1. Introduction

Water distribution systems (WDSs) are lifelines of communities, as they enable security, health, and economic prosperity. The latest American Society of Civil Engineers (ASCE) report card gave a “C” grade for drinking water infrastructure in the United States, highlighting inadequate maintenance and a significant funding gap as the primary causes of its condition [

1]. Key indicators of the condition of our WDSs are the high number of water main breaks and the significant amount of pipeline leakage. Water utilities strive to maintain and retrofit aging infrastructure to minimize water quality problems, leaks, pipe breaks, and energy consumption. Across the globe, water utility operators face multiple challenges daily in keeping up with these goals while considering the infrastructure condition and operational constraints [

2]. Conventional WDS operations are primarily controlled by predefined system settings that are developed based on past data or practical standards. Although conventional operational practices depend on some system conditions, such as tank levels, they are mostly predetermined and intended to provide conservative and safe operations. Therefore, WDS operational strategies do not change in real-time based on prevailing system conditions other than tank levels. This may lead to suboptimal operations resulting in, for example, more energy consumption than optimal. It is estimated that about 30–60% of a city’s energy bill is accounted for by water utilities (water and wastewater) [

3], which is mainly because of pumps (~80%) that are used to distribute drinking water and collect wastewater [

4]. Clearly, reducing the energy demand of water utilities will have a significant positive impact, both in terms of operational cost and environmental sustainability.

Several previous studies focused on optimal pump scheduling using a variety of offline optimization methods [

5,

6]. Initially, local search methods were used, such as linear programming [

7,

8]. Later on, global search methods became more popular, such as simulated annealing [

9], evolutionary algorithms such as genetic algorithms [

10,

11], and ant colony optimization [

12,

13]. Lastly, hybrid optimization methods were introduced to overcome the limitations of local search and global search methods [

14,

15]. In addition to pumps, optimal WDS operations can be achieved through the control of valves; for example, pressure-reducing valves (PRVs) may be controlled to enable leakage reduction through better pressure management [

16]. The optimal joint operation of valves and pumps has not yet been fully exploited [

17], especially in terms of upgrading the computational approaches and overcoming the real-time-process bottlenecks, such as variation in water demand, shortage of monitoring and control devices, and computational efficiency. In addition, many of these previous studies are not real-time focused, which is a gap that needs to be filled using the increasing availability of real-time monitoring data from WDSs.

In addition to the challenge of jointly controlling the pumps and valves, an appropriate operational interval analysis is critical to the optimal control of WDSs. The operational interval (or time step) should be short enough to assume steady-state conditions, while at the same time long enough to allow sufficient computational time. Furthermore, the operational control horizon is important, as WDS conditions change, e.g., water demand varies during the day, and optimal control settings need to respond to those changes before becoming outdated. Several previous studies investigated the concept of near real-time optimal control of WDSs using single- or multiobjective optimization approaches. For a single objective, for example, [

