3.1. Feed Water Characteristics

Table 2 compares the analyzed parameters of the SSE along with the mandatory standards established in Italy and in the State of California (U.S.) for unrestricted agriculture wastewater reuse. The State of California’s agriculture wastewater reuse regulations were considered because most developed countries defined their wastewater reuse standards on this basis.

Table 2.

Characteristics of the secondary settled effluent (SSE) coming from the City of Taranto (South Italy) Municipal Wastewater Treatment Plant (TMWTP).

Table 2.

Characteristics of the secondary settled effluent (SSE) coming from the City of Taranto (South Italy) Municipal Wastewater Treatment Plant (TMWTP).

| | | | | | MAC a |

|---|

| Parameter | unit of measurement | min | max | average | Italy b | State of California c |

|---|

| pH | | 6.3 | 7.5 | 7.2 | 6–9.5 | N.S. d |

| Temperature | °C | 19 | 25 | 23 | N.S. | N.S. |

| Conductivity | µS/cm | 1,584 | 1,950 | 1,800 | N.S. | N.S. |

| Turbidity | NTU e | 1 | 7 | 5 | N.S. | 2 |

| Total Suspended Solids (TSS) | mg/L | 1 | 8 | 3 | 10 | N.S. |

| Chemical Oxygen Demand (COD) | mg/L | 26 | 69 | 49 | 100 | N.S. |

| E. coli | CFU e/100 mL | 3,000 | 36,000 | 17,000 | 10 | N.S. |

| Total coliforms | CFU e/100 mL | 9,100 | 96,000 | 33,334 | N.S. | 2.2 |

The SSE characteristics of the TMWTP were quite constant during the experimentation. The concentrations of E. coli and total coliforms were always higher than the respective regulatory targets. As a consequence, a treatment specifically aimed at assuring compliance with the microbial standard regulations was required.

With regard to the other physical-chemical parameters, the SSE was already in compliance with the Italian regulation, whilst the wastewater turbidity was higher than the State of California’s threshold. This is in agreement with the requirement of an oxidized, coagulated, clarified and filtered wastewater to be in compliance with Title 22 of the California Wastewater Reclamation Criteria.

The UF membrane cut-off is potentially able to contemporaneously remove suspended particles and coli-organisms from the SSE. Achievement of the above regulatory targets was firstly evaluated using SOC and then in COC in order to deeply investigate the UF performance.

3.2. Stressed Operating Conditions versus Conventional Ones: Effect on the UF System Key Parameters

In the first part of the experiment (from 13 September to 2 October), a poor backwashing flow rate was applied during the backwash period (SOC phase). On the contrary, a higher flow rate was used to backwash the membranes in the second part of the experiment (from 7 October to 16 October; COC phase).

