1. Introduction

Wastewater sludge management is considered to be one of the greatest environmental challenges in the last decades and for the coming ones. In Europe, about 10 million tons of sludge dry solids (DS) per year arise. For its final disposal and reuse, the proportions are as follows: 45% agriculture, 23% thermal treatment (incineration), 18% sea disposal, 7% landfill, and other 7% [

1]. In most cases, sludge treatment requires some kind of dewatering in order to reduce sludge volume before storage, transport, and final disposal. Conventionally, technical equipment such as centrifuges, belt filter presses are used for this purpose. Sludge treatment in reed beds is an alternative to dewater sewage sludge without using high tech equipment and without need of chemicals and energy except pumping. One drawback is the demand of land, which means that this method appears most practical for smaller and medium-sized wastewater treatment plants (WWTPs).

Furthermore, the end product is suitable for use as a fertilizer and soil conditioner, rather than for incineration, because of its structure. This technology was also examined worldwide and has proved to be a potential alternative to common treatment methods. Some pilot plants were established, for example, in Egypt, and the results achieved were positive and encouraged an application of the technology in practice [

2].

Recently in Germany there have been a quite number of reed beds that have been in operation, but the availability of results from full-scale reed beds for sludge treatment plants is limited. Especially, data about properties of the end product and experiences with emptying the sludge polders are scarce.

This paper aims at evaluating data of a full-scale reed bed plant for waste water sludge treatment with special emphasis on the mass balances of the process, i.e., the solids and volume reduction achieved on a large scale. Nutrient content of the sludge is not addressed. However, it should be mentioned that the total amount of sludge excavated was utilized as a fertilizer in agriculture. Concentrations of pollutants such as heavy metals, halogenated hydrocarbons were well below German legal limits, but the concentrations increased during the treatment in reed beds due to solids decomposition.

2. The WWTP of Wathlingen

The WWTP of Wathlingen (52°32′51″ N 10°09′09″ E), Germany, has a design capacity of 20,500 p.e. In 2000, the existing dewatering machines were replaced by four sludge polders with a total area of 3000 m2 each. All loading rates in this report refer to this total area; however, because of the sloped walls, the area at the bottom is only 2100 m2. Since then, the entire amount of sewage sludge, which consisted of primary sludge after anaerobic digestion and secondary sludge from extended aeration, was pumped into the sludge polders.

The region of Wathlingen has a mild humid climate with warm summers and no dry season. The area within 40 km of this station is covered by croplands (95%) and built-up areas (4%). The length of the day varies significantly over the course of the year. The shortest day is 7 h of daylight; the longest day is 17 h of daylight. Over the entire year, the most common forms of precipitation are moderate rain, moderate snow, and thunderstorms. Over the course of the year, the relative humidity typically ranges from 46% (comfortable) to 98% (very humid), and the wind speeds vary from 1 m/s to 6 m/s. Typically, the temperature varies through the year from −2 to 24 °C and is rarely below −10 °C or above 30 °C. The average monthly amount of precipitation has been recorded at around 39 mm, and the annual evaporation varies between 450 and 650 mm [

3].

