Parameter Optimization of Bionic Hydrofoil System and Its Application in Algal Bloom Control in Plain River Networks

Abstract

1. Introduction

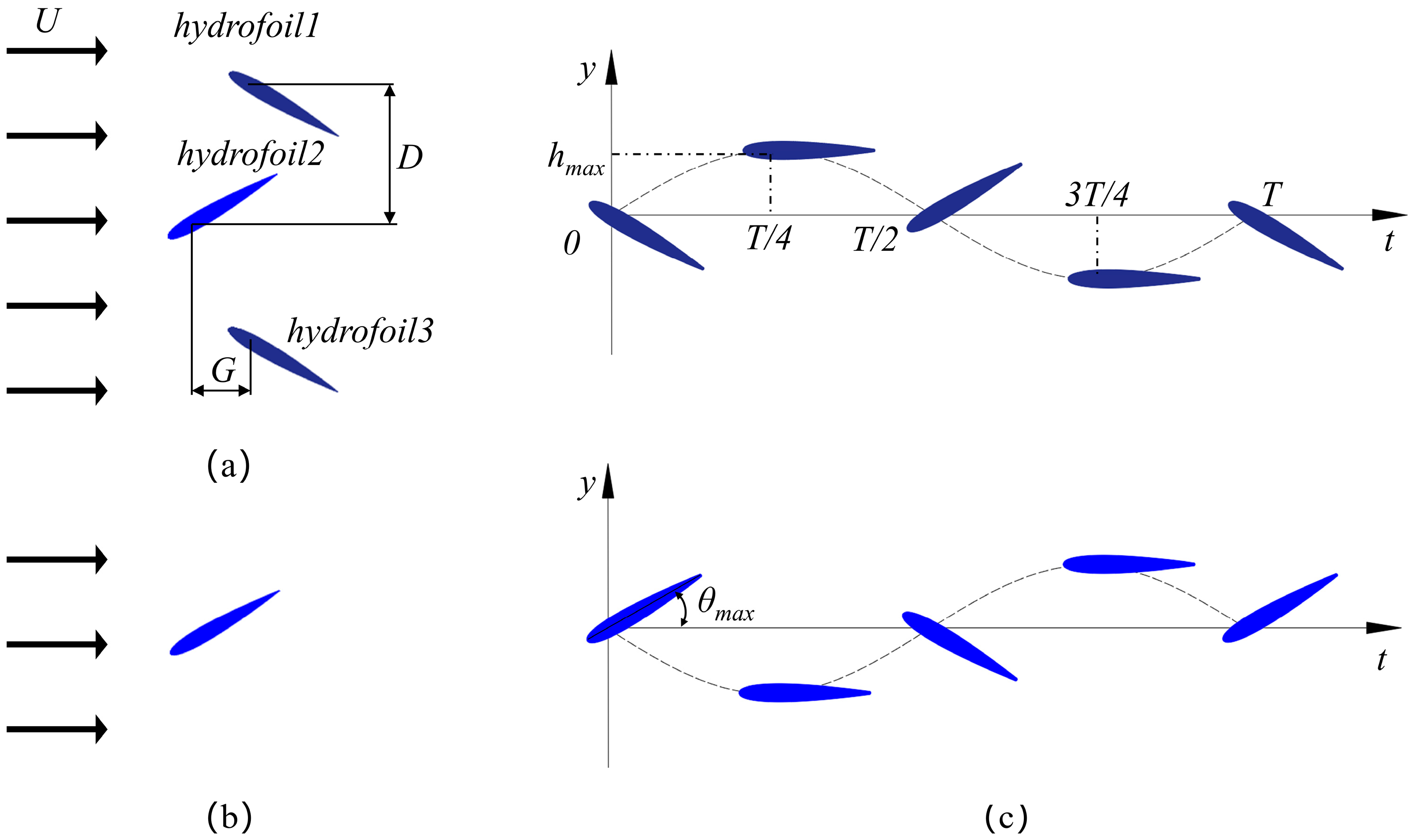

2. Physical Model

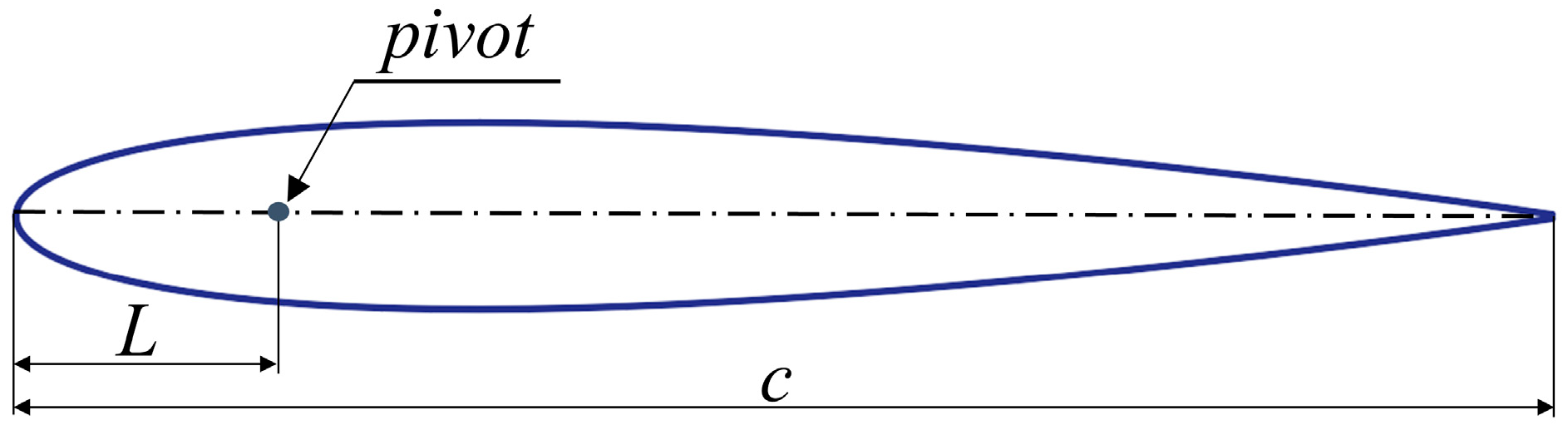

2.1. Hydrofoil System Model and Performance Parameters

- Single-hydrofoil system dynamic coefficients

- 2.

- Multi-hydrofoil system dynamic coefficients

- 3.

- Input power calculation

- 4.

