Data–Physics-Driven Multi-Point Hybrid Deformation Monitoring Model Based on Bayesian Optimization Algorithm–Light Gradient-Boosting Machine

Abstract

1. Introduction

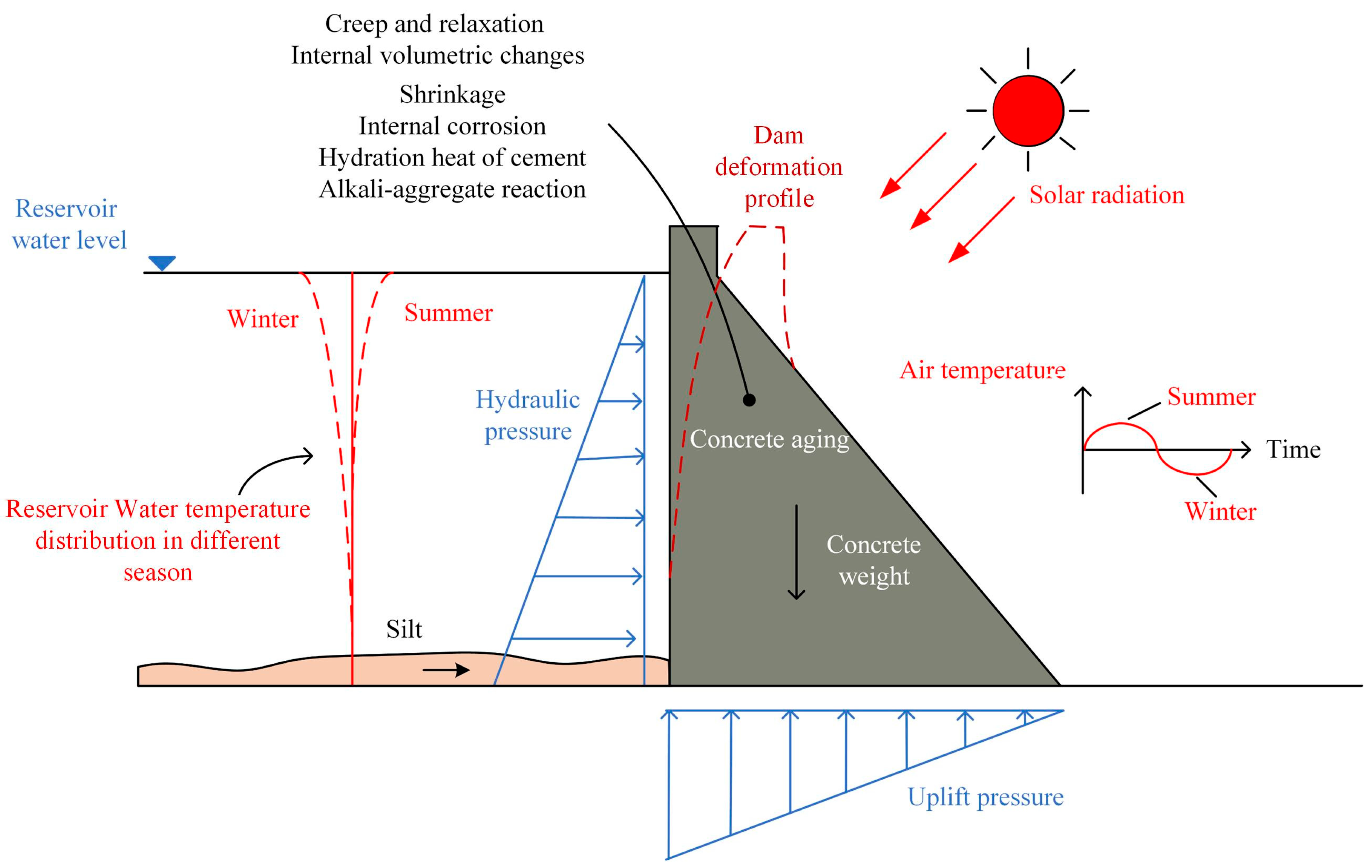

2. Basic Theory of Multi-Point Deformation Monitoring for Concrete Gravity Dam

2.1. Basic Principles and Spatial Correlation of Concrete Dam Deformation

2.2. Hybrid Model for Deformation Monitoring of Multiple Measurement Points

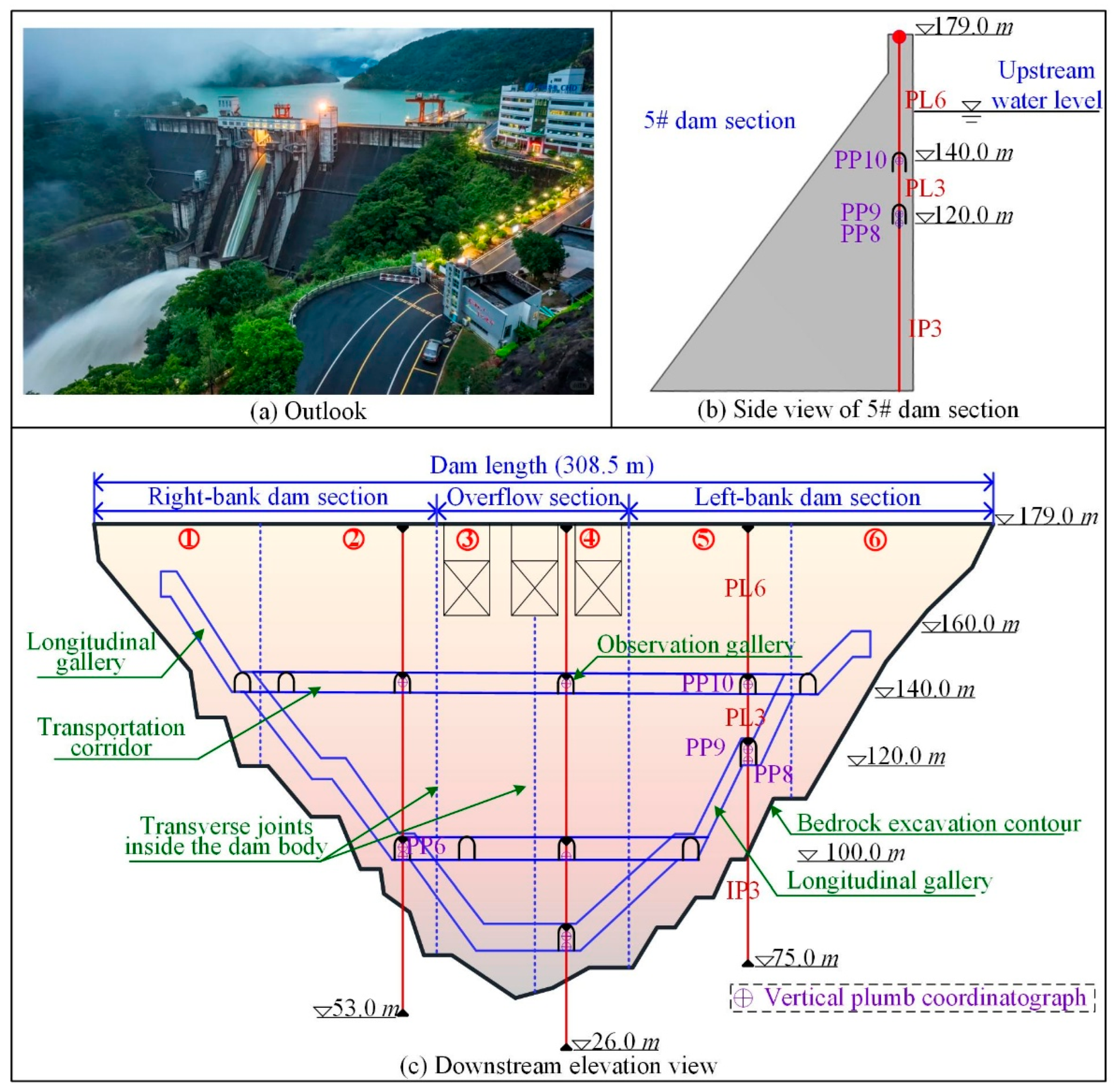

3. Construction of Multi-Point Hybrid Deformation Monitoring Model Based on BOA-LightGBM

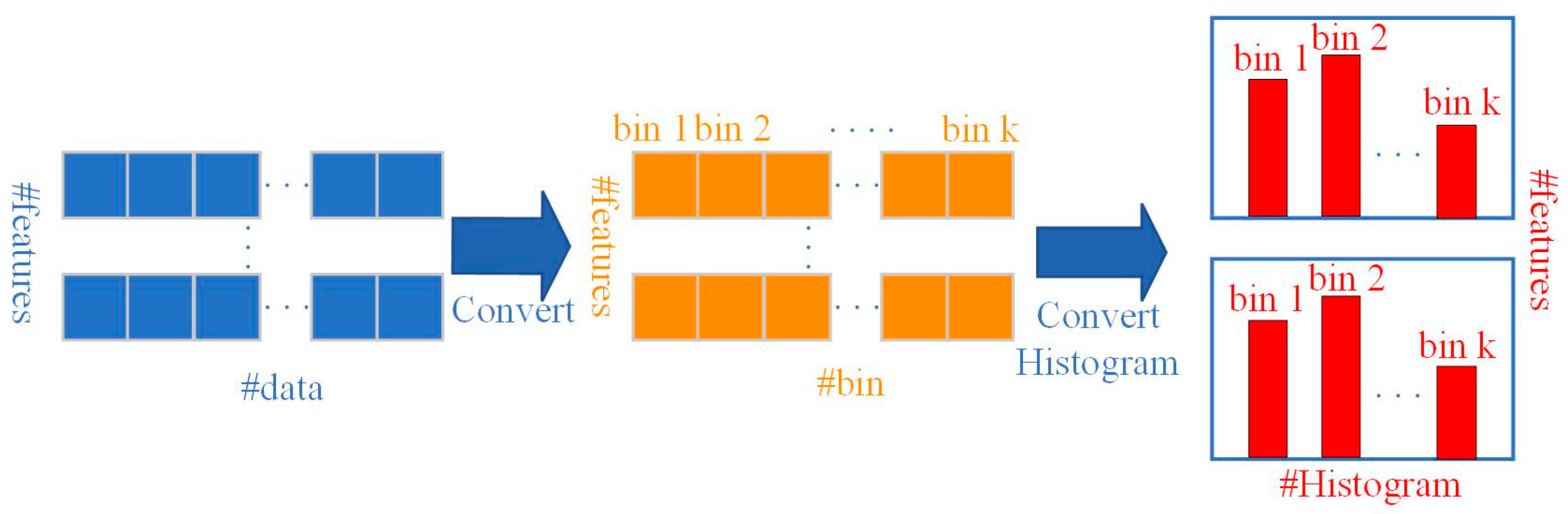

3.1. Multi-Point Deformation Prediction of Gravity Dams Based on LightGBM

3.2. The Construction of a Multi-Point Hybrid Deformation Monitoring Model Based on Bayesian-Optimized LightGBM

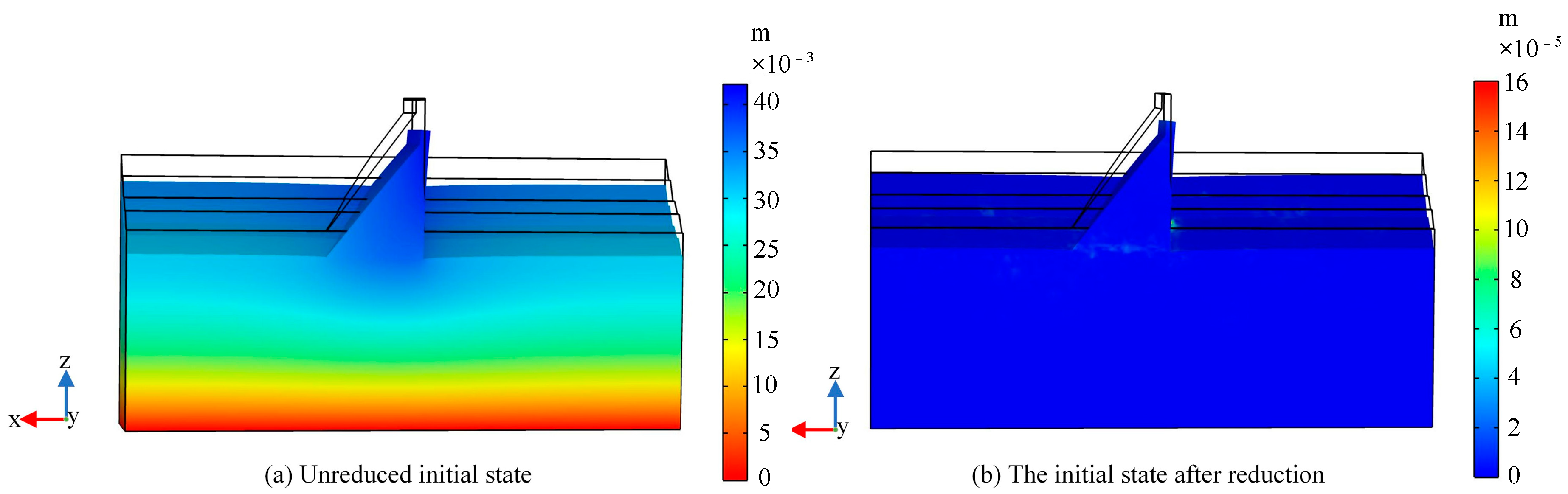

