables. Eng. Appl. Artif. Intell. 2007, 20, 735–744. [Google Scholar] [CrossRef]

- Wang, W.C.; Xu, D.M.; Chau, K.W.; Lei, G.J. Assessment of river water quality based on theory of variable fuzzy sets and fuzzy binary comparison method. Water Resour. Manag. 2014, 28, 4183–4200. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Cheng, C.T.; Chau, K.W.; Li, G. Multiple criteria data envelopment analysis for full ranking units associated to environment impact assessment. Int. J. Environ. Pollut. 2006, 28, 448–464. [Google Scholar] [CrossRef]

- Bektas, N.; Kara, S. Removal of lead from aqueous solutions by natural clinoptilolite: Equilibrium and kinetic studies. Sep. Purif. Technol. 2004, 39, 189–200. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Sun, X.; Wang, L.; Sun, X. Evaluation of zeolites synthesized from fly ash as potential adsorbents for wastewater containing heavy metals. J. Environ. Sci. 2009, 21, 127–136. [Google Scholar] [CrossRef]

- Anari-Anaraki, M.; Nezamzadeh-Ejhieh, A. Modification of an Iranian clinoptilolite nano-particles by hexadecyltrimethyl ammonium cationic surfactant and dithizone for removal of Pb(II) from aqueous solution. J. Colloid Interf. Sci. 2015, 440, 272–281. [Google Scholar] [CrossRef] [PubMed]

- Borandegi, M.; Nezamzadeh-Ejhieh, A. Enhanced removal efficiency of clinoptilolite nano-particles toward Co(II) from aqueous solution by modification with glutamic acid. Colloids Surfaces A Physicochem. Eng. Asp. 2015, 479, 35–45. [Google Scholar] [CrossRef]

- Curkovic, L.; Cerjan-Stefanovic, S.; Filipan, T. Metal ion exchange by natural and modified zeolites. Wat. Res. 1997, 31, 1379–1382. [Google Scholar] [CrossRef]

- Helfferich, F. Equilibria; Kinetics. In Ion Exchange; Series in Advanced Chemistry; McGraw-Hill Book Company: New York, NY, USA, 1962; pp. 95–322. [Google Scholar]

- Inglezakis, V.J.; Poulopoulos, S.G. Chapter 4—Adsorption and Ion-Exchange (Kinetics). In Adsorption, Ion Exchange and Catalysis—Design of Operations and Environmental Applications, 1st ed.; Elsevier Science: Amsterdam, The Netherlands, 2006; pp. 262–266, ISBN-13: 978-0-444-52783-7. [Google Scholar]

- Wang, S.; Peng, Y. Natural zeolites as effective adsorbents in water and wastewater treatment. Chem. Eng. J. 2010, 156, 11–24. [Google Scholar] [CrossRef]

- Fu, F.; Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef] [PubMed]

- Tsitsishvili, G.V. Perspectives of Natural Zeolite Applications. Occurrence. In Properties and Utilization of Natural Zeolites—2nd International Conference 1985; Akademiai Kiado: Budapest, Hungary, 1988; pp. 367–393. [Google Scholar]

- Nezamzadeh-Ejhieh, A.; Shirzadi, A. Enhancement of the photocatalytic activity of Ferrous Oxide by doping onto the nano-clinoptilolite particles towards photodegradation of tetracycline. Chemosphere 2014, 107, 136–144. [Google Scholar] [CrossRef] [PubMed]

- Bekkum, H.V.; Flanigen, E.M.; Jansen, J.C. Ion-Exchange in Zeolites. In Introduction to Zeolite Science and Practice—Studies in Surface Science and Catalysis, 1st ed.; Elsevier Science: Zeist, The Netherlands, 1991; Volume 58, pp. 359–390. [Google Scholar]

- Inglezakis, V.J.; Loizidou, M.D.; Grigoropoulou, H.P. Equilibrium and kinetic ion exchange studies of Pb2+, Cr3+, Fe3+ and Cu2+ on natural clinoptilolite. Water Res. 2002, 36, 2784–2792. [Google Scholar] [CrossRef]

- Ersoy, B.; Celik, M.S. Electrokinetic properties of clinoptilolite with mono- and multivalent electrolytes. Micropor. Mesopor. Mater. 2002, 55, 305–312. [Google Scholar] [CrossRef]

