A Linear Model for Irrigation Canals Operating in Real Time Applied in ASCE Test Cases

Abstract

1. Introduction

2. Methodology: The Him Model

2.1. Free Surface Flow Equations

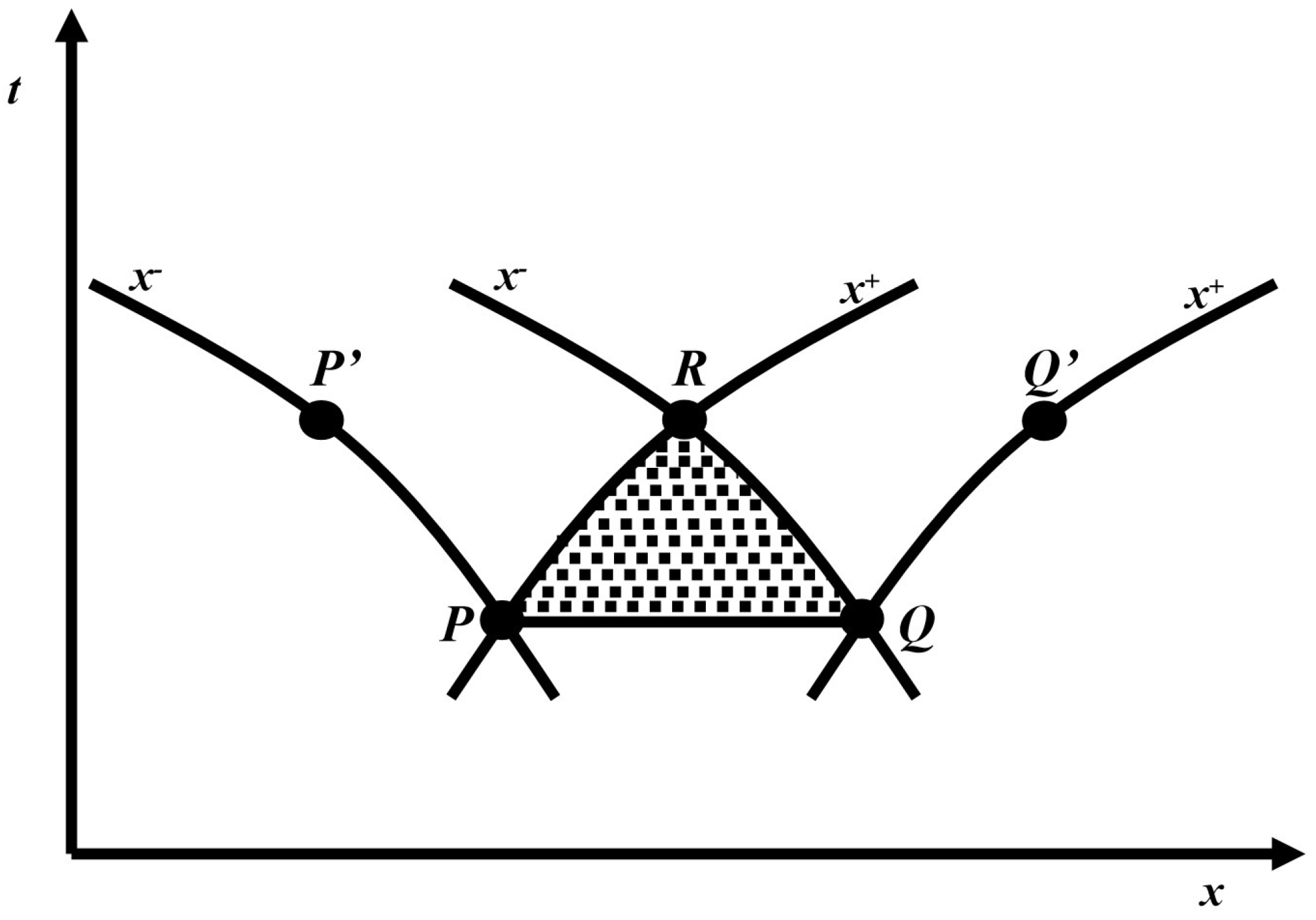

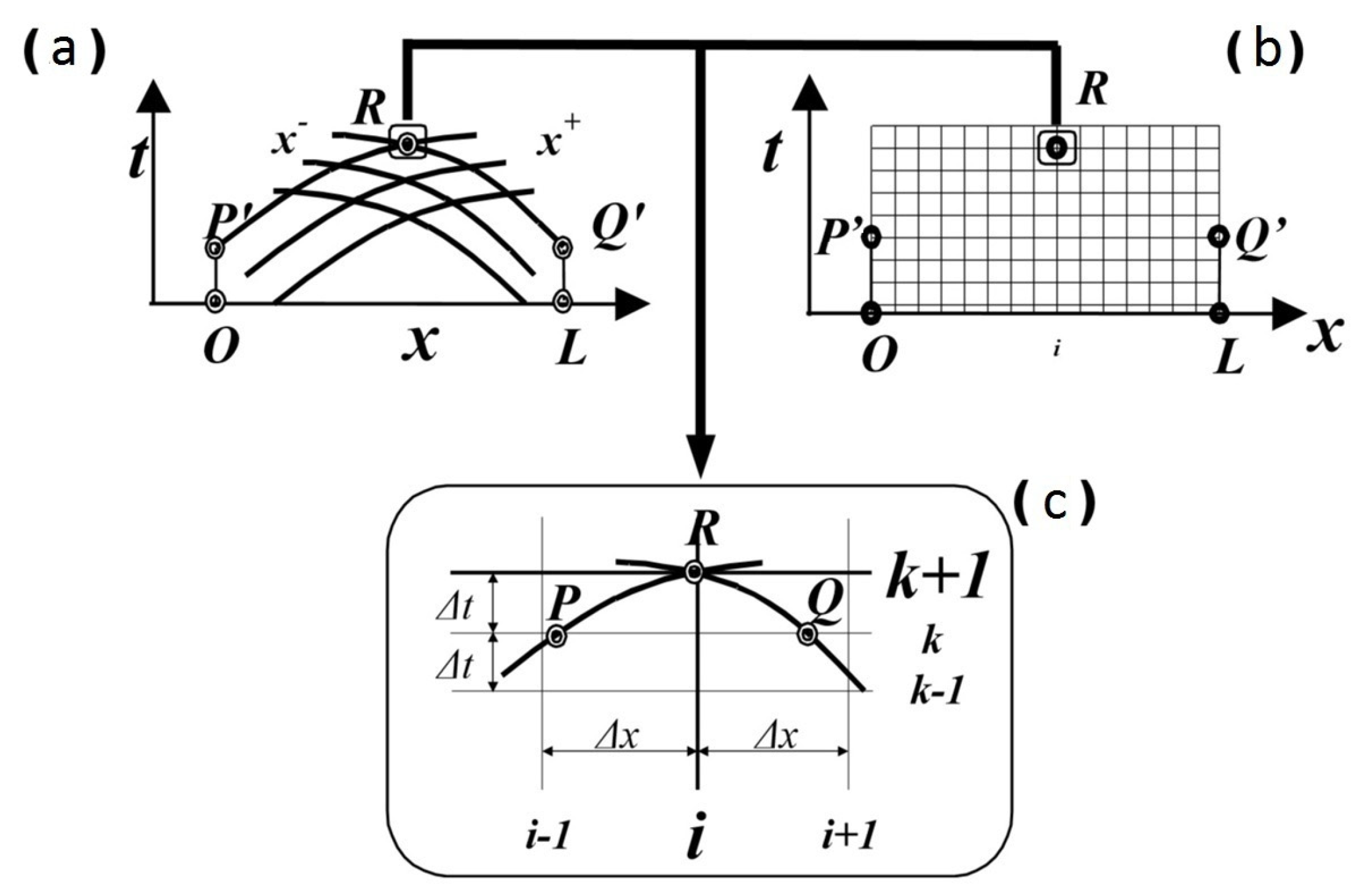

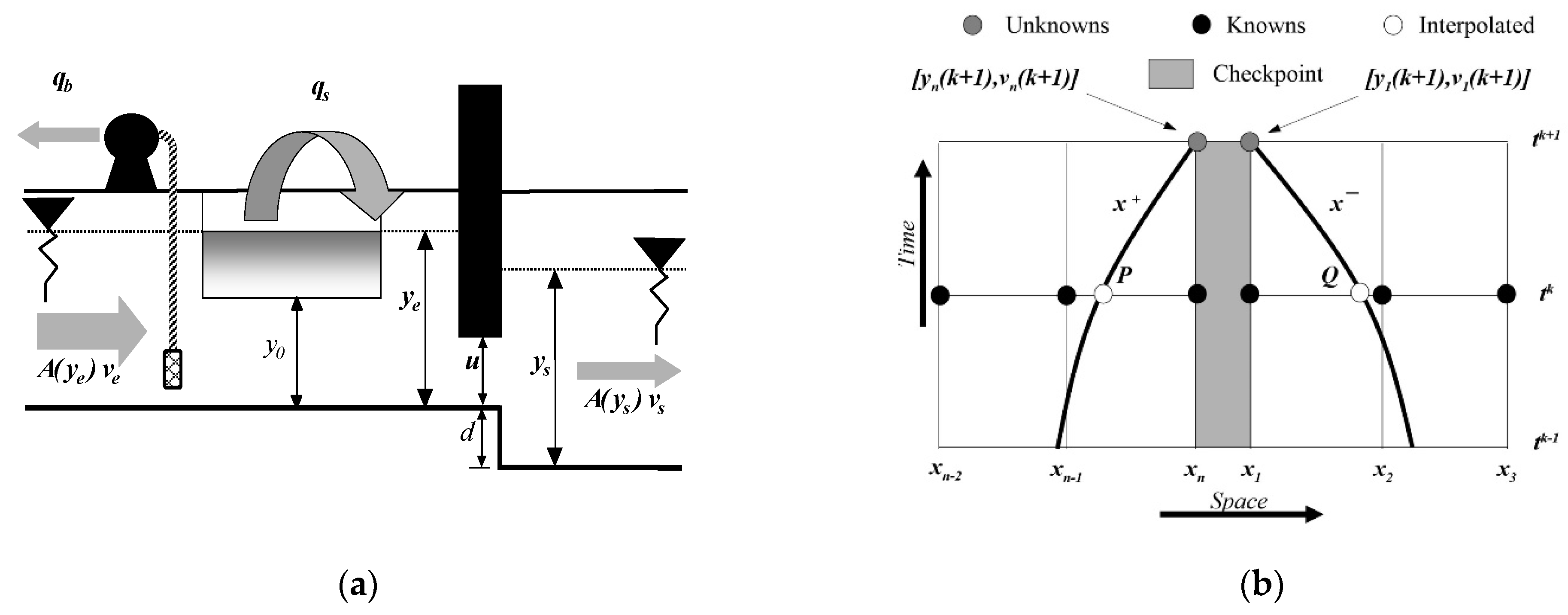

2.2. The Discretization of the Characteristic Equations

3. The Linear Hydraulic Model

4. Results: Verification of the Linear Hydraulic Model

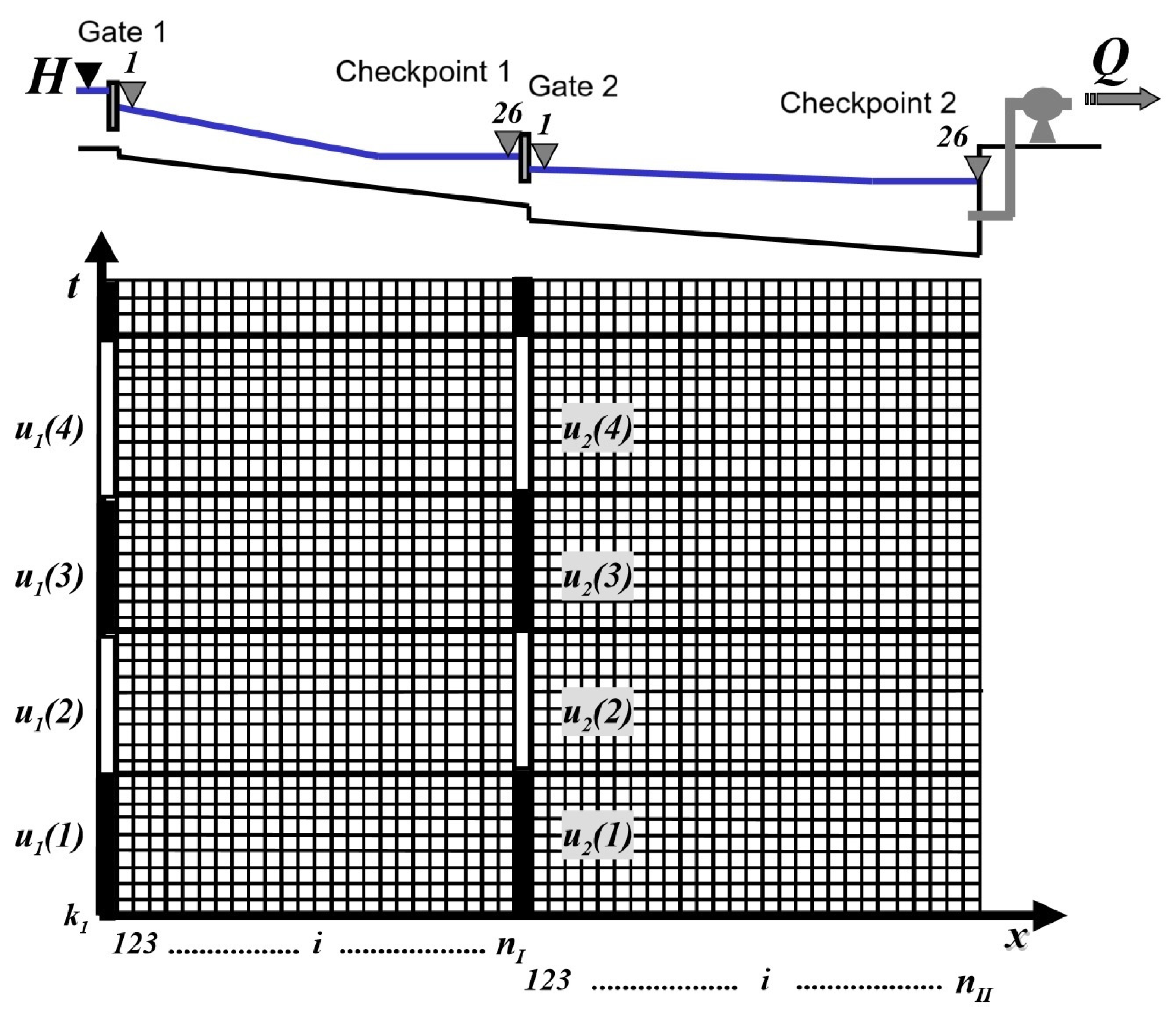

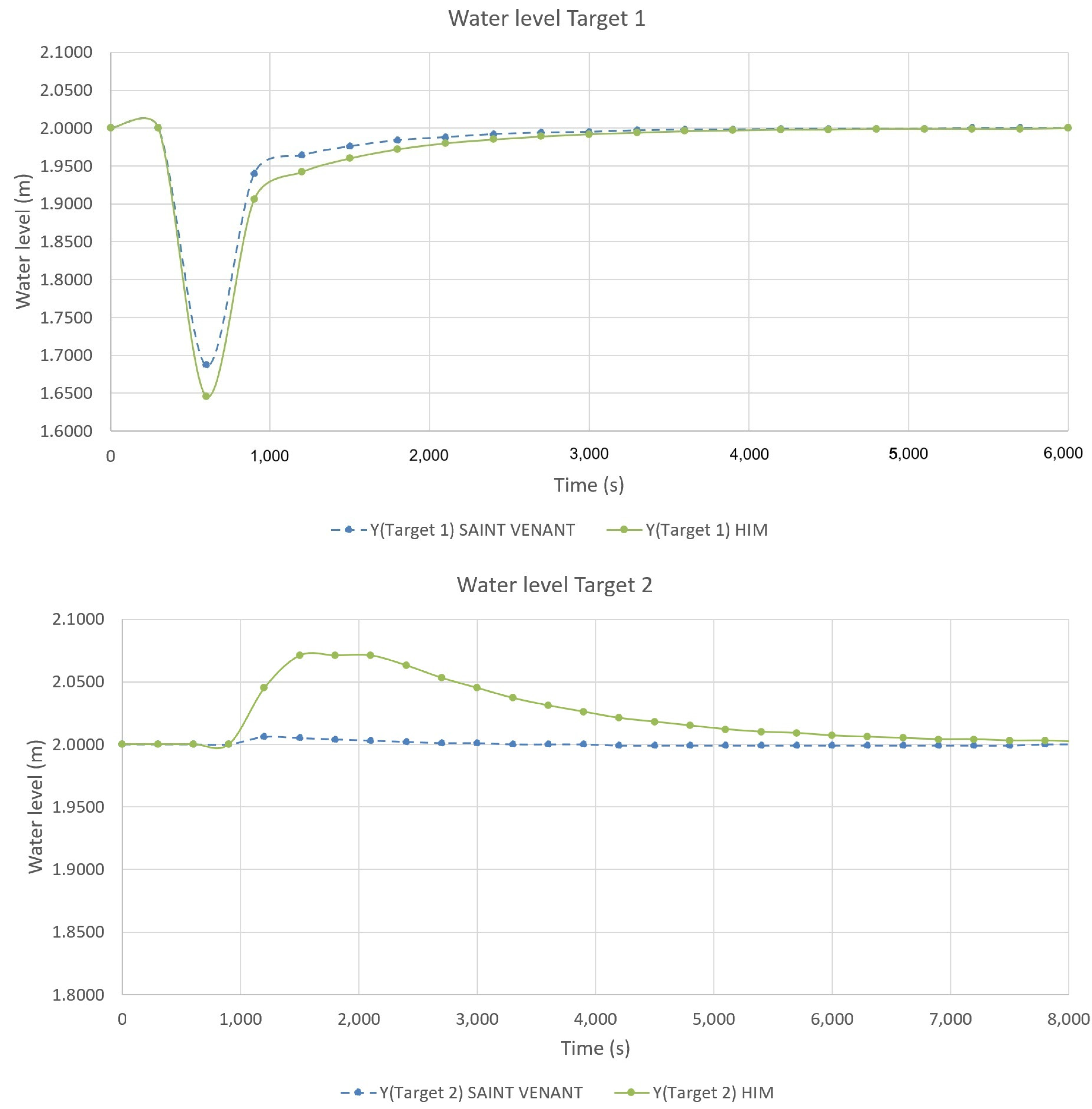

4.1. First Test Case: Irrigation Canal with Two Pools

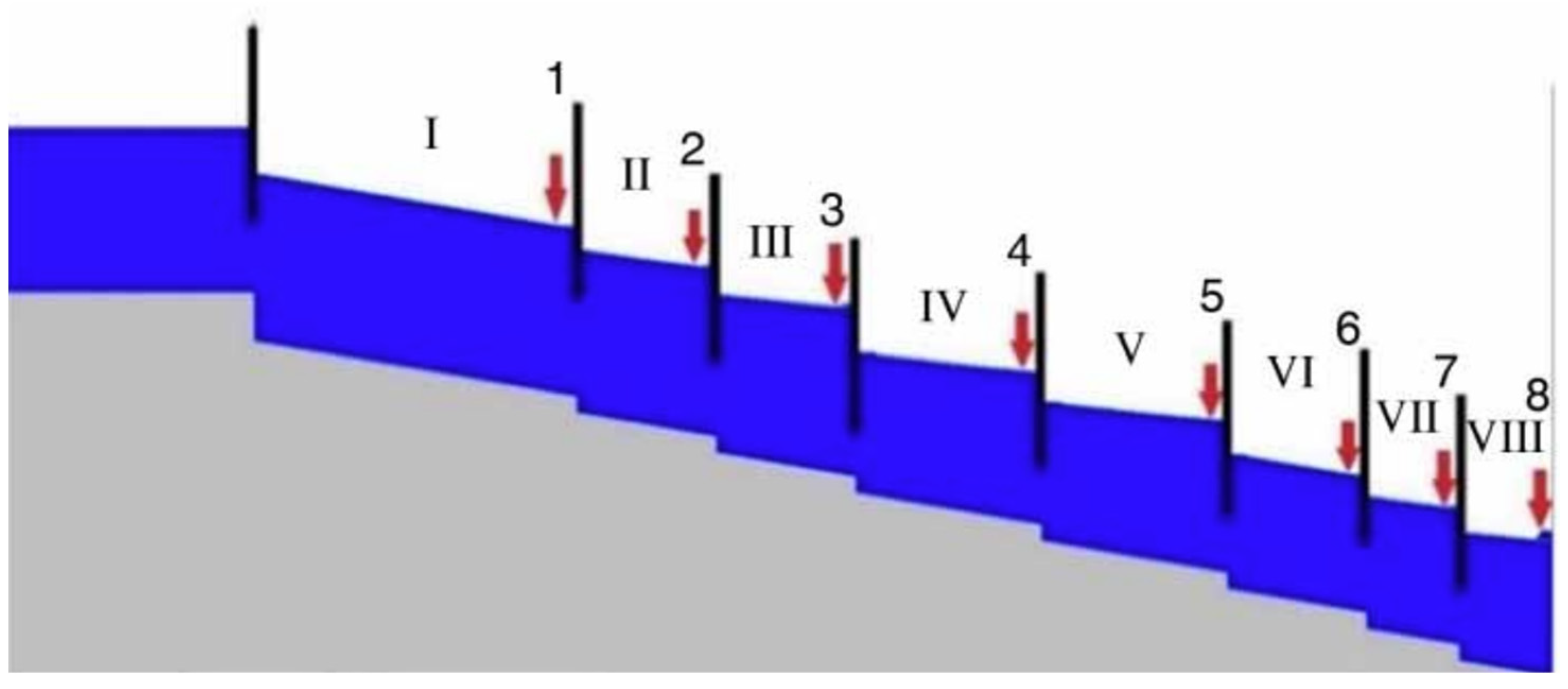

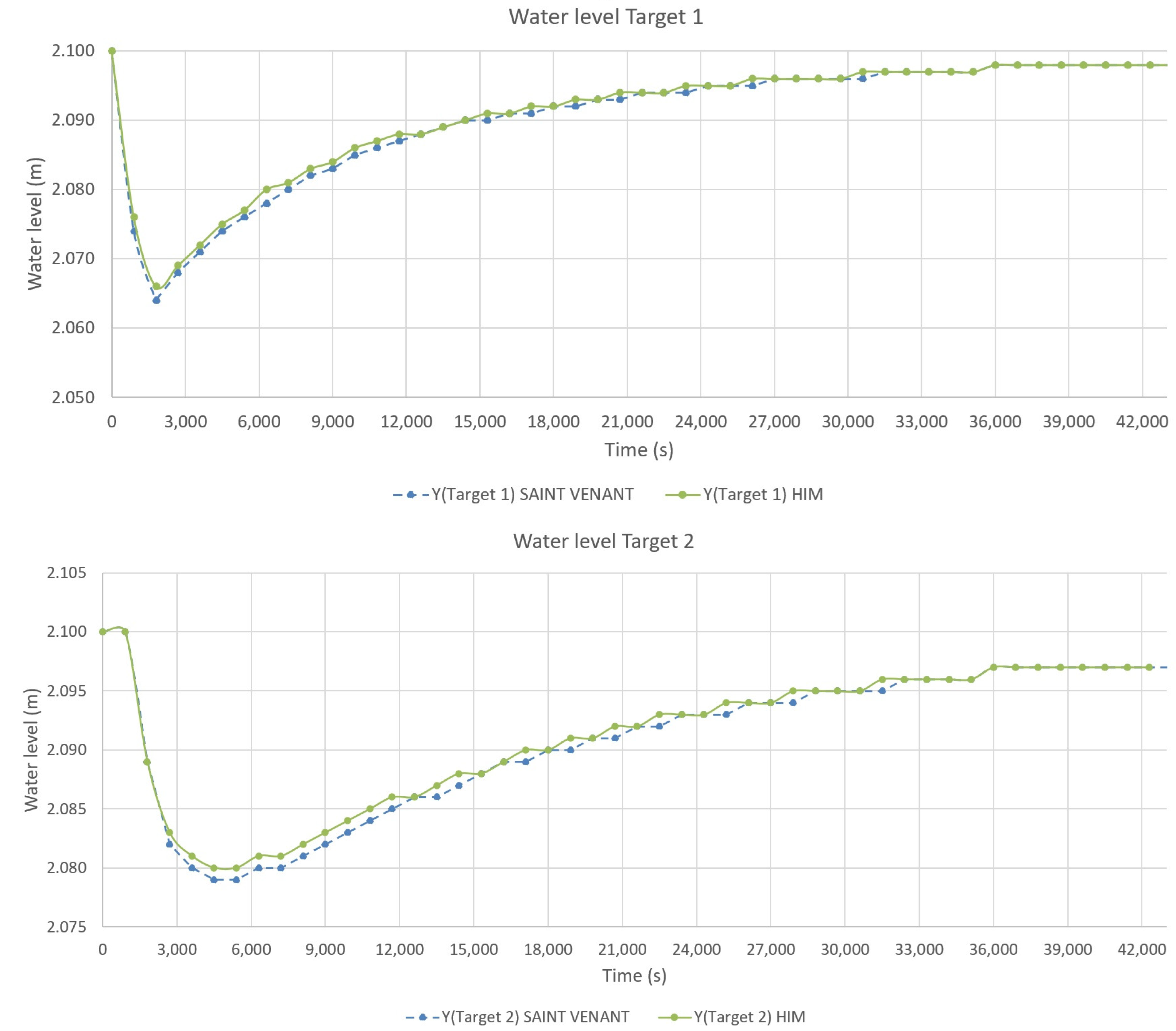

4.2. Second Test Case: ASCE Test Cases

5. Discussion

5.1. Evaluation and Comparison

5.2. HIM Limitations

5.3. Future Research

- The accuracy of the HIM model could be enhanced by refining its boundary condition formulations, particularly for systems with more complex geometries;

- Although the HIM model significantly reduces simulation time, further research is required to evaluate the propagation of small errors, particularly under extreme or highly nonlinear conditions. Recalculating the HIM model should be considered only in cases of discrepancies between the Saint-Venant complete model and the HIM model due to nonlinearity;