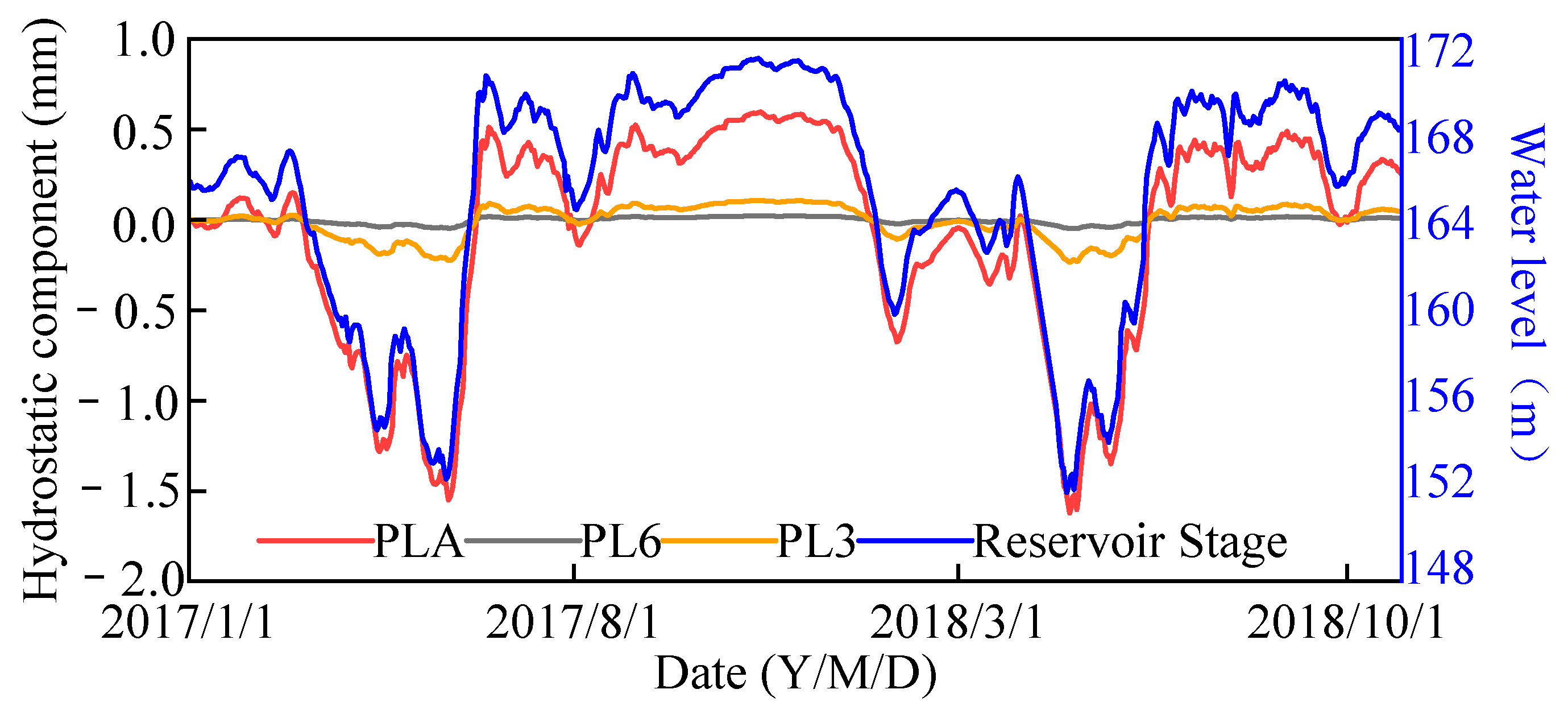

- A multi-point deformation monitoring dataset was constructed by combining the measured water levels, time, and spatial coordinates according to Equation (7). The hydrostatic components at each monitoring point under the actual water pressure load were calculated using the FEM, and the results were fitted with the polynomial expression of the hydrostatic component field given in Equation (7). The fitted hydrostatic components, together with the temperature and time-effect-related factors, were subsequently normalized to serve as the input features (independent variables) of the LightGBM model, while the measured multi-point deformation sequences were taken as the target variable (dependent variable).

- To optimize the model, the initial parameters of the Bayesian Optimization Algorithm (BOA) and the search ranges for the LightGBM hyperparameters were defined. An initial LightGBM model was trained under the starting hyperparameter set, and its prediction accuracy was used as the objective function. The BOA then iteratively evaluated the objective function, updated the search positions using Gaussian Process and the acquisition function, and trained new LightGBM models with the proposed hyperparameter sets. This process continued until the maximum number of BOA iterations was reached.

- Finally, the BOA optimization process was terminated, and the best-found LightGBM hyperparameters were obtained. Using these optimal parameters, the final data–physics-driven hybrid multi-point deformation monitoring model for the concrete dam was constructed. The construction process of this model is illustrated in Figure 4.

