Abstract

This research assesses the design efficiency of the future centralized wastewater treatment plant (WWTP) in Prishtina, which also takes into consideration rapidly expanding suburban areas, such as Fushë Kosova, Obiliq, and Graçanica. Using a combination of both ATV-DVWK-A 131E deterministic calculations and dynamic simulation with IWASP, this study focuses on the planned configurations for the future Prishtina wastewater treatment plant (WWTP) to evaluate design efficiency alongside operational feasibility. The primary goal was to determine if meeting projected loads for the year 2040 would be possible with compliance requirements for a single-stage CAS system. Simulation data suggest that reliable nitrogen removal would not be possible with a sole CAS stage (aerobic), particularly considering seasonal and peak load dynamics. Alternatively, an optimized three-reactor CAS model, including one anoxic pre-denitrification zone coupled with two alternating aerobic zones, achieved an average total nitrogen (TN) removal efficiency of about 85%, maintaining effluent TN below 10 mg/L. Additional advantages saw COD being removed at rates between 90 and 92%, along with MLSS levels stabilizing around 3500 mg/L. The flexibly scalable design also provides adaptive operation features, including expanded tertiary nutrient removal in phase II. In scenario two’s site comparative analysis, Lismir’s centralized WWTP emerges as the most economically and technically rational option due to the enhanced reactor layout optimization. These findings confirm that enhanced configurations, validated through both static and dynamic analyses, are essential for long-term treatment efficiency and regulatory compliance.

1. Introduction

The sewer system is a very important element of wastewater treatment plants (WWTPs), as it not only has a significant influence on the quality and quantity of the wastewater which enters these facilities, but also leads to great improvements in these respects. The difference is very striking, mainly in newly developing parts of the world like the Western Balkans. Investigations from recent WWTP installations illustrate the difficulties associated with the inlet load parameters; this is often seen in the situation where there is a high dilution of wastewater and low levels of BOD and COD, compared to the requirements of standard biological treatment processes. The activity of the influent in this region makes it clear that we need quite a few design strategies to be invented, which are specially devoted to the treatment of both sewer systems and WWTPs, i.e., design strategies which match the influent characteristics of this region. In the case of the successful operation of the Prishtina WWTP, the transition from the combined system to the separate storm and sewer system is a key priority. The preparatory and design stages of the Prishtina WWTP were based on the results of a detailed measurement campaign, which revealed the influent design load parameters, and the expected population growth and network improvements were already considered. Additionally, the operation of the plant must also comply with the requirements from country level, which outline the treatment steps of the pre-treatment, primary treatment, secondary treatment, and tertiary treatment for the second phase. Among the first steps, the mission is to take residues, grit, and grease out of the system, going through the process of the secondary treatment, where there is an emphasis on the removal of organic pollutants and nutrients by using biological treatments to deal with them, and ultimately, the tertiary stages are aimed at eradicating the rest of the pathogens and the particles [1]. This systematic plan is required to be followed to meet the legal regulations and have the plant in a good working condition. The proposed inflow design data lead to the above four main points as the essential factors that should be considered in controlled pollution treatments, namely, the prediction of pollution loads per capita and the level of leakage that is estimated to be the same as that of demographic changes. The design specifications outline the details of the required percentage of pollutants, such as BOD, COD, and the total suspended solids, which all need careful handling to ensure that the plant will operate without any issues when it is installed and commissioned [2,3]. Simply, the successful planning of wastewater treatment depends on a coordinated scheme involving the improvement of sewerage networks and the introduction of new treatment methods. A successful example of a WWTP like the one in Prishtina was conducted to serve the purpose of a good practice of wastewater treatment, as it fits the local requirements, and at the same time, the long-term maintenance from the utility staff gives extra weight to the urban sustainable practices of wastewater management [4].

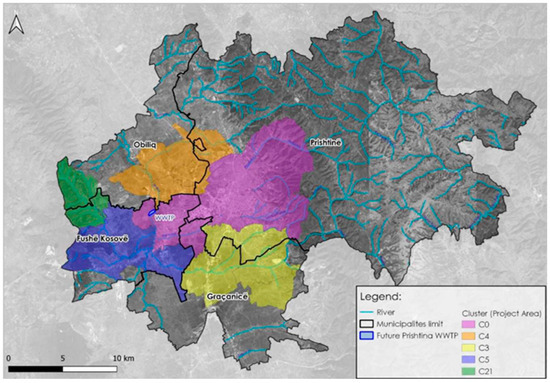

The map in Figure 1 shows Prishtina and surrounding towns, including the delineation of catchment zones, discharging into interceptors, and trunk mains; these are divided in clusters, starting with C0, which covers the majority of the capital city, and continuing with C3, C4, C5 and C21, which partially cover the village.

Figure 1.

Cities—municipalities covered with WWTP.

Cluster 0 represents the catchment zone of Prishtina capital city and Fushë Kosova and discharging directly to the pumping station, C3 represents the major part of Gracanica town, C4 represents Obilic town, collected with interceptors from north Prishtina and a main collector, and C5 represents rural areas of Fushe Kosova town. The zones with different colors represent zones with major inhabitants who have a sewer network and will discharge in future WWTP; the rest of the zones with a grey color are rural areas to be covered with a small decentralized WWTP.

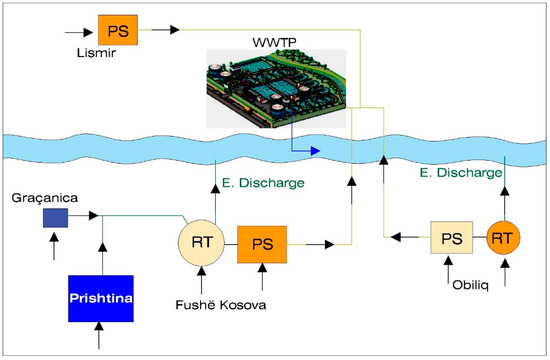

The basic influent data for the future WWTP include the population for the design period for 2040; there are 479,800 PE, with a specific water consumption of q = 120 L/person/d, including nondomestic wastewater flow, which is rather low, as there is no heavy industry in the zone. A generalized layout composition of the WWTP and the system is presented in Figure 2, including retention tanks (RTs) and pumping stations (PSs), which act as inlet pumping stations; to optimize energy efficiency, these pumps will pump the sewage directly to the mechanical part of the treatment (screens).