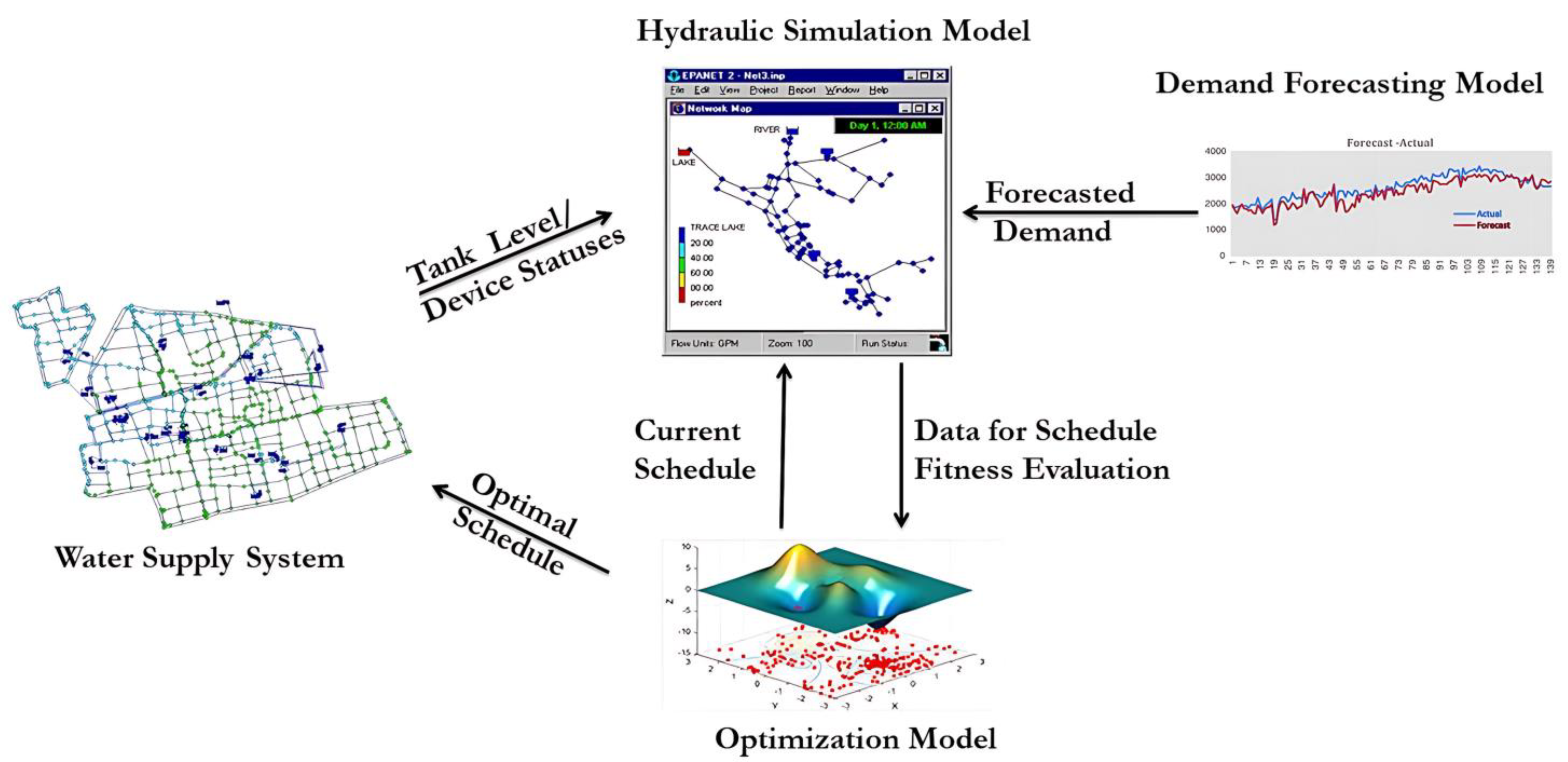

18] presented a pump control framework in near real-time using continuous pump speeds to control the pressure and minimize operational costs. Their optimal pump-scheduling model was developed by coupling water demand forecasting, EPANET hydraulic simulation, and genetic algorithm (GA)-based optimization models [

18]. On the other hand, [

19] developed a multiobjective optimization methodology based on the integration of a multialgorithm-genetically-adaptive-method (AMALGAM), EPANET 2.0 for hydraulic simulations, and water demand forecasting using the DAN2-H model, which is a hybrid model developed by [

20] that uses the error produced by the Fourier series forecasting as input to the dynamic neural network. The Pareto front was determined for two objectives: minimum energy consumption, and maximum operational reliability. The WDS benchmark used in previous studies varied in terms of size and complexity, with some studies considering portions of real-world WDSs or twisted versions to preserve their anonymity, while others considering simplified versions of real-world WDSs for proof-of-concept evaluations. These previous studies only varied pump statuses to control WDS operations, and those controls were determined at once for the upcoming 24 h period. The reported computational time in these studies was more than 16 min for each time step (hourly) considering a 24 h operational horizon.

More recently, [

17] proposed a hybrid near real-time optimization algorithm to control the settings on pumps (i.e., variable speed) and PRVs for maximizing operational efficiency. They used one hour operational time steps, which may be reduced to shorter time steps for better efficiency. Based on a systematic review of relevant previous studies, Mala-Jetmarova reported that the optimal real-time control of WDS devices (pumps and valves) using the predictive approach is a research field still to be fully explored [

21].

Many studies were published on the topic of optimized pump operation for the control of WDSs. In addition, there are a couple of commercially available software applications that have been used to solve this problem for many years, such as Derceto’s (now part of Suez) Aquadapt software and Bentley Darwin Scheduler software. However, the application of these techniques and software in practice has been limited. There are a variety of reasons for the limited practical suitability of such pump optimization-based models. Firstly—optimization complexity—the pump scheduling problem is formulated as a mixed-integer linear program (MILP) due to the changing operational states of pumps. Specifically, it is a nondeterministic polynomial (NP) time-hard problem that is challenging to solve for global optimality for large networks over a long time horizon. Secondly—data availability and requirements—long history data sets are needed for many water demand forecasting algorithms so that reliable predictions are obtained [

22]. Even if the data are available, there are changes in the WDS and water demand baseline over time, which make the use of long-term historical data series less reliable. Thirdly—computational efficiency in the context of real-time models—the models need to run rapidly to respond to the changing hydraulic conditions in WDSs [

23]. Additionally, [

24] mentioned focusing on minimizing energy costs and ignoring system performance as one of the aspects that made previous real-time control schemes impractical for real-world applications.

Taking into account the complexity and computational challenges of operating and controlling WDSs in real-world operating practices, and given that integrated water and energy demand forecasting is highlighted as a priority research area in [

25], this study proposes a handy approach for optimized near real-time operational control that proactively responds to short-term (e.g., every 15, 30, and 60 min) water demand variations, while attaining the energy minimization goal. The proposed framework combines (a) a water demand forecasting model, (b) a network-wide hydraulic model, and (c) an optimization-based control model. Features of the proposed model compared to the existing models include: (1) implementing a shorter time step-based operational control schedule to respond to the dynamic nature of WDSs; (2) jointly optimizing the schedules of varying-speed pumps and valve settings (open/closed/active); and (3) guaranteeing hydraulic continuity between different operational and control time steps by carrying forward the hydraulic statuses (tanks levels, pumps, and valve statuses) derived from actual water demands (as opposed to forecasted water demands) from the preceding time steps.

3. Results and Discussion

3.1. Proposed Real-Time Scheduling Framework Performance

This section attempts to make a reasonable comparison between the model’s performance under different dynamic time steps and the conservative, static scenario where rules are predefined (i.e., the current practice at most water utilities).