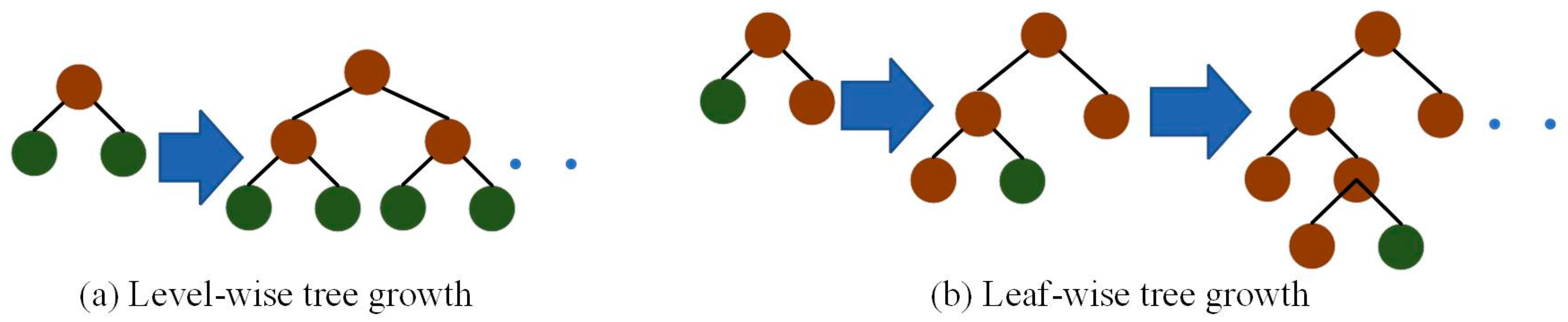

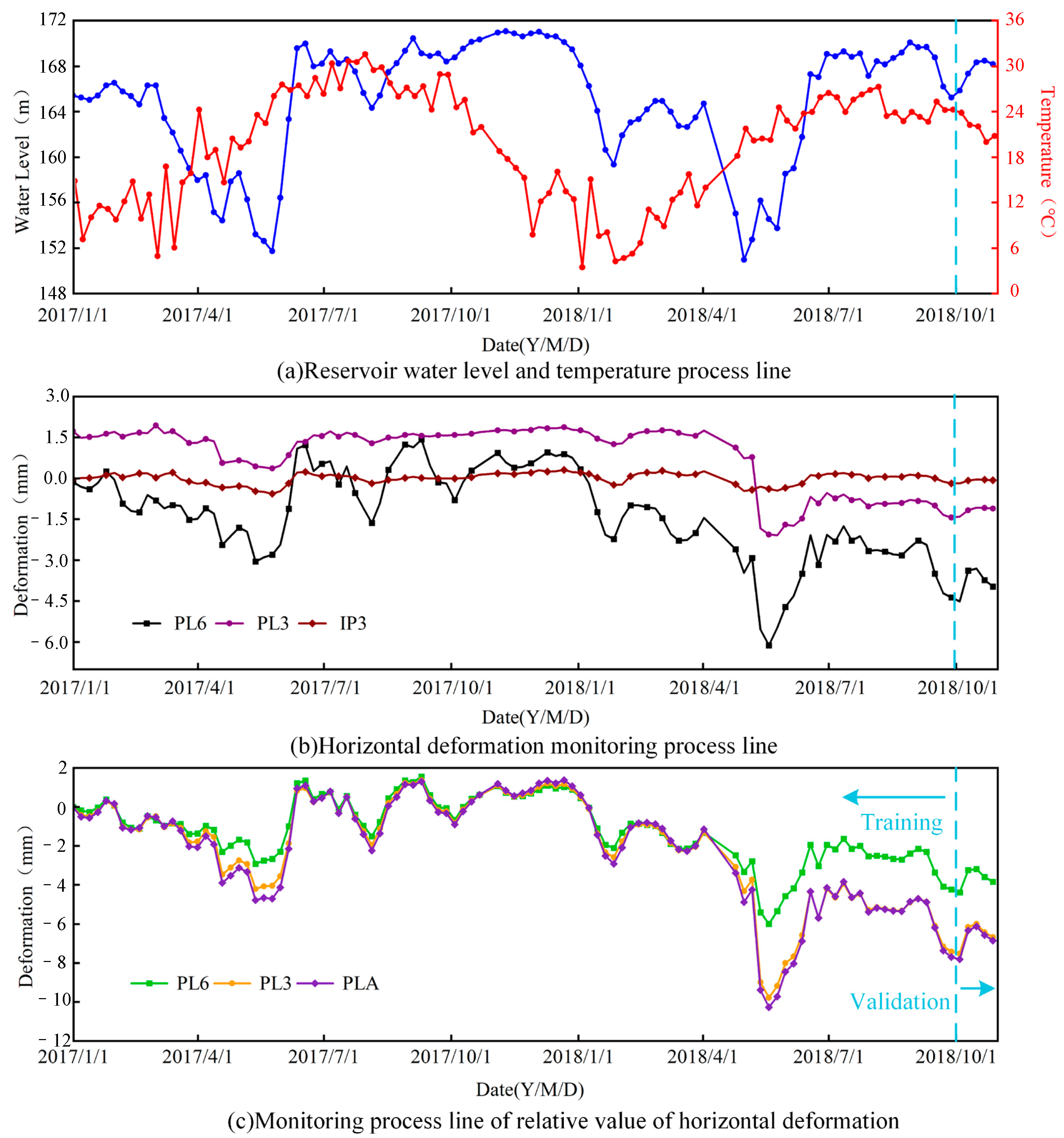

4. Case Study

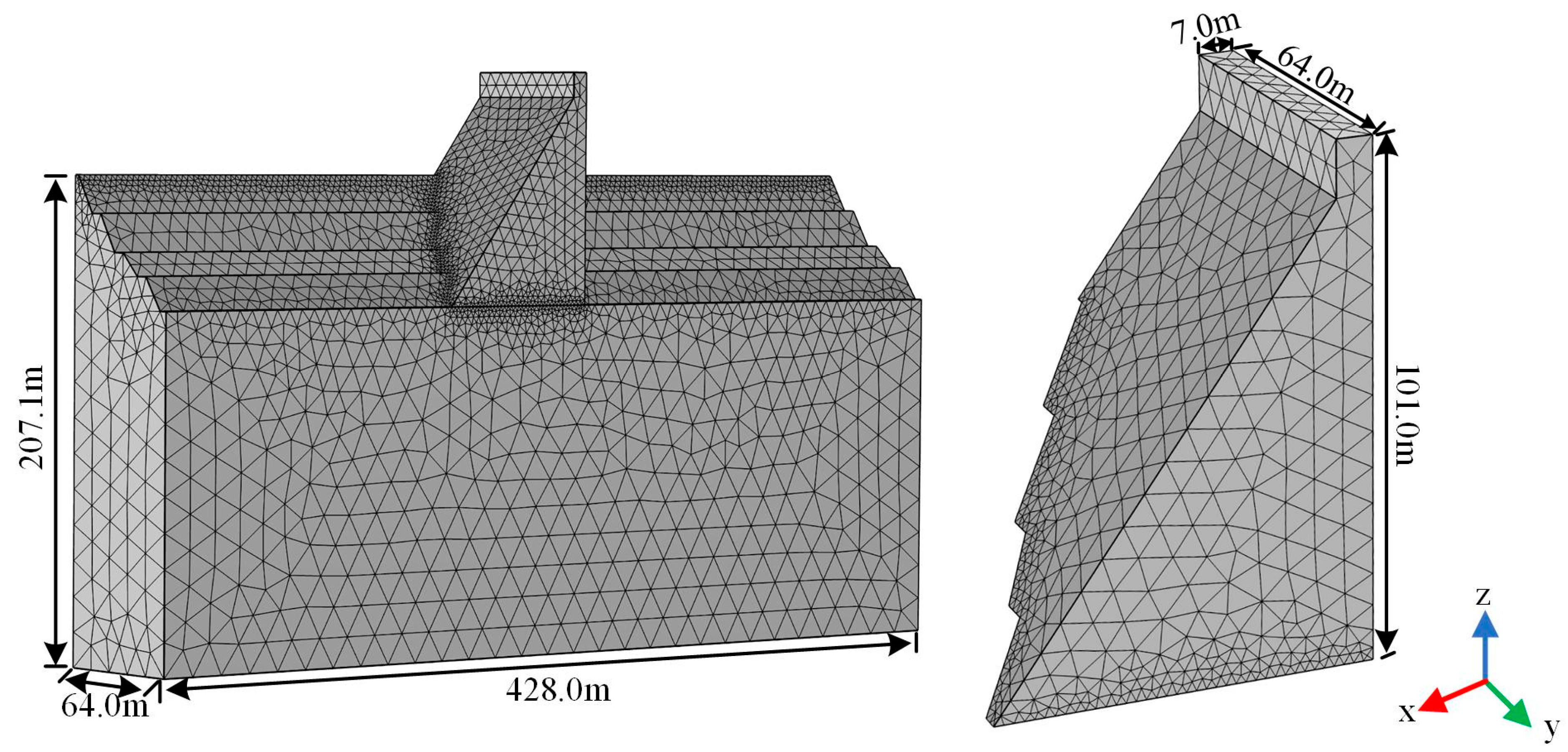

4.1. Numerical Simulation Model of Concrete Gravity Dam

4.2. Construction of the Data–Physics-Driven Multi-Point Hybrid Deformation Monitoring Model Based on BOA-LightGBM

5. Conclusions

- (1)

