Critical State Analysis for Iron Ore Tailings with a Fine-Grained Interlayer: Effects of Layering Thickness and Dip Angle

Abstract

1. Introduction

2. Materials and Testing Procedures

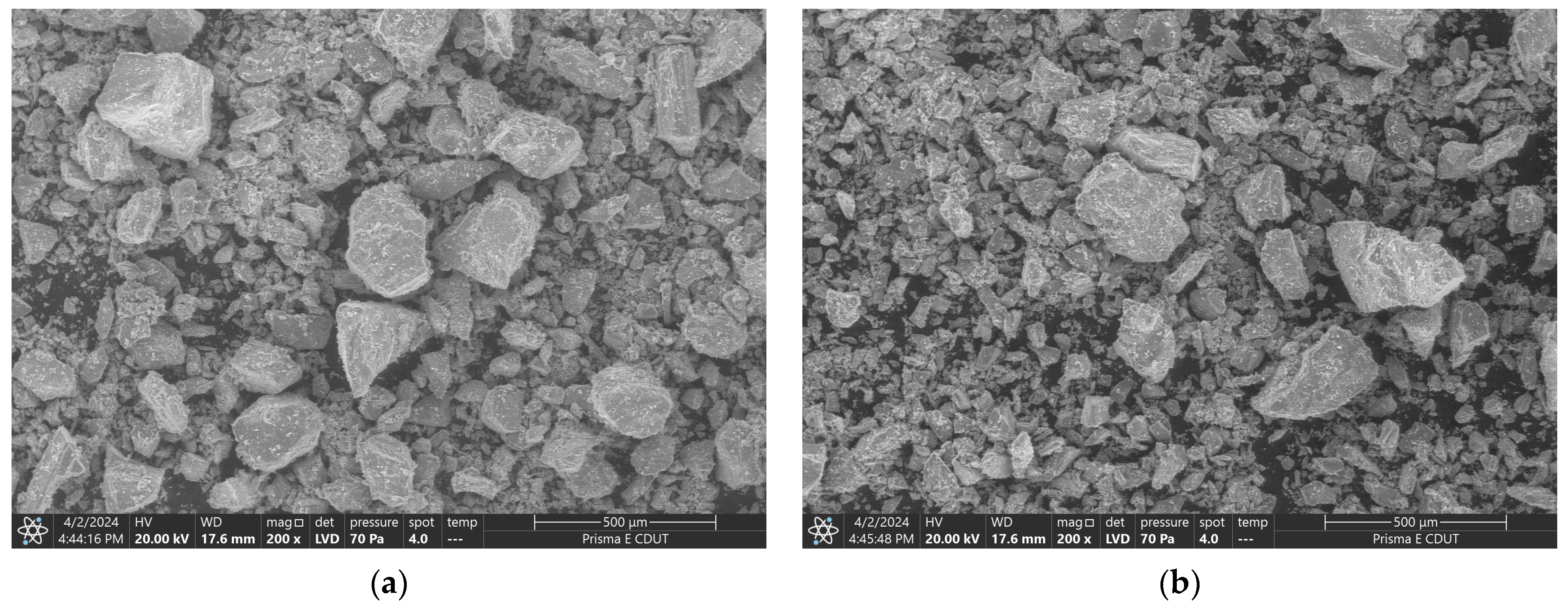

2.1. Materials Tested

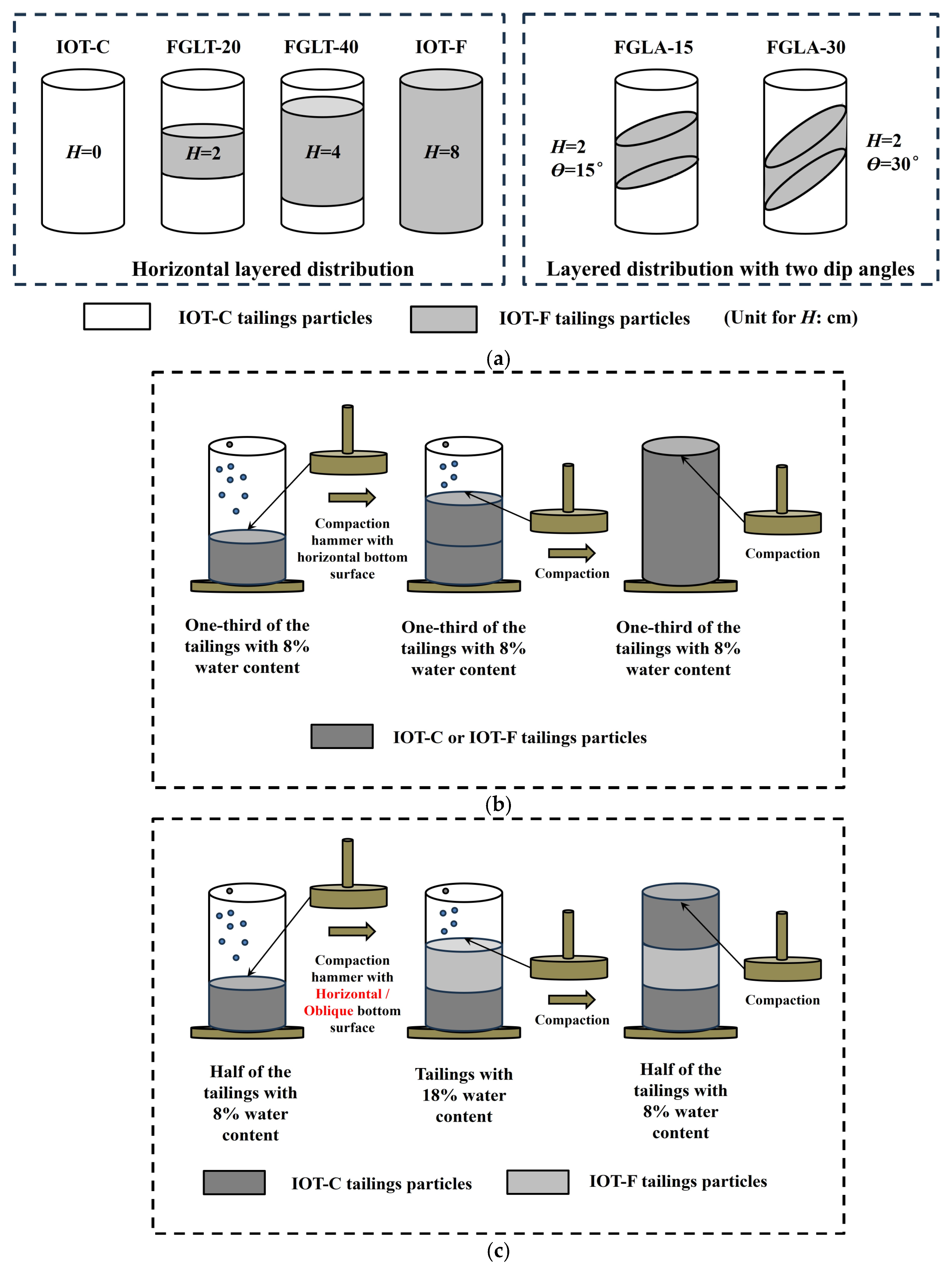

2.2. Standard Triaxial Compression Test

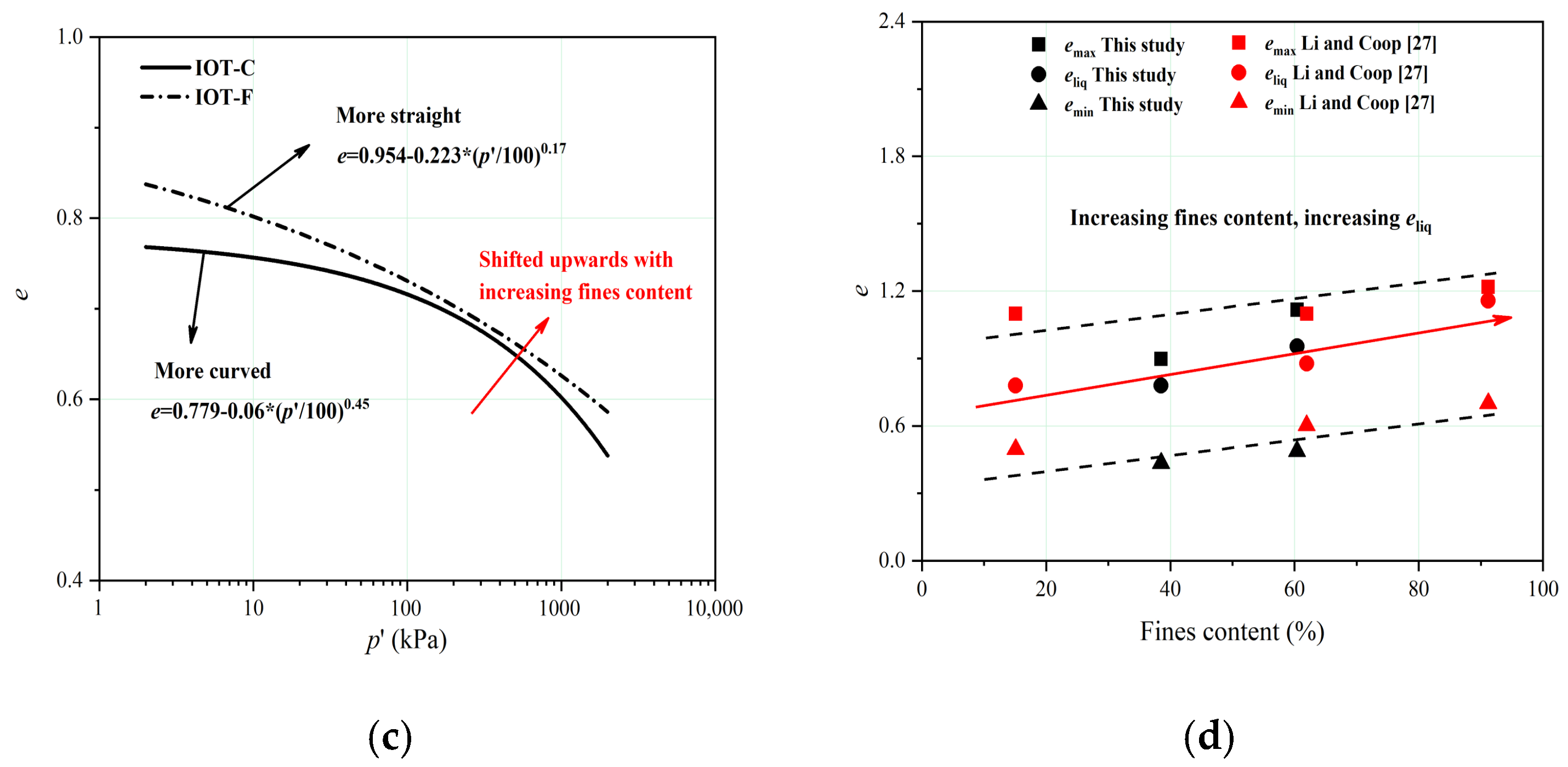

3. Shearing Behavior of Iron Ore Tailings without a Fine-Grained Interlayer

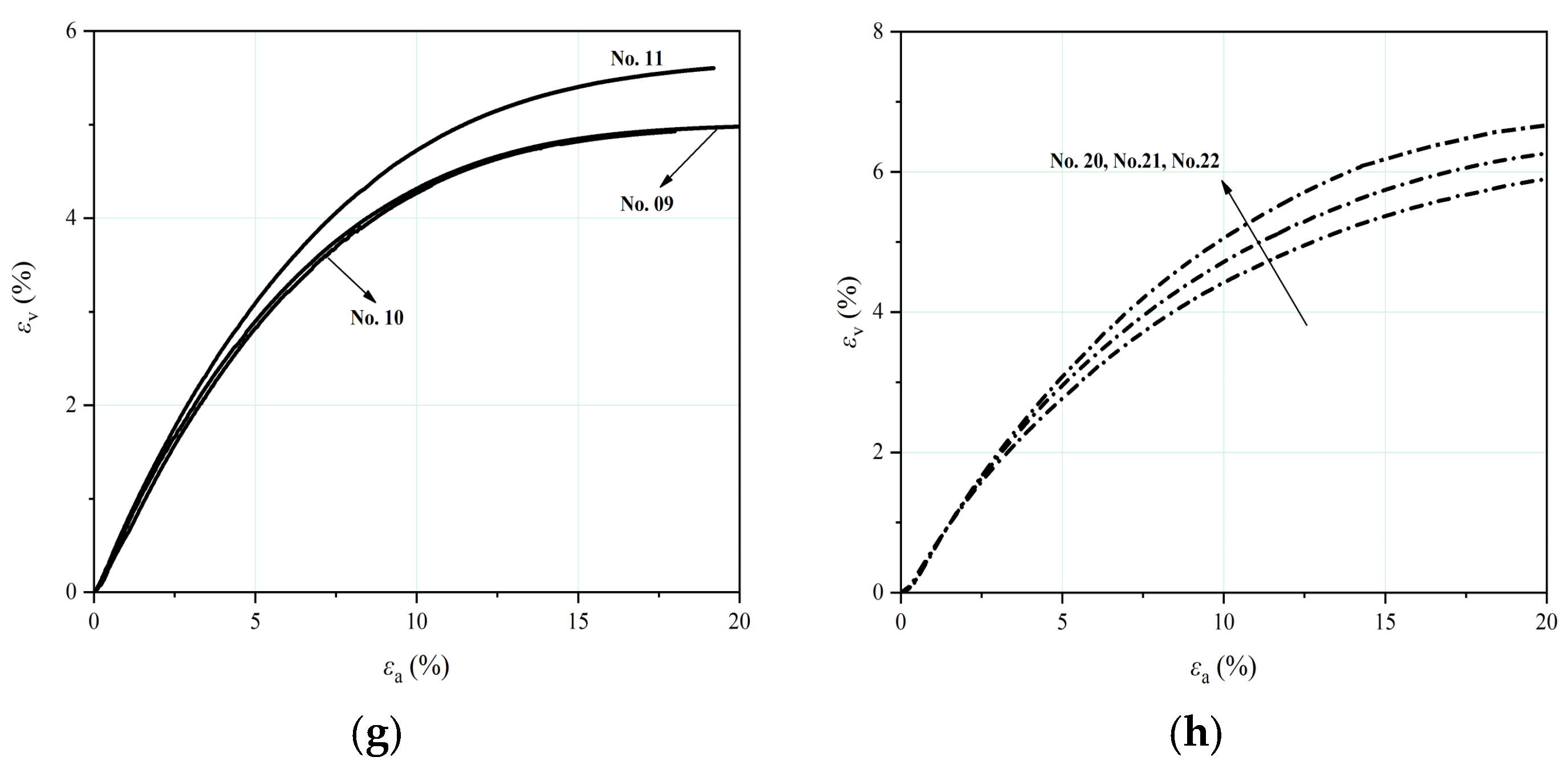

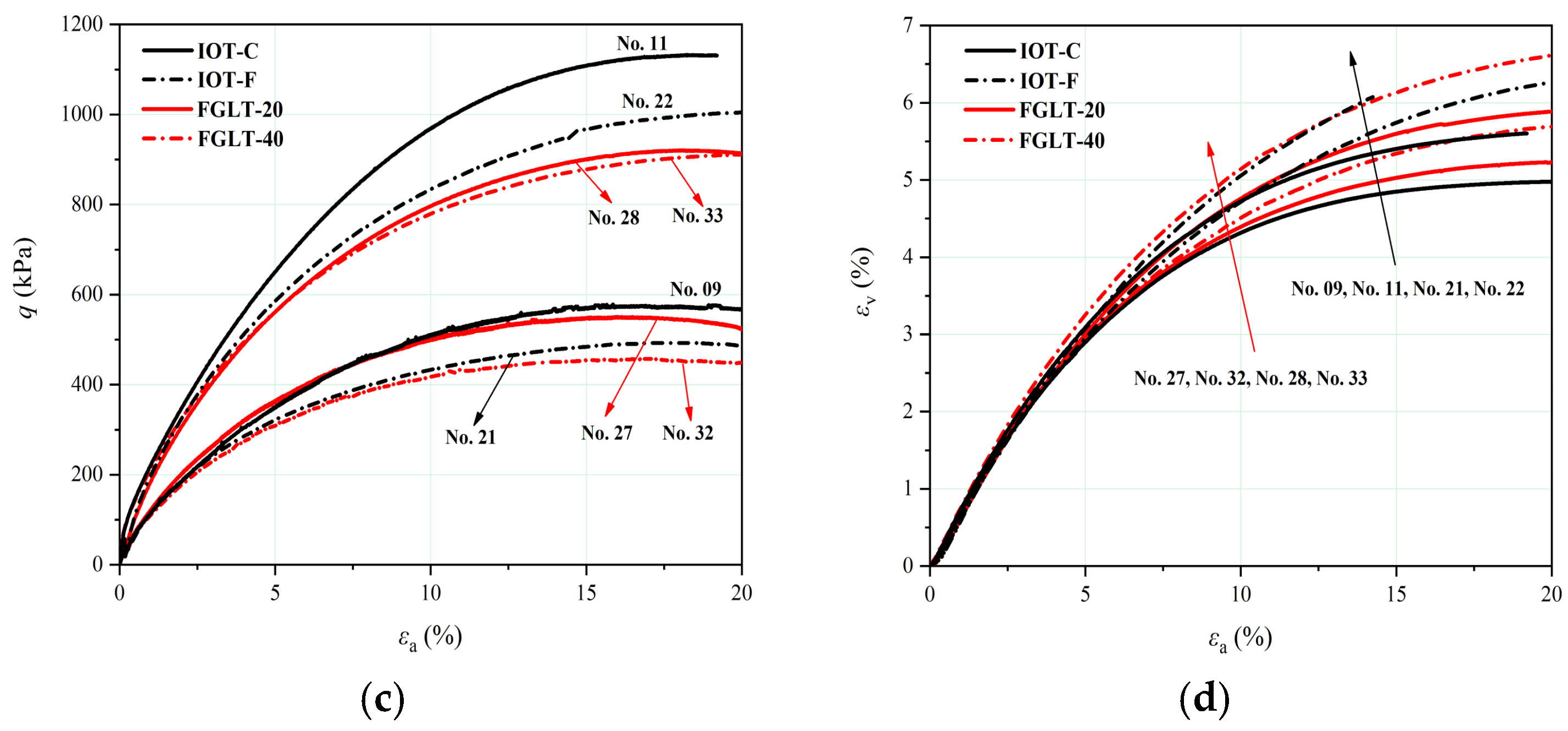

3.1. Stress–Strain Responses

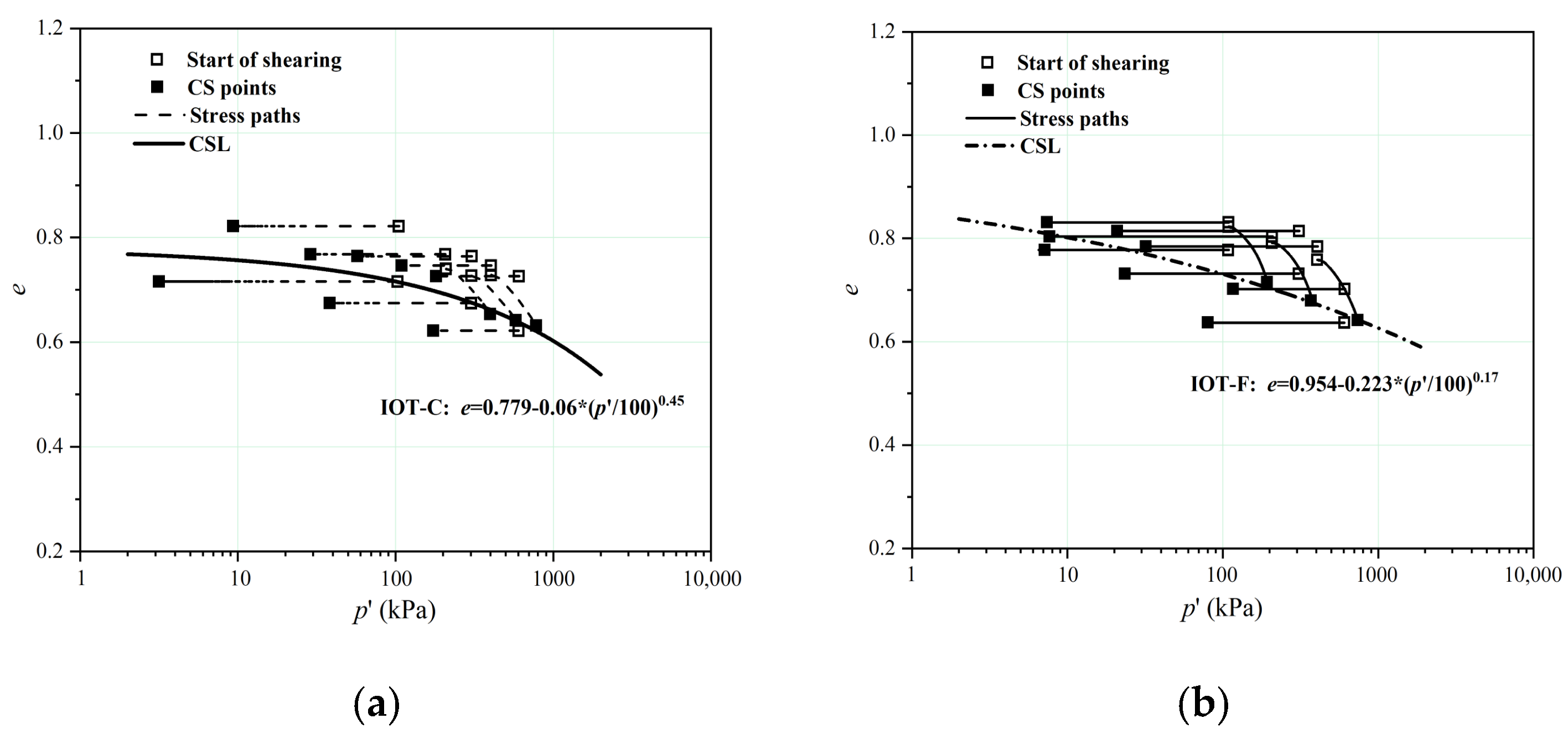

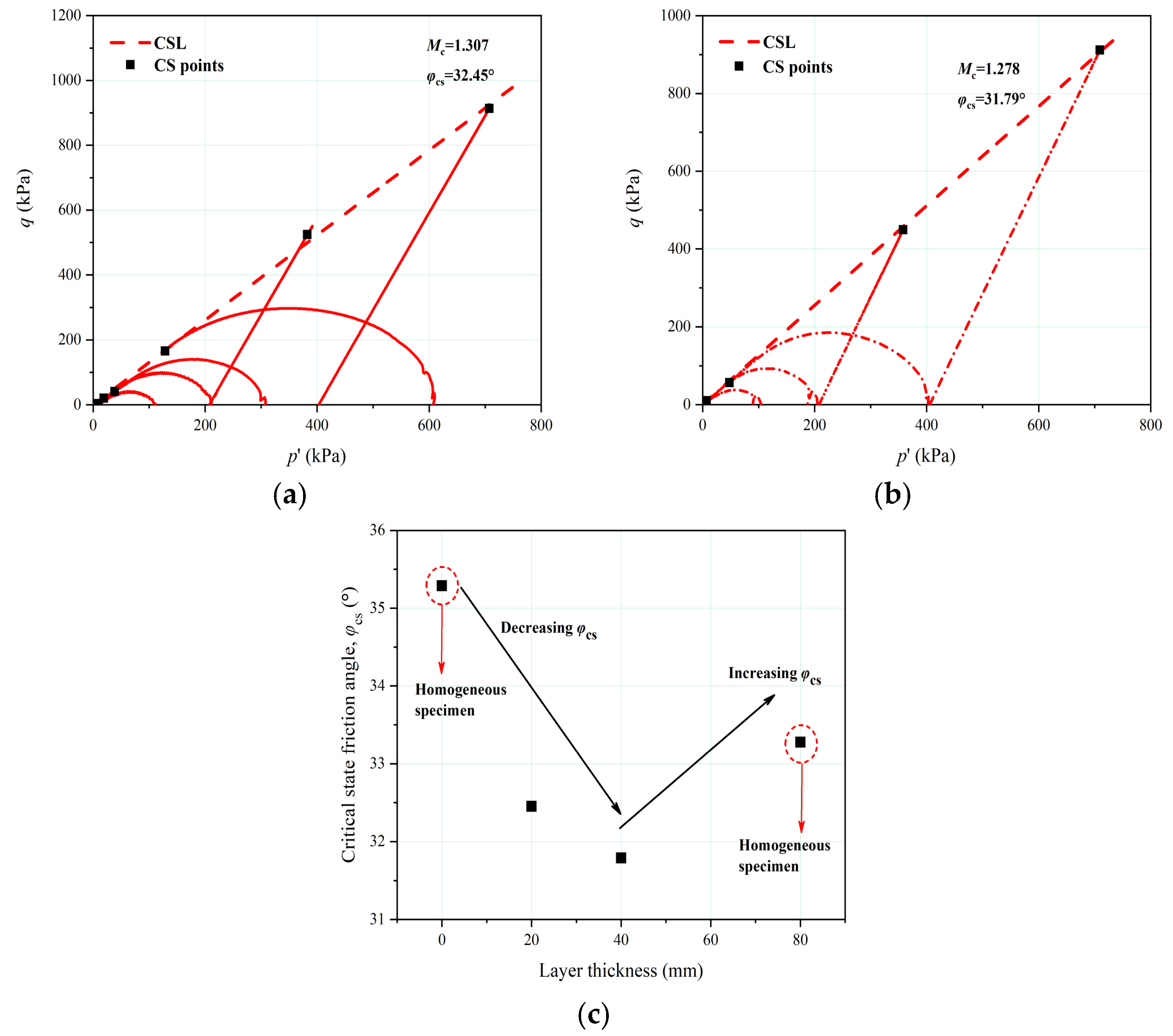

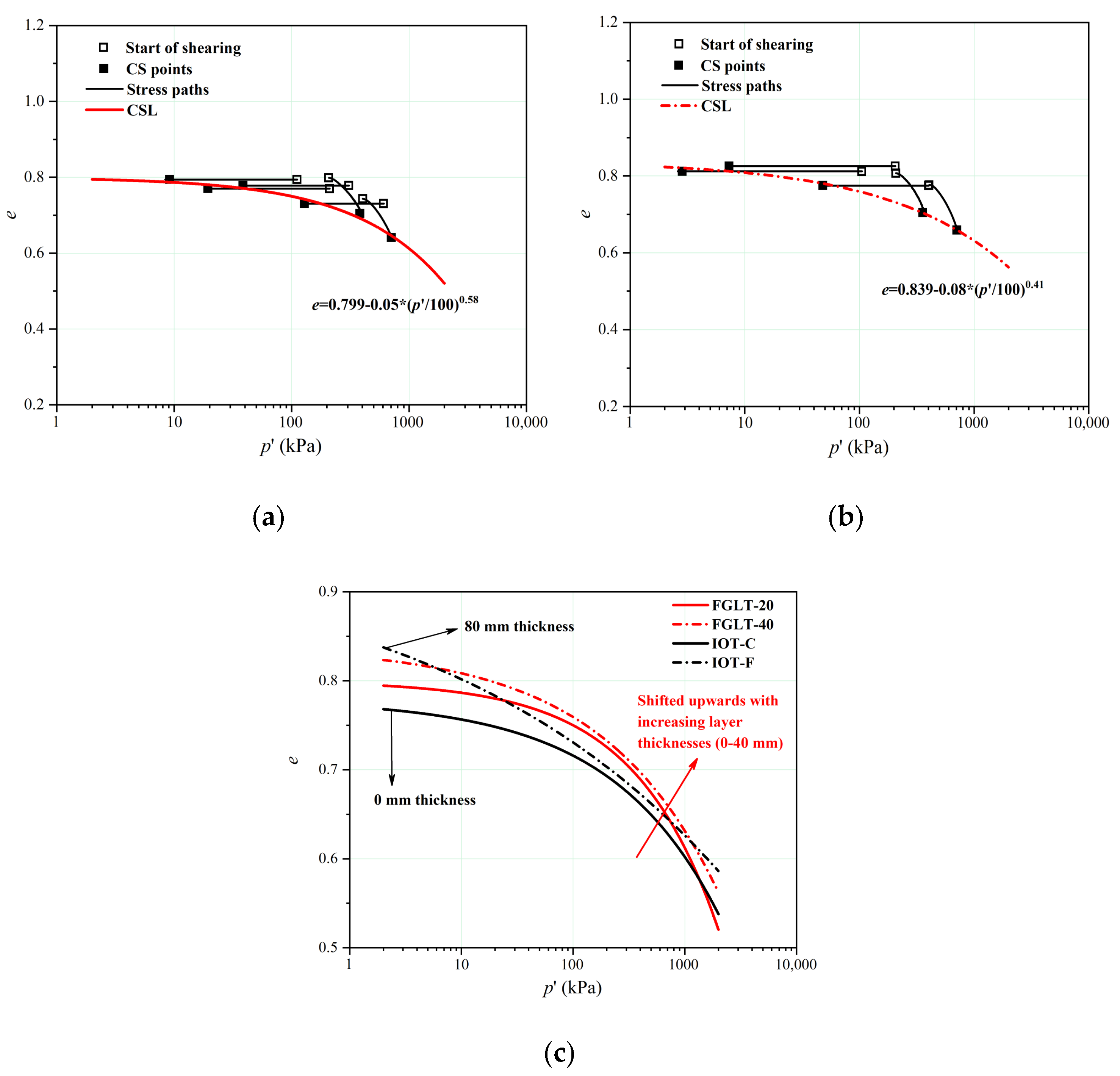

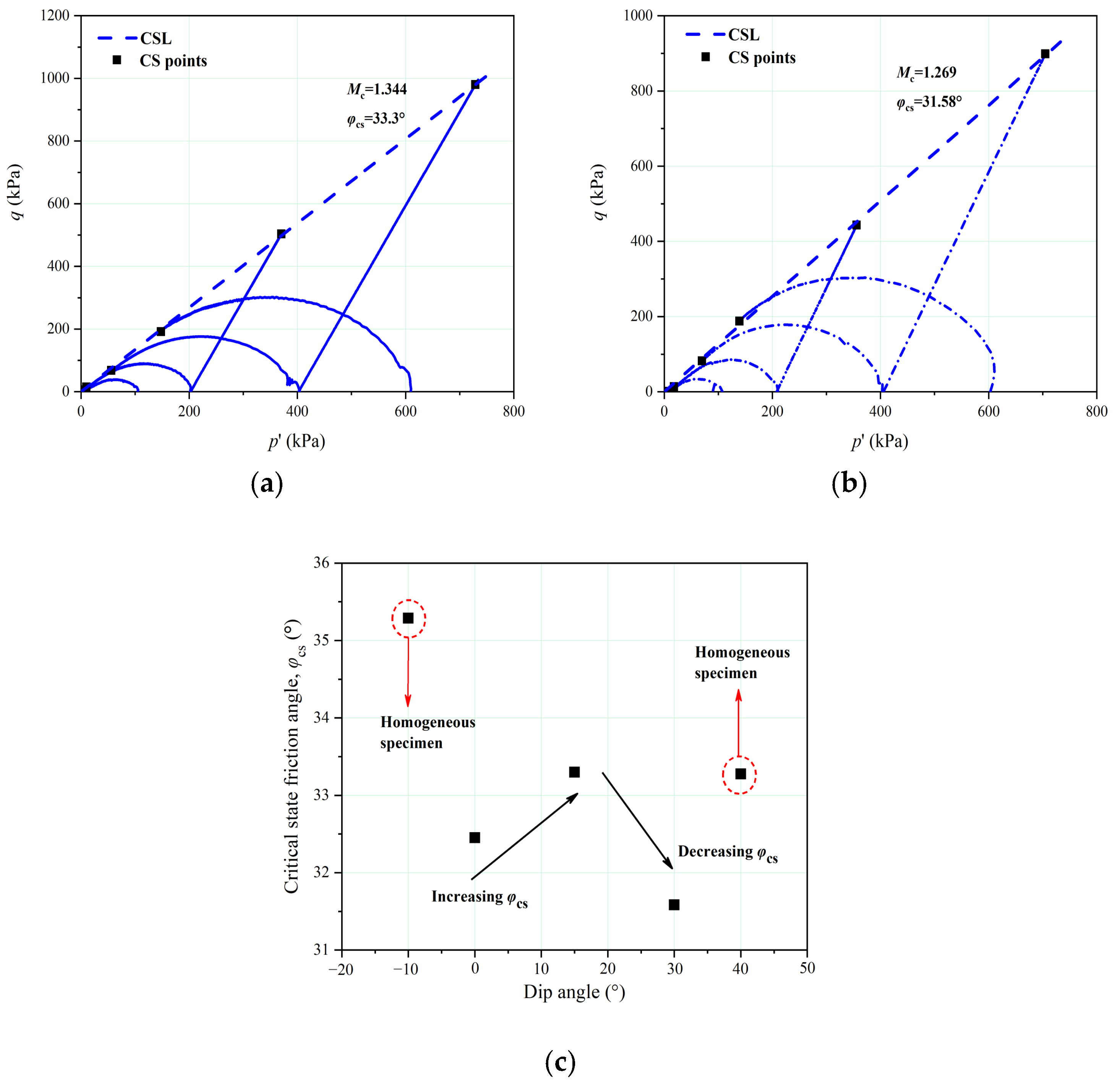

3.2. Stress Paths and Critical States

4. Shearing Behavior of Iron Ore Tailings Containing a Fine-Grained Interlayer

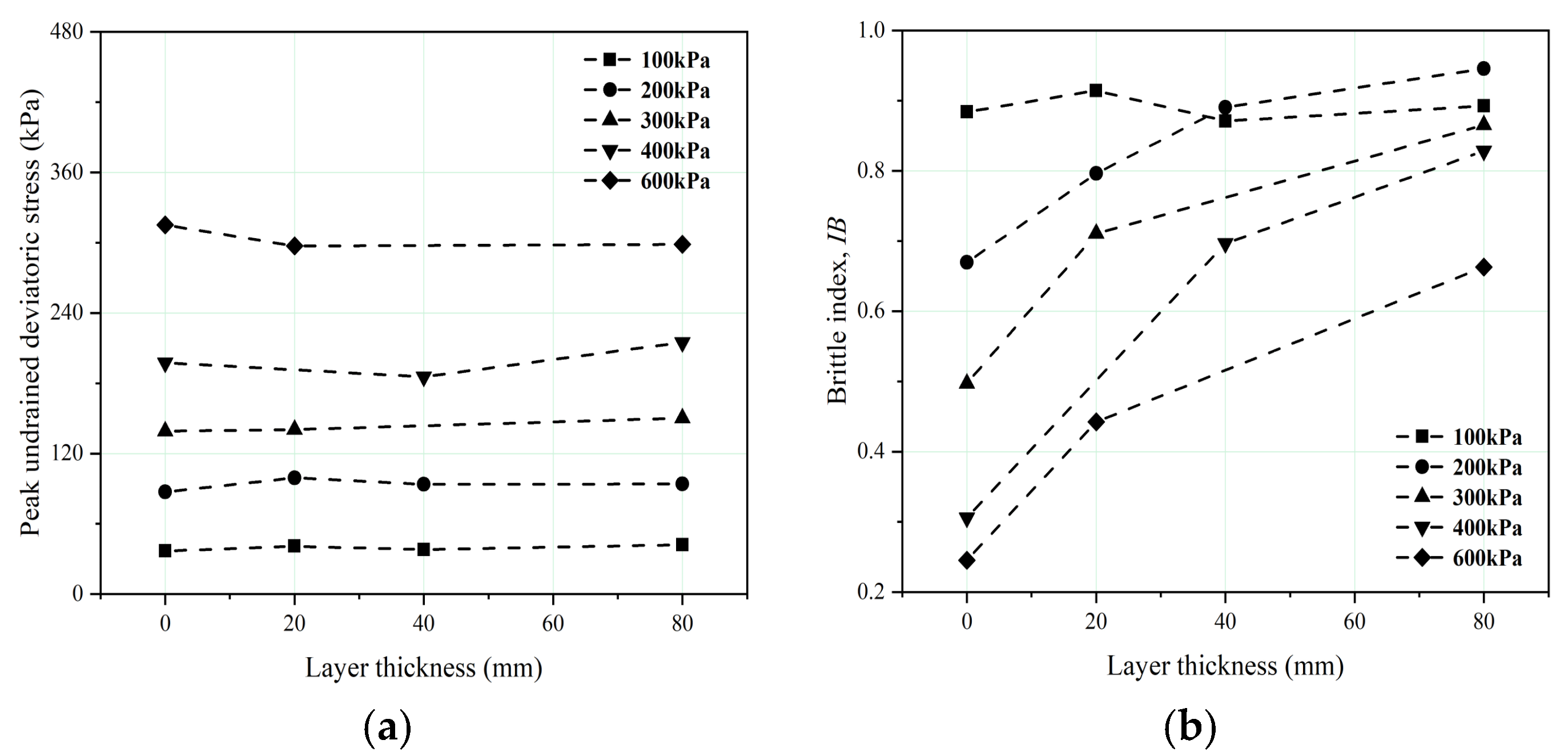