Figure 2.

City schematic flow for future Prishtina WWTP, PS (pumping station). RT (retention tank).

The first proposed idea for the WWTP treatment technology was activated sludge technology, which was later updated to conventional activated sludge (CAS), as a treatment process which achieves effluent criteria with a rather lower cost for operation and maintenance, and a lower cost for plant surface compared to classic activated sludge technology. A single-stage CAS (aerobic) was also recommended from previous experience at a national level in Kosova, but as the requirement standard for the effluent for the future operation will be additionally for P and N removal, there will be a need to alternate treatment technology based on results of model calculation with the pre-denitrification process.

The WWTP effluent receiving water body (the Sitnica River) is considered non-sensitive, but with the possibility for the plant to be extended easily in the future with a tertiary treatment stage for nitrogen and phosphorus removal (and comply with a sensitive receiving body).

The effluent requirements regarding urban WWTP, as expressed in local Administrative Instruction 30/2014, are Article 4 and 5, with its Annex II, Table 1, and Table 2 (note: both Tables are the same as 91/271/EEC).

Building on the presented criteria, we evaluate how biological treatment processes perform under Prishtina’s influent conditions with respect to different wastewater models. The ATV-DVWK-A 131E calculation framework, alongside dynamic ASM3BioP simulations in the IWASP platform, will benchmark conventional activated sludge designs with alternate activated sludge incorporating an anoxic tank for future development for 2040.

When it comes to effluent compliance, we look at key factors like BOD, COD, nitrogen, and phosphorus removal for each method during the first phase. We also run optimization tests to see how different infiltration rates, influent loads, and operational settings affect the outcomes. Our aim is to forecast capacity expansions up to 2040, considering the growing population and the related energy needs, sludge production, and environmental impacts. Ultimately, the results from these biological treatments will play a crucial role in our comparative scenarios and socio-environmental impact analysis, ensuring we deliver the thorough assessment we raised.

This research provides an evaluation of the design and operational effectiveness for the proposed central wastewater treatment plant (WWTP) in Prishtina by using both deterministic and dynamic modeling to respond to complex influent characteristics as well as future capacity challenges. Scientifically, this study incorporates static design processes described in German ATV-DVWK-A 131E guidelines with sophisticated design simulations using the IWASP platform integrated with activated sludge Model No. 3 with Biological Phosphorus Removal (ASM3bioP). This combined methodology allows for a mechanistic evaluation of carbon, nitrogen, and phosphorus removal over a range of influent loadings and seasonal variability, capturing both steady and transient behaviors of the treatment system. From an engineering practice point of view, it assesses phased development scenarios based on evolving demographics, aligned with discharge limits for treated effluent aimed at meeting EU requirements for sensitive waters. The results obtained justify that the configuration based on a modified conventional activated sludge (CAS) system with pre-denitrification features provided greater flexibility in operation, better energy performance, and potential for tertiary treatment expansion. The findings contribute to the improvement of design methods for municipal WWTPs in rapidly growing urban areas. They highlight the connection between practical design standards and predictive dynamic modeling for strong, reliable infrastructure planning.

2. Materials and Methods

The biological treatment methods for the Prishtina wastewater treatment plant (WWTP) aimed at understanding their influent and future effluent parameters first, which is the basis for this study. The authors gathered information from a water utility and engineering company, who made hydraulic calculations, and set the pollutant load design period, which allows for calculations based on real calculated data from the number of PEs and catchment areas, through hydraulic modelling and retention tanks.

2.1. Inputs and Assumptions Used in Design

Projected consumption of water in an area as well as its population growth rate were used as baseline criteria for the design estimation. Specific water consumption was set at 120 L/person/d; this includes non-domestic wastewater services, adding around 20% on top of that number. It is assumed that about 80% of total water utilized goes through sewerage systems. For the design, specific pollutant loading rates are as follows.

Table 1 represents daily pollutant loads and expresses the effluent requirements regarding urban WWTP as expressed in local Administrative Instruction 30/2014 are Article 4 and 5 with its Annex II, Table 1 & Table 2 (note: such both Tables are the same as of 91/271/EEC).

Table 1.

Specific daily pollutant loads.

Another basic operating condition is a design temperature range of 12–22 °C, and a minimum concentration of dewatered sludge (DS) of 30% for temporary storage that complies with regulations for landfill sites.

Based on census data from 2025 to 2040, population equivalents (PEs) and flow forecasts also include increasing dry weather flow (Qd), wet weather volumes, introduction of CSO, as well as pollutant loads, which are critical for determining the process size and treatment efficiency benchmarks.

Table 2 represents inflow data, calculated by RWC Prishtina, for the specific project in Kosova (Prishtina and surrounding).

Table 2.

Inflow data of proposed WWTP.

2.2. Regulatory Framework

Kosovo’s Administrative Instruction 30/2014 corresponding to the EU Urban Wastewater Treatment Directive 91/271/EEC serves as the guiding regulation on limits for effluent discharge. For non-sensitive receiving bodies (phase I), required removal efficiencies are as follows: the discharge requirements for non-sensitive water bodies (phase I) are as follows. Table 3 expresses the effluent requirements regarding urban WWTP as expressed in local Administrative Instruction 30/2014 are Article 4 and 5 with its Annex II, Table 2 (note: such both Tables are the same as of 91/271/EEC).

Table 3.

Design parameters for effluent according to AI 30/2014.

For sensitive-area water bodies (phase II), tertiary treatments with enhanced removal of nutrients must be applied, to meet the criteria given below.

Table 4 expresses the effluent requirements regarding urban WWTP as expressed in local Administrative Instruction 30/2014 for sensitive water bodies in relation also with Directive (EU) 2024/3019.

Table 4.

Design parameters for sensitive bodies—AI 30/2014.