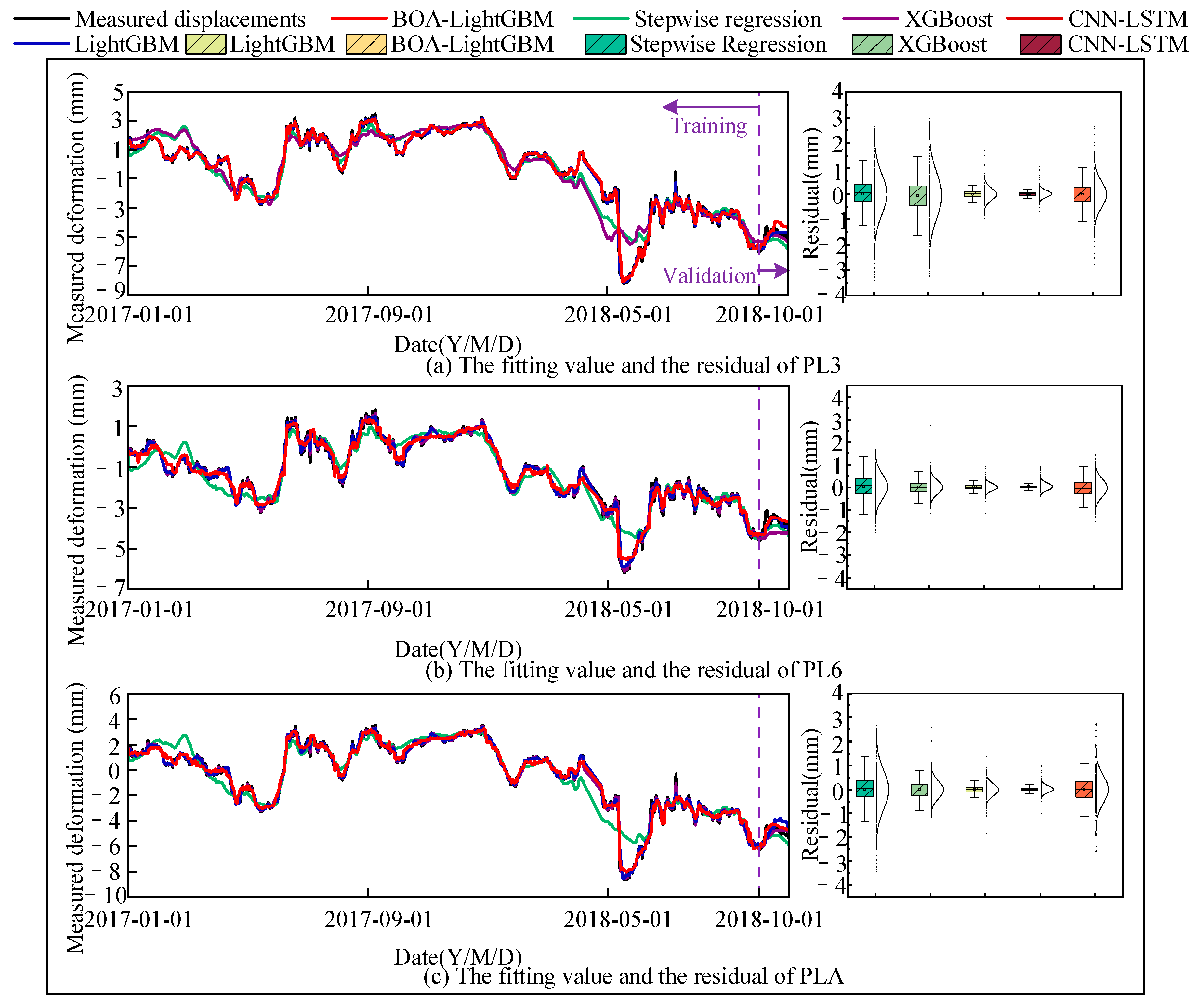

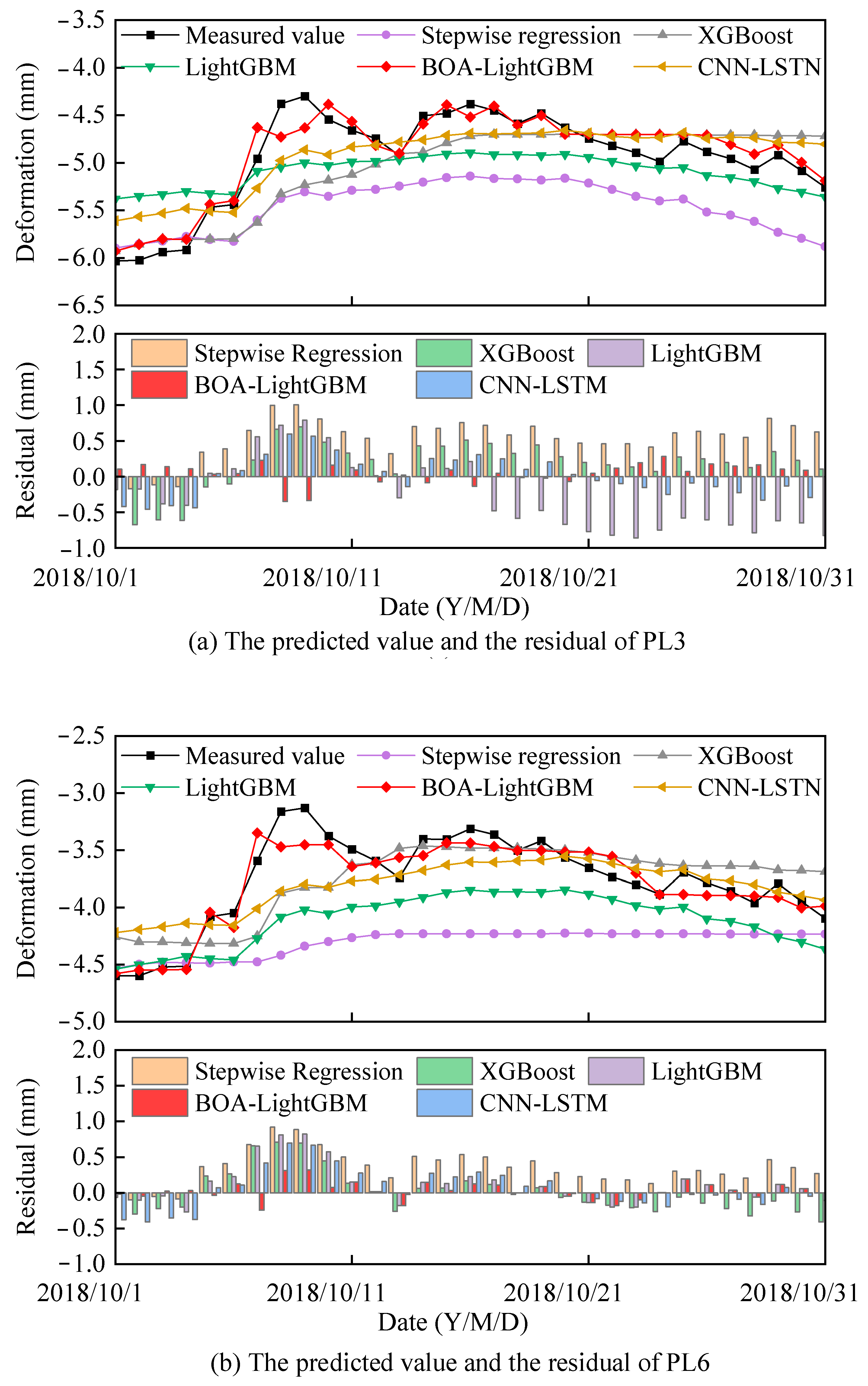

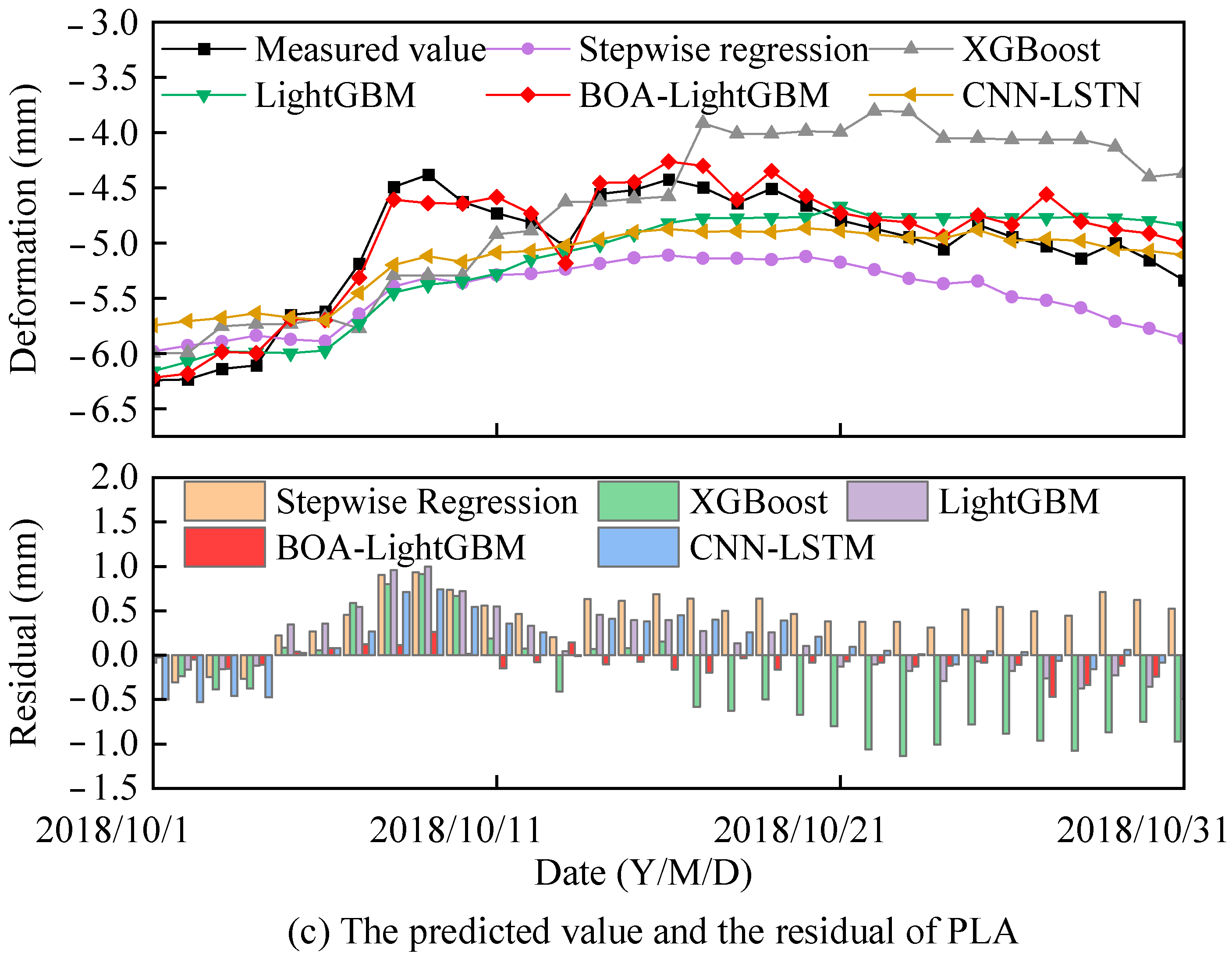

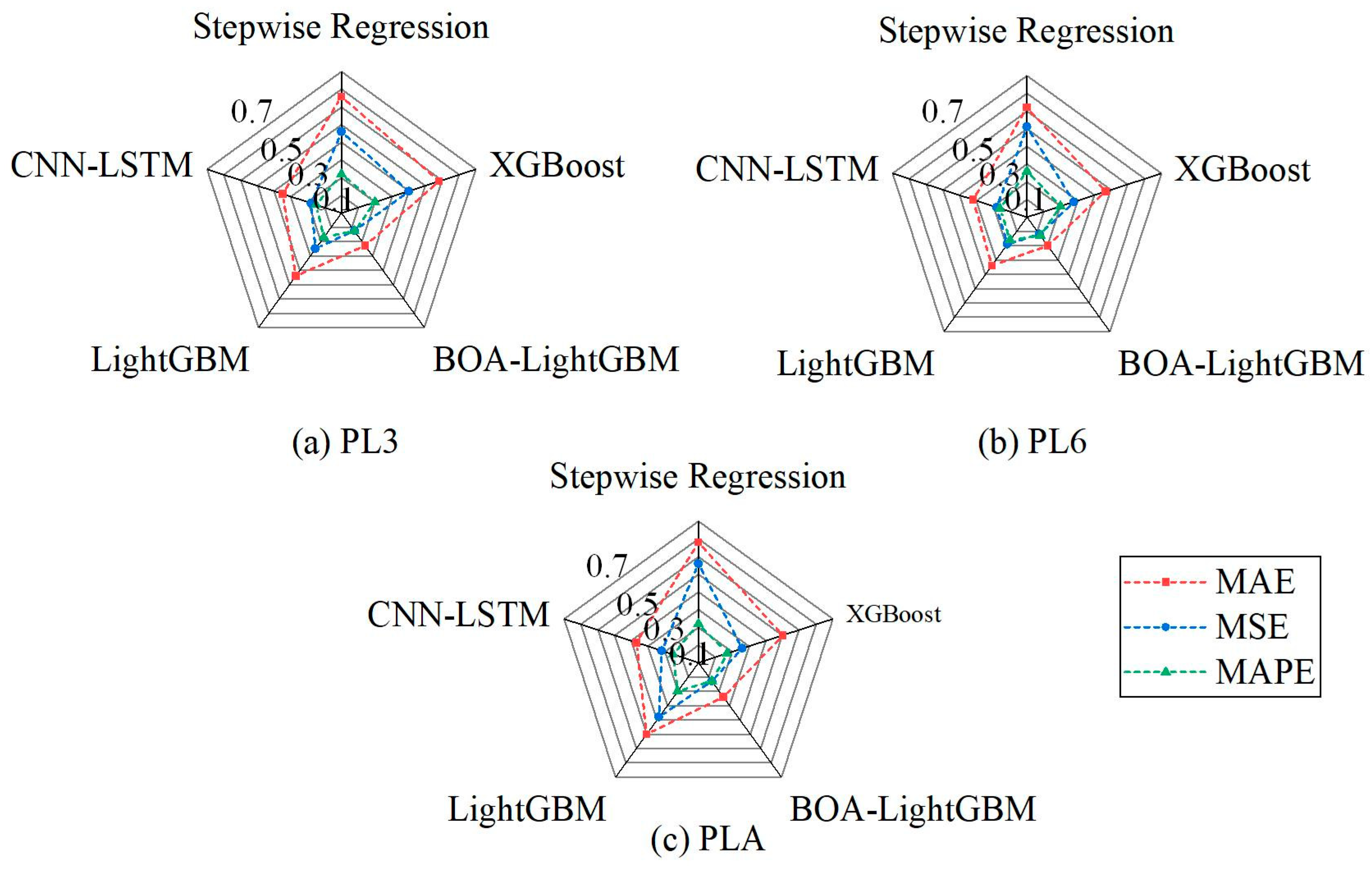

- The proposed hybrid multi-point deformation monitoring model incorporates spatial coordinates and FEM-assisted components, effectively capturing spatial correlations of dam deformation. Combined with BOA-LightGBM, it achieves accurate representation of nonlinear relationships, significantly enhancing fitting and prediction performance.

- (2)

- Compared with four conventional models, the proposed approach demonstrates superior adaptability without overfitting or underfitting. It improves fitting accuracy by up to 43% and prediction accuracy by 27%, outperforming stepwise regression, LightGBM, XGBoost, and CNN-LSTM models.

- (3)

- The multi-point deformation predictions align well with prototype monitoring data from the concrete dam, significantly enhancing the reliability of simultaneous deformation predictions at multiple points and providing a scientific basis for evaluating the structural performance of the dam. With appropriate improvements and extensions, the modeling theory and methodology proposed in this study can also serve as a valuable reference for safety monitoring of other hydrostatic structures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gu, C.S.; Li, Y.; Song, J.X. Study on safety monitoring model for deformation of RCCD. Chin. J. Comput. Mech. 2010, 27, 286–290. [Google Scholar]

- Yu, S.Y.; Sun, Z.H.; Yu, J.; Yang, J.; Zhu, C.H. An improved meshless method for modeling the mesoscale cracking processes of concrete containing random aggregates and initial defects. Constr. Build. Mater. 2023, 363, 129770. [Google Scholar] [CrossRef]

