Hydrodynamic Porosity: A New Perspective on Flow through Porous Media, Part II

Abstract

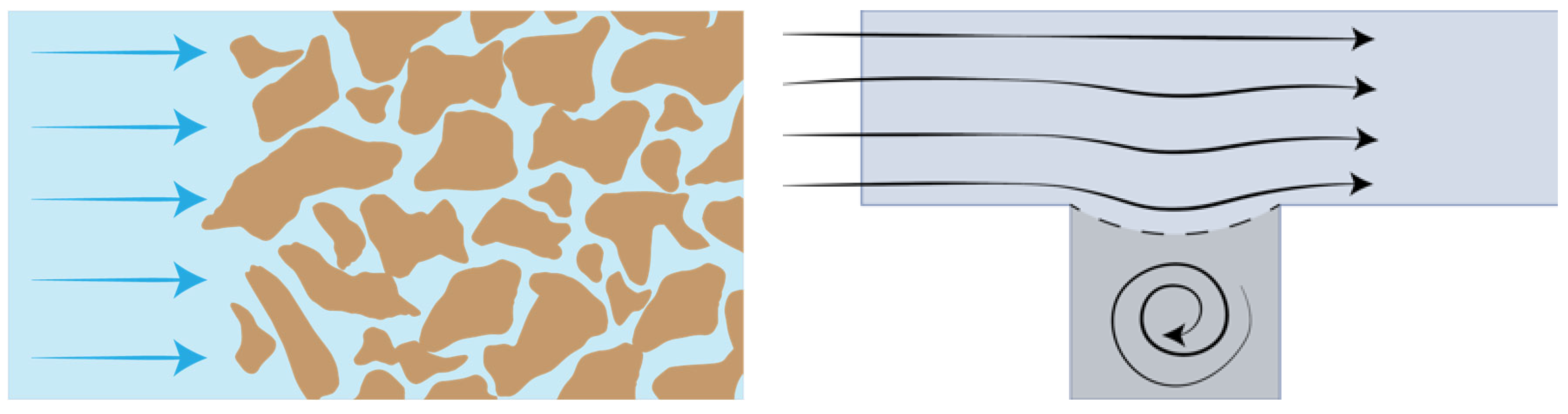

1. Introduction

2. Related Work

2.1. Flows Past Cavities

2.2. Pore-Scale Flow Modeling

2.3. Our Previous Work

3. Methods

4. Results

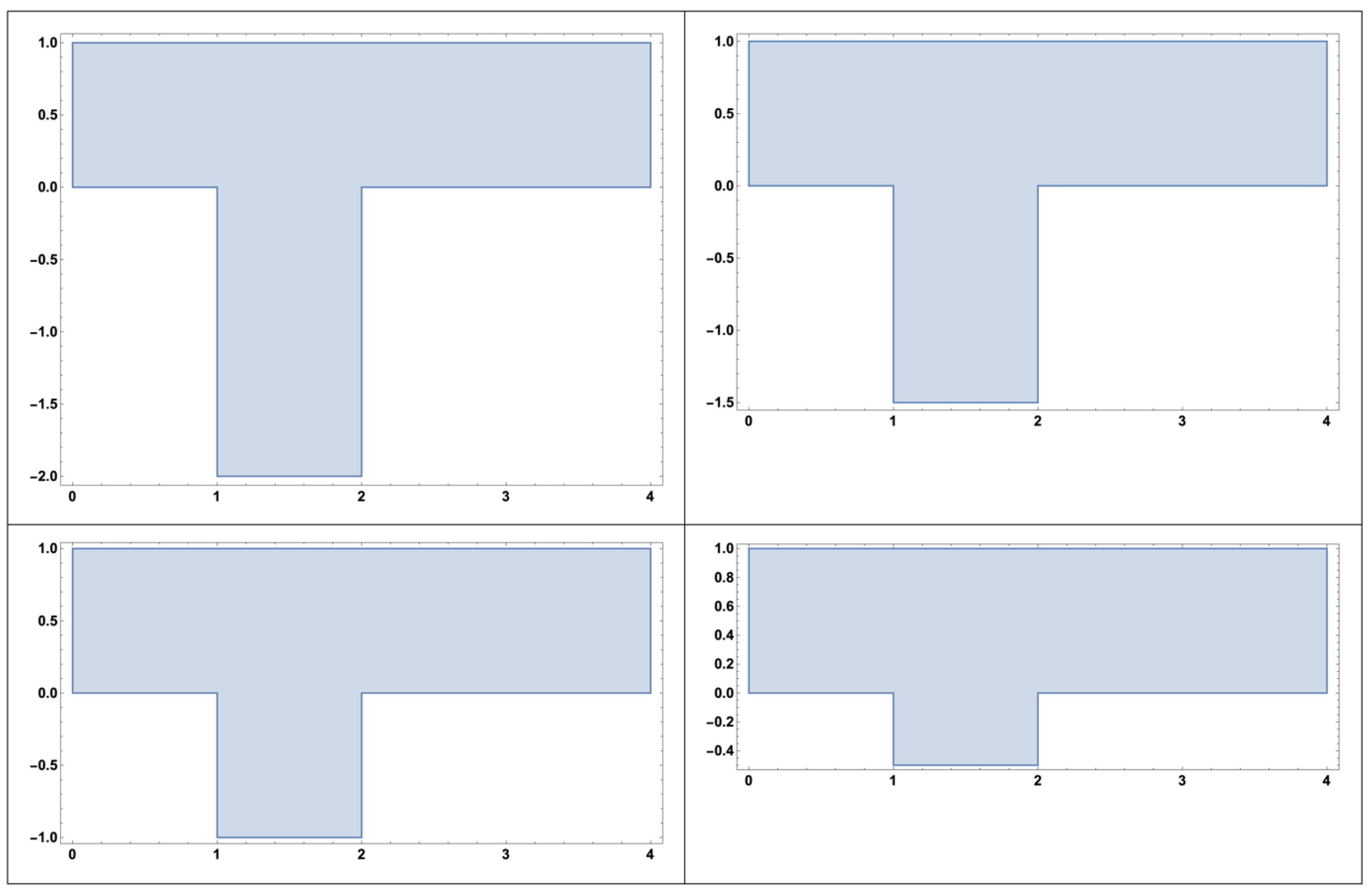

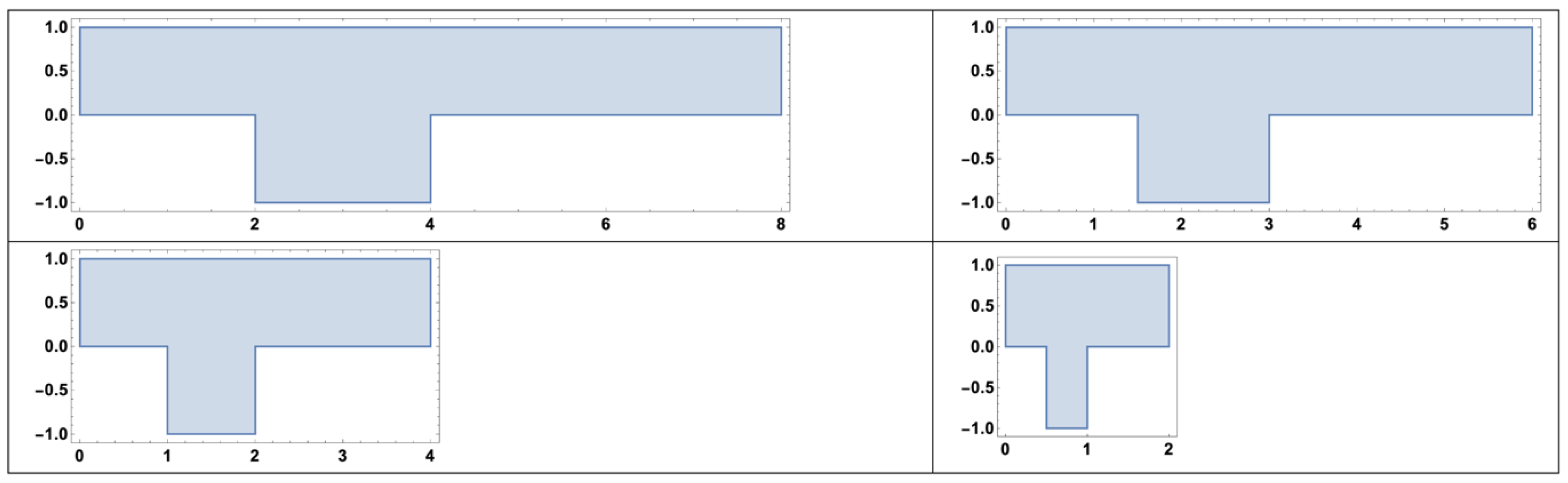

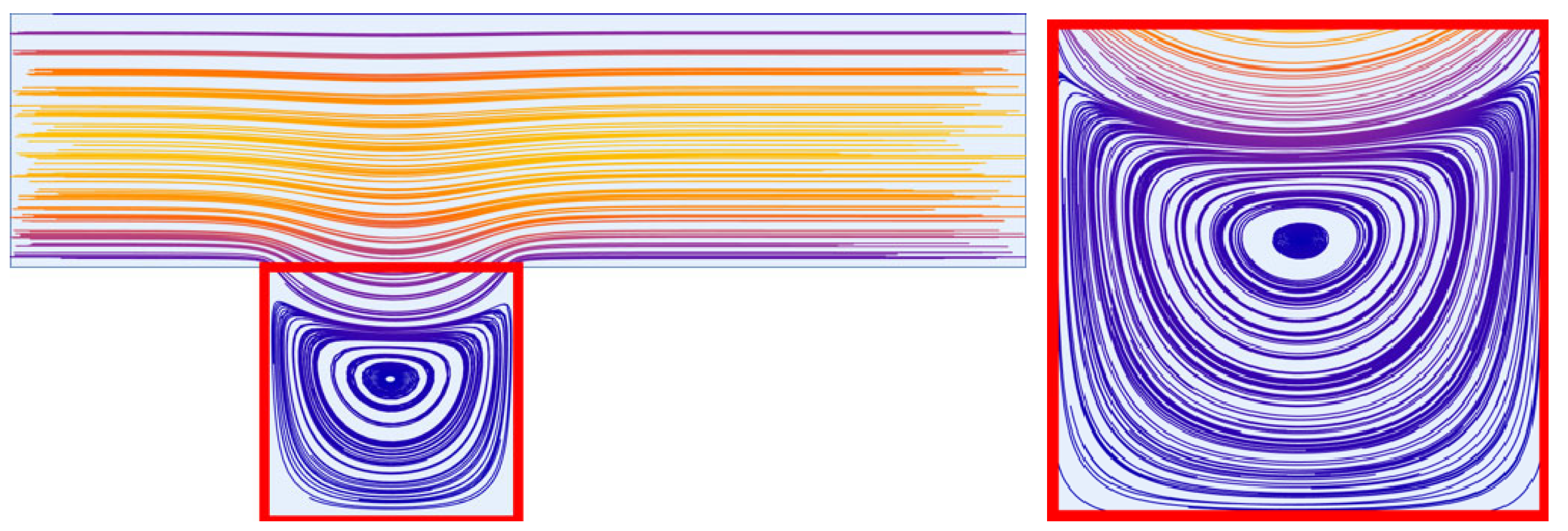

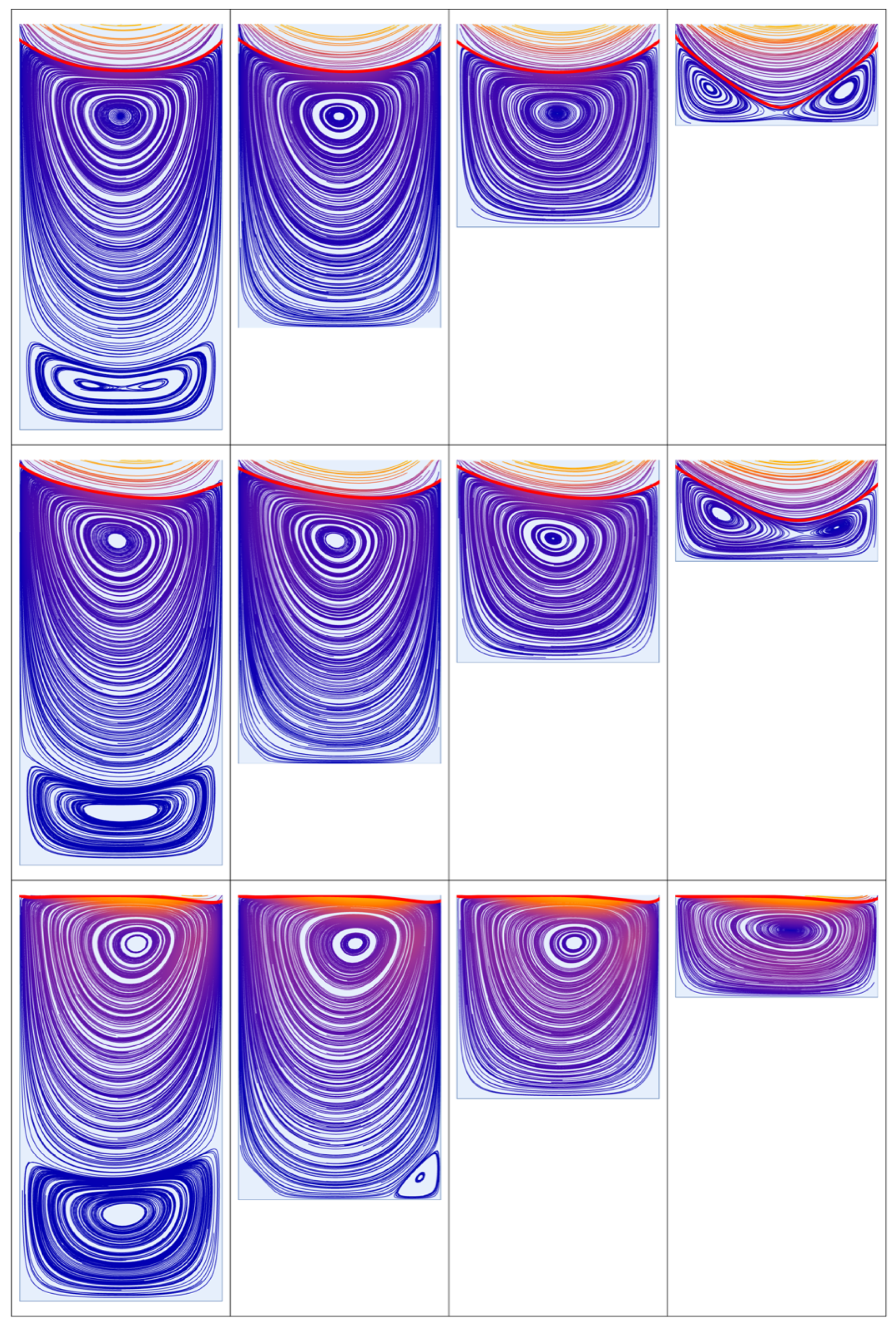

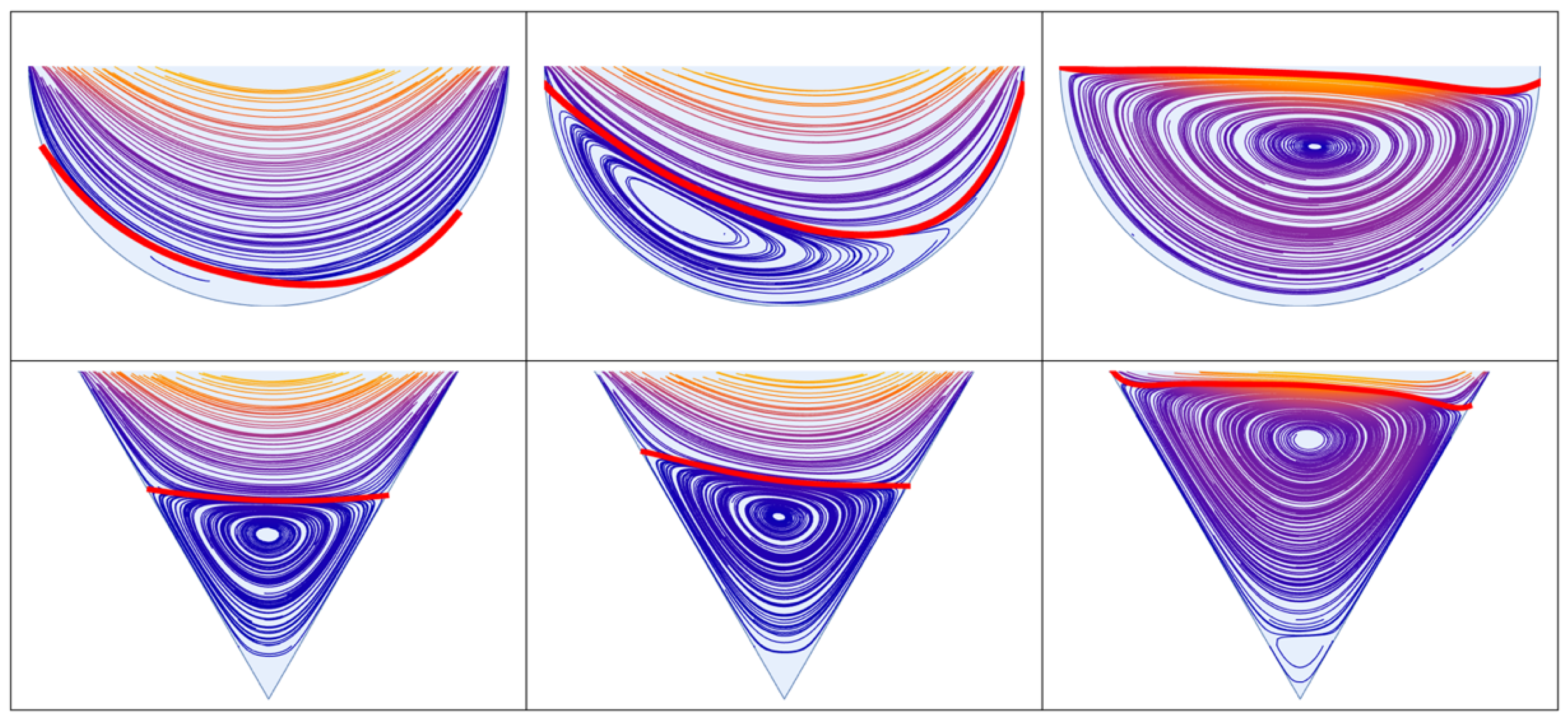

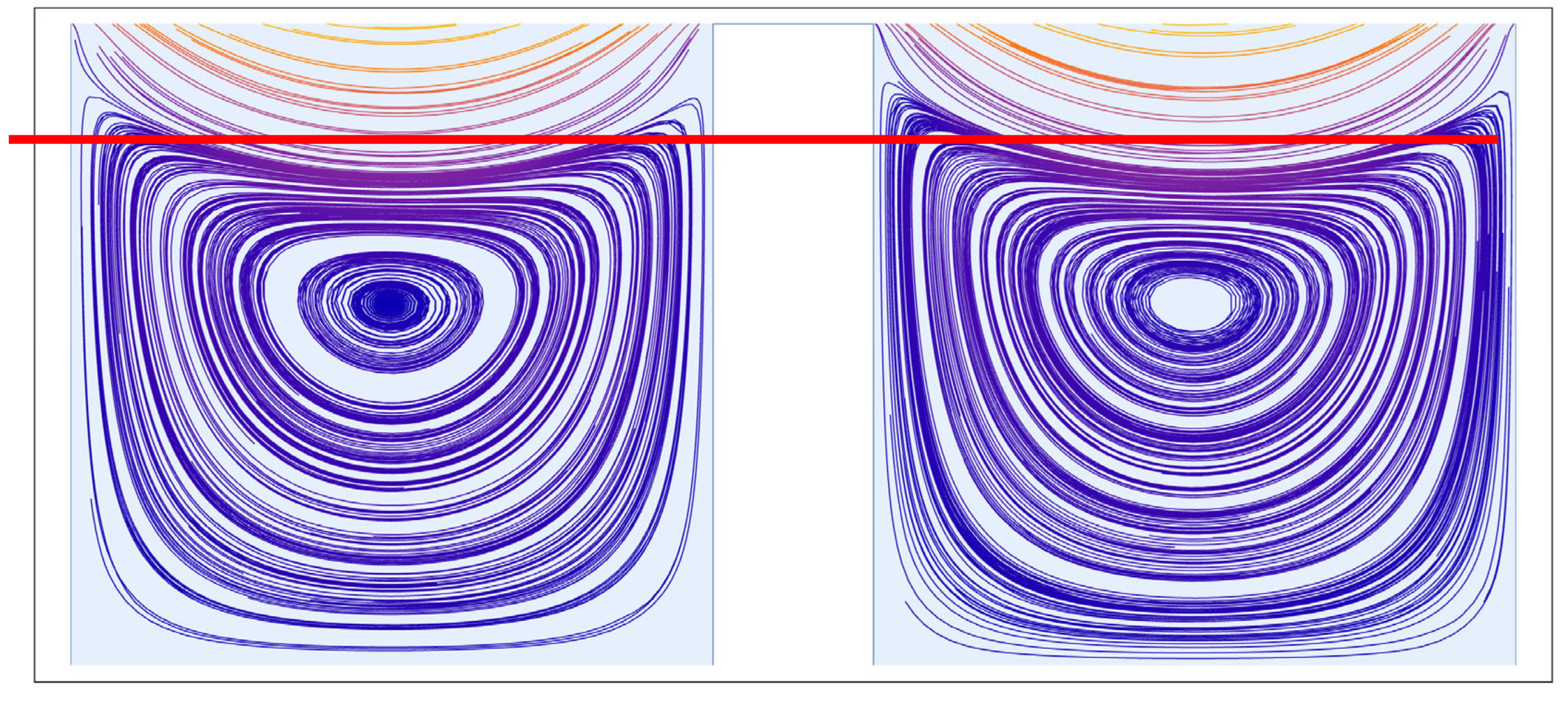

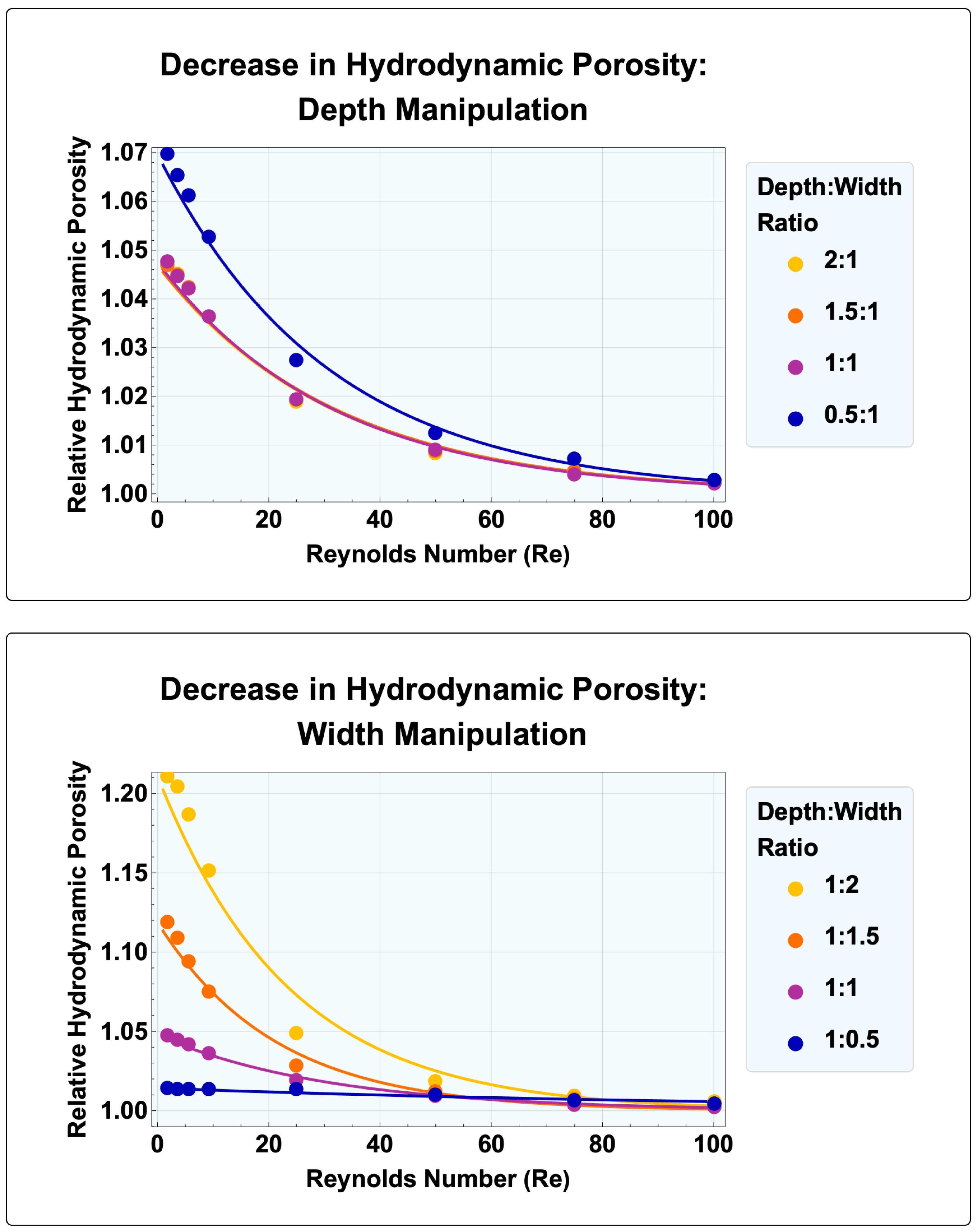

4.1. Separatrix Movement: Rectangular Cavity Geometry Manipulation

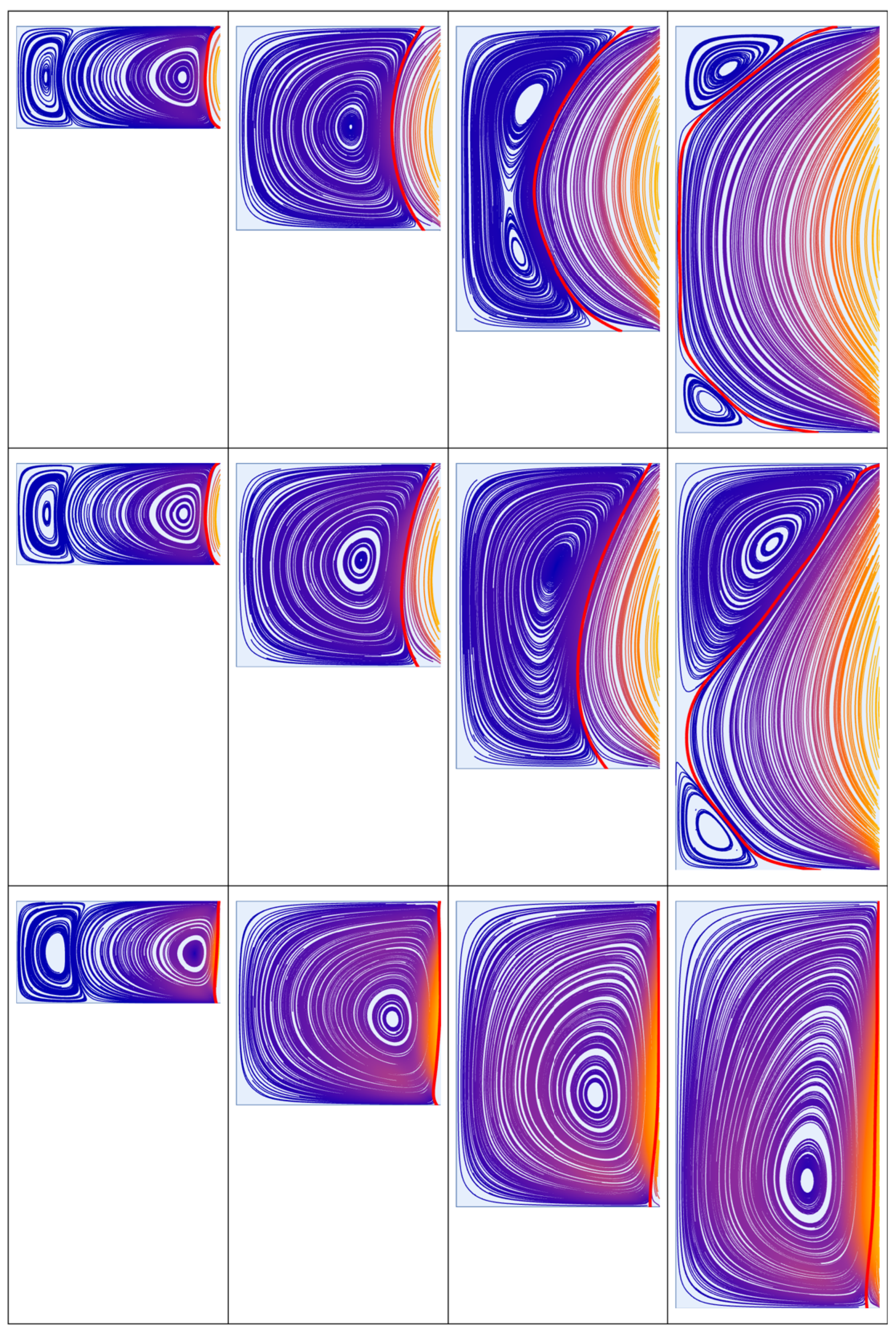

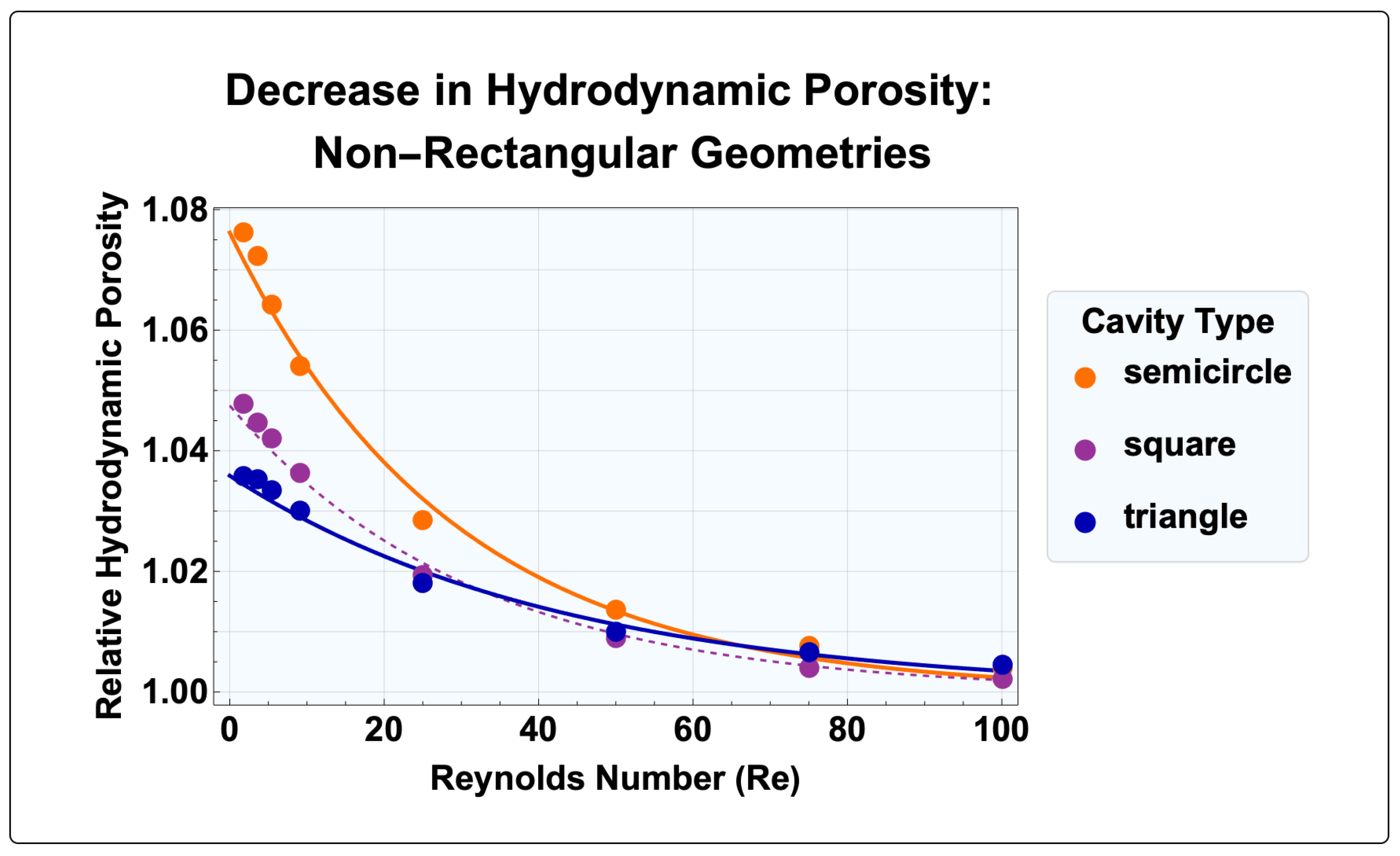

