Advances and Prospects of Modified Activated Carbon-Based Slow Sand Filtration for Microplastic Removal

Abstract

1. Introduction

2. Environmental Behavior and Removal Demand of MPs

2.1. Sources and Distribution Characteristics of MPs

2.2. Environmental Transport and Behavioral Mechanisms of MPs

2.3. Ecological and Human Health Risks of MPs

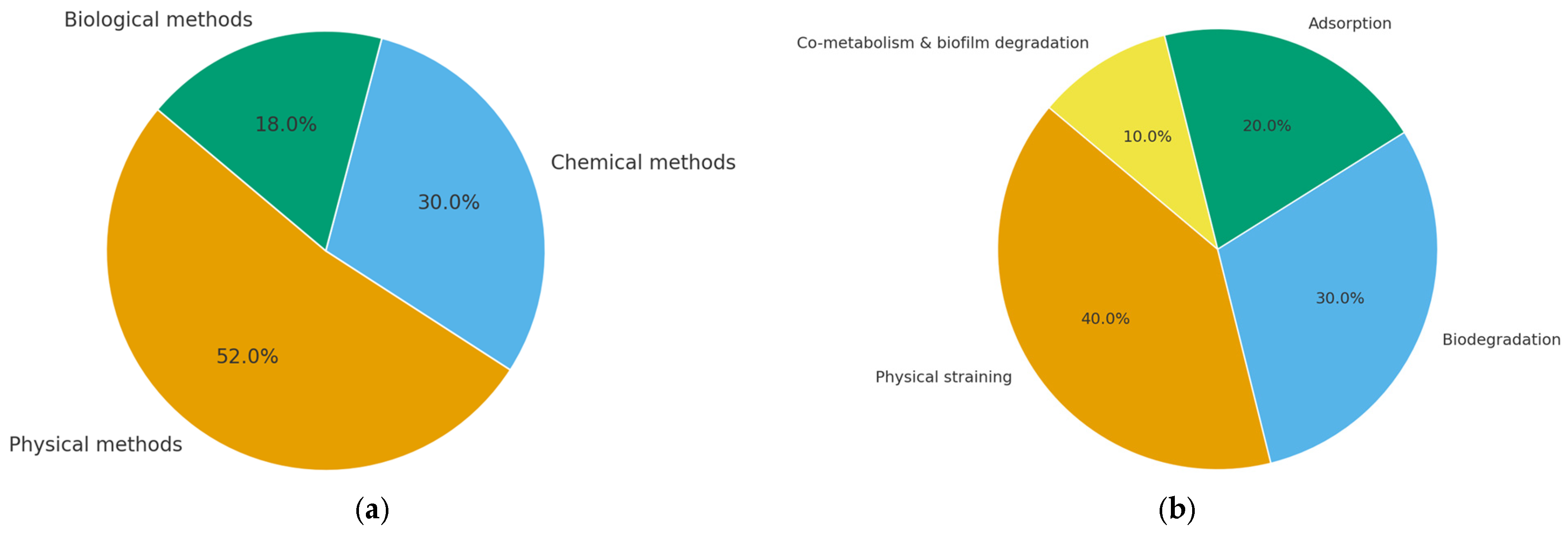

2.4. Current Removal Status and Limitations of Wastewater and Drinking Water Treatment Processes

2.5. Technical Requirements for Microplastic Removal and the Potential of SSF

3. Structure and Pollutant Removal Mechanisms of SSF Systems

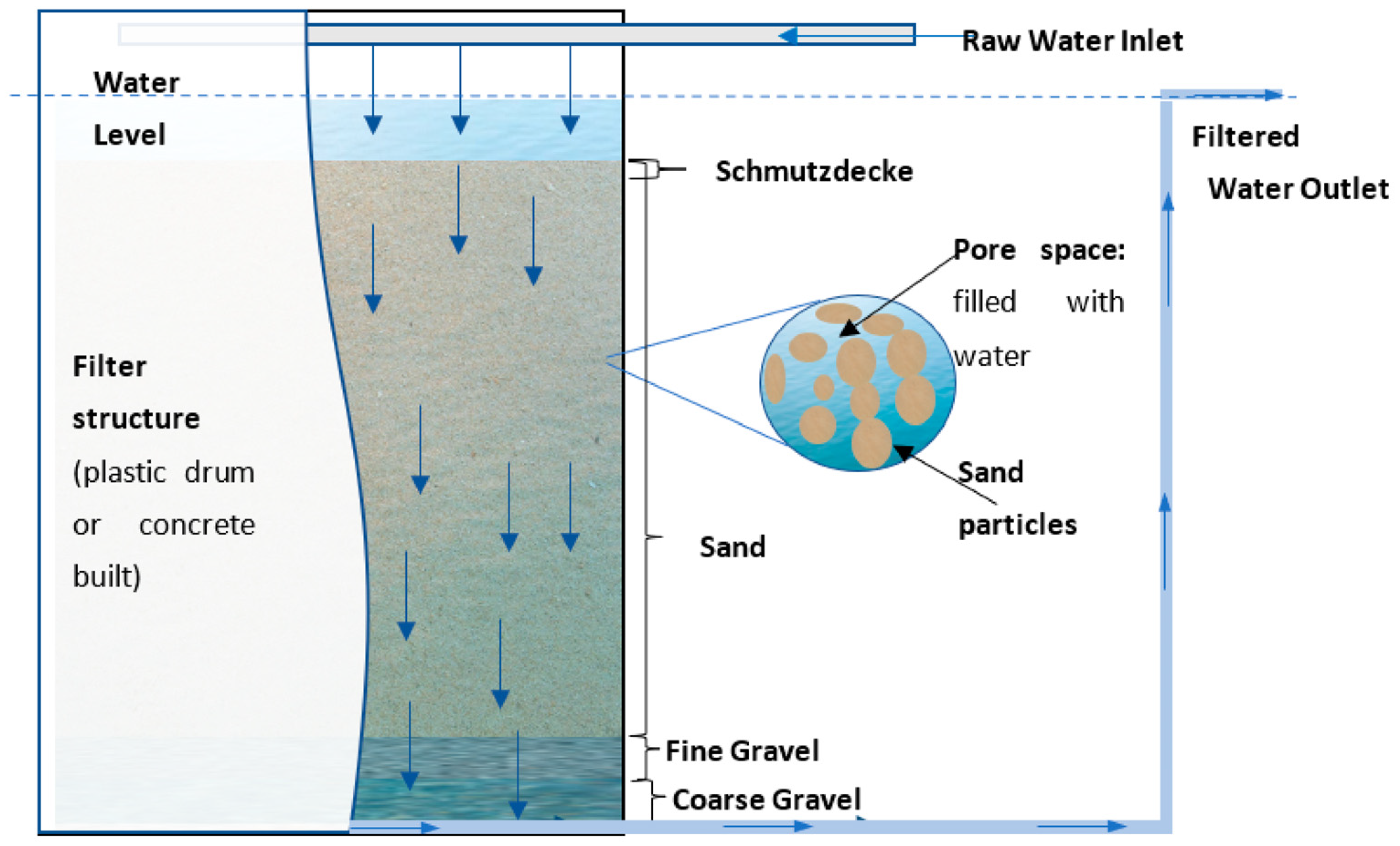

3.1. Structure and Operating Principles

3.2. Pollutant Removal Mechanisms and Influencing Factors

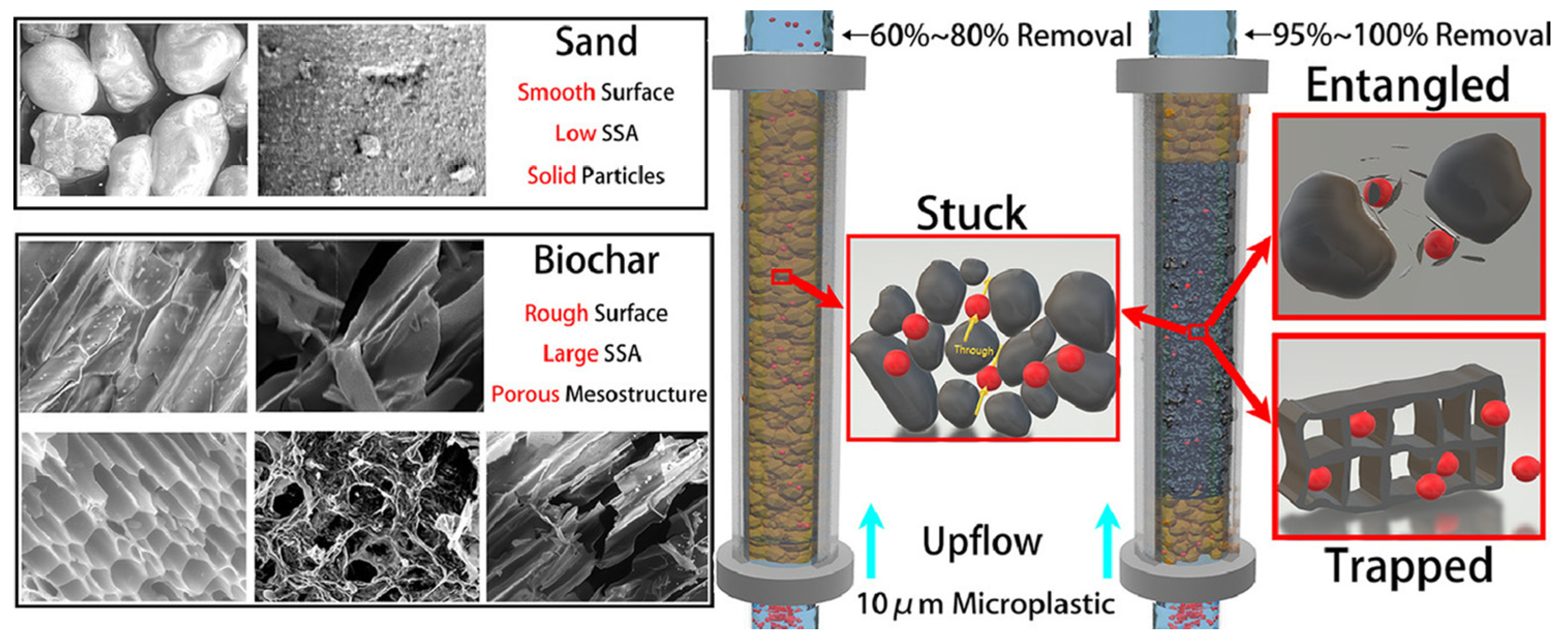

3.2.1. Physical Straining

3.2.2. Biodegradation

3.2.3. Adsorption

3.2.4. Co-Metabolism and Biofilm-Associated Degradation

3.3. Removal Potential and Challenges of SSF for MPs

4. Preparation and Adsorption Mechanisms of MAC

