Water Reuse—Retrospective Study on Sustainable Future Prospects

Abstract

1. Background

1.1. History of Water Reuse in the Americas, Arizona, and Japan

Prospectus

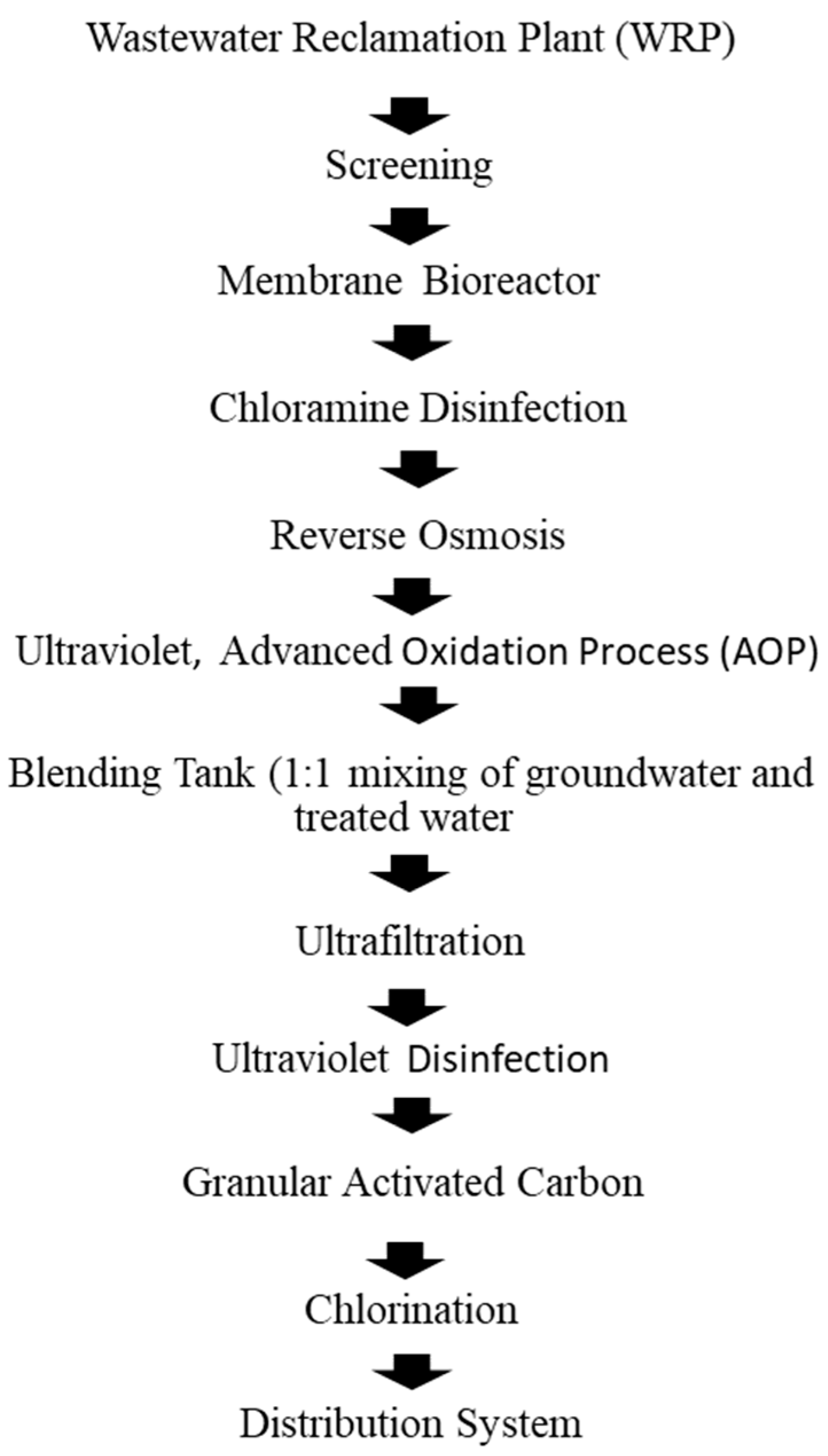

1.2. Reclamation Technologies

1.3. Groundwater Recharge

1.4. Groundwater Management

1.5. Agriculture/Irrigation

2. Legal and Regulatory Landscape

2.1. National and Regional Regulations

2.2. Direct Potable Reuse

3. Emerging Contaminants

3.1. Pathogens

3.2. Log-Reduction Monitoring Implementation in OCWD

3.3. Per- and Poly-Fluoroalkyl Substances (PFAS)

- (i)