- Qiu, H.; Lv, L.; Pan, B.C.; Zhang, Q.J.; Zhang, W.M.; Zhang, Q.X. Critical review in adsorption kinetic models. J. Zhejiang Univ. Sci. A 2009, 18, 716–724. [Google Scholar] [CrossRef]

- Kocaoba, S.; Orhan, Y.; Akyuz, T. Kinetics and equilibrium studies of heavy metal ions removal by use of natural zeolite. Desalination 2007, 214, 1–10. [Google Scholar] [CrossRef]

- Oter, O.; Akcay, H. Use of natural clinoptilolite to improve, water quality: Sorption and selectivity studies of lead(II), copper(II), zinc(II), and nickel(II). Water Environ. Res. 2007, 79, 329–335. [Google Scholar] [CrossRef] [PubMed]

- Panayotova, M.; Velikov, B. Kinetics of Heavy Metal Ions Removal by Use of Natural Zeolite. J. Environ. Sci. Health 2002, 37, 139–147. [Google Scholar] [CrossRef]

- Inglezakis, V.J.; Loizidou, M.D.; Grigoropoulou, H.P. Ion exchange of Pb2+, Cu2+, Fe3+, and Cr3+ on natural clinoptilolite: Selectivity determination and influence of acidity on metal uptake. J. Colloid Interface Sci. 2003, 261, 49–54. [Google Scholar] [CrossRef]

- Wingenfelder, U.; Hansen, C.; Furrer, G.; Schulin, R. Removal of Heavy Metals from Mine Waters from Natural Zeolites. Environ. Sci. Technol. 2005, 39, 4606–4613. [Google Scholar] [CrossRef] [PubMed]

- Bear River Zeolite Co. Inc. Zeolite—Specifications and MSDS. Available online: http://www.bearriverzeolite.com (accessed on 1 September 2012 and 1 April 2017).

- Ciosek, A.L.; Luk, G.K. Lead Removal from Mine Tailings with Multiple Metallic Ions. Int. J. Water Wastewater Treat 2017, 3, 1–9. [Google Scholar] [CrossRef]

- Inglezakis, V.J.; Hadjiandreou, K.J.; Loizidou, M.D.; Grigoropoulou, H.P. Pretreatment of Natural Clinoptilolite in a Laboratory-Scale Ion Exchange Packed Bed. Water Res. 2001, 35, 2161–2166. [Google Scholar] [CrossRef]

- Inglezakis, V.J.; Papadeas, C.D.; Loizidou, M.D.; Grigoropoulou, H.P. Effects of Pretreatment on Physical and Ion Exchange Properties of Natural Clinoptilolite. Environ. Technol. 2001, 22, 75–82. [Google Scholar] [CrossRef] [PubMed]

- Wilson, L.J. Canada-Wide Survey of Acid Mine Drainage Characteristics. Project Report 3.22.1—Job No. 50788. Mineral Sciences Laboratories Division Report MSL 94–32 (CR). Ontario Ministry of Northern Development and Mines. Mine Environment Neutral Drainage (MEND) Program: Canada, 1994. Available online: http://mend-nedem.org/wp-content/uploads/2013/01/3.22.1.pdf (accessed on 30 October 2014).

- Canadian Minister of Justice—Metal Mining Effluent Regulations. Consolidation SOR/2002-222. Justice Laws—Government of Canada. Available online: http://laws-lois.justice.gc.ca (accessed on 1 September 2014).

- Kragovic, M.; Dakovic, A.; Markovic, M.; Krstic, J.; Gatta, G.D.; Rotiroti, N. Characterization of lead sorption by natural and Fe (III)-modified zeolite. Appl. Surf. Sci. 2013, 283, 764–774. [Google Scholar] [CrossRef]

- Motsi, T.; Rowson, N.A.; Simmons, M.J.H. Adsorption of heavy metals from acid mine drainage by natural zeolite. Int. J. Miner. Process. 2009, 92, 42–48. [Google Scholar] [CrossRef]

- Rice, E.W.; Baird, R.B.; Eaton, A.D.; Clesceri, L.S. Part 1000-Introduction, Part 3000-METALS. In Standard Methods for the Examination of Water and Wastewater, 22nd ed.; APHA, AWWA, WEF: Washington, DC, USA, 2012; pp. 1.1-68–3.1-112. ISSN 978-087553-013-0. [Google Scholar]