An appropriate selection of treatment technology for the Prishtina wastewater treatment plant (WWTP) requires an assessment of the operational, environmental, and technological factors in conjunction with local context. ‘Non-Confined’ design criteria for the plant encompass more than just its hydraulic and pollutant cataloging capabilities; other multifactorial considerations such as maintainability, long-term sustainability, operations, and environmental impact also play a crucial role. The operational capacity of local utilities, spare parts, reagents supply chain logistics, and sustainable sludge management that intersects with energy and land use, are all critical technology selection drivers. Furthermore, viable design solutions are greatly influenced by cost constraints, including capital expenditures (CAPEX), operation and maintenance (OM) expenses, and logistics of final sludge disposal. In addition to traditional focuses on efficiency, modern WWTPs face multidimensional challenges like releasing endotoxins alongside other micropollutants that endanger both ecosystems downstream and community health: this multicriteria optimization is necessary to cater to evolving priorities [5].

Several technological options were evaluated for the biological treatment process in Prishtina, analyzing their potential to biologically remove organic and nutrient pollutants through microbial metabolism. These included conventional activated sludge (CAS), Sequential Batch Reactors (SBRs), Moving Bed Biofilm Reactors (MBBRs), Membrane Bioreactors (MBRs), Submerged Biological Filters, Upflow Anaerobic Sludge Blanket Reactors (UASBRs), and Trickling Filters. Due to these advantages, CAS became the preferred option as it performs reliably, efficiently removes toxins and nutrients over a sustained period, and integrates well with adapted staged nutrient removal systems. Its reliability has been corroborated in multiple studies showing effective reductions in organic and nutrient loads across varied operating conditions [6]. Furthermore, managed systems discharging effluents from CASs fulfill international requirements for receiving bodies while reducing risks of eutrophication and algal blooms [7]. For the initial phase of the project, the layout is proposed based on the actual conditions of the plot area, particularly for the water line. The discharge of treated or untreated wastewater poses significant health and environmental challenges, therefore underscoring the need for comprehensive treatment approaches. For instance, the quality of biologically treated effluent impacts downstream water bodies, as noted in sub-Saharan studies [7], and more recently, interdisciplinary research has shown that certain parameters of waste products influence outcomes in medicine organ transplant viability [8]. These cases demonstrate how specialized knowledge from various disciplines increases attention to choosing an appropriate WWTP, which considers local design conditions and global best practices.

2.3. Advanced Design Approaches for WWTP: From Conventional to Digital Modeling Tools

The biological treatment process on this research is studied in line with design requirements, according to (ATV-DVWK-A 131E, 2000) [9]. ATV-DVWK-A 131 is a German guideline used for the design and dimensioning of activated sludge wastewater treatment plants, focusing on biological treatment processes based on hydraulic and pollutant loads. It provides standardized methods for calculating key parameters like sludge age, aeration, and nutrient removal. The guideline is published by the DWA (German Association for Water, Wastewater, and Waste).

2.4. The Wastewater Simulator IWASP

IWASP operates in a similar way to commercial wastewater treatment simulators—such as BioWin, GPS-X, SIMBA, and SUMO—by enabling the construction and dynamic modeling of a full treatment plant. It supports ASM2d, ASM3-bioP, and Barker–Dold reactor models, and offers both a one-dimensional clarifier or zero-dimensional phase-splitter modules for primary and secondary settling, thickening, and dewatering units. Beyond its core simulation capabilities, IWASP [10] incorporates an automatic calibration engine that can mirror real-world plant behavior, and it includes prototype tools for the automated design of bioreactors and recirculation streams. A stochastic process analysis module (Markov Decision Process) further allows users to optimize the programmable logic controllers at existing treatment facilities and to develop new control strategies. Examples of applicability for the design phase are as follows: During preliminary design, simulations can confirm which equipment capacities, layouts, and process technologies are most appropriate and cost-effective for the new plant. It becomes possible to predict in advance whether the facility will meet effluent standards under the expected influent loadings and across a range of operating temperatures. Upgrading existing plants: Testing new layouts, process modifications, or operational changes in the real plant is invariably more expensive and labor-intensive than running a model. From the very first concept, IWASP can be used to explore alternatives, helping to identify the most cost- and energy-efficient configuration. As a decision-support tool, it brings transparency to plant operation by leveraging detailed process models. We chose ASM3bioP for the Prishtina WWTP simulations, because it uniquely combines carbon, nitrogen, and phosphorus transformations in a single, mass-balanced framework. Its built-in representation of intracellular storage and flexible phosphorus uptake under both aerobic and anoxic conditions makes it especially reliable when influent composition or recirculation rates change. By capturing the coupled dynamics of organic removal, nitrification–denitrification, and bio-P processes, ASM3bioP lets us compare different CAS or pre-denitrification layouts, recirculation strategies, and loading scenarios on equal footing. In practice, this means we can confidently assess how each configuration will perform across a range of population equivalents and seasonal temperature swings. Ultimately, using ASM3bioP ensures our design and operational recommendations are grounded in a mechanistic, dynamically responsive model.

2.5. ASM3BioP Model

The ASM3bioP model [11] serves as the foundation for the models presented—it is defined by 17 state variables (wastewater fractions) and 23 governing processes [12], which can be solved numerically as a system of ordinary differential equations. In our work, we have employed the ASM3BioP–EAWAG variant, which describes the removal of organic matter, nitrogen, and phosphorus. The ASM3 model describes the behavior of organic matter and nitrogen through the following sub-model characteristics:: The framework partitions the degradation and transformation of organic carbon and nitrogen into twelve interlinked biological reactions, each governed by its own stoichiometry and kinetic expression. At the outset, a particulate biodegradable substrate is enzymatically hydrolyzed into a soluble readily biodegradable substrate, a process whose rate depends on the ratio of active heterotrophs. The readily biodegradable substrate pool of carbon can follow one of two intracellular storage pathways: under aerated conditions, heterotrophs convert SS into internal polymers at a rate modulated by dissolved oxygen, while under anoxic denitrifying conditions, a parallel storage reaction proceeds, substituting nitrate/nitrite for oxygen as the electron acceptor. The stored polymer and free substrate then fuel heterotrophic biomass growth. Aerobic heterotrophic growth consumes and dissolves oxygen to build new heterotrophic biomass, simultaneously releasing ammonium and altering alkalinity according to known yield coefficients. Under anoxic conditions, denitrifying heterotrophs similarly assimilate carbonaceous material and nitrate, producing nitrogen gas and contributing to alkalinity flux. When external substrates decline, endogenous respiration of heterotrophs takes over: aerobically, cells oxidize their own biomass in the presence of oxygen, whereas anoxic endogenous decay uses nitrate and yields N2 along with residual soluble by-products. A third set of reactions addresses the fate of the stored polymers themselves: cell storage is respired aerobically, each pathway governed by Monod-type dependence on the respective electron acceptor. Finally, the nitrifying autotrophs perform two linked processes: ammonium oxidation to nitrate (nitrite/nitrate step is not directly modelled). Under substrate scarcity, autotrophic cells undergo endogenous decay, releasing nitrogen gas. Together, these twelve reactions—hydrolysis, aerobic and anoxic storage, aerobic and anoxic heterotrophic growth, aerobic and anoxic heterotrophic decay, aerobic and anoxic storage polymer respiration, autotrophic nitrification, and autotrophic decay—form a mass-balanced, dynamically responsive network that underpins the ASM3 model’s ability to predict carbon removal, nitrification, and denitrification in activated sludge systems.