- Pumping performance metrics

2.2. Motion Parameter Settings

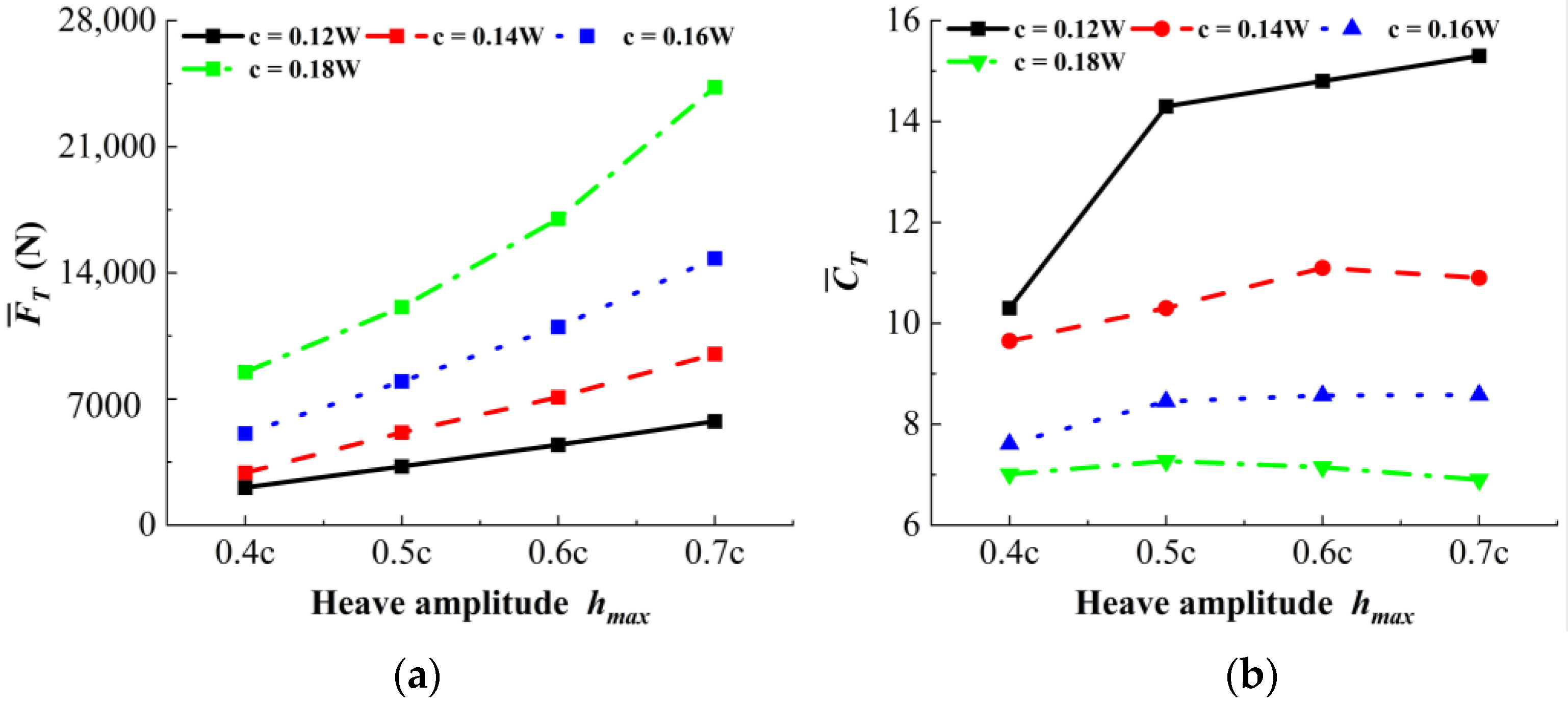

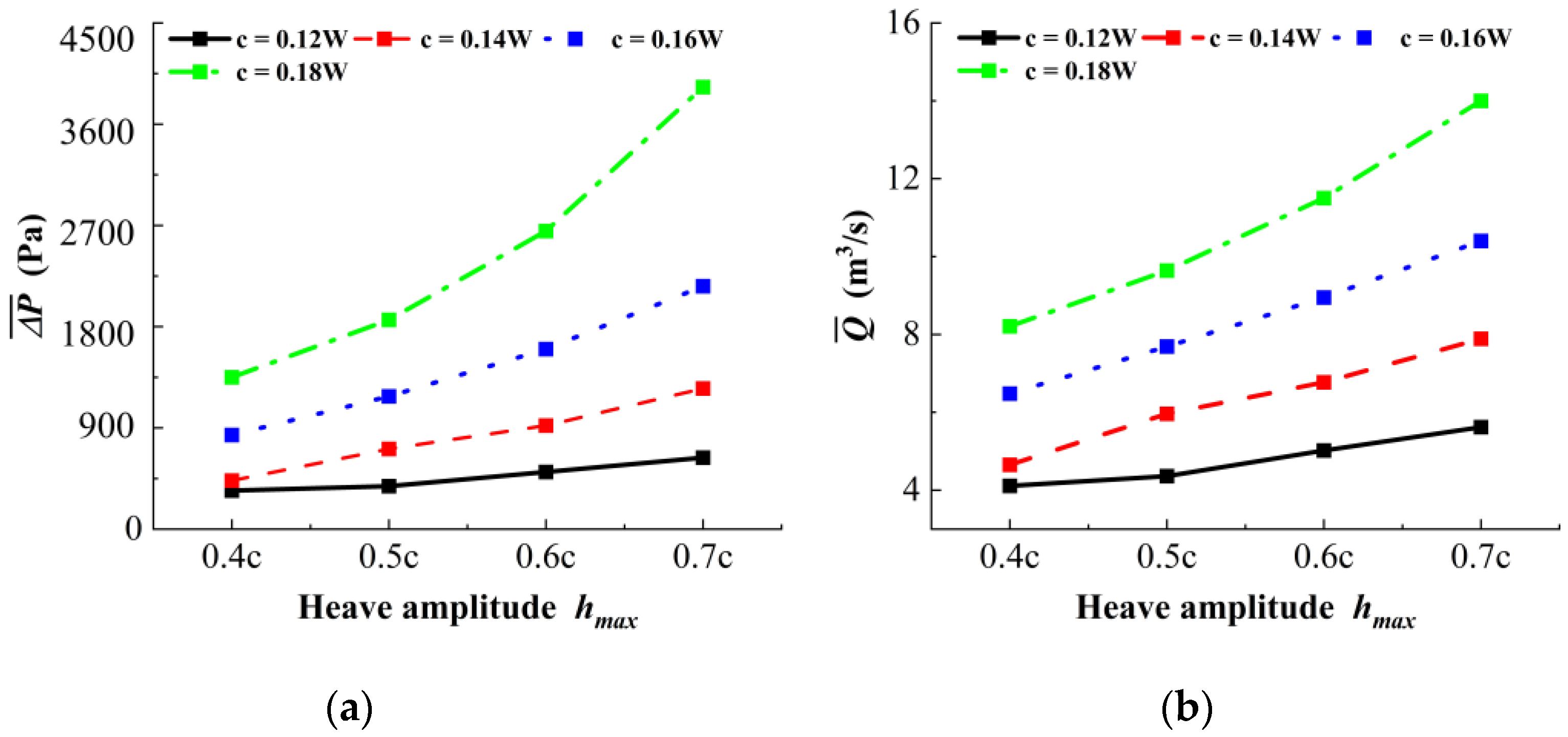

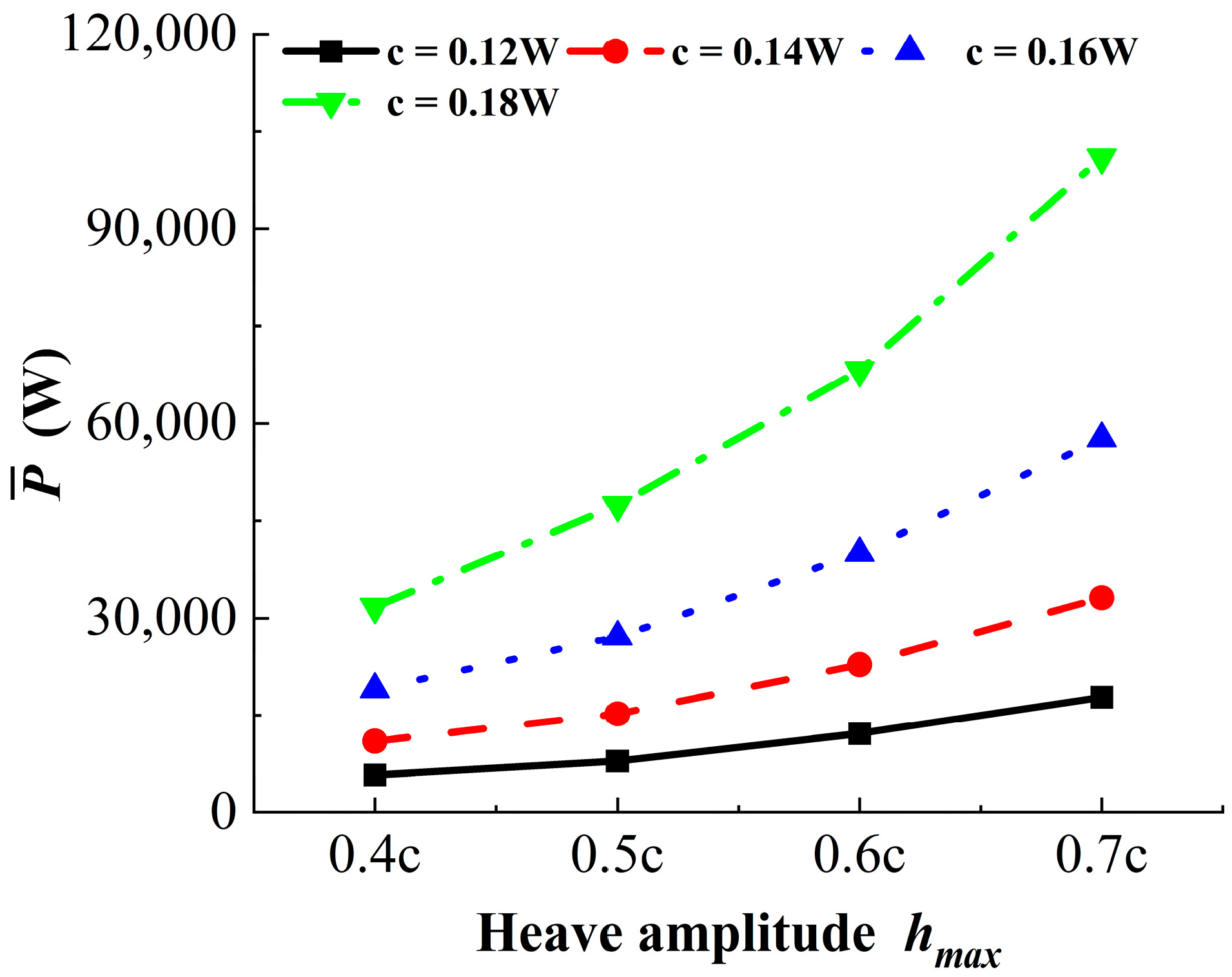

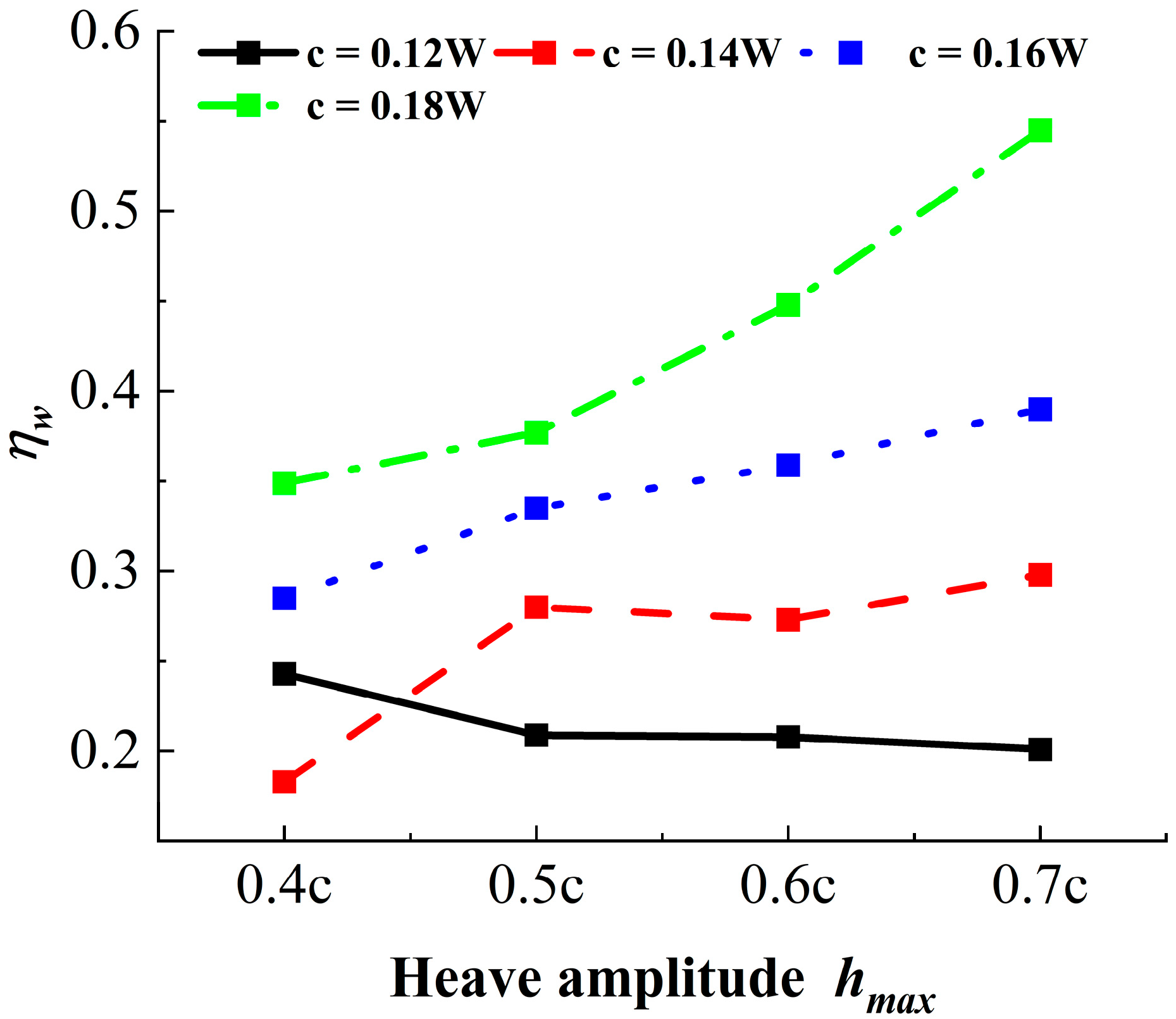

- In the multi-hydrofoil system, to avoid inter-foil interference, relatively small ranges of chord length and heave amplitude are adopted. The chord length c is set to 0.18W, 0.16W, 0.14W, and 