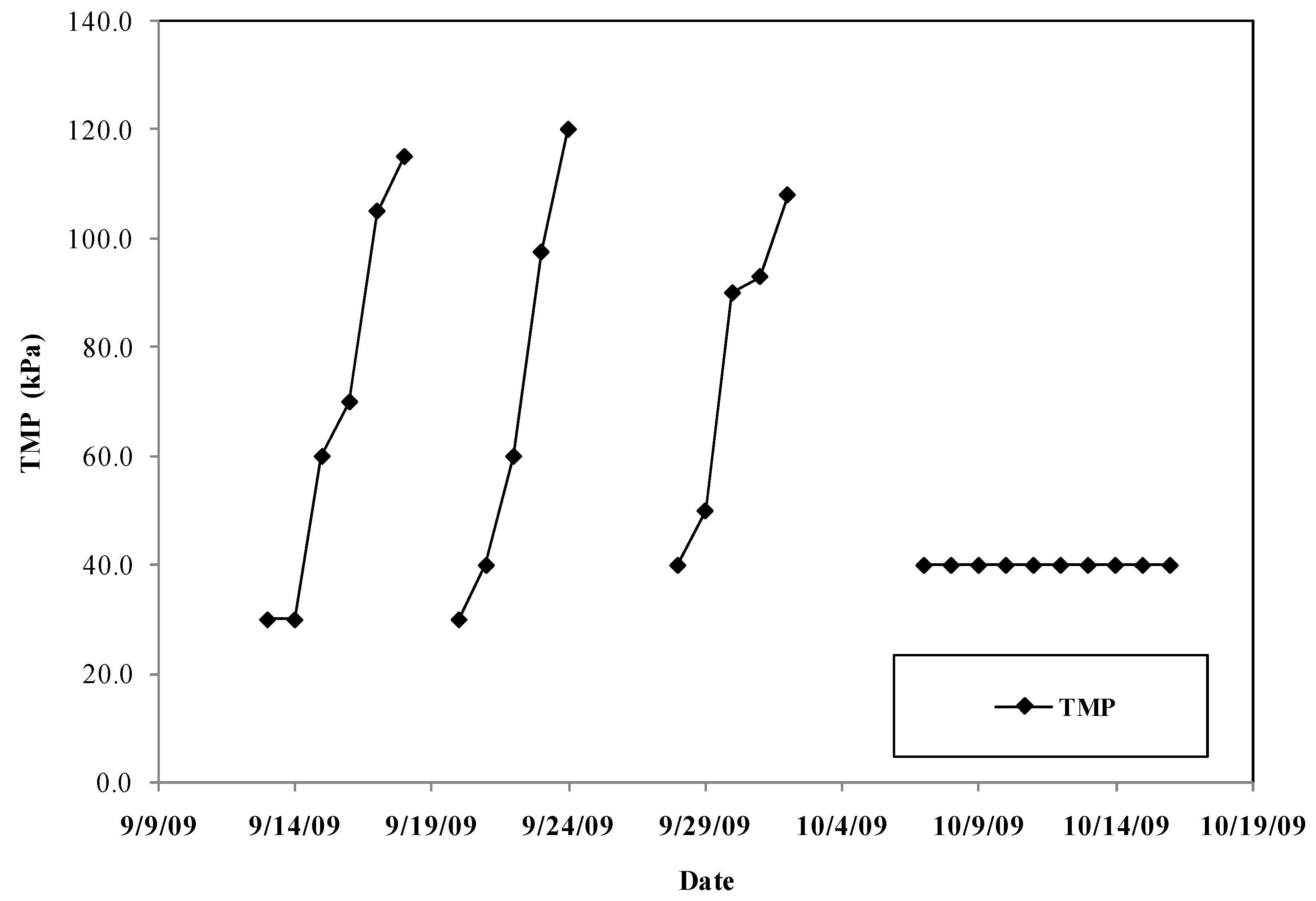

The UF process cycle performance in both experimental phases was assessed by monitoring TMP and MP. The variation of TMP and MP over time is shown in

Figure 2 and

Figure 3, respectively.

Figure 2.

Variation of the daily average TMP data over time calculated according to equation (2).

Figure 2.

Variation of the daily average TMP data over time calculated according to equation (2).