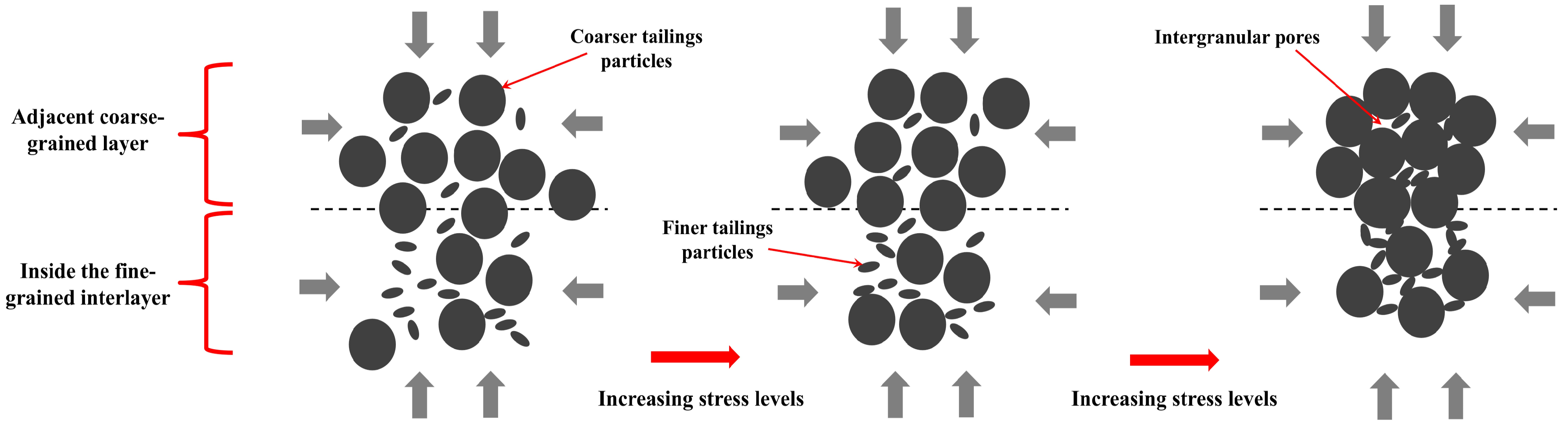

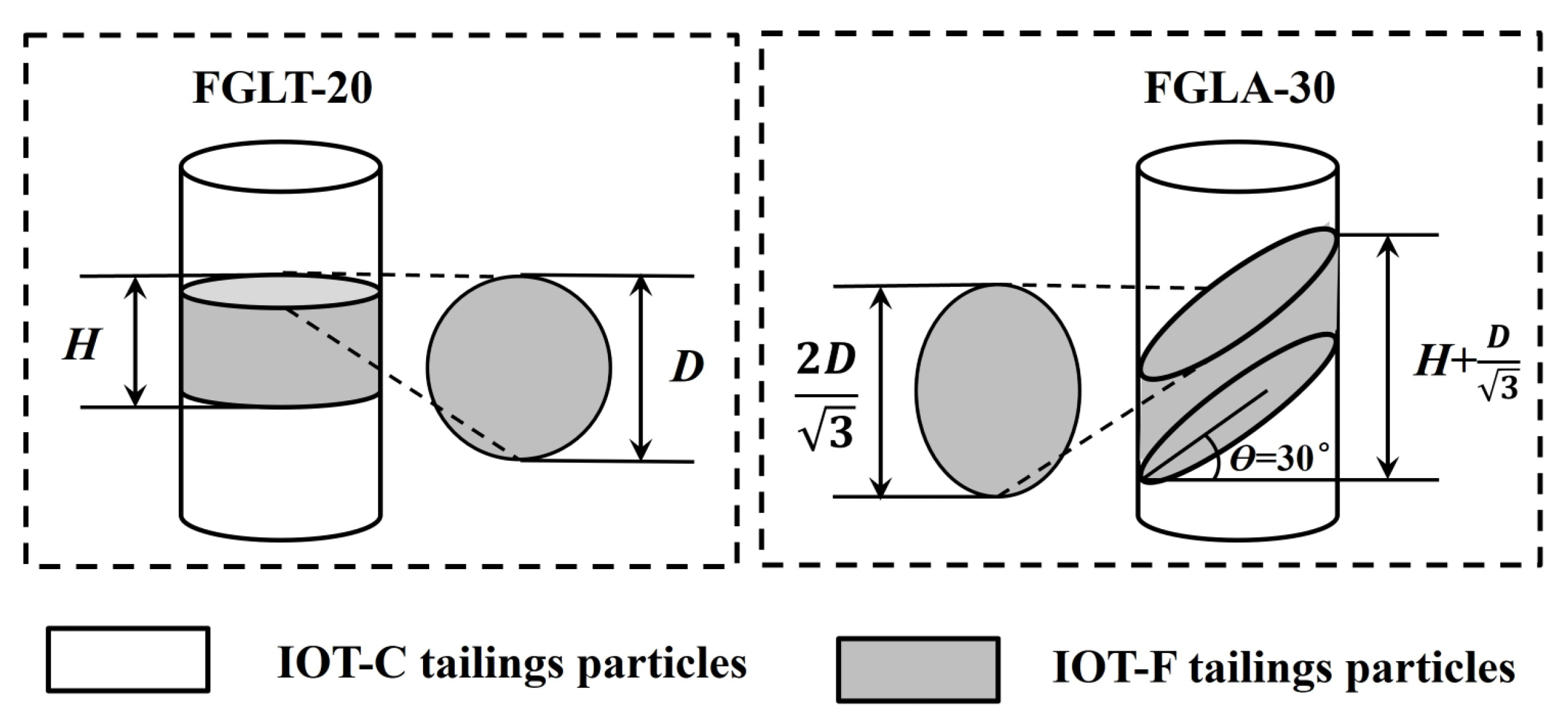

4.1. Effect of the Layer Thickness

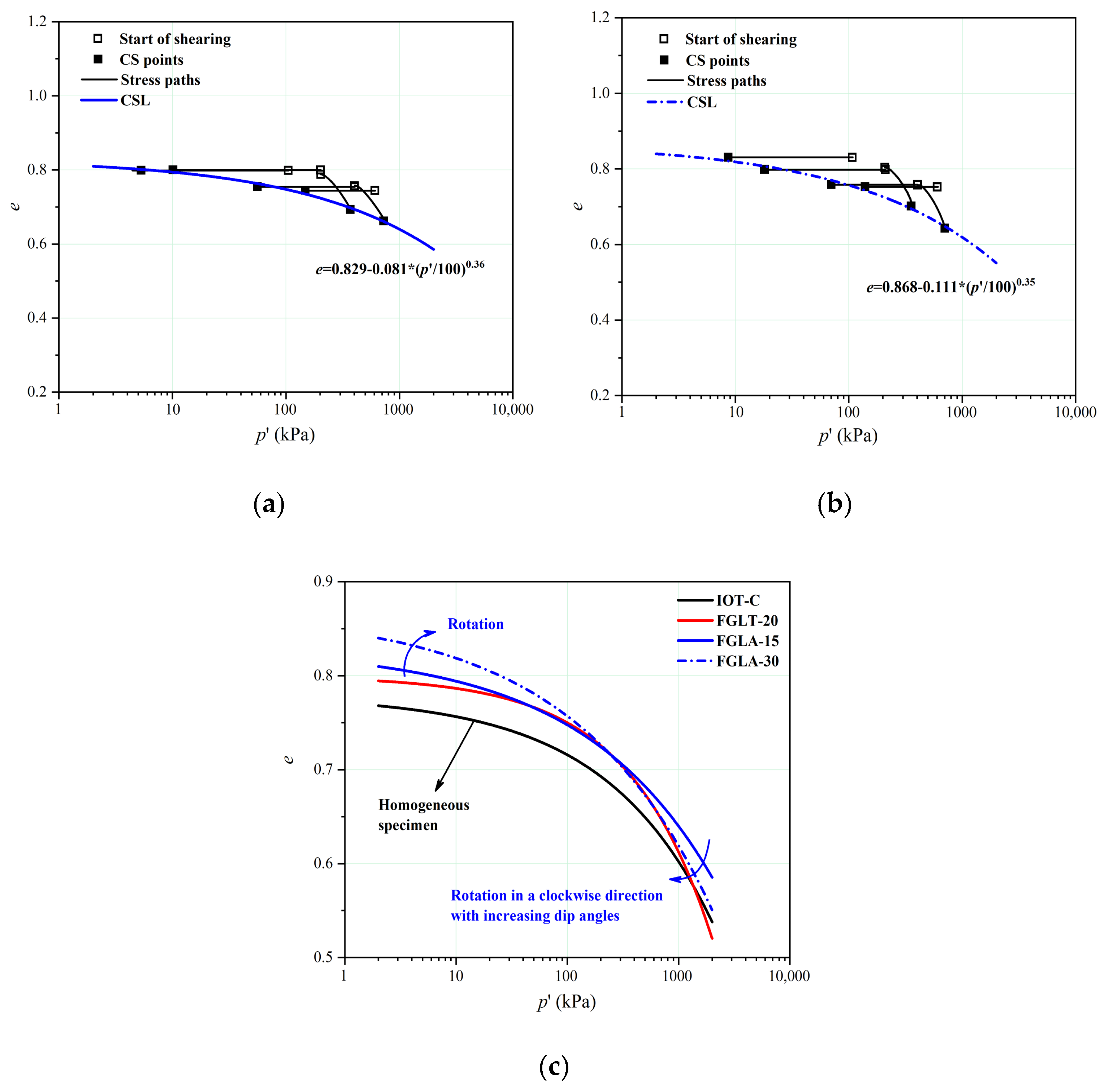

4.2. Effect of the Dip Angle

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Harbottle, D.; Liu, Q.; Xu, Z. Current state of fine mineral tailings treatment: A critical review on theory and practice. Miner. Eng. 2014, 58, 113–131. [Google Scholar] [CrossRef]

- Kossoff, D.; Dubbin, W.E.; Alfredsson, M.; Edwards, S.J.; Macklin, M.G.; Hudson-Edwards, K.A. Mine tailings dams: Characteristics, failure, environmental impacts, and remediation. Appl. Geochem. 2014, 51, 229–245. [Google Scholar] [CrossRef]

- Santamarina, J.C.; Torres-Cruz, L.A.; Bachus, R.C. Why coal ash and tailings dam disasters occur. Science 2019, 364, 526–528. [Google Scholar] [CrossRef]

- Li, W.; Coop, M.R.; Senetakis, K.; Schnaid, F. The mechanics of a silt-sized gold tailing. Eng. Geol. 2018, 241, 97–108. [Google Scholar] [CrossRef]