The ASM3bioP framework inherits its organic carbon and nitrogen pathways directly from the standard ASM3 formulation, and its treatment of phosphorus diverges from the ASM2d [13] approach in several important respects. First, the readily biodegradable substrate pool remains intact as a single fraction—ASM3bioP assumes that fermentative hydrolysis never becomes rate-limiting and therefore omits any further subdivision of that pool. Second, under aerobic conditions and in the presence of phosphate-accumulating organisms (PAOs), orthophosphate is actively converted into intracellular polyphosphate, producing a measurable decrease in soluble phosphorus within the aeration basin. Crucially, however, PAO activity is not confined to aerated environments: field observations frequently report higher effluent phosphorus concentrations when nitrate is present, suggesting that either inhibitory effects limit phosphorus release or that PAOs and glycogen-accumulating organisms compete under denitrifying conditions. To capture this behavior, ASM3bioP explicitly couples anoxic PAO growth to nitrate uptake and denitrification yet retains the rule that phosphate release is solely driven by carbon assimilation.

2.6. Clarifier Model

In WWTP modeling, clarifiers are typically represented either as idealized separators for the simplest mass-balance calculations or as one-dimensional layer models to capture key vertical settling dynamics. The 1D approach divides the tank into multiple horizontal strata, allowing simulation of the solid flux and sludge blanket movement under varying load and flow conditions. This level of physical detail is sufficient to predict effluent TSS performance and assess sludge withdrawal strategies across our ATV and ASM-based scenarios. By using a 1D clarifier model, we maintain computational efficiency while ensuring a robust evaluation of settlement behavior in design-phase simulations.

The depth-dependent concentration profile in a one-dimensional settling tank is governed by the advection–diffusion–reaction equation:

(∂C(z,t))/∂t = −(∂(v(C(z,t))∙C(z,t)))/∂z + ∂/∂z (D(z,t) × ∂C(z,t)/∂z) + s(z,t).

To transform this partial differential equation into a system of ordinary differential equations, the tank is discretized in this case into vertical layers—typically at least ten—to form a “layer model.” Each layer falls into one of three categories:

Above-inlet layers, where the withdrawal of treated effluent induces an upward compensating flow.

Inlet layer, where the raw influent is introduced.

Sludge-withdrawal layer, where downward flow associated with solids removal enhances settling.

Within any layer outside the inlet (i.e., for 0 ≤ z < zf0 ≤ z < zf), the rate of change of concentration obeys

(∂C(z,t))/∂t = [V_s (C(z,t),t) − (Q_e (t))/A(z)]∙C(z,t); 0 ≤ z < z_f.

Here, Vs is the net settling flux (the combined downward flux of particles from the layer above and the upward flux into the layer below), Qe is the effluent flowrate, A(z) is the cross-sectional area of the layer, and zf is the elevation of the inlet layer. By convention, no settling flux enters from above the topmost layer. At the inlet layer itself, the influent addition modifies the balance as follows:

where Qu(t) denotes the sludge withdrawal rate. Below the inlet layer, the mass balance becomes as follows:

(∂C(z,t))/∂t = [V_s (C(z,t),t) − (Q_e (t))/A(z) + Q_u (t)/A(z)]∙C(z,t); z = z_f,

(∂C(z,t))/∂t = [V_s (C(z,t),t) + Q_u (t)/A(z)]∙C(z,t); z_f < z ≤ H.

Industrial simulators such as GPS-X, SIMBA, and BioWin generally adopt one-dimensional descriptions on the simplifying assumption that horizontal velocity profiles remain uniform and lateral concentration gradients are negligible. In our simulator IWASP, the same methodology is being used. Settling velocities are most often calculated using either the Vesilind equation or the modified double-exponential model of [14]. The Takács formulation employs two exponential terms to capture both hindered settling and the more rapid settling of flocculated particles, yielding more accurate predictions of effluent suspended solids concentrations.

2.7. Selection of Treatment Process

The adoption of a conventional activated sludge (CAS) system for the Prishtina WWTP is justified by several inherent benefits. This process is particularly well-suited for the scale and context of the plant, as it generates highly digestible sludge that produces significant amounts of biogas during anaerobic digestion. Furthermore, the CAS process allows for the integration of nutrient removal, ensuring that the resulting effluent meets high-quality standards suitable for environmental discharge [15,16]. The CAS technology is proposed for phase I development, as the second stage also consists of a sensitive water body of effluent by 2040, and needed further analysis, as we will present in Section 3.

Table 5 shows comparison between different biological treatment technologies, with cross references from well-known experienced operators and researchers.

Table 5.

Advantages and disadvantages of the conventional activated sludge (CAS) process.

To address the challenges associated with sudden influxes in flow—such as during storm events—it is designed with two retention tank/basins (RTs) in front of the inlet pumping station (PS). The current design is primarily focused on carbon removal (phase I), with future expansion phases planned for nitrogen and phosphorus removal.

3. Results

After running different trials into the model calculation, the results show that one of the best options is to use tanks with rectangular bottoms and a water depth of a maximum of 6 m, as per the standards. This setup not only maximizes the oxygen transfer rates but also the premises of the installation are compressed. The new aeration system, which will be implemented to achieve decreased energy consumption, is of its kind and has turbo blowers and fine bubble diffusers as parts of its components. Moreover, the design will be made expandable for future constructions so that the plant can be easily modified as per the changed requirements of the future.

The design parameters supply information on the major factors, such as sludge ages of carbon for 5–6 days and nitrogen for 8–10 days, that will be required. Our approach to phosphorus removal will be through biological methods, with chemical methods as a backup solution. The design will involve not less than six final clarifiers, an activated sludge (AS) pumping station with a proper circulation rate and system efficiency, as well as a smooth reduced sludge return, which will ensure at least six sludge retention times; thus, almost 100% of BOD will be removed. To sum up, the conventional activated sludge process is the most suitable method for phase I development, in that it is a combination of efficiency, economy, and eco-friendliness, and the system is adapted to ambient conditions and the resources of the local environment [20].

The computation was performed with the help of the ATV-DVWK-A 131 standard, and the findings are tabulated. In addition, using a dynamic digital model with IWASP, we modeled the parameters of the treatment steps with the same parameters, and the models were found to have all the parameters in the same temperature range. At the same time, we traced the content of the papers showing a comparison of the results taken out of SM1 against the experimental and numerical ones from ASM. This way, we managed to effectively test the model on the capacity of the system to remove phosphorus.

Table 6 represents calculation made with ATV 131E, including first and second phase of development, based on received data from the utility operator.

Table 6.

Results of calculation with ATV-131 standard for CAS—including second phase!

3.1. Phases for Project Development

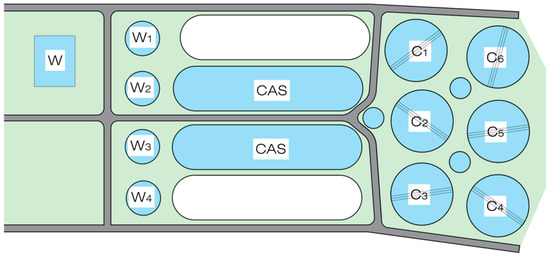

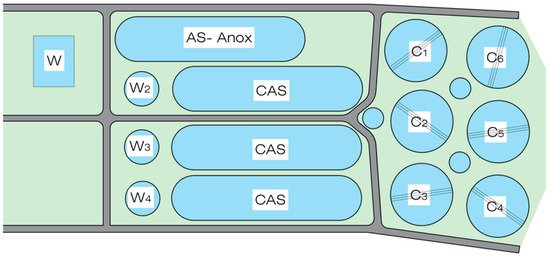

The development of project is foreseen to develop on two phases, which will cover the current connected PE, and planning to start tentatively on 2027–28, and second phase is foreseen to start with operation by 2040. According to the proposed site location, the best fit organization of treatment steps, technology and hydraulic structures as bellow on Figure 3 and Figure 4.

Figure 3.

Water line of WWTP—proposed—phase I. Wn—Pre-treatment, CAS—Biological Reactors, Cn—Secondary Clarifiers.

Figure 4.

WWTP water line layout for phase II. Wn—Pre-treatment, CAS—Biological Reactors, AS—Anox—Anoxic Reactors, Cn—Secondary Clarifiers.

Figure 3 represents general layout for phase I—waterline part, including inlet point, reactors and clarifiers.

3.2. Model from IWASP—Results

The dynamic model was implemented, generating different scenarios, after running for the period 2040. The ASM-based layout optimization included over 100 tested configurations. The best-fit scheme involved the following:

- a.

- One pre-denitrification (anoxic) reactor.

- b.

- Two intermittent aeration reactors.

- c.

- One fully aerobic reactor.

This configuration enabled simultaneous nitrogen and phosphorus removal while lowering energy use for aeration. The superiority of this setup is in line with the existing literature and real-world experiences in similar treatment plants. The model comparison affirms that the deterministic ATV design offers a conservative upper estimate but lacks estimates regarding phosphorus removal, while the ASM simulation enables energy and volume-optimized configurations that perform reliably under varying operational loads, including the conditions for a sensitive water body for effluent discharge, and the layout is inserted into the software.

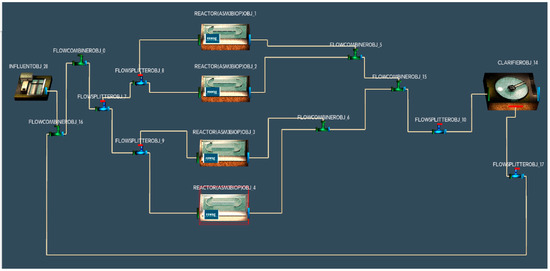

In Figure 5, the layout from the IWASP model is shown for the scenario 4 CAS aerobic system is shown.

Figure 5.

Dynamic model layout from the software and setup of treatment steps with 4 CAS system.

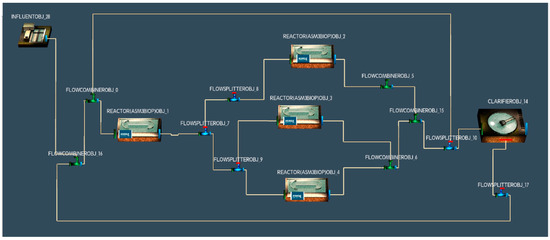

In Figure 6, a layout of the WWTP with the IWASP software configuration, a model with one CAS aerobic reactor, two CAS reactors with intermittent oxygenation, and one fully working anoxic/anaerobic reactor is presented.

Figure 6.

Dynamic model layout from the software and 2 + 1 + 1 setup (CAS + CASa + Anox).

In the software, there are several trials, and the result shows the best fit scenario for the respective WWTP and data, in relation to effluent standard requirements.