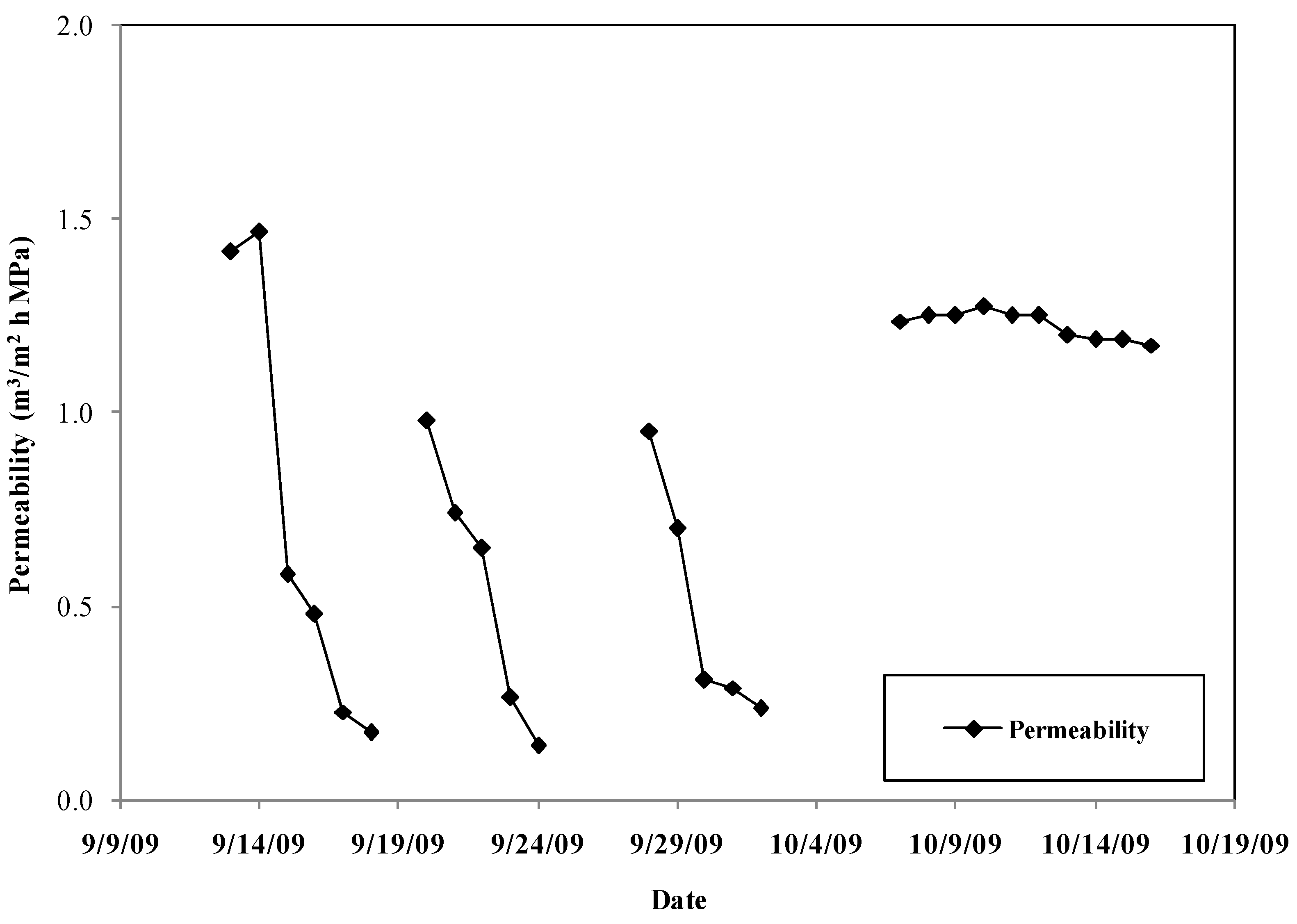

Figure 3.

Variation of the daily average MP data over time calculated according to equation (3).

Figure 3.

Variation of the daily average MP data over time calculated according to equation (3).

During the SOC phase, the TMP rapidly increased and the maximum TMP value (120 kPa) was achieved within five days of operation. Therefore, the pilot plant was stopped and the chemical cleaning procedure was applied. After each chemical cleaning, the TMP recovered to the initial value showing that the chemical cleaning successfully restored the initial cleaned membrane surface condition. In the COC phase, the TMP remained constant during the whole production time. With such conditions, the overall UF membrane operation period was nine days. Then the pilot plant was stopped even if the TMP data indicated that the UF pilot plant could continue to work indefinitely.

Since the SSE characteristics were constant during the experiment (see

Table 2), such a difference in the TMP variation over time between the two phases can be explained by the different backwash efficacy achieved in the SOC and COC phase, respectively.

The increase in TMP over time in the SOC phase could be associated with the limited solids removal obtained during the backwash period. Coherently, once the backwashing flow rate was increased in the COC phase, the backwash period was more effective in removing the particulate matter deposited on the membrane surface (and consequently the TMP was constant). The particulate matter term generally refers to the aggregation of suspended solids and natural organic matter initially present in the SSE that remains blocked on the membrane surface. Since bacterial attachment to surfaces has been demonstrated in a wide variety of environments [

15], such particulate matter could include also the presence of attached organisms hidden in particles.

The ineffectiveness of the backwash period in SOC to remove all particulate matter deposited on the membrane surface accelerated the progressive fouling phenomenon over time. This is confirmed by the variation in MP over time for the SOC phase as shown in

Figure 3. As more and more particulate matter accumulated on the membrane surface during the production period, the MP of the UF membrane also reduced. Because of the progressive particulate matter deposition, the pore size became more and more plugged during the SOC phase. On the contrary, the MP slightly decreased during the COC phase. Therefore, a minor plugging of the membrane pores can be hypothesized.

Cheryan [

16] reported that membrane fouling is caused by deposition and accumulation of particulate matter on the membrane surface and/or within the membrane pores. Ahn

et al. [

17] described the three deposition and accumulation mechanisms on the basis of fouling formation: gel/cake formation, pore plugging and pore narrowing. Gel/cake formation occurs when a large amount of matter accumulates on the surface due to size exclusion from the pores. Pore plugging occurs when particulate matter becomes stuck within the pores of the membrane. Pore narrowing consists of solid material attached to the interior surface of the pores.

Although the impossibility of performing particle size distribution of membrane foulants prevented a univocal definition of the fouling mechanism in the investigated conditions, the TMP and MP behaviors shown in

Figure 2 and

Figure 3 are quite similar to those that Bourgeous

et al. [

6] found during the ultrafiltration of a filtered primary effluent with a well known particle size distribution. In particular, the rapid TMP increase and the contemporary MP decrease are mainly due to the attachment of particulate matter inside the pores that caused a large resistance to flow. Therefore, it is believed that the SSE also contained large amounts of molecules with sizes similar to, or smaller than the membrane pores (approximately 0.01 µm).