- Wu, Z.R. Deterministic model and hybrid model for safety monitoring of concrete dams. J. Hydrostatic Eng. 1989, 05, 64–70. [Google Scholar]

- Wang, S.; Gu, C.; Liu, Y.; Wu, B.B. Displacement observation data-based structural health monitoring of concrete dams: A state-of-art review. Structures 2024, 68, 107072. [Google Scholar] [CrossRef]

- Ren, D.J.; Gao, M.J.; Li, G.G. Application of mixing model in deformation analysis of dam. Water Conserv. Sci. Technol. Econ. 2008, 1, 29–30. [Google Scholar]

- Wei, B.W.; Yuan, D.Y.; Xu, Z.K.; Li, L.H. Modified hybrid forecast model considering chaotic residual errors for dam deformation. Struct. Control Health Monit. 2018, 25, e2188. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, Y.T.; Yang, Y. GNSS signal extraction using CEEMDAN-WPD for deformation monitoring of ropeway pillars. Remote Sens. 2025, 17, 224. [Google Scholar] [CrossRef]

- Xu, L.Y.; Shi, S.M.; Bao, Y. Corrosion monitoring and assessment of steel under impact loads using discrete and distributed fiber optic sensors. Opt. Laser Technol. 2024, 174, 110553. [Google Scholar] [CrossRef]

- Li, Y.X.; Yang, K.M.; Ding, X.M. Research on time series InSAR monitoring method for multiple types of surface deformation in mining area. Nat. Hazards 2022, 114, 2479–2508. [Google Scholar] [CrossRef]

- Gu, C.S.; Fu, X.; Shao, C.F.; Shi, Z.W.; Su, H.Z. Application of spatiotemporal hybrid model of deformation in safety monitoring of high arch dams: A case study. Int. J. Environ. Res. Public Health 2020, 17, 319. [Google Scholar] [CrossRef]

- Yang, G.; Gu, H.; Chen, X.; Zhao, K.; Qiao, D.; Chen, X. Hybrid hydrostatic-seasonal-time model for predicting the deformation behaviour of high concrete dams during the operational period. Struct. Control. Health Monit. 2021, 28, e2685. [Google Scholar] [CrossRef]

