Seepage Piping Evolution Characteristics in Bimsoils -An Experimental Study

Abstract

:1. Introduction

2. Experimental Study

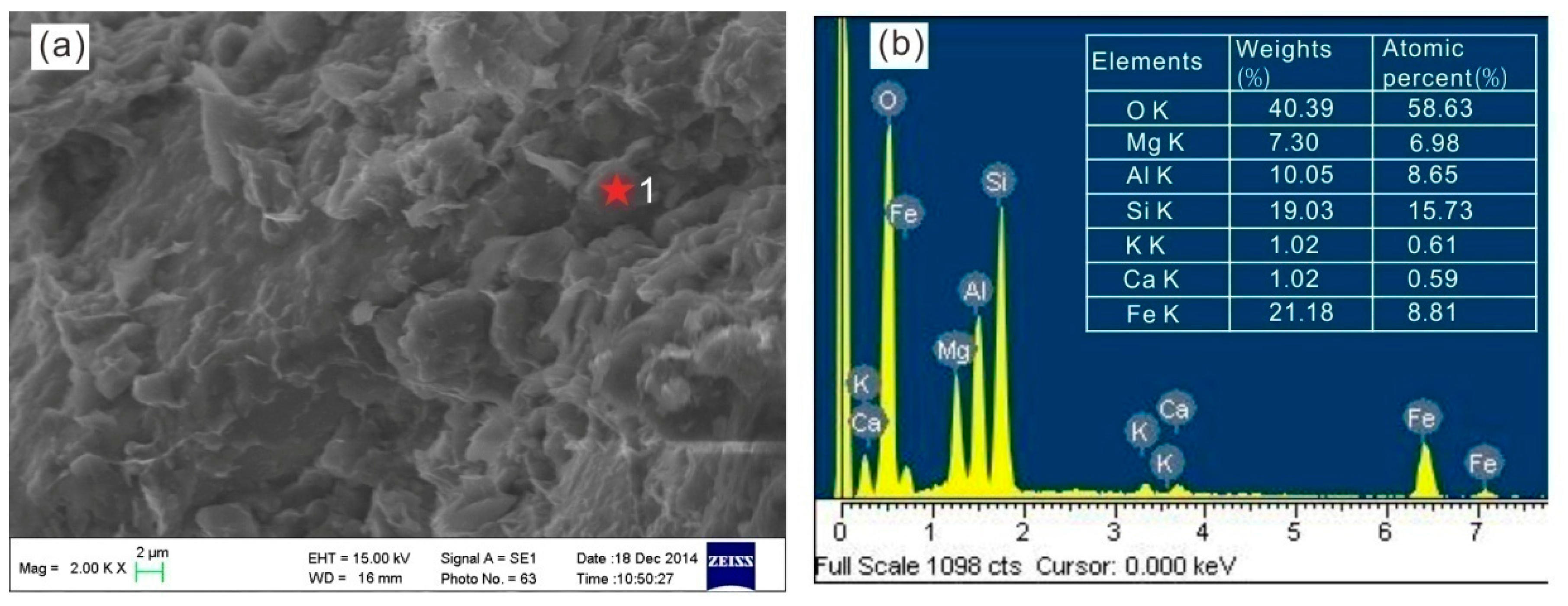

2.1. The Testing Materials

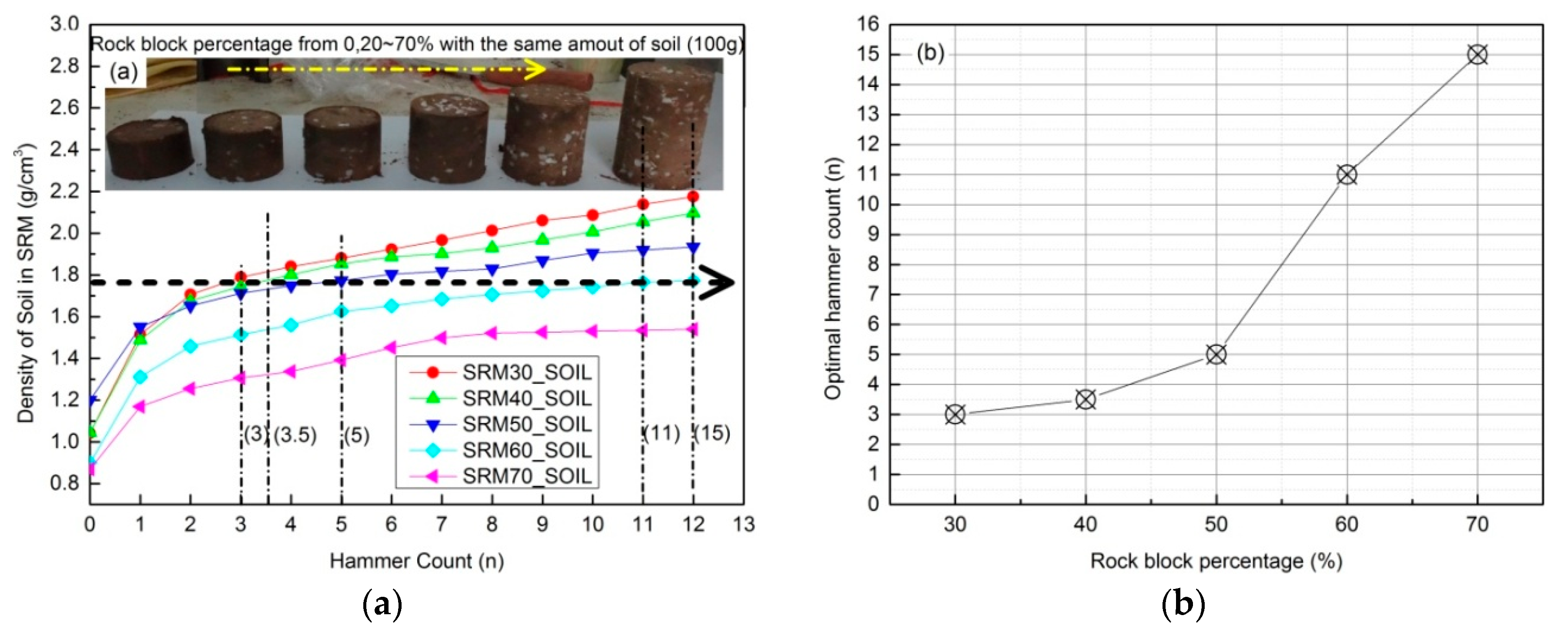

2.2. Remolded Sample Preparation

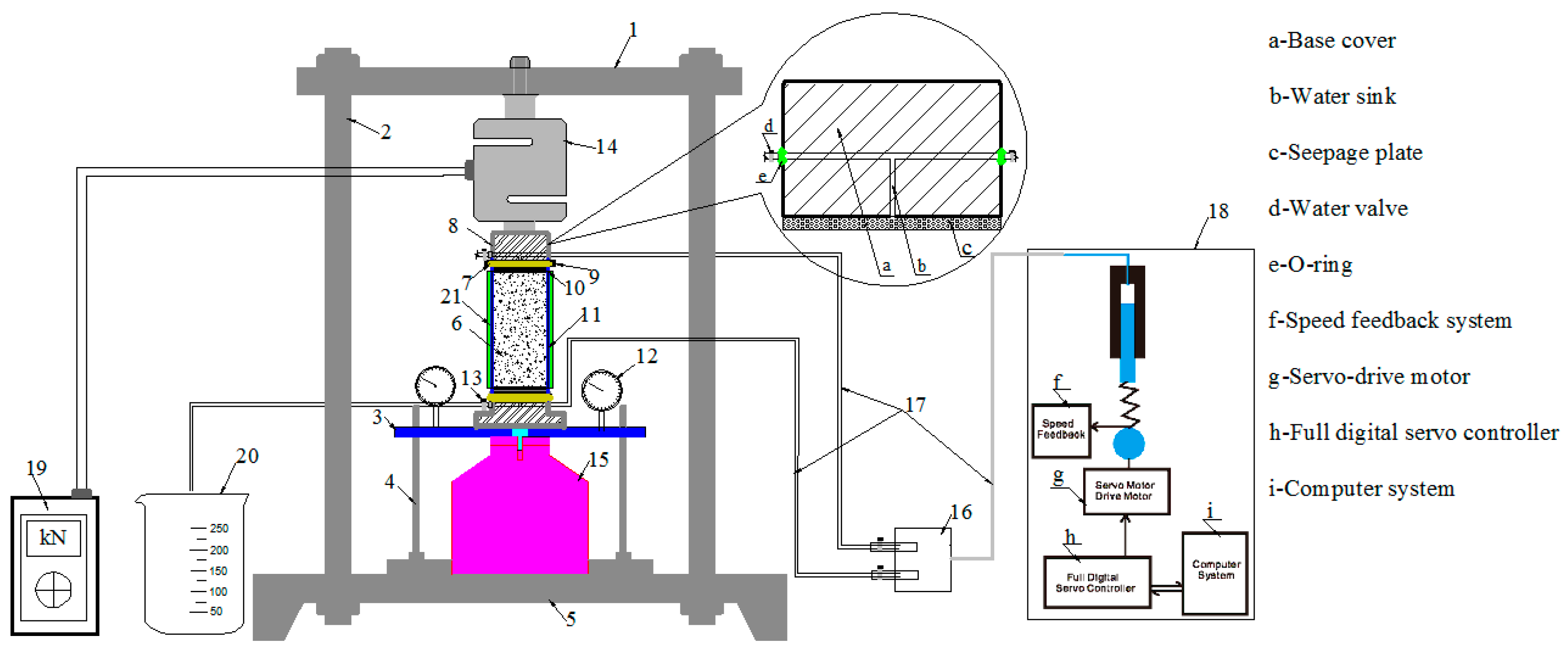

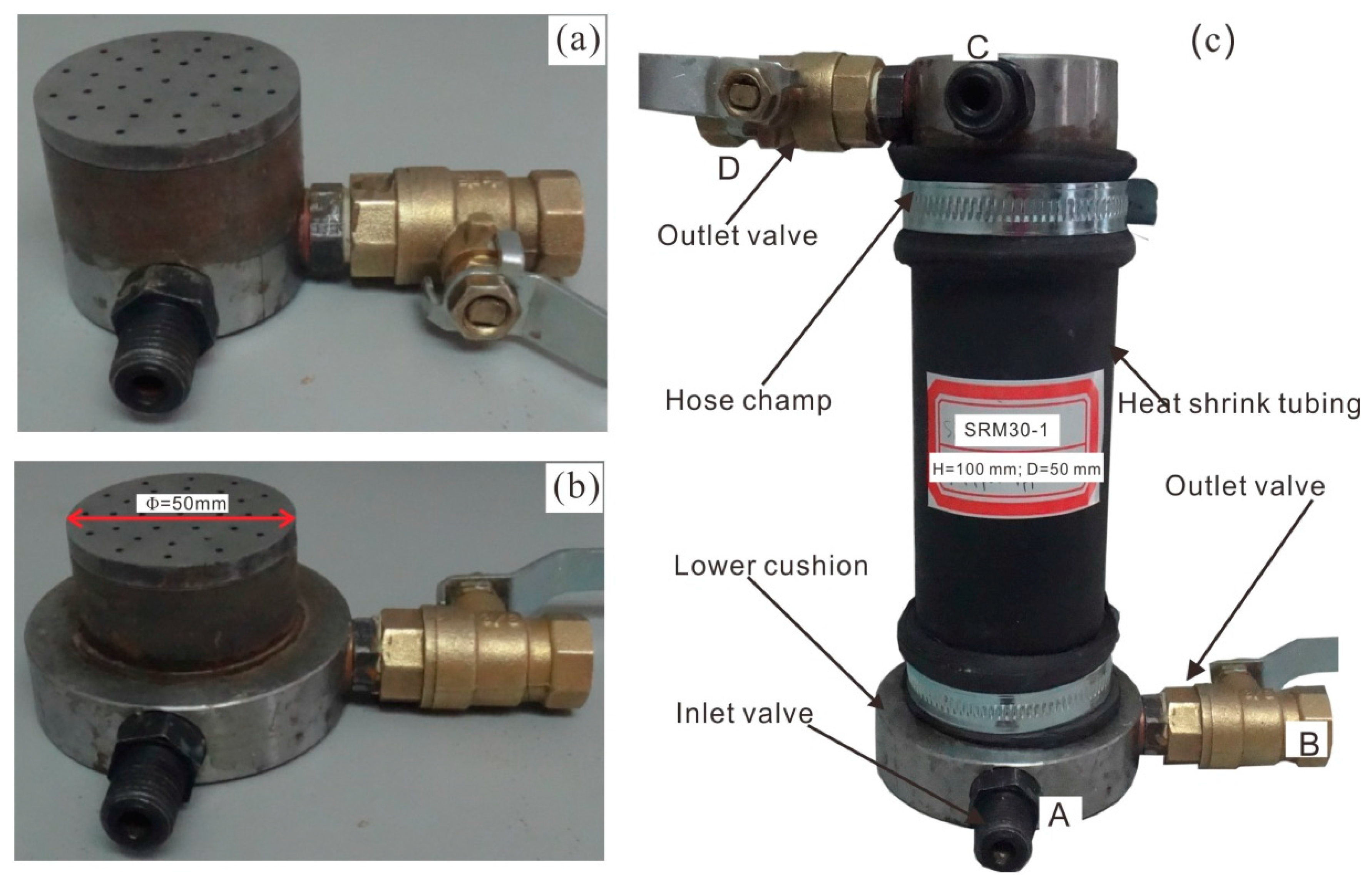

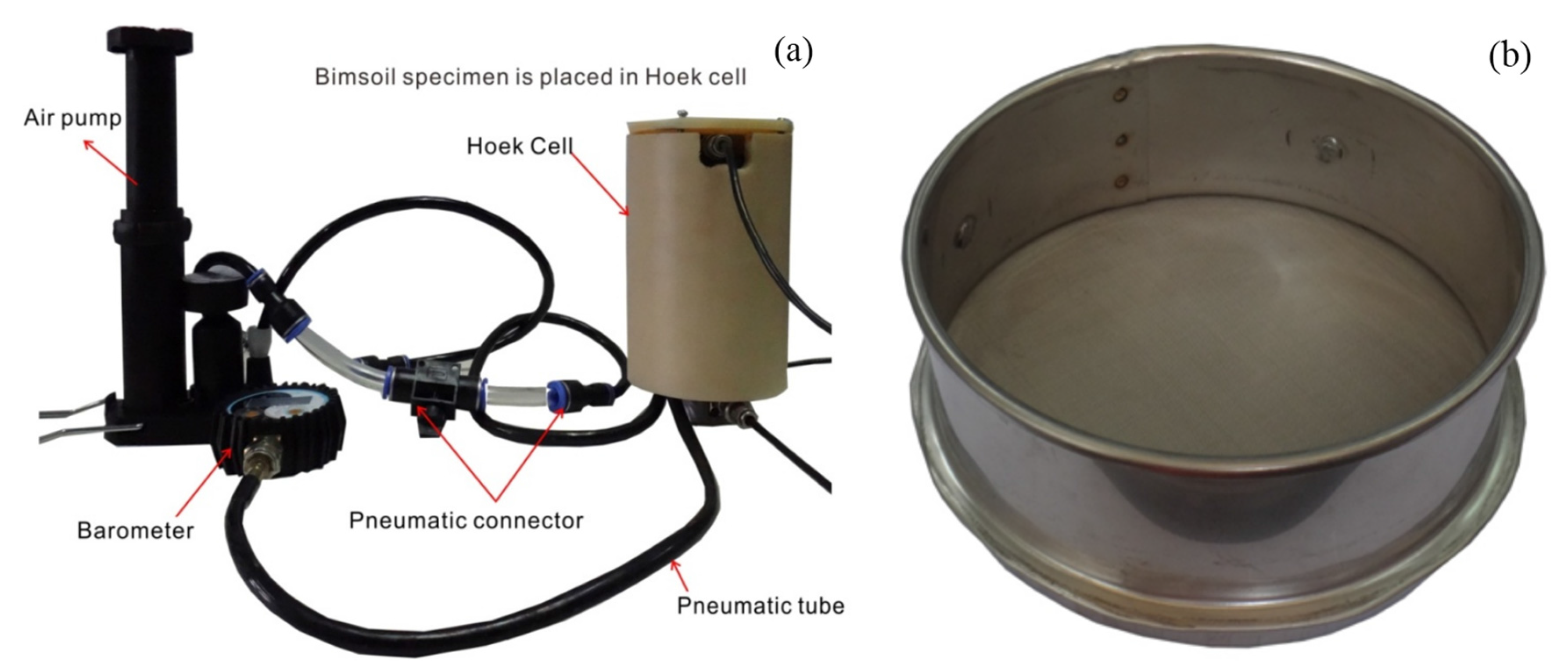

2.3. Experimental Setup

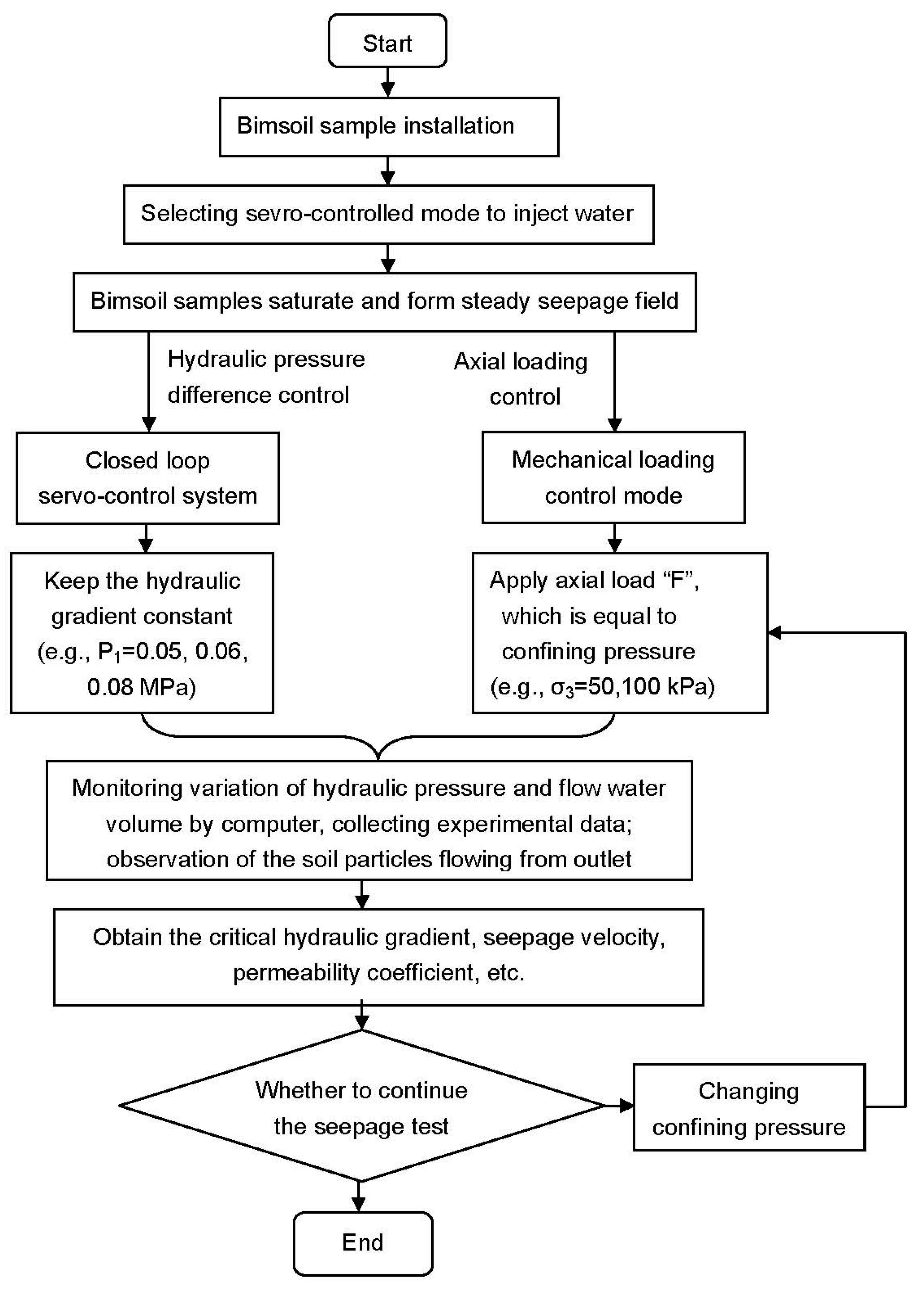

2.4. Piping Test Procedure

3. Results and Discussion

3.1. General Observations

3.2. Piping Characteristic Curves Analysis

- (1)

- The value of the hydraulic gradient, seepage velocity, and permeability increases with the increasing of initial hydraulic pressure until the maximum. This