Anaerobic Dynamic Membrane Bioreactors (AnDMBRs): Are They an Efficient Way to Treat High-Strength Wastewater?

Abstract

1. Introduction

2. Materials and Methods

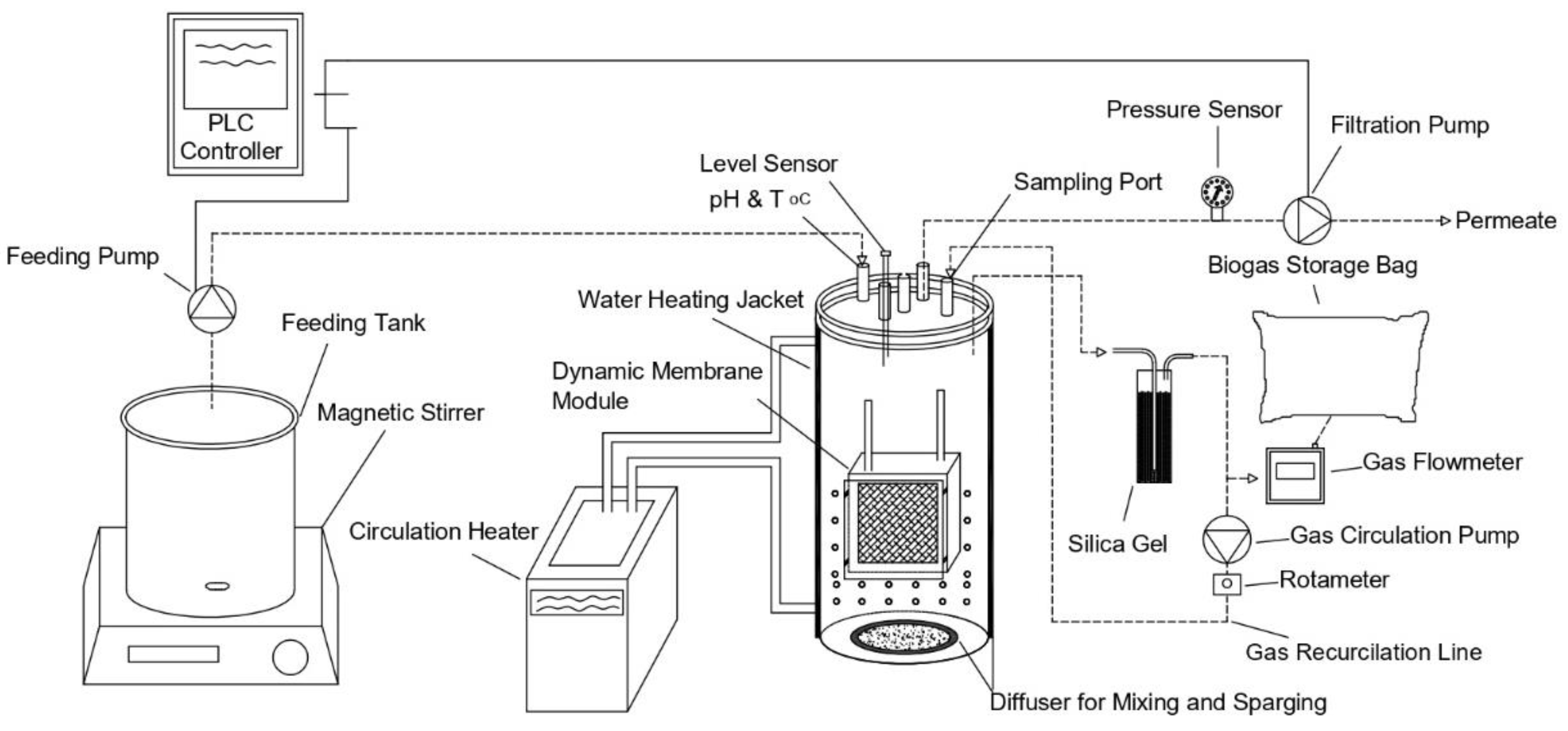

2.1. AnDMBR Setup