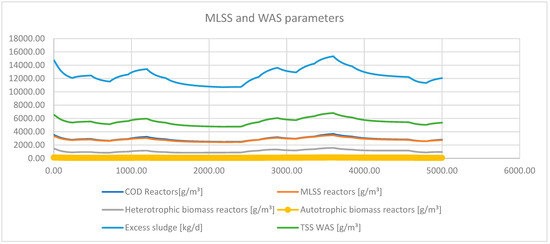

The analysis from the model was from different loads, starting from low to medium and high loads, and the results show that for a high load, it gives better results, which also proves that the first necessity for network improvement is to receive a high load concentration from the influent. Regarding WAS and MLSS, the model gave a higher quantity for excess sludge, and it varies from 10,000 kg/day to 14,000 kg/day.

Due to the low influent TSS load, the model produced more realistic values by accounting for an inert fraction of approximately 300 mg/L. The simulated MLSS was around 3500 mg/L, with settled sludge concentrations in the clarifier ranging from 4500 to 6500 mg/L. The RAS flow rate was set equal to 100% of the influent flow.

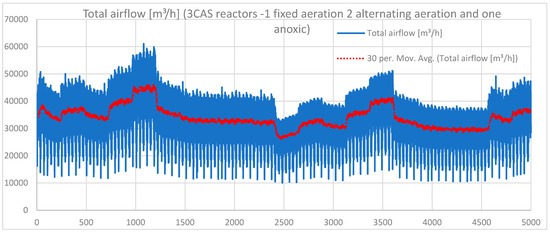

In this paper, operational parameters were also analyzed in relation to treatment quality at the water line. The scenarios were derived after several trials, and in this case, from the airflow part, we conclude that the best fit to reach proper results at the reactors is when we have three CAS reactors, one fixed aeration reactor, two alternating aeration reactors, and one anoxic reactor.

After reactors, the treatment process proceeds to clarifiers, where we set proper rules to have a good working plant. Given these rules, we setup a pre-denitrification layout; one reactor was set to anoxic, which feeds three CAS reactors, from which two have alternating aeration and one is fully aerated, and the nitrate recirculation is set to 300% of the influent, as shown in Figure 7. Underflow of influent was set to 100%, with WASQ = 2550 m3/d, SRT around 11 days. It is considered that NH4-n, N03-N, 3% of COD contributes to organic nitrogen. The temperature from 0 to 2500 h = 20 °C, and then from 2500 to 5000 h = 12 °C. There were also simulations conducted with 1D clarifiers with different surface areas of clarifiers, and in both cases, the biological part works properly for effluent requirements with regards to TSS as well.

Figure 7.

Chart with MLSS and WAS parameters on running regime.

Figure 7 shows results from the model on MLSS and other biological parameters including WAS parameter, for the selected scenario and treatment technology.

Figure 8 shows results from the model on air flow/oxygen demand for the selected scenario and treatment technology.

Figure 8.

Airflow chart on reactors part.

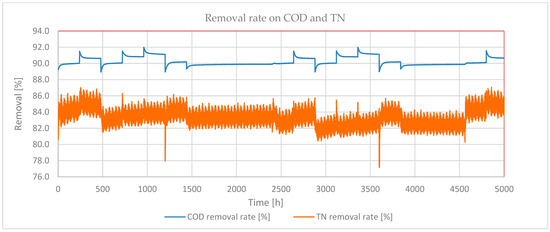

Figure 9 shows results from the model on COD and TN Removal for the selected scenario and treatment technology.

Figure 9.

Removal rate of COD and TN.

We observed that COD removal is around 90–92%, or 55–65 mg/L, where full biodegradation occurs, which is practically realistic.

N removal from the simulation resulted in very good values, around 85%, and it can work even for elevated influent COD.

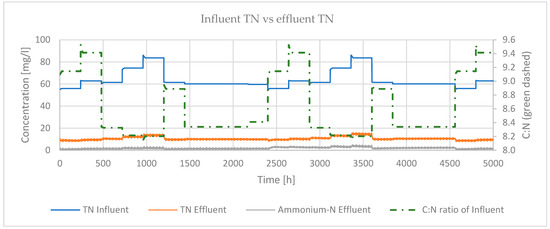

The C/N ratio is an important limiting condition (orange dashed line—right axis). According to the ASM3bioP model, if this is over 8:1 (biodegradable carbon ratio is optimal), the denitrification works properly.

- TN effluent below 10 mg/L can be achieved by this way, as per the requirement on the local standard for effluent on TN removal.

- The temperature drop is now visually more effective; nitrification is critical in wintertime, and 15 mg/L of total N is more realistic in these cases.

- After running the model, its results were compared with conventional calculations based on ATV-DVWK-A 131 to verify accuracy. The comparison, shown in Table 7, confirms the model’s reliability.

Table 7. Compared results between two trials: one with fully CAS and the second with CAS including Pre-DN.

Table 7. Compared results between two trials: one with fully CAS and the second with CAS including Pre-DN.

Figure 10 shows results from the model on TN Removal for the selected scenario and treatment technology.

Figure 10.

TN removal from inlet and outlet.

4. Discussion

This study went into detail to analyze both the design and the operational performance of the proposed Prishtina WWTP. It employed not only the traditional standard of ATV-DVWK-A 131E calculations but also innovative dynamic modeling through the IWASP platform. The main objective was to verify the ability of the plant to keep up with the future discharge standards until 2040, especially concerning nitrogen and phosphorus elimination in an efficient way, as the population and load would keep growing.

The main challenges of design efficiency measures are related to proper technology setup and treatment steps in different contexts, from water/sewer quality, quantity fluctuations, and regional or local experience. Another key context is the operational and maintenance part, including energy consumption. Another key point analyzed during this study was the design efficiency in relation to load variability, including seasonal changes in the load at the inlet of the WWTP. At the beginning of the study and research, one of the most priority points was analyzed, i.e., the importance of the sewer network, and its performance on hydraulic capabilities, infiltration, and exfiltration from the network as the key indicator on design and operation of WWTP.

The design part was analyzed from different perspectives of technology, including CAS, SBR, MMBR, and MBR. Finally, it was found that CAS technology offers a balance between cost-effectiveness, simplicity of operation, and a process which covers proper removal of high BOD and COD and integration of further stages for the future of phosphorus removal.

