A Risk Assessment of Water Inrush in Deep Mining in Metal Mines Based on the Coupling Methods of the Analytic Hierarchy Process and Entropy Weight Method: A Case Study of the Huize Lead–Zinc Mine in Northeastern Yunnan, China

Abstract

:1. Introduction

2. Geological Background

3. Methods

3.1. AHP

3.2. EWM

3.3. AHP-EWM Comprehensive Weights

3.4. Determination of Water Inrush Evaluation Factors

3.5. Quantification of the Evaluation Factor

4. Results and Discussion

4.1. Subjective Weight Calculation Based on AHP

4.2. Objective Weight Calculation Based on EWM

4.3. Comprehensive Weight Determination

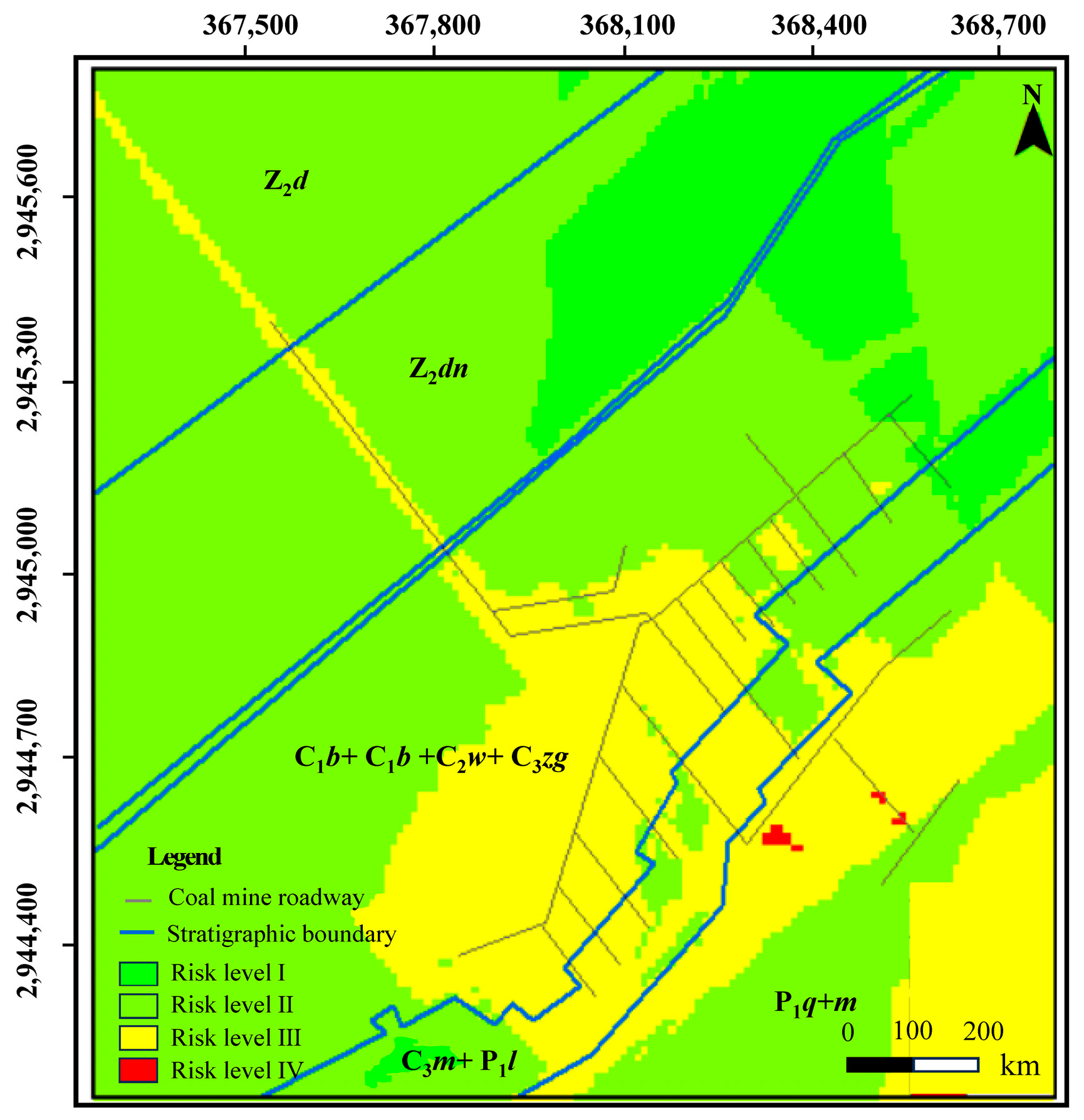

4.4. Water Inrush Risk Assessment

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, H.; Chen, Z.H.; Wang, T.; Zhou, G.M.; Martin, J.B.; Zhang, L.; Meng, X.M. Origins and mixing contributions of deep warm groundwater in a carbonate hosted ore deposit, Sichuan-Yunnan-Guizhou Pb-Zn triangle, southwestern China. J. Hydrol. 2020, 590, 125400. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.; Li, M.; Liu, X. Risk assessment of floor water inrush in coal mines based on secondary fuzzy comprehensive evaluation. Int. J. Rock. Mech. Min. 2012, 52, 50–55. [Google Scholar] [CrossRef]

- Gu, Q.; Huang, Z.; Li, S.; Zeng, W.; Zhao, K. An approach for water-inrush risk assessment of deep coal seam mining: A case study in Xinlongzhuang coal mine. Environ. Sci. Pollut. R 2020, 27, 43163–43176. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Sun, Y.J.; Xu, Z.M.; Chen, G. Water sources classification and inrush hazard assessment approach in coal mining. Coal Eng. 2023, 55, 108–115. [Google Scholar] [CrossRef]

- Yuan, S.C.; Sui, W.H.; Han, G.L.; Duan, W.Q. An optimized combination of mine water control, treatment, utilization, reinjection for environmentally sustainable mining: A case study. Mine Water Environ. 2022, 41, 828–839. [Google Scholar] [CrossRef]