Table 2 summarizes the results from each operational scheme in terms of average operational cost over the 24 h horizon period. As expected, a shorter time step duration of 15 min led to more energy-friendly control of WDS operations based on operational costs. Operational efficacy is defined in this study as the capability of a WDS to deliver service to its customers in the most cost-effective manner possible, while still ensuring the acceptable quality of its service by maintaining minimum pressures at the demand nodes and tanks. It can be seen from

Table 2 that a 60 min operational time step in the dynamic analysis resulted in about 17.1% savings in operational costs compared to the baseline scenario, followed by 17.4% for 30 min, and 17.8% for 15 min operational time steps. These savings could be more for larger WDSs. The average computational time needed to complete the control-based optimization for the shortest time step of 15 min duration (which is the most computationally intensive) was found to be less than 11 min in this study when used on a cluster using parallel computing. This is an important consideration for realizing the near real-time control vision, as the computational time cannot exceed the operational time step duration.

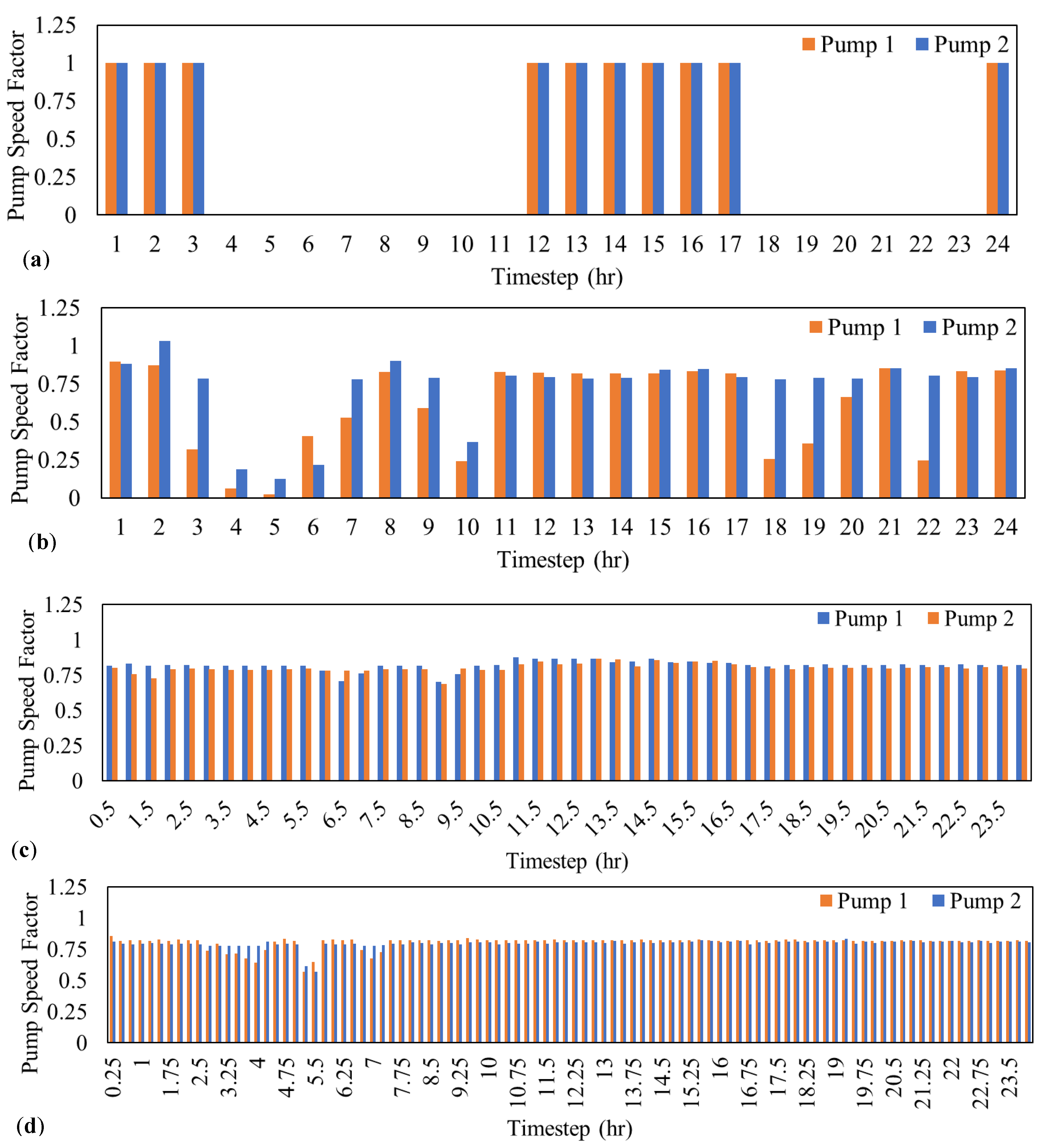

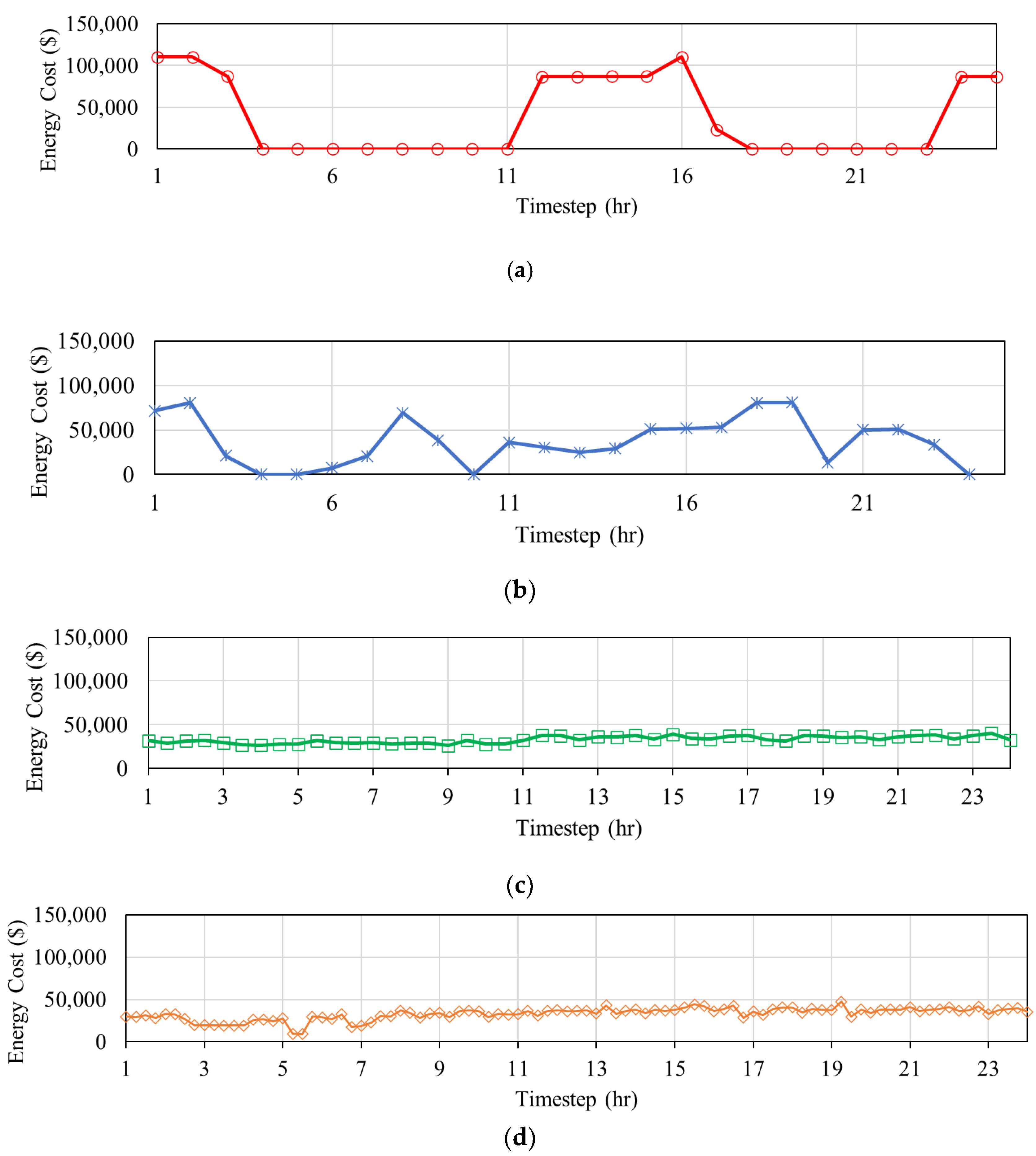

Figure 4 illustrates the schedules of both pumps for all the control schemes. Additionally, the pump energy profile over the 24 h horizon for all time steps is provided in

Figure 5 to illustrate the kind of solutions the real-time control method produced.

The following points provide insights into why the optimal real-time scheme minimized energy consumption compared to the baseline scheme:

In the real-time scheme, energy consumption reduction is achieved by having the operational speed of pumps and valves vary compared to the conservative baseline scenario operations of tanks and pumps, where the criterion for operating a pump is solely based on whether a tank has reached its minimum or maximum level. However, the range within which tank levels can vary remains similar in real-time, dynamic operations to make the scenarios more comparable. One practical reason for the energy reduction is associated with the reduction in the speed, and thus the energy, of the pumps, which sets the priority on energy conservation rather than filling up the tanks suboptimally using pumps running at higher speeds. However, there are other plausible factors contributing to energy conservation, such as dynamic controls of valve settings. According to

Figure 2, some of the valves are strategically located, in that they can alter pressure zone boundaries, and thus the dynamic controls of their settings can contribute to the reduction in the overall system pressure and, hence, the less consumed energy;

Because the objective in the real-time operation is energy conservation, the tank levels have to follow the optimization purpose, and the observation associated with it turns out to be more numbers of fill/draft trends compared to the baseline scenario;

The number of pump switches is not a critical issue, as the pumps undergo speed variations rather than the operationally expensive fact of being “on” or “off”; this means that the pumps experience less friction, fewer constant on/off changes, and thus experience a higher lifespan in the long run.