4.1. Structural Characteristics and Adsorption Fundamentals of AC

4.2. Preparation and Structural Regulation of MAC

4.2.1. Chemical Activation

4.2.2. Magnetic and Composite Modification

4.2.3. Bio-Based and Low-Carbon Synthesis Routes

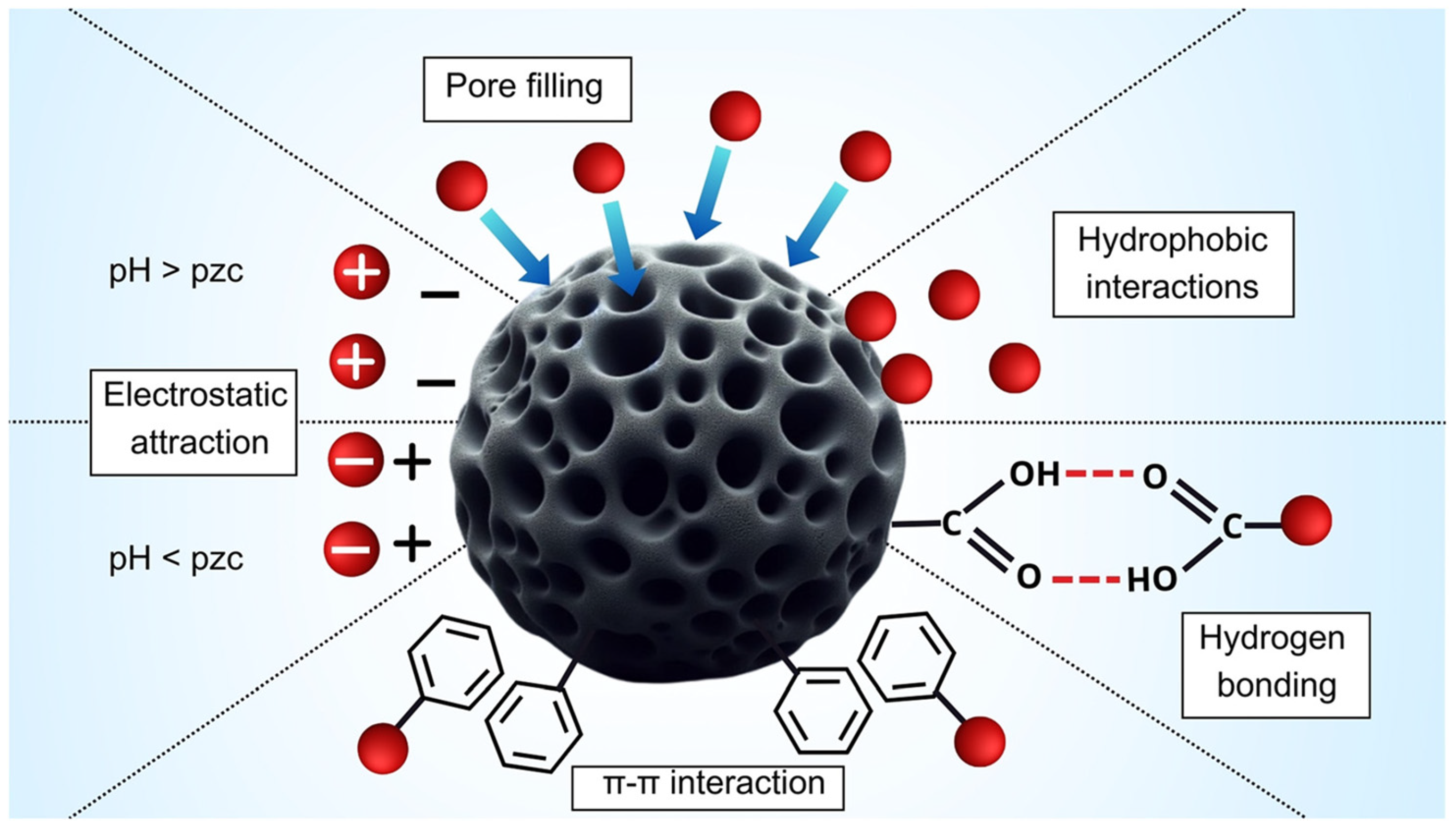

4.3. Adsorption Mechanisms of MAC

4.3.1. Physical Confinement and Pore Trapping

4.3.2. Hydrophobic Interaction and π–π Stacking

4.3.3. Electrostatic Adsorption and Hydrogen Bonding

4.3.4. Biofilm-Assisted Adsorption and Degradation

4.4. Adsorption Kinetics and Model Analysis

4.5. Reusability and Recovery of MAC

5. MAC-Enhanced SSF for MP Removal: Progress and Prospects

5.1. Development of the Design Concept and Synergistic Mechanisms of MAC–SSF Systems

- Mixed filter layer configuration: The MAC granules were mixed with filter sand in this configuration, and the specific surface area and porosity were increased to make MAC–SSF systems play the dual role of physical straining and deep adsorption [121].