indicates that the flow rule of bimsoil does not obey the Darcy flow law. The permeability capacity is variational and not constant. After a critical value of the three studied parameters, the curves fluctuate as the initial hydraulic pressure increases.

- (2)

- Although the curves show a fluctuating trend, the value cannot exceed the critical peak value. This result implies that irreversible damage occurs in bimsoil during piping. During the process of piping, the erosion and the movement of soil particles results in a change of permeability. Fine soil particles clog the pores during movement, leading to an incremental increase in the hydraulic gradient, seepage velocity, and the associated permeability coefficient; and when the clogged pores break through again, these values suddenly decrease. This non-linear multiple fluctuation always exist with the piping process.

- (3)

- The non-linear fluctuation behavior of the curves shows that the evolution of piping includes a series of complex movement behaviors, such as the erosion, migration of fine soil particles; contact erosion of the rock–soil interface; forming of the pore channel; blocking of the flow channel by fine soil particles; breakdown of the blocked flow channel; and re-blocking of the flow channel, etc. The characteristics of piping in bimsoil are progressive and repeated. The blocked flow channel can be attributed to two factors, one is the fine soil particles; the other is the movement of rock blocks, as the structure of bimsoil sample changes, the blocks would sink along the direction of water flow. From the non-linear evolution of piping flow in bimsoil, existence of rock blocks has a strong influence on the piping characteristics, which is different from the piping process in clay soil and sandy gravels [49,50,51,52,53].

- (4)

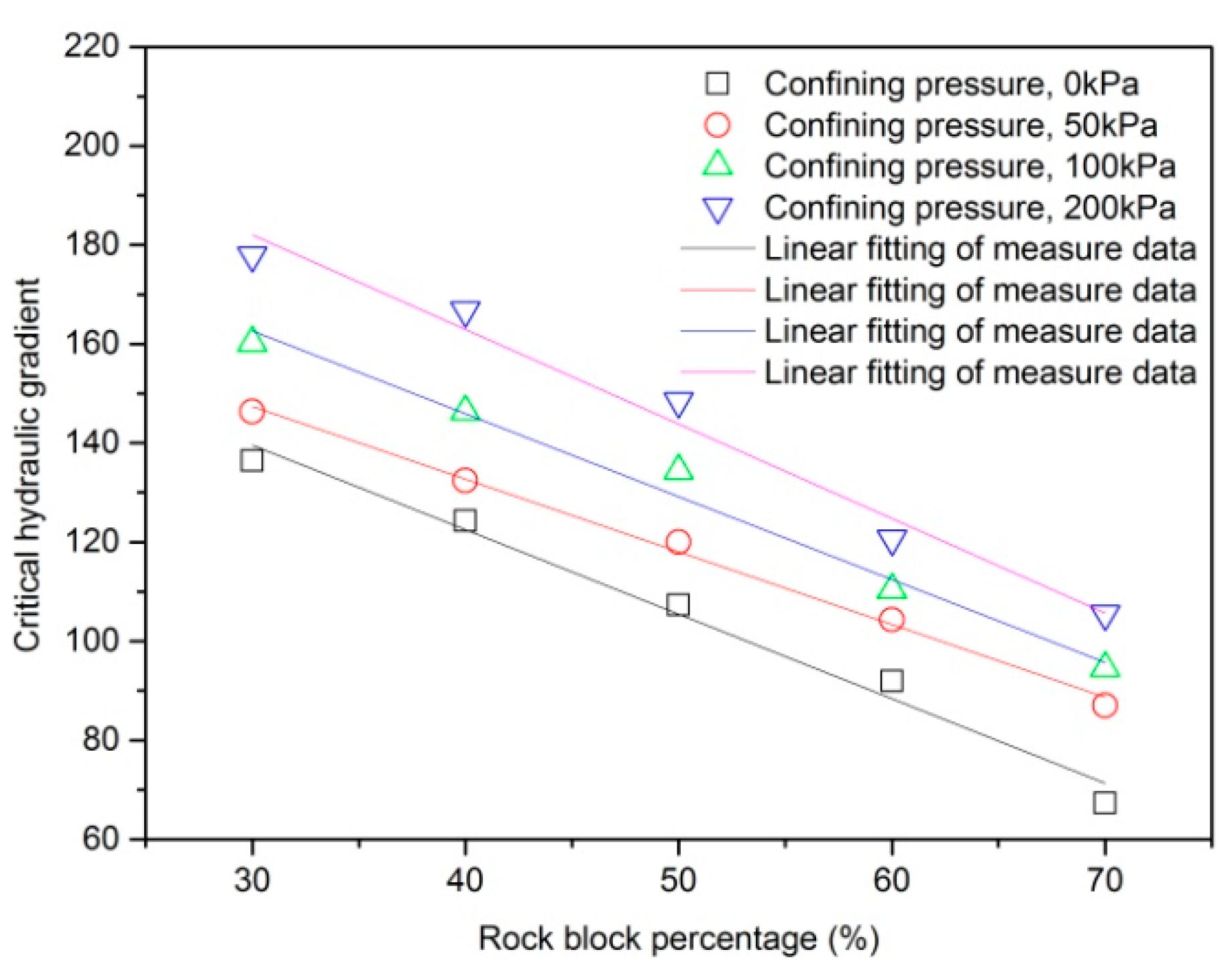

- The critical hydraulic gradient decreases with the increase of RBP (Figure 11). Existence of rock blocks not only influences the flow rule, but also the degree of contact erosion at rock–soil interfaces. With the increases of RBP, the number of rock–soil interfaces increases and the contact erosion at rock–soil interface becomes severe, resulting in the decrease of the hydraulic gradient.

