Compression Characteristics and Damage Constitutive Model of Loess Under Dry–Wet and Freeze–Thaw Cycles

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Dry–Wet and Freeze–Thaw Cycles (DWFT)

- (1)

- Dry and wet cycle: The prepared triaxial specimens (height: 80 mm, diameter: 39.1 mm) were humidified by adding pure water to simulate the rainfall process in the humidifying cylinder, and then artificially dried in the electric blast drying box to simulate the evaporation behavior. The lower limit moisture content was 0.6 times the moisture content, and the upper limit was set as the saturated moisture content, and one cycle was 24 h.

- (2)

- Freeze–thaw cycle: The sample after the dry–wet cycle was placed in a freeze–thaw tester, and was frozen at −20 °C for 12 h, and the remaining 12 h were at a temperature of 20 °C, that is, the test time of each freeze–thaw cycle was 24 h.

2.3. Mechanical Test and NMR Test Scheme

- (1)

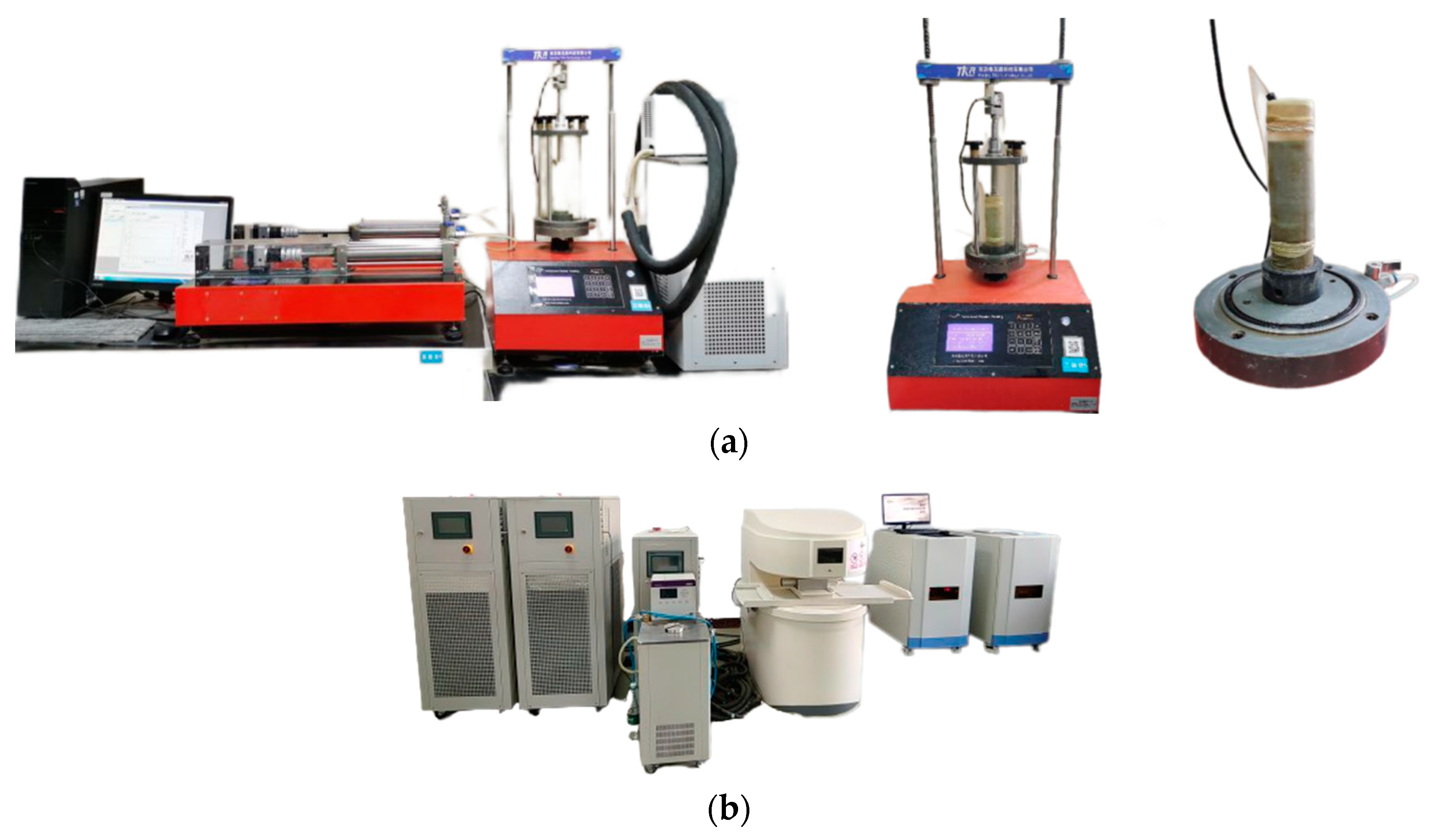

- Triaxial shear test: After the completion of cyclic action, the triaxial shear test of loess samples was carried out; the test apparatus is shown in Figure 2a. The confining pressure was set to 50 kPa, 100 kPa, 200 kPa, and 400 kPa, and the loading axial displacement rate was set to 0.08 mm/min. The test was terminated by samples failure or axial strain of 15%.

- (2)