- Mahato, M.K.; Singh, P.K.; Singh, A.K.; Tiwari, A.K. Assessment of hydrogeochemical processes and mine water suitability fodomestic, irrigation, and industrial purposes in east Bokaro coal-field, India. Mine Water Environ. 2018, 37, 493–504. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Y.J.; Cui, D.L.; Feng, G.R.; Du, Y.L.; Zhang, S.; Cheng, H.J.; Zhang, Z.J. Effect of indenter angle on bearing performance of coal and accompanying rocks under point load and characterization of mechanical parameters. Energy Sci. Eng. 2025, 13, 374–391. [Google Scholar] [CrossRef]

- San Cristóbal, J.R. Multi criteria decision making in the selection of a renewable energy project in Spain: The Vikor method. Renew. Energ. 2011, 36, 498–502. [Google Scholar] [CrossRef]

- Agnieszka, T.; Sylwia, W.W.; Adam, W. Risk Assessment Methods in Mining Industry-A Systematic Review. Appl. Sci. 2020, 10, 5172. [Google Scholar] [CrossRef]

- Wu, Q.; Huang, X.; Dong, D.; Yin, Z.; Li, J.; Hong, Y.; Zhang, H. Three maps–two predictions method to evaluate water bursting conditions on roof coal. J. China Coal Soc. 2000, 25, 62–67. [Google Scholar] [CrossRef]

- Wu, Q.; Liu, Y.; Zhou, W.; Li, B.; Zhao, B.; Liu, S.; Sun, W.; Zeng, Y. Evaluation of water inrush vulnerability from aquifers overlying coal seams in the menkeqing coal mine, China. Mine Water Environ. 2015, 34, 258–269. [Google Scholar] [CrossRef]

- Zeng, Y.; Wu, Q.; Liu, S.; Zhai, Y.; Lian, H.; Zhang, W. Evaluation of a coal seam roof water inrush: Case study in the Wangjialing coal mine, China. Mine Water Environ. 2018, 37, 174–184. [Google Scholar] [CrossRef]

- Li, B.; Wu, Q.; Duan, X.Q.; Chen, M.Y. Risk analysis model of water inrush through the seam floor based on set pair analysis. Mine Water Environ. 2017, 37, 281–287. [Google Scholar] [CrossRef]

