Physical Modeling on Hydraulic Performance of Rectangular Bridge Deck Drains

Abstract

:1. Introduction

2. Background

3. Physical Model

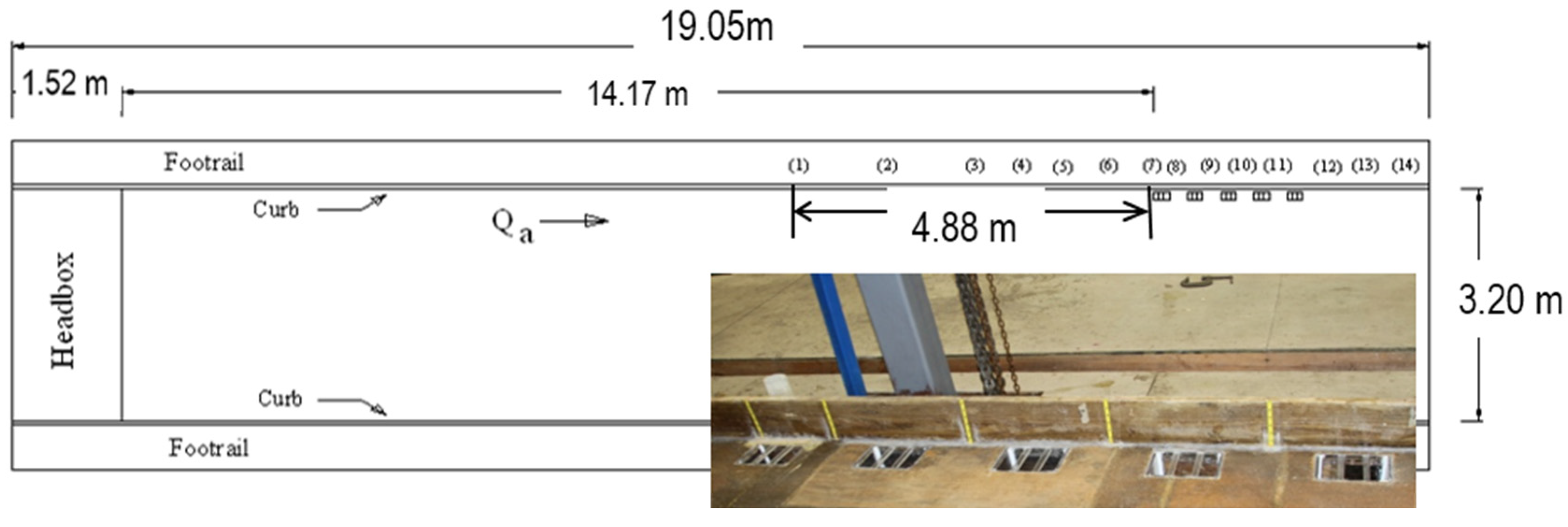

3.1. Facility Setup

3.2. Model Manning’s Roughness Coefficient Determination

3.3. Experiment Procedures

4. Experiment Data Analysis and Model Development

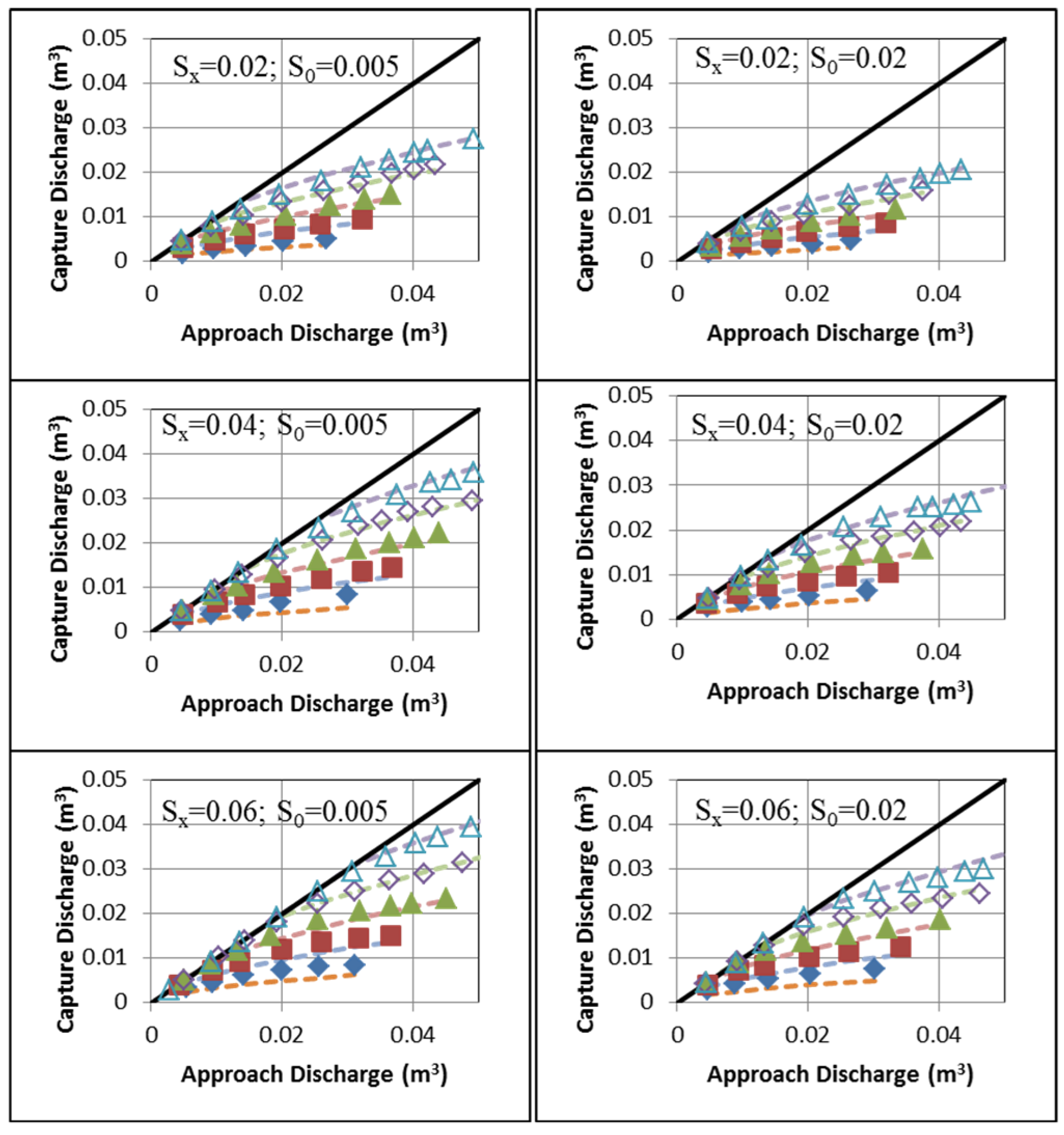

4.1. Data Analysis and Equation Development

4.2. Model Results

4.3. Discussion

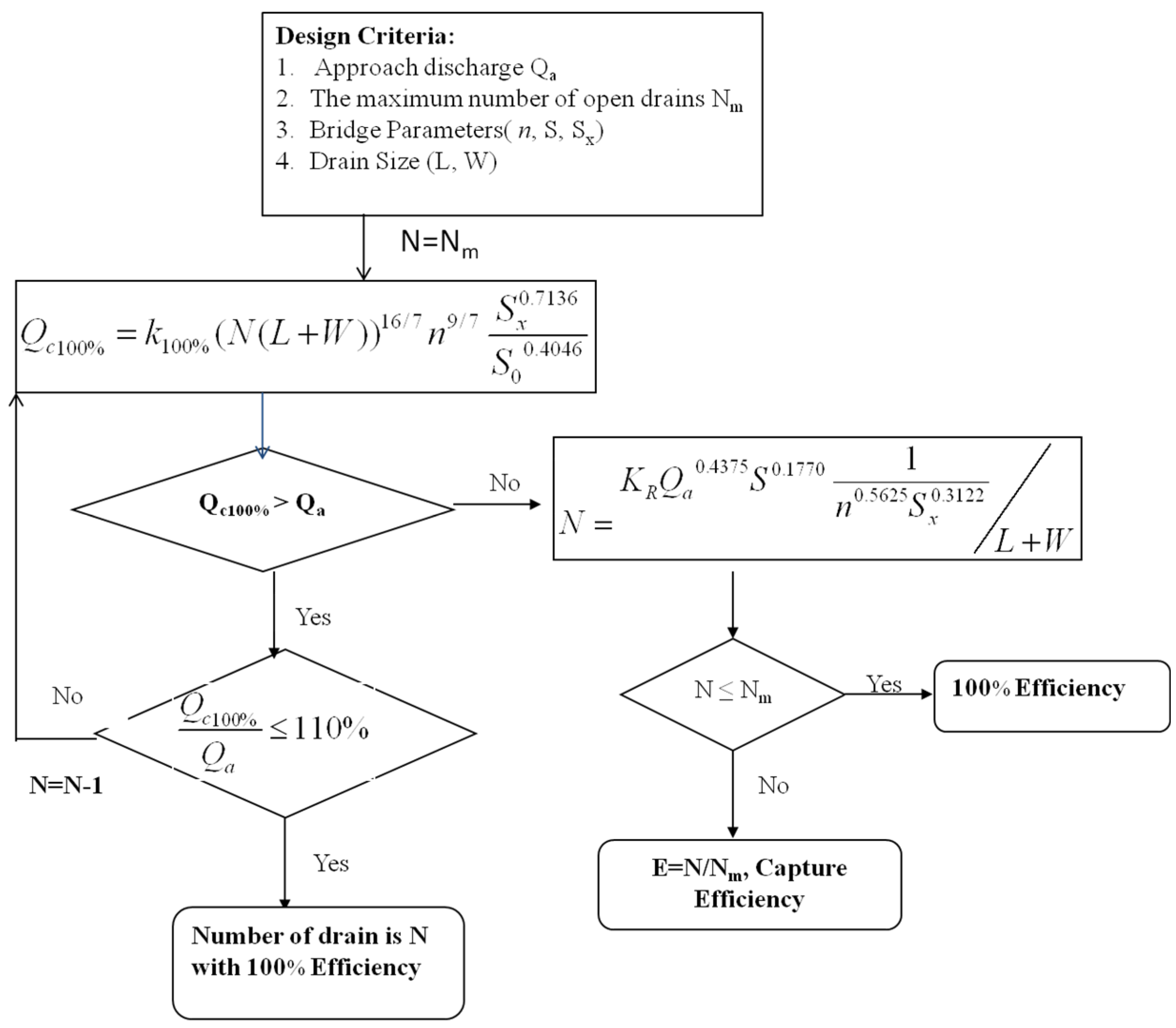

5. Design Guidance

Design Steps

6. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Smith, M.A.; Holley, E.R. Hydraulic Characteristics of Flush Depressed Curb Inlets