- Perkin Elmer Inc. Atomic Spectroscopy—A Guide to Selecting the Appropriate Technique and System: World Leader in AA, ICP-OES, and ICP-MS; Perkin Elmer Inc.: Waltham, MA, USA, 2011. [Google Scholar]

- Perkin Elmer Inc. WinLab32 for ICP—Instrument Control Software, version 5.0; Perkin Elmer Inc.: Waltham, MA, USA, 2010. [Google Scholar]

- Fierro, V.; Torne-Fernandez, V.; Montane, D.; Celzard, A. Adsorption of phenol onto activated carbons having different textural and surface properties. Micropor. Mesopor. Mater. 2008, 111, 276–284. [Google Scholar] [CrossRef]

- Olu-Owolabi, B.I.; Diagboya, P.N.; Adebowale, K.O. Evaluation of pyrene sorption—Desorption on tropical soils. J. Environ. Manag. 2014, 137, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Ho, Y.; Ofomaja, A.E. Pseudo-second-order model for lead ion sorption from aqueous solutions onto palm kernel fiber. J. Hazard. Mater. 2006, B129, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Jovanovic, M.; Rajic, N.; Obradovic, B. Novel kinetic model of the removal of divalent heavy metal ions from aqueous solutions by natural clinoptilolite. J. Hazard. Mater. 2012, 233, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Ouki, S.K.; Kavannagh, M. Treatment of metals-contaminated wastewaters by use of natural zeolites. Water. Sci. Technol. 1999, 39, 115–122. [Google Scholar] [CrossRef]

- Bosso, S.T.; Enzweiler, J. Evaluation of heavy metal removal from aqueous solution onto scolecite. Water. Res. 2002, 36, 4795–4800. [Google Scholar] [CrossRef]

- Cincotti, A.; Mameli, A.; Locci, A.M.; Orru, R.; Cao, G. Heavy metals uptake by Sardinian natural zeolites: Experiment and modeling. Ind. Eng. Chem. Res. 2006, 45, 1074–1084. [Google Scholar] [CrossRef]

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|

| Analyte | Sample ID | %RSD | Concentration (mg/L) | meq/g | %R | |

| Triplicate Mean (Calib) | DIL | |||||

| Pb | [P]-S4 | 0.24 | 75.93 | 1214.81 | 0.1919 | 76.8 |

| 220.353 | [P]1803 | 0.59 | 35.20 | 281.63 | ||

| Cu | [C]-S2 | 0.40 | 105.37 | 421.49 | 0.0533 | 21.4 |

| 327.393 | [C]1802 | 0.16 | 82.84 | 331.37 | ||

| Fe | [F]-S1 | 0.53 | 105.83 | 211.65 | 0.0757 | 30.3 |

| 238.204 | [F]1801 | 0.55 | 73.73 | 147.46 | ||

| Ni | [N]-S2 | 0.32 | 87.30 | 349.19 | 0.0268 | 10.7 |

| 231.604 | [N]1802 | 0.36 | 77.92 | 311.69 | ||

| Zn | [Z]-S2 | 1.10 | 104.67 | 418.68 | 0.0494 | 19.8 |

| 206.200 | [Z]1802 | 0.74 | 83.94 | 335.77 | ||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Analyte | Sample ID | %RSD | Concentration (mg/L) | meq/g | %R | Analyte | Sample ID | %RSD | Concentration (mg/L) | meq/g | %R | ||