0.12W (where W is the channel width), while the heave amplitude is set to 0.4c, 0.5c, 0.6c, and 0.7c;

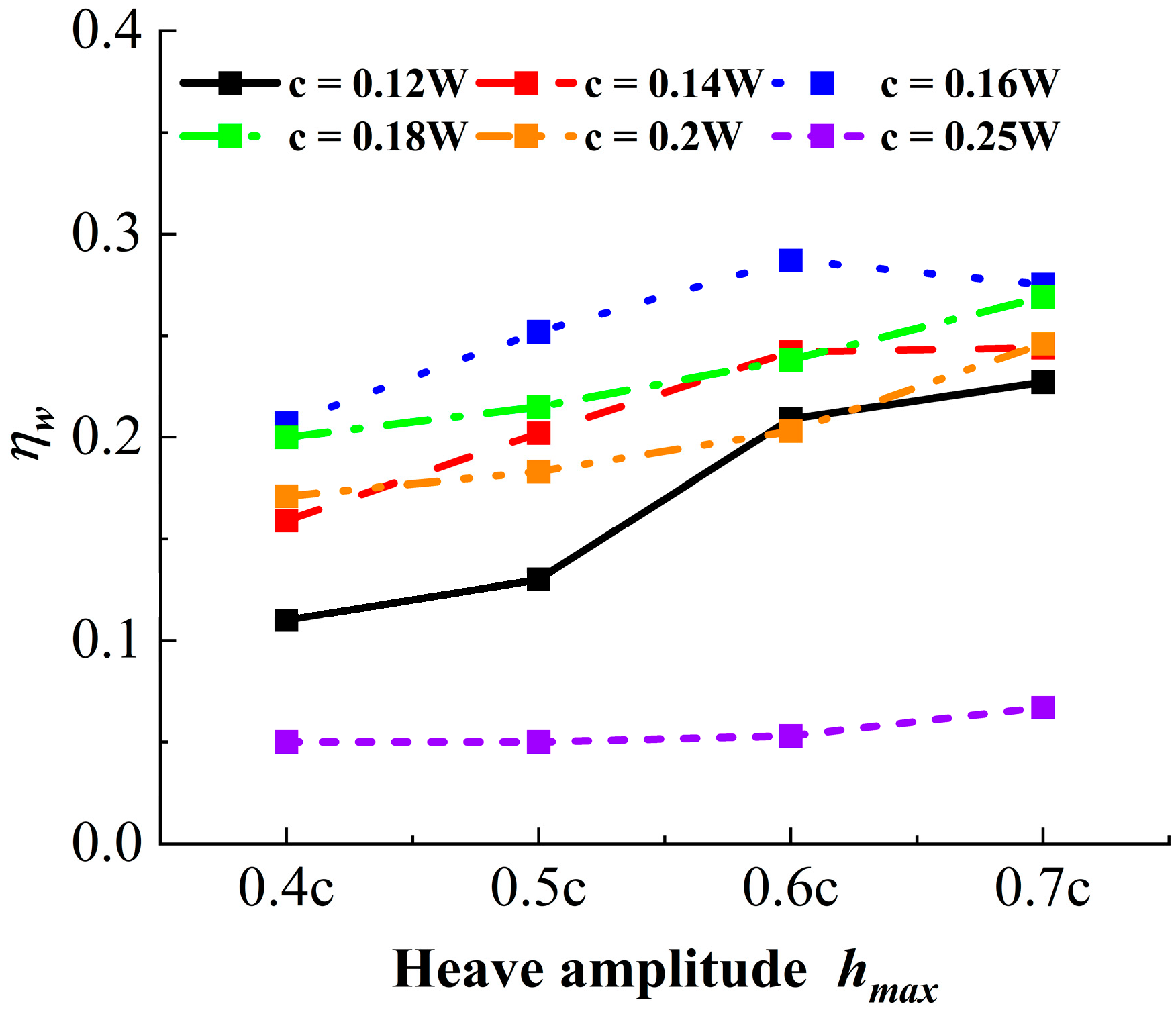

- In the single-hydrofoil system, because there is no inter-foil interference, the parameter ranges can be extended. The chord length c is set to 0.12W, 0.14W, 0.16W, 0.18W, 0.20W, and 0.25W, while the heave amplitude remains the same as in the multi-hydrofoil system.