- Feng, Y.Q.; Chen, W.Y.; Tao, C.C.; Wang, F. Application of ridge regression model to dam safety monitoring based on genetic algorithm. Water Resour. Power 2010, 28, 51–52. [Google Scholar]

- Wang, S.; Xu, Y.; Gu, C.; Xia, Q.; Hu, K. Two spatial association-considered mathematical models for diagnosing the long-term balanced relationship and short-term fluctuation of the deformation behaviour of high concrete arch dams. Struct. Health Monit.-Int. J. 2020, 19, 1421–1439. [Google Scholar] [CrossRef]

- Yang, H.; Yue, J.P.; Xing, Y.; Zhou, Q.K. Research on dam deformation prediction based on deep fully connected neural network. J. Geod. Geodyn. 2021, 41, 162–166. [Google Scholar]

- Wei, B.W.; Yuan, D.Y.; Xie, B.; Chen, L.J. Chicken swarm optimization algorithm used optimization of relevance vector machine model for concrete dam deformation prediction. Water Resour. Hydropower Eng. 2020, 51, 98–105. [Google Scholar]

- Zhang, Y.; Zhong, W.; Li, Y.; Wen, L. A deep learning prediction model of DenseNet-LSTM for concrete gravity dam deformation based on feature selection. Eng. Struct. 2023, 295, 116827. [Google Scholar] [CrossRef]

- Kao, C.Y.; Loh, C.H. Monitoring of long-term static deformation data of Fei-Tsui arch dam using artificial neural network-based approaches. Struct. Control. Health Monit. 2013, 20, 282–303. [Google Scholar] [CrossRef]

- Wei, B.W.; Liu, B.; Xu, F.G.; Li, H.K.; Mao, Y. Multi-point hybrid model based on PSO-SVM for concrete arch dam deformation monitoring. Geomat. Inf. Sci. Wuhan Univ. 2023, 48, 396–407. [Google Scholar]

- Wang, R.J.; Bao, T.F.; Li, Y.T.; Song, B.G.; Xiang, Z.Y. Combined prediction model of dam deformation based on multi-factor fusion and stacking ensemble learning. J. Hydrostatic Eng. 2023, 54, 497–506. [Google Scholar]