- It is expected that future research could improve the HIM model by integrating machine learning techniques to adjust parameters in real time, leading to even faster and more accurate simulations;

- Testing a real-time controller using the HIM model and the complete Saint-Venant equations and analyzing the gate control trajectories in both models and estimating the final control precision would be helpful;

- Future work should also include testing the HIM model in a real-world irrigation system to assess its practical performance and applicability. Despite its promising performance, applying the HIM model to real-world agricultural irrigation systems presents several challenges:

- Data availability and quality: Accurate simulations require detailed input data, including terrain features, water sources, soil properties, and crop types. Obtaining and maintaining such datasets can be challenging, particularly in remote or less-documented regions. For instance, high-quality topographical and hydrological data might not always be readily available, which can impact the model’s precision. In some cases, satellite imagery or remote sensing technologies may help to mitigate data scarcity, but their accuracy still needs to be validated for specific environments;

- Calibration and validation: The model must be calibrated and validated using real field data to ensure its reliability in practice. While several methods exist in the literature to address this challenge [61], further empirical studies are necessary to refine the HIM model for use in several environments. Ideally, calibration should involve long-term field studies that capture the dynamic changes in the irrigation system, where coefficients involved in the Saint-Venant equations, such as the Manning coefficient, gate coefficient, or orifice off-take coefficient, may change over time. The lack of such data can hinder the validation process and lead to potential inaccuracies in real-world application;

- Model adaptability: Agricultural fields are inherently heterogeneous, with varying weather conditions, water availability, and crop growth affecting irrigation dynamics. These factors pose a significant challenge for the HIM model, which must be adaptable to such variability to ensure long-term applicability. The model should integrate real-time seasonal variations in water demand and assess its accuracy in this new environment, which may require additional modifications or extensions;