- Treatment Technologies (High-Pressure Membrane Processes): Reverse Osmosis and Nanofiltration

- (ii)

- Treatment Technologies (Adsorption Processes): GAC and IEX

4. Contaminants Removal and Performance Monitoring Technologies

4.1. Hard Senor

- (i)

- Sensors for Physical Properties

- (ii)

- Sensors for Microbial Detection

4.2. Soft Sensors

4.3. Industrial Wastewater Reuse

5. Wastewater Reuse in Semiconductor Industry

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ekwurzel, B.; Schlosser, P.; Smethie, W.M., Jr.; Plummer, L.N.; Busenberg, E.; Michel, R.L.; Weppernig, R.; Stute, M. Dating of shallow groundwater: Comparison of the transient tracers 3H/3He, chlorofluorocarbons and 85Kr. Water Resour. Res. 1994, 30, 1693–1708. [Google Scholar] [CrossRef]

- USGS. Groundwater Age. 2019. Available online: https://www.usgs.gov/mission-areas/water-resources/science/groundwater-age\ (accessed on 8 August 2023).

- McMahon, P.B.; Plummer, L.N.; Böhlke, J.K.; Shapiro SDHinkle, S.R. A comparison of recharge rates in aquifers of the United States based on groundwater-age data. Hydrogeol. J. 2011, 19, 779–800. [Google Scholar] [CrossRef]

- Schladweiler, J.C. Tracking Down the Roots of Our Sanitary Sewers. Historian: Arizona Water and Pollution Control Association (WEF, Section—AWWA) (Phoenix, AZ). 2002. Available online: http://www.sewerhistory.org/time-lines/tracking-down-the-roots-of-our-sanitary-sewers (accessed on 8 August 2023).

- Smith, M. The aztec silent majority: William, T. Sanders and the study of the aztec peasantry. In Arqueología Mesoamericana: Homenaje a William; Sanders, T., Mastache, A.G., Parsons, J.R., Santley, R.S., Serra Puche, M.C., Eds.; Instituto Nacional de Antropología e Historia: Mexico City, Mexico, 1996; Volume 1, pp. 375–386. [Google Scholar]

- Villalonga, G.A. Hydraulic Imperialist from Aztecs in the Mexico Valley. Water Technol. 2007, 27, 78–91. (In Spanish) [Google Scholar]

- UNESCO. World Heritage Convention. World Heritage Office (INAH) Mexico’s National Commission for UNESCO (CONALMEX) Puebla 95. 2004. Available online: https://whc.unesco.org/en/tentativelists/1968/ (accessed on 8 August 2023).

- Barshan, M. Rocks, Clay and Bricks, Water in Persepolis, Burned City and Bam; Oragh Publisher: Tehran, Iran, 2011. [Google Scholar]

- USEPA. Summary of the Clean Water Act. 2023. Available online: https://www.epa.gov/laws-regulations/history-clean-water-act (accessed on 14 May 2024).

- Angelakis, A.N.; Asano, T.; Bahri, A.; Jimenez, B.E.; Tchobanoglous, G. Water Reuse: From Ancient to Modern Times and the Future. Front. Environ. Sci. 2018, 6, 26. [Google Scholar] [CrossRef]

- McGuire, M.J. The Chlorine Revolution: Water Disinfection and the Fight to Save Lives; American Water Works Association: Denver, CO, USA, 2013. [Google Scholar]

- Tchobanoglous, G.; Leverenz, H.; Nellor MMCrook, J. Direct Potable Reuse: A Path Forward; WateReuse Research Foundation: Alexandria, VA, USA, 2011. [Google Scholar]

- Davis, M.L. 2019. Direct and Indirect Potable Reuse. In Water and Wastewater Engineering: Design Principles and Practice, 2nd ed.; McGraw-Hill Education. Government of Canada: New York, NY, USA, 2017; pp. 1237–1252. [Google Scholar]

- Available online: https://www.canada.ca/en/environment-climate-change/services/water-overview/pollution-causes-effects/groundwater-contamination.html (accessed on 5 July 2024).