- Huang, L.; Chen, J.; Tan, X. BP-ANN based bond strength prediction for FRP reinforced concrete at high temperature. Eng. Struct. 2022, 257, 114026. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, J.; Zhang, T.; Lu, B.; Zheng, D.; Zhou, H. A prediction method for oblique load stability of multi-cell tubes based on SVM. Eng. Struct. 2023, 283, 115885. [Google Scholar] [CrossRef]

- Wu, Z.M.; Hu, X.C. Algorithm optimization of credit risk control model based on Lightgbm. Comput. Appl. Softw. 2022, 39, 342–349. [Google Scholar]

- Zhao, B.; Li, B.; Zhang, J.; Cao, W.; Gao, Y. DCLGM: Fusion recommendation model based on LightGBM and deep learning. Neural Process. Lett. 2024, 56, 17. [Google Scholar] [CrossRef]

- Wu, Z.R. Safety Monitoring Theory and Its Application of Hydrostatic Structures; Higher Education: Beijing, China, 2003. (In Chinese) [Google Scholar]

- Li, S.P.; Zhang, B.; Liu, Z.Q. A new prediction model of dam deformation and successful application. Buildings 2025, 15, 818. [Google Scholar] [CrossRef]

- Cao, W.H.; Wen, Z.P.; Su, H.Z. Spatiotemporal clustering analysis and zonal prediction model for deformation behavior of super-high arch dams. Expert Syst. Appl. 2023, 216, 119464. [Google Scholar] [CrossRef]

- Shi, Y.Q.; Cheng, L.; Xu, W.; He, J.P. Multiple observation points fusion diagnosis model of dam deformation based on multrscale theory and wavelet entropy. Water Resour. Power 2013, 31, 95–98. [Google Scholar]

- Yao, K.; Wen, Z.; Yang, L.; Chen, J.; Hou, H.; Su, H. A multipoint prediction model for nonlinear displacement of concrete dam. Comput.-Aided Civ. Infrastruct. Eng. 2022, 37, 1932–1952. [Google Scholar] [CrossRef]

- Ke, G.; Meng, Q.; Finley, T.; Wang, T.; Chen, W.; Ma, W.; Ye, Q.; Liu, T.Y. Lightgbm: A highly efficient gradient boosting decision tree. In Proceedings of the 31st International Conference on Neural Information Processing Systems, Long Beach, CA, USA, 4–9 December 2017; pp. 3149–3157. [Google Scholar]

- Xie, Y. Prediction of Medical Service Waiting-Time Based on Ensemble Learning Algorithm. Master’s Thesis, Ningbo University, Ningbo, China, 2022. [Google Scholar]

- Tang, M.; Zhao, Q.; Ding, S.X.; Wu, H.; Li, L.; Long, W.; Huang, B. An improved LightGBM algorithm for online fault detection of wind turbine gearboxes. Energies 2020, 13, 807. [Google Scholar] [CrossRef]

- Gao, Z.X.; Bao, T.F.; Li, Y.T.; Wang, Y.B. Dam deformation prediction model based on bayesian optimization and LightGBM. J. Chang. River Sci. Res. Inst. 2021, 38, 46–50. [Google Scholar]

- Tang, M.; Meng, C.; Wu, H.; Zhu, H.; Yi, J.; Tang, J.; Wang, Y. Fault detection for wind turbine blade bolts based on GSG combined with CS-LightGBM. Sensors 2022, 22, 6763. [Google Scholar] [CrossRef]

- Liang, J.; Bu, Y.; Tan, K.; Pan, J.; Yi, Z.; Kong, X.; Fan, Z. Estimation of stellar atmospheric parameters with light gradient boosting machine algorithm and principal component analysis. Astron. J. 2022, 163, 153. [Google Scholar] [CrossRef]

- Cui, J.X.; Yang, B. Survey on Bayesian optimization methodology and applications. J. Softw. 2018, 29, 3068–3090. [Google Scholar]

- Wei, B.W.; Wan, X.; Xu, F.G.; Guo, Y.J. Fast inversion method of composite elastic modulus concrete gravity dam based on SBFEM and PSO-LSSVM. J. Basic Sci. Eng. 2023, 31, 894–905. [Google Scholar]

| Hyperparameters | Range | Optimized Value |

|---|---|---|

| Max_depth | (4, 40) | 33 |

| Num_leaves | (5, 130) | 103 |

| Min_data_in_leaf | (5, 30) | 20 |

| Feature_fraction | (0.7, 1.0) | 0.72 |

| Bagging_fraction | (0.7, 1.0) | 0.72 |

| Statistical Index | PL3 | PL6 | PLA | |

|---|---|---|---|---|

| Stepwise regression | MAE/mm | 0.53 | 0.41 | 0.55 |

| MSE/mm | 0.64 | 0.29 | 0.67 | |

| MAPE | 0.94 | 0.78 | 0.75 | |

| R2 | 0.91 | 0.89 | 0.91 | |

| XGBoost | MAE/mm | 0.23 | 0.22 | 0.27 |

| MSE/mm | 0.27 | 0.09 | 0.13 | |

| MAPE | 0.41 | 0.40 | 0.31 | |

| R2 | 0.93 | 0.97 | 0.93 | |

| LightGBM | MAE/mm | 0.12 | 0.10 | 0.13 |

| MSE/mm | 0.04 | 0.02 | 0.04 | |

| MAPE | 0.20 | 0.15 | 0.13 | |

| R2 | 0.95 | 0.98 | 0.95 | |

| BOA-LightGBM | MAE/mm | 0.07 | 0.06 | 0.07 |

| MSE/mm | 0.01 | 0.01 | 0.01 | |

| MAPE | 0.11 | 0.09 | 0.08 | |

| R2 | 0.99 | 0.99 | 0.99 | |

| CNN-LSTM | MAE/mm | 0.40 | 0.32 | 0.39 |

| MSE/mm | 0.34 | 0.19 | 0.35 | |

| MAPE | 0.58 | 0.46 | 0.41 | |

| R2 | 0.95 | 0.93 | 0.95 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, L.; Hu, Y. Data–Physics-Driven Multi-Point Hybrid Deformation Monitoring Model Based on Bayesian Optimization Algorithm–Light Gradient-Boosting Machine. Water 2025, 17, 2926. https://doi.org/10.3390/w17202926

Song L, Hu Y. Data–Physics-Driven Multi-Point Hybrid Deformation Monitoring Model Based on Bayesian Optimization Algorithm–Light Gradient-Boosting Machine. Water. 2025; 17(20):2926. https://doi.org/10.3390/w17202926

Chicago/Turabian StyleSong, Lei, and Yating Hu. 2025. "Data–Physics-Driven Multi-Point Hybrid Deformation Monitoring Model Based on Bayesian Optimization Algorithm–Light Gradient-Boosting Machine" Water 17, no. 20: 2926. https://doi.org/10.3390/w17202926

APA StyleSong, L., & Hu, Y. (2025). Data–Physics-Driven Multi-Point Hybrid Deformation Monitoring Model Based on Bayesian Optimization Algorithm–Light Gradient-Boosting Machine. Water, 17(20), 2926. https://doi.org/10.3390/w17202926