| Triplicate Mean (Calib) | DIL | Triplicate Mean (Calib) | DIL | ||||||||||

| Pb | [D-PC]-S3 | 0.13 | 75.47 | 603.79 | 0.1102 | 88.3 | Cu | [D-CF]-S1 | 0.90 | 95.76 | 191.51 | 0.0283 | 22.7 |

| 220.353 | [D-PC]1802 | 0.59 | 17.68 | 70.73 | 327.393 | [D-CF]1801 | 0.58 | 74.06 | 148.13 | ||||

| Cu | [D-PC]-S3 | 0.11 | 24.18 | 193.44 | 0.0153 | 12.2 | Fe | [D-CF]-S1 | 2.75 | 50.61 | 101.21 | 0.0534 | 42.8 |

| 327.393 | [D-PC]1802 | 0.61 | 42.44 | 169.77 | 238.204 | [D-CF]1801 | 0.70 | 28.95 | 57.90 | ||||

| Pb | [D-PF]-S3 | 0.42 | 75.98 | 607.82 | 0.0992 | 79.5 | Cu | [D-CN]-S1 | 0.50 | 94.92 | 189.85 | 0.0361 | 28.9 |

| 220.353 | [D-PF]1802 | 0.54 | 31.19 | 124.77 | 327.393 | [D-CN]1801 | 0.40 | 67.46 | 134.92 | ||||

| Fe | [D-PF]-S3 | 0.31 | 13.01 | 104.11 | 0.0471 | 37.7 | Ni | [D-CN]-S1 | 0.23 | 80.53 | 161.06 | 0.0125 | 10.0 |

| 238.204 | [D-PF]1802 | 0.45 | 16.21 | 64.82 | 231.604 | [D-CN]1801 | 0.48 | 72.48 | 144.96 | ||||

| Pb | [D-PN]-S3 | 0.82 | 77.16 | 617.29 | 0.1112 | 89.1 | Fe | [D-FZ]-S1 | 2.31 | 51.15 | 102.30 | 0.0546 | 43.7 |

| 220.353 | [D-PN]1802 | 0.68 | 16.81 | 67.22 | 238.204 | [D-FZ]1801 | 0.20 | 28.78 | 57.56 | ||||

| Ni | [D-PN]-S3 | 0.86 | 21.05 | 168.37 | 0.0092 | 7.40 | Zn | [D-FZ]-S1 | 2.69 | 90.55 | 181.09 | 0.0236 | 18.9 |

| 231.604 | [D-PN]1802 | 0.12 | 38.99 | 155.94 | 206.200 | [D-FZ]1801 | 0.22 | 73.43 | 146.85 | ||||

| Pb | [D-PZ]-S3 | 1.01 | 76.78 | 614.22 | 0.1105 | 88.5 | Ni | [D-NZ]-S1 | 1.22 | 80.15 | 160.31 | 0.0067 | 5.4 |

| 220.353 | [D-PZ]1802 | 0.50 | 17.68 | 70.72 | 231.604 | [D-NZ]1801 | 3.49 | 75.85 | 151.71 | ||||

| Zn | [D-PZ]-S3 | 0.92 | 23.46 | 187.65 | 0.0138 | 11.0 | Zn | [D-NZ]-S1 | 1.30 | 89.51 | 179.02 | 0.0244 | 19.6 |

| 206.200 | [D-PZ]1802 | 0.83 | 41.75 | 166.98 | 206.200 | [D-NZ]1801 | 3.84 | 71.99 | 143.99 | ||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|

| Analyte | Sample ID | %RSD | Concentration (mg/L) | meq/g | %R | |

| Triplicate Mean (Calib) | DIL | |||||

| Pb | [T]-S2 | 1.27 | 100.05 | 400.21 | 0.0750 | 90.2 |

| 220.353 | [T]1801 | 0.21 | 19.66 | 39.32 | ||

| Cu | [T]-S2 | 1.16 | 33.76 | 135.03 | 0.0158 | 19.0 |

| 327.393 | [T]1801 | 1.58 | 54.70 | 109.40 | ||

| Fe | [T]-S2 | 0.59 | 17.23 | 68.92 | 0.0412 | 49.5 |

| 238.204 | [T]1801 | 1.81 | 17.40 | 34.80 | ||

| Pb | [M]-S1 | 0.53 | 117.76 | 235.52 | 0.0469 | 94.0 |

| 220.353 | [M]1800 | 0.67 | 14.20 | 14.20 | ||

| Cu | [M]-S1 | 1.96 | 37.58 | 75.16 | 0.0109 | 21.9 |

| 327.393 | [M]1800 | 0.99 | 58.74 | 58.74 | ||

| Fe | [M]-S1 | 2.26 | 20.52 | 41.03 | 0.0281 | 56.2 |

| 238.204 | [M]1800 | 1.24 | 17.97 | 17.97 | ||

| Ni | [M]-S1 | 0.56 | 32.87 | 65.75 | 0.0045 | 9.10 |

| 231.604 | [M]1800 | 1.48 | 59.76 | 59.76 | ||

| Zn | [M]-S1 | 2.23 | 35.99 | 71.98 | 0.0082 | 16.5 |

| 206.200 | [M]1800 | 1.63 | 60.12 | 60.12 | ||

| SYSTEM | CC | Equilibrium Sorption | Sorption Rate Constant | Initial Sorption Rate | ||