3. Polder Construction and Operation

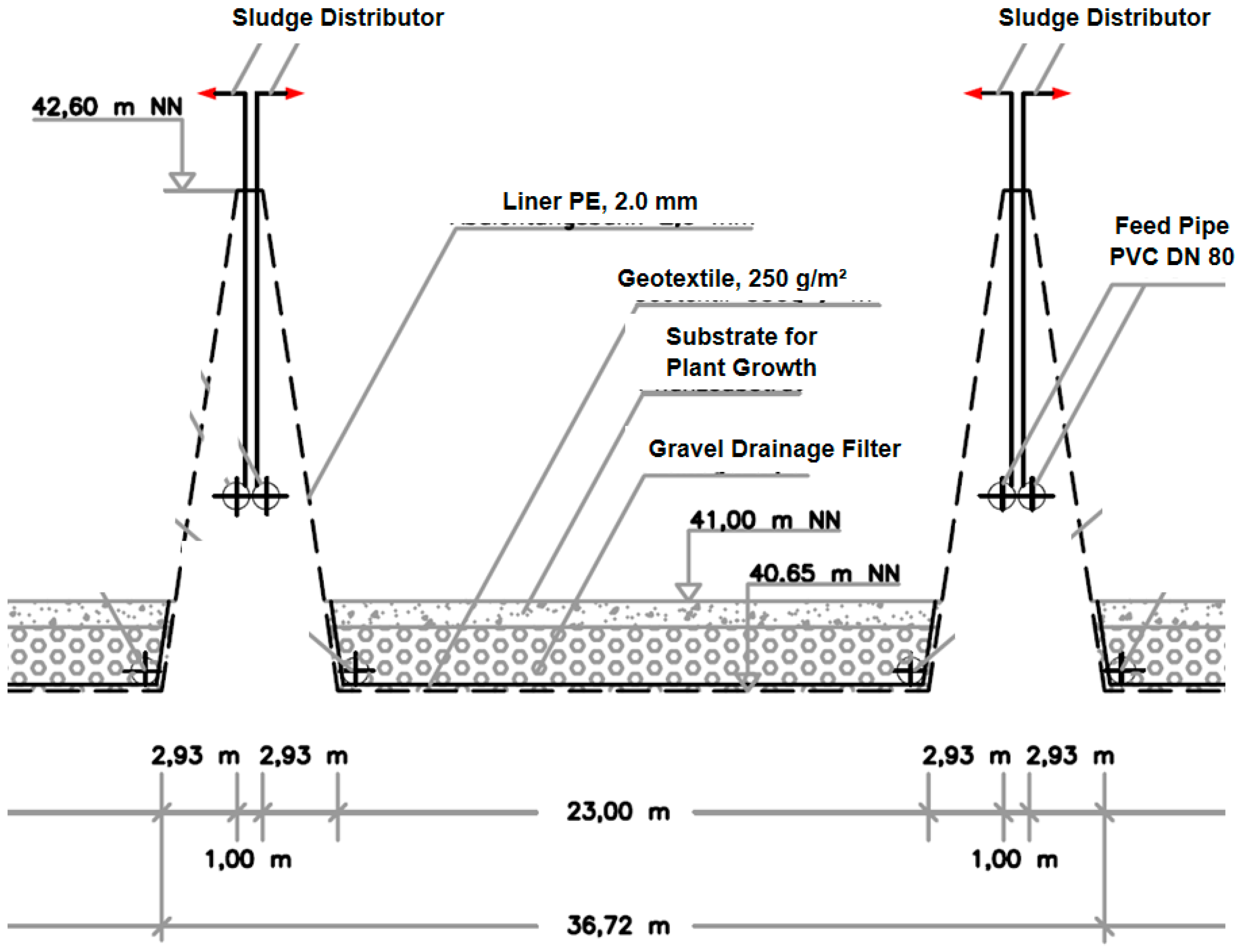

Initially, four polders were constructed with a length of approx. 108 m and a width of 28 m each. The area of each polder is 3000 m

2, yielding a total area of 12,000 m

2. The polders are surrounded using earth dams 1.95 m high, and the polder basis including the dams is sealed from the underground using a 2 mm poly ethylene liner. For protection against mechanical damage, a geotextile was applied on top of the plastic liner. The polder bottom is covered with a gravel drainage layer (0.25 m), which also contains the perforated drainage pipes DN 80. Due to the fact that sludge amounts had increased, in 2010 a fifth polder was added and is in operation (

Figure 1).

Feeding of the polders started in mid 2000. Polders 1, 2, and 3 were charged with excess sludge from the extended aeration plant, while Polder 4 was fed with digested primary sludge. Since July 2001, Polder 4 was fed with both excess sludge and primary sludge; the reason for this was that the amount of primary sludge was very low compared to the excess sludge. The reed vegetation in Polder 4 had developed well. In 2010, the primary sedimentation and the digester went out of operation and only excess sludge has been treated since then.

During the first year of operation, locally the reed plants died or were overgrown by other plants like grasses. Therefore, some replanting was necessary during the first year of operation. Since the second year, there have not been any more problems encountered with the vegetation of the polders.