2.3. Flow Velocity Requirements for Algal Bloom Control

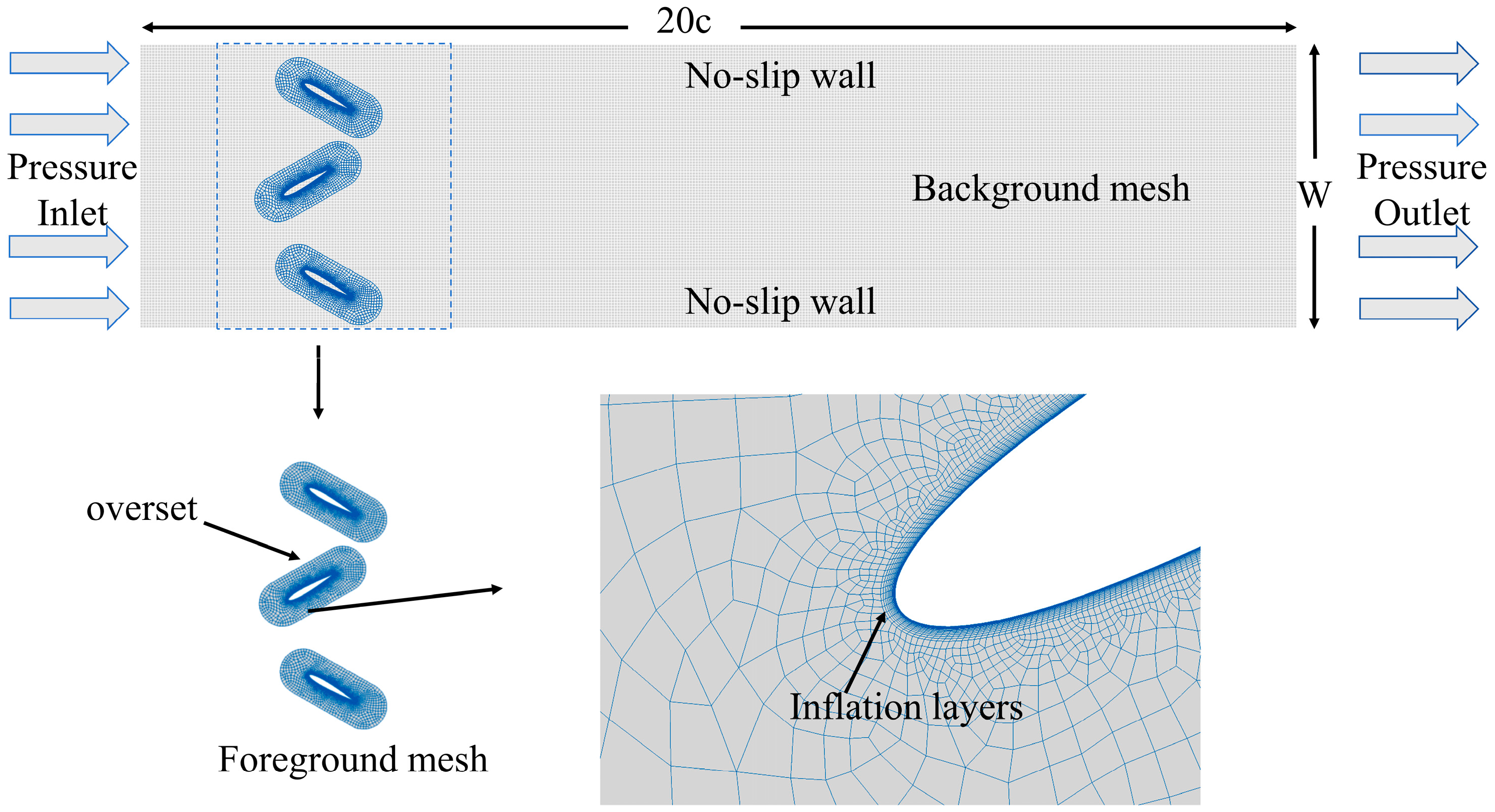

3. Numerical Methods

3.1. Governing Equations and Turbulence Model

- 1.

- Continuity equation

- 2.

- Momentum equation

- 3.