|---|---|---|---|---|---|---|

| (meq/g) | (g/meq·min) | (meq/g·min) | ||||

| [P] | 4.098 | 217.01 | 0.9926 | 0.244 | 0.077 | 0.0046 |

| [C] | 15.750 | 836.09 | 0.9291 | 0.063 | 0.297 | 0.0012 |

| [F] | 11.872 | 419.08 | 0.9708 | 0.084 | 0.336 | 0.0024 |

| [N] | 34.919 | 739.14 | 0.9806 | 0.029 | 1.650 | 0.0014 |

| [Z] | 15.237 | 1106,10 | 0.9147 | 0.066 | 0.210 | 0.0009 |

| [D-PC]-Pb | 7.474 | 299.43 | 0.9941 | 0.134 | 0.187 | 0.0033 |

| [D-PC]-Cu | 55.217 | 2840,90 | 0.9282 | 0.018 | 1.073 | 0.0004 |

| [D-PC] | 6.596 | 269.78 | 0.9906 | 0.152 | 0.161 | 0.0037 |

| [D-PF]-Pb | 7.692 | 448.41 | 0.9904 | 0.130 | 0.132 | 0.0022 |

| [D-PF]-Fe | 18.375 | 727.45 | 0.9703 | 0.054 | 0.464 | 0.0014 |

| [D-PF] | 5.489 | 275.71 | 0.9837 | 0.182 | 0.109 | 0.0036 |

| [D-PN]-Pb | 7.465 | 284.48 | 0.9957 | 0.134 | 0.196 | 0.0035 |

| [D-PN]-Ni | 109.750 | 3126,00 | 0.5378 | 0.009 | 3.853 | 0.0003 |

| [D-PN] | 6.976 | 254.36 | 0.9914 | 0.143 | 0.191 | 0.0039 |

| [D-PZ]-Pb | 7.436 | 293.22 | 0.9973 | 0.134 | 0.189 | 0.0034 |

| [D-PZ]-Zn | 40.653 | 5898,50 | 0.4358 | 0.025 | 0.280 | 0.0002 |

| [D-PZ] | 6.534 | 280.74 | 0.9946 | 0.153 | 0.152 | 0.0036 |

| [D-CF]-Cu | 21.169 | 2683,00 | 0.9629 | 0.047 | 0.167 | 0.0004 |

| [D-CF]-Fe | 16.655 | 581.48 | 0.9750 | 0.060 | 0.477 | 0.0017 |

| [D-CF] | 10.297 | 488.73 | 0.9703 | 0.097 | 0.217 | 0.0020 |

| [D-CN]-Cu | 21.936 | 1271,30 | 0.9453 | 0.046 | 0.379 | 0.0008 |

| [D-CN]-Ni | 72.008 | 1686,80 | 0.9498 | 0.014 | 3.074 | 0.0006 |

| [D-CN] | 17.329 | 747.04 | 0.9471 | 0.058 | 0.402 | 0.0013 |

| [D-FZ]-Fe | 16.438 | 502.40 | 0.9778 | 0.061 | 0.538 | 0.0020 |

| [D-FZ]-Zn | 28.869 | 3101,00 | 0.6387 | 0.035 | 0.269 | 0.0003 |

| [D-FZ] | 11.140 | 451.04 | 0.9554 | 0.090 | 0.275 | 0.0022 |

| [D-NZ]-Ni | 133.600 | 999.38 | 0.9731 | 0.007 | 17.860 | 0.0010 |

| [D-NZ]-Zn | 19.459 | 3808,80 | 0.3642 | 0.051 | 0.099 | 0.0003 |

| [D-NZ] | 24.852 | 1452,00 | 0.9113 | 0.040 | 0.425 | 0.0007 |

| [T]-Pb | 11.194 | 394.10 | 0.9980 | 0.089 | 0.318 | 0.0025 |

| [T]-Cu | 48.524 | 3252,90 | 0.9141 | 0.021 | 0.724 | 0.0003 |

| [T]-Fe | 21.496 | 721.14 | 0.9807 | 0.047 | 0.641 | 0.0014 |

| [T] | 6.438 | 237.29 | 0.9918 | 0.155 | 0.175 | 0.0042 |

| [M]-Pb | 18.593 | 465.67 | 0.9990 | 0.054 | 0.742 | 0.0021 |

| [M]-Cu | 58.274 | 6429,20 | 0.8600 | 0.017 | 0.528 | 0.0002 |

| [M]-Fe | 31.695 | 989.38 | 0.9830 | 0.032 | 1.015 | 0.0010 |

| [M]-Ni | 190.820 | 5086,10 | 0.9747 | 0.005 | 7.159 | 0.0002 |

| [M]-Zn | −51.894 | 2,5482,00 | 0.1723 | -0.019 | 0.106 | 0.0000 |

| [M] | 8.630 | 303.14 | 0.9931 | 0.116 | 0.246 | 0.0033 |

| SYSTEM | Diffusion Rate Constant A | CCA | SYSTEM | Diffusion Rate Constant B | Boundary Constant B | CCB |