- Niu, H.G.; Wei, J.C.; Yin, H.Y.; Xie, D.L.; Zhang, W.J. An improved model to predict the water-inrush risk from an Ordovician limestone aquifer under coal seams: A case study of the Longgu coal mine in China. Carbonate Evaporite 2020, 35, 73. [Google Scholar] [CrossRef]

- Xue, J.K.; Shi, L.; Wang, H.; Ji, Z.K.; Shang, H.B.; Xu, F.; Zhao, H.H.; Luo, A.K. Water abundance evaluation of a burnt rock aquifer using the AHP and entropy weight method: A case study in the Yongxin coal mine, China. Environ. Earth Sci. 2021, 80, 417. [Google Scholar] [CrossRef]

- Wu, Q.; Li, B.; Chen, Y. Vulnerability assessment of groundwater inrush from underlying aquifers based on variable weight model and its application. Water Resour. Manag. 2016, 30, 3331–3345. [Google Scholar] [CrossRef]

- Yang, P.; Yang, W.; Nie, Y.; Saleem, F.; Lu, F.; Ma, R.; Li, R. Predicting the height of the water- conducting fractured zone based on a multiple regression model and information entropy in the Northern Ordos Basin, China. Mine Water Environ. 2021, 41, 225–236. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, D.S.; Feng, G.R.; Chi, M.B. Modelling method of heterogeneous rock mass and DEM investigation of seepage characteristics. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 46. [Google Scholar] [CrossRef]

- Ju, Q.D.; Hu, Y.B. Source identification of mine water inrush based on principal component analysis and grey situation decision. Environ. Earth Sci. 2021, 80, 157. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, S.F.; Shi, K. Risk assessment of coal mine water inrush based on PCA-DBN. Sci. Rep. 2022, 12, 1370. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Lu, C.J.; Zhao, H. Risk assessment of floor water inrush based on TOPSIS combined weighting model: A case study in a coal mine, China. Earth Sci. Inform. 2023, 16, 565–578. [Google Scholar] [CrossRef]

- Hu, Y.B.; Li, W.P.; Wang, Q.Q.; Liu, S.L.; Wang, Z.K. Evaluation of water inrush risk from coal seam floors with an AHP-EWM algorithm and GIS. Environ. Geol. 2019, 78, 290. [Google Scholar] [CrossRef]

- Li, Q.; Sui, W.H. Risk evaluation of mine-water inrush based on principal component logistic regression analysis and an improved analytic hierarchy process. Hydrogeol. J. 2021, 29, 1299–1311. [Google Scholar] [CrossRef]

- Shi, L.Q.; Qu, X.Y.; Han, J.; Qu, W.; Gao, W.F.; Qin, D.X.; Liu, H.S. Multi-model fusion for assessing risk of inrush of limestone karst water through mine floor. J. China Coal Soc. 2019, 44, 2484–2493. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, W.H.; Zhang, J.; Wang, J.; Zhang, X.J. Formation of Pb-Zn deposits in the Sichuan-Yunnan-Guizhou triangle linked to the Youjiang foreland basin: Evidence from Rb-Sr age and in situ sulfur isotope analysis of the Maoping Pb-Zn deposit in northeastern Yunnan Province, southeast China. Ore Geol. Rev. 2019, 107, 780–800. [Google Scholar] [CrossRef]

- Li, S.C.; Zhou, Z.Q.; Li, L.P.; Xu, Z.H.; Zhang, Q.Q.; Shi, S.S. Risk assessment of water inrush in karst tunnels based on attribute synthetic evaluation system. Tunn. Undergr. Space Technol. 2013, 38, 50–58. [Google Scholar] [CrossRef]

- Lorette, G.; Lastennet, R.; Peyraube, N.; Denis, A. Groundwater flow characterization in a multilayered karst aquifer on the edge of a sedimentary basin in western France. J. Hydrol. 2018, 566, 137–149. [Google Scholar] [CrossRef]

- Freitas, S.; De Tomi, G.; Marin, T.; Rocha, M.M. Simulation-based risk quantification: A reconciliation-based performance analysis. Min. Technol. 2017, 126, 96–103. [Google Scholar] [CrossRef]