and Bridge Deck Drains; Rep. No. FHWA/TX-95/0-1409-2F; Center for Transportation Research, the University of Texas at Austin: Austin, TX, USA, 1995. [Google Scholar]

- Young, G.K.; Walker, S.E.; Chang, F. Design of Bridge Deck Drainage; FHWA-SA-92-010, Hydraulic Engineering Circular 21 (HEC 21); Federal Highway Administration (FHWA): Washington, DC, USA, 1993; p. 129. [Google Scholar]

- Qian, Q.; Liu, X.; Charbeneau, R.; Barrett, M. Hydraulic Performance of Small Scale Bridge Deck Drains; Rep. No. FHWA/TX-12/06653-1; Center for Transportation Research, the University of Texas at Austin: Austin, TX, USA, 2013. [Google Scholar]

- Brown, S.A.; Schall, J.D.; Morris, J.L.; Doherty, C.L.; Stein, S.M.; Warner, J.C. Urban Drainage Design Manual: FHWA-NHI-10–009, Hydraulic Engineering Circular 22(HEC-22), 3rd ed.; Federal Highway Administration (FHWA): Washington, DC, USA, 2009; p. 478. [Google Scholar]

- Charbeneau, R.J.; Jeong, J.; Barrett, M.E. Highway Drainage at Superelevation Transitions; Rep. No. FHWA/TX-08/0-4875-1; Center for Transportation Research, the University of Texas at Austin: Austin, TX, USA, 2008. [Google Scholar]

- Izzard, C.F. Hydraulics of runoff from developed surfaces. In Proceedings of the 26th Annual Meeting of Highway Research Board National Research Council, Washington, DC, USA, 5–8 December 1946; pp. 129–150.