- Pre-activated carbon layer configuration: A thin activated carbon layer (about 5 cm) was placed above the sand layer. The preferential adsorption of MPs and natural organic matter (NOM) by activated carbon could decrease the biofilm load and extend the operation stability [120].

- Post-activated carbon segment configuration: A granular activated carbon (GAC) unit was installed after the sand filter as a polishing section to remove residual MPs and biodegradable organics [46].

5.2. Advances in Experimental and Pilot-Scale Studies

5.3. Technical and Economic Challenges in Engineering Applications

6. Research Prospects and Future Directions

- Material development and sustainability. The cost of AC (and its environmental footprint) limits the large-scale use of MAC–SSF. The use of bio-based activated carbons from agricultural and forestry residues is the hope of the future, based on the assumption that carbonization and activation parameters can be adjusted to reflect reproducible pore structures and surface functions. Modification strategies that are environmentally friendly with low energy and chemical consumption need to be given priority to enhance overall sustainability.

- Interfacial and bio-physical mechanisms. The capture and retention of MPs are governed by coupled interfacial adsorption and biofilm-mediated processes. Behavior in adsorption is dependent on the properties of the polymer, surface aging, and surface heterogeneity of carbon, and biofilm formation has a significant impact on the stability of the system in the long term. Molecular simulations should be used in conjunction with in situ characterization and microbial ecological analysis to develop integrated studies on specific dominant binding interactions and bio-physical synergies in the presence of realistic operating conditions.

- Life-cycle assessment (LCA) and regeneration. LCA is essential for evaluating the environmental performance of MAC–SSF at the engineering scale. Energy consumption, carbon emissions, material usage, and regeneration efficiency should be quantitatively assessed. Special consideration should be paid to the destiny of retained MPs in the process of activated carbon regeneration and disposal to reduce secondary pollution.

- System integration and multi-pollutant removal. In real-life water treatment conditions, the MAC-SSF systems need to be subjected to multifaceted mixtures of MPs, heavy metals, and organic pollution. The combination of MAC–SSF and other techniques, including catalytic oxidation or multifunctional adsorption media, can help to improve the treatment capacity and increase the application of the technology in water reuse, groundwater recharge, and advanced drinking water treatment.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MPS | Microplastics |

| NPS | Nanoplastics |

| SSF | Slow Sand Filtration |

| AC | Activated Carbon |

| MAC | Modified Activated Carbon |

| POPs | Persistent Organic Pollutants |

| WWTP(s) | Wastewater Treatment Plant(s) |

| PE | Polyethylene |

| PP | Polypropylene |

| PET | Polyethylene Terephthalate |

| PS | Polystyrene |

| PA | Polyamide (commonly known as Nylon) |

| PVC | Polyvinyl Chloride |

| COD | Chemical Oxygen Demand |

| DOM | Dissolved Organic Matter |

| HMs | Heavy Metals |

| PZC | Point of zero charge |

| PCBs | Polychlorinated Biphenyls |

| HRT | Hydraulic Retention Time |

| EPS | Extracellular Polymeric Substances |

| MBR | Membrane Bioreactor |

| CTAB | Cetyltrimethylammonium Bromide |

| NOM | Natural Organic Matter |

| GAC | Granular Activated Carbon |

| HAC | Hardwood-based Activated Carbon |

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Mason, S.A.; Welch, V.G.; Neratko, J. Synthetic Polymer Contamination in Bottled Water. Front. Chem. 2018, 6, 407. [Google Scholar] [CrossRef] [PubMed]

- Mintenig, S.M.; Löder, M.G.J.; Primpke, S.; Gerdts, G. Low numbers of microplastics detected in drinking water from ground water sources. Sci. Total Environ. 2019, 648, 631–635. [Google Scholar] [CrossRef]

- Choi, D.; Jung, S.; Lee, J.; Kwon, E.E. Analysis of microplastics distributed in the environment: Case studies in South Korea. Energy Environ. 2024, 36, 3941–3963. [Google Scholar] [CrossRef]

- Rai, P.K.; Lee, J.; Brown, R.J.C.; Kim, K.-H. Micro– and nano–plastic pollution: Behavior, microbial ecology, remediation technologies. J. Clean. Prod. 2021, 291, 125240. [Google Scholar] [CrossRef]

- Rai, P.K.; Lee, J.; Brown, R.J.C.; Kim, K.-H. Environmental fate, ecotoxicity biomarkers, and potential health effects of micro– and nano–scale plastic contamination. J. Hazard. Mater. 2021, 403, 123910. [Google Scholar] [CrossRef]

- Pitt, J.A.; Trevisan, R.; Massarsky, A.; Kozal, J.S.; Levin, E.D.; Di Giulio, R.T. Maternal transfer of nanoplastics to offspring in zebrafish (Danio rerio): A case study with nanopolystyrene. Sci. Total Environ. 2018, 643, 324–334. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, Y.; Deng, Y.; Jiang, W.; Zhao, Y.; Geng, J.; Ding, L.; Ren, H. Uptake and Accumulation of Polystyrene Microplastics in Zebrafish (Danio rerio) and Toxic Effects in Liver. Environ. Sci. Technol. 2016, 50, 4054–4060. [Google Scholar] [CrossRef]

- Murphy, F.; Ewins, C.; Carbonnier, F.; Quinn, B. Wastewater Treatment Works (WwTW) as a Source of Microplastics in the Aquatic Environment. Environ. Sci. Technol. 2016, 50, 5800–5808. [Google Scholar] [CrossRef]

- Sol, D.; Laca, A.; Laca, A.; Díaz, M. Approaching the environmental problem of microplastics: Importance of WWTP treatments. Sci. Total Environ. 2020, 740, 140016. [Google Scholar] [CrossRef]

- Carr, S.A.; Liu, J.; Tesoro, A.G. Transport and fate of microplastic particles in wastewater treatment plants. Water Res. 2016, 91, 174–182. [Google Scholar] [CrossRef] [PubMed]

- Franco, A.A.; Arellano, J.M.; Albendín, G.; Rodríguez, R.; Quiroga, J.M.; Coello, M.D. Microplastic pollution in wastewater treatment plants in the city of Cádiz: Abundance, removal efficiency and presence in receiving water body. Sci. Total Environ. 2021, 776, 145795. [Google Scholar] [CrossRef]

- Abdiyev, K.; Azat, S.; Kuldeyev, E.; Ybyraiymkul, D.; Kabdrakhmanova, S.; Berndtsson, R.; Khalkhabai, B.; Kabdrakhmanova, A.; Sultakhan, S. Review of Slow Sand Filtration for Raw Water Treatment with Potential Application in Less–Developed Countries. Water 2023, 15, 2007. [Google Scholar] [CrossRef]

- Ma, B.; Xue, W.; Ding, Y.; Hu, C.; Liu, H.; Qu, J. Removal characteristics of microplastics by Fe–based coagulants during drinking water treatment. J. Environ. Sci. 2019, 78, 267–275. [Google Scholar] [CrossRef]

- Zhou, T.; Song, S.; Min, R.; Liu, X.; Zhang, G. Advances in chemical removal and degradation technologies for microplastics in the aquatic environment: A review. Mar. Pollut. Bull. 2024, 201, 116202. [Google Scholar] [CrossRef]