- (5)

- The evolution of the bimsoil permeability coefficient is directly related to the erosion of the fine soil. Because the soil–rock interface is the weakest part of the bimsoil, the degree of erosion is most severe; therefore, the interface seepage effect controls the whole eroded soil.

3.3. Seepage Force Analysis

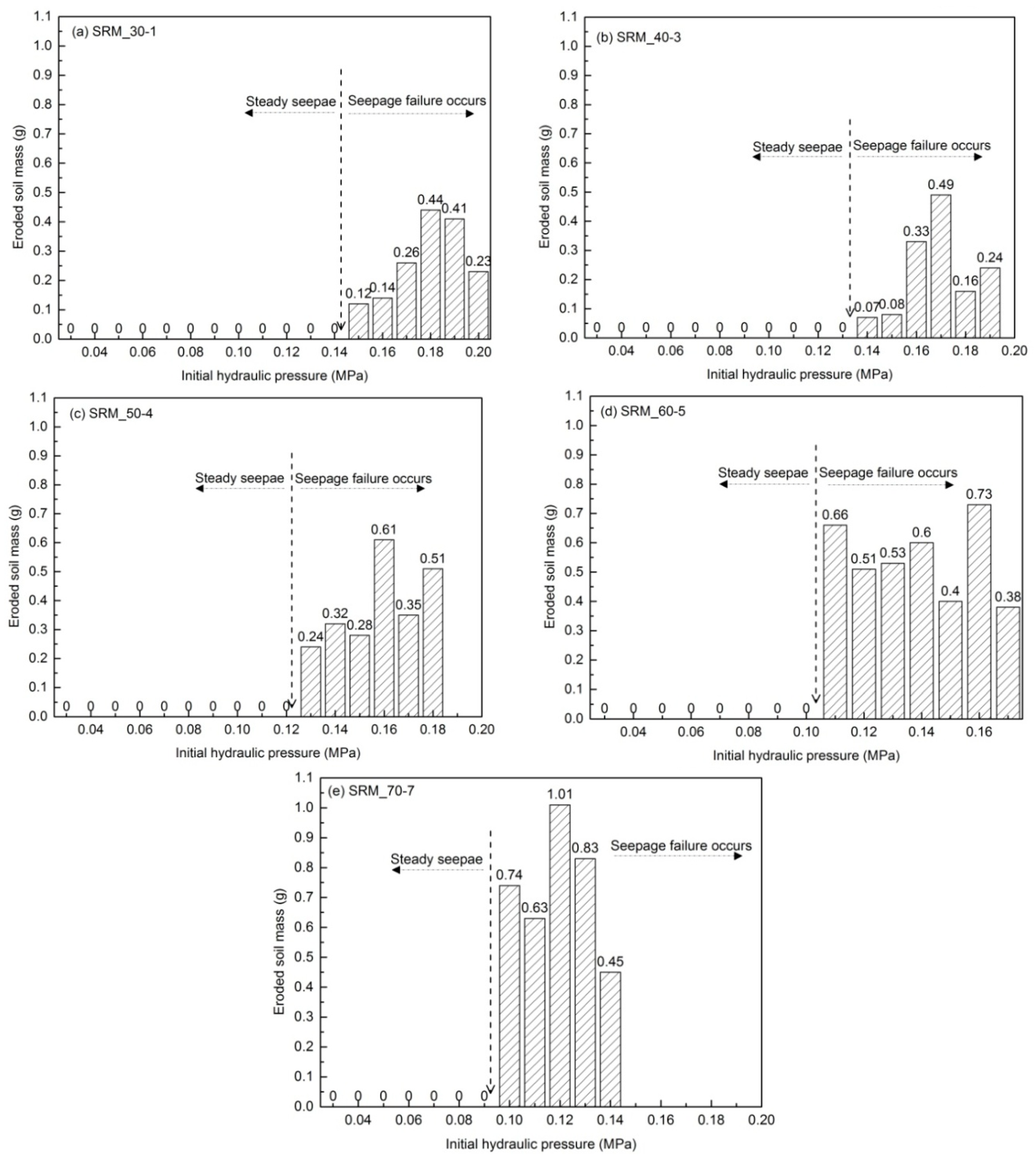

3.4. Eroded Soil Mass Analysis

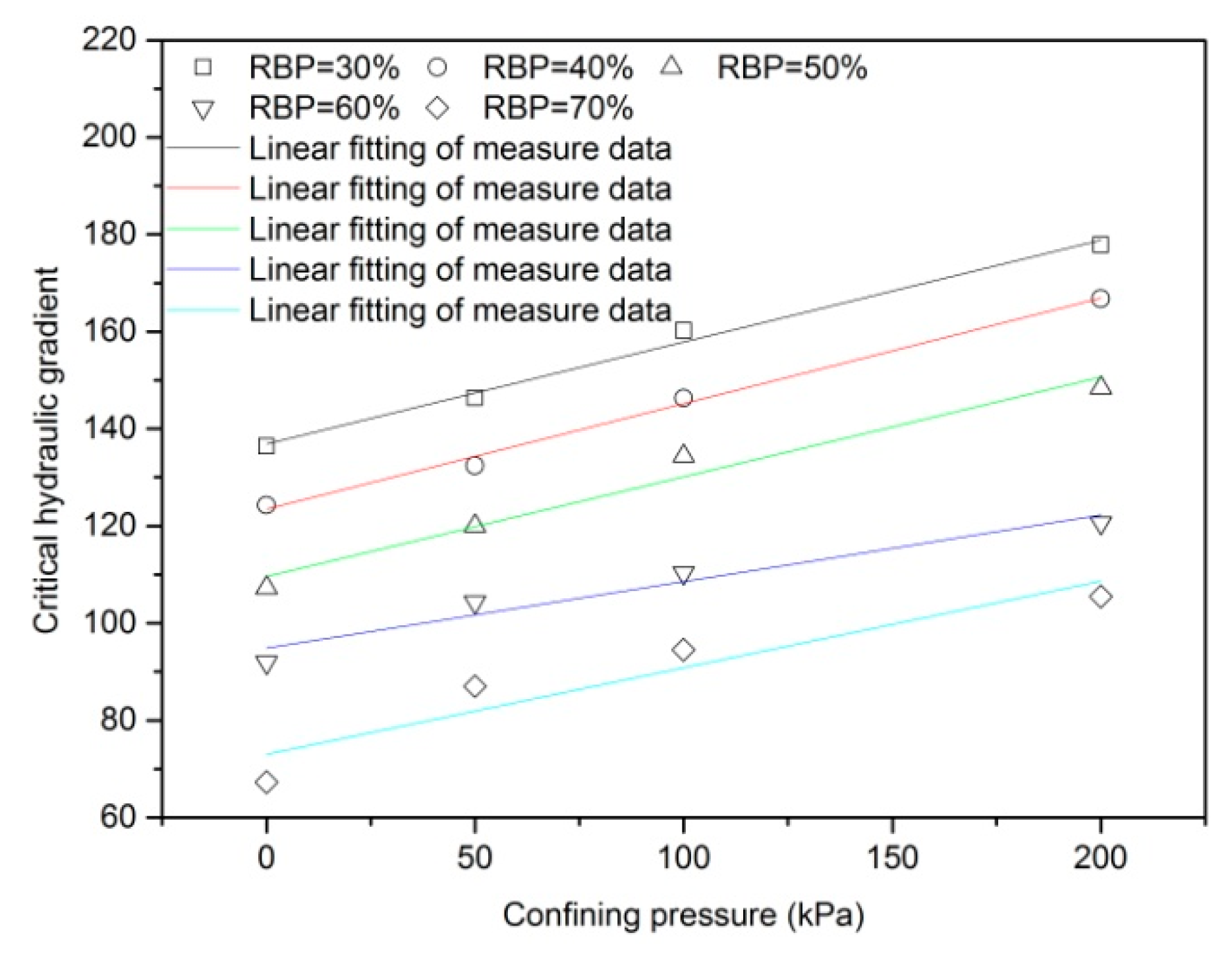

3.5. Effect of Confining Pressure on Piping Evolution

3.6. Discussion

4. Conclusions

- (1)

- Piping of bimsoilis a multiphase and multifield coupling phenomenon involving numerous complicated mechanical behaviors such as the erosion, migration of fine soil particles, contact erosion of rock–soil interfaces, formation of pore channels, blocking of flow channels by fine soil particles, breakdown of the blocked flow channel, re-blocking of the flow channel, etc.

- (2)

- From the change of hydraulic gradient, permeability coefficient, and eroded soil mass, piping of bimsoils is characterized by being progressive and circulated. The clog and suffusion of soil particles initiates from rock–soil interfaces, and the initiation of suffusion required seepage velocity is an order of magnitude more than the critical value.

- (3)

- Stress state has an obvious effect on the critical hydraulic gradient, seepage velocity, permeability, erosion, and migration of soil particles. It is found that an increase in confining pressure causes an increase in critical hydraulic gradient, and the relationship between critical hydraulic gradient and confining pressure follows a linear function with good correlation.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lindquist, E.S. The Strength and Deformation Properties of Melange. Ph.D. Thesis, Department of Civil Engineering, University of California, Berkeley, CA, USA, 1994. [Google Scholar]

- Kahraman, S.; Alber, M. Estimating unconned compressive strength and elastic modulus of a fault breccias mixture of weak block sand strong matrix. Int. J. Rock Mech. Min. Sci. 2006, 43, 1277–1287. [Google Scholar] [CrossRef]

- Kahraman, S.; Alber, M. Triaxial strength of a fault breccias of weak rocks in a strong matrix. Bull. Eng. Geol. Environ. 2008, 67, 435–441. [Google Scholar] [CrossRef]