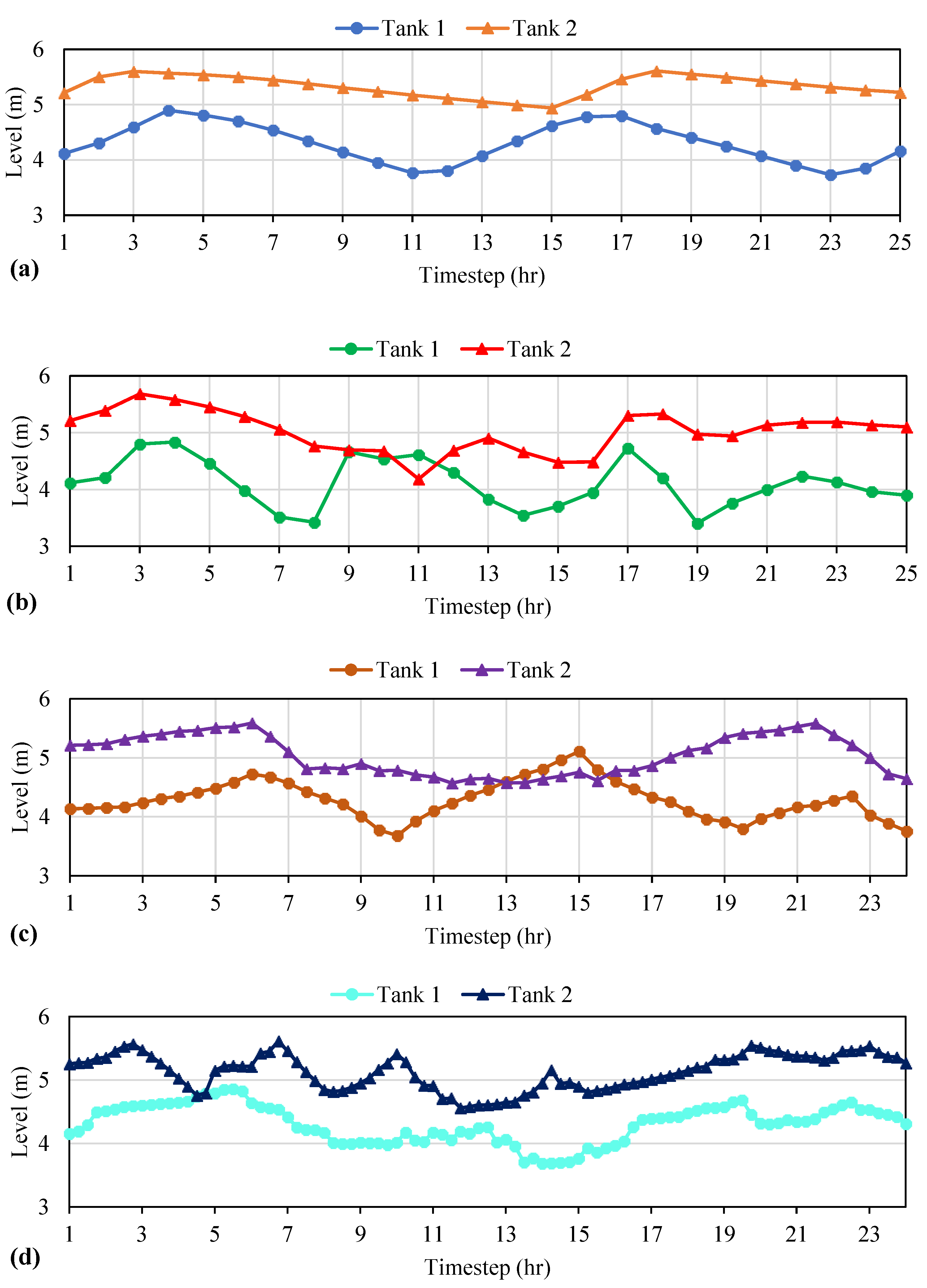

Tank levels for both optimized and baseline schemes over the operational horizon are presented below in

Figure 6. It can be seen that tanks are constrained to run a normal turnover throughout the 24 h horizon for all scenarios. One notable observation is the fact that tanks undergo more cycles of filling and drafting in the real-time scenarios compared to the baseline scenario, which suggests that when pumps are running at lower speeds, tanks play a more significant role than in the baseline scheme.

3.2. Sensitivity Analyses

Sensitivity analyses were conducted to investigate the sensitivity of the proposed near real-time control framework to variation in certain critical model parameters. The sensitivity analysis parameters of interest to be evaluated toward the energy cost in the proposed model are (1) the percentage of actual water demand variation (σ) and (2) minimum tank levels. These parameters are selected based on their importance in operational practices and potential influence on costs and WDS control strategies. All operational time step durations in this study (i.e., 60 min, 30 min, and 15 min) are considered for conducting all the sensitivity analyses using three runs for each analysis. The purpose of this sensitivity analysis is not only to test the robustness of the model under different operational circumstances, but also to compare the model’s performance under the three dynamic time steps to draw inferences as to whether shorter time steps result in better solutions.