- Turbulence model

3.2. Mesh Generation and Computational Setup

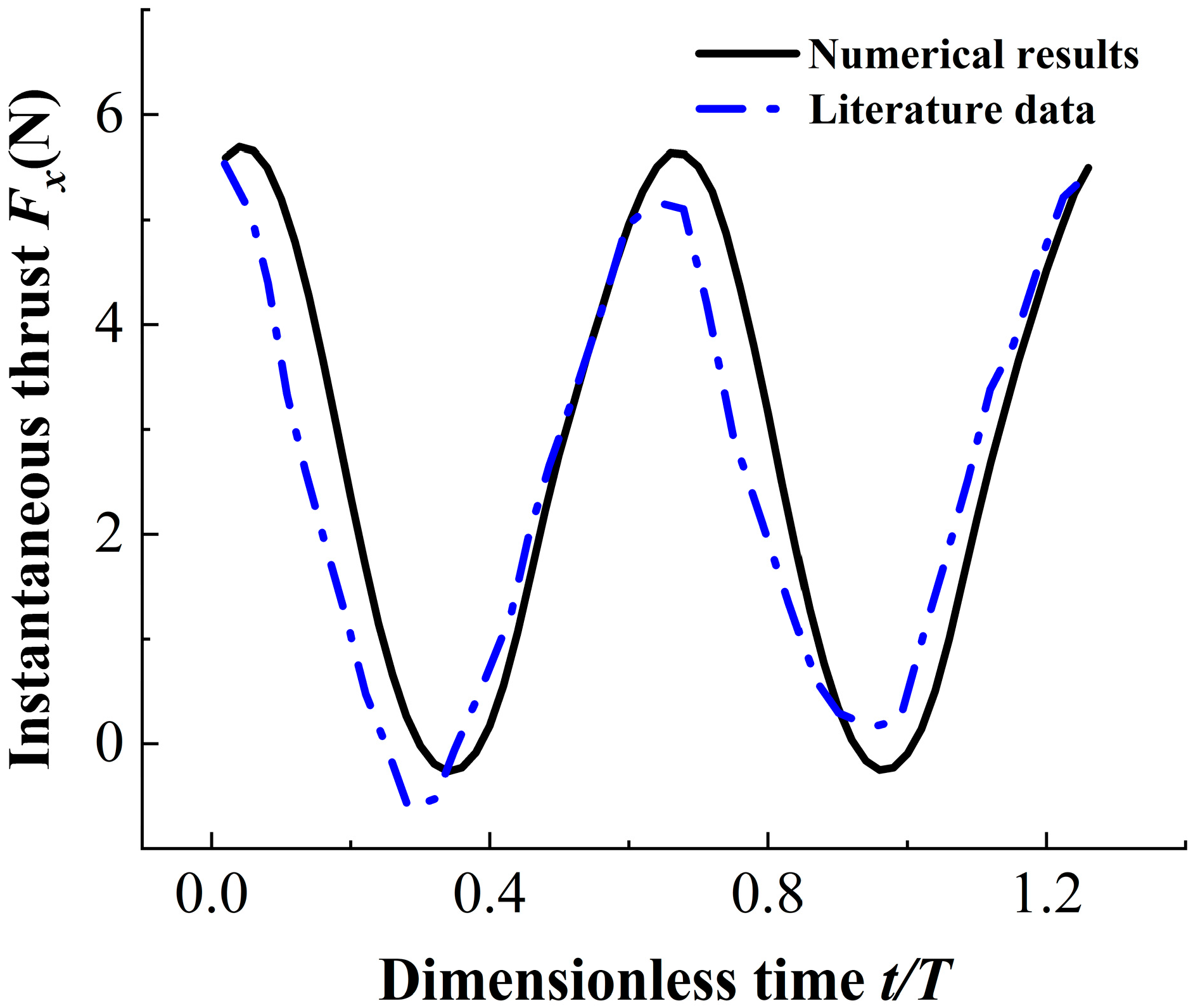

3.3. Numerical Model Validation

3.4. Validation of the Method

4. Results and Discussion

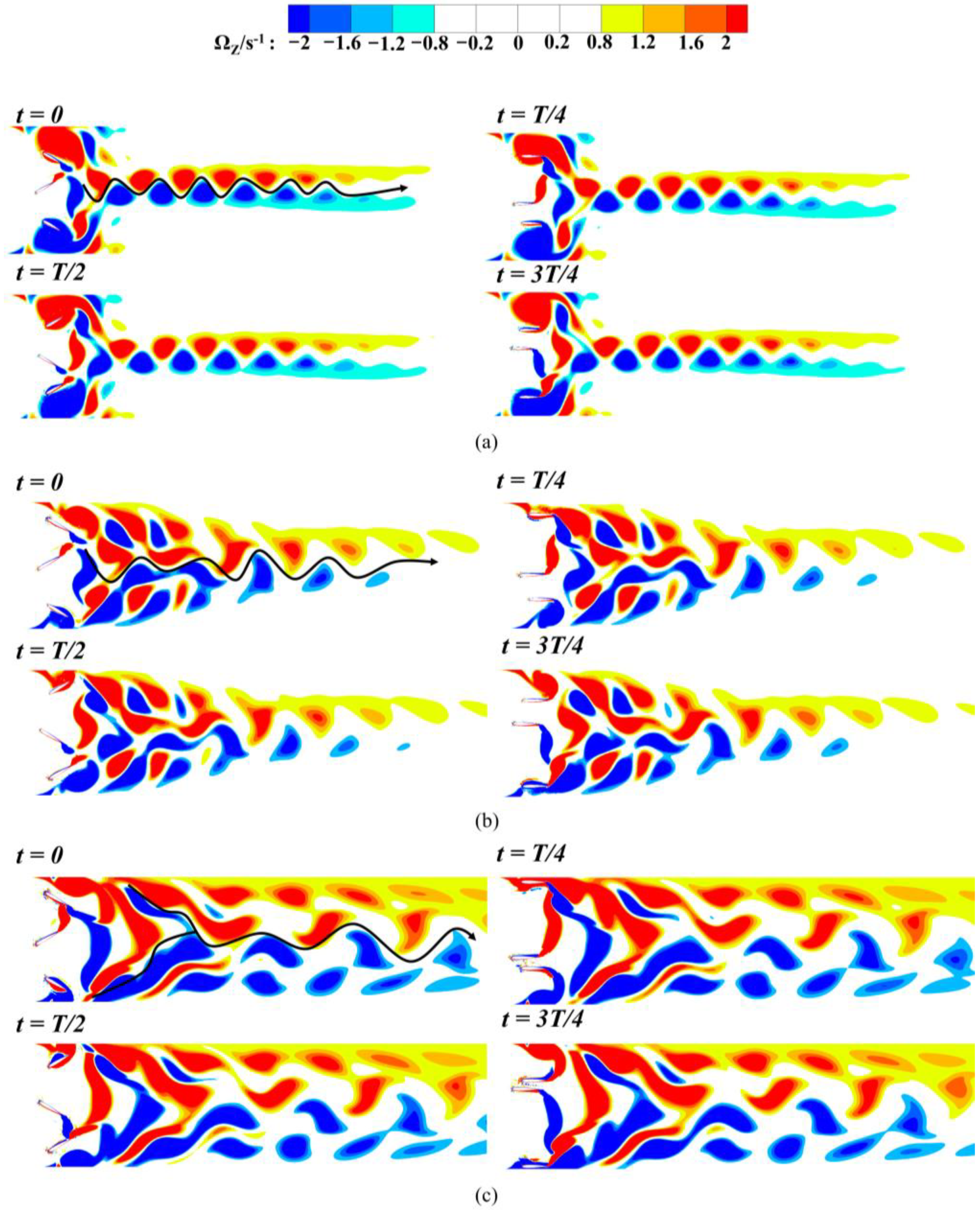

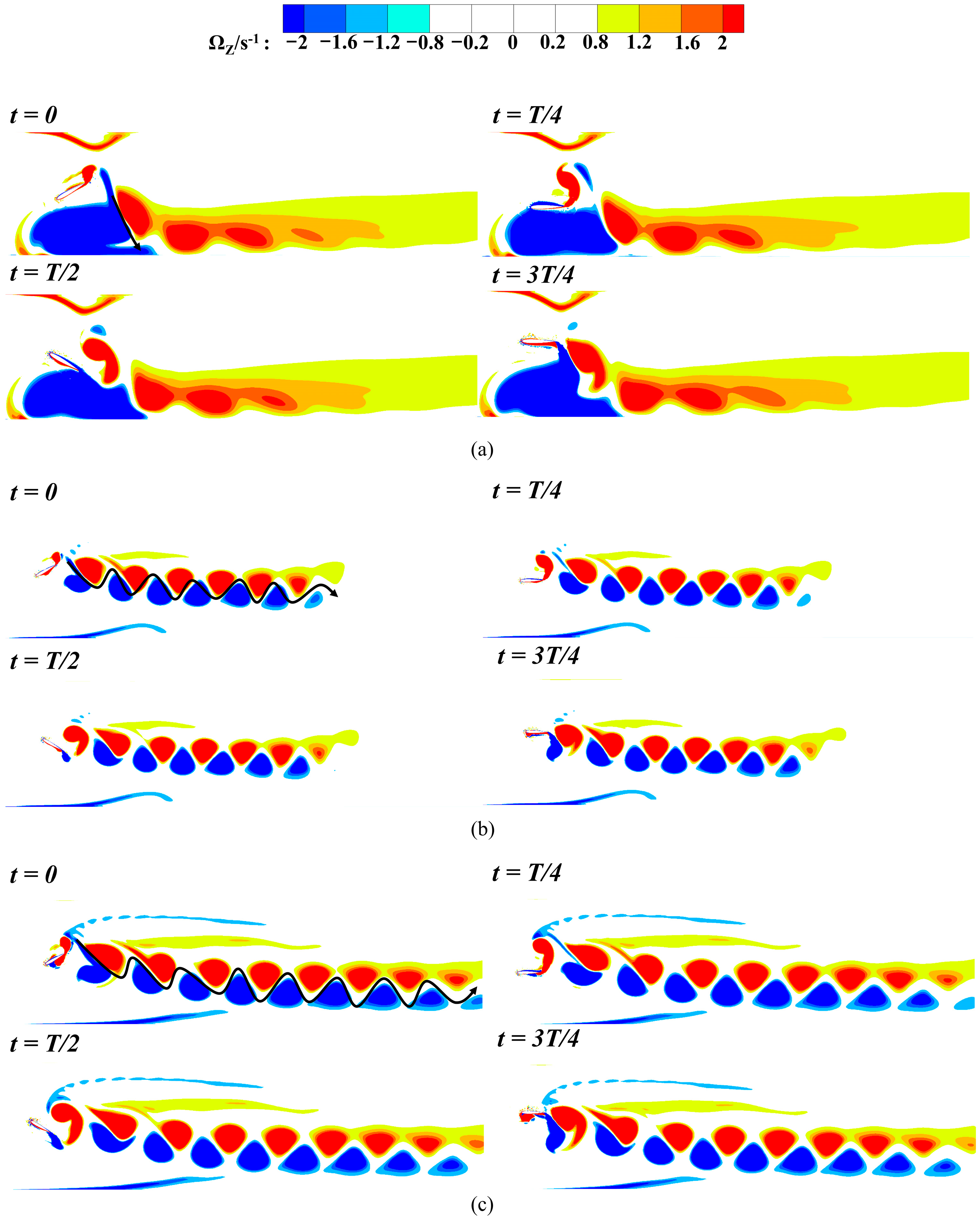

4.1. Influence of Heave Amplitude and Chord Length on the Multi-Hydrofoil System

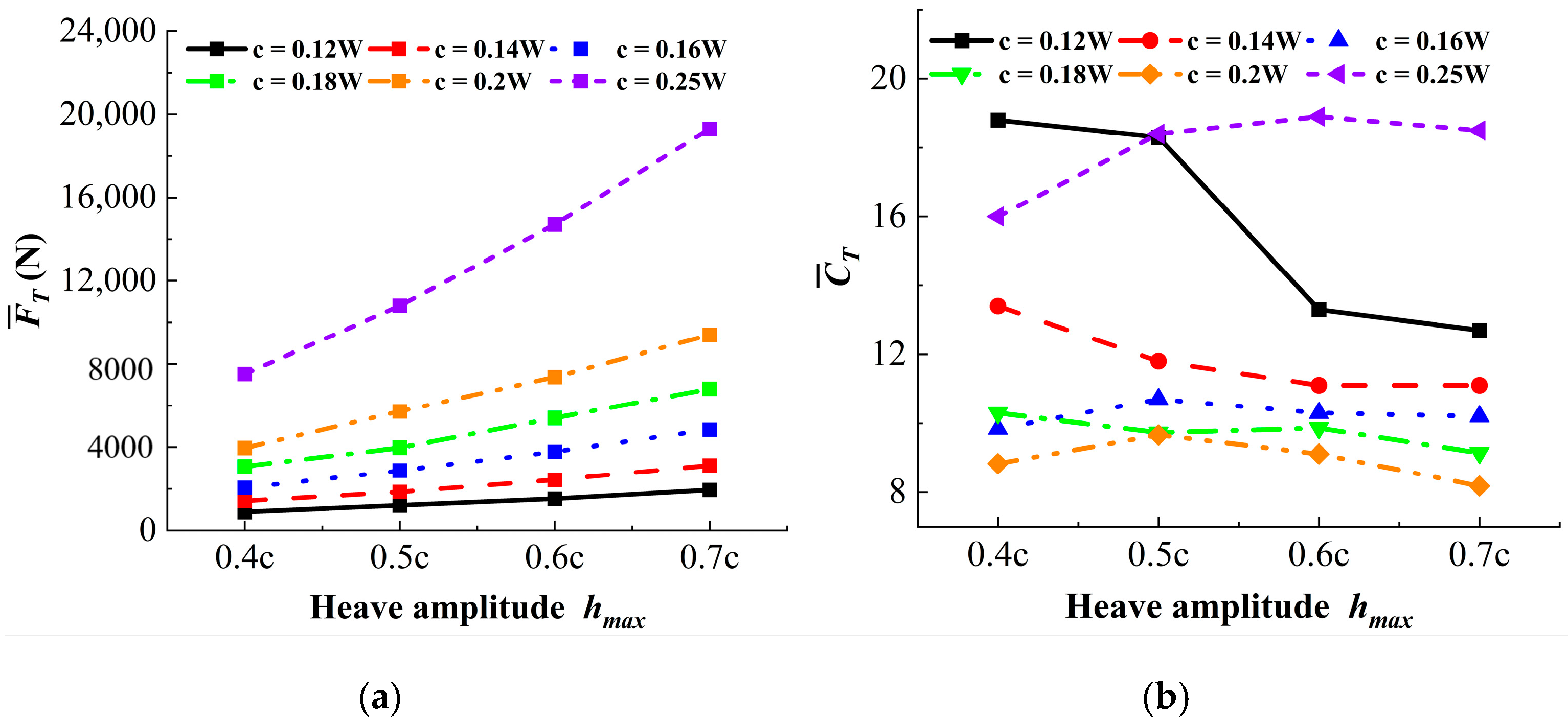

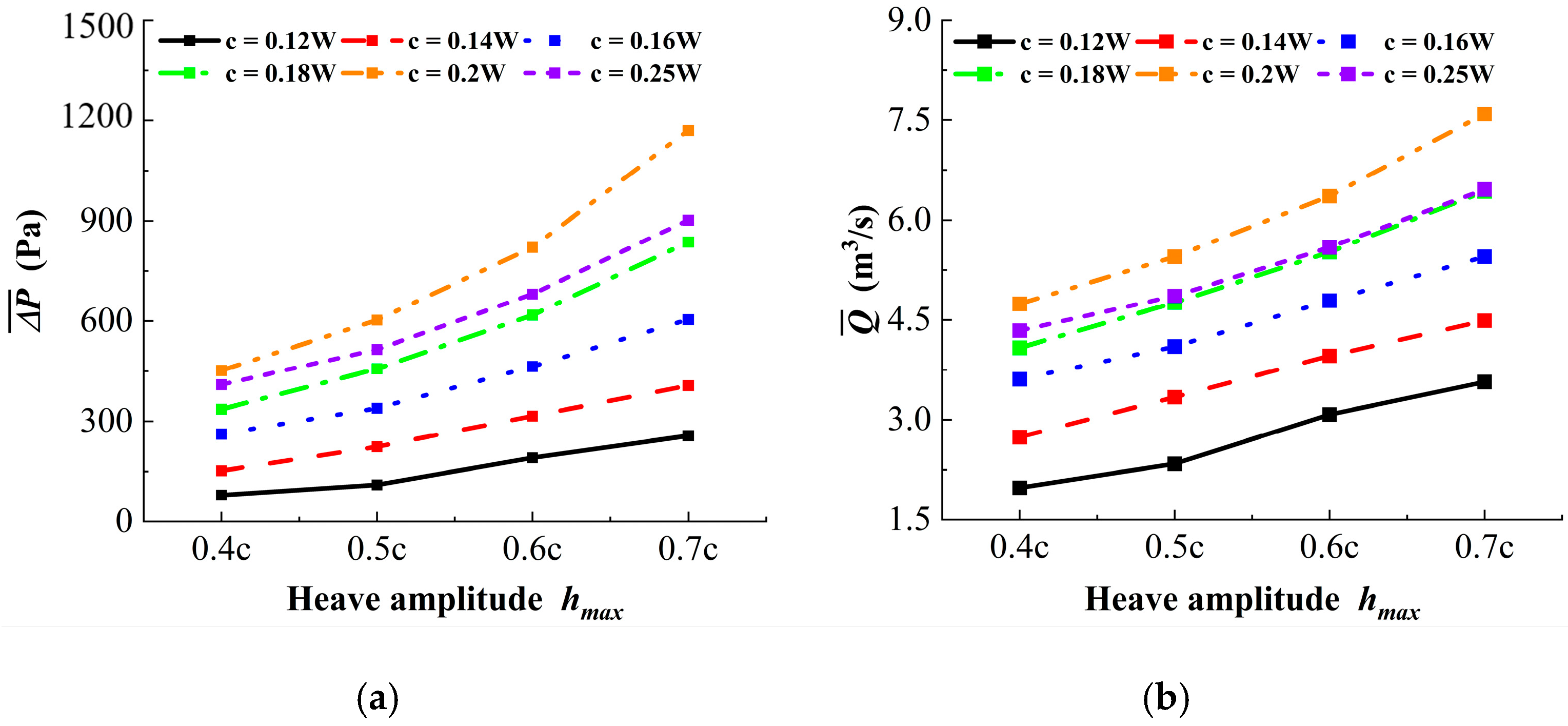

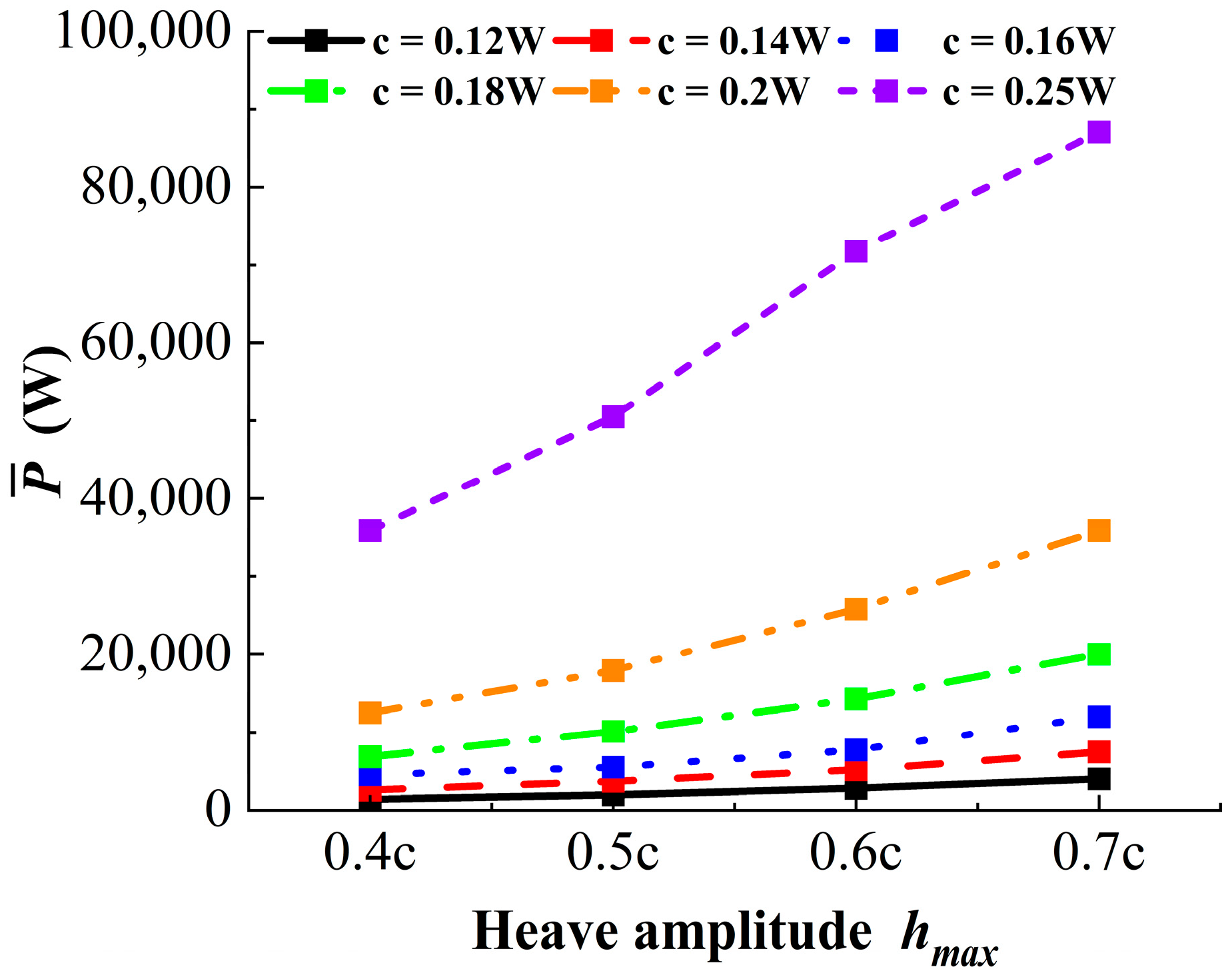

4.2. Influence of Heave Amplitude and Chord Length on the Single-Hydrofoil System

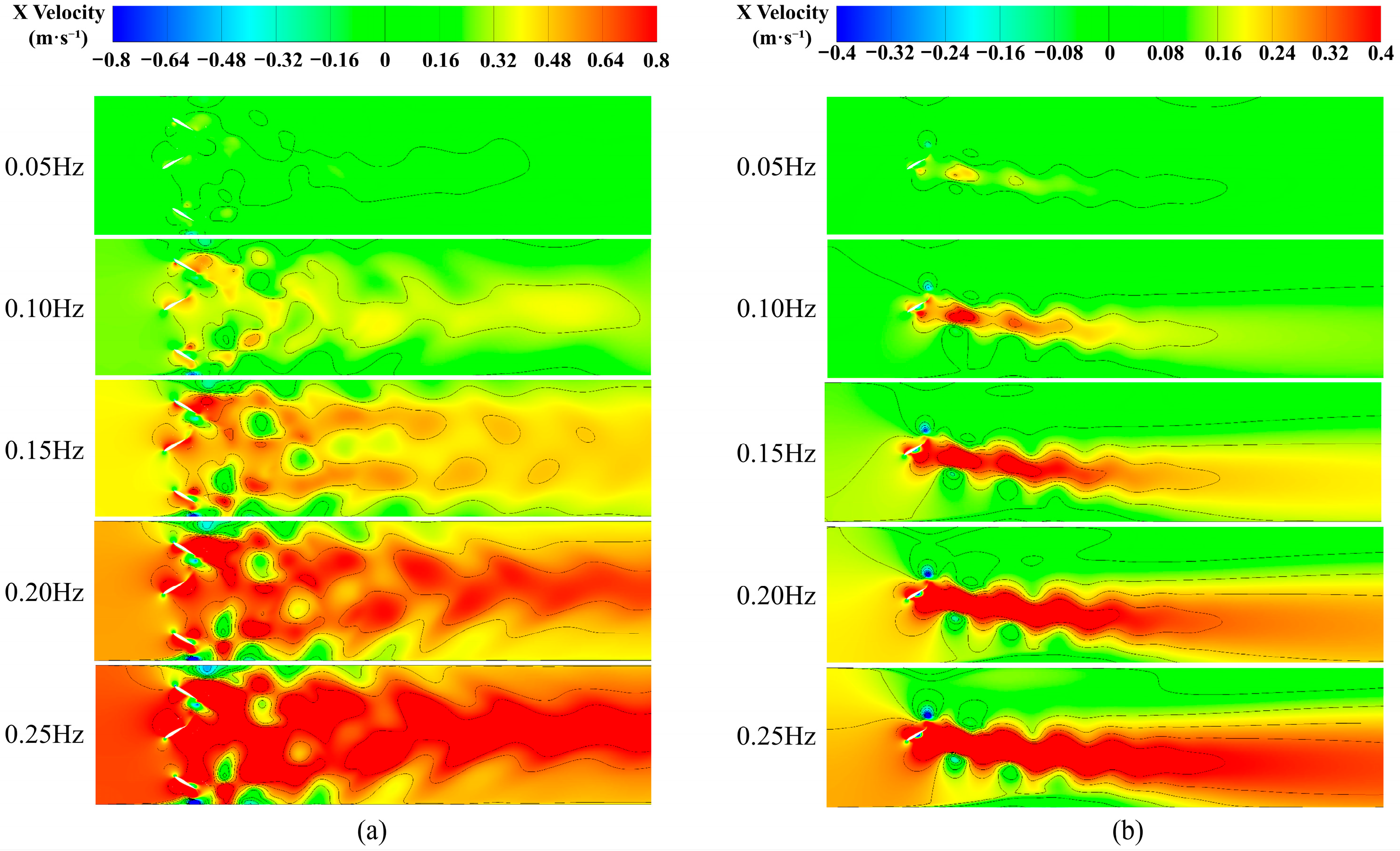

4.3. Comparative Analysis and Parameter Selection Based on the Inhibition Velocity

5. Conclusions

- Multi-hydrofoil system performance: The multi-hydrofoil system exhibits a consistent enhancement in performance. As chord length and heave amplitude increase, the size and strength of the shed vortices grow accordingly, while their vorticity dissipation rate decreases. This enables thrust to be converted more efficiently into propulsion, thereby improving pumping efficiency. When the chord length is 0.18W and the heave amplitude is 0.7c, the maximum efficiency reaches 54.5%.

- Single-hydrofoil system performance: The single-hydrofoil system shows a distinct performance peak. Although larger chord lengths and amplitudes generate higher thrust, vortex deflection causes the momentum to deviate from the streamwise direction, with most of the energy dissipated near the wall. As a result, pumping efficiency follows a “rise–then–fall” trend. The highest efficiency of 28.7% is achieved when the chord length is 0.16W and the heave amplitude is 0.6c.