- McBurnett, L.R.; Holt, N.T.; Alum, A.; Abbaszadegan, M. Legionella—A threat to groundwater: Pathogen transport in recharge basin. Sci. Total Environ. 2018, 621, 1485–1490. [Google Scholar] [CrossRef]

- Abbaszadegan, M.; LeChevallier, M.; Gerba, C.P. Occurrence of viruses in US groundwaters. J.-Am. Water Work. Assoc. 2003, 95, 107–120. [Google Scholar] [CrossRef]

- Borchardt, M.A.; Bertz, P.D.; Spencer, S.K.; Battigelli, D.A. Incidence of enteric viruses in groundwater from household wells in Wisconsin. Appl. Environ. Microbiol. 2003, 69, 1172–1180. [Google Scholar] [CrossRef]

- Locas, A.; Barthe, C.; Barbeau, B.; Carrière, A.; Payment, P. Virus occurrence in municipal groundwater sources in Quebec, Canada. Can. J. Microbiol. 2007, 53, 688–694. [Google Scholar] [CrossRef]

- Bluefield Research. Looking Beyond Drought, 17 States Invest in Water Reuse as a Long-Term Supply Strategy. 2017. Available online: https://www.bluefieldresearch.com/ns/looking-beyond-drought-17-states-invest-water-reuse/ (accessed on 9 August 2023).

- Wada, Y.; van Beek, L.P.H.; van Kempen, C.M.; Reckman, J.W.T.M.; Vasak, S.; Bierkens, M.F.P. Global depletion of groundwater resources. Geophys. Res. Lett. 2010, 37, L20402. [Google Scholar] [CrossRef]

- Seo, K.W.; Ryu, D.; Eom, J.; Jeon, T.; Kim, J.S.; Youm, K. Drift of Earth’s pole confirms groundwater depletion as a significant contributor to global sea level rise 1993–2010. Geophys. Res. Lett. 2023, 50, e2023GL103509. [Google Scholar] [CrossRef]

- Jasechko, S.; Seybold, H.; Perrone, D. Rapid groundwater decline and some cases of recovery in aquifers globally. Nature 2024, 625, 715–721. [Google Scholar] [PubMed]

- Van der Gun, J. Large Aquifer Systems Around the World; The Groundwater Project: Guelph, ON, Canada, 2022. [Google Scholar] [CrossRef]

- Hussein, H.; Poplawsky, M.; Mohapatra, T. The political context of change in transboundary freshwater agreements. Environ. Sci. Policy 2023, 149, 103572. [Google Scholar] [CrossRef]

- Richey, A.S.; Thomas, B.F.; Lo, M.H.; Reager, J.T.; Famiglietti, J.S.; Voss, K.; Swenson, S.; Rodell, M. Quantifying renewable groundwater stress with GRACE. Water Resour. Res. 2015, 51, 5217–5238. [Google Scholar] [CrossRef]

- Angelakis, A.N.; Snyder, S.A. Wastewater Treatment and Reuse: Past, Present, and Future. Water 2015, 7, 4887–4895. [Google Scholar] [CrossRef]

- Sneegas, G.; Seghezzo, L.; Brannstrom, C.; Jepson, W.; Eckstein, G. Do not put all your eggs in one basket: Social perspectives on desalination and water recycling in Israel. Water Policy 2022, 24, 1772–1795. [Google Scholar] [CrossRef]

- USEPA. Water Reuse Regulations and Guidelines. Available online: https://www.epa.gov/waterreuse/maps-states-water-reuse-regulations-or-guidelines (accessed on 23 March 2024).

- Gerling, A. Potable Reuse 101: An Innovative and Sustainable Water Supply Solution; American Water Works Association: Denver, CO, USA, 2016. [Google Scholar]

- Tchobanoglous, G.; Cotruvo, J.; Crook, J.; McDonald, E.; Olivieri, A.; Salveson, A.; Trussell, R.S. Framework for Direct Potable Reuse; WateReuse Research Foundation: Alexandria, VA, USA, 2015. [Google Scholar]

- Padervand, M.; Lichtfouse, E.; Robert, D. Removal of microplastics from the environment. A review. Environ. Chem. Lett. 2020, 18, 807–828. [Google Scholar] [CrossRef]

- Abbaszadegan, M.; Monteiro, P.; Nwachuku, N.; Alum, A.; Ryu, H. Removal of adenovirus, calicivirus, and bacteriophages by conventional drinking water treatment. J. Environ. Sci. Health Part A 2008, 43, 171–177. [Google Scholar] [CrossRef]

- Grabow, W. Bacteriophages: Update on application as models for viruses in water. Water SA 2001, 27, 251–268. [Google Scholar] [CrossRef]

- Jofre, J. Indicators of waterborne viruses. In Human Viruses in Water; Bosch, A., Ed.; Perspectives in Medical Virology, 17; Elsevier Science: Amsterdam, The Netherlands, 2007. [Google Scholar]

- QEPA. Queensland Water Recycling Guidelines; WaterWise; Queensland Environmental Protection Agency: Brisbane, Australia, 2005. [Google Scholar]

- NHMRC-NRMMC. Australian Drinking Water Guidelines; Natural Resource Management Ministerial Council, National Health and Medical Research Council: Canberra, Australia, 2011.