- Carrera, A.; Coop, M.; Lancellotta, R. Influence of grading on the mechanical behaviour of Stava tailings. Géotechnique 2011, 61, 935–946. [Google Scholar] [CrossRef]

- Gens, A.; Alonso, E.E. Aznalcóllar dam failure. Part 2: Stability conditions and failure mechanism. Géotechnique 2006, 56, 185–201. [Google Scholar] [CrossRef]

- Fourie, A.; Blight, G.; Papageorgiou, G. Static liquefaction as a possible explanation for the Merriespruit tailings dam failure. Can. Geotech. J. 2001, 38, 707–719. [Google Scholar] [CrossRef]

- Morgenstern, N.R.; Vick, S.G.; Van Zyl, D. Report on Mount Polley Tailings Storage Facility Breach, Report of Independent Expert Engineering Investigation and Review Panel to Province of British Columbia; Mount Polley Independent Expert Engineering Investigation and Review Panel: Victoria, BC, Canada, 30 January 2015. [Google Scholar]

- Zabolotnii, E.; Morgenstern, N.R.; Wilson, G.W. Mechanism of failure of the Mount Polley Tailings Storage Facility. Can. Geotech. J. 2022, 59, 1503–1518. [Google Scholar] [CrossRef]

- Reid, D. Additional Analyses of the Fundão Tailings Storage Facility: In Situ State and Triggering Conditions. J. Geotech. Geoenviron. Eng. 2019, 145, 04019088. [Google Scholar] [CrossRef]

- Bayaraa, M.; Sheil, B.; Rossi, C. InSAR and numerical modelling for tailings dam monitoring—The Cadia failure case study. Géotechnique 2024, 74, 985–1003. [Google Scholar] [CrossRef]

- Jefferies, M.; Morgenstern, N.; Van Zyl, D.; Wates, J. Report on NTSF Embankment Failure, Cadia Valley Operations, for Ashurst Australia; Newcrest: Melbourne, Australia, 2019. [Google Scholar]

- Rana, N.M.; Ghahramani, N.; Evans, S.G.; McDougall, S.; Small, A.; Take, W.A. Catastrophic mass flows resulting from tailings impoundment failures. Eng. Geol. 2021, 292, 106262. [Google Scholar] [CrossRef]