4.2. Separatrix Movement: Non-Rectangular Cavity Geometries

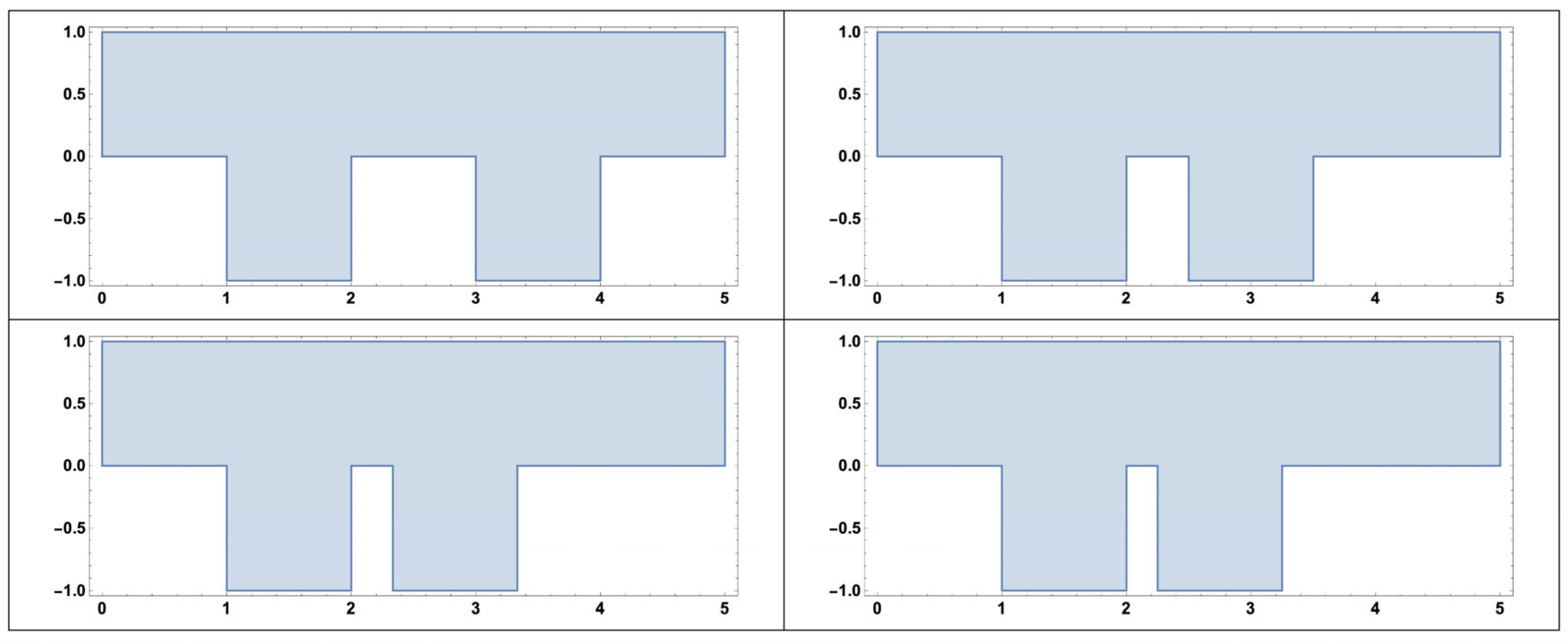

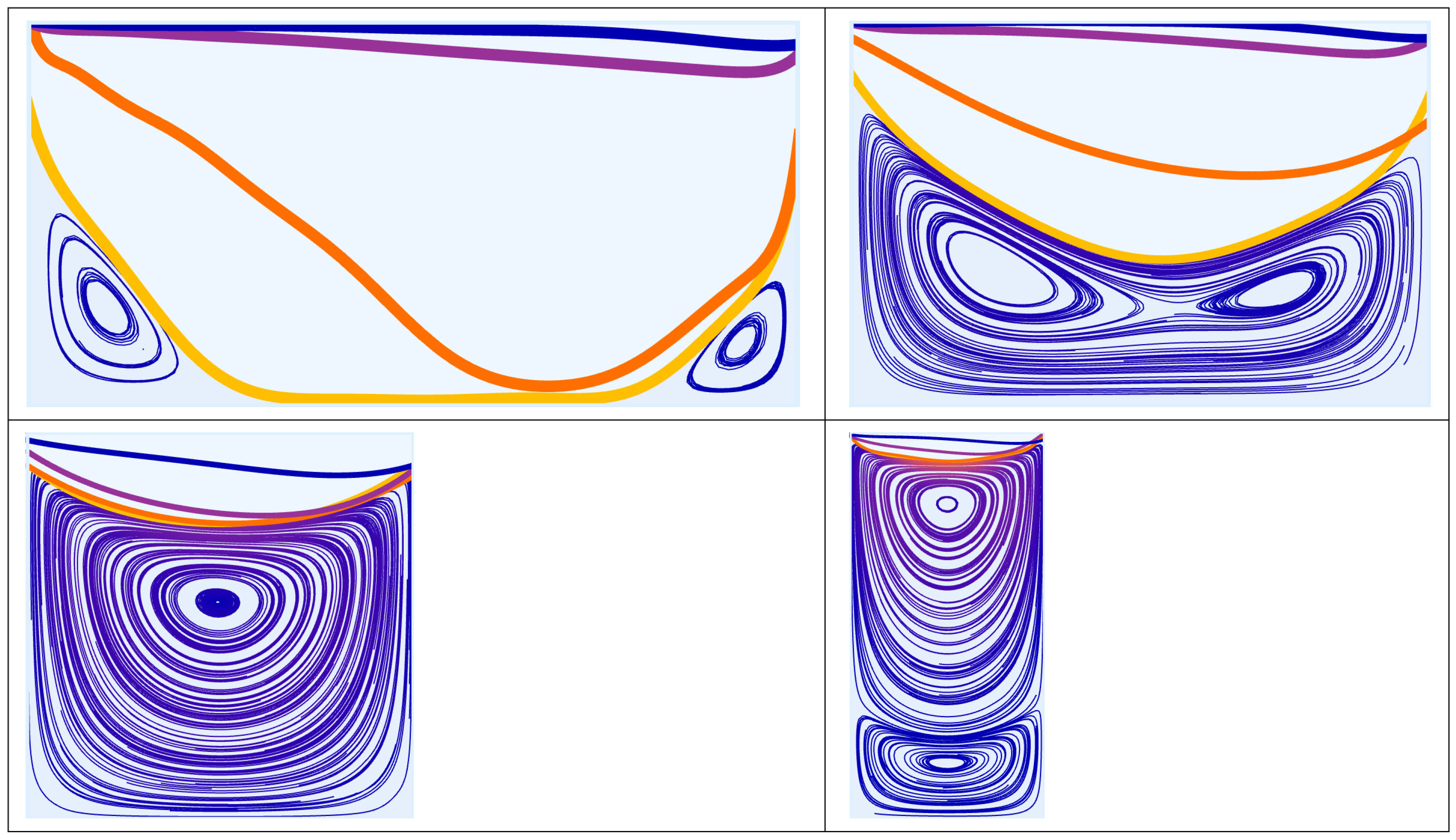

4.3. Separatrix Movement: Periodic Cavity Geometry

4.4. Applying the Exponential Dependence of Hydrodynamic Porosity on Pore-Scale Flow Velocity

4.5. Sampling Error

5. Discussion

6. Study Limitations

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Worthington, S.R. Estimating effective porosity in bedrock aquifers. Groundwater 2022, 60, 169–179. [Google Scholar] [CrossRef]

- Yan, S.; Yang, M.; Sun, C.; Xu, S. Liquid Water Characteristics in the Compressed Gradient Porosity Gas Diffusion Layer of Proton Exchange Membrane Fuel Cells Using the Lattice Boltzmann Method. Energies 2023, 16, 6010. [Google Scholar] [CrossRef]