2.2. Seed Sludge and Synthetic Wastewater Composition

2.3. Experimental Operation

2.4. Analytical Methods

3. Results and Discussion

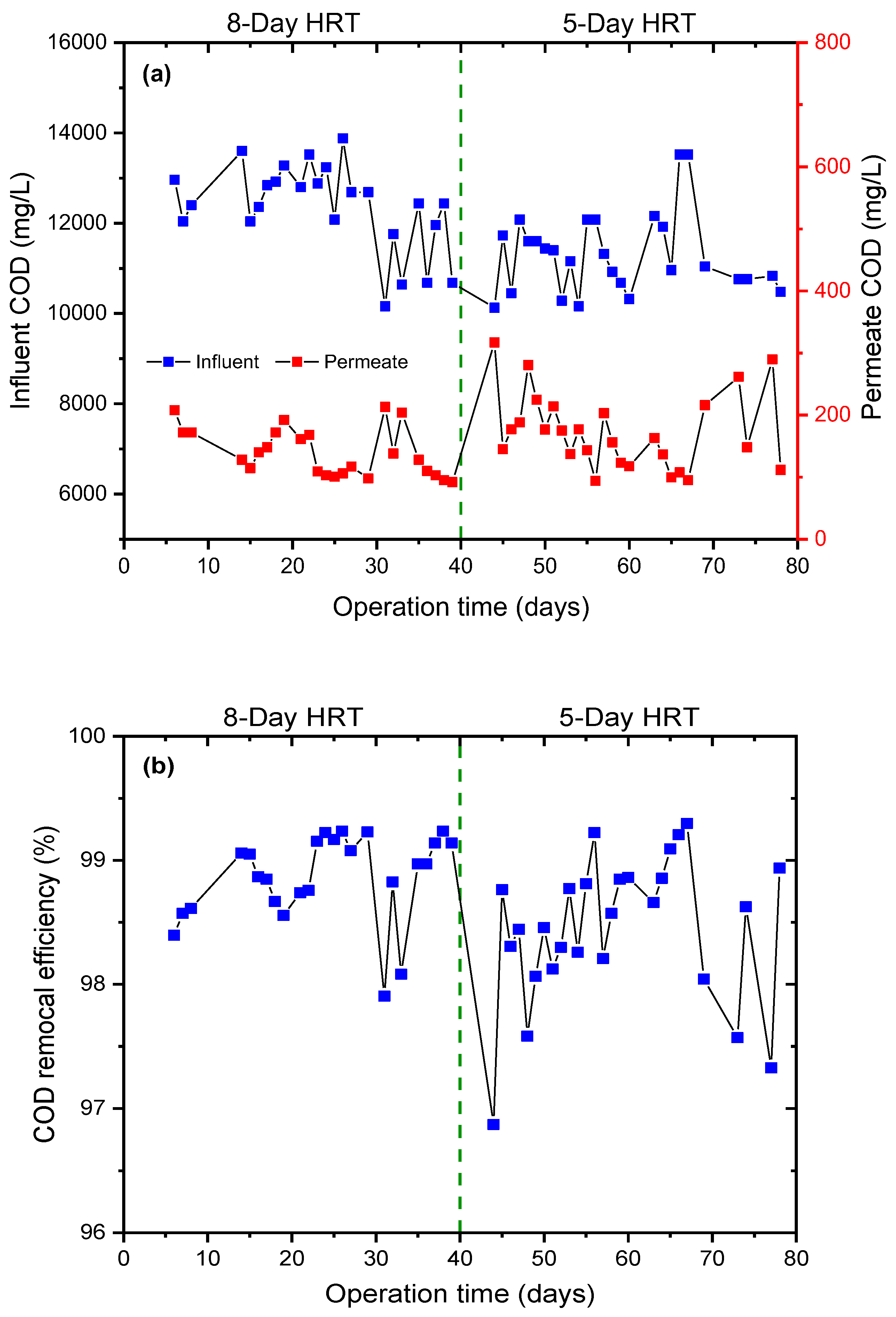

3.1. Treatment Performance of AnDMBR

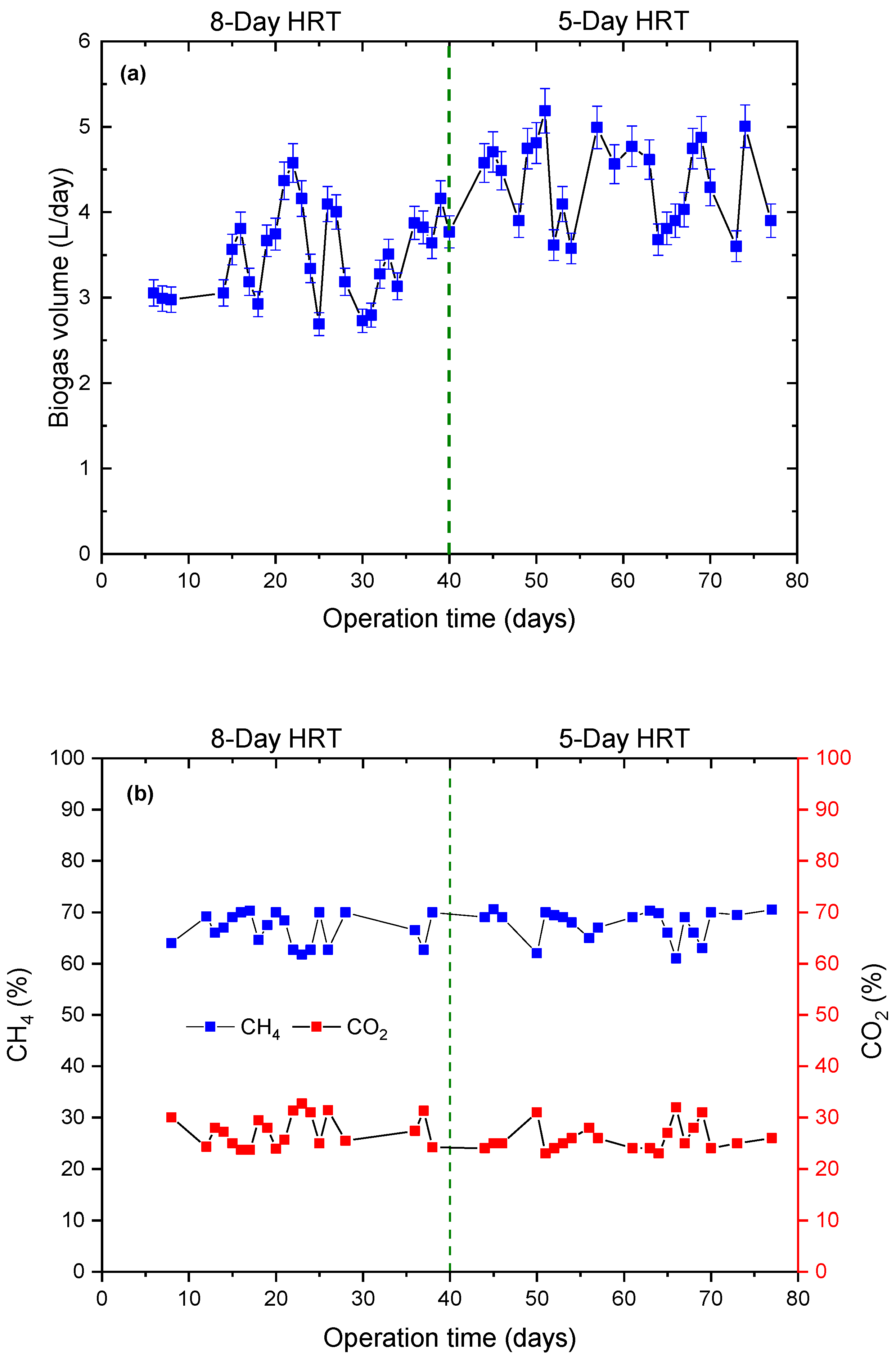