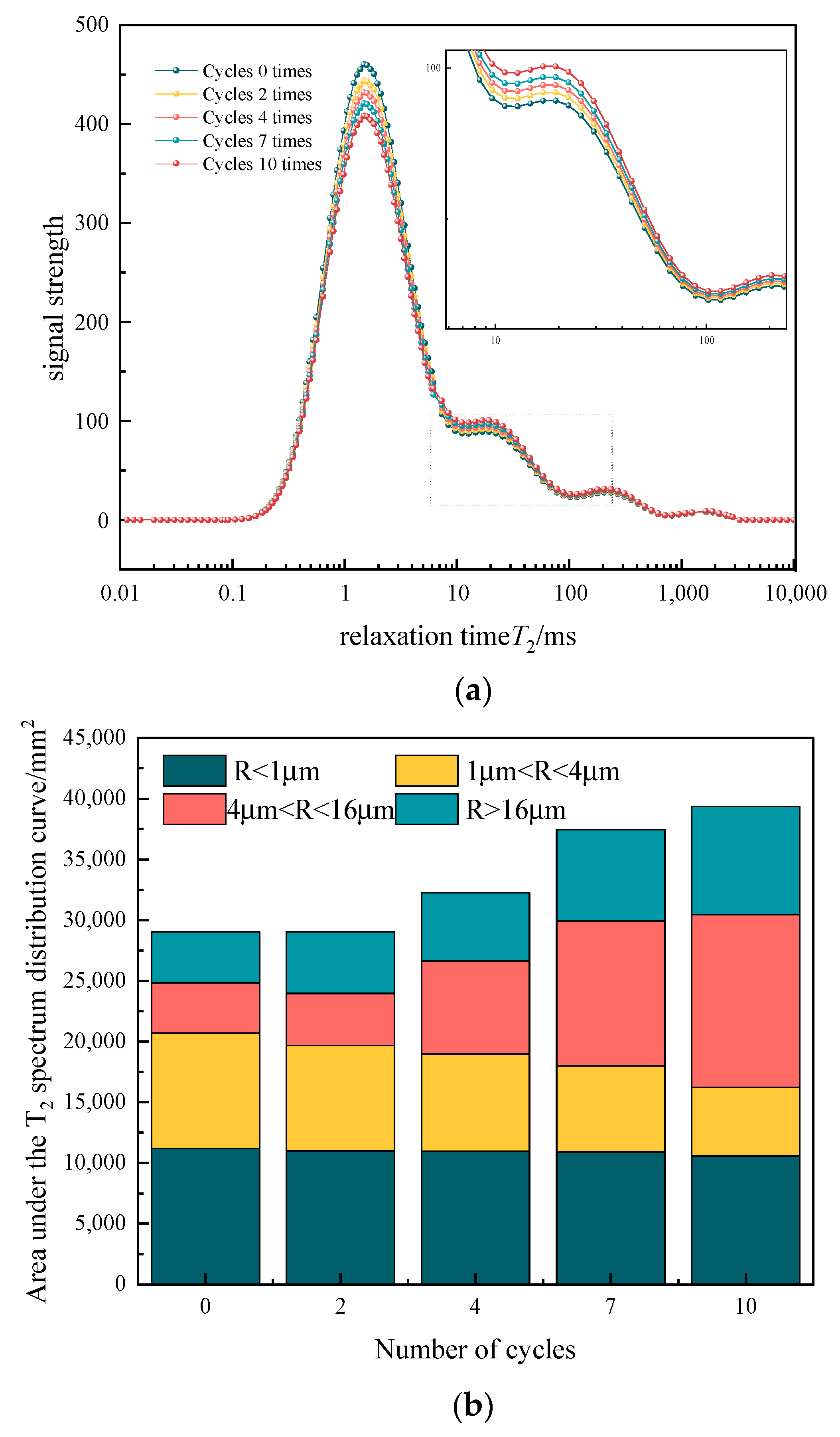

- Nuclear magnetic resonance testing of internal pores (NMR): The test principle of this method is to invert the internal pore structure of the saturated sample by measuring the signal amplitude of the fluid inside the sample, as shown in Figure 2b. After the loess sample is saturated, the surface relaxation time T2 of the pores is measured, and the distribution curve is given to determine the proportion of pores of different scales [25].