- Applicability to algal-bloom containment: Based on the suppression threshold of 0.15 m s−1, the multi-hydrofoil system reaches the required velocity across the entire flow section at only 0.10 Hz due to its uniform wake-velocity distribution. It is therefore suitable for large-scale applications requiring full-section velocity enhancement and whole-water-body algal-bloom suppression. In contrast, the single-hydrofoil system produces high velocities primarily in the lower part of the flow field; even at 0.25 Hz, the upper region remains below the threshold. Accordingly, it is more appropriate for localized circulation improvement and targeted inhibition of algal aggregation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liang, C.; Wang, J.; Zhang, X.; Liu, L.; Wu, F. Research on Simulation of Drainage in Plain River Network Areas Based on Hydrological and Hydrodynamic Models. China Rural. Water Hydropower 2025, 67, 17–23. [Google Scholar]

- Liao, Y.; LI, D.; Li, Y.; Su, Y.; Fan, Z. Research on Hydrodynamic Regulation Schemes for Water Environment Improvement in Plain Urban River Networks. Hydro-Sci. Eng. 2024, 46, 14–23. [Google Scholar]

- Wang, T.; Hou, J.; Luan, G.; Shen, T.; Zhang, R.; Shen, J.; Sun, X. Study on Response Relationship between Hydrodynamic Optimization Scheduling and Water Environment Improvement in Plain River Networks. J. Hydroelectr. Eng. 2024, 43, 98–111. [Google Scholar]