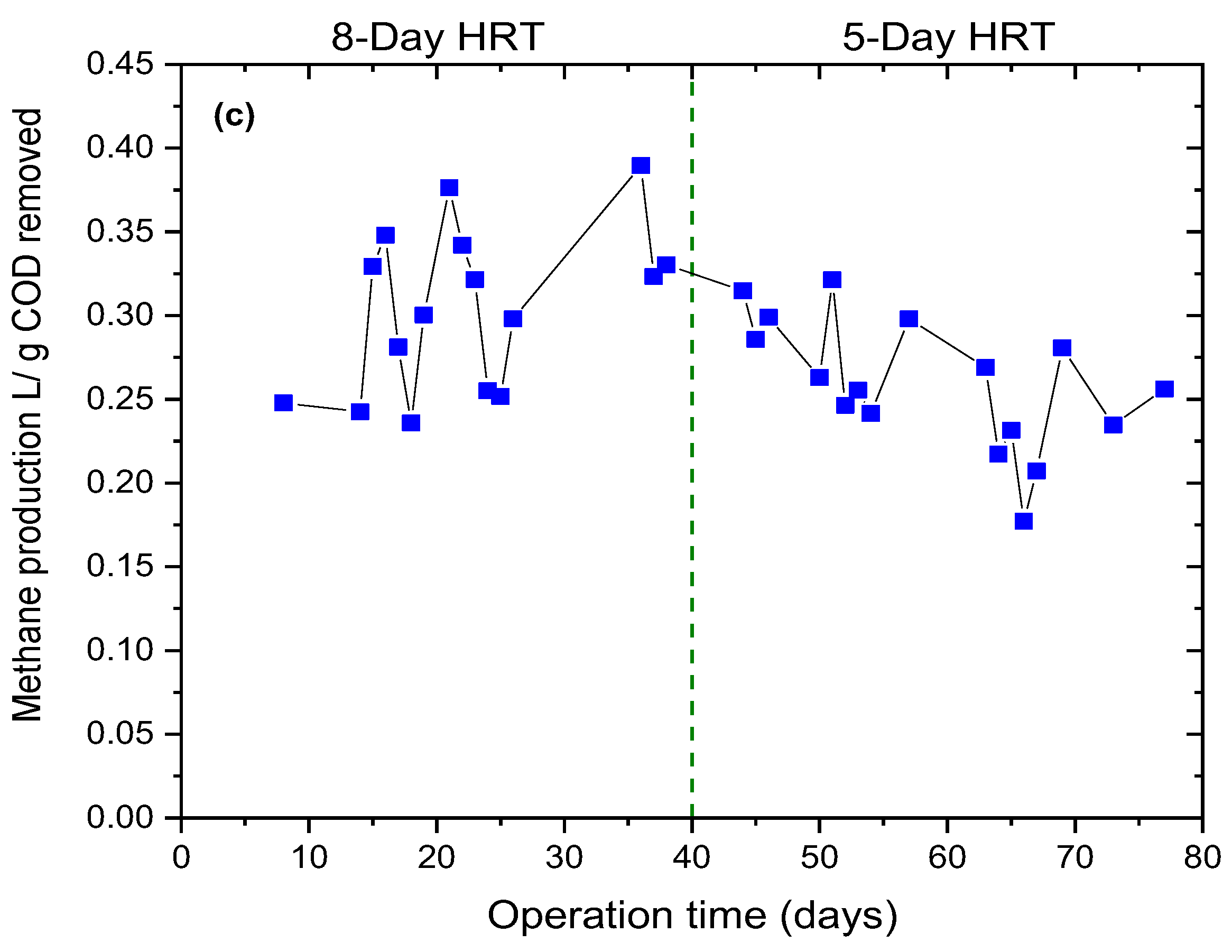

3.2. Biogas Production and Composition

3.3. Membrane Fouling

3.3.1. Membrane Performance of AnDMBRs

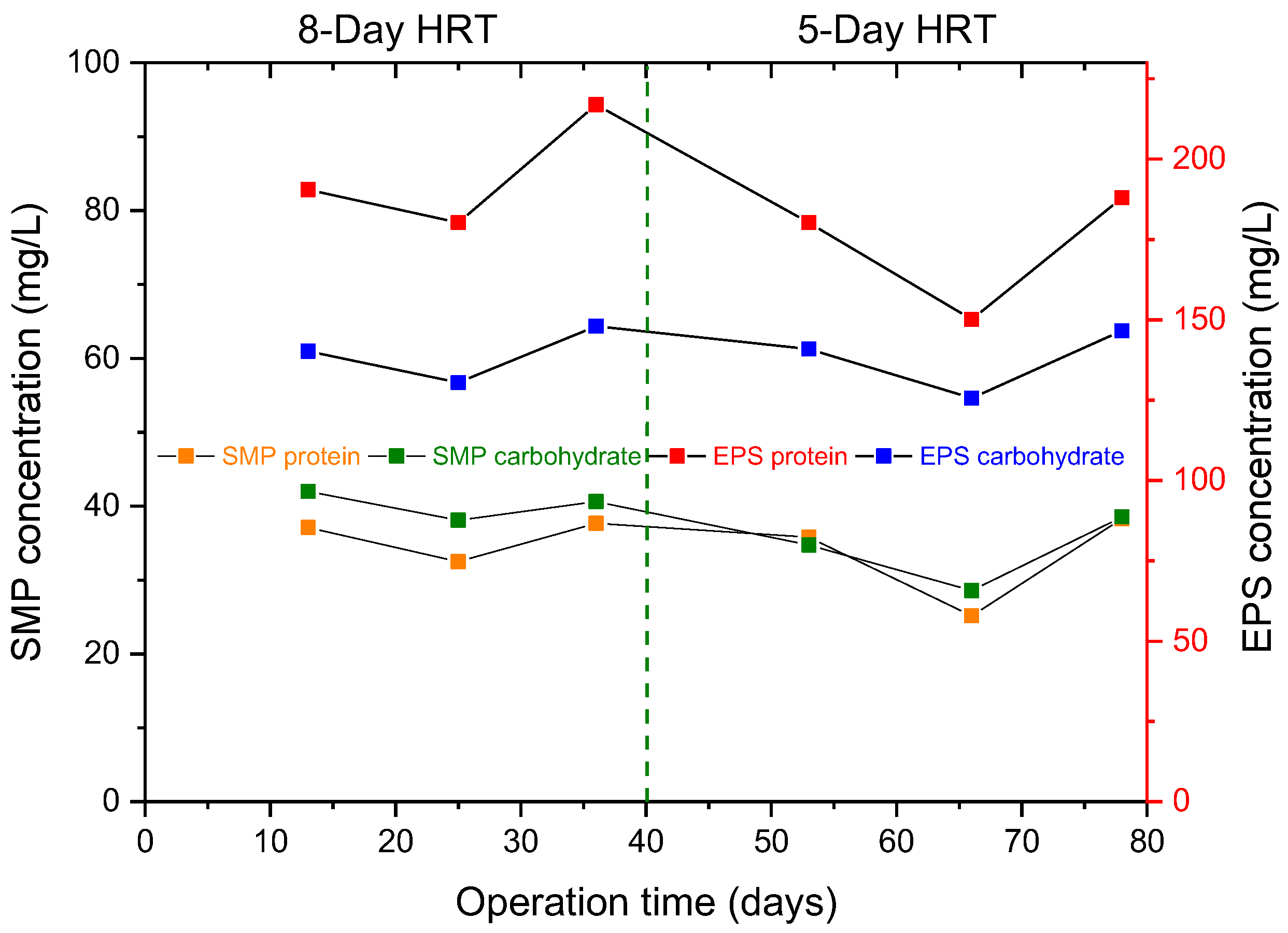

3.3.2. SMP and EPS Concentrations in AnDMBRs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- An, Z.; Zhu, J.; Zhang, M.; Zhou, Y.; Su, X.; Lin, H.; Sun, F. Anaerobic membrane bioreactor for the treatment of high-strength waste/wastewater: A critical review and update. Chem. Eng. J. 2023, 470, 144322. [Google Scholar] [CrossRef]

- Mutamim, N.S.A.; Noor, Z.Z.; Hassan, M.A.A.; Olsson, G. Application of membrane bioreactor technology in treating high strength industrial wastewater: A performance review. Desalination 2012, 305, 1–11. [Google Scholar] [CrossRef]