- Operational challenges: Besides technical hurdles, implementing the HIM model in real-world irrigation systems also requires addressing practical issues such as the cost and time associated with data collection, model deployment, and continuous monitoring. Operators may face difficulties in integrating the model into existing infrastructure, especially if they lack the necessary technical expertise or resources. Therefore, developing user-friendly interfaces and automated systems for real-time model application and feedback could facilitate the adoption of the model in operational settings.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UNESCO, 2021. United Nations World Water Development Report 2021: Valuing Water; Facts and Figures. Available online: https://unesdoc.unesco.org/ark:/48223/pf0000375751.locale=en (accessed on 16 December 2024).

- United Nations, 2024. The Sustainable Development Goals Report 2023, United Nations Department of Economic and Social Affairs. [Online]. Available online: https://unstats.un.org/sdgs/report/2023/The-Sustainable-Development-Goals-Report-2023.pdf (accessed on 10 March 2025).

- Ingrao, C.; Strippoli, R.; Lagioia, G.; Huisingh, D. Water scarcity in agriculture: An overview of causes, impacts and approaches for reducing the risks. Heliyon 2023, 9, e18507. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. Four billion people facing severe water scarcity. Sci. Adv. 2016, 2, e1500323. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Jägermeyr, J.; Pastor, A.; Biemans, H.; Gerten, D. Reconciling irrigated food production with environmental flows for Sustainable Development Goals implementation. Nat. Commun. 2017, 8, 15900. [Google Scholar] [CrossRef]

- Qin, J.; Duan, W.; Zou, S.; Chen, Y.; Huang, W.; Rosa, L. Global energy use and carbon emissions from irrigated agriculture. Nat. Commun. 2024, 15, 3084. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Tzanakakis, V.A.; Paranychianakis, N.V.; Angelakis, A.N. Water Supply and Water Scarcity. Water 2020, 12, 2347. [Google Scholar] [CrossRef]

- Dinar, A.; Tieu, A.; Huynh, H. Water scarcity impacts on global food production. Glob. Food Secur. 2019, 23, 212–226. [Google Scholar] [CrossRef]

- Aiswarya, L.; Siddharam; Gaddikeri, V.; Jatav, M.S.; Dimple; Rajput, J. Canal Automation and Management System to Improve Water Use Efficiency. In Recent Advancements in Sustainable Agricultural Practices; Yasheshwar, Mishra, A.K., Kumar, M., Eds.; Springer: Singapore, 2024. [Google Scholar] [CrossRef]

- Kadpan, W.R.; Mustafa, F.F.; Kadhim, H.T. A review of control automatically water irrigation canal using multi controllers and sensors. J. Eur. Des Systèmes Automatisés 2024, 57, 717–727. [Google Scholar] [CrossRef]