Accordingly, the pore plugging and pore narrowing seem to play the key role in the deposition and accumulation mechanism taking place in our investigation. On the contrary, the gel/cake formation has only a minor contribution to the overall membrane fouling mechanism. Therefore, the effect of the poor backwashing flow rate applied during the SOC phase was to induce and promote a fouling mechanism on membrane surfaces mainly characterized by pore plugging and/or pore narrowing.

In the COC phase, TMP and MP remained constant, as shown in

Figure 2 and

Figure 3, respectively. Due to the effectiveness of the backwash period, no cumulative fouling (resulting in increasing TMP and decreasing MP) occurred over time. Furthermore, there was no indication that this performance would not have continued indefinitely. As a consequence, only a small amount of gel/cake formation was hypothesized to have occurred under the investigated conditions and the backwash period was extremely effective at removing all the matter accumulated on the membrane surface, consequently preventing both pore plugging and pore narrowing.

The above results also underlined that, regardless of the UF operating conditions, the free chlorine concentration (100 mg/L) used to prevent the gel/cake biofouling might be reduced. This is relevant because reducing sodium hypochlorite dosage makes the UF membrane application more economically attractive.

3.3. Stressed Operating Conditions versus Conventional Ones: Effect on Wastewater Physicochemical Parameters

Besides the above UF system key parameter analysis, the UF performance in both the SOC and COC phase was also assessed by taking into consideration the impact of the membrane treatment on the physicochemical characteristics of the UF inlet and UF outlet samples.

Table 3 summarizes the turbidity, COD and TSS average values measured on the UF permeate samples collected during the SOC and COC phases.

Table 3.

UF permeate wastewater characteristics during the SOC and COC phases.

Table 3.

UF permeate wastewater characteristics during the SOC and COC phases.

| Parameter | Unit of measurement | Min | Max | Average |

|---|

| Turbidity | NTU a | <0.2 |

| Total Suspended Solids (TSS) | mg/L | <0.2 |

| Chemical Oxygen Demand (COD) | mg/L | 20 | 60 | 36 |

Turbidity and TSS determinations were always below the detection limits, in agreement with previous research results [

6,

18]. The complete removal of TSS occurred since the pore size of the UF membrane (

i.e., 0.01 µm) was approximately one-and-a-half orders of magnitude smaller than the filter used to perform the TSS test (

i.e., 0.45 µm). As particles generally increase the turbidity of water [

19], turbidity values below the detection limit suggests that particles smaller than 0.45 µm were also removed.

Therefore, the size-cut operated by the UF membranes effectively removed the TSS initially present in the feed water and such size-cut was independent of the specific phase investigated (i.e., the SOC or COC phase). Consequently, the TSS removal effectiveness was not affected by the specific fouling condition established on the membrane surface during the operation.

With regard to the COD parameter, the average percentage of removal achieved was 30% and this result was analogous in both the SOC and COC phase. Indeed, the organic compounds (

i.e., simple organic molecules) with molecular weights smaller than the membrane pore size easily permeate the membrane. As highlighted in similar experiences, such organic compounds are normally found in secondary settled effluent [

6,

18]. Therefore, the COD removed is the fraction associated with TSS that remains blocked on the membrane surface.

Different from the above parameters, the schedule of the microbial samplings was developed in order to take into consideration the progressive membrane fouling described above. Accordingly, in agreement with the TMP and MP variation with time, shown in

Figure 2 and

Figure 3, respectively, the sampling days were as follows:

- -

for each one of the three trials carried out in the SOC phase, the day after the first pilot plant working-day and the day immediately before the pilot plant shut down

- -

for the unique trial in the COC phase, the day after the first pilot plant working-day and then every four days

Thus,

E. coli and total coliforms analyses were performed on the two samples taken for the UF inlet and UF outlet.

Table 4 summarizes the

E. coli and total coliforms microbial densities measured during the SOC and COC phase.

Table 4.

E. coli and total coliforms microbial densities measured for the UF inlet and UF outlet samples during the SOC and COC phase.

Table 4.