- Liew, Y.X.; Chan, Y.J.; Manickam, S.; Chong, M.F.; Chong, S.; Tiong, T.J.; Lim, J.W.; Pan, G.T. Enzymatic pretreatment to enhance anaerobic bioconversion of high strength wastewater to biogas: A review. Sci. Total Environ. 2020, 713, 136373. [Google Scholar] [CrossRef] [PubMed]

- Lim, K. Anaerobic Membrane Bioreactors for Domestic Wastewater Treatment: Treatment Performance and Fouling Characterization; Kansas State University: Manhattan, KS, USA, 2021. [Google Scholar]

- Perendeci, A.; Arslan, S.; Tanyolaç, A.; Çelebi, S.S. Evaluation of Input Variables in Adaptive-Network-Based Fuzzy Inference System Modeling for an Anaerobic Wastewater Treatment Plant under Unsteady State. J. Environ. Eng. 2007, 133, 765–771. [Google Scholar] [CrossRef]

- Hamza, R.A.; Iorhemen, O.T.; Tay, J.H. Advances in biological systems for the treatment of high-strength wastewater. J. Water Process Eng. 2016, 10, 128–142. [Google Scholar] [CrossRef]

- Samaei, S.H.A.; Chen, J.; Li, G.; Whitman, A.; Xue, J. Anaerobic dynamic membrane bioreactors (AnDMBRs): A promising technology for high-strength wastewater treatment. J. Environ. Chem. Eng. 2023, 11, 111139. [Google Scholar] [CrossRef]

- Cakir, F.Y.; Stenstrom, M.K. A dynamic model for anaerobic filter. J. Environ. Sci. Health-Part A Toxic/Hazard. Subst. Environ. Eng. 2003, 38, 2069–2076. [Google Scholar] [CrossRef]

- Chan, Y.J.; Chong, M.F.; Law, C.L.; Hassell, D.G. A review on anaerobic-aerobic treatment of industrial and municipal wastewater. Chem. Eng. J. 2009, 155, 1–18. [Google Scholar] [CrossRef]

- Tran Thi Viet, N.; Vu, D.C.; Duong, T.H. Effect of Hydraulic retention time on performance of anaerobic membrane bioreactor treating slaughterhouse wastewater. Environ. Res. 2023, 233, 116522. [Google Scholar] [CrossRef]

- Lin, H.; Peng, W.; Zhang, M.; Chen, J.; Hong, H.; Zhang, Y. A review on anaerobic membrane bioreactors: Applications, membrane fouling and future perspectives. Desalination 2013, 314, 169–188. [Google Scholar] [CrossRef]

- Alsalhy, Q.F.; Al-Ani, F.H.; Al-Najar, A.E. A new Sponge-GAC-Sponge membrane module for submerged membrane bioreactor use in hospital wastewater treatment. Biochem. Eng. J. 2018, 133, 130–139. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, X.C.; Ngo, H.H.; Sun, Q.; Yang, Y. Anaerobic dynamic membrane bioreactor (AnDMBR) for wastewater treatment: A review. Bioresour. Technol. 2018, 247, 1107–1118. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Li, Y.; Kato, H.; Li, Y.Y. Enhancement of sustainable flux by optimizing filtration mode of a high-solid anaerobic membrane bioreactor during long-term continuous treatment of food waste. Water Res. 2020, 168, 115195. [Google Scholar] [CrossRef] [PubMed]

- Dereli, R.K.; Ersahin, M.E.; Ozgun, H.; Ozturk, I.; Jeison, D.; van der Zee, F.; van Lier, J.B. Potentials of anaerobic membrane bioreactors to overcome treatment limitations induced by industrial wastewaters. Bioresour. Technol. 2012, 122, 160–170. [Google Scholar] [CrossRef]

- Yurtsever, A.; Basaran, E.; Ucar, D.; Sahinkaya, E. Self-forming dynamic membrane bioreactor for textile industry wastewater treatment. Sci. Total Environ. 2021, 751, 141572. [Google Scholar] [CrossRef]

- Ozgun, H.; Ersahin, M.E.; Tao, Y.; Spanjers, H.; van Lier, J.B. Effect of upflow velocity on the effluent membrane fouling potential in membrane coupled upflow anaerobic sludge blanket reactors. Bioresour. Technol. 2013, 147, 285–292. [Google Scholar] [CrossRef]