- Abioye, E.A.; Abidin, M.S.Z.; Aman, M.N.; Mahmud, M.S.A.; Buyamin, S. A model predictive controller for precision irrigation using discrete lagurre networks. Comput. Electron. Agric. 2021, 181, 105953. [Google Scholar] [CrossRef]

- Soler, J.; Gómez, M.; Rodellar, J. A control tool for irrigation canals with scheduled demands. J. Hydraul. Res. 2008, 46, 152–167. [Google Scholar] [CrossRef]

- Bonet Gil, E. Experimental Design and Verification of a Centralized Controller for Irrigation Canals. Tesi Doctoral, UPC, Escola Tècnica Superior d'Enginyers de Camins, Canals i Ports de Barcelona, 2015. Available online: http://hdl.handle.net/2117/95654 (accessed on 3 March 2025). [CrossRef]

- Liao, W.; Guan, G.; Tian, X. Exploring Explicit Delay Time for Volume Compensation in Feedforward Control of Canal Systems. Water 2019, 11, 1080. [Google Scholar] [CrossRef]

- Huang, M.; Tian, M.; Liu, Y.; Zhang, Y.; Zhou, J. Parameter optimization of PID controller for water and fertilizer control system based on partial attraction adaptive firefly algorithm. Sci. Rep. 2022, 12, 12182. [Google Scholar] [CrossRef]

- Chen, P.C.; Luo, Y.; Peng, Y.B.; Chen, Y.Q. Optimal robust fractional order (PID)-D-lambda controller synthesis for first order plus time delay systems. ISA Trans. 2021, 114, 136–149. [Google Scholar] [CrossRef]

- Arauz, T.; Maestre, J.M.; Tian, X.; Guan, G. Design of PI controllers for irrigation canals based on linear matrix inequalities. Water 2020, 12, 855. [Google Scholar] [CrossRef]

- Malaterre, P.O. PILOTE: Optimal control of irrigation canals. In Proceedings of the First International Conference on Water Resources Engineering, Irrigation and Drainage, San Antonio, TX, USA, 14–18 August 1995. [Google Scholar]

- Malaterre, P.O. Modelisation, Analysis and LQR Optimal Control of an Irrigation Canal. Ph.D. Thesis, LAAS-CNRS-ENGREF-Cemagref, Etude EEE nº14. FR. École Nationale du Génie Rural, des Eaux et des Forêts, Paris, France, 1994. [Google Scholar]

- Durdu, O.F. Optimal control of irrigation canals using recurrent dynamic neural network (RDNN). Crit. Transit. Water Environ. Resour. Manag. 2012, 1–12. [Google Scholar] [CrossRef]

- Heyden, M.; Pates, R.; Rantzer, A. A Structured Optimal Controller for Irrigation Networks. In Proceedings of the 2022 European Control Conference (ECC), London, UK, 11–14 July 2022; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar]

- Gómez, M.; Rodellar, J.; Mantecón, J. Predicitve control method for decentralized operation of irrigation canals. Appl. Math. Model. J. 2001, 26, 1039–1056. [Google Scholar] [CrossRef]

- Rodellar, J.; Gómez, M.; Martín, J.P. Stable Predictive Control of Open-Channel Flow. J. Irrig. Drain. Eng. 1989, 115, 701–713. [Google Scholar] [CrossRef]

- Gejadze, I.; Malaterre, P.O. Discharge estimation under uncertainty using variational methods with application to the full Saint-Venant hydraulic network model. Int. J. Numer. Meth. Fluids 2016, 83, 405–430. [Google Scholar] [CrossRef]

- Hernández López, Y.; Rivas-Pérez, R.; Feliu-Batlle, V. IMC-PID controller with fractional-order filter for a main irrigation canal section. Rev. Científica De Ing. Electrónica Automática Comun. 2021, 42, 74–88. [Google Scholar]

- Alla, A.; Berardi, M.; Saluzzi, L. A feedback control strategy for optimizing irrigation in a Richards’ Equation framework. arXiv 2024, arXiv:2407.06477. [Google Scholar]

- Walker, W.R.; Skogerboe, G.V. Surface Irrigation: Theory and Practice; Prentice-Hall, Inc.: Englewood Cliffs, NJ, USA, 1987. [Google Scholar]

- Wylie, E.B. Control of transient free-surface flow. J. Hydr. Div. (ASCE) 1969, 40, 347–361. [Google Scholar] [CrossRef]

- Gómez, M. Contribución al Estudio del Movimiento Variable en Lámina Libre, en las Redes de Alcantarillado. Ph.D. Thesis, UPC, Barcelona, Spain, 1988. [Google Scholar]

- Ames, W.F. Numerical Methods for Partial Differential Equations; Academic Press Inc.: Orlando, FL, USA, 1977. [Google Scholar]

- Ducheteau, P.; Zachmann, D.W. Ecuaciones Diferenciales Parciales; McGraw-Hill Interamericana de México: Ciudad de México, Mexico, 1988. [Google Scholar]

- Crandall, S.H. Engineering Analysis—A Survey of Numercial Procedures; Wiley (Interescience): New York, NY, USA, 1956. [Google Scholar]

- Bonet, E. Experimental Design and Verification of a Centralize Controller for Irrigation Canals. Ph.D. Thesis, UPC, Technical University of Catalonia, Barcelona, Spain, 2015. [Google Scholar]

- Soler, J.; Gómez, M.; Bonet, E. Canal monitoring algorithm. J. Irrig. Drain. Eng. 2016, 142, 04015058. [Google Scholar] [CrossRef]

- Bautista, E.; Clemmens, A.J.; Strelkoff, T. Comparison of numerical procedures for gate stroking. J. Irrig. Drain. Eng. ASCE 1997, 113, 129–136. [Google Scholar] [CrossRef]

- Liu, F.; Feyen, J.; Berlamont, J. Computation method for regulating unsteady flow in open channels. J. Irrig. Drain. Eng. ASCE 1992, 118, 674–689. [Google Scholar] [CrossRef]

- Chevereau, G. Contribution à L’étude de la Régulation dans les Systems Hydrauliques à Surface Libre. Ph.D. Thesis, de l’Institut National Polytechnic de Grenoble, Grenoble, France, 1991. [Google Scholar]