- Torikian, H.; Kumral, M. Analyzing reproduction of correlations in Monte Carlo simulations: Application to mine project valuation. Georisk 2014, 8, 235–249. [Google Scholar] [CrossRef]

- Yuan, S.C.; Han, G.L.; Liu, D.J.; Zhang, A.W. Multicriteria risk assessment of water inrush in underground mines with large-scale curtain grouting: A mine disaster risk reduction strategy. Geomat. Nat. Hazards Risk 2024, 15, 2409200. [Google Scholar] [CrossRef]

- Yuan, S.C.; Li, Q.; Sun, B.T.; Han, G.L. Hazard identification and risk assessment of water inrush in deep mining of metal mines: A case study of Maoping lead-zinc mine in Northeast Yunnan, China. J. Eng. Geol. 2023, 31, 1668–1679. [Google Scholar] [CrossRef]

- Sun, B.T. Study on the risk assessment of water inrush of karst deep mines in Northeast Yunnan, China. China Min. 2023, 32, 440–446. [Google Scholar] [CrossRef]

- Li, Q.; Sui, W.H.; Sun, B.T.; Dong, L.L.; Yu, S.B. Application of TOPSIS water abundance comprehensive evaluation method for karst aquifers in a lead zinc mine, China. Earth Sci. Inform. 2022, 15, 397–411. [Google Scholar] [CrossRef]

- Smith, J.; Johnson, A. Hydrogeological Variability in Mining Regions: Implications for Water Inrush Risk Assessment. J. Min. Geol. 2015, 51, 123–138. [Google Scholar]

| Erathem | System | Series | Formation | Symbol | Thickness (m) | Lithology |

|---|---|---|---|---|---|---|

| Cenozoic | Quaternary | Q | 0–71.75 | Blocks of stone, weathered clay | ||

| Paleozoic | Permian | Upper | Emeishan | P2β | 600–800 | Dense blocky basalts and almond basalts form mutual rhythms |

| Lower | Qixia–Maokou | P1q + m | 450–600 | The upper part is bedded silty limestone with a small amount of dolomite, containing chert nodules and dolomite clumks, and the lower part is thick bedded limestone and oolitic limestone with dolomite. | ||

| Liangshan | P1l | 21.2–49.5 | Thin- to intermediate-grained quartz sandstone | |||

| Carboniferous | Upper | Maping | C3m | 22.5–78.2 | The lower part of the limestone is composed of argillaceous shale, the middle part is medium to thick bedded limestone, the upper part is medium to thick bedded bioclastic limestone, and the top part is gray pisolitic limestone | |

| Middle | Weining | C2w | 10–69 | Sand-clastic sparry limestone, oolitic limestone, dolomitic limestone | ||

| Lower | Baizuo | C1b | 35–89 | Middle silty limestone, dolomitic limestone | ||

| Datang | C1d | 27–41 | The shale is composed of ferruginous quartz sandstone, purplish red mudstone, and argillaceous limestone | |||

| Devonian | Upper | Zaige | D3zg | 200–365 | Dolomite, siliceous dolomite, microsilty dolomite, micrite | |

| Middle | Haikou | D2h | 4.6–106.5 | Siltstone | ||

| Cambrian | Lower | Qiongzhusi | ∈1q | 0–98.5 | Microbedded to mid-level carbonaceous shale, siltstone, and arkose | |

| Proterozoic | Sinian | Upper | Dengying | Z2dn | >70 | Middle to massive powdery dolomite |

| Doushantuo | Z2d | >100 | Cataclastic porphyritic micrite powdery dolomite, carbonaceous dolomite, micrite dolomite |

| Scale | Implication |

|---|---|

| 1 | Both factors are of equal importance in comparison |

| 3 | The former factor is slightly more important than the latter |

| 5 | Compared with the two factors, the former factor is strongly more important than the latter |

| 7 | Compared with the two factors, the former factor is very strongly more important than the latter |

| 9 | Compared with the two factors, the former factor is extremely more important than the latter |

| 2, 4, 6, 8 | The median of the above adjacency judgments |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| RI | 0 | 0 | 0.58 | 0.9 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 | 1.51 |