- Londoño, Y.A.; Rodríguez, D.C.; Peñuela, G. The operation of two EGSB reactors under the application of different loads of oxytetracycline and florfenicol. Water Sci. Technol. 2012, 66, 2578–2585. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Waste Water, 21st ed.; American Public Health Association/American Water Works Association/Water Environment Federation: Washington DC, USA, 2008. [Google Scholar]

- Pascale, R.; Caivano, M.; Buchicchio, A.; Mancini, I.M.; Bianco, G.; Caniani, D. Validation of an analytical method for simultaneous high-precision measurements of greenhouse gas emissions from wastewater treatment plants using a gas chromatography-barrier discharge detector system. J. Chromatogr. A 2017, 1480, 62–69. [Google Scholar] [CrossRef]

- Wilson, R.M.; Tfaily, M.M.; Rich, V.I.; Keller, J.K.; Bridgham, S.D.; Zalman, C.M.; Meredith, L.; Hanson, P.J.; Hines, M.; Pfeifer-Meister, L.; et al. Hydrogenation of organic matter as a terminal electron sink sustains high CO2:CH4 production ratios during anaerobic decomposition. Org. Geochem. 2017, 112, 22–32. [Google Scholar] [CrossRef]

- Ferraz-Almeida, R.; Spokas, K.A.; De Oliveira, R.C. Columns and Detectors Recommended in Gas Chromatography to Measure Greenhouse Emission and O2 Uptake in Soil: A Review. Commun. Soil Sci. Plant Anal. 2020, 51, 582–594. [Google Scholar] [CrossRef]

- Dubois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F. Colorimetric Method for Determination of Sugars and Related Substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Liu, L.; Lee, K.; Miao, J. Review of Biological Processes in a Membrane Bioreactor (MBR): Effects of Wastewater Characteristics and Operational Parameters on Biodegradation Efficiency When Treating Industrial Oily Wastewater. J. Mar. Sci. Eng. 2022, 10, 1229. [Google Scholar] [CrossRef]

- Ersahin, M.E.; Tao, Y.; Ozgun, H.; Gimenez, J.B.; Spanjers, H.; van Lier, J.B. Impact of anaerobic dynamic membrane bioreactor configuration on treatment and filterability performance. J. Memb. Sci. 2017, 526, 387–394. [Google Scholar] [CrossRef]

- Liao, B.Q.; Kraemer, J.T.; Bagley, D.M. Anaerobic Membrane Bioreactors: Applications and Research Directions. Crit. Rev. Environ. Sci. Technol. 2006, 36, 489–530. [Google Scholar] [CrossRef]

- Al-Iraqi, A.R.; Gandhi, B.P.; Folkard, A.M.; Barker, P.A.; Semple, K.T. Influence of Inoculum to Substrate Ratio and Substrates Mixing Ratio on Biogas Production from the Anaerobic Co-digestion of Phragmites australis and Food Waste. Bioenergy Res. 2023, 17, 1277–1287. [Google Scholar] [CrossRef]

- Ersahin, M.E.; Ozgun, H.; Tao, Y.; van Lier, J.B. Applicability of dynamic membrane technology in anaerobic membrane bioreactors. Water Res. 2014, 48, 420–429. [Google Scholar] [CrossRef]

- Ariunbaatar, J.; Bair, R.; Ozcan, O.; Ravishankar, H.; Esposito, G.; Lens, P.N.L.; Yeh, D.H. Performance of AnMBR in Treatment of Post-consumer Food Waste: Effect of Hydraulic Retention Time and Organic Loading Rate on Biogas Production and Membrane Fouling. Front. Bioeng. Biotechnol. 2021, 8, 594936. [Google Scholar] [CrossRef] [PubMed]

- Balcıoğlu, G.; Yilmaz, G.; Gönder, Z.B. Evaluation of anaerobic membrane bioreactor (AnMBR) treating confectionery wastewater at long-term operation under different organic loading rates: Performance and membrane fouling. Chem. Eng. J. 2021, 404, 126261. [Google Scholar] [CrossRef]