- Zhu, M.; Zhao, K.; Kang, R.; Zhang, Y.; Lu, W.; Liao, R.; Huo, J.; Sun, F.; Feng, L. Current research progress on carbon-sand filter process. Desalin. Water Treat. 2024, 320, 100750. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, X.; Gao, W.; Zhang, Y.; He, D. Removal of microplastics from water by magnetic nano–Fe3O4. Sci. Total Environ. 2022, 802, 149838. [Google Scholar] [CrossRef]

- Perren, W.; Wojtasik, A.; Cai, Q. Removal of Microbeads from Wastewater Using Electrocoagulation. ACS Omega 2018, 3, 3357–3364. [Google Scholar] [CrossRef]

- Kaetzl, K.; Lübken, M.; Nettmann, E.; Krimmler, S.; Wichern, M. Slow sand filtration of raw wastewater using biochar as an alternative filtration media. Sci. Rep. 2020, 10, 1229. [Google Scholar] [CrossRef]

- Amobonye, A.; Bhagwat, P.; Raveendran, S.; Singh, S.; Pillai, S. Environmental Impacts of Microplastics and Nanoplastics: A Current Overview. Front. Microbiol. 2021, 12, 768297. [Google Scholar] [CrossRef]

- Tun, T.Z.; Mon, E.E.; Nakata, H. Microplastics Distribution in Sediments Collected from Myanmar. Arch. Environ. Contam. Toxicol. 2024, 86, 1–12. [Google Scholar] [CrossRef]

- Anagnosti, L.; Varvaresou, A.; Pavlou, P.; Protopapa, E.; Carayanni, V. Worldwide actions against plastic pollution from microbeads and microplastics in cosmetics focusing on European policies. Has the issue been handled effectively? Mar. Pollut. Bull. 2021, 162, 111883. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Yang, F.; Singh, S. Global analysis of marine plastics and implications of control measure strategies. Front. Mar. Sci. 2023, 10, 1305091. [Google Scholar] [CrossRef]

- Sharma, S.; Basu, S.; Shetti, N.P.; Nadagouda, M.N.; Aminabhavi, T.M. Microplastics in the environment: Occurrence, perils, and eradication. Chem. Eng. J. 2021, 408, 127317. [Google Scholar] [CrossRef]

- Hu, D.; Zhang, Y.; Shen, M. Investigation on microplastic pollution of Dongting Lake and its affiliated rivers. Mar. Pollut. Bull. 2020, 160, 111555. [Google Scholar] [CrossRef]

- Mao, R.; Hu, Y.; Zhang, S.; Wu, R.; Guo, X. Microplastics in the surface water of Wuliangsuhai Lake, northern China. Sci. Total Environ. 2020, 723, 137820. [Google Scholar] [CrossRef]

- Li, X.; Bao, L.; Wei, Y.; Zhao, W.; Wang, F.; Liu, X.; Su, H.; Zhang, R. Occurrence, Bioaccumulation, and Risk Assessment of Microplastics in the Aquatic Environment: A Review. Water 2023, 15, 1768. [Google Scholar] [CrossRef]

- Besseling, E.; Wang, B.; Lürling, M.; Koelmans, A.A. Nanoplastic Affects Growth of S. obliquus and Reproduction of D. magna. Environ. Sci. Technol. 2014, 48, 12336–12343. [Google Scholar] [CrossRef]

- Pan, Z.; Guo, H.; Chen, H.; Wang, S.; Sun, X.; Zou, Q.; Zhang, Y.; Lin, H.; Cai, S.; Huang, J. Microplastics in the Northwestern Pacific: Abundance, distribution, and characteristics. Sci. Total Environ. 2019, 650, 1913–1922. [Google Scholar] [CrossRef]

- Abayomi, O.A.; Range, P.; Al–Ghouti, M.A.; Obbard, J.P.; Almeer, S.H.; Ben–Hamadou, R. Microplastics in coastal environments of the Arabian Gulf. Mar. Pollut. Bull. 2017, 124, 181–188. [Google Scholar] [CrossRef]

- Song, Y.K.; Hong, S.H.; Eo, S.; Jang, M.; Han, G.M.; Isobe, A.; Shim, W.J. Horizontal and Vertical Distribution of Microplastics in Korean Coastal Waters. Environ. Sci. Technol. 2018, 52, 12188–12197. [Google Scholar] [CrossRef] [PubMed]

- Yin, L.; Jiang, C.; Wen, X.; Du, C.; Zhong, W.; Feng, Z.; Long, Y.; Ma, Y. Microplastic Pollution in Surface Water of Urban Lakes in Changsha, China. Int. J. Environ. Res. Public Health 2019, 16, 1650. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, W.; Chen, Y.; Wang, J. Microplastics in surface waters of Dongting Lake and Hong Lake, China. Sci. Total Environ. 2018, 633, 539–545. [Google Scholar] [CrossRef] [PubMed]

- Yin, L.; Wen, X.; Huang, D.; Zhou, Z.; Xiao, R.; Du, L.; Su, H.; Wang, K.; Tian, Q.; Tang, Z.; et al. Abundance, characteristics, and distribution of microplastics in the Xiangjiang river, China. Gondwana Res. 2022, 107, 123–133. [Google Scholar] [CrossRef]

- Simon, M.; Van Alst, N.; Vollertsen, J. Quantification of microplastic mass and removal rates at wastewater treatment plants applying Focal Plane Array (FPA)–based Fourier Transform Infrared (FT–IR) imaging. Water Res. 2018, 142, 1–9. [Google Scholar] [CrossRef]

- Zhaxylykova, D.; Alibekov, A.; Lee, W. Seasonal variation and removal of microplastics in a central Asian urban wastewater treatment plant. Mar. Pollut. Bull. 2024, 205, 116597. [Google Scholar] [CrossRef]

- Estahbanati, S.; Fahrenfeld, N.L. Influence of wastewater treatment plant discharges on microplastic concentrations in surface water. Chemosphere 2016, 162, 277–284. [Google Scholar] [CrossRef]

- Kye, H.; Kim, J.; Ju, S.; Lee, J.; Lim, C.; Yoon, Y. Microplastics in water systems: A review of their impacts on the environment and their potential hazards. Heliyon 2023, 9, e14359. [Google Scholar] [CrossRef]

- Chen, Y.-N.; Rani, A.; Chiang, C.-Y.; Kim, H.; Pan, S.-Y. Monitoring, control and assessment of microplastics in bioenvironmental systems. Environ. Technol. Innov. 2023, 32, 103250. [Google Scholar] [CrossRef]

- Yin, K.; Wang, Y.; Zhao, H.; Wang, D.; Guo, M.; Mu, M.; Liu, Y.; Nie, X.; Li, B.; Li, J.; et al. A comparative review of microplastics and nanoplastics: Toxicity hazards on digestive, reproductive and nervous system. Sci. Total Environ. 2021, 774, 145758. [Google Scholar] [CrossRef]

- Leslie, H.A.; Van Velzen, M.J.M.; Brandsma, S.H.; Vethaak, A.D.; Garcia, J.J.; Lamoree, M.H. Discovery and quantification of plastic particle pollution in human blood. Environ. Int. 2022, 163, 107199. [Google Scholar] [CrossRef]

- Pitt, J.A.; Kozal, J.S.; Jayasundara, N.; Massarsky, A.; Trevisan, R.; Geitner, N.; Wiesner, M.; Levin, E.D.; Di Giulio, R.T. Uptake, tissue distribution, and toxicity of polystyrene nanoparticles in developing zebrafish (Danio rerio). Aquat. Toxicol. 2018, 194, 185–194. [Google Scholar] [CrossRef] [PubMed]