3.2.1. Actual Water Demand Variation

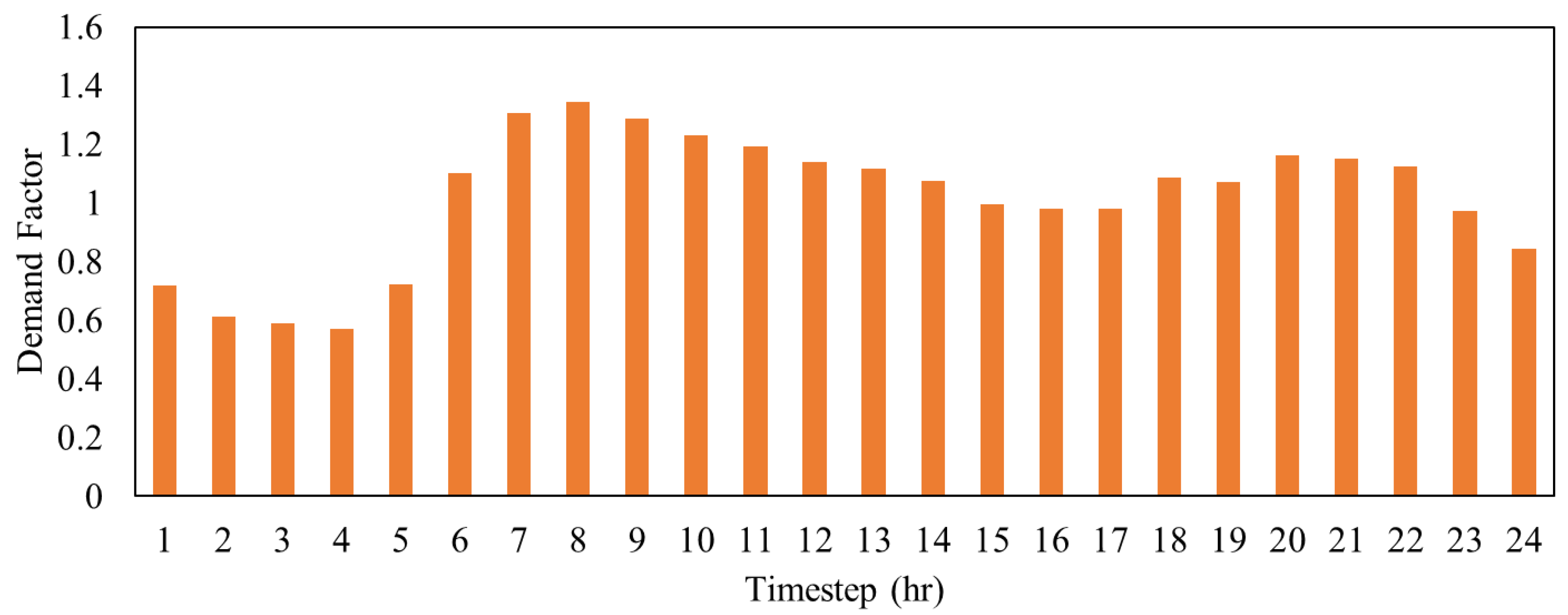

There is uncertainty associated with nodal water demands. This uncertainty has been characterized in this study using ±5% variation compared to the hourly base water demand pattern, as presented in Equation (1). This variation was considered in both past synthetic water demand data that was used in the water demand forecast model, and in the actual nodal demand generation during the hydraulic modeling in this study. The sensitivity of the results from the proposed framework to the variation in the water demand uncertainty is evaluated in this scenario. The water demand variation of ±1% and ±15% are considered in this scenario, while the default scenario considered ±5% variation.

Table 3 illustrates the energy consumption cost, as well as the relative improvement in energy conservation in all dynamic time steps.