- Meier, H.; Zimmerhackl, E.; Zeitler, G. Modeling of colloid-associated radionuclide transport in porous groundwater aquifers at the Gorleben site, Germany. Geochem. J. 2003, 37, 325–350. [Google Scholar] [CrossRef]

- Coats, K.H.; Smith, B.D. Dead-End Pore Volume and Dispersion in Porous Media. Soc. Petrol. Eng. J. 1964, 4, 73–84. [Google Scholar] [CrossRef]

- Yuan, Y.; Rezaee, R. Comparative Porosity and Pore Structure Assessment in Shales: Measurement Techniques, Influencing Factors and Implications for Reservoir Characterization. Energies 2019, 12, 2094. [Google Scholar] [CrossRef]

- Li, B.; Li, X.-S.; Li, G.; Jia, J.-L.; Feng, J.-C. Measurements of Water Permeability in Unconsolidated Porous Media with Methane Hydrate Formation. Energies 2013, 6, 3622–3636. [Google Scholar] [CrossRef]

- Foroughi, S.; Bijeljic, B.; Gao, Y.; Blunt, M.J. Incorporation of Sub-Resolution Porosity into Two-Phase Flow Models with a Multiscale Pore Network for Complex Microporous Rocks. Water Resour. Res. 2024, 60, e2023WR036393. [Google Scholar] [CrossRef]

- Verbovšek, T. Variability of Double-Porosity Flow, Interporosity Flow Coefficient λ and Storage Ratio ω in Dolomites. Water 2024, 16, 1072. [Google Scholar] [CrossRef]

- Fenni, M.; Guellal, M.; Hamimid, S. Influence of Porosity Properties on Natural Convection Heat Transfer in Porous Square Cavity. Phys. Fluids 2024, 36, 056108. [Google Scholar] [CrossRef]