- DEC. Western Australian Guidelines for Biosolids Management; Department of Environment and Conservation: Perth, Australia, 2012. [Google Scholar]

- USEPA. National Primary Drinking Water Regulations: Groundwater Rule; Final Rule. 40 CFR, Federal Register; The Daily Journal of the United States Government: Washington, DC, USA, 2006; Volume 71.

- Jofre, J.; Lucena, F.; Blanch, A.R.; Muniesa, M. Coliphages as Model Organisms in the Characterization and Management of Water Resources. Water 2016, 8, 199. [Google Scholar] [CrossRef]

- Arts, P.J.; Kelly, J.D.; Midgley, C.M.; Anglin, K.; Lu, S.; Abedi, G.R.; Andino, R.; Bakker, K.M.; Banman, B.; Boehm, A.B.; et al. Longitudinal and quantitative fecal shedding dynamics of SARS-CoV-2, pepper mild mottle virus, and crAssphage. mSphere 2023, 8, e0013223. [Google Scholar] [CrossRef]

- Park, G.W.; Ng, T.F.F.; Freeland, A.L.; Marconi, V.C.; Boom, J.A.; Staat, M.A.; Montmayeur, A.M.; Browne, H.; Narayanan, J.; Payne, D.C.; et al. CrAssphage as a Novel Tool to Detect Human Fecal Contamination on Environmental Surfaces and Hands. Emerg. Infect. Dis. 2020, 26, 1731–1739. [Google Scholar] [CrossRef]

- Kitajima, M.; Sassi, H.P.; Torrey, J.R. Pepper mild mottle virus as a water quality indicator. NPI Clean Water 2018, 1, 19. [Google Scholar] [CrossRef]

- NRMMC-EPHC-AHMC. Australian Guidelines for Water Recycling: Managing Health and Environmental Risks: Phase 1. National Water Quality Management Strategy; Natural Resource Management Ministerial Council, Environment Protection and Heritage Council, Australian Health Ministers’ Conference: Canberra, Australia, 2006. [Google Scholar]

- WHO. Guidelines for the Safe Use of Wastewater, Excreta and Greywater; World Health Organization: Geneva, Switzerland, 2006; Volume 2, Wastewater Use in Agriculture. [Google Scholar]

- USEPA. Guidelines for Water Reuse; (EPA/600/R-12/618); United States Environmental Protection Agency: Washington, DC, USA, 2012.

- Havelaar, A.; Melse, J. Quantifying Public Health Risk in the WHO Guidelines for Drinking-Water Quality: A Burden of Disease Approach; WHO: Geneva, Switzerland, 2003. [Google Scholar]

- Ryu, H.; Addor, Y.; Brinkman, N.E.; Ware, M.W.; Boczek, L.; Hoelle, J.; Villegas, E.N. Understanding microbial loads in wastewater treatment works as source water for water reuse. Water 2021, 13, 1452. [Google Scholar] [CrossRef] [PubMed]

- California Regional Water Quality Control Board. Groundwater Replenishment System 2022 Annual Report. 2022. Available online: https://www.waterboards.ca.gov/santaana/board_decisions/adopted_orders/orders/2022/r8-2022-0002.pdf (accessed on 15 May 2024).

- Orange County Water District, Groundwater Replenishment System. Annual Report (2022). 2022. Available online: https://www.ocwd.com/wp-content/uploads/2022-GWRS-Annual-Report.pdf (accessed on 6 August 2023).

- State Water Resources Control Board 2018. The 2018 California Integrated Report Is Available on the State Water Board’s Website. Available online: https://www.waterboards.ca.gov/water_issues/programs/water_quality_assessment/2018_integrated_report.html (accessed on 15 May 2024).