- Van Cauwenberghe, L.; Claessens, M.; Vandegehuchte, M.B.; Janssen, C.R. Microplastics are taken up by mussels (Mytilus edulis) and lugworms (Arenicola marina) living in natural habitats. Environ. Pollut. 2015, 199, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Qiu, G.; Wang, Q.; Wang, T.; Zhang, S.; Song, N.; Yang, X.; Zeng, Y.; Sun, Z.; Wu, G.; Yu, H. Microplastic risk assessment and toxicity in plants: A review. Environ. Chem. Lett. 2024, 22, 209–226. [Google Scholar] [CrossRef]

- Mattsson, K.; Johnson, E.V.; Malmendal, L.-A.; Linse, S.; Hansson, A.; Cedervall, T. Brain damage and behavioural disorders in fish induced by plastic nanoparticles delivered through the food chain. Sci. Rep. 2017, 7, 11452. [Google Scholar] [CrossRef] [PubMed]

- Wolff, S.; Weber, F.; Kerpen, J.; Winklhofer, M.; Engelhart, M.; Barkmann, L. Elimination of Microplastics by Downstream Sand Filters in Wastewater Treatment. Water 2020, 13, 33. [Google Scholar] [CrossRef]

- Shi, C.; Zhang, S.; Zhao, J.; Ma, J.; Wu, H.; Sun, H.; Cheng, S. Experimental study on removal of microplastics from aqueous solution by magnetic force effect on the magnetic sepiolite. Sep. Purif. Technol. 2022, 288, 120564. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, C.; Li, F.; Chen, L. Fatigue resistance, re–usable and biodegradable sponge materials from plant protein with rapid water adsorption capacity for microplastics removal. Chem. Eng. J. 2021, 415, 129006. [Google Scholar] [CrossRef]

- Zhou, G.; Huang, X.; Xu, H.; Wang, Q.; Wang, M.; Wang, Y.; Li, Q.; Zhang, Y.; Ye, Q.; Zhang, J. Removal of polystyrene nanoplastics from water by Cu Ni carbon material: The role of adsorption. Sci. Total Environ. 2022, 820, 153190. [Google Scholar] [CrossRef]

- Subair, A.; Priya, K.L.; Chellappan, S.; A, T.R.; Hridya, J.; Devi, P.; S, M.S.; Indu, M.; Pugazhendhi, A.; Chinglenthoiba, C. Evaluating the performance of electrocoagulation system in the removal of polystyrene microplastics from water. Environ. Res. 2024, 243, 117887. [Google Scholar] [CrossRef]

- Ariza-Tarazona, M.C.; Siligardi, C.; Carreón-López, H.A.; Valdéz-Cerda, J.E.; Pozzi, P.; Kaushik, G.; Villarreal-Chiu, J.F.; Cedil-lo-González, E.I. Low environmental impact remediation of microplastics: Visible–light photocatalytic degradation of PET microplastics using bio–inspired C, N–TiO2/SiO2 photocatalysts. Mar. Pollut. Bull. 2023, 193, 115206. [Google Scholar] [CrossRef]

- Talvitie, J.; Mikola, A.; Koistinen, A.; Setälä, O. Solutions to microplastic pollution—Removal of microplastics from wastewater effluent with advanced wastewater treatment technologies. Water Res. 2017, 123, 401–407. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Liu, D.; Song, K.; Zhou, Y. Performance evaluation of MBR in treating microplastics polyvinylchloride contaminated polluted surface water. Mar. Pollut. Bull. 2020, 150, 110724. [Google Scholar] [CrossRef] [PubMed]

- Sultakhan, S.; Kunarbekova, M.; Khalkhabai, B.; Kakimov, U.; Kuldeyev, E.; Berndtsson, R.; Lee, J.; Azat, S. Performance of a Zeolite-Filled Slow Filter for Dye Removal and Turbidity Reduction. Water 2025, 17, 3557. [Google Scholar] [CrossRef]

- Yeszhan, Y.N.; Sultakhan, S.; Kuldeyev, E.; Khalkhabay, B.; Xu, Q.; Azat, S. Slow sand filtration for water treatment. In Innovative Materials for Industrial Applications: Synthesis, Characterization and Evaluation; Mabrouk, A., Bachar, A., Azat, S., Amrousse, R., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 75–96. [Google Scholar] [CrossRef]

- Guchi, E. Review on Slow Sand Filtration in Removing Microbial Contamination and Particles from Drinking Water. Am. J. Food Nutr. 2015, 3, 47–55. [Google Scholar] [CrossRef]

- Haig, S.J.; Collins, G.; Davies, R.L.; Dorea, C.C.; Quince, C. Biological aspects of slow sand filtration: Past, present and future. Water Supply 2011, 11, 468–472. [Google Scholar] [CrossRef]

- Maiyo, J.K.; Dasika, S.; Jafvert, C.T. Slow Sand Filters for the 21st Century: A Review. Int. J. Environ. Res. Public Health 2023, 20, 1019. [Google Scholar] [CrossRef]

- Bellamy, W.D.; Hendricks, D.W.; Logsdon, G.S. Slow Sand Filtration: Influences of Selected Process Variables. J. AWWA 1985, 77, 62–66. [Google Scholar] [CrossRef]

- Kubare, M.; Haarhoff, J. Rational design of domestic biosand filters. J. Water Supply Res. Technol. 2010, 59, 1–15. [Google Scholar] [CrossRef]

- Grace, M.A.; Healy, M.G.; Clifford, E. Performance and surface clogging in intermittently loaded and slow sand filters containing novel media. J. Environ. Manag. 2016, 180, 102–110. [Google Scholar] [CrossRef]

- Bai, X.; Samari–Kermani, M.; Schijven, J.; Raoof, A.; Dinkla, I.J.T.; Muyzer, G. Enhancing slow sand filtration for safe drinking water production: Interdisciplinary insights into Schmutzdecke characteristics and filtration performance in mini–scale filters. Water Res. 2024, 262, 122059. [Google Scholar] [CrossRef]

- Lubarsky, H.; Fava, N.d.M.N.; Freitas, B.L.S.; Terin, U.C.; Oliveira, M.; Lamon, A.W.; Pichel, N.; Byrne, J.A.; Sabogal-Paz, L.P.; Fernandez-Ibañez, P. Biological Layer in Household Slow Sand Filters: Characterization and Evaluation of the Impact on Systems Efficiency. Water 2022, 14, 1078. [Google Scholar] [CrossRef]

- Hijnen, W.A.M.; Schijven, J.F.; Bonné, P.; Visser, A.; Medema, G.J. Elimination of viruses, bacteria and protozoan oocysts by slow sand filtration. Water Sci. Technol. 2004, 50, 147–154. [Google Scholar] [CrossRef] [PubMed]

- Trikannad, S.A.; Van Halem, D.; Foppen, J.W.; Van Der Hoek, J. The contribution of deeper layers in slow sand filters to pathogens removal. Water Res. 2023, 237, 119994. [Google Scholar] [CrossRef] [PubMed]

- Tundia, K.R.; Ahammed, M.M.; George, D. The effect of operating parameters on the performance of a biosand filter: A statistical experiment design approach. Water Supply 2016, 16, 775–782. [Google Scholar] [CrossRef]

- Fogel, D.; Isaac-Renton, J.; Guasparini, R.; Moorehead, W.; Ongerth, J. Removing Giardia and Cryptosporidium by Slow Sand Filtration. J. AWWA 1993, 85, 77–84. [Google Scholar] [CrossRef]

- Schuler, P.F.; Ghosh, M.M.; Gopalan, P. Slow sand and diatomaceous earth filtration of cysts and other particulates. Water Res. 1991, 25, 995–1005. [Google Scholar] [CrossRef]

- Tellen, V.; Nkeng, G.; Dentel, S. Improved Filtration Technology for Pathogen Reduction in Rural Water Supplies. Water 2010, 2, 285–306. [Google Scholar] [CrossRef]