- Li, Y.; Pan, Y.; Zhang, L.; Chen, X.; Qin, T.; Lv, L.; Li, S. Apparent Pollution Evaluation and Source Analysis of River Water Bodies in Thetidal River Network Area of the Plains. J. Environ. Eng. 2023, 13, 1839–1848. [Google Scholar]

- Hua, E.; Chen, W.; Tang, S.; Xie, R.; Guo, X.; Xu, G. Water Pushing Flow Characteristics of Flapping Hydrofoil Device in Small River. Trans. Chin. Soc. Agric. Mach. 2022, 53, 154–162. [Google Scholar]

- Hua, E.; Wu, X.; Xiang, M.; Li, S.; Lin, Y. The Hydrodynamic Performance of Multi-Hydrofoil Formations in Plain River Networks Based on Fish Schooling Dynamics. Phys. Fluids 2025, 37, 087134. [Google Scholar] [CrossRef]

- Lu, K.; Xie, Y.H.; Zhang, D. Numerical Study of Large Amplitude, Nonsinusoidal Motion and Camber Effects on Pitching Airfoil Propulsion. J. Fluids Struct. 2013, 36, 184–194. [Google Scholar] [CrossRef]

- Xiong, Z.; Liu, X. Numerical Investigation on Evolutionary Characteristics of the Leading-Edge Vortex Induced by Flapping Caudal Fin. Phys. Fluids 2019, 31, 125117. [Google Scholar] [CrossRef]

- Krishnadas, A.; Ravichandran, S.; Rajagopal, P. Analysis of Biomimetic Caudal Fin Shapes for Optimal Propulsive Efficiency. Ocean Eng. 2018, 153, 132–142. [Google Scholar] [CrossRef]

- Esfahani, J.A.; Barati, E.; Karbasian, H.R. Fluid Structures of Flapping Airfoil with Elliptical Motion Trajectory. Comput. Fluids 2015, 108, 142–155. [Google Scholar] [CrossRef]

- Kelly, J.M.; Khalid, M.S.U.; Han, P.; Dong, H. Geometric Characteristics of Flapping Foils for Enhanced Propulsive Efficiency. J. Fluids Eng. 2023, 145, 061104. [Google Scholar] [CrossRef]