|---|---|---|---|---|---|---|

| (meq/g·min1/2) | (meq/g·min1/2) | (meq/g) | ||||

| [P] | 0.015 | 0.9818 | [P] | 0.016 | −0.004 | 0.9828 |

| [C] | 0.004 | 0.9882 | [C] | 0.004 | −0.000 | 0.9883 |

| [F] | 0.006 | 0.9548 | [F] | 0.005 | 0.006 | 0.9747 |

| [N] | 0.002 | 0.6930 | [N] | 0.002 | 0.007 | 0.9629 |

| [Z] | 0.004 | 0.9729 | [Z] | 0.004 | −0.003 | 0.9846 |

| [D-PC]-Pb | 0.009 | 0.9597 | [D-PC]-Pb | 0.009 | 0.004 | 0.9627 |

| [D-PC]-Cu | 0.001 | 0.9658 | [D-PC]-Cu | 0.001 | 0.000 | 0.9669 |

| [D-PC] | 0.010 | 0.9662 | [D-PC] | 0.010 | 0.004 | 0.9690 |

| [D-PF]-Pb | 0.008 | 0.9790 | [D-PF]-Pb | 0.008 | −0.004 | 0.9827 |

| [D-PF]-Fe | 0.004 | 0.9860 | [D-PF]-Fe | 0.003 | 0.003 | 0.9951 |

| [D-PF] | 0.012 | 0.9873 | [D-PF] | 0.012 | −0.001 | 0.9876 |

| [D-PN]-Pb | 0.009 | 0.9569 | [D-PN]-Pb | 0.009 | 0.005 | 0.9622 |

| [D-PN]-Ni | 0.001 | 0.4479 | [D-PN]-Ni | 0.001 | 0.002 | 0.5521 |

| [D-PN] | 0.010 | 0.9527 | [D-PN] | 0.009 | 0.007 | 0.9616 |

| [D-PZ]-Pb | 0.009 | 0.9542 | [D-PZ]-Pb | 0.009 | 0.004 | 0.9576 |

| [D-PZ]-Zn | 0.001 | 0.9088 | [D-PZ]-Zn | 0.001 | −0.002 | 0.9378 |

| [D-PZ] | 0.010 | 0.9639 | [D-PZ] | 0.010 | 0.003 | 0.9649 |

| [D-CF]-Cu | 0.002 | 0.9523 | [D-CF]-Cu | 0.002 | −0.004 | 0.9933 |

| [D-CF]-Fe | 0.004 | 0.9666 | [D-CF]-Fe | 0.004 | 0.005 | 0.9902 |

| [D-CF] | 0.006 | 0.9923 | [D-CF] | 0.006 | 0.001 | 0.9925 |

| [D-CN]-Cu | 0.003 | 0.9888 | [D-CN]-Cu | 0.003 | −0.001 | 0.9915 |

| [D-CN]-Ni | 0.001 | 0.6540 | [D-CN]-Ni | 0.001 | 0.003 | 0.9089 |

| [D-CN] | 0.004 | 0.9795 | [D-CN] | 0.004 | 0.002 | 0.9843 |

| [D-FZ]-Fe | 0.005 | 0.9332 | [D-FZ]-Fe | 0.004 | 0.007 | 0.9906 |

| [D-FZ]-Zn | 0.002 | 0.9303 | [D-FZ]-Zn | 0.002 | −0.002 | 0.9494 |

| [D-FZ] | 0.006 | 0.9777 | [D-FZ] | 0.006 | 0.005 | 0.9907 |

| [D-NZ]-Ni | 0.001 | −0.2510 | [D-NZ]-Ni | 0.000 | 0.003 | 0.6264 |

| [D-NZ]-Zn | 0.002 | 0.9348 | [D-NZ]-Zn | 0.002 | −0.004 | 0.9801 |

| [D-NZ] | 0.002 | 0.9605 | [D-NZ] | 0.002 | −0.000 | 0.9605 |

| [T]-Pb | 0.006 | 0.9434 | [T]-Pb | 0.006 | 0.005 | 0.9536 |

| [T]-Cu | 0.001 | 0.9747 | [T]-Cu | 0.001 | −0.001 | 0.9826 |