One problem was encountered emptying the polders, which was the clogging of the drainage pipes. Some clogged sections were found due to material failure and/or intrusion of roots. Additionally, in some places, soil material had entered the pipes. This in return impaired the dewatering of sludge. Thus, it was decided that cleaning the pipes using water under high pressure is necessary.

Operation data of the plant are summarized in

Table 1,

Table 2 and

Table 3. Over the whole period, the sludge pumped to the polders had an average DS concentration of approx. 20 kg/m

3 (2%).

Important aspects governing the processes taking place in the reed beds are the sludge loading rate (SLR) and the hydraulic loading rate (HLR). Generally, an SLR up to 100 kg DS/(m

2 × y) can be reached depending on the nature of sludge and climatic conditions. In Germany, according to climatic reasons, the maximum specific load of aerobically stabilized sludge is estimated to be about 30 kg DS/(m

2 × y) [

4]. Some experience in Denmark illustrates that an SLR up to 60 kg DS/(m

2 × y) can be reached [

5]. The typical HLR reported is 7.5–10 cm every 7 to 10 days [

5,

6,

7].

The data, especially the hydraulic and solids loading rates, were analyzed. The HLR of the polders varied between 1300 and 1900 mm/y, as can be seen from

Table 1. The higher loading rates were achieved in periods, where one of the polders was due for emptying and was not fed with sludge. Considering the average solids concentrations of 2% in the liquid sludge pumped into the polders, this corresponds to an SLR of approx. 25 to 40 kg DS/(m

2 × y). During the 10 years of operation, it was concluded that, in the long run, loading rates should not be any higher. Otherwise, problems with vegetation and with sludge dewatering may arise.

4. Data Evaluation and Discussion

4.1. Solids and Water Balances

Meanwhile, the four polders were emptied once and put into operation again, which allowed for an evaluation of complete operation cycles from startup to sludge removal. In 2010, an additional (fifth) polder was constructed and taken into operation in order to cope with increased sludge amounts and to reduce the loading rates during idle phases of single polders before and during emptying.

The balance of sludge solids clearly shows that biological processes within the sludge bed led to a significant reduction of sludge solids. The DS reduction was calculated to vary between 23 and 52% with an average of 40%. However, there is no clear relationship between the time of operation and solids reduction efficiency, as is expected.

The volume balances are calculated from the total input and the sludge volume at the time of emptying the polders, where a part of the sludge was removed and another part remained in the polders containing rhizome fragments for regrowth of Phragmites plants. The reduction of sludge volume was found to be high (between 92 and 94%) due to the drainage and evaporation processes. One aspect which was not achieved was that the treated sludge should have a solids concentration of at least 30% (300 kg/m3). On the contrary, it was found that the water content of the excavated sludge varied between 12.5 and 21.4% and is strongly dependent on weather conditions mainly a few weeks before and during emptying. As polders emptying have to be planned and tendered, which is carried out by private companies, it is not easy to get the accurate time for this work. As a consequence, it was decided that an additional “drying and storage” area would be constructed for the excavated sludge that is equipped with a basis liner for groundwater protection. This storage also allows for bridging the time until weather conditions are favorable for the farmers to use the sludge as a fertilizer. Polder 3 was the first polder available for the storage; thus, DS concentrations of 21.4% (while emptying) and 31.1% (after 8 months of additional storage) were achieved. This led to an additional reduction of sludge volume to be transported to the final user.

By balancing the total input water volume (liquid sludge and rain water) and the output volume, it was found that, depending on weather conditions, the amount of evaporation was approximately equal to 50% of the input rain water, while the amount of drainage water from 2005 to 2010 was 1900 mm/y on average.

As mentioned above, the solids balance indicates that a significant biological degradation of DS took place during the treatment process. This led to a lower total solids load, which had to be disposed off compared to the initial solids load. Furthermore, the organic fraction of the sludge was reduced. As example, in Polder 3, at the time of emptying, volatile solids (VS) in the treated sludge were 48% and 35% of total so lids (DS) in 30 and 80 cm depth, respectively, as shown in

Table 3. It was observed that at the deepest layer of the polder (oldest sludge layer) had a low organic content, which slightly increased towards the top layer of the polder. This shows that; the long-term sludge storage in the polders leads to a significant breakdown of organics.