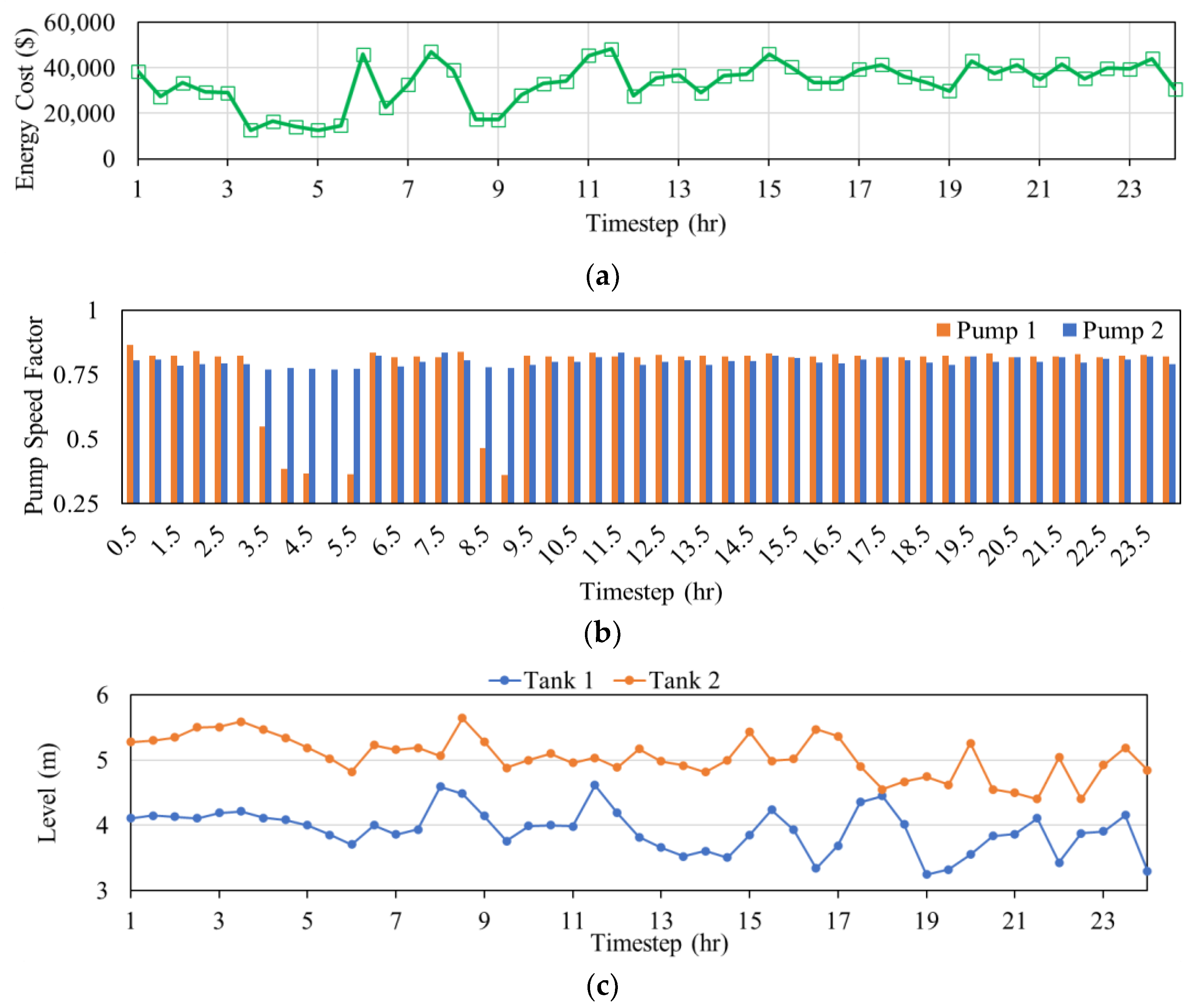

The relative improvements (savings) are associated with the baseline value of the corresponding conventional or real-time scenario. As opposed to the real-time scheme, the conventional method relies on fixed pattern-based demand data; therefore, no dynamic water demand variations are applied in its sensitivity analyses. Accordingly, no significant variations in the operational costs were observed from the results between either of the considered water demand-varied scenarios (i.e., ±15% and ±1%). To showcase a scenario granularly, the ±15% case for the 30 min time step has been depicted in

Figure 7 in terms of operational features. The variations are not much different from those in the dynamic baseline scenario in terms of pump speed factor, tank levels, and energy variations for the 30 min case. Furthermore, according to

Table 3, the ±15% and ±1% scenarios resulted in total energy consumption of roughly within −4% and 1%, respectively, compared to those conservative-scenario values of each time step in

Table 2. This observed lack of sensitivity of the real-time control scheme to water demand variation of up to 15% is likely because the majority of the nodal demands in the BWDN are small (<6.81

), and variation of up to 15% of these water demands may not have affected the system stability to require more pumping. Furthermore, even if the system stability is affected to a certain extent, tanks can be better used in the real-time scheme to meet higher water demands without having to turn on the pumps. Additionally, the energy consumption does not show significant improvements for different dynamic time steps.