E. coli and total coliforms microbial densities measured for the UF inlet and UF outlet samples during the SOC and COC phase.

| | | Phase (sampling date) |

|---|

| | | SOC | COC |

| Parameter | (9/14/09) | (9/17/09) | (9/21/09) | (9/23/09) | (9/29/09) | (10/1/09) | (10/8/09) | (12/8/09) | (10/16/09) |

| UF inlet | E. coli | CFU/100 mL | 8,600 | 15,400 | 36,000 | 25,000 | 10,000 | 26,000 | 3,000 | 17,000 | 12,000 |

| Total coliforms | CFU/100 mL | 9,100 | 40,500 | 96,000 | 40,000 | 15,000 | 48,000 | 18,000 | 9,500 | 24,000 |

| UF outlet | E. coli | CFU/100 mL | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Total coliforms | CFU/100 mL | 0 | 7 | 0 | 8 | 0 | 0 | 0 | 0 | 0 |

When the pilot plant worked in the SOC phase, E. coli were always completely removed from the feed water. On the contrary, total coliforms were completely removed from all samples taken the day after the first working pilot day, while positive results were found in two of the three samples taken the day before the pilot plant shutdown.

When the pilot plan worked in the COC phase, no positive microbial density was measured for both microbial indicators and for all samples taken.

As the membrane pore size (0.01 µm) in a 200,000 molecular weight cutoff membrane is much smaller than the coliform bacteria, the membrane should block the coli-species. Therefore, a positive result was not expected in any experimental condition and for both investigated microbial indicators.

One can theorize that a well maintained UF system without membrane defects or equipment leakage should prevent passage of bacteria. However, the experimental conditions seem to exclude membrane damage or equipment leakages. Indeed, in the presence of any of such issues, the positive results for the microbial densities should be recurrent for every sample taken, independent of the specific experimental phase. Similarly, an accidental sample contamination is unlikely as the positive microbial density results are not randomly distributed with respect to the sampling day or the microbial indicator considered.

Indeed, the total coliforms positive results were measured in the SOC phase and, specifically, the day immediately before the pilot plant shut down. As shown in

Figure 2 and

Figure 3, UF membranes were working in extremely severe process conditions characterized by TMP close to its threshold and low MP due to the heavy pore occlusion. On the contrary, no positive coliform count was measured during COC, generally characterized by lower and constant TMP and MP.

An explanation of such sporadic total coliform counts could be due to isolated pore micro enlargements under the more severe UF membrane working conditions. Indeed, the majority of the membrane pores are blocked and the measured TMP is close to its manufacturing threshold. Under such stressed conditions, it was hypothesized that the TMP on the membrane surface can locally achieve values even higher than that measured. Accordingly, the permeation of the smaller coli-species could be locally possible as a consequence of membrane pore enlargements resulting from such high pressure. The consistent measurements of TSS below the detection limits (

i.e., 0.45 µm) highlights the little importance (

i.e., micro) of pore enlargements that preclude particles passing the UF membrane while only the smallest bacteria are able to permeate. Other authors also reported the presence of species related to the group of coliform microorganisms (i.e

Aeromonas hydrophila and

Pseudomonas) in permeate samples of well-maintained UF systems [

6,

7]. Further research is in progress in order to definitively clear the cause(s) of microbial contaminations.

3.4. Stressed Operating Conditions versus Conventional Ones: Effect on Agriculture Wastewater Reuse Regulations

As reported in

Table 2, the SSE was not in compliance with

E. coli MAC established by the Italian agriculture wastewater reuse regulation while total coliforms and turbidity were higher than the standards set by the State of California for unrestricted agriculture wastewater reuse.

Regardless of working conditions (

i.e., SOC or COC), the initial

E. coli population was completely removed (see

Table 4). Therefore, UF membranes proved to be a reliable technology to achieve the Italian agriculture wastewater reuse standards.

If the UF system worked in COC, total coliforms were always below the related standard established by the State of California. As the UF membranes represented an effective barrier to the overall particulate matter (see

Table 3), turbidity was also lowered under the target. Finally, the membrane blocked the organic content associated with the particulate matter, consequently lowering the biological oxygen demand (BOD) of the UF permeate. Therefore, the UF system produced an effluent equivalent to those of an oxidized, coagulated, clarified, and filtered wastewater as per Title 22.

When the UF system worked in SOC, the total coliform counts in the permeate could be higher than the related standard established by the State of California, while turbidity always remained under the MAC. Therefore, operators of wastewater facilities should prudentially avoid working the UF system under too severe conditions. In particular, in order to identify and differentiate between SOC and COC, the operators should carefully monitor the TMP value achieved during the production period. Before achieving the maximum TMP value as per manufacturer instructions, a stronger backwash period or membrane chemical cleaning should be applied so that membrane operators can prevent functioning under “stressed” membranes.

Finally, the above results confirm that the UF membranes cannot be considered a complete barrier to pathogens. As a consequence, the integration of the UF system in an overall disinfection strategy based on a multibarrier disinfection approach and long-term residual disinfection strategy should be taken in consideration.