3. Results

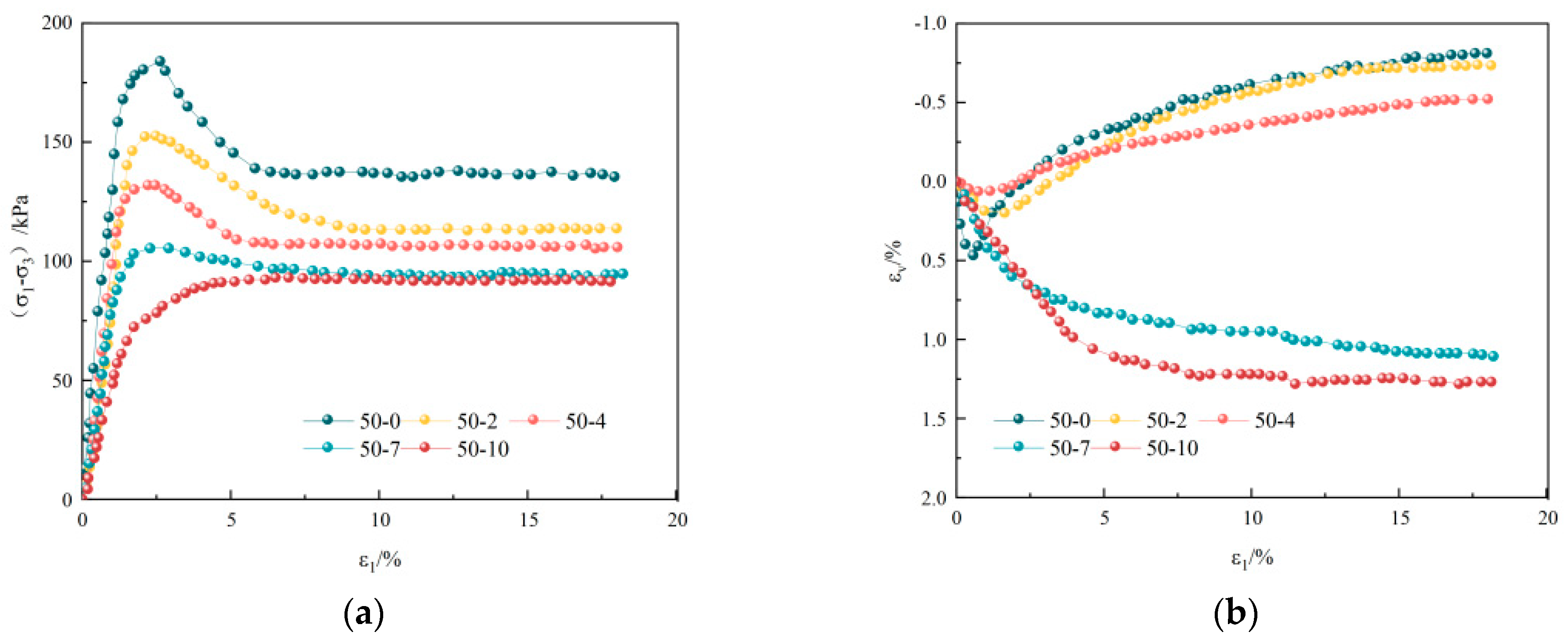

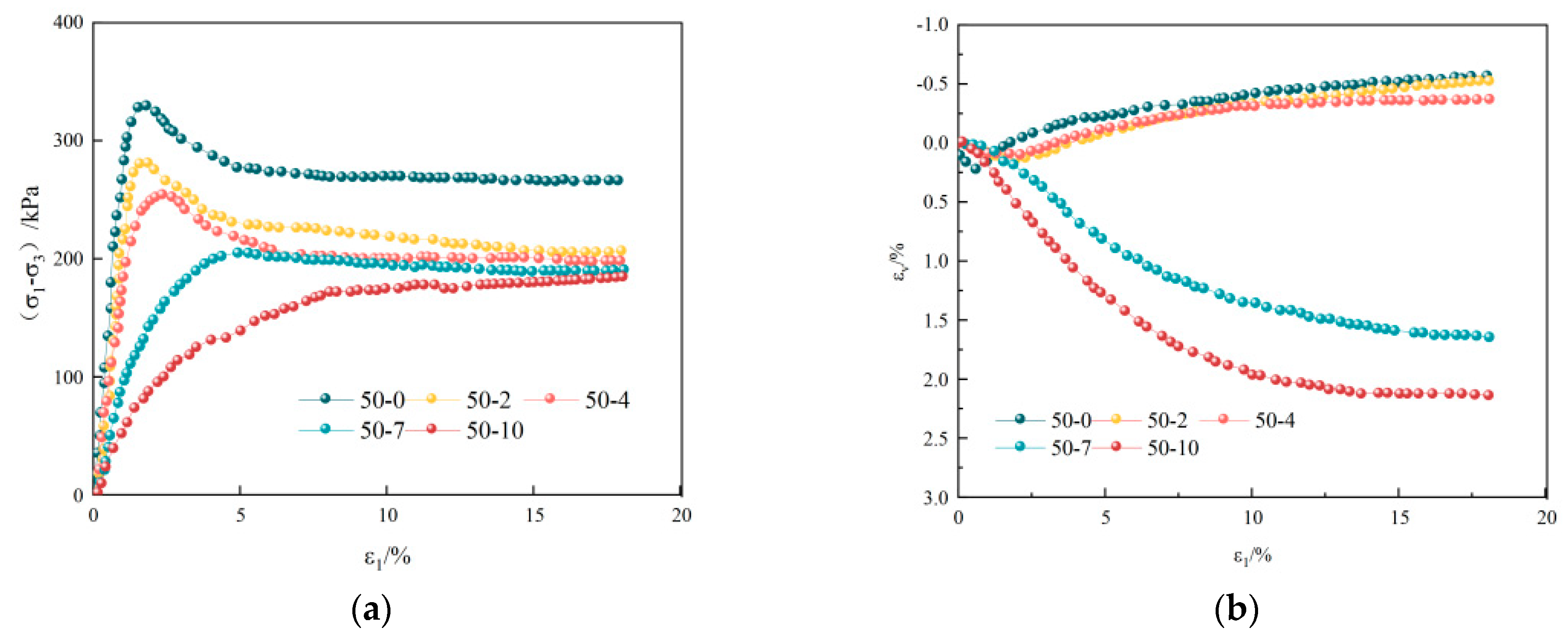

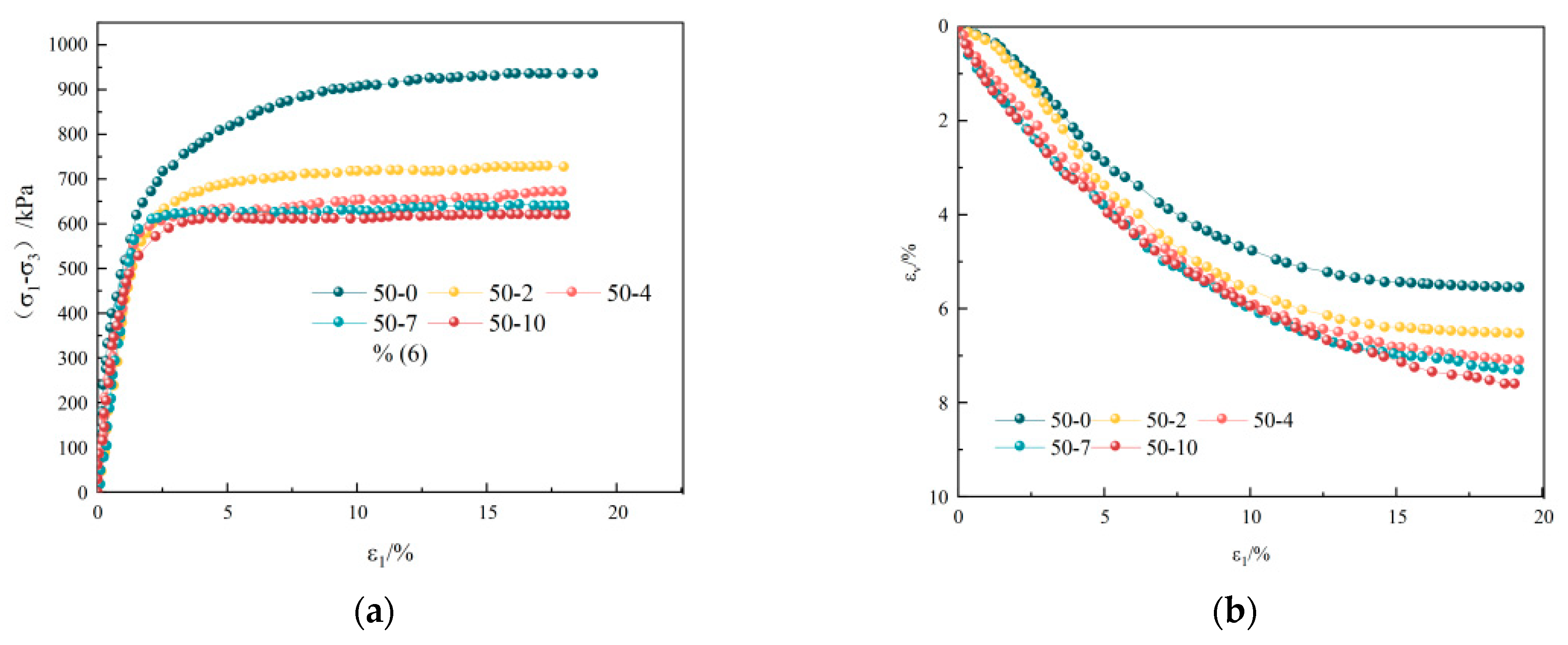

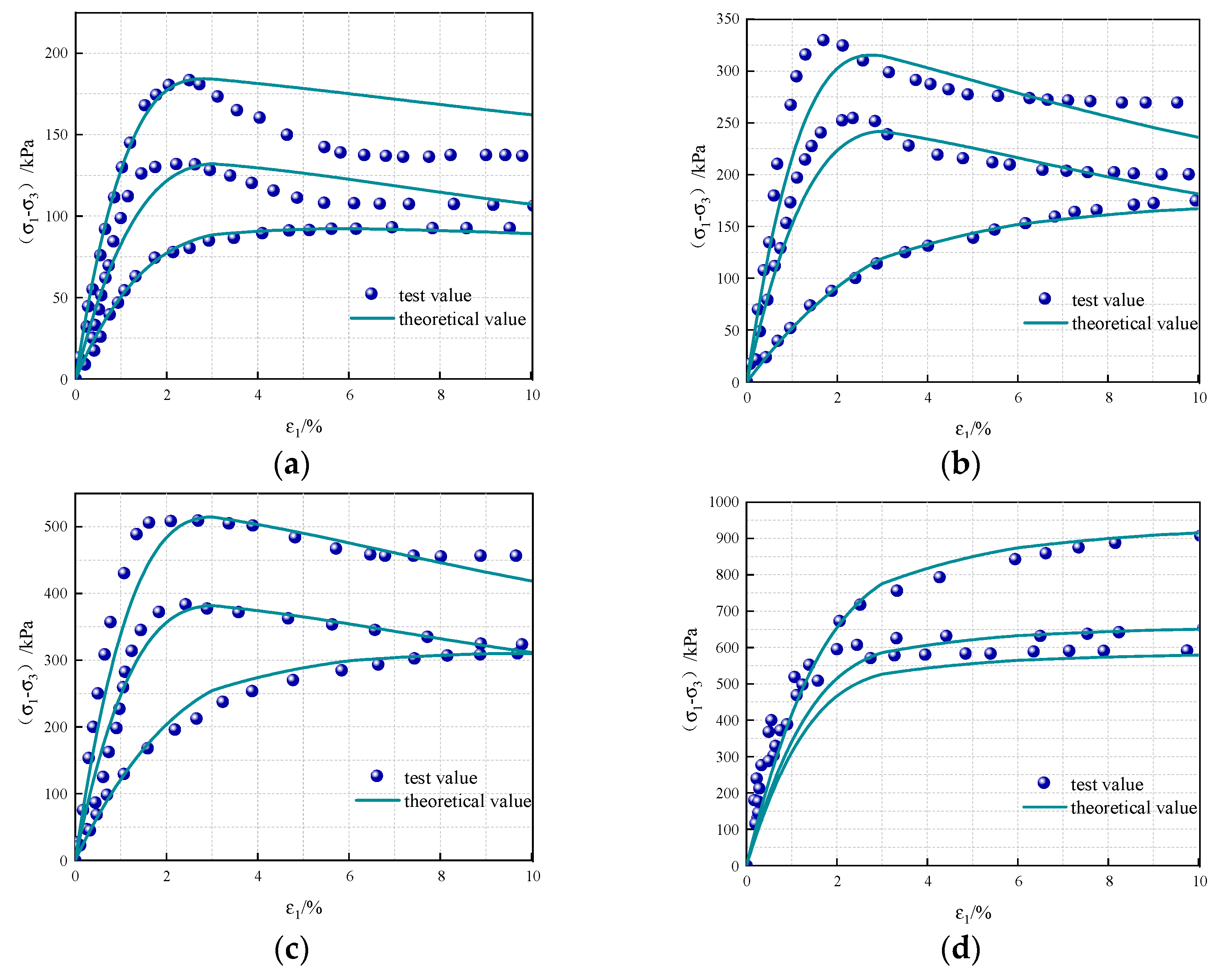

3.1. Stress–Strain Curve After Freeze–Thaw Dry–Wet Cycle of Loess

3.2. Analysis of Inner Pore Mechanisms

4. Damage Constitutive Modeling

4.1. Modeling

4.2. Model Validation

5. Conclusions

- (1)

- In the shear test, the deformation characteristics of loess samples show strain softness under low confining pressure and low cycle times and gradually transform into hardening with the increase in cycle times. In the shear process, the DWFT cycle makes the internal cementation damage control the macroscopic mechanical behavior.

- (2)

- The dry–wet and freeze–thaw cycles can change the internal pore structure of loess samples. After multiple dry–wet and freeze–thaw cycles, small pores changed into medium and large pores, and the pore area increased by 35%.

- (3)

- Based on the mechanical properties and local damage law for loess, a damage factor is proposed under the the dry–wet and freeze–thaw cycle effect, and a damage model of loess is proposed based on the improved D-C model and the principle of equivalent effect variation, and its validity is confirmed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wei, L.; Zeng, Z.; Yan, J. Factors Affecting the Stability of Loess Landslides: A Review. Appl. Sci. 2024, 14, 2735. [Google Scholar] [CrossRef]

- Dijkstra, T.A.; Wasowski, J.; Winter, M.G.; Meng, X.M. Introduction to geohazards of central China. Quart. J. Eng. Geol. Hydrogeol. 2014, 47, 195–199. [Google Scholar] [CrossRef]