- Weber-Shirk, M.L.; Dick, R.I. Biological mechanisms in slow sand filters. J. AWWA 1997, 89, 72–83. [Google Scholar] [CrossRef]

- Campos, L.C.; Su, M.F.J.; Graham, N.J.D.; Smith, S.R. Biomass development in slow sand filters. Water Res. 2002, 36, 4543–4551. [Google Scholar] [CrossRef]

- Kennedy, T.J.; Hernandez, E.A.; Morse, A.N.; Anderson, T.A. Hydraulic Loading Rate Effect on Removal Rates in a BioSand Filter: A Pilot Study of Three Conditions. Water Air Soil Pollut. 2012, 223, 4527–4537. [Google Scholar] [CrossRef]

- Rao, S.M.; Malini, R.; Lydia, A.; Lee, Y. Contaminants removal by bentonite amended slow sand filter. J. Water Chem. Technol. 2013, 35, 23–29. [Google Scholar] [CrossRef]

- Bradley, I.; Straub, A.; Maraccini, P.; Markazi, S.; Nguyen, T.H. Iron oxide amended biosand filters for virus removal. Water Res. 2011, 45, 4501–4510. [Google Scholar] [CrossRef]

- Ahammed, M.M.; Davra, K. Performance evaluation of biosand filter modified with iron oxide–coated sand for household treatment of drinking water. Desalination 2011, 276, 287–293. [Google Scholar] [CrossRef]

- Li, J.; Zhou, Q.; Campos, L.C. The application of GAC sandwich slow sand filtration to remove pharmaceutical and personal care products. Sci. Total Environ. 2018, 635, 1182–1190. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Narihiro, T.; Straub, A.P.; Pugh, C.R.; Tamaki, H.; Moor, J.F.; Bradley, I.M.; Kamagata, Y.; Liu, W.-T.; Nguyen, T.H. MS2 Bacteriophage Reduction and Microbial Communities in Biosand Filters. Environ. Sci. Technol. 2014, 48, 6702–6709. [Google Scholar] [CrossRef]

- Nitzsche, K.S.; Weigold, P.; Lösekann–Behrens, T.; Kappler, A.; Behrens, S. Microbial community composition of a household sand filter used for arsenic, iron, and manganese removal from groundwater in Vietnam. Chemosphere 2015, 138, 47–59. [Google Scholar] [CrossRef]

- Nair, A.T.; Ahammed, M.M.; Davra, K. Influence of operating parameters on the performance of a household slow sand filter. Water Supply 2014, 14, 643–649. [Google Scholar] [CrossRef]

- De Tender, C.A.; Devriese, L.I.; Haegeman, A.; Maes, S.; Ruttink, T.; Dawyndt, P. Bacterial Community Profiling of Plastic Litter in the Belgian Part of the North Sea. Environ. Sci. Technol. 2015, 49, 9629–9638. [Google Scholar] [CrossRef]

- Napotnik, J.A.; Baker, D.; Jellison, K.L. Influence of sand depth and pause period on microbial removal in traditional and modified biosand filters. Water Res. 2021, 189, 116577. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, X.; Liu, C.; Wang, S.; Wang, X.; Hou, H.; Wang, J.; Li, H. Purification of harvested rainwater using slow sand filters with low–cost materials: Bacterial community structure and purifying effect. Sci. Total Environ. 2019, 674, 344–354. [Google Scholar] [CrossRef] [PubMed]

- Demir, N.M. Experimental Study of Factors that Affect Iron and Manganese Removal in Slow Sand Filters and Identification of Responsible Microbial Species. Pol. J. Environ. Stud. 2016, 25, 1453–1465. [Google Scholar] [CrossRef] [PubMed]

- Gupta, V.K.; Saleh, T.A. Sorption of pollutants by porous carbon, carbon nanotubes and fullerene—An overview. Environ. Sci. Pollut. Res. 2013, 20, 2828–2843. [Google Scholar] [CrossRef] [PubMed]

- Foo, K.Y.; Hameed, B.H. Insights into the modeling of adsorption isotherm systems. Chem. Eng. J. 2010, 156, 2–10. [Google Scholar] [CrossRef]

- Tan, X.; Liu, Y.; Zeng, G.; Wang, X.; Hu, X.; Gu, Y.; Yang, Z. Application of biochar for the removal of pollutants from aqueous solutions. Chemosphere 2015, 125, 70–85. [Google Scholar] [CrossRef] [PubMed]

- Hu, M.; Wu, W.; Lin, D.; Yang, K. Adsorption of fulvic acid on mesopore–rich activated carbon with high surface area. Sci. Total Environ. 2022, 838, 155918. [Google Scholar] [CrossRef]

- Wang, Z.; Sedighi, M.; Lea–Langton, A. Filtration of microplastic spheres by biochar: Removal efficiency and immobilisation mechanisms. Water Res. 2020, 184, 116165. [Google Scholar] [CrossRef]

- Li, Z.; Gao, X.; Wu, L.; Wang, K.; Kobayashi, N. Preparation of activated carbons from poplar wood by chemical activation with KOH. J. Porous Mater. 2017, 24, 193–202. [Google Scholar] [CrossRef]

- Panwar, N.L.; Pawar, A. Influence of activation conditions on the physicochemical properties of activated biochar: A review. Biomass Conv. Bioref. 2022, 12, 925–947. [Google Scholar] [CrossRef]

- Figueiredo, J.L.; Pereira, M.F.R.; Freitas, M.M.A.; Órfão, J.J.M. Modification of the surface chemistry of activated carbons. Carbon 1999, 37, 1379–1389. [Google Scholar] [CrossRef]

- Magid, A.S.I.A.; Islam, S.; Chen, Y.; Weng, L.; Li, J.; Ma, J.; Li, Y. Enhanced adsorption of polystyrene nanoplastics (PSNPs) onto oxidized corncob biochar with high pyrolysis temperature. Sci. Total Environ. 2021, 784, 147115. [Google Scholar] [CrossRef] [PubMed]

- Xing, X.; Zhang, Y.; Zhou, G.; Zhang, Y.; Yue, J.; Wang, X.; Yang, Z.; Chen, J.; Wang, Q.; Zhang, J. Mechanisms of polystyrene nanoplastics adsorption onto activated carbon modified by ZnCl2. Sci. Total Environ. 2023, 876, 162763. [Google Scholar] [CrossRef]

- Wu, J.; Yang, C.; Zhao, H.; Shi, J.; Liu, Z.; Li, C.; Song, F. Efficient removal of microplastics from aqueous solution by a novel magnetic biochar: Performance, mechanism, and reusability. Environ. Sci. Pollut. Res. 2022, 30, 26914–26928. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Zhang, S.; Su, Y.; Wu, D.; Zhao, Y.; Xie, B. Removal of microplastics from aqueous solutions by magnetic carbon nanotubes. Chem. Eng. J. 2021, 406, 126804. [Google Scholar] [CrossRef]

- Shi, Y.; Du, J.; Zhao, T.; Feng, B.; Bian, H.; Shan, S.; Meng, J.; Christie, P.; Wong, M.H.; Zhang, J. Removal of nanoplastics from aqueous solution by aggregation using reusable magnetic biochar modified with cetyltrimethylammonium bromide. Environ. Pollut. 2023, 318, 120897. [Google Scholar] [CrossRef]

- Zhou, X.; Zhu, Y.; Niu, Q.; Zeng, G.; Lai, C.; Liu, S.; Huang, D.; Qin, L.; Liu, X.; Li, B.; et al. New notion of biochar: A review on the mechanism of biochar applications in advannced oxidation processes. Chem. Eng. J. 2021, 416, 129027. [Google Scholar] [CrossRef]