Table 3 shows that values of the total solids reduction were between 40 and 60% due to organic degradation.

4.2. Physical and Chemical Properties of End Product

Physically, the treated sludge has a structure which looks more like a compost or young topsoil than typical wastewater sludge. This is basically due to the roots of plants, which were distributed over the whole sludge volume. Since the sludge is used as a fertilizer in agriculture, concentrations of metals and AOX (halogenated hydrocarbons) are monitored regularly. Generally, the removal of metals during secondary wastewater treatment is based upon the uptake of metals by the microbial biomass, which causes an accumulation within the sludge solids.

Approximately 60–80% of most elements in raw sewage are removed and transferred to the sludge [

8]. In order to avoid high metal concentrations, industrial discharges into the public sewer system are monitored regularly. Concentrations of heavy metals and chlorinated organics (AOX) were analyzed several times according to the German regulation for the application of sewage sludge to agriculture. As can be seen in

Table 4, the concentrations of all elements were far below the legal limits. There was only a slight accumulation effect, which led to an increase in heavy metal concentrations. However, this effect was lower than that calculated on a mass balance basis considering the solids degradation.

4.3. Amount and Properties of Drainage Water

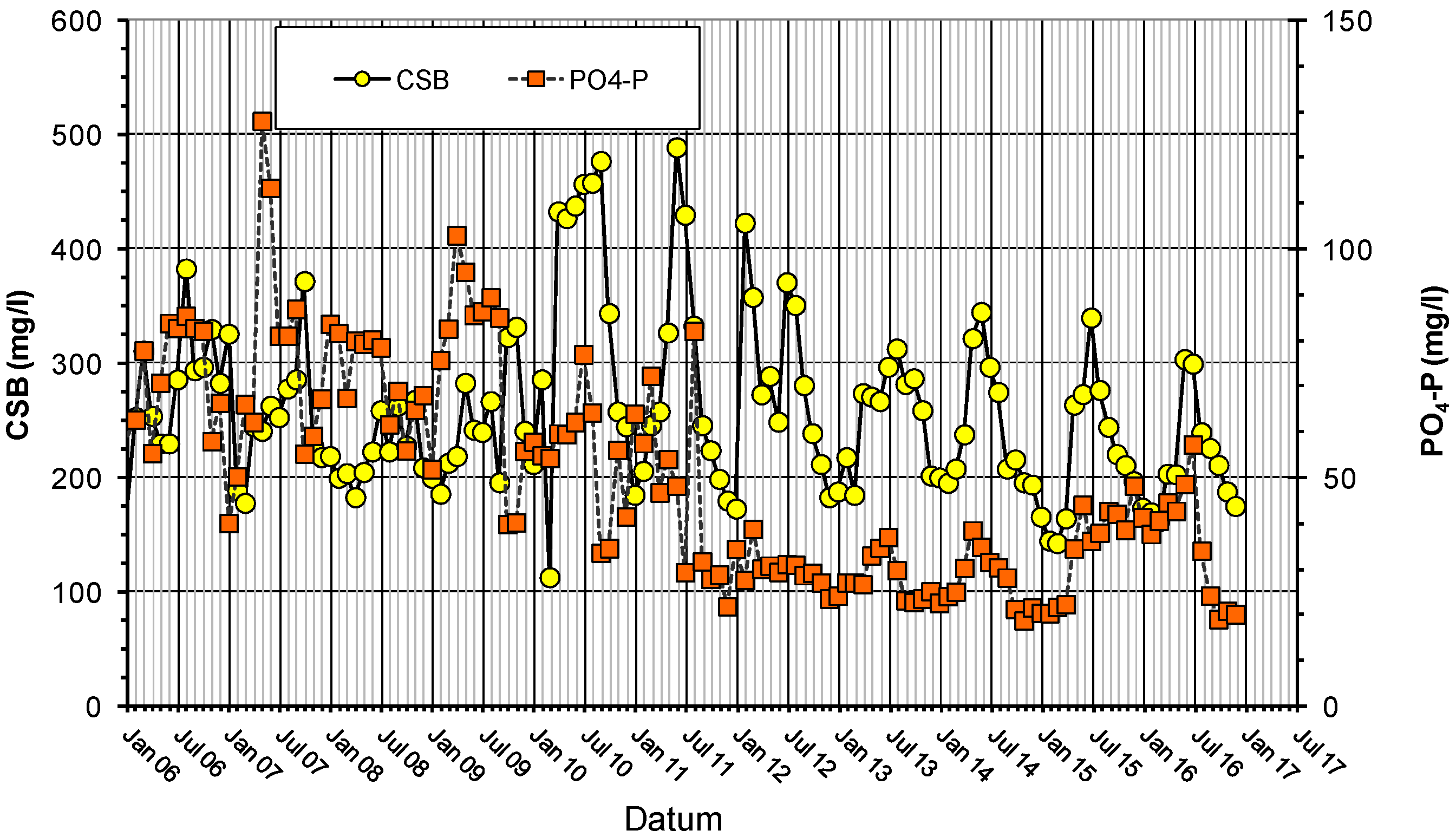

As mentioned above, large amounts of the total water input will eventually become drainage water. Due to biological and chemical reactions, this water is polluted with components arising from the sludge. By analyzing different parameters (

Figure 2), Chemical Oxygen Demand (COD) concentrations were found to vary between 100 and 450 mg/L, without any long-term trend, but an apparent tendency towards higher concentrations was found during summer One possible reason is that, during summer, oxygen is used up in the upper sludge layer, resulting in low Dissolved Oxygen (DO) concentrations at the bottom of the polders, causing remobilization of organics. Results for phosphorous (PO

4-P) showed that, until 2011, the concentrations varied between 50 and 80 mg/L. Because the WWTP was operated with enhanced biological phosphorus removal (EBPR) until 2011, the change from aerobic to anaerobic conditions in the lower layers of sludge led to a resolution of P. Compared to the P load of the sewage entering the WWTP, the P load of drainage water was about 10% during that phase. In 2011, phosphorous removal was changed to simultaneous precipitation using iron. Since then as can be seen, P concentrations in the drainage water are significantly reduced (20 to 50 mg/L).