- Steinle-Darling, E.; Salveson, A.; Sutherland, J.; Dickenson, E.; Hokanson, D.; Trussell, S.; Stanford, B. Direct Potable Reuse Monitoring: Testing Water Quality in a Municipal Wastewater Effluent Treated to Drinking Water Standards, Texas Water Development. 2016. Available online: https://www.twdb.texas.gov/publications/reports/contracted_reports/doc/1348321632_vol1.pdf (accessed on 6 August 2023).

- Ghisi, R.; Vamerali, T.; Manzetti, S. Accumulation of perfluorinated alkyl substances (PFAS) in agricultural plants: A review. Environ. Res. 2019, 169, 326–341. [Google Scholar] [CrossRef]

- Davis, M.J.B.; Evich, M.G.; Goodrow, S.M.; Washington, J.W. Environmental Fate of Cl-PFPECAs: Accumulation of Novel and Legacy Perfluoroalkyl Compounds in Real-World Vegetation and Subsoils. Environ. Sci. Technol. 2023, 57, 8994–9004. [Google Scholar] [CrossRef]

- Barisci, S.; Suri, R. Occurrence and Removal of Poly/Perfluoroalkyl Substances (PFAS) in Municipal and Industrial Wastewater Treatment Plants. Water Sci. Technol. 2021, 84, 3442–3468. [Google Scholar] [CrossRef] [PubMed]

- Thompson, K.A.; Mortazavian, S.; Gonzalez, D.J.; Bott, C.; Hooper, J.; Schaefer, C.E.; Dickenson, E.R. Poly- and Perfluoroalkyl Substances in Municipal Wastewater Treatment Plants in the United States: Seasonal Patterns and Meta-Analysis of Long-Term Trends and Average Concentrations. ACS EST Water 2022, 2, 690–700. [Google Scholar] [CrossRef]

- Dixit, F.; Dutta, R.; Barbeau, B.; Berube, P.; Mohseni, M. PFAS removal by ion exchange resins: A review. Chemosphere 2021, 272, 129777. [Google Scholar] [CrossRef]

- Lee, T.; Speth TFNadagouda, M.N. High-pressure membrane filtration processes for separation of Per- and polyfluoroalkyl substances (PFAS). Chem. Eng. J. 2022, 431, 134023. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, X.; Faria, A.F.; Deliz Quiñones, K.Y.; Zhang, C.; He, Q.; Ma, J.; Shen, Y.; Zhi, Y. Evaluating the efficiency of nanofiltration and reverse osmosis membrane processes for the removal of per- and polyfluoroalkyl substances from water: A critical review. Sep. Purif. Technol. 2022, 302, 122161. [Google Scholar] [CrossRef]

- Murray, C.C.; Marshall, R.E.; Liu, C.J.; Vatankhah HBellona, C.L. PFAS treatment with granular activated carbon and ion exchange resin: Comparing chain length, empty bed contact time, and cost. J. Water Process Eng. 2021, 44, 102342. [Google Scholar] [CrossRef]

- WHO. Potable Reuse: Guidance for Producing Safe Drinking Water; World Health Organization: Geneva, Switzerland, 2017. [Google Scholar]

- Verma, S.; Varma, R.S.; Nadagouda, M.N. Remediation and mineralization processes for per- and polyfluoroalkyl substances (PFAS) in water: A review. Sci. Total Environ. 2021, 794, 148987. [Google Scholar] [CrossRef] [PubMed]

- Mastropietro, T.F.; Bruno, R.; Pardo, E.; Armentano, D. Reverse osmosis and nanofiltration membranes for highly efficient PFASs removal: Overview, challenges and future perspectives. Dalton Trans. 2021, 50, 5398–5410. [Google Scholar] [CrossRef]

- Fujioka, T.; Khan, S.J.; Poussade, Y.; Drewes, J.E.; Nghiem, L.D. N-nitrosamine removal by reverse osmosis for indirect potable water reuse—A critical review based on observations from laboratory-, pilot- and full-scale studies. Sep. Purif. Technol. 2012, 98, 503–515. [Google Scholar] [CrossRef]

- Solley, D.; Gronow, C.; Tait, S.; Bates JBuchanan, A. Managing the reverse osmosis concentrate from the Western Corridor Recycled Water Scheme. Water Pract. Technol. 2010, 5, 18. [Google Scholar] [CrossRef]