- Ma, F.; Yang, J.; Bai, X. Water sensitivity and microstructure of compacted loess. Transp. Geotech. 2017, 11, 41–56. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, J. Controlling factors of loess landslides in western China. Environ. Earth Sci. 2010, 59, 1671–1680. [Google Scholar] [CrossRef]

- Liu, K.; Ye, W.; Jing, H. Multiscale evaluation of the structural characteristics of intact loess subjected to wet/dry cycles. Nat. Hazards 2024, 120, 1215–1240. [Google Scholar] [CrossRef]

- Zhou, W.; Cheng, J.; Zhang, G.; Li, H.; Cheng, Y.; Ma, G.; Ji, X. Effects of wetting–drying cycles on the breakage characteristics of slate rock grains. Rock Mech. Rock Eng. 2021, 54, 6323–6337. [Google Scholar] [CrossRef]

- Han, X.; Hu, Z.; Li, H.; Yin, Y.; Zhang, B.; Zhang, L. Study on the mechanical properties and microstructural evolution of loess under different wet-dry and freeze-thaw coupled cycling paths. Case Stud. Constr. Mater. 2024, 21, e03924. [Google Scholar] [CrossRef]

- Li, J.; Chen, H.; Gao, X.; Ding, Q.; Shan, W.; Guo, H.; Zhuo, J. Cracks evolution and micro mechanism of compacted clay under wet-dry cycles and wet-dry-freeze-thaw cycles. Cold Reg. Sci. Technol. 2023, 214, 103944. [Google Scholar] [CrossRef]

- Xu, J.; Hu, K.; Zhou, L.; Li, Y.; Ye, W.; Wang, S. Influence of wet–dry cycles on uniaxial compression behavior of fissured loess. Environ. Earth Sci. 2023, 82, 5. [Google Scholar] [CrossRef]

- Fan, P.; Zhang, L.; Ding, X. Deterioration law of shear and compression characteristics of wetted loess under dry-wet-freeze-thaw cycle. Geotechnics 2024, 45, 2050–2060. [Google Scholar]

- Zhang, L.; Cui, Z. Changing law of compression and permeability characteristics of expansive soils under dry-wet-freeze-thaw cycle. Geotechnics 2023, 44, 728–740. [Google Scholar]

- Zhang, L.; Zhang, H.; Cui, Z. Study on the variation rule of mechanical properties of expansive soil and its physical mechanism under different cyclic mode conditions. J. Civil Eng. 2023, 56, 135–148. [Google Scholar]

- Mu, M. Research on the Effect of Coarse Particle Cracking and Microstructure of Soil Under Freeze-Thaw Dry-Wet Cycling Conditions. Ph.D. Thesis, Ningxia University, Yinchuan City, China, 2023. [Google Scholar]

- Gao, R.; Li, X.-A.; An, M.; Hao, Z.; Qin, B.; Wen, F. Experimental study on structural effects of particle migration in Malan loess under different dry and wet conditions. Environ. Earth Sci. 2024, 83, 353. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.; Lei, G.; Liu, Z.; Zhou, X. Microporosity study of sulfate saline soil under freeze-thaw-dry-wet cycle. J. Undergr. Space Eng. 2023, 19, 465–473. [Google Scholar]

- Lian, B.Q.; Wang, X.G.; Zhan, H.B.; Wang, J.D.; Peng, J.B. Creep mechanical and microstructural insights into the failure mechanism of loess landslides induced by dry-wetcycles in the Heifangtai platform, China. Eng. Geol. 2022, 300, 106589. [Google Scholar] [CrossRef]

- Li, G.; Wang, F.; Ma, W.; Fortier, R.; Mu, Y.; Mao, Y.; Hou, X. Variations in strength and deformation of compacted loess exposed to wetting-drying and freeze-thaw cycles. Cold Reg. Sci. Technol. 2018, 151, 159–167. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Hu, W.; Zhang, Y. Evolution and influencing mechanisms of the Yili loess mechanical properties under combined wetting-drying and freeze-thaw cycling. Materials 2023, 16, 4727. [Google Scholar] [CrossRef]