- Feng, P.; Li, J.; Wang, H.; Xu, Z. Biomass-Based Activated Carbon and Activators: Preparation Activated Carbon from Corncob by Chemical Activation with Biomass Liquids. ACS Omega 2020, 5, 24064. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, N.; Lei, S.; Yan, R.; Tian, X.; Wang, J.; Song, Y.; Xu, D.; Guo, Q.; Liu, L. Promising Biomass-Based Activated Carbons Derived from Willow Catkins for High Performance Supercapacitors. Electrochim. Acta 2015, 166, 1–11. [Google Scholar] [CrossRef]

- Klass, D.L. Energy Consumption, Reserves, Depletion, and Environmental Issues. In Biomass for Renewable Energy, Fuels, and Chemicals; Academic Press: San Diego, CA, USA, 1998; pp. 1–27. [Google Scholar]

- Ahmad, M.; Lubis, N.M.A.; Usama, M.; Ahmad, J.; Al-Wabel, M.I.; Al-Swadi, H.A.; Rafique, M.I.; Al-Farraj, A.S.F. Scavenging microplastics and heavy metals from water using jujube waste–derived biochar in fixed–bed column trials. Environ. Pollut. 2023, 335, 122319. [Google Scholar] [CrossRef]

- Zhao, H.; Huang, X.; Wang, L.; Zhao, X.; Yan, F.; Yang, Y.; Li, G.; Gao, P.; Ji, P. Removal of polystyrene nanoplastics from aqueous solutions using a novel magnetic material: Adsorbability, mechanism, and reusability. Chem. Eng. J. 2022, 430, 133122. [Google Scholar] [CrossRef]

- Yong, J.B.; Tan, L.S.; Tan, J. Comparative Life Cycle Assessment of Biomass-Based and Coal-Based Activated Carbon Production. Progress. Energy Environ. 2022, 20, 1–15. [Google Scholar] [CrossRef]

- Amstaetter, K.; Eek, E.; Cornelissen, G. Sorption of PAHs and PCBs to Activated Carbon: Coal versus Biomass-Based Quality. Chemosphere 2012, 87, 573–578. [Google Scholar] [CrossRef] [PubMed]

- Ekinci, E.; Budinova, T.; Yardim, F.; Petrov, N.; Razvigorova, M.; Minkova, V. Removal of Mercury Ion from Aqueous Solution by Activated Carbons Obtained from Biomass and Coals. Fuel Process Technol. 2002, 77–78, 437–443. [Google Scholar] [CrossRef]

- Mota, L.S.O.; De Oliveira, P.C.O.; Peixoto, B.S.; Bezerra, E.S.; De Moraes, M.C. Biochar applications in microplastic and nanoplastic removal: Mechanisms and integrated approaches. Environ. Sci. Water Res. Technol. 2024, 11, 222–241. [Google Scholar] [CrossRef]

- Hüffer, T.; Hofmann, T. Sorption of non–polar organic compounds by micro–sized plastic particles in aqueous solution. Environ. Pollut. 2016, 214, 194–201. [Google Scholar] [CrossRef]

- Mustafa, D.; Ibrahim, B.; Erten, A. Adsorptive removal of anticarcinogen pazopanib from aqueous solutions using activated carbon: Isotherm, kinetic and thermodynamic studies. Sci. Rep. 2024, 14, 17765. [Google Scholar] [CrossRef]

- Zhang, P.; Duan, W.; Peng, H.; Pan, B.; Xing, B. Functional Biochar and Its Balanced Design. ACS Environ. Au 2022, 2, 115–127. [Google Scholar] [CrossRef]

- Rasoolzadeh, R.; Baptista, L.; Vajedi, F.S.; Nikoofard, V. Molecular Insights into the Binding and Conformational Changes of Hepcidin25 Blood Peptide with 4-Aminoantipyrine and Their Sorption Mechanism by Carboxylic-Functionalized Multiwalled Carbon Nanotubes: A Comprehensive Spectral Analysis and Molecular Dynamics Simulation Study. ACS Omega 2024, 9, 35821–35836. [Google Scholar] [CrossRef]

- Ho, Y.S.; McKay, G. Pseudo–second order model for sorption processes. Process Biochem. 1999, 34, 451–465. [Google Scholar] [CrossRef]

- Tran, H.N.; You, S.J.; Hosseini-Bandegharaei, A.; Chao, H.P. Mistakes and inconsistencies regarding adsorption of contaminants from aqueous solutions: A critical review. Water Res. 2017, 120, 88–116. [Google Scholar] [CrossRef]

- Chu, K.H.; Hashim, M.A.; Zawawi, M.H.; Bollinger, J.-C. The Weber–Morris model in water contaminant adsorption: Shattering long-standing misconceptions. J. Environ. Chem. Eng. 2025, 13, 117266. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, Z.; Wang, J.; Liu, X.; Zhang, H.; Wang, S.; Sun, H. Revealing the combined effect of active sites and intra-particle diffusion on adsorption mechanism of methylene blue on activated red-pulp pomelo peel biochar. Molecules 2023, 28, 415. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, A.; Rakib, M.R.J.; Gupta, P.K.; Sharma, P.; Garg, A.; Girard, P.; Aminabhavi, T.M. Adsorptive behavior of micro(nano)plastics through biochar: Co–existence, consequences, and challenges in contaminated ecosystems. Sci. Total Environ. 2023, 856, 159097. [Google Scholar] [CrossRef] [PubMed]

- Mahanty, B.; Mondal, S. Synthesis of Magnetic Biochar Using Agricultural Waste for the Separation of Cr (VI) From Aqueous Solution. Arab. J. Sci. Eng. 2021, 46, 10803–10818. [Google Scholar] [CrossRef]

- Wang, J.; Sun, C.; Huang, Q.-X.; Chi, Y.; Yan, J.-H. Adsorption and thermal degradation of microplastics from aqueous solutions by Mg/Zn modified magnetic biochars. J. Hazard. Mater. 2021, 419, 126486. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, R.; Eshaq, G.; Winkler, M.K.H.; Pihlajamäki, A. Magnetic Biochar Aluminum Cross-Linked Composite Beads for Preferential Phosphate Separation from Phosphate-Rich Effluents. J. Environ. Chem. Eng. 2025, 13, 116815. [Google Scholar] [CrossRef]

- Ye, M.; Li, Z.; Wen, L.; Duan, F.; Zhang, L. Enhanced Cr (VI) Removal via Surfactant-Tailored Magnetic Functionalized-Biochar: Synergistic Alkyl Grafting and Iron Dispersion for Broad-Spectrum PH Adaptability. J. Environ. Chem. Eng. 2025, 13, 117877. [Google Scholar] [CrossRef]

- Hsieh, L.; He, L.; Zhang, M.; Lv, W.; Yang, K.; Tong, M. Addition of biochar as thin preamble layer into sand filtration columns could improve the microplastics removal from water. Water Res. 2022, 221, 118783. [Google Scholar] [CrossRef]

- Sembiring, E.; Fajar, M.; Handajani, M. Performance of rapid sand filter—single media to remove microplastics. Water Supply 2021, 21, 2273–2284. [Google Scholar] [CrossRef]

- Garfansa, M.P.; Zalizar, L.; Husen, S.; Triwanto, J.; Iswahyudi, I.; Bakhtiar, A.; Lasaksi, P.; Ekalaturrahmah, Y.A.C. Addition of biochar based–activated carbon into sand filtration columns to improved removal efficiency microplastic from water. Bioresour. Technol. Rep. 2025, 30, 102099. [Google Scholar] [CrossRef]

- Ji, G.; Xing, Y.; You, T. Biochar as adsorbents for environmental microplastics and nanoplastics removal. J. Environ. Chem. Eng. 2024, 12, 113377. [Google Scholar] [CrossRef]

- Ji, H.; Liu, Z.; Jiang, W. Transport behavior of nanoplastics in activated carbon column. Environ. Sci. Pollut. Res. 2022, 30, 26256–26269. [Google Scholar] [CrossRef] [PubMed]

- Siipola, V.; Pflugmacher, S.; Romar, H.; Wendling, L.; Koukkari, P. Low-Cost Biochar Adsorbents for Water Purification Including Microplastics Removal. Appl. Sci. 2020, 10, 788. [Google Scholar] [CrossRef]

- Velasco, A.N.; Gentile, S.R.; Zimmermann, S.; Le Coustumer, P.; Stoll, S. Contamination and removal efficiency of microplastics and synthetic fibres in a conventional drinking water treatment plant in Geneva, Switzerland. Sci. Total Environ. 2023, 880, 163270. [Google Scholar] [CrossRef]

- Parashar, N.; Hait, S. Cetyl trimethyl ammonium bromide–modified magnetic biochar–integrated sand filter for microplastics removal from secondary–treated sewage effluents: Performance evaluation and mechanistic insights. J. Water Process Eng. 2024, 59, 105035. [Google Scholar] [CrossRef]

- Arenas, L.R.; Gentile, S.R.; Zimmermann, S.; Stoll, S. Nanoplastics adsorption and removal efficiency by granular activated carbon used in drinking water treatment process. Sci. Total Environ. 2021, 791, 148175. [Google Scholar] [CrossRef]

- Fan, M.; Li, C.; Sun, Y.; Zhang, L.; Zhang, S.; Hu, X. In situ characterization of functional groups of biochar in pyrolysis of cellulose. Sci. Total Environ. 2021, 799, 149354. [Google Scholar] [CrossRef]

- Cao, B.; Zheng, Y.; Esakkimuthu, S.; Jiang, D.; Hu, Y.; Yuan, C.; Abomohra, A.; Gong, X.; Wang, S. Catalytic pyrolysis of wood dust for monophenol over macroalgal biochar–based catalyst: Effects of activation agents and atmospheres during catalyst synthesis on its performance. Algal Res. 2024, 80, 103544. [Google Scholar] [CrossRef]

- Li, J.; Chen, X.; Yu, S.; Cui, M. Removal of pristine and aged microplastics from water by magnetic biochar: Adsorption and magnetization. Sci. Total Environ. 2023, 875, 162647. [Google Scholar] [CrossRef]

- Li, X.; Liu, W.; Zhang, J.; Wang, Z.; Guo, Z.; Ali, J.; Wang, L.; Yu, Z.; Zhang, X.; Sun, Y. Effective removal of microplastics by filamentous algae and its magnetic biochar: Performance and mechanism. Chemosphere 2024, 358, 142152. [Google Scholar] [CrossRef]

- Subair, A.; Lakshmi, P.K.; Chellappan, S.; Chinghakham, C. Removal of polystyrene microplastics using biochar–based continuous flow fixed–bed column. Env. Sci. Pollut. Res. 2024, 31, 13753–13765. [Google Scholar] [CrossRef]

| Area | Aquatic Environment | Microplastic Type | Concentration | Ref. |

|---|---|---|---|---|

| Northwest Pacific | Seawater | Polyethylene (PE), polypropylene (PP), nylon | 640–42,000 pieces/km2 | [29] |

| Arabian Gulf | Seawater | PE, PP, polystyrene (PS) | 4.38 × 104–1.46 × 106 pieces/km2 | [30] |

| Coastal South Korea | Seawater | PE, PP, PS | 394–1051 pieces/m3 | [31] |

| Changsha, China | Surface water | Polyamide (PA), PP, PS, PE, polyvinyl chloride (PVC), polyethylene terephthalate (PET) | 2425–7050 pieces/m3 | [32] |

| Dongting Lake, China | Surface water | PE, PP, PS | 900–2800 pieces/m3 1250–4650 pieces/m3 | [33] |

| Xiangjiang River, China | Sediment | PP, PS, PE, PVC, PET | 144,510 pieces/kg | [34] |

| Demark | Sewage treatment plant | PE, PE, PS | 19,447 pieces/L | [35] |

| America | Sewage treatment plant | PET, PP | 0.004–0.195 pieces/L | [32] |

| Astana, Kazakhstan | Sewage treatment plant | PP | 47.06–69.44 pieces/L | [36] |

| Model | Expression | Correlation Coefficient (R2) | Rate-Controlling Step/ Main Mechanism | Adsorption Characteristics and Interpretation | |

|---|---|---|---|---|---|

| Kinetic model | Pseudo-first-order model | ln(qe − qt) = lnqe − k1t | 0.95–0.99 | Chemical adsorption control | Main mechanisms: electrostatic attraction, ion exchange, and chemical bonding. |

| Pseudo-second-order model | t/qt = 1/(k2qe2) + t/qe | 0.95–0.99 | Chemical adsorption control | Adsorption rate depends on chemical interactions. | |

| Internal diffusion model | qt = kidt1/2 + C | 0.85–0.92 | Intraparticle diffusion control | Non-zero intercept indicates that both film and intraparticle diffusion contribute. | |

| Isotherm model | Langmuir model | qe = (qmKLCe)/(1 + KLCe) | 0.85–0.93 | Monolayer adsorption; homogeneous surface | Monolayer adsorption with constant energy and finite adsorption capacity. |

| Freundlich model | qe = KFCe1/n | 0.94–0.99 | Multilayer adsorption; heterogeneous surface | Multilayer adsorption; adsorption energy decreases with surface coverage. | |

| Thermodynamic analysis | Thermodynamic parameters | ΔG0 = −RT lnK, ΔH0, ΔS0 | – | Process spontaneity and thermal effect | ΔG < 0 indicates spontaneity; ΔH < 0 indicates exothermic; ΔS can be positive or negative. |

| Configuration Type | Carbon Arrangement | Main Function | Enhancement of Removal Efficiency | Ref. |

|---|---|---|---|---|

| Mixed filter layer | MAC blended with sand | Increases surface area and enables dual adsorption–filtration | 15–25% | [121] |

| Pre-carbon layer | Thin layer (~5 cm) above sand | Adsorbs MPs and NOM, reduces biofilm load | 20% | [120] |

| Post-carbon segment | GAC unit downstream of sand filter | Polishing treatment, removes escaped NPs | 30% | [46] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Qu, Z.; Zhantikeyev, U.; Kakimov, U.; Toshtay, K.; Rysbekov, K.; Yusof, N.N.B.; Berndtsson, R.; Azat, S. Advances and Prospects of Modified Activated Carbon-Based Slow Sand Filtration for Microplastic Removal. Water 2026, 18, 228. https://doi.org/10.3390/w18020228

Qu Z, Zhantikeyev U, Kakimov U, Toshtay K, Rysbekov K, Yusof NNB, Berndtsson R, Azat S. Advances and Prospects of Modified Activated Carbon-Based Slow Sand Filtration for Microplastic Removal. Water. 2026; 18(2):228. https://doi.org/10.3390/w18020228

Chicago/Turabian StyleQu, Zhuangzhuang, Ulan Zhantikeyev, Ulan Kakimov, Kainaubek Toshtay, Kanay Rysbekov, Nur Nabihah Binti Yusof, Ronny Berndtsson, and Seitkhan Azat. 2026. "Advances and Prospects of Modified Activated Carbon-Based Slow Sand Filtration for Microplastic Removal" Water 18, no. 2: 228. https://doi.org/10.3390/w18020228

APA StyleQu, Z., Zhantikeyev, U., Kakimov, U., Toshtay, K., Rysbekov, K., Yusof, N. N. B., Berndtsson, R., & Azat, S. (2026). Advances and Prospects of Modified Activated Carbon-Based Slow Sand Filtration for Microplastic Removal. Water, 18(2), 228. https://doi.org/10.3390/w18020228