3.2.2. Minimum Allowed Tank Levels

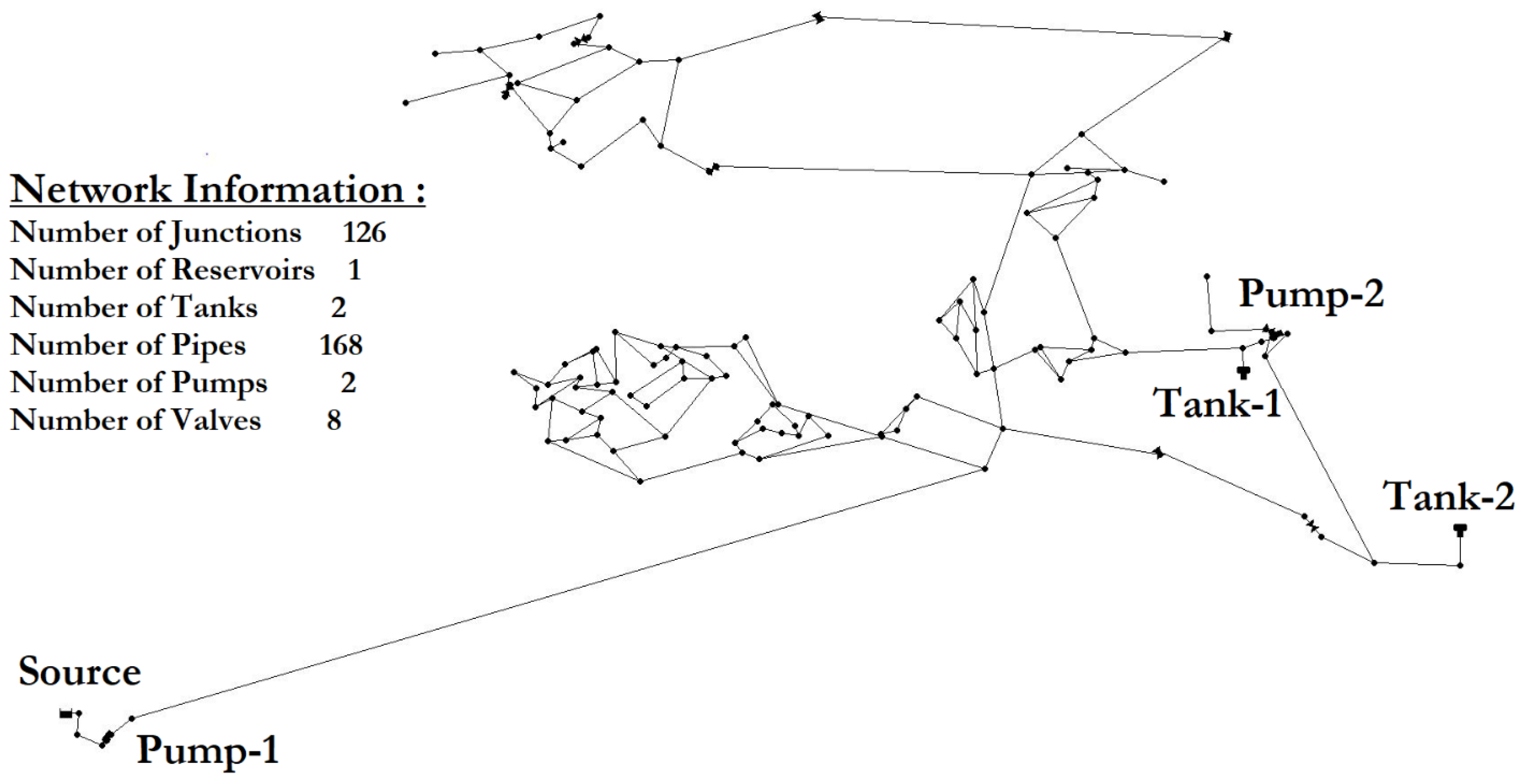

The minimum allowed tank level constraints (derived from the rule-based, conservative scenario) are varied in this scenario to investigate the sensitivity of the results to these parameters. There are two different-sized tanks in the BWDS with a diameter of 56.7 m and 32.3 m, and heights of 32.1 m and 9.8 m, respectively. Minimum allowed tank levels variation was investigated by increasing and decreasing them by one foot (0.305 m) compared to the two tank levels used in the default scenario.

Table 3 demonstrates the effects of the minimum allowed tank levels’ variations on the energy consumption in the conservative vs. dynamic scenarios. As can be observed, relaxing the minimum tank level constraint lowers the energy consumption, whereas tightening the tank level constraint brings about more energy consumption in both the conservative and dynamic approaches. However, according to

Table 3, the conservative approach is much more sensitive to the variations in the allowed minimum tank levels than the dynamic method. The relative savings in the conventional scenario are within a double-digit percentage (13.3% for lowering the tank level constraint by 0.305 m, and −20.5% for increasing the minimum tank level by 0.305 m), whereas those in the dynamic approach for all considered time steps vary within shortly above 1%. Specifically, as can be observed from the results presented in

Table 3, when the minimum tank level constraint increased by 0.305 m, the operational cost in the real-time scheme marginally increased by 1.02%. On the other hand, relaxing constraints by reducing the minimum tank levels by 0.305 m produced lower operational costs, with savings of up to 0.45%. It is noteworthy that there is no linear correlation between the minimum tank levels and energy consumption, but it is found that, as a rule of thumb, increasing the minimum tank levels will increase the energy consumption, and decreasing them will reduce the system energy consumption in all dynamic time steps. Overall, it is fair to state that the dynamic approach shows more resistance than the conservative scenario to maintain a certain level of energy consumption amid variations in the minimum allowed tank levels. This may, in turn, be due both to the dynamicity of pump operations as opposed to flicking them on or off at different time steps, and to the real-time controls of valves that regulate the energy supply more consistently at each time step.

Although tank levels have some direct relation with pump operations, as elevated tanks could use available storage (buffer) to supply the WDS demand and reduce the pump operation times, the system can consume more energy to fill the tanks back up in case the minimum tank levels are lowered. It also applies to the scenario when less energy is required to fill the tanks back up when the minimum tank levels are increased; therefore, the variations of minimum tank levels are found to be slightly impacting the energy consumption in direct relation. There are more increments in cost amid increased allowable minimum tank levels when the dynamic time step is reduced from 60 to 15 min intervals, according to

Table 3. This suggests the existence of more volatility and flexibility in the meta-heuristic optimization model when predicting the next time step.

In the sensitivity analysis section, it was observed that the real-time dynamicity (as opposed to predefined static rules) of operating system components plays a more significant role than merely reducing the time step from 60 min to 15 min. The variations in the parametric assumptions affect the energy consumption much less in the dynamic scenario and more in the conservative scenario.

3.3. Future Work and Limitations

Despite much research in the field of real-time control, it has not evolved enough for water utility practitioners to embrace its various aspects in practice. Multiple practical demonstrations of these approaches need to be undertaken before the experimental or computational research could yield much direct impact [

6].

This study focused on ensuring that the computational time is shorter than the hydraulic time step. For real-time control, the computational time depends on the network size and, to some extent, on the number of sources, tanks, and other components. Still, the authors believe that the computational time can be shorter than a 15 min operational time step, even for very large networks, using the presented approach. The hydraulic simulation can be replaced with a trained neural network with reasonably high accuracy and considerable computational time savings. This claim needs to be validated in future research, and the proposed methodology should be tested with a large real-life WDS with multiple sources, pumps, and tanks to validate its merits. In addition, an extreme demand pattern (peak demand loading) was considered, along with contingency tank storage (minimum tank level) in this study, as reliability measures of WDSs; however, future work needs to address the sensitivity of the proposed approach to unusual and extraordinary events or demand loading, as well as uncertainties in large WDS networks.

Additionally, a multiobjective optimization model could be used to improve the scheduling framework by maximizing the operational resilience as an additional proