BIM Lightweight Technology in Water Conservancy Engineering Operation and Maintenance: Improvement of the QEM Algorithm and Construction of the Evaluation System

Abstract

1. Introduction

1.1. Research Background and Problem Statement

1.2. Literature Review

1.2.1. Application and Research of BIM

1.2.2. Application and Research of BIM in Hydrological Engineering Operations Management

1.2.3. Research on BIM Model Lightweight Processing

1.2.4. Research on the Establishment of an Evaluation System

1.3. Research Methods

2. The Application of BIM Technology in Operations and Maintenance (O&M)

2.1. The Advantages of BIM Technology in Operations and Maintenance (O&M)

- (1)

- Information Integration and Sharing

- (2)

- Visualized Management

2.2. Large AI Models for Predicting the Running Status of Water Conservancy Equipment

2.3. Challenges of BIM Technology in Addressing Lightweight Issues Within Operations and Maintenance Management

3. Lightweight Analysis

3.1. Lightweight Fineness Level Classification

3.2. Lightweight Process

3.2.1. The Introduction of Traditional QEM Algorithm

- 1.

- A simpler strategy involves selecting the position of from or that minimizes the collapse cost

- 2.

- A more advanced strategy involves numerically solving for the position of that minimizes . Since is expressed in quadratic form, its minimum is found by setting the first derivative to zero, which reduces to solving as follows:

3.2.2. Improvement on the Quadratic Error Metric (QEM) Algorithm

- (1)

- Boundary curve constraints

- (2)

- Taking into account the modifications resulting from normal vector offsets

4. Instance Analysis

4.1. Lightweight Processing

4.2. Analysis and Evaluation of Lightweight Processing Results

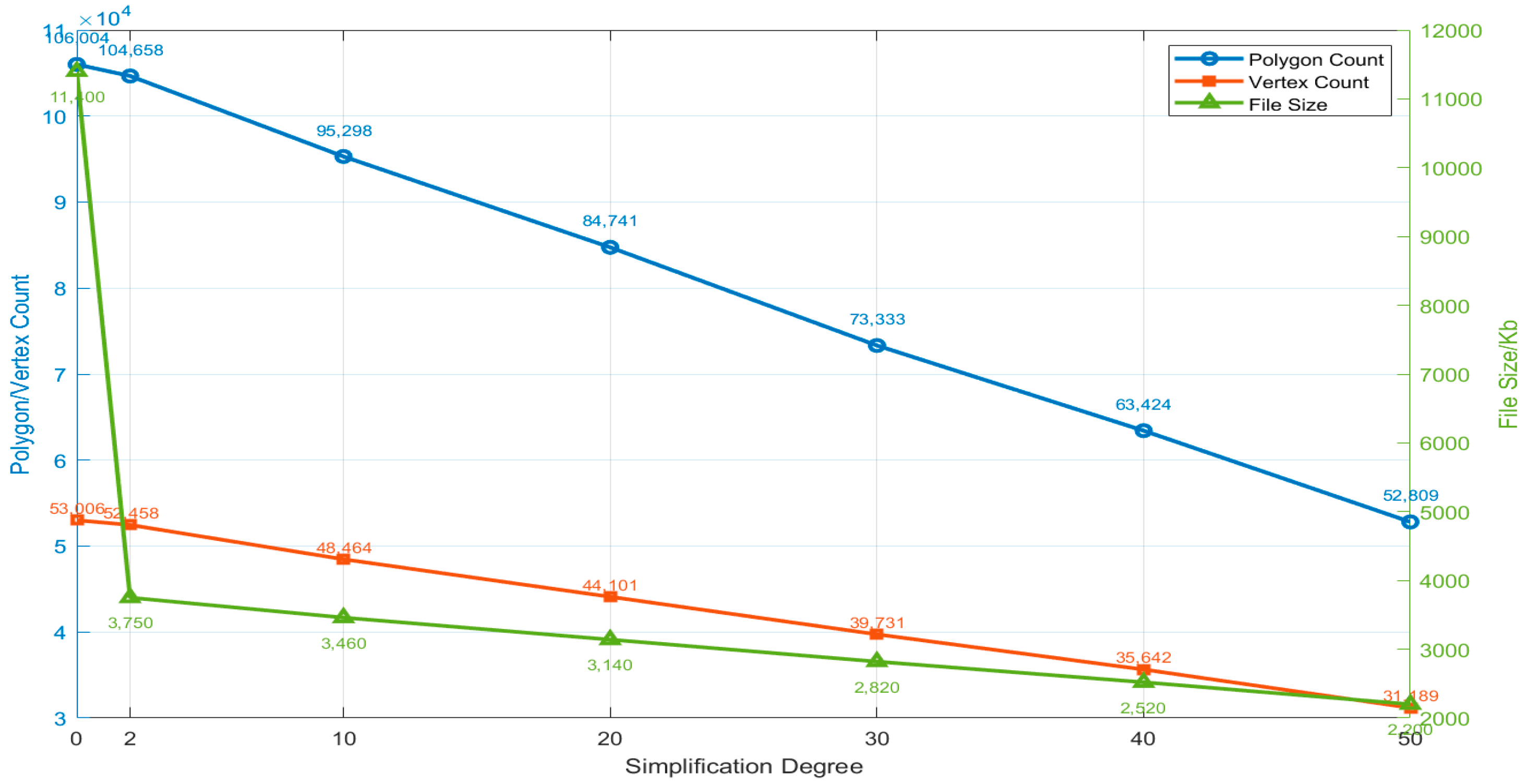

- (1)

- Analysis of Simplification Degree on Face Count, Vertex Count, and File Size

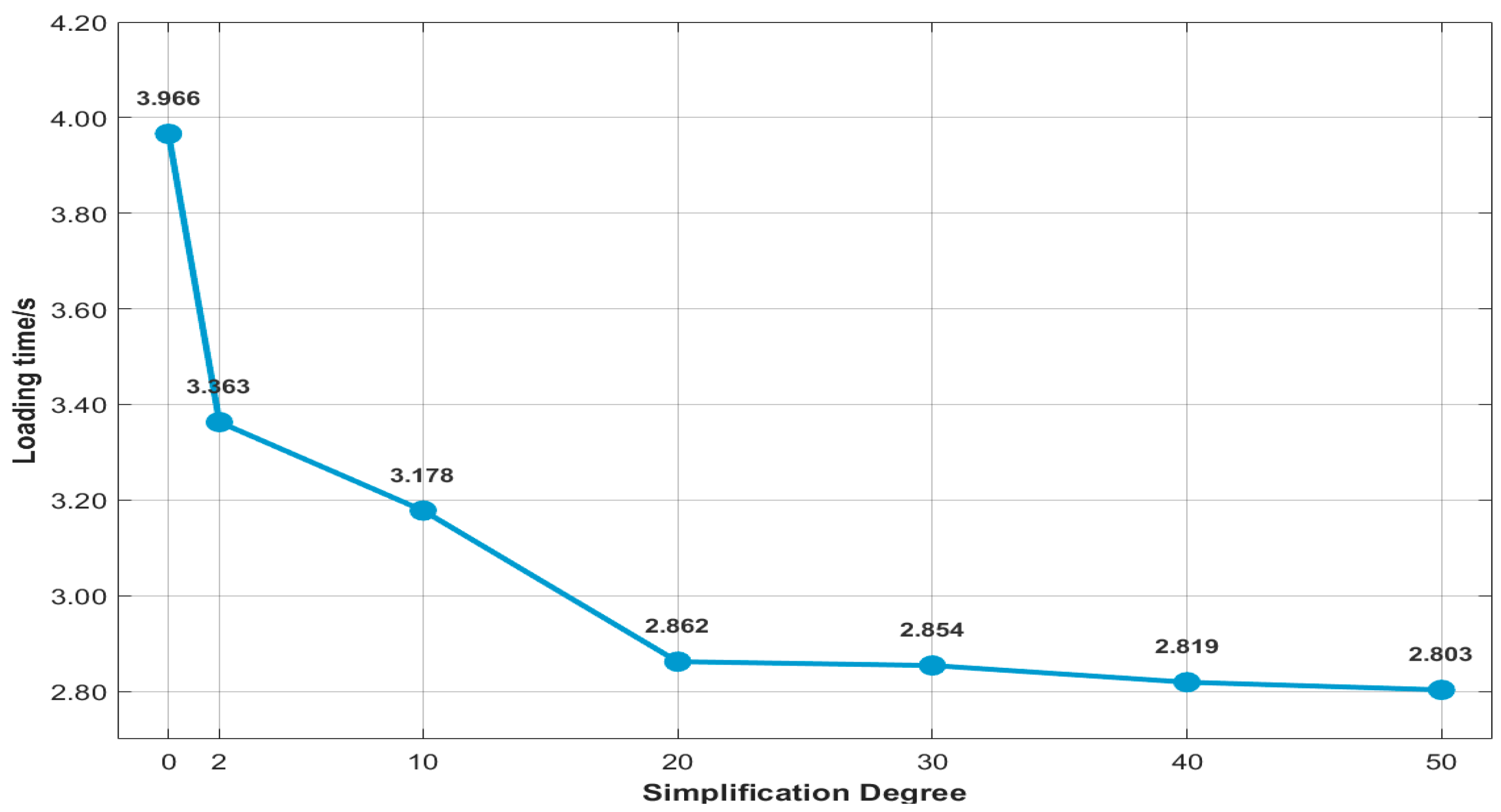

- (2)

- Analysis of Simplification Degree on Model Loading Time

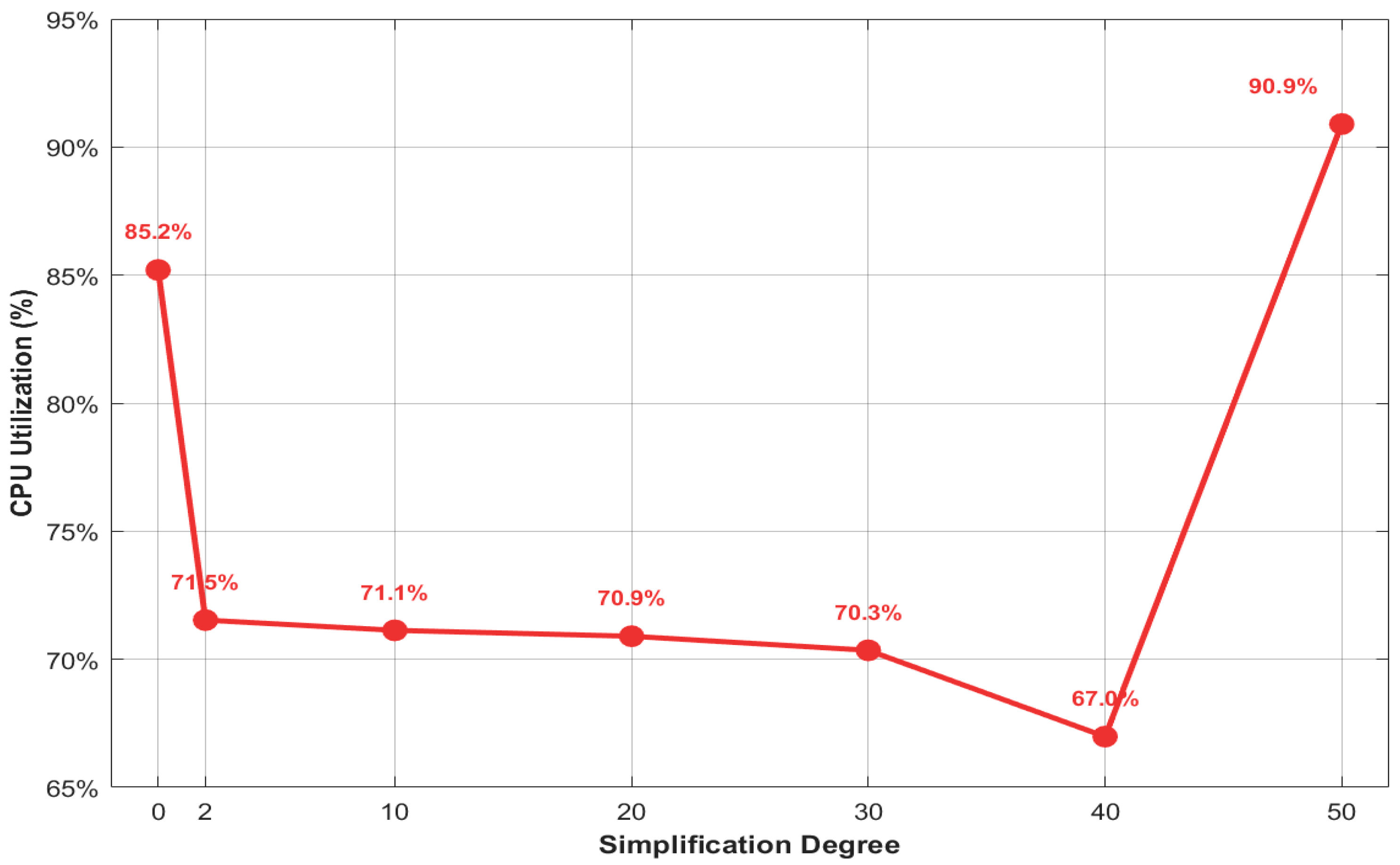

- (3)

- Analysis of the Effect of Simplification Level on CPU Usage

- (4)

- Universality Analysis of Model Lightweighting Methodology

5. Evaluation System Construction

5.1. Lightweighting Effect Evaluation

5.2. Evaluation System Establishment

5.2.1. Establishment of the Evaluation System

- (1)

- Definition of Evaluation Objectives

- (2)

- Determination of Evaluation Metrics

- (3)

- Weight Assignment via Analytic Hierarchy Process (AHP)

- (4)

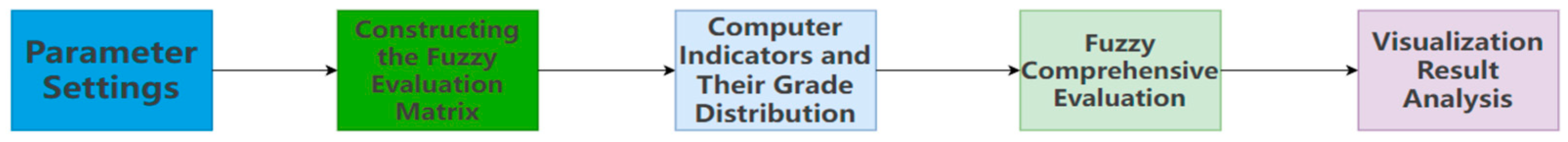

- Implementation of Fuzzy Comprehensive Evaluation Model

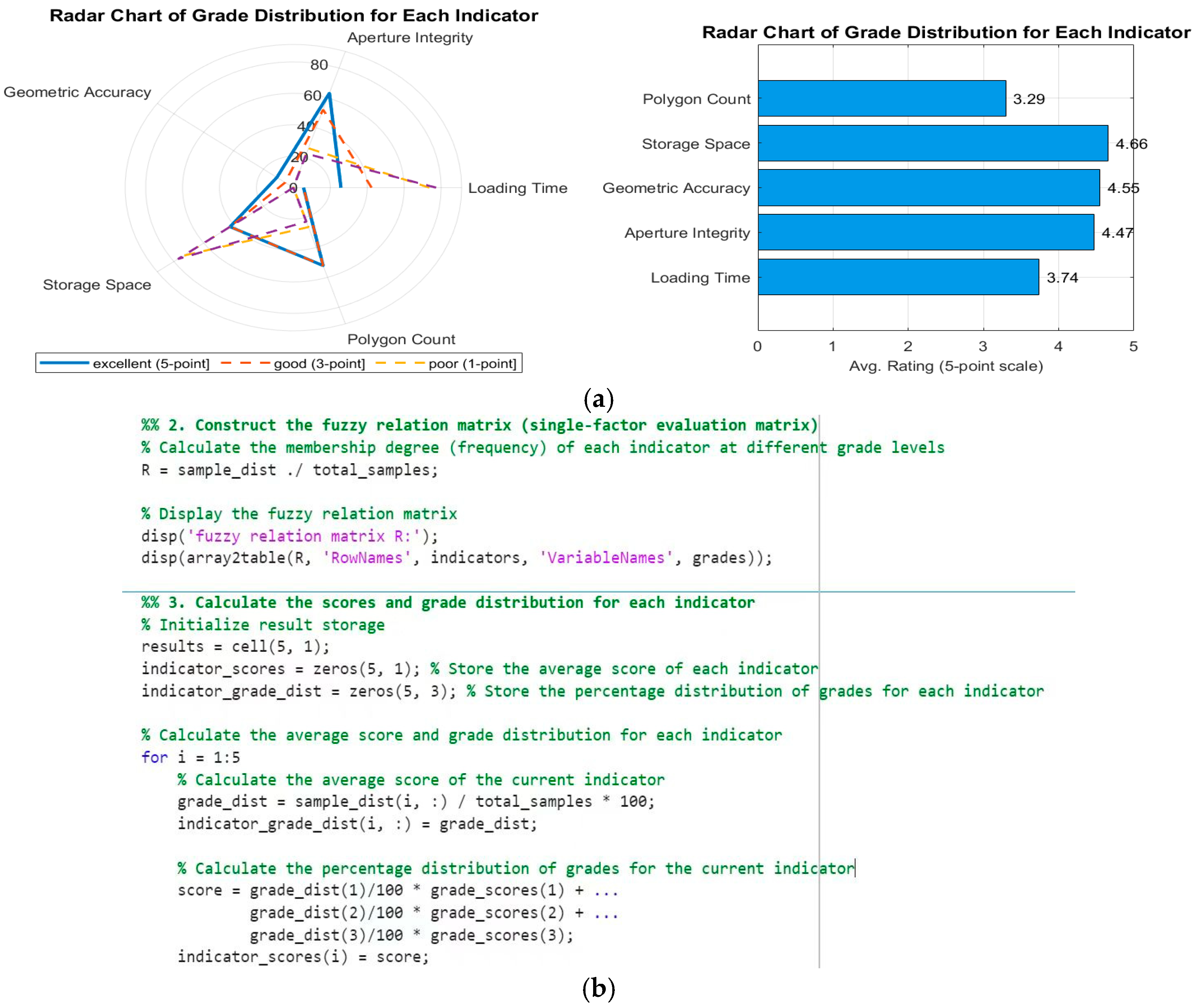

5.2.2. Instance Analysis

Determining Indicator Weights

- Analysis of Model Quality Determinants

- 2.

- Hierarchical Indicator System Construction

- 3.

- Weight Calculation Methodology

| X | |||||

|---|---|---|---|---|---|

| 1 | 4 | 1 | 2 | 1/3 | |

| 1/4 | 1 | 1/3 | 1/5 | 1/6 | |

| 1 | 3 | 1 | 3 | 1/2 | |

| 1/2 | 5 | 1/3 | 1 | 1/4 | |

| 3 | 6 | 2 | 4 | 1 | |

| Sum | 5.75 | 19 | 4.66 | 10.5 | 2.25 |

Constructing the Evaluation Model

5.2.3. Results and Model Innovation Analysis

Model Features and Innovations

- Weight Normalization:

- 2.

- Multidimensional Visualization Analysis:

- 3.

- Interactive Design:

Runtime Results Analysis

6. Conclusions and Future Work

6.1. Conclusions

- (1)

- Methodologically, an improved Quadric Error Metric (QEM) algorithm was proposed in this study, and a comprehensive evaluation framework was established, together providing new tools and a theoretical foundation for BIM model lightweighting. Furthermore, the introduced evaluation framework addresses a significant gap in the field—namely, the lack of systematic methods for assessing the effectiveness of existing lightweighting techniques—thus laying a groundwork for future research.

- (2)

- In practical terms, the findings of this study can be directly applied to the operation and maintenance management of hydraulic engineering. They offer a solution to enhance the operational efficiency of existing BIM platforms by mitigating issues related to large model data volume through lightweight processing. Experimental results demonstrate that the processed BIM models significantly improve operational responsiveness in large-scale and complex scenarios, optimize user interaction experience, and further promote the broader application of BIM technology in engineering management; The established evaluation framework is capable of effectively assessing the effectiveness of the lightweighting process and providing relevant recommendations.

- (3)

- While the Quadric Error Metric (QEM) algorithm can reduce memory usage, shorten model loading time, and improve rendering efficiency, its primary operation involves the reduction in triangular faces. Consequently, its effectiveness in enhancing loading speed and rendering performance remains limited. Therefore, integrating QEM with other algorithms—such as Level of Detail (LOD)—presents a viable strategy to overcome these limitations.

6.2. Future Work

- (1)

- Algorithm Refinement and Optimization: Future research will focus on exploring strategies to integrate the improved QEM algorithm with Level of Detail (LOD) technology. This approach not only can effectively avoid potential distortion issues during the model lightweight processing but also optimize resource loading strategies, thereby further reducing model loading time and improving overall operational efficiency.

- (2)

- Performance Metric Maintenance and Optimization: For the performance metrics where the current algorithm excels, further optimizations of existing strategies will be pursued. Additionally, a comprehensive monitoring mechanism will be established to identify and prevent performance regression phenomena in a timely manner, ensuring the stability and reliability of the algorithm during long-term applications.

- (3)

- Technology Application Expansion: BIM model lightweight processing allows for the establishment of a more concise and efficient working platform during water conservancy engineering operation and maintenance, thereby enhancing work efficiency. The application value of BIM model lightweight technology is not only evident in the field of water conservancy engineering operation and maintenance but also extends to multiple scenarios such as Web, VR, and AR. Specifically, lightweight models ensure smooth model loading and rendering on WebGL-based digital twin platforms; facilitate the construction of dynamic interactive web presentations in React frameworks; and significantly improve application runtime efficiency and user immersive interaction experience on mobile VR/AR devices. These advantages underscore the vast application potential of BIM lightweight technology in the fields of engineering management, digital twins, and virtual reality. Based on the current research outcomes, subsequent studies will actively explore the application potential of the improved QEM algorithm in WebGL engines, React frameworks, and mobile VR/AR scenarios. This will further validate the algorithm’s applicability and superiority in various application contexts. Such efforts will provide critical technical support for the deeper integration of BIM technology into emerging fields such as digital twins and virtual reality.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chu, P.; Zhao, E.; Madiniyetti, J. Research on Whole Life Cycle Management of Water Conservancy and Hydropower Engineering Based on BIM. Water Resour. Hydropower Eng. 2018, 36, 133–136. [Google Scholar] [CrossRef]

- Jiang, P.; Wu, J.; Liu, H.; Liu, Z.; Zhang, S. Research on Lightweight Technology of Digital Twin Water Conservancy Engineering Based on BIM. People’s Yellow River 2024, 46, 133–137+144. [Google Scholar] [CrossRef]

- Guo, S.; Chen, Y. A Lightweight Method for Information Models in the Building Operation and Maintenance Stage. J. Graph. 2018, 39, 123–128. [Google Scholar] [CrossRef]

- Bao, S.; Bu, H.; Lou, X.; Fang, X. Status and Outlook of BIM-based Operation and Maintenance. Constr. Technol. 2024, 53, 28–35+50. [Google Scholar]

- Yalcinkaya, M.; Singh, V. Patterns and trends in Building Information Modeling (BIM) research: A Latent Semantic Analysis. Autom. Constr. 2015, 59, 68–80. [Google Scholar] [CrossRef]

- Vberlo, L.; Krijnen, T. Using the BIM Collaboration Format in a Server Based Workflow. Procedia Environ. Sci. 2014, 22, 325–332. [Google Scholar] [CrossRef]

- Zhao, N.; Li, W.; Chen, Y. Research on Whole Life Cycle Management of Water Conservancy Engineering Based on BIM Technology. Sichuan Water Resour. 2022, 43, 116–121. [Google Scholar]