- Fourie, A.; Verdugo, R.; Bjelkevik, A.; Torres-Cruz, L.; Znidarcic, D. Geotechnics of mine tailings: A 2022 state of the art. In Proceedings of the 20th International Conference on Soil Mechanics and Geotechnical Engineering, Sydney, Australia, 1–5 May 2022. [Google Scholar]

- Goñi, C.; Celi, D.; Concha, F. Determination of the volumetric solids fraction of saturated polydisperse ore tailing sediments. Powder Technol. 2017, 305, 528–537. [Google Scholar] [CrossRef]

- Liu, Y.; Lv, C.; Ding, J.; Qian, P.; Yu, Y.; Ye, S.; Chen, Y. Characterization of a hybrid polyacrylamide and its flocculation properties in cyanide tailing suspensions. Water Sci. Technol. 2017, 76, 2482–2493. [Google Scholar] [CrossRef]

- Høeg, K.; Dyvik, R.; Sandbækken, G. Strength of Undisturbed versus Reconstituted Silt and Silty Sand Specimens. J. Geotech. Geoenviron. Eng. 2000, 126, 606–617. [Google Scholar] [CrossRef]

- Chang, N.; Heymann, G.; Clayton, C. The effect of fabric on the behaviour of gold tailings. Géotechnique 2011, 61, 187–197. [Google Scholar] [CrossRef]

- Reid, D.; Fanni, R. A comparison of intact and reconstituted samples of a silt tailings. Géotechnique 2022, 72, 176–188. [Google Scholar] [CrossRef]

- Reid, D.; Fanni, R.; Koh, K.; Orea, I. Characterisation of a subaqueously deposited silt iron ore tailings. Géotechnique Lett. 2018, 8, 278–283. [Google Scholar] [CrossRef]

- Oda, M.; Nemat-Nasser, S.; Konishi, J. Stress-Induced Anisotropy in Granular Masses. Soils Found. 1985, 25, 85–97. [Google Scholar] [CrossRef]

- Zhang, Q.; Yin, G.; Wei, Z.; Fan, X.; Wang, W.; Nie, W. An experimental study of the mechanical features of layered structures in dam tailings from macroscopic and microscopic points of view. Eng. Geol. 2015, 195, 142–154. [Google Scholar] [CrossRef]