- Wei, C.; Hu, Q.; Li, S.; Shi, X. Hydrodynamic Interactions and Wake Dynamics of Fish Schooling in Rectangle and Diamond Formations. Ocean Eng. 2023, 267, 113258. [Google Scholar] [CrossRef]

- Daghooghi, M.; Borazjani, I. The Hydrodynamic Advantages of Synchronized Swimming in a Rectangular Pattern. Bioinspir. Biomim. 2015, 10, 056018. [Google Scholar] [CrossRef] [PubMed]

- Ambolkar, M.; Arumuru, V. Propulsive Performance of a Pitching Foil in a Side-by-Side Arrangement with Auxiliary Pitching Foil. J. Fluids Struct. 2022, 110, 103537. [Google Scholar] [CrossRef]

- Dewey, P.A.; Quinn, D.B.; Boschitsch, B.M.; Smits, A.J. Propulsive Performance of Unsteady Tandem Hydrofoils in a Side-by-Side Configuration. Phys. Fluids 2014, 26, 041903. [Google Scholar] [CrossRef]

- Gungor, A.; Khalid, M.S.U.; Hemmati, A. Classification of Vortex Patterns of Oscillating Foils in Side-by-Side Configurations. J. Fluid Mech. 2022, 951, A37. [Google Scholar] [CrossRef]

- Kurt, M.; Eslam Panah, A.; Moored, K.W. Flow Interactions Between Low Aspect Ratio Hydrofoils in In-Line and Staggered Arrangements. Biomimetics 2020, 5, 13. [Google Scholar] [CrossRef]

- Huera-Huarte, F.J. Propulsive Performance of a Pair of Pitching Foils in Staggered Configurations. J. Fluids Struct. 2018, 81, 1–13. [Google Scholar] [CrossRef]

- Wu, X.; Li, Q. Reviews of Influences from Hydrodynamic Conditions on Algae. Ecol. Environ. Sci. 2010, 19, 1732–1738. [Google Scholar]

- Wei, Z.; Jia, H.; Jiang, Q.; Meng, D.; Yang, S. Simulation Experiment of Phytoplankton Growth Induced by Flow Velocity in Rivers Replenished with Reclaimed Water. Chin. J. Environ. Eng. 2017, 11, 6540–6546. [Google Scholar]

- Cao, C.; Xu, Z.; Long, Y.; Zhu, H. Effect of Flow Velocity on Algal Bloom in Landscape Water Replenished with Reclaimed Water. China Water Wastewater 2023, 39, 65–69. [Google Scholar]

- Wang, L. Research on the Relevant Factors of the Algal Growth in Hydrodynamic Condition. Master’s Thesis, Chongqing University, Chongqing, China, 2006. [Google Scholar]

- Jiao, S. The Effects of Velocity of Glow to the Growth of Algae in Low Current Area of the Three Gorges. Master’s Thesis, Southwest University, Chongqing, China, 2007. [Google Scholar]

- Li, F.; Gao, Y.; Zhang, H.; Xiao, Y.; Chen, L. Simulation Experiment on the Effect of Flow Velocity on Phytoplankton Growth and Composition. J. Lake Sci. 2015, 27, 44–49. [Google Scholar]

- Zhang, H.; Chen, R.; Li, F.; Chen, L. Effect of Flow Rate on Environmental Variables and Phytoplankton Dynamics: Results from Field Enclosures. Chin. J. Ocean. Limnol. 2015, 33, 430–438. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, H.; Li, F.; Chen, L. Enclosure Experiments About the Hydrodynamics Effects on the Plankton. Environ. Sci. 2010, 31, 69–75. [Google Scholar]

- Hua, E.; Su, Z.; Xie, R.; Chen, W.; Tang, S.; Luo, H. Optimization and Experimental Verification of Pivot Position of Flapping Hydrofoil. J. Hydroelectr. Eng. 2023, 42, 128–138. [Google Scholar]

- Hua, E.; Qiu, L.; Xie, R.; Su, Z.; Zhu, W. Comparative Analysis of the Hydrodynamic Performance of Dual Flapping Foils with In-Phase and Out-of-Phase Oscillations. Water 2023, 15, 3275. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Zhang, L.; Gao, Y.; Zhao, Y. The Influence of Lake Hydrodynamics on Blue Algal Growth. China Environ. Sci. 2007, 27, 707–711. [Google Scholar]

- Song, Y.; Zhang, L.L.; Li, J.; Chen, M.; Zhang, Y. Mechanism of the Influence of Hydrodynamics on Microcystis Aeruginosa, a Dominant Bloom Species in Reservoirs. Sci. Total Environ. 2018, 636, 230–239. [Google Scholar] [CrossRef]

- Lin, L.; Zhu, W.; Cheng, F.L.; Wang, T.; Tan, X. Effects of Continuous Water Flow on Growth of the Microcystis Aeruginosa under High Nutrient Levels. Energy Procedia 2012, 17, 1793–1797. [Google Scholar] [CrossRef][Green Version]

- He, G.; Xie, H.; Wang, W.; Mo, W.; Yang, H. Influence of Wing-in-Surface-Effect on Power Extraction of Parallel Oscillating Hydrofoils. J. Vib. Shock 2023, 42, 58–64+86. [Google Scholar]

- Ding, H.; Song, B.; Tian, W. Exploring Propulsion Performance Analysis of Bionic Flapping Hydrofoil. J. Northwest. Polytech. Univ. 2013, 31, 150–156. [Google Scholar]

- Du, X.; Zhang, Z. Numerical Analysis of Influence of Four Flapping Modes on Propulsion Performance of Underwater Flapping Foils. Eng. Mech. 2018, 35, 249–256. [Google Scholar]

- Schouveiler, L.; Hover, F.S.; Triantafyllou, M.S. Performance of Flapping Foil Propulsion. J. Fluids Struct. 2005, 20, 949–959. [Google Scholar] [CrossRef]

| Mesh Count | Foreground Mesh Count | Background Mesh Count | Mean Thrust Coefficient |

|---|---|---|---|

| 68,773 | 55,569 | 13,204 | 6.17 |

| 79,012 | 57,249 | 21,763 | 6.98 |

| 111,896 | 58,627 | 53,269 | 5.89 |

| 232,452 | 64,093 | 168,359 | 5.83 |

| Time Step | Mean Thrust Coefficient |

|---|---|

| 9.21 | |

| 8.07 | |

| 5.89 | |

| 5.76 |

| Frequency (Hz) | Simulation Velocity (m/s) | Experimental Velocity (m/s) |

|---|---|---|

| 0.20 | 0.046 | 0.05 |

| 0.40 | 0.01 | 0.096 |

| 0.60 | 0.143 | 0.147 |

| 0.80 | 0.211 | 0.205 |

| Case | Chord Length | Heave Amplitude |

|---|---|---|

| A | 0.14W | 0.4c |

| B | 0.18W | 0.4c |

| C | 0.18W | 0.7c |

| Case | Chord Length | Heave Amplitude |

|---|---|---|

| A | 0.25W | 0.4c |

| B | 0.16W | 0.4c |

| C | 0.16W | 0.6c |

| Multi-/Single-Hydrofoil System | Frequency (Hz) | Mean Outlet Velocity (m/s) |

|---|---|---|

| Multi-hydrofoil system | 0.05 | 0.133 |

| 0.10 | 0.268 | |

| 0.15 | 0.413 | |

| 0.20 | 0.552 | |

| 0.25 | 0.691 | |

| Single-hydrofoil system | 0.05 | 0.049 |

| 0.10 | 0.096 | |

| 0.15 | 0.144 | |

| 0.20 | 0.192 | |

| 0.25 | 0.241 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hua, E.; Wu, X.; Lin, Y.; Li, S. Parameter Optimization of Bionic Hydrofoil System and Its Application in Algal Bloom Control in Plain River Networks. Water 2025, 17, 3012. https://doi.org/10.3390/w17203012

Hua E, Wu X, Lin Y, Li S. Parameter Optimization of Bionic Hydrofoil System and Its Application in Algal Bloom Control in Plain River Networks. Water. 2025; 17(20):3012. https://doi.org/10.3390/w17203012

Chicago/Turabian StyleHua, Ertian, Xiaopeng Wu, Yang Lin, and Sihan Li. 2025. "Parameter Optimization of Bionic Hydrofoil System and Its Application in Algal Bloom Control in Plain River Networks" Water 17, no. 20: 3012. https://doi.org/10.3390/w17203012

APA StyleHua, E., Wu, X., Lin, Y., & Li, S. (2025). Parameter Optimization of Bionic Hydrofoil System and Its Application in Algal Bloom Control in Plain River Networks. Water, 17(20), 3012. https://doi.org/10.3390/w17203012