- Kango, R.; Chandel, A.; Shankar, V. A Statistical Model for Estimating Porosity Based on Various Parameters of Flow Through Porous Media. Water Pract. Technol. 2024, 19, 1936–1947. [Google Scholar] [CrossRef]

- Yao, P.; Zhang, J.; Qin, Z.; Fan, A.; Feng, G.; Vandeginste, V.; Zhang, P.; Zhang, X. Effect of Pore Structure Heterogeneity of Sandstone Reservoirs on Porosity-Permeability Variation by Using Single-Multi-Fractal Models. ACS Omega 2024, 9, 23339–23354. [Google Scholar] [CrossRef] [PubMed]

- Young, A.H.; Kabala, Z.J. Hydrodynamic Porosity: A New Perspective on Flow Through Porous Media, Part I. Water 2024, 16, 2158. [Google Scholar] [CrossRef]

- van Genuchten, M.T.; Wierenga, P.J. Mass-Transfer Studies in Sorbing Porous-Media. I. Analytical Solutions. Soil Sci. Soc. Am. J. 1976, 40, 473–480. [Google Scholar] [CrossRef]

- Moffatt, H.K. Viscous and Resistive Eddies near a Sharp Corner. J. Fluid Mech. 1963, 18, 1–18. [Google Scholar] [CrossRef]

- Higdon, J.J.L. Stokes Flow in Arbitrary Two-Dimensional Domains: Shear Flow over Ridges and Cavities. J. Fluid Mech. 1985, 159, 195–226. [Google Scholar] [CrossRef]

- Shen, C.; Floryan, J.M. Low Reynolds Number Flow over Cavities. Phys. Fluids 1985, 28, 3191–3202. [Google Scholar] [CrossRef]

- Fang, L.C.; Cleaver, J.W.; Nicolaou, D. Hydrodynamic Cleansing of Cavities. In Proceedings of the 8th International Conference on Computational Methods and Experimental Measurements (CMEM 97), Rhodes, Greece, 21–23 May 1997; pp. 391–401. [Google Scholar]

- Mehta, U.B.; Lavan, Z. Flow in a Two-Dimensional Channel with a Rectangular Cavity. J. Appl. Mech. 1969, 36, 897–901. [Google Scholar] [CrossRef]

- O’Brien, V. Closed Streamlines Associated with Channel Flow over a Cavity. Phys. Fluids 1972, 15, 2089–2097. [Google Scholar] [CrossRef]

- O’Neill, M.E. Separation of a Slow Linear Shear-Flow from a Cylindrical Ridge or Trough in a Plane. Z. Angew. Math. Phys. 1977, 28, 439–448. [Google Scholar] [CrossRef]

- Kahler, D.M.; Kabala, Z.J. Acceleration of Groundwater Remediation by Deep Sweeps and Vortex Ejections Induced by Rapidly Pulsed Pumping. Water Resour. Res. 2016, 52, 3930–3940. [Google Scholar] [CrossRef]