- Litrico, X.; Fromion, V. Tuning of Robust Distant Downstream PI Controllers for an Irrigation Canal Pool. I: Theory. J. Irrig. Drain. Eng. 2006, 132, 359–368. [Google Scholar] [CrossRef]

- Aguilar, J.V.; Langarita, P.; Rodellar, J.; Linares, L.; Horváth, K. Predictive control of irrigation canals robust design and real-time implementation. Water Resour Manag. 2016, 30, 3829–3843. [Google Scholar] [CrossRef]

- Wu, Y.; Li, L.; Liu, Z.; Chen, X.; Huang, H. Real-Time Control of the Middle Route of South-to-North Water Diversion Project. Water 2021, 13, 97. [Google Scholar] [CrossRef]

- Clemmens, A.J.; Kacerek, T.F.; Grawitz, B.; Schuurmans, W. Test Cases for Canal Control Algorithms. J. Irri. Drain. ASCE 1998, 124, 23–30. [Google Scholar] [CrossRef]

- Durdu, O. Regulation of irrigation canals using a two-stage linear quadratic reliable control. Turk. J. Agric. For. 2004, 28, 111–120. [Google Scholar]

- Durdu, O. Control of transient flow in irrigation canals using Lyapunov fuzzy filter-based gaussian regulator. Int. J. Numer. Methods Fluids 2006, 50, 491–509. [Google Scholar] [CrossRef]

- Feng, X.; Wang, K. Stability analysis on automatic control methods of open canal. Wuhan Univ. J. Nat. Sci. 2011, 16, 325–331. [Google Scholar] [CrossRef]

- Garcia, A.; Hubbard, M.; De Vries, J. Open channel transient flow control by discrete time LQR methods. Automatica 1992, 28, 255–264. [Google Scholar] [CrossRef]

- Bonet, E.; Gómez, M.; Yubero, M.; Fernández-Francos, J. GoRoSoBo: An overall control diagram to improve the efficiency of water transport systems in real time. J. Hydroinformatics 2017, 19, 364–384. [Google Scholar] [CrossRef]

- Breckpot, M.; Agudelo, O.; Moor, B.; De Moor, B. Flood control with model predictive control for river systems with water reservoirs. J. Irrig. Drain. Eng. 2013, 139, 532–541. [Google Scholar] [CrossRef]

- Cen, L.; Wu, Z.; Chen, X.; Zou, Y.; Zhang, S. On modeling and constrained model predictive control of open irrigation canals. J. Control. Sci. Eng. 2017, 2017, 6257074. [Google Scholar] [CrossRef]

- Lacasta, A.; Morales-Hernández, M.; Brufau, P.; García-Navarro, P. Application of an adjoint-based optimization procedure for the optimal control of internal boundary conditions in the shallow water equations. J. Hydraul. Res. 2018, 56, 111–123. [Google Scholar] [CrossRef]

- Shang, Y.; Liu, R.; Li, T.; Zhang, C.; Wang, G. Transient flow control for an artificial open channel based on finite difference method. Sci. China Technol. Sci. 2011, 54, 781–792. [Google Scholar] [CrossRef]

- Xu, M.; Negenborn, R.; van Overloop, P.; van de Giesen, N. De saint-venant equations-based model assessment in model predictive control of open channel flow. Adv. Water Resour. 2012, 49, 37–45. [Google Scholar] [CrossRef]

- McCarthy, G. The Unit Hydrograph and Flood Routing; U.S. Engineer Office: Providence, RI, USA, 1939. [Google Scholar]

- Koenig, D.; Bedjaoui, N.; Litrico, X. Unknown input observers design for time-delay systems application to an open-channel. In Proceedings of the 44th IEEE conference on decision and control, Seville, Spain, 15 December 2005; pp. 5794–5799. [Google Scholar]

- Litrico, X.; Fromion, V. Modeling and Control of Hydrosystems; Springer: London, UK, 2009; pp. 1–409. [Google Scholar]

- Horváth, K.; Galvis, E.; Rodellar, J.; Valentín, M. Experimental comparison of canal models for control purposes using simulation and laboratory experiments. J. Hydroinformatics 2014, 16, 1390–1408. [Google Scholar] [CrossRef]

- Puig, V.; Ocampo-Martinez, C.; Negenborn, R. Transport of water versus transport over water: Model predictive control for combined water supply and navigability/sustainability in river systems. In Transport of Water Versus Transport Over Water; Ocampo-Martinez, C., Negenborn, R.R., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; pp. 13–32. [Google Scholar]

- Van Overloop, P.; Horvath, K.; Ekin, B. Model predictive control based on an integrator resonance model applied to an open water channel. Control. Eng. Pract. 2014, 27, 54–60. [Google Scholar] [CrossRef]

- Zheng, Z.; Wang, Z.; Zhao, J.; Zheng, H. Constrained model predictive control algorithm for cascaded irrigation canals. J. Irrig. Drain. Eng. 2019, 145, 04019009. [Google Scholar] [CrossRef]

- Tavares, I.; Borges, J.; Mendes, M.; Botto, M. Assessment of data-driven modeling strategies for water delivery canals. Neural Comput. Appl. 2013, 23, 625–633. [Google Scholar] [CrossRef]

- Herrera, J.; Ibeas, A.; De La Sen, M. Identification and control of integrative MIMO systems using pattern search algorithms: An application to irrigation channels. Eng. Appl. Artif. Intell. 2013, 26, 334–346. [Google Scholar] [CrossRef]