- Sonmez, H.; Kasapoglu, K.E.; Coskun, A.; Tunusluoglu, C.; Medley, E.W.; Zimmerman, R.W. A conceptional empirical approach for the overall strength of unwelded bimrocks. In Rock Engineering in Difficult Ground Conditions, Karst and Soft Rock, Proceeding of the International Society Rock Mechanics Regional Symposium, Dubrovnik, Croatia, 29–31 October 2009; pp. 29–31.

- Coli, N.; Boldin, I.D.; Bandini, A.; Lopes, D.S. Modeling of complex geological rock mixtures under triaxial testing conditions. In Proceedings of the International Symposium on Rock Engineering &Technology for Sustainable Underground Construction (Eurock), Stockholm, Sweden, 28–30 May 2012. [Google Scholar]

- Xu, W.J.; Xu, Q.; Hu, R.L. Study on the shear strength of soil–rock mixture by large scale direct shear test. Int. J. RockMech. Min. Sci. 2011, 48, 1235–1247. [Google Scholar]

- Wang, Y.; Li, X.; Wu, Y.F.; Lin, C.; Zhang, B. Experimental study on meso-damage cracking characteristics of RSA by CT test. Environ. Earth Sci. 2015, 73, 5545–5558. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zheng, B.; Zhang, B.; Wang, J.B. Real-time ultrasonic experiments and mechanical properties of soil and rock mixture during triaxial deformation. Géotech. Lett. 2015, 5, 281–286. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zheng, B.; Zhang, Y.X.; Li, G.F. Experimental study on the non-Darcy flow characteristics of soil-rock mixture. Environ. Earth Sci. 2016, 75, 1–18. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zheng, B.; Li, S.D.; Duan, Y.T. A laboratory study of the effect of confining pressure on permeable property in soil-rock mixture. Environ. Earth Sci. 2016, 75, 1–16. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zheng, B.; Ma, C.F. An Experimental Investigation of the Flow–Stress Coupling Characteristics of Soil–Rock Mixture under Compression. Transp. Porous Med. 2016. [Google Scholar] [CrossRef]

- Medley, E.; Lindquist, E.S. The engineering significance of the scale-independence of some Franciscan Melanges in California, USA. In Proceedings of the 35th US Rock Mechanics Symposium, Rotterdam, The Netherlands, 5–7 June 1995; Daemen, J.K., Schultz, R.A., Eds.; Balkema: Rotterdam, The Netherlands, 1995; pp. 907–914. [Google Scholar]

- Medley, E.W. Systematic characterization of mélange bimrocks and other chaotic soil/rock mixtures. Felsbau 1999, 17, 152–162. [Google Scholar]

- Medley, E.W. Observations on tortuous failure surfaces in Bimrocks. Felsbau 2004, 5, 35–43. [Google Scholar]