- Chen, R.; Lei, W.; Li, Z. Anisotropic shear strength characteristics of a tailings sand. Environ. Earth Sci. 2014, 71, 5165–5172. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, C.; Yang, C.; Ma, C.; Pan, Z.; Daemen, J.J.K. Strength and deformation of tailings with fine-grained interlayers. Eng. Geol. 2019, 256, 110–120. [Google Scholar] [CrossRef]

- Fourie, A.B.; Tshabalala, L. Initiation of static liquefaction and the role of K0 consolidation. Can. Geotech. J. 2005, 42, 892–906. [Google Scholar] [CrossRef]

- Bedin, J.; Schnaid, F.; Fonseca, A.V.D.; Filho, L.D.M.C. Gold tailings liquefaction under critical state soil mechanics. Géotechnique 2012, 62, 263–267. [Google Scholar] [CrossRef]

- Li, W.; Coop, M.R. Mechanical behaviour of Panzhihua iron tailings. Can. Geotech. J. 2019, 56, 420–435. [Google Scholar] [CrossRef]

- Torres-Cruz, L.A.; Santamarina, J.C. The critical state line of nonplastic tailings. Can. Geotech. J. 2020, 57, 1508–1517. [Google Scholar] [CrossRef]

- Reid, D.; Fourie, A.; Ayala, J.L.; Dickinson, S.; Ochoa-Cornejo, F.; Fanni, R.; Garfias, J.; Fonseca, A.V.D.; Ghafghazi, M.; Ovalle, C.; et al. Results of a critical state line testing round robin programme. Géotechnique 2021, 71, 616–630. [Google Scholar] [CrossRef]

- Riveros, G.A.; Sadrekarimi, A. Static liquefaction behaviour of gold mine tailings. Can. Geotech. J. 2021, 58, 889–901. [Google Scholar] [CrossRef]

- Fotovvat, A.R.; Sadrekarimi, A. Instability of a Gold Mine Tailings Subjected to Different Stress Paths. J. Geotech. Geoenviron. Eng. 2022, 148, 04022020. [Google Scholar] [CrossRef]

- Karim, M.E.; Rahman, M.M.; Karim, M.R.; Fourie, A.B.; Reid, D. Characteristics of Copper Tailings in Direct Simple Shearing: A Critical State Approach. J. Geotech. Geoenviron. Eng. 2023, 149, 04023018. [Google Scholar] [CrossRef]

- Macedo, J.; Vergaray, L. Properties of mine tailings for static liquefaction assessment. Can. Geotech. J. 2022, 59, 667–687. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Crous, P.A.; Jacobsz, S.W. Centrifuge and Numerical Modeling of Liquefied Flow and Nonliquefied Slide Failures of Tailings Dams. J. Geotech. Geoenviron. Eng. 2023, 149, 04023075. [Google Scholar] [CrossRef]

- Silva, J.P.S.; Rissoli, A.L.C.; Cacciari, P.P.; da Fonseca, A.J.P.V.; Filho, H.C.S.; Wagner, A.C.; Carvalho, J.V.D.A.; Festugato, L.; Consoli, N.C. Triaxial testing response of compacted iron ore tailings considering a broad spectrum of confining pressures. Soils Found. 2024, 64, 101438. [Google Scholar] [CrossRef]

- Fotovvat, A.; Sadrekarimi, A.; Etezad, M. Instability of gold mine tailings subjected to undrained and drained unloading stress paths. Géotechnique 2024, 74, 174–192. [Google Scholar] [CrossRef]

- Sarkar, G.; Sadrekarimi, A. Undrained shearing behaviour of oil sands tailings. Soil Dyn. Earthq. Eng. 2022, 161, 107410. [Google Scholar] [CrossRef]

- Verdugo, R. Static liquefaction in the context of steady state/critical state and its application in the stability of tailings dams. Soil Dyn. Earthq. Eng. 2024, 176, 108270. [Google Scholar] [CrossRef]

- Reid, D.; Fourie, A.; Moggach, S. Characterization of a gold tailings with hypersaline pore fluid. Can. Geotech. J. 2020, 57, 482–496. [Google Scholar] [CrossRef]

- Baziar, M.H.; Dobry, R. Residual Strength and Large-Deformation Potential of Loose Silty Sands. J. Geotech. Eng. 1995, 121, 896–906. [Google Scholar] [CrossRef]

- Morgenstern, N.; Vick, S.; Viotti, C.; Watts, B. Fundão Tailings Dam Review Panel Report on the Immediate Causes of the Failure of the Fundão Dam; Cleary Gottlieb Steen & Hamilton LLP: New York, NY, USA, 2016. [Google Scholar]

- Jefferies, M.; Been, K. Soil Liquefaction: A Critical State Approach; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Yao, G.; Liu, Q.; Wang, J.; Wu, P.; Lyu, X. Effect of mechanical grinding on pozzolanic activity and hydration properties of siliceous gold ore tailings. J. Clean. Prod. 2019, 217, 12–21. [Google Scholar] [CrossRef]

- Zhao, X.; Fourie, A.; Qi, C.-C. Mechanics and safety issues in tailing-based backfill: A review. Int. J. Miner. Metall. Mater. 2020, 27, 1165–1178. [Google Scholar] [CrossRef]

- Chen, B.; Pang, L.; Zhou, Z.; Chang, Q.; Fu, P. Study on the activation mechanism and hydration properties of gold tailings activated by mechanical-chemical-thermal coupling. J. Build. Eng. 2022, 48, 104014. [Google Scholar] [CrossRef]

- Sladen, J.A.; Handford, G. A potential systematic error in laboratory testing of very loose sands. Can. Geotech. J. 1987, 24, 462–466. [Google Scholar] [CrossRef]

- Bishop, A. Progressive failure-with special reference to the mechanism causing it. Proc. Geotech. Conf. 1967, 2, 142–150. [Google Scholar]

- Poulos, S.J.; Castro, G.; France, J.W. Liquefaction evaluation procedure. J. Geotech. Eng. 1985, 111, 772–792. [Google Scholar] [CrossRef]

- Yamamuro, J.A.; Covert, K.M. Monotonic and cyclic liquefaction of very loose sands with high silt content. J. Geotech. Geoenviron. Eng. 2001, 127, 314–324. [Google Scholar] [CrossRef]

- Wagner, A.C.; de Sousa Silva, J.P.; de Azambuja Carvalho, J.V.; Rissoli, A.L.C.; Cacciari, P.P.; Chaves, H.M.; Filho, H.C.S.; Consoli, N.C. Mechanical behavior of iron ore tailings under standard compression and extension triaxial stress paths. J. Rock Mech. Geotech. Eng. 2023, 15, 1883–1894. [Google Scholar] [CrossRef]

- Consoli, N.C.; Silva, J.P.S.; Wagner, A.C.; Carvalho, J.V.D.A.; Baudet, B.A.; Coop, M.R.; Filho, H.C.S.; Carvalho, I.; de Sousa, G.M.; Cacciari, P.P. Critical state analysis of two compacted filtered iron ore tailings with different gradings and mineralogy at different stages of treatment. Acta Geotech. 2024, 19, 881–898. [Google Scholar] [CrossRef]

- Vergaray, L.; Macedo, J.; Arnold, C. Static and Cyclic Liquefaction of Copper Mine Tailings. J. Geotech. Geoenviron. Eng. 2023, 149, 04023021. [Google Scholar] [CrossRef]

- Yang, S.L.; Sandven, R.; Grande, L. Steady-state lines of sand–silt mixtures. Can. Geotech. J. 2006, 43, 1213–1219. [Google Scholar] [CrossRef]

- Thevanayagam, S.; Shenthan, T.; Mohan, S.; Liang, J. Undrained Fragility of Clean Sands, Silty Sands, and Sandy Silts. J. Geotech. Geoenviron. Eng. 2002, 128, 849–859. [Google Scholar] [CrossRef]

- Fourie, A.B.; Papageorgiou, G. Defining an appropriate steady state line for Merriespruit gold tailings. Can. Geotech. J. 2001, 38, 695–706. [Google Scholar] [CrossRef]

- Been, K.; Jefferies, M.G. A state parameter for sands. Géotechnique 1985, 35, 99–112. [Google Scholar] [CrossRef]

- Been, K.; Jefferies, M.G.; Hachey, J. The critical state of sands. Géotechnique 1991, 41, 365–381. [Google Scholar] [CrossRef]

- Verdugo, R.; Ishihara, K. The Steady State of Sandy Soils. Soils Found. 1996, 36, 81–91. [Google Scholar] [CrossRef]