| [T]-Fe | 0.003 | 0.9622 | [T]-Fe | 0.003 | 0.004 | 0.9900 |

| [T] | 0.011 | 0.9668 | [T] | 0.010 | 0.008 | 0.9761 |

| [M]-Pb | 0.004 | 0.8584 | [M]-Pb | 0.004 | 0.007 | 0.9130 |

| [M]-Cu | 0.001 | 0.9473 | [M]-Cu | 0.001 | −0.001 | 0.9851 |

| [M]-Fe | 0.002 | 0.9465 | [M]-Fe | 0.002 | 0.003 | 0.9886 |

| [M]-Ni | 0.000 | 0.8566 | [M]-Ni | 0.000 | 0.001 | 0.9251 |

| [M]-Zn | 0.001 | 0.8479 | [M]-Zn | 0.001 | −0.002 | 0.9720 |

| [M] | 0.008 | 0.9585 | [M] | 0.008 | 0.007 | 0.9713 |

| SYSTEM | (meq/g) | % Achieved of at 3 h | OBSERVATION | |||||

|---|---|---|---|---|---|---|---|---|

| SINGLE HMI | [P] | 0.1919 | 0.2440 | 78.7 | Highest Single Uptake of 76.8% for [P] | |||

| [C] | 0.0533 | 0.0635 | 84.0 | |||||

| [F] | 0.0757 | 0.0842 | 89.8 | |||||

| [N] | 0.0268 | 0.0286 | 93.5 | Lowest Single Uptake of 10.7% for [N] | ||||

| [Z] | 0.0494 | 0.0656 | 75.3 | |||||

| DUAL [D] | [PC] | 0.1255 | 0.1516 | 82.7 | ||||

| [PF] | 0.1462 | 0.1822 | 80.3 | Highest [D] Uptake of 58.5% for [PF] | ||||

| [PN] | 0.1204 | 0.1433 | 84.0 | |||||

| [PZ] | 0.1243 | 0.1530 | 81.2 | |||||

| [CF] | 0.0817 | 0.0971 | 84.1 | |||||

| [CN] | 0.0486 | 0.0577 | 84.1 | |||||

| [FZ] | 0.0782 | 0.0898 | 87.1 | |||||

| [NZ] | 0.0311 | 0.0402 | 77.3 | Lowest [D] Uptake of 12.4% for [NZ] | ||||

| TRIPLE [T] | 0.1320 | 0.1553 | 85.0 | [D-PC] | Increased | 5.2% | 2.5% | |

| [D-PF] | Decreased | 9.8% | 14.7% | |||||

| [D-CF] | Increased | 61.5% | 59.9% | |||||

| MULTI [M] | 0.0986 | 0.1159 | 85.1 | [D-PC] | Decreased | 21.4% | 23.6% | |

| [D-PF] | Decreased | 32.6% | 36.4% | |||||

| [D-CF] | Increased | 20.7% | 19.3% | |||||

| [T] | Decreased | 25.3% | 25.4% | |||||

| Sorbent Material | HMI | Sorption Trends | Reference | |

|---|---|---|---|---|

| American 85–95% Clinoptilolite | (meq/g) | This Study | ||

| Pb2+ | 0.1919 | 0.2440 | ||

| Fe3+ | 0.0757 | 0.0842 | ||

| Cu2+ | 0.0533 | 0.0635 | ||

| Zn2+ | 0.0494 | 0.0656 | ||

| Ni2+ | 0.0268 | 0.0286 | ||

| Pb2+ >> Fe3+Cu2+ > Zn2+ > Ni2+ | ||||

| Brazilian Zeolite (Scolecite) | Cu2+ | 130 μeq/g | Bosso and Enzweiler (2002) [47] | |