- Bonet, E.; Russo, B.; González, R.; Yubero, M.T.; Gómez, M.; Sánchez-Juny, M. The FC Algorithm to Estimate the Manning’s Roughness Coefficients of Irrigation Canals. Agriculture 2023, 13, 1351. [Google Scholar] [CrossRef]

| Pool Number (nº) | Pool Length (km) | Bottom Slope (%) | Side Slopes (H:V) | Manning’s Coefficient (n) | Bottom Width (m) | Canal Depth (m) | Gate Discharge Coefficient (-) | Gate Width (m) | Gate Height (m) | Step (m) |

|---|---|---|---|---|---|---|---|---|---|---|

| I | 2.5 | 0.1 | 1.5:1 | 0.025 | 5 | 2.5 | 0.61 | 5.0 | 2.5 | 0.6 |

| II | 2.5 | 0.1 | 1.5:1 | 0.025 | 5 | 2.5 | 0.61 | 5.0 | 2.5 | 0.6 |

| Number of Control Structure or Checkpoint (nº) | Discharge Coef./ Diameter Orifice Offtake (m) | Orifice Offtake Height (m) | Pump Flow (m3/s) |

|---|---|---|---|

| 1 | 2/0.85 | 0.8 | - |

| 2 | - | - | 5.0 |

| Control Structure | Initial Flow Rate (m3/s) | Control Structure (nº) | Initial Water Level Upstream (m)/ Offtake Orifice Outflow (m3/s) | Control Structure (nº) | Pump Flow Discharge (m3/s) |

|---|---|---|---|---|---|

| Gate 1 | 10.0 | Checkpoint 1 | 2.0/5.0 | Checkpoint 2 | 5.0 |

| I1 (cm) | I2 (%) | I3 (cm) | I4 (Dimensionless) | |||||

|---|---|---|---|---|---|---|---|---|

| Checkpoint 1 | Checkpoint 2 | Checkpoint 1 | Checkpoint 2 | Checkpoint 1 | Checkpoint 2 | Checkpoint 1 | Checkpoint 2 | |

| Case 1 | 4.0 | 6.7 | 0.17 | 0.65 | 0.9 | 2.41 | 0.96 | −137.2 |

| Case 2 | 0.9 | 3.3 | 0.03 | 0.32 | 0.18 | 1.2 | 0.99 | −73.9 |

| Case 3 | 0.1 | 0.7 | 0 | 0.06 | 0.014 | 0.23 | 0.999 | −35.02 |

| Case 4 | 0 | 0.4 | 0 | 0.03 | 0 | 0.012 | 1 | −12.1 |

| Pool/Checkpoint Number (nº) | Pool Length (km) | Bottom Slope (-) | Side Slopes (H:V) | Manning’s Coefficient (n) | Bottom Width (m) | Canal Depth (m) | Gate Width (m) | Gate Height (m) | Gate Discharge Coefficient (-) | Step (m) | Length from Gate 1 (km) | Orifice Offtake Height (m) | Lateral Spillway Height (m) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 7 | 2.3 | 0.61 | 0.2 | 0 | - | 3 |

| I | 7 | 10−4 | 1.5:1 | 0.02 | 7 | 2.5 | 7 | 2.3 | 0.61 | 0.2 | 7 | 1.05 | 2.5 |

| II | 3 | 10−4 | 1.5:1 | 0.02 | 7 | 2.5 | 7 | 2.3 | 0.61 | 0.2 | 10 | 1.05 | 2.5 |

| III | 3 | 10−4 | 1.5:1 | 0.02 | 7 | 2.5 | 7 | 2.3 | 0.61 | 0.2 | 13 | 1.05 | 2.5 |

| IV | 4 | 10−4 | 1.5:1 | 0.02 | 6 | 2.3 | 6 | 2.1 | 0.61 | 0.2 | 17 | 0.95 | 2.3 |

| V | 4 | 10−4 | 1.5:1 | 0.02 | 6 | 2.3 | 6 | 2.1 | 0.61 | 0.2 | 21 | 0.95 | 2.3 |

| VI | 3 | 10−4 | 1.5:1 | 0.02 | 5 | 2.3 | 5 | 1.8 | 0.61 | 0.2 | 24 | 0.85 | 1.9 |

| VII | 2 | 10−4 | 1.5:1 | 0.02 | 5 | 1.9 | 5 | 1.8 | 0.61 | 0.2 | 26 | 0.85 | 1.9 |

| VIII | 2 | 10−4 | 1.5:1 | 0.02 | 5 | 1.9 | - | - | - | - | 28 | 0.85 | 1.9 |

| Offtake Initial Flow (m3/s) | Check Initial Flow (m3/s) | |

|---|---|---|

| Heading | - | 13.7 |

| 1 | 1.7 | 12.0 |

| 2 | 1.8 | 10.2 |

| 3 | 2.7 | 7.5 |

| 4 | 0.3 | 7.2 |

| 5 | 0.2 | 7.0 |

| 6 | 0.8 | 6.2 |

| 7 | 1.2 | 5.0 |

| 8 | 2.3 | 2.7 |

| I1 (cm) | I2 (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Checkpoint 1 | Checkpoint 2 | Checkpoint 3 | Checkpoint 4 | Checkpoint 1 | Checkpoint 2 | Checkpoint 3 | Checkpoint 4 | |

| Case 1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.023 | 0.020 | 0.018 | 0.022 |

| Case 2 | 0.01 | 0.01 | 0.02 | 0.02 | 0.008 | 0.01 | 0.007 | 0.01 |

| I3 (cm) | I4 (Dimensionless) | |||||||

|---|---|---|---|---|---|---|---|---|

| Checkpoint 1 | Checkpoint 2 | Checkpoint 3 | Checkpoint 4 | Checkpoint 1 | Checkpoint 2 | Checkpoint 3 | Checkpoint 4 | |

| Case 1 | 0.07 | 0.06 | 0.006 | 0.006 | 0.99 | 0.98 | 0.98 | 0.95 |

| Case 2 | 0.04 | 0.04 | 0.004 | 0.004 | 0.99 | 0.98 | 0.95 | 0.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonet, E.; Yubero, M.T.; Bascompta, M.; Alfonso, P. A Linear Model for Irrigation Canals Operating in Real Time Applied in ASCE Test Cases. Water 2025, 17, 1368. https://doi.org/10.3390/w17091368

Bonet E, Yubero MT, Bascompta M, Alfonso P. A Linear Model for Irrigation Canals Operating in Real Time Applied in ASCE Test Cases. Water. 2025; 17(9):1368. https://doi.org/10.3390/w17091368

Chicago/Turabian StyleBonet, Enrique, Maria Teresa Yubero, Marc Bascompta, and Pura Alfonso. 2025. "A Linear Model for Irrigation Canals Operating in Real Time Applied in ASCE Test Cases" Water 17, no. 9: 1368. https://doi.org/10.3390/w17091368

APA StyleBonet, E., Yubero, M. T., Bascompta, M., & Alfonso, P. (2025). A Linear Model for Irrigation Canals Operating in Real Time Applied in ASCE Test Cases. Water, 17(9), 1368. https://doi.org/10.3390/w17091368