- Jeison, D.; van Lier, J.B. Cake formation and consolidation: Main factors governing the applicable flux in anaerobic submerged membrane bioreactors (AnSMBR) treating acidified wastewaters. Sep. Purif. Technol. 2007, 56, 71–78. [Google Scholar] [CrossRef]

- Musa, M.A.; Idrus, S.; Man, H.C.; Daud, N.N.N. Wastewater treatment and biogas recovery using anaerobic membrane bioreactors (AnMBRs): Strategies and achievements. Energies 2018, 11, 1675. [Google Scholar] [CrossRef]

- Chen, R.; Nie, Y.; Hu, Y.; Miao, R.; Utashiro, T.; Li, Q.; Xu, M.; Li, Y.Y. Fouling behaviour of soluble microbial products and extracellular polymeric substances in a submerged anaerobic membrane bioreactor treating low-strength wastewater at room temperature. J. Memb. Sci. 2017, 531, 1–9. [Google Scholar] [CrossRef]

- Yu, H.; Wang, Z.; Wu, Z.; Zhu, C. Dynamic membrane formation in anaerobic dynamic membrane bioreactors: Role of extracellular polymeric substances. PLoS ONE 2015, 10, e0139703. [Google Scholar] [CrossRef] [PubMed]

| Chemical | Amount (g/L) | Note |

|---|---|---|

| Glucose | 9.6 | Main component |

| Starch | 0.8 | |

| Peptone | 0.8 | |

| Urea | 0.88 | |

| Monopotassium phosphate | 0.08 | |

| Sodium bicarbonate | 8 | |

| Ammonium chloride | 1.4 | Macronutrients stock solution; 1 mL for each L of feeding solution |

| Magnesium sulfate heptahydrate | 0.5 | |

| Calcium chloride dihydrate | 0.05 | |

| Sodium carbonate | 2 | |

| Yeast extract | 0.5 | |

| Boric acid | 0.05 | Micronutrients stock solution; 1 mL for each L of feeding solution |

| Ferrous chloride tetrahydrate | 1 | |

| Zinc chloride | 0.05 | |

| Manganese (Ii) chloride tetrahydrate | 0.25 | |

| Copper (Ii) chloride dihydrate | 0.03 | |

| Ammonium molybdate tetrahydrate | 0.05 | |

| Cobalt (Ii) chloride hexahydrate | 1 | |

| Sodium thiosulfate pentahydrate | 0.1 | |

| Aluminum sulfate | 0.09 | |

| Nickel (Ii) chloride hexahydrate | 0.05 | |

| Edta | 0.1 | |

| Resazurin | 0.1 | |

| Hydrochloric acid | pH adjustment |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghanim, M.S.; Soydemir, G.; Yılmaz, F.; Perendeci, N.A.; Karagündüz, A.; Alazaiza, M.Y.D. Anaerobic Dynamic Membrane Bioreactors (AnDMBRs): Are They an Efficient Way to Treat High-Strength Wastewater? Water 2025, 17, 787. https://doi.org/10.3390/w17060787

Ghanim MS, Soydemir G, Yılmaz F, Perendeci NA, Karagündüz A, Alazaiza MYD. Anaerobic Dynamic Membrane Bioreactors (AnDMBRs): Are They an Efficient Way to Treat High-Strength Wastewater? Water. 2025; 17(6):787. https://doi.org/10.3390/w17060787

Chicago/Turabian StyleGhanim, Mohammed Sameer, Gülfem Soydemir, Fatih Yılmaz, N. Altınay Perendeci, Ahmet Karagündüz, and Motasem Y. D. Alazaiza. 2025. "Anaerobic Dynamic Membrane Bioreactors (AnDMBRs): Are They an Efficient Way to Treat High-Strength Wastewater?" Water 17, no. 6: 787. https://doi.org/10.3390/w17060787

APA StyleGhanim, M. S., Soydemir, G., Yılmaz, F., Perendeci, N. A., Karagündüz, A., & Alazaiza, M. Y. D. (2025). Anaerobic Dynamic Membrane Bioreactors (AnDMBRs): Are They an Efficient Way to Treat High-Strength Wastewater? Water, 17(6), 787. https://doi.org/10.3390/w17060787