- Kachnov, L.M. Time of the rupture process under creep conditions. Izv. Akad. Nauk. 1958, 8, 26–31. [Google Scholar]

- Li, J.; Zhu, L.; Zhou, K.; Chen, H.; Gao, L.; Lin, Y.; Shen, Y. Non-linear creep damage model of sandstone under freeze-thaw cycle. J. Cent. South Univ. 2021, 28, 954–967. [Google Scholar] [CrossRef]

- Liu, Q.; Huang, S.; Kang, Y.; Liu, X. A prediction model for uniaxial compressive strength of deteriorated rocks due to freeze-thaw. Cold Reg. Sci. Technol. 2015, 120, 96–107. [Google Scholar] [CrossRef]

- Li, B.; Zhu, Z.; Ning, J.; Li, T.; Zhou, Z. Viscoelastic-plastic constitutive model with damage of frozen soil under impact loading and freeze-thaw loading. Int. J. Mech. Sci. 2022, 214, 537–548. [Google Scholar] [CrossRef]

- Ye, W.; Qiang, Y.; Jing, H.; Zou, Y. Experimental study on freeze-thaw cycles of paleosols in loess with different water contents based on nuclear magnetic resonance. J. Eng. Geol. 2022, 30, 144–153. [Google Scholar]

- Kang, S.; Jia, X.; Zhao, Y.; Han, L.; Ma, C.; Bai, Y. Spatiotemporal Variation and Driving Factors of Ecological Environment Quality on the Loess Plateau in China from 2000 to 2020. Remote Sens. 2024, 16, 4778. [Google Scholar] [CrossRef]

- Kondner, R.L. Hyperbolic Stress-Strain Response: Cohesive Soils. J. Soil. Mech. Found. Div. 1963, 89, 115–143. [Google Scholar] [CrossRef]

- Duncanj, M.; Chang, C.Y. Nonlinear analysis of stress and strain in soils. J. Soil Mech. Found. Div. ASCE 1970, 96, 1629–1653. [Google Scholar] [CrossRef]

| Indexes | Dry Density (g/cm3) | Water Content (%) | Liquid Limit (%) | Plastic Limit (%) |

|---|---|---|---|---|

| Value | 1.62 | 12.56 | 28.8 | 18.6 |

| Pressure/kPa | Cycle Number | |||||

|---|---|---|---|---|---|---|

| 400 | 0 | 8.6608 × 10−4 | 9.7713 × 10−4 | 2.3776 × 10−6 | −0.8658 | 0.0201 |

| 2 | 1.06 × 10−3 | 1.2557 × 10−3 | 3.2851 × 10−6 | |||

| 4 | 7.1574 × 10−4 | 1.4064 × 10−3 | 2.23997 × 10−6 | |||

| 7 | 8.8213 × 10−4 | 1.4663 × 10−3 | 2.72806 × 10−6 | |||

| 10 | 6.8938 × 10−4 | 1.5338 × 10−3 | 2.12208 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Zhang, H.-M.; Liu, H.; Wang, P. Compression Characteristics and Damage Constitutive Model of Loess Under Dry–Wet and Freeze–Thaw Cycles. Water 2025, 17, 1328. https://doi.org/10.3390/w17091328

Yuan Y, Zhang H-M, Liu H, Wang P. Compression Characteristics and Damage Constitutive Model of Loess Under Dry–Wet and Freeze–Thaw Cycles. Water. 2025; 17(9):1328. https://doi.org/10.3390/w17091328

Chicago/Turabian StyleYuan, Yuan, Hui-Mei Zhang, Hao Liu, and Pan Wang. 2025. "Compression Characteristics and Damage Constitutive Model of Loess Under Dry–Wet and Freeze–Thaw Cycles" Water 17, no. 9: 1328. https://doi.org/10.3390/w17091328

APA StyleYuan, Y., Zhang, H.-M., Liu, H., & Wang, P. (2025). Compression Characteristics and Damage Constitutive Model of Loess Under Dry–Wet and Freeze–Thaw Cycles. Water, 17(9), 1328. https://doi.org/10.3390/w17091328