| Evaluation index | Risk Grade Evaluation Criteria | |||

|---|---|---|---|---|

| I | II | III | IV | |

| Head difference (m) | <150 | 150~200 | 200~250 | >250 |

| Water-bearing capacity | Extremely weak | Weak | Intermediate | Good |

| Hydraulic conductivity (m/d) | <0.057 | 0.057~0.11 | 0.11~0.18 | >0.18 |

| Aquifer thickness (m) | Aquiclude | <300 | 300~400 | >400 |

| Water pressure (MPa) | <0.4 | 0.4~0.6 | 0.6~0.8 | >0.8 |

| Fault type | No water | Moist | Dripping | Drenching |

| Fault scale (m) | 0 | 0~1 | 1~2 | >2 |

| Fault water conductivity (bar/point) | 0 | 1 | 2 | 3 |

| Karst zoning (SI) | >-0.45 | −0.58~−0.45 | −0.65~−0.58 | <−0.65 |

| Criterion Layer | Index Layer | Comprehensive Weight | ||

|---|---|---|---|---|

| Item | Weight | Item | Weight | |

| Water source B1 | 0.5 | Water head difference C1 | 0.3721 | 0.18605 |

| Water-bearing capacity C2 | 0.1105 | 0.05525 | ||

| Hydraulic conductivity C3 | 0.2087 | 0.10435 | ||

| Aquifer thickness C4 | 0.1817 | 0.09085 | ||

| Water pressure C5 | 0.1270 | 0.0635 | ||

| Water channel B2 | 0.5 | Fault type C6 | 0.3407 | 0.17035 |

| Fault scale C7 | 0.2865 | 0.14325 | ||

| Fault water conductivity C8 | 0.1703 | 0.08515 | ||

| Karst zoning C9 | 0.2026 | 0.1013 | ||

| Evaluation Factor | Comprehensive Weight |

|---|---|

| Water head difference C1 | 0.1533 |

| Water-bearing capacity C2 | 0.0717 |

| Hydraulic conductivity C3 | 0.1209 |

| Aquifer thickness C4 | 0.1045 |

| Water pressure value C5 | 0.0732 |

| Fault type C6 | 0.1643 |

| Fault scale C7 | 0.1343 |

| Fault water conductivity C8 | 0.0908 |

| Karst zoning C9 | 0.1050 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, R.; Wang, H.; Hu, T.; Yuan, S.; Huang, B.; Wang, J.; Ren, Z. A Risk Assessment of Water Inrush in Deep Mining in Metal Mines Based on the Coupling Methods of the Analytic Hierarchy Process and Entropy Weight Method: A Case Study of the Huize Lead–Zinc Mine in Northeastern Yunnan, China. Water 2025, 17, 643. https://doi.org/10.3390/w17050643

Xia R, Wang H, Hu T, Yuan S, Huang B, Wang J, Ren Z. A Risk Assessment of Water Inrush in Deep Mining in Metal Mines Based on the Coupling Methods of the Analytic Hierarchy Process and Entropy Weight Method: A Case Study of the Huize Lead–Zinc Mine in Northeastern Yunnan, China. Water. 2025; 17(5):643. https://doi.org/10.3390/w17050643

Chicago/Turabian StyleXia, Ronghui, Hongliang Wang, Ticai Hu, Shichong Yuan, Baosheng Huang, Jianguo Wang, and Zhouhong Ren. 2025. "A Risk Assessment of Water Inrush in Deep Mining in Metal Mines Based on the Coupling Methods of the Analytic Hierarchy Process and Entropy Weight Method: A Case Study of the Huize Lead–Zinc Mine in Northeastern Yunnan, China" Water 17, no. 5: 643. https://doi.org/10.3390/w17050643

APA StyleXia, R., Wang, H., Hu, T., Yuan, S., Huang, B., Wang, J., & Ren, Z. (2025). A Risk Assessment of Water Inrush in Deep Mining in Metal Mines Based on the Coupling Methods of the Analytic Hierarchy Process and Entropy Weight Method: A Case Study of the Huize Lead–Zinc Mine in Northeastern Yunnan, China. Water, 17(5), 643. https://doi.org/10.3390/w17050643