The integration and comparison with dynamic models from the IWASP platform with ASM3bioP was achieved to simulate a quite realistic model scenario for the Prishtina WWTP. A conventional calculation with ATV DVWK-A 131 was remade after trials on dynamic models; the results show that it cannot work smoothly on forecasting, taking into consideration seasonal and load fluctuations. After all these discussions raised by the team, we concluded that the best fit for this specific WWTP would be to introduce CAS technology in the first phase of development, with an update during the second phase, to achieve a combination of CAS systems in 2040 with anoxic, aerobic and intermittent aerobic—non aerobic reactors.

Project Alternative Cost Analysis

Two options for project location compatible with the outcomes of the first step of analysis of the project alternatives and with the developments of the network component were studied:

- Option 1: the wastewater treatment schema with one main WWTP in Lismir and a lower point which will obtain water from cities and towns (municipalities—hereafter called “Option 1 WWTP”); this model was calculated and run in the model as the best scenario.

- Option 2: a treatment schema with a small WWTP in Obiliq (with an inlet pumping station) and a main WWTP in Lismir with two inlet pumping stations (identical flows and heads as option 1) processing the wastewater from Prishtina, Fushë-Kosovë, Gracanica, and Lizmir (hereafter called “Option 2 WWTP”).

In the end, option 1 has been selected; it is the option presented in the research paper and dynamic model as well.

Table 8 represents total capital investment, comparison between two options with centralized and semi centralized WWTP, calculated by consultancy company with inputs from RWC Prishtina.

Table 8.

Comparison between option 1 and 2, CAPEX.

Table 9 shows calculation based on current situation and predictions for operational expenditures for future operations.

Table 9.

Comparison between option 1 and 2, annual OPEX.

5. Conclusions

Firstly, the plant was furnished with four CAS reactors that were running aerobically and which to some extent effectively contributed to the removal of BOD5, COD, and TSS. However, it could not suppress the total nitrogen (TN) concentration to less than 10 mg/L, specifically during the cold months of the year. Thus, the revised configuration that deals with the three new CAS reactors was thought over. Out of those, two were running alternate aeration, and one was a completely anoxic tank to make the pre-denitrification stage efficient.

The observed reduction in aeration demand in the “3 CEAS + anaerobic” configuration compared to the baseline four CAS system is not unorthodox, but a direct consequence of the process layout and with an impact on the microbial stratification. It may appear counterintuitive that a system with one fewer aerated reactors achieves comparable or even superior effluent quality with less energy but is consistent with biokinetics.

The difference lies in the incorporation of a dedicated partial anaerobic/anoxic zone, combined with recirculation of nitrate-rich mixed liquor (200% NO3-N recirc). This enables effective pre-denitrification and biological phosphorus uptake without reliance on aeration. The system therefore avoids unnecessary oxygen supply for processes that can be managed more efficiently via internal cycling. The four CAS system relies solely on intermittent aeration across all tanks, limiting the selectivity and functional differentiation in microbial structure. This is the key difference between statistic-based models and biokinetic based gray-box models. The “3 CAS + anaerobic” layout supports significantly higher autotrophic and PAO biomass concentrations, as well as higher total MLSS. These differences are not artifacts but emergent from process stratification (spatial or functional separation of process zones): the anaerobic phase promotes PAO selection, the anoxic phase ensures nitrate removal without oxygen, and the aerobic CAS reactors operate at higher efficiency due to reduced inert load. In effect, the microorganisms are better structured for the removal tasks required. Energy-wise, this translates into a measurable gain. Both SAED (kWh/kg COD) and SAED (kWh/kg TN) are ~19% lower in the three ICEAS + anaerobic system. These values are not only realistic but align with published benchmarks for well-optimized configurations.

Table 10 represents comparisons in details and results from the selected design option.

Table 10.

Summary of upgraded 3 CAS + 1 anoxic reactor configuration and benefits.

Author Contributions

S.X. contributed to data collection, calculation with conventional calculation through ATV DVWK-A 131, preparation of drawings, cost calculations, and technology comparison. T.K. contributed to IWASP dynamic modelling, including inputs on all calculations and models for IWASP ASM, ASM3 bioP, clarifier calculations, recommendations, and discussion. M.P. contributed to the revision of the paper, with proper professional experience and recommendation on technology selection, advantages and disadvantages, and discussion. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

We declare that there is no conflict of interest at any stage on this paper preparation or publication. It is sole study within BME (Budapest University of Technology and Economics), and official data from the RWC Prishtina.

Abbreviations

The following abbreviations are used in this manuscript:

| AI | Administrative Instruction |

| ASM | Activated Sludge Model |

| ASM2d | Activated Sludge Model No. 2d |

| ASM3bioP | Activated Sludge Model No. 3 with Biological Phosphorus Removal |

| ATV-DVWK-A 131(E) | Arbeitsblatt ATV-DVWK-A 131 (Guideline for Dimensioning of Single-Stage Activated Sludge Plants) |

| BME | Budapest University of Technology and Economics |

| BOD5 | Biochemical Oxygen Demand over 5 days |

| CAPEX | Capital Expenditure |

| CAS | Conventional Activated Sludge |

| CASa | Conventional Activated Sludge with alternating work system |

| COD | Chemical Oxygen Demand |

| DS | Dewatered Sludge |

| DWA | German Association for Water, Wastewater, and Waste |

| EAWAG | Swiss Federal Institute of Aquatic Science and Technology |

| EPS | Excess Phosphorus Storage |

| EU | European Union |

| HRT | Hydraulic Retention Time |

| IWASP | Integrated Wastewater Simulation Platform |

| IPS | Inlet Pumping Station |

| MBR | Membrane Bioreactor |

| MLSS | Mixed Liquor Suspended Solids |

| MBBR | Moving Bed Biofilm Reactor |

| O&M | Operation and Maintenance |

| OPEX | Operational Expenditure |

| PAO | Phosphate-Accumulating Organism |

| PE | Population Equivalent |

| PS | Pumping Station |

| q | Specific Water Consumption |

| RAS | Return Activated Sludge |

| RT | Retention Tank |

| SBR | Sequencing Batch Reactor |

| SIMBA | Simulation of Biofilm Activity |

| SS | Suspended Solids |

| SRT | Sludge Retention Time |

| TN | Total Nitrogen |

| TP | Total Phosphorus |

| TSS | Total Suspended Solids |

| UASB or UASBR | Upflow Anaerobic Sludge Blanket (Reactor) |

| WAS | Waste Activated Sludge |

| WASQ | Waste Activated Sludge Flowrate |

| WWTP | Wastewater Treatment Plant |

References

- Papadopoulou, A.; Stefanakou, G.; Fougias, E. Promotion of environmental projects to conform with UWWTD and integrated water management. Water Pract. Technol. 2022, 17, 1421–1432. [Google Scholar] [CrossRef]