- Tang, C.Y.; Fu, Q.S.; Criddle, C.S.; Leckie, J.O. Effect of Flux (Transmembrane Pressure) and Membrane Properties on Fouling and Rejection of Reverse Osmosis and Nanofiltration Membranes Treating Perfluorooctane Sulfonate Containing Wastewater. Environ. Sci. Technol. 2007, 41, 2008–2014. [Google Scholar] [CrossRef]

- Tang, C.Y.; Fu, Q.S.; Robertson, A.P.; Criddle CSLeckie, J.O. Use of Reverse Osmosis Membranes to Remove Perfluorooctane Sulfonate (PFOS) from Semiconductor Wastewater. Environ. Sci. Technol. 2006, 40, 7343–7349. [Google Scholar] [CrossRef] [PubMed]

- Soriano, Á.; Gorri, D.; Urtiaga, A. Selection of High Flux Membrane for the Effective Removal of Short-Chain Perfluorocarboxylic Acids. Ind. Eng. Chem. Res. 2019, 58, 3329–3338. [Google Scholar] [CrossRef]

- Cyna, B.; Chagneau, G.; Bablon, G.; Tanghe, N. Two years of nanofiltration at the Méry-sur-Oise plant, France. Desalination 2002, 147, 69–75. [Google Scholar] [CrossRef]

- Boo, C.; Wang, Y.; Zucker, I.; Choo, Y.; Osuji, C.O.; Elimelech, M. High Performance Nanofiltration Membrane for Effective Removal of Perfluoroalkyl Substances at High Water Recovery. Environ. Sci. Technol. 2018, 52, 7279–7288. [Google Scholar] [CrossRef]

- Hang, X.; Chen, X.; Luo, J.; Cao, W.; Wan, Y. Removal and recovery of perfluorooctanoate from wastewater by nanofiltration. Sep. Purif. Technol. 2015, 145, 120–129. [Google Scholar] [CrossRef]

- Toure, H.; Anwar Sadmani, A.H.M. Nanofiltration of perfluorooctanoic acid and perfluorooctane sulfonic acid as a function of water matrix properties. Water Supply 2019, 19, 2199–2205. [Google Scholar] [CrossRef]

- Rostvall, A.; Zhang, W.; Dürig, W.; Renman, G.; Wiberg, K.; Ahrens, L.; Gago-Ferrero, P. Removal of pharmaceuticals, perfluoroalkyl substances and other micropollutants from wastewater using lignite, Xylit, sand, granular activated carbon (GAC) and GAC+Polonite® in column tests—Role of physicochemical properties. Water Res. 2018, 137, 97–106. [Google Scholar] [CrossRef]

- Zeidabadi, F.A.; Esfahani, E.B.; Mohseni, M. Effects of water matrix on per- and poly-fluoroalkyl substances (PFAS) treatment: Physical-separation and degradation processes—A review. J. Hazard. Mater. Adv. 2023, 10, 100322. [Google Scholar] [CrossRef]

- Chow, S.J.; Croll, H.C.; Ojeda, N.; Klamerus, J.; Capelle, R.; Oppenheimer, J.; Jacangelo, J.G.; Schwab, K.J.; Prasse, C. Comparative investigation of PFAS adsorption onto activated carbon and anion exchange resins during long-term operation of a pilot treatment plant. Water Res. 2022, 226, 119198. [Google Scholar] [CrossRef]

- Dixit, F.; Barbeau, B.; Mostafavi, S.G.; Mohseni, M. PFAS and DOM removal using an organic scavenger and PFAS-specific resin: Trade-off between regeneration and faster kinetics. Sci. Total Environ. 2021, 754, 142107. [Google Scholar] [CrossRef] [PubMed]

- Mohamad, E.; Alum, A.; Abbaszadegan, M. Biochemical signature assay for use in a biosensor platform to detect bacteria in drinking water biofilms. J. Environ. Sci. Health Part A 2013, 48, 925–932. [Google Scholar]

- Hesari, N.; Alum, A.; Elzein, M.; Abbaszadegan, M. A biosensor platform for rapid detection of E. coli in drinking water. Enzym. Microb. Technol. 2015, 83, 22–28. [Google Scholar] [CrossRef]

- Kato, T.; Miura, T.; Okabe, S.; Sano, D. Bayesian modeling of enteric virus density in wastewater using left-censored data. Food Environ. Virol. 2013, 5, 185–193. [Google Scholar] [CrossRef]

- Kadoya, S.S.; Nishimura, O.; Kato, H.; Sano, D. Predictive water virology using regularized regression analyses for projecting virus inactivation efficiency in ozone disinfection. Water Res. X 2021, 11, 100093. [Google Scholar] [CrossRef]