- Goodman, R.E.; Ahlgren, C.S. Evaluating safety of concrete gravity dam on weak rock. J. Geotech. Geoenviron. Eng. 2000, 126, 429–442. [Google Scholar] [CrossRef]

- Medley, E.W.; Wakabayashi, J. Geological characterization of mélange for practitioners. Felsbau 2004, 22, 10–18. [Google Scholar]

- Afifipour, M.; Moarefvand, P. Failure patterns of geomaterials with block-in-matrix texture: Experimental and numerical evaluation. Arab. J.Geosci. 2014, 7, 2781–2792. [Google Scholar] [CrossRef]

- Li, X.; Liao, Q.L.; He, J.M. In-situ tests and astochastic structural model of rock and soil aggregate in the three Gorges Reservoir Area, China. Int. J. Rock Mech. Min. Sci. 2004, 41, 702–707. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zhang, B.; Wu, Y. Meso-damage cracking characteristics analysis for rock and soil aggregate with CT test. Sci. China Technol. Sci. 2014, 57, 1361–1371. [Google Scholar] [CrossRef]

- Akram, M.S. Physical and Numerical Investigation of Conglomeratic Rocks. Ph.D. Thesis, University New South Wales, Sydney, Australia, 2010. [Google Scholar]

- Sunuwar, S.C. Challenges on Estimating Shear Strength Parameters of Colluvium Slopes for Reservoir Slope Stability Analysis of Tamakoshi 3 Hydroelectric Project. Int. J. Landslide Environ. 2013, 1, 93–94. [Google Scholar]

- Terzaghi, K.; Peck, R.B. Soil Mechanics in Engineering Practice; John Wiley & Sons, Inc.: New York, NY, USA; London, UK; Sydney, Australia, 1956. [Google Scholar]

- Dykhovichnyi, Y.A.; Maksimenko, V.A. Design and Construction on Territories Subjected to Karst-Piping Processes in Moscow. Soil Mech. Found. Eng. 1979, 163, 147–151. [Google Scholar] [CrossRef]

- Seed, H.B. Laboratory Study of Hydraulic Fracturing. J. Geotech. Eng. Div. 1981, 107, 713–732. [Google Scholar]

- Lubochkov, E.A. Piping Resistant Non Cohesive Soils. Isvestia VN II G 71, May 1962; 61–89. [Google Scholar]

- Van Zyl, D.; Harr, M.E. Seepage Erosion Analysis of Structures. In Proceedings of the Tenth International Conference on Soil Mechanics and Foundation Engineering, Stockholm, Sweden, 15–19 June 1981; p. 503. [Google Scholar]

- Sherard, J.L.; Dunnigan, L.P.; Talbot, J.R. Basic properties of sand and gravel filters. J. Geotech. Eng. 1984, 110, 684–700. [Google Scholar] [CrossRef]

- Foster, M.A.; Fell, R.; Spannagle, M. The statistics of embankment dam failures and accidents. Can. Geotech. J. 2000, 37, 1000–1024. [Google Scholar] [CrossRef]

- Sellmeijer, J.B. On the Mechanism of Piping under Impervious structures. Ph.D. Thesis, University of Delft, Delft, The Netherlands, 1998. [Google Scholar]

- Ubilla, J.; Abdoun, T.; Sasaakul, L.; Sharp, M.; Steadman, S.; Vanadat-Ellis, W.; Zimmie, T. New Orleans levee system performance during hurricane Katrina, London Avenue and Orleans Canal South. J. Geotech. Geoenviron. Eng. ASCE 2008, 134, 668–680. [Google Scholar] [CrossRef]

- Cyril, G.; Yves-Henri, F.; Rémi, B. Contact erosion at the interface between granular coarse soil and various base soils under tangential flow condition. J. Geotech. Geoenviron. Eng. 2009, 136, 741–750. [Google Scholar] [CrossRef]

- Das, A.; Viswanadham, B.V.S. Experiments on the piping behaviour of geofiber-reinforced soil. Geosynth. Int. 2010, 17, 171–182. [Google Scholar] [CrossRef]

- Richards, K.S.; Reddy, K.R. Experimental investigation of initiation of backward erosion piping in soils. Géotechnique 2012, 62, 933–942. [Google Scholar] [CrossRef]

- Kevin, S.; Krishna, R.R. True triaxial piping test apparatus for evaluation of piping potential in earth structures. Geotech. Test. J. 2009, 33, 83–95. [Google Scholar]

- Midgley, T.L.; Fox, G.A.; Wilson, G.V. In situ soil pipeflow experiments on contrasting streambank soils. Trans. ASABE 2013, 56, 479–488. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Soltannajad, K.; Javadi, A.A. Improving piping resistance using randomly distributed fibers. Geotext. Geomembr. 2014, 42, 15–24. [Google Scholar] [CrossRef]

- Covelli, C.; Palumbo, A.; Pianese, D. A few criteria for the evaluation of the hydraulic causes of the levees’ failure. In River Flow 2008, Proceedings of the International Conference on Fluvial Hydraulics, Cesme, Izmir, Turkey, 3–5 September 2008; KUBABA Congress Department and Travel Services.

- Ojha, C.S.P.; Singh, V.P.; Adrian, D.H. Determination of Critical Head in Soil Piping. J. Hydraul. Eng. 2003, 129, 511–518. [Google Scholar] [CrossRef]

- Fleshman, M.; Rice, J. Laboratory Modeling of the Mechanisms of Piping Erosion Initiation. J. Geotech. Geoenviron. Eng. 2014, 140, 1–12. [Google Scholar] [CrossRef]

- Weijers, J.B.A.; Sellmeijer, J.B. A New Model to Deal with Piping Mechanism. In Filters in Geotechnical and Hydraulic Engineering, Proceedings of the 1st International Conference “Geo-Filters”, Karlsruhe, Germany, 20–22 October 1992; Brauns, J., Heibaum, M., Schuler, U., Eds.; Balkema: Rotterdam, The Netherlands, 1993; pp. 349–355. [Google Scholar]

- Gao, Q.; Liu, Z.H.; Li, X.; Li, J.H. Permeability Characteristics of Rock and Soil Aggregate of Backfilling Open-Pit And Particle Element Numerical Analysis. Chin. J. Rock Mech. Eng. 2009, 28, 2342–2348. (In Chinese) [Google Scholar]

- Chen, Z.H.; Chen, S.J.; Chen, J.; Sheng, Q.; Yan, H.; Hu, W. In-situ Double-Ring Infiltration Test of Soil-Rock Mixture. J. Yangtze River Sci. Res. Inst. 2012, 29, 52–56. (In Chinese) [Google Scholar]