- Bouckovalas, G.D.; Andrianopoulos, K.I.; Papadimitriou, A.G. A critical state interpretation for the cyclic liquefaction resistance of silty sands. Soil Dyn. Earthq. Eng. 2003, 23, 115–125. [Google Scholar] [CrossRef]

| Parameter | IOT-C | IOT-F |

|---|---|---|

| Specific gravity, Gs | 2.962 | 3.037 |

| Mean particle size, D50 (mm) | 0.124 | 0.072 |

| Fines content (%) | 38.5 | 60.4 |

| Coefficient of uniformity, Cu | 7.384 | 3.571 |

| Coefficient of curvature, Ccr | 1.008 | 1.639 |

| Maximum void ratio, emax | 0.898 | 1.116 |

| Minimum void ratio, emin | 0.435 | 0.488 |

| Plastic limit (%) | - | 8.93 |

| Liquid limit (%) | - | 23.09 |

| Plasticity index (%) | - | 14.16 |

| Mean aspect ratio | 0.669 | 0.697 |

| Mean convexity | 0.929 | 0.916 |

| Mean sphericity | 0.832 | 0.850 |

| Sample | Non-Clay Minerals | Clay Minerals | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mica (%) | Hornblende (%) | Gypsum (%) | Quartz (%) | Plagioclase (%) | Calcite (%) | Pyroxene (%) | Ilmenite (%) | Hematite (%) | Magnetite (%) | Pyrite (%) | Olivine (%) | Chlorite (%) | |

| IOT-C | 2.0 | - | 0.3 | 9.8 | 57.6 | 0.1 | 2.7 | 1.1 | 0.3 | 3.5 | 0.2 | 2.7 | 19.7 |

| IOT-F | 5.4 | 6.6 | 0.4 | 5.0 | 43.2 | 0.3 | 5.4 | 2.3 | 0.2 | 8.5 | 0.6 | 7.0 | 15.1 |

| Sample | Na2O (%) | MgO (%) | Al2O3 (%) | SiO2 (%) | P2O5 (%) | K2O (%) | CaO (%) | TiO2 (%) | MnO (%) | Fe2O3 (%) | LOI (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| IOT-C | 2.11 | 12.30 | 13.48 | 44.03 | 0.089 | 0.652 | 7.60 | 2.54 | 0.208 | 14.30 | 2.38 |

| IOT-F | 2.13 | 15.74 | 11.66 | 41.48 | 0.109 | 0.369 | 7.24 | 3.24 | 0.255 | 15.10 | 2.82 |

| Sample Name | Test Sample No. | Void Ratio After Saturation | Confining Effective Stress, kPa | Void Ratio After Consolidation | End of Test | ||

|---|---|---|---|---|---|---|---|

| Deviatoric Stress, qcs: kPa | Mean Effective Stress, p′cs: kPa | Void Ratio | |||||

| IOT-C | 01 | 0.896 | 100 | 0.821 | 4.27 | 9.35 | 0.821 |

| 02 | 0.865 | 200 | 0.768 | 28.82 | 28.90 | 0.768 | |

| 03 | 0.890 | 300 | 0.764 | 69.97 | 57.434 | 0.764 | |

| 04 | 0.880 | 400 | 0.746 | 137.05 | 109.33 | 0.746 | |

| 05 | 0.877 | 600 | 0.726 | 237.13 | 181.04 | 0.726 | |

| 06 | 0.790 | 100 | 0.716 | 1.30 | 3.17 | 0.716 | |

| 07 | 0.788 | 300 | 0.674 | 50.44 | 38.35 | 0.674 | |

| 08 | 0.786 | 600 | 0.622 | 235.14 | 173.77 | 0.622 | |

| 09 * | 0.840 | 200 | 0.740 | 567.10 | 398.76 | 0.653 | |

| 10 * | 0.854 | 300 | 0.727 | 830.58 | 580.39 | 0.642 | |

| 11 * | 0.871 | 400 | 0.728 | 1130.83 | 780.74 | 0.632 | |

| IOT-F | 12 | 0.901 | 100 | 0.831 | 4.52 | 7.41 | 0.831 |

| 13 | 0.887 | 200 | 0.804 | 5.11 | 7.68 | 0.804 | |

| 14 | 0.909 | 300 | 0.814 | 20.19 | 20.96 | 0.814 | |

| 15 | 0.896 | 400 | 0.784 | 36.84 | 31.96 | 0.784 | |

| 16 | 0.896 | 600 | 0.637 | 100.63 | 80.34 | 0.637 | |

| 17 | 0.805 | 100 | 0.778 | 3.80 | 7.15 | 0.778 | |

| 18 | 0.796 | 300 | 0.732 | 25.45 | 23.45 | 0.732 | |

| 19 | 0.812 | 600 | 0.702 | 146.45 | 116.65 | 0.702 | |

| 20 * | 0.896 | 100 | 0.823 | 249.73 | 192.60 | 0.715 | |

| 21 * | 0.889 | 200 | 0.791 | 485.97 | 369.61 | 0.679 | |

| 22 * | 0.899 | 400 | 0.758 | 1004.62 | 739.96 | 0.652 | |

| Sample Name | Test Sample No. | Void Ratio After Saturation | Confining Effective Stress, kPa | Void Ratio After Consolidation | End of Test | ||

|---|---|---|---|---|---|---|---|

| Deviatoric Stress, qcs: kPa | Mean Effective Stress, p′cs: kPa | Void Ratio | |||||

| FGLT-20 | 23 | 0.870 | 100 | 0.794 | 3.50 | 9.15 | 0.794 |

| 24 | 0.868 | 200 | 0.770 | 20.24 | 19.41 | 0.770 | |

| 25 | 0.898 | 300 | 0.778 | 40.67 | 38.62 | 0.778 | |

| 26 | 0.899 | 600 | 0.731 | 165.81 | 128.85 | 0.731 | |

| 27 * | 0.896 | 200 | 0.799 | 523.88 | 382.74 | 0.705 | |

| 28 * | 0.883 | 400 | 0.744 | 913.18 | 707.45 | 0.641 | |

| FGLT-40 | 29 | 0.875 | 100 | 0.812 | 4.90 | 2.85 | 0.812 |

| 30 | 0.909 | 200 | 0.825 | 10.25 | 7.32 | 0.825 | |

| 31 | 0.912 | 400 | 0.775 | 56.34 | 48.17 | 0.775 | |

| 32 * | 0.900 | 200 | 0.807 | 449.11 | 358.05 | 0.704 | |

| 33 * | 0.921 | 400 | 0.776 | 911.39 | 709.40 | 0.661 | |

| FGLA-15 | 34 | 0.878 | 100 | 0.799 | 5.36 | 5.31 | 0.799 |

| 35 | 0.893 | 200 | 0.800 | 14.47 | 10.12 | 0.800 | |

| 36 | 0.898 | 400 | 0.755 | 67.52 | 56.22 | 0.755 | |

| 37 | 0.907 | 600 | 0.744 | 191.45 | 148.11 | 0.744 | |

| 38 * | 0.899 | 200 | 0.788 | 503.17 | 370.40 | 0.693 | |

| 39 * | 0.899 | 400 | 0.758 | 979.60 | 729.07 | 0.662 | |

| FGLA-30 | 40 | 0.909 | 100 | 0.831 | 1.04 | 8.67 | 0.831 |

| 41 | 0.909 | 200 | 0.798 | 13.31 | 18.18 | 0.798 | |

| 42 | 0.903 | 400 | 0.759 | 82.02 | 70.04 | 0.759 | |

| 43 | 0.913 | 600 | 0.752 | 187.51 | 139.33 | 0.752 | |

| 44 * | 0.896 | 200 | 0.804 | 443.22 | 356.09 | 0.701 | |

| 45 * | 0.901 | 400 | 0.757 | 898.52 | 705.11 | 0.643 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, X.; Xu, Q.; Ren, K.; Wei, L.; Wang, W. Critical State Analysis for Iron Ore Tailings with a Fine-Grained Interlayer: Effects of Layering Thickness and Dip Angle. Water 2024, 16, 2958. https://doi.org/10.3390/w16202958

Ji X, Xu Q, Ren K, Wei L, Wang W. Critical State Analysis for Iron Ore Tailings with a Fine-Grained Interlayer: Effects of Layering Thickness and Dip Angle. Water. 2024; 16(20):2958. https://doi.org/10.3390/w16202958

Chicago/Turabian StyleJi, Xu, Qiang Xu, Kaiyi Ren, Lanting Wei, and Wensong Wang. 2024. "Critical State Analysis for Iron Ore Tailings with a Fine-Grained Interlayer: Effects of Layering Thickness and Dip Angle" Water 16, no. 20: 2958. https://doi.org/10.3390/w16202958

APA StyleJi, X., Xu, Q., Ren, K., Wei, L., & Wang, W. (2024). Critical State Analysis for Iron Ore Tailings with a Fine-Grained Interlayer: Effects of Layering Thickness and Dip Angle. Water, 16(20), 2958. https://doi.org/10.3390/w16202958