- Ching, P.M.L.; So, H.Y.; Morck, T. Advances in soft sensors for wastewater treatment plants: A systematic review. J. Water Process Eng. 2021, 44, 102367. [Google Scholar] [CrossRef]

- McMeekin, T.; Olley, J.; Ratkowsky, D.; Corkrey, R.; Ross, T. Predictive microbiology theory and application: Is it all about rates? Food Control 2013, 29, 290–299. [Google Scholar] [CrossRef]

- Baranyi, J.; Tamplin, M.L. ComBase: A common dataset on microbial responses to food environments. J. Food Prot. 2004, 67, 1967–1971. [Google Scholar] [CrossRef] [PubMed]

- WHO. Water Safety Plan Manual: Step-by-Step Risk Management for Drinking-Water Suppliers, 2nd ed.; WHO: Geneva, Switzerland, 2023; Available online: https://www.who.int/publications/i/item/9789240067691 (accessed on 6 August 2023).

- WHO. Sanitation Safety Planning: Manual for Safe Use and Disposal of Wastewater Greywater and Excreta. 2015. Available online: https://apps.who.int/iris/handle/10665/171753 (accessed on 6 August 2023).

- Cornu, M.; Billoir, E.; Bergis, H.; Beaufort, A.; Zuliani, V. Modeling microbial competition in food: Application to the behavior of Listeria monocytogenes and lactic acid flora in pork meat products. Food Microbiol. 2011, 28, 639–647. [Google Scholar] [CrossRef] [PubMed]

- Kadoya, S.S.; Nishimura, O.; Kato, H.; Sano, D. Predictive water virology: Hierarchical Bayesian modeling for estimating virus inactivation curve. Water 2019, 11, 2187. [Google Scholar] [CrossRef]

- Kadoya, S.S.; Nishimura, O.; Kato, H.; Sano, D. Regularized regression analysis for the prediction of virus inactivation efficiency by chloramine disinfection. Environ. Sci. Water Res. Technol. 2020, 6, 3341. [Google Scholar] [CrossRef]

- Oishi, W.; Kadoya, S.; Nishimura, O.; Rose, B.J.; Sano, D. Hierarchical Bayesian modeling for predictive environmental microbiology toward a safe use of human excreta: Systematic review and meta-analysis. J. Environ. Manag. 2021, 284, 112088. [Google Scholar] [CrossRef]

- OECD. Forward-Looking Scenarios of Climate Finance Provided and Mobilised by Developed Countries in 2021–2025: Technical Note, Climate Finance and the USD 100 Billion Goal; OECD Publishing: Paris, France, 2021. [Google Scholar] [CrossRef]

- Wang, Q.; Huang, N.; Cai, H.; Chen, X.; Wu, Y. Water strategies and practices for sustainable development in the semiconductor industry. Water Cycle 2023, 4, 12–16. [Google Scholar] [CrossRef]

- You, S.H.; Tseng, D.H.; Guo, G.L. A case study on the wastewater reclamation and reuse in the semiconductor industry. Resour. Conserv. Recycl. 2001, 32, 73–81. [Google Scholar] [CrossRef]

- Eng, C.Y.; Yan, D.; Withanage, N.; Liang, Q.; Zhou, Y. Wastewater treatment and recycle from a semiconductor industry: A demo-plant study. Water Pract. Technol. 2019, 14, 371–379. [Google Scholar] [CrossRef]

- Huang, C.J.; Yang, B.M.; Chen, K.S.; Chang, C.C.; Kao, C.M. Application of membrane technology on semiconductor wastewater reclamation: A pilot-scale study. Desalination 2011, 278, 203–210. [Google Scholar] [CrossRef]

| Non-Potable Reuse | Potable Reuse | ||

|---|---|---|---|

| Planned Potable Reuse | Un-Planned (de facto) Potable Reuse | ||

| Indirect | Direct | Indirect | |

| • Agriculture • Parks, roadways, and sports fields • Fire suppression • Construction • Dust control • Industry • Power plants and refineries • Toilet flushing • Replenishment of lakes, reservoirs, and aquifers | GWRS: percolation basins in Anaheim filter through sand and gravel before returning to the drinking water system | Windhoek, Namibia, since 1968 CRMWD Texas, Started operation in April 2013 Other • Brownwood, Texas, • Wichita Falls | Trinity River—treated wastewater from Dallas/Fort Worth is delivered to Lake Livingston, the main drinking water source for Houston |