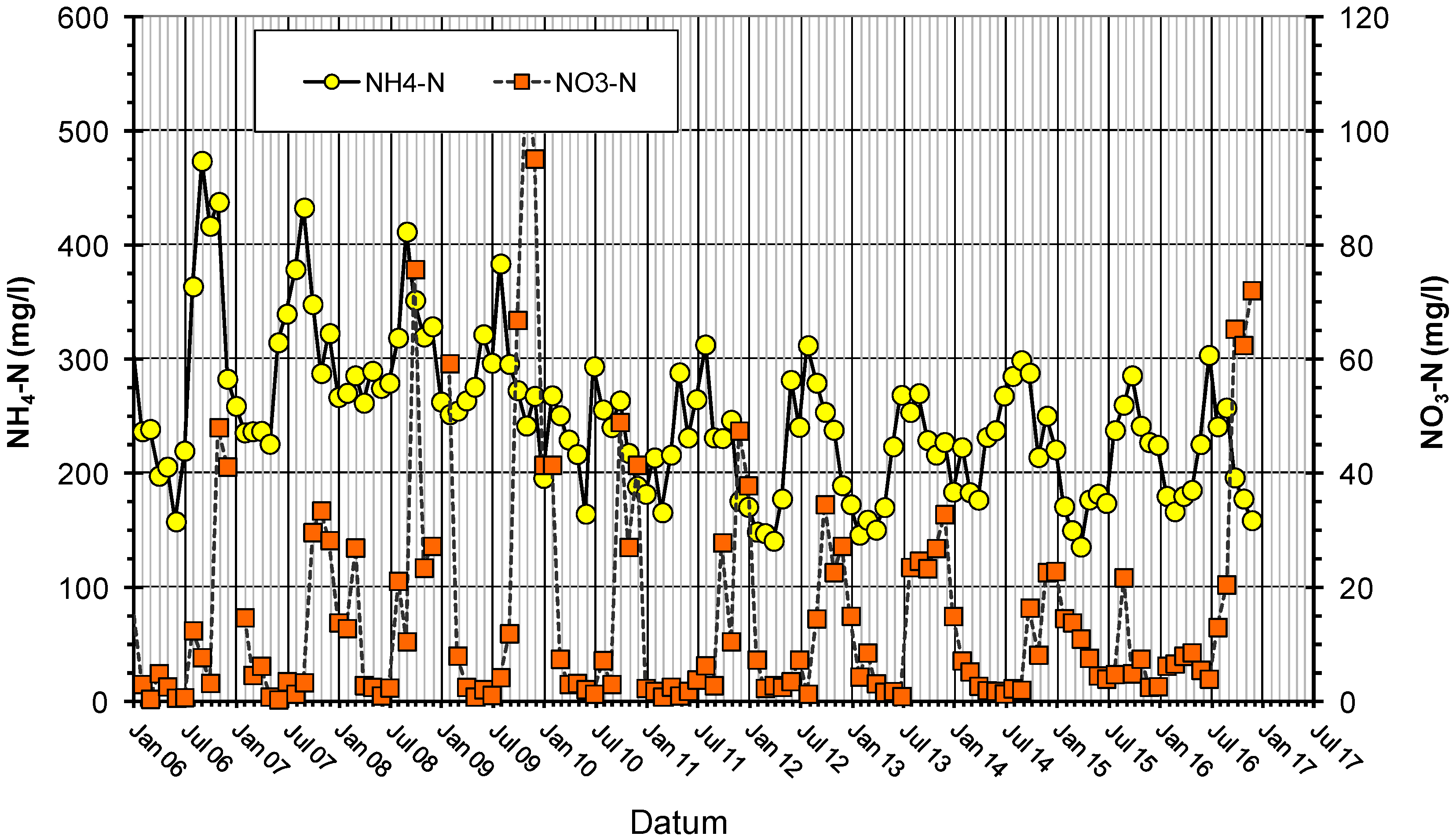

Furthermore, nitrogen dynamics follow a clear yearly pattern (

Figure 3). During late autumn, nitrate (NO

3-N) concentration increases as ammonia concentration (NH

4-N) decreases, which indicates nitrification. Because of the higher temperature, one would expect nitrification in summer rather than in winter. However, as mentioned in connection with COD pattern, the high heterotrophic activity and lower oxygen solubility in the summer seem to inhibit nitrification.

5. Economic Evaluation

Economic data which specify the total costs of the sludge treatment and disposal of the Wathlingen WWTP, including capital, operating costs, and costs for final disposal, are summarized in

Table 5. Over 12 years of operation, the four polders were emptied and disposed. The costs were calculated according to the total amount to date of disposed sludge. On a DS base, treatment and disposal cost were 132 € per t DS. If sludge is applied to agriculture in liquid form (a DS concentration of around 4%), which is common for small WWTPs in Germany, costs range from 200 to 370 € per t DS. For dewatered sludge, the range is from 120 to 180 € per t DS [

9]. This shows that, in this particular plant, sludge treatment in reed beds is not a particularly cheap solution due to high costs in the beginning, but in the long run, for smaller WWTPs especially, can compete with other (conventional) alternatives.

6. Conclusions

In the Wathlingen WWTP. the choice of a “low-tech” solution to sludge dewatering and storage has proven to be a competitive economical solution. One important boundary condition is that the final metal concentrations of the sludge should be low enough to be used for agricultural purposes. If sludge is planned for incineration. treatment in reed beds will not be the most favorable solution. regarding the inhomogeneous structure of the end product and the reduction of organic value. i.e., the heating value of the sludge.

Results show that. after treatment in reed beds. the sludge DS mass to be finally disposed of may be reduced by at least 23 and at most 52%. Additionally. water concentration was reduced. However. under mid-European climate conditions. the DS concentration of the product excavated was not higher than around 200 kg/m3 (20% DS).

Operation experiences proved that the system is very user-friendly and with limited maintenance and control work. To make the best use of this technique. it is recommended that a separate area for additional storage and dewatering is provided after the sludge from the polders is removed. This allows for the possibility for the operators to determine the appropriate time and conditions for final disposal.