| Zn2+ | 64 μeq/g | |||

| Pb2+ | 56 μeq/g | |||

| Ni2+ | 31 μeq/g | |||

| Co2+ | 7.8 μeq/g | |||

| Cd2+ | 3.2 μeq/g | |||

| Cu2+ >> Zn2+ > Pb2+ > Ni2+ > Co2+ > Cd2+ | ||||

| Turkish 70% Clinoptilolite | Co2+ | 77.96% (0.448 meq/g) | Erdem et al. (2004) [2] Wang and Peng (2010) [18] | |

| Cu2+ | 66.10% (0.282 meq/g) | |||

| Zn2+ | 45.96% (0.268 meq/g) | |||

| Mn2+ | 19.84% (0.153 meq/g) | |||

| Co2+ > Cu2+ > Zn2+ > Mn2+ | ||||

| Ukrainian 75% Clinoptilolite | Pb2+ | 27.7 mg/g | Sprynskyy et al. (2006) [4] | |

| Cu2+ | 25.76 mg/g | |||

| Ni2+ | 13.03 mg/g | |||

| Cd2+ | 4.22 mg/g | |||

| Pb2+ > Cu2+ > Cd2 > Ni2+ | ||||

| Sardinian 40–70% Clinoptilolite | Pb2+ | 0.34 meq/g | Cincotti et al. (2006) [48] | |

| Cu2+ | 0.27–1.2 meq/g | |||

| Zn2+ | 0.1 meq/g | |||

| Cd2+ | 0.05-0.19 meq/g | |||

| Pb2+ > Cu2+ > Cd2+ ≅ Zn2+ | ||||

| Turkish Zeolite(Clinoptilolite and Heulandite) | Single- | Multi- | Oter and Akcay (2007) [27] Wang and Peng (2010) [18] | |

| Pb2+ | 0.730 meq/g | 0.299 meq/g | ||

| Zn2+ | 0.251 meq/g | 0.108 meq/g | ||

| Cu2+ | 0.227 meq/g | 0.022 meq/g | ||

| Ni2+ | 0.173 meq/g | 0.017 meq/g | ||

| Pb2+ > Zn2+ > Cu2+ > Ni2+ | ||||

| Turkish Clinoptilolite | Fe3+ | 6.41 mg/g | Motsi et al. (2009) [38] | |

| Zn2+ | 1.60 mg/g | |||

| Cu2+ | 0.44 mg/g | |||

| Mn2+ | 0.37 mg/g | |||

| Fe3+ > Zn2+ > Cu2+ > Mn2+ | ||||

| Brine Sediments | Zn2+ | 4.85 mg/g | Fu and Wang (2011) [19] | |

| Cu2+ | 2.58 mg/g | |||

| Sawdust Materials | Zn2+ | 4.69 mg/g | ||

| Cu2+ | 2.31 mg/g | |||

| Dried Marine Green Macroalga Algal Biomass | Cu2+ | 1.46 mmol/g | ||

| Zn2+ | 1.97 mmol/g | |||

| Rhizopus Oryzae Fungi Biomass | Cu2+ | 19.4 mg/g (Natural) | ||

| 43.7 mg/g (NaOH-treated) | ||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciosek, A.L.; Luk, G.K. Kinetic Modelling of the Removal of Multiple Heavy Metallic Ions from Mine Waste by Natural Zeolite Sorption. Water 2017, 9, 482. https://doi.org/10.3390/w9070482

Ciosek AL, Luk GK. Kinetic Modelling of the Removal of Multiple Heavy Metallic Ions from Mine Waste by Natural Zeolite Sorption. Water. 2017; 9(7):482. https://doi.org/10.3390/w9070482

Chicago/Turabian StyleCiosek, Amanda L., and Grace K. Luk. 2017. "Kinetic Modelling of the Removal of Multiple Heavy Metallic Ions from Mine Waste by Natural Zeolite Sorption" Water 9, no. 7: 482. https://doi.org/10.3390/w9070482

APA StyleCiosek, A. L., & Luk, G. K. (2017). Kinetic Modelling of the Removal of Multiple Heavy Metallic Ions from Mine Waste by Natural Zeolite Sorption. Water, 9(7), 482. https://doi.org/10.3390/w9070482