- Izzard, C.F. Tentative Results on Capacity of Curb Opening Inlet; Research Report No. 11-B; Highway Research Board: Washington, DC, USA, 1950; pp. 36–51. [Google Scholar]

- Johnson, F.L.; Chang Fred, F.M. Drainage of Highway Pavements; FHWA-TS-84-202, Hydraulic Engineering Circular 12(HEC12); Federal Highway Adimistration (FHWA): Washington, DC, USA, 1984; p. 136. [Google Scholar]

- Li, W.H.; Sorteberg, K.K.; Geyer, J.C. Hydraulic behavior of storm-water inlets. II. Flow into curb-opening inlets. In Sewage and Industrial Waters; The Federation, the University of California: Berkeley, CA, USA, 1954; Volume 23, pp. 143–159. [Google Scholar]

- Holley, E.R.; Woodward, C.; Brigneti, A.; Ott, C. Hydraulic Characteristics of Recessed Curb Inlets and Bridge Drains; Rep. No. FHWA/TX-92/0-1267-2F; Center for Transportation Research, the University of Texas at Austin: Austin, TX, USA, 1992. [Google Scholar]

- Hammons, M.A.; Holley, E.R. Hydraulic Characteristics of Flush Depressed Curb Inlets and Bridge Deck Drains; Rep. No. FHWA/TX-95/0-1409-01; Center for Transportation Research, the University of Texas at Austin: Austin, TX, USA, 1995. [Google Scholar]

- Bos, M.G. Discharge Measurement Structures; Delft Hydraulic Laboratory: Delft, The Netherlands, 1989. [Google Scholar]

- Kehoe, G.; Charbeneau, R.; Barrett, M. Errors Introduced by Using Manning’s Equation to Estimate Ponded Width on Roadways with Mild Slopes. In Proceedings of the Transportation Research Board Annual Conference, Washington, DC, USA, 11–15 January 2015.

- Texas Department of Transportation. Hydraulic Design Manual; Texas Department of Transportation (TxDOT): Austin, TX, USA, 2009. [Google Scholar]

| Run | Drain Size (cm) | Longitudinal Slope | Cross Slope |

|---|---|---|---|

| 1 | 10 × 20 | 0.1%, 0.5%,1%, 2% and 4% | 2% |

| 2 | 10 × 20 | 0.1%, 0.5%,1%, 2% and 4% | 4% |

| 3 | 10 × 20 | 0.1%, 0.5%,1%, 2% and 4% | 6% |

| 4 | 15 × 20 | 0.5% and 2% | 2% |

| 5 | 15 × 20 | 0.5% and 2% | 4% |

| 6 | 15 × 20 | 0.5% and 2% | 6% |

| Variables | Drain 10 × 20 (cm) | Drain 15 × 20 (cm) | Both Drains |

|---|---|---|---|

| a | 0.3602 | 0.5469 | 0.3989 |

| α | 0.1043 | 0.1205 | 0.1043 |

| β | −0.2816 | −0.1760 | −0.2503 |

| R square | 0.9532 | 0.9760 | 0.9328 |

| Standard Error (m3/s) | 0.0011 | 0.0007 | 0.0012 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, Q.; Liu, X.; Barrett, M.E.; Charbeneau, R.J. Physical Modeling on Hydraulic Performance of Rectangular Bridge Deck Drains. Water 2016, 8, 67. https://doi.org/10.3390/w8020067

Qian Q, Liu X, Barrett ME, Charbeneau RJ. Physical Modeling on Hydraulic Performance of Rectangular Bridge Deck Drains. Water. 2016; 8(2):67. https://doi.org/10.3390/w8020067

Chicago/Turabian StyleQian, Qin, Xinyu Liu, Michael E. Barrett, and Randall J. Charbeneau. 2016. "Physical Modeling on Hydraulic Performance of Rectangular Bridge Deck Drains" Water 8, no. 2: 67. https://doi.org/10.3390/w8020067

APA StyleQian, Q., Liu, X., Barrett, M. E., & Charbeneau, R. J. (2016). Physical Modeling on Hydraulic Performance of Rectangular Bridge Deck Drains. Water, 8(2), 67. https://doi.org/10.3390/w8020067