| US EPA 2012 | WHO 2016 | EU 2020 | ||||||

|---|---|---|---|---|---|---|---|---|

| Parameter/Category | A | B | A | B | A | B | C | D |

| E. coli (CFU/100 mL) | - | - | 1000 | - | 10 | 100 | 1000 | 10,000 |

| Fecal coliforms (CFU/100 mL) | 0 | 200 | - | - | - | - | - | - |

| BOD5 (mg/L) | 10 | 30 | - | - | 10 | 25 | 25 | 25 |

| TSS (mg/L) | - | 30 | - | - | 10 | 35 | 35 | 35 |

| Turbidity (NTU) | 2 | - | - | - | 5 | - | - | - |

| Intestinal nematodes (eggs/L) | - | - | 1 | 1 | 1 | 1 | 1 | 1 |

| Categories of Reuse Applications—Based on End Use | U.S States That Have Developed Regulations or Guidelines for the Respective End Use Category |

|---|---|

| Agriculture Reuse | WA, OR, CA, ID, MT, NV, AZ, UT, WY, CO, NM, NE, OK, TX, MN, IN, AL, GA, FL, NC, VA, PA, MD, DE, NJ, RI, MA, HI |

| Environmental Restoration Reuse | WA, MT, ID, NV, FL, NC, PA, MA |

| Impoundments Reuse | WA, OR, CA, NV, MT, UT, AZ, NM, TX, PA, MA, HI |

| Industry Reuse | OR, CA, NV, UT, HI, MN, WI, GA, FL, VA, PA, RI, MA, NJ, MD |

| Landscaping Reuse | WA, OR, CA, NV, ID, MT, WY, UT, AZ, NM, CO, SD, OK, TX, MN, IA, WI, IN, OH, PA, VA, MD, DE, NJ, RI. NH, MA, SC, GA, AL, FL |

| Consumption by Livestock Reuse | OR, AZ, NM, HI, OK, VA |

| Centralized Non-Potable Reuse | WA, OR, CA, NV, ID, MT, UT, AZ, NM, CO, OK, TX, MN, WI, GA, VA, PA, VT, MA, HI |

| Onsite Non-Potable Reuse | OR, CA, NM, CO, TX, OK, MN, WI, OH, GA, FL, HI |

| Potable Reuse | WA, OR, CA, NV, MT, CO, NM, TX, OK, OH, PA, MA, VA, NC, FL |

| Agency | Pathogen | ||

|---|---|---|---|

| Enteric Virus | Cryptosporidium | Giardia | |

| NWRI 2013 | 12 | 10 | 9 (Salmonella) |

| California for IPR Using Groundwater Replenishment | 12 | 10 | 10 |

| California Water Board draft | 16 | 11 | 10 |

| California Water Board 2021 | 20 | 15 | 14 |

| Texas (Big Spring Project) | 8 | 5.5 | 6 |

| Texas Commission on Environmental Quality (TCEQ) 2014 | 2.2 × 107 | 3 × 105 | 7 × 107 |

| Altamonte Springs, Florida (2018) | 11.2 (Genome) 5.8 (Culture) | 3.9 | 4.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbaszadegan, M.; Alum, A.; Kitajima, M.; Fujioka, T.; Matsui, Y.; Sano, D.; Katayama, H. Water Reuse—Retrospective Study on Sustainable Future Prospects. Water 2025, 17, 789. https://doi.org/10.3390/w17060789

Abbaszadegan M, Alum A, Kitajima M, Fujioka T, Matsui Y, Sano D, Katayama H. Water Reuse—Retrospective Study on Sustainable Future Prospects. Water. 2025; 17(6):789. https://doi.org/10.3390/w17060789

Chicago/Turabian StyleAbbaszadegan, Morteza, Absar Alum, Masaaki Kitajima, Takahiro Fujioka, Yasuhiro Matsui, Daisuke Sano, and Hiroyuki Katayama. 2025. "Water Reuse—Retrospective Study on Sustainable Future Prospects" Water 17, no. 6: 789. https://doi.org/10.3390/w17060789

APA StyleAbbaszadegan, M., Alum, A., Kitajima, M., Fujioka, T., Matsui, Y., Sano, D., & Katayama, H. (2025). Water Reuse—Retrospective Study on Sustainable Future Prospects. Water, 17(6), 789. https://doi.org/10.3390/w17060789