- Kang, I.S.; Chang, H.N. The Effect of Turbulence Promoters on Mass-Transfer—Numerical-Analysis and Flow Visualization. Int. J. Heat Mass Transf. 1982, 25, 1167–1181. [Google Scholar] [CrossRef]

- Alkire, R.C.; Deligianni, H.; Ju, J.B. Effect of Fluid-Flow on Convective-Transport in Small Cavities. J. Electrochem. Soc. 1990, 137, 818–824. [Google Scholar] [CrossRef]

- Horner, M.; Metcalfe, G.U.; Wiggins, S.; Ottino, J.M. Transport Enhancement Mechanisms in Open Cavities. J. Fluid Mech. 2002, 452, 199–229. [Google Scholar] [CrossRef]

- Wolfram Numerical Solutions of PDEs. Available online: https://reference.wolfram.com/language/tutorial/NDSolvePDE.html (accessed on 15 June 2024).

- Takematsu, M. Slow viscous flow past a cavity. J. Phys. Soc. Jpn. 1966, 21, 1816–1821. [Google Scholar] [CrossRef]

- Friedman, M. Flow in a circular pipe with recessed walls. J. Fluid Mech. 1970, 37, 5–8. [Google Scholar] [CrossRef]

- Stevenson, J.F. Flow in a tube with a circumferential wall cavity. J. Appl. Mech. Trans. ASME 1973, 40, 355–361. [Google Scholar] [CrossRef]

- Driesen, C.H.; Kuerten, J.G.M.; Streng, M. Low-Reynolds-number flow over partially covered cavities. J. Eng. Math. 1998, 34, 3–21. [Google Scholar] [CrossRef]

- Taneda, S. Visualization of separating Stokes flows. J. Phys. Soc. Jpn. 1979, 46, 1935–1942. [Google Scholar] [CrossRef]

- Shankar, P.N.; Deshpande, M.D. Fluid Mechanics in the Driven Cavity. Annu. Rev. Fluid Mech. 2000, 32, 93–136. [Google Scholar] [CrossRef]

- Laskowska, A. Experimental Studies of Flows in Porous Media and Selected Models of the Pore Space. Ph.D. Dissertation, Strata Mechanics Research Institute Polish Academy, Krakow, Poland, 1996; p. 179. [Google Scholar]

- Pan, F.; Acrivos, A. Steady flows in rectangular cavities. J. Fluid Mech. 1967, 28, 643–655. [Google Scholar] [CrossRef]

- Jolls, K.R.; Hanratty, T.J. Transition to Turbulence for Flow through a Dumped Bed of Spheres. Chem. Eng. Sci. 1966, 21, 1185–1191. [Google Scholar] [CrossRef]

- Wegner, T.H.; Karabelas, A.J.; Hanratty, T.J. Visual Studies of Flow in a Regular Array of Spheres. Chem. Eng. Sci. 1971, 26, 59–63. [Google Scholar] [CrossRef]

- Latifi, M.A.; Midoux, N.; Storck, A.; Gence, J.N. The Use of Micro-Electrodes in the Study of the Flow Regimes in a Packed-Bed Reactor with Single-Phase Liquid Flow. Chem. Eng. Sci. 1989, 44, 2501–2508. [Google Scholar] [CrossRef]

- Rode, S.; Midoux, N.; Latifi, M.A.; Storck, A.; Saatdjian, E. Hydrodynamics of Liquid Flow in Packed Beds: An Experimental Study Using Electrochemical Shear Rate Sensors. Chem. Eng. Sci. 1994, 49, 889–900. [Google Scholar] [CrossRef]

- Bu, S.; Yang, Y.; Zhang, X.; Tao, W. Experimental Study of Transition Flow in Packed Beds of Spheres with Different Particle Sizes Based on Electrochemical Microelectrodes Measurement. Appl. Therm. Eng. 2014, 73, 1525–1532. [Google Scholar] [CrossRef]

- Elderkin, R.H. Separatrix Structure for Elliptic Flows. Am. J. Math. 1975, 97, 221–247. [Google Scholar] [CrossRef]

- Weiss, J.B. Transport and Mixing in Traveling Waves. Phys. Fluids A 1991, 3, 1379–1384. [Google Scholar] [CrossRef]

| Cavity Geometry | ||

|---|---|---|

| Rectangular | Non-Rectangular | Periodic |

| Equation (1) Exponential Fit Parameters | ||||

|---|---|---|---|---|

| Cavity Geometry | ||||

| Square | 0.80 | 3.80 | 3.19 | 0.9999 |

| Rectangle | ||||

| 2:1 | 0.67 | 3.13 | 3.16 | 0.9998 |

| 1.5:1 | 0.73 | 3.41 | 3.11 | 0.9999 |

| 0.5:1 | 0.89 | 6.19 | 3.26 | 0.9999 |

| 1:2 | 0.80 | 16.88 | 4.26 | 0.9999 |

| 1:1.5 | 0.80 | 9.50 | 4.73 | 0.9999 |

| 1:0.5 | 0.80 | 1.14 | 0.91 | 0.9999 |

| Circle | 0.91 | 6.94 | 3.47 | 0.9999 |

| Triangle | 0.90 | 3.24 | 2.33 | 0.9999 |

| % Decrease in Pore-Space Partitioning Coefficient, | |

|---|---|

| Cavity Geometry | Dead-End Pore Geometry |

| Square | 4.10 |

| Rectangle | |

| 2:1 | 4.05 |

| 1.5:1 | 4.04 |

| 0.5:1 | 5.91 |

| 1:2 | 16.09 |

| 1:1.5 | 9.73 |

| 1:0.5 | 0.81 |

| Circle | 6.45 |

| Triangle | 2.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Young, A.H.; Kabala, Z.J. Hydrodynamic Porosity: A New Perspective on Flow through Porous Media, Part II. Water 2024, 16, 2166. https://doi.org/10.3390/w16152166

Young AH, Kabala ZJ. Hydrodynamic Porosity: A New Perspective on Flow through Porous Media, Part II. Water. 2024; 16(15):2166. https://doi.org/10.3390/w16152166

Chicago/Turabian StyleYoung, August H., and Zbigniew J. Kabala. 2024. "Hydrodynamic Porosity: A New Perspective on Flow through Porous Media, Part II" Water 16, no. 15: 2166. https://doi.org/10.3390/w16152166

APA StyleYoung, A. H., & Kabala, Z. J. (2024). Hydrodynamic Porosity: A New Perspective on Flow through Porous Media, Part II. Water, 16(15), 2166. https://doi.org/10.3390/w16152166