- An, M.; He, W.; Degefu, D.M.; Liao, Z.; Zhang, Z.; Yuan, L. Spatial Patterns of Urban Wastewater Discharge and Treatment Plants Efficiency in China. Int. J. Environ. Res. Public Health 2018, 15, 1892. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Qian, Y.; Shi, Y.; Miao, Y.; Luo, M. Application of biofilm-membrane bioreactor in municipal wastewater treatment. Appl. Math. Nonlinear Sci. 2024, 9, 8–10. [Google Scholar] [CrossRef]

- Pazdar, S.; Eslamian, S.; Gholami, H.; Ostad-Ali-Askari, K. Evaluation of Treated Wastewater in Terms of Environmental Standards. Am. J. Eng. Appl. Sci. 2019, 12, 450–459. [Google Scholar] [CrossRef]

- Barcõn, T.; Alvarino, T.; Gõmez, M.; Omil, F. Strategies to minimize the release of endotoxins in effluents from sewage treatment plants. Environ. Prog. Sustain. Energy 2015, 34, 432–436. [Google Scholar] [CrossRef]

- Park, C.; Sheppard, D.; Yu, D.; Dolan, S.; Eom, H.; Brooks, J.; Borgatti, D. Comparative assessment on the influences of effluents from conventional activated sludge and biological nutrient removal processes on algal bloom in receiving waters. Environ. Eng. Res. 2016, 21, 276–283. [Google Scholar] [CrossRef]

- Asibor, G.I.; Oghenekohwiroro, E.; Adeniyi, F. Impact of Biologically Treated Effluent on the Physico-chemical Quality of a Receiving Stream in Ile-Ife, Southwest Nigeria. J. Sustain. Dev. 2015, 8, 213. [Google Scholar] [CrossRef][Green Version]

- Oweira, H.; Lahdou, I.; Daniel, V.; Schmidt, J.; Mehrabi, A.; Sadeghi, M. Association of Graft Effluent Parameters with Donor Body Mass Index, Graft Quality, and Post-Transplant Events. Ann. Transplant. 2018, 23, 136–143. [Google Scholar] [CrossRef] [PubMed]

- DWA-A 131E—Dimensioning of Single-Stage Activated Sludge Plants. June 2016 (Translation May 2022). Available online: https://www.dinmedia.de/en/technical-rule/dwa-a-131/255921935 (accessed on 26 May 2025).

- Koncsos, T. Bioreactor Simulation with Quadratic Neural Network Model Approximations and Cost Optimization with Markov Decision Process. Period. Polytech. Civ. Eng. 2020, 64, 614–622. [Google Scholar] [CrossRef]

- Rieger, L.; Koch, G.; Kühni, M.; Gujer, W.; Siegrist, H. The eawag bio-p module for activated sludge model no. 3. Water Res. 2001, 35, 3887–3903. [Google Scholar] [CrossRef] [PubMed]

- Fux, C.; Boehler, M.; Huber, P.; Brunner, I.; Siegrist, H. Biological treatment of ammonium-rich wastewater by partial nitritation and subsequent anaerobic ammonium oxidation (anammox) in a pilot plant. J. Biotechnol. 2002, 99, 295–306. [Google Scholar] [CrossRef] [PubMed]

- Henze, M.; Gujer, W.; Mino, T.; Matsuo, T.; Wentzel, M.C.; Marais, G.V.R.; Van Loosdrecht, M.C.M. Activated Sludge Model No.2d, ASM2D. Water Sci. Technol. 1999, 39, 165–182. [Google Scholar] [CrossRef]

- Takács, I.; Patry, G.G.; Nolasco, D. A dynamic model of the clarification-thickening process. Water Res. 1991, 25, 1263–1271. [Google Scholar] [CrossRef]

- Llorens, E.; Thiery, F.; Grieu, S.; Polit, M. Evaluation of WWTP discharges into a Mediterranean river using KSOM neural networks and mass balance modelling. Chem. Eng. J. 2008, 142, 135–146. [Google Scholar] [CrossRef]

- Pretel, R.; Robles, A.; Ruano, M.V.; Seco, A.; Ferrer, J. Economic and environmental sustainability of submerged anaerobic MBR-based (AnMBR-based) technology as compared to aerobic-based technologies for moderate-/high-loaded urban wastewater treatment. J. Environ. Manag. 2016, 166, 45–54. [Google Scholar] [CrossRef] [PubMed]

- Weissbrodt, D.G.; Holliger, C.; Morgenroth, E. Modeling hydraulic transport and anaerobic uptake by PAOs and GAOs during wastewater feeding in EBPR granular sludge reactors. Biotechnol. Bioeng. 2017, 114, 1688–1702. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Purev, O.; Cho, K.; Choi, N.; Lee, J.; Yoon, S. Removal of Inorganic Salts in Municipal Solid Waste Incineration Fly Ash Using a Washing Ejector and Its Application for CO2 Capture. Int. J. Environ. Res. Public Health 2022, 19, 2306. [Google Scholar] [CrossRef] [PubMed]

- Razali, M.A.A.; Ahmad, Z.; Ahmad, M.S.B.; Ariffin, A. Treatment of pulp and paper mill wastewater with various molecular weight of polyDADMAC induced flocculation. Chem. Eng. J. 2011, 166, 529–535. [Google Scholar] [CrossRef]

- Bersinger, T.; Le Hécho, I.; Bareille, G.; Pigot, T.; Lecomte, A. Continuous monitoring of turbidity and conductivity in wastewater networks: An easy tool to assess the pollution load discharged into receiving water. Rev. Des Sci. L’eau 2015, 28, 9–17. [Google Scholar] [CrossRef][Green Version]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).