- Fu, X.; Tian, L.; Zhang, Q.; Chang, H.; Li, S.; Wu, W. Application of Digital Twin Technology in Operation and Maintenance Management of Water Conservancy Engineering. Water Hydropower News 2024, 45, 104–107. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Z.; Kou, B.; Yu, Q. Three-Dimensional Visualization Operation and Maintenance Management Platform for Building Models Based on BIM. Green Constr. Intell. Build. 2023, 4, 33–36+40. [Google Scholar]

- Su, Q. Development and Application of a BIM+GIS Collaborative Management Platform for Water Conservancy Engineering. Yellow River 2024, 46, 133–136+148. [Google Scholar] [CrossRef]

- Liu, H.; Zhong, Q.; Xie, J.; Zhang, G.; Fu, C. Research and Application of an Intelligent Operation and Maintenance Management Platform for Pumping Stations Based on Knowledge-Driven Methods. Water Hydropower Technol. 2025, 56, 484–490. [Google Scholar] [CrossRef]

- Zhao, F. Research and Implementation of Lightweight Ancient Building BIM Models Based on WebGL; Xi’an University of Architecture and Technology: Xi’an, China, 2018. [Google Scholar]

- Du, Z.; Wang, H.; Tan, Z.; Huang, H. Research on Lightweight Application of Water Conservancy Engineering BIM Based on IFC and WebGL. Rural Water Conserv. Hydropower 2020, 11, 199–203. [Google Scholar]

- Wang, D.; Wang, S.; Zeng, W. Lightweight Application of BIM in Rail Transit Based on WebGL. Railw. Comput. Appl. 2021, 30, 30–34. [Google Scholar] [CrossRef]

- Wei, A.; Ding, Z.; Wang, L.; Zeng, L.; Yan, L. Clinical Comprehensive Evaluation of Specific Plasminogen Activator for Thrombolysis in Acute Myocardial Infarction. Guide to Pharmacology. 2025, pp. 1–13. Available online: http://kns.cnki.net/kcms/detail/42.1293.R.20250613.1115.028.html (accessed on 16 June 2025).

- Zhao, J.; Yuan, P.; Yan, J. Research on the Generation Logic, Theoretical Connotation, and Evaluation System of Emerging Productive Forces. Xinjiang Financ. Econ. 2025, 3, 5–15. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.; Sun, J.; Lin, H.; Li, C. Comprehensive Evaluation Method for Cloud Model-Based Dynamic Adjustment of Topological Restriction Short-Circuit Current Fast Switching Device Placement. Trans. China Electrotech. Soc. 2025, 1–16. [Google Scholar] [CrossRef]

- Gu, Y. Construction of Practice Teaching Quality Evaluation System for Logistics Management Majors in Higher Vocational Colleges Based on the CIPP Evaluation Model. Logist. Technol. 2025, 48, 170–172+184. [Google Scholar] [CrossRef]

- Xu, N.; Gong, Y. Research on the Framework System of BIM-Based Building Operation and Maintenance Management–Taking the Xuzhou Civil Service Center Project as an Example. Constr. Econ. 2018, 39, 45–48. [Google Scholar] [CrossRef]

- Lou, X.; Zhang, J. Thinking on the Path of Campus Digital Intelligent Operation and Maintenance Management Based on BIM. Informatiz. China Constr. 2022, 17, 58–59. [Google Scholar]

- Kensek, K. BIM guidelines inform facilities management data bases: A case study over time. Buildings 2015, 5, 899–916. [Google Scholar] [CrossRef]

- Wang, Z. The Application of BIM Technology in Building Operation and Maintenance. Constr. Econ. 2013, 9, 94–97. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, H.; Lü, B.; Sun, S. Research on the Application of BIM Technology in the Operation Phase of Projects. J. Zhongzhou Univ. 2016, 33, 120–124. [Google Scholar] [CrossRef]

- Chen, X.; Fu, W.; Liu, C.; Liu, Z.; Li, P.; Hu, Z.; Hu, D. Exploring the Application of Large Artificial Intelligence Models in Power Equipment Maintenance Scenarios. Chin. Eng. Sci. 2025, 27, 180–192. [Google Scholar]

- Yang, J.; Chen, Y.; Wang, T.; Zhou, Y.; Xia, J. The Application of BIM Technology in Operation and Maintenance Management of Water Conservancy Engineering. Water Hydropower Technol. 2020, 51, 185–190. [Google Scholar] [CrossRef]

- GB/T 51301-2018; Technical Standard for Building Information Model Delivery. China Standards Press: Beijing, China, 2018.