- Wu, J.H.; Chen, J.H.; Lu, C.W. Investigation of the Hsien-du-Shan rock avalanche caused by typhoon Morakot in 2009 at Kaohsiung county, Taiwan. Int. J. Rock Mech. Min. Sci. 2013, 60, 148–159. [Google Scholar] [CrossRef]

- ASTM D 2434-68. Standard Test Method for Permeability of Granular Soils (Revised, Constant Head); ASTM International Press: West Conshohocken, PA, USA, 2006. [Google Scholar]

- BS1377-1. Methods of Test for SOILS for Civil Engineering Purposes—Part 1: General Requirements and Sample Preparation; British Standard: London, UK, 1990. [Google Scholar]

- Donaghe, R.T.; Torrey, V.H. Proposed New Standard Test Method for Laboratory Compaction Testing of Soil-Rock Mixtures Using Standard Effort. Geotech. Test. J. 1994, 3, 387–392. [Google Scholar]

- Rücknagel, J.; Götze, P.; Hofmann, B.; Christen, O.; Marschall, K. The influence of soil gravel content on compaction behaviour and pre-compression stress. Geoderma 2013, 209–210, 226–232. [Google Scholar] [CrossRef]

- Zhou, Z.; Fu, H.L.; Liu, B.C. Orthogonal tests on permeability of soil-rock mixture. Chin. J. Rock Mech. Eng. 2006, 28, 1132–1138. (In Chinese) [Google Scholar]

- Khilar, K.C.; Fogler, H.S.; Gray, D.H. Model for Piping-Plugging in Earthen Structures. J. Geotech. Eng. ASCE 1985, 111, 833–846. [Google Scholar] [CrossRef]

- Ozkan, S. Analytical Study on Flood Induced Seepage under River Levees. Ph. D. Thesis, Louisiana State University, Baton Rouge, LA, USA, 2003. [Google Scholar]

- Xu, W.J.; Wang, Y.G. Meso-structural permeability of S-RM based on numerical tests. China J. Rock Mech. Eng. 2010, 32, 543–550. [Google Scholar]

- Skempton, A.W.; Brogan, J.M. Experiments on piping in sandy gravels. Geotechnique 1994, 44, 449–460. [Google Scholar] [CrossRef]

- Yalin, M.S.; Karahan, E. Inception of sediment transport. J. Hydraul. Div. 1979, 105, 1433–1443. [Google Scholar]

- Mao, C.X. Discussion of “Seepage control of earth dam on the sand-gravel foundation”. J. Hydraul. Eng. 1963, 4, 66–69. (In Chinese) [Google Scholar]

- Cao, D.L. Cofferdam seepage control of Gezhouba Project. J. Hydraul. Eng. 1988, 19, 49–55. (In Chinese) [Google Scholar]

- Kenney, T.C.; Lau, D. Internal stability of granular filters. Can. Geotech. J. 1985, 22, 215–225. [Google Scholar] [CrossRef]

- Palmeira, E.M.; Fannin, R.J.; Vaid, Y.P. A study on the behavior of soil-geotextile systems in filtration tests. Can. Geotech. J. 1996, 33, 899–912. [Google Scholar] [CrossRef]

- Luo, Y.L.; Wu, Q.; Zhan, M.L.; Sheng, G.C. Development of Seepage-Erosion-Stress Coupling Piping Test Apparatus and Its Primary Application. Chin. J. Rock Mech. Eng. 2013, 32, 2108–2114. (In Chinese) [Google Scholar]

- Tomlinson, S.S.; Vaid, Y.P. Seepage forces and confining pressure effects on piping erosion. Can. Geotech. J. 2000, 37, 1–13. [Google Scholar] [CrossRef]

| Index | Soil Matrix | Rock Block |

|---|---|---|

| Bulk density (g/cm3) | 1.64 | 2.53 |

| Dry weight density (g/cm3) | 2.06 | / |

| Optimum water content (%) | 10.2 | / |

| Specific gravity (GS) | 2.73 | / |

| Effective particle size, D10 (mm) | 0.01 | / |

| Coefficient of uniformity, Cu | 4.2 | / |

| Coefficient of curvature, Cc | 1.32 | / |

| Liquid limit (%) | 64 | / |

| Plastic limit (%) | 36 | / |

| Plasticity index | 28 | / |

| Liquidity index | 0.121 | / |

| Wet UCS (MPa) | 0.57 | 43.21 |

| Dry UCS (MPa) | 2.27 | 80.75 |

| Mineral | Soil Sample #1 | Soil Sample #2 |

|---|---|---|

| Montmorillonite | 61.27 | 60.31 |

| Kaolinite | 26.34 | 24.07 |

| Illite | 6.43 | 6.55 |

| chlorite | 5.96 | 3.31 |

| Confining Pressure (kPa) | Coefficient | Correlation Coefficient (r) | |

|---|---|---|---|

| a | b | ||

| 0 | −1.7062 | 190.752 | 0.9792 |

| 50 | −1.4673 | 191.395 | 0.9945 |

| 100 | −1.6735 | 212.845 | 0.9816 |

| 200 | −1.9089 | 239.283 | 0.9749 |

| RBP (%) | Coefficient | Correlation Coefficient (r) | |

|---|---|---|---|

| a | b | ||

| 30 | 0.2097 | 136.862 | 0.9879 |

| 40 | 0.2171 | 123.448 | 0.9912 |

| 50 | 0.2051 | 109.599 | 0.9555 |

| 60 | 0.1369 | 94.893 | 0.9213 |

| 70 | 0.1782 | 72.991 | 0.8923 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, C.; Zhou, X.; Wei, X. Seepage Piping Evolution Characteristics in Bimsoils -An Experimental Study. Water 2017, 9, 458. https://doi.org/10.3390/w9070458

Wang Y, Li C, Zhou X, Wei X. Seepage Piping Evolution Characteristics in Bimsoils -An Experimental Study. Water. 2017; 9(7):458. https://doi.org/10.3390/w9070458

Chicago/Turabian StyleWang, Yu, Changhong Li, Xiaolong Zhou, and Xiaoming Wei. 2017. "Seepage Piping Evolution Characteristics in Bimsoils -An Experimental Study" Water 9, no. 7: 458. https://doi.org/10.3390/w9070458

APA StyleWang, Y., Li, C., Zhou, X., & Wei, X. (2017). Seepage Piping Evolution Characteristics in Bimsoils -An Experimental Study. Water, 9(7), 458. https://doi.org/10.3390/w9070458