- Li, X.; Li, G.; Zhang, X.; Li, H. Edge collapse simplification base on subdivision. J. Comput. Aided Des. Comput. Graph. 2002, 14, 8–13. [Google Scholar]

- Garland, M.; Heckbert, P.S. Surface simplification using quadric error metrics. In SIGGRAPH Proceedings; ACM Press: New York, NY, USA, 1997; pp. 209–216. [Google Scholar] [CrossRef]

- Sun, S.; Dong, G.; Jiao, H.; Li, B. Research on Lightweighting of Digital Twin Virtual Entities in Hydraulic Engineering. China Rural. Water Hydropower 2025, 1, 168–174. [Google Scholar]

| Evaluation of Model Lightweighting | Assessment Metrics | Specifications |

|---|---|---|

| Model Quality () | Loading Time () | Time required for complete model initialization |

| Aperture Integrity () | Preservation of void structures without collapse or fusion | |

| Geometric Accuracy () | Magnitude of deviation in dimensional parameters | |

| Storage Space () | File size of the processed model | |

| Polygon Count () | File size of the processed model Number of triangular meshes in the model geometry | |

| User Experience () | Visual Satisfaction () | Perceived quality assessed through user rating scales |

| Shape Discernibility () | Recognizability of critical structural components | |

| Texture Quality () | Preservation of color and texture resolution | |

| Interaction Responsiveness () | System latency during view manipulation operations | |

| Computational Performance () | Frame Rate () | Rendering frames per second (FPS) during navigation |

| Cross-platform Compatibility () | Operational stability across diverse hardware/software environments | |

| Resource Utilization () | CPU/GPU occupancy rates and memory consumption during runtime | |

| Long-term Viability () | Operational Stability () | Reliability under extended usage scenarios |

| Maintenance Scalability () | Resource requirements for future updates and optimizations |

| X | |||||||

|---|---|---|---|---|---|---|---|

| 0.17 | 0.21 | 0.215 | 0.19 | 0.147 | 0.1864 | 0.987 | |

| 0.04 | 0.05 | 0.071 | 0.019 | 0.074 | 0.0508 | 0.262 | |

| 0.17 | 0.157 | 0.215 | 0.28 | 0.222 | 0.2088 | 1.1316 | |

| 0.087 | 0.26 | 0.071 | 0.095 | 0.111 | 0.1248 | 0.646 | |

| 0.521 | 0.32 | 0.43 | 0.381 | 0.444 | 0.4192 | 2.2 |

| 0.1864 | 0.0508 | 0.2088 | 0.1248 | 0.4192 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, Z.; Tang, Z.; He, L.; Ding, J. BIM Lightweight Technology in Water Conservancy Engineering Operation and Maintenance: Improvement of the QEM Algorithm and Construction of the Evaluation System. Water 2025, 17, 2929. https://doi.org/10.3390/w17202929

Zhan Z, Tang Z, He L, Ding J. BIM Lightweight Technology in Water Conservancy Engineering Operation and Maintenance: Improvement of the QEM Algorithm and Construction of the Evaluation System. Water. 2025; 17(20):2929. https://doi.org/10.3390/w17202929

Chicago/Turabian StyleZhan, Zhengjie, Zihao Tang, Lihong He, and Junzhi Ding. 2025. "BIM Lightweight Technology in Water Conservancy Engineering Operation and Maintenance: Improvement of the QEM Algorithm and Construction of the Evaluation System" Water 17, no. 20: 2929. https://doi.org/10.3390/w17202929

APA StyleZhan, Z., Tang, Z., He, L., & Ding, J. (2025). BIM Lightweight Technology in Water Conservancy Engineering Operation and Maintenance: Improvement of the QEM Algorithm and Construction of the Evaluation System. Water, 17(20), 2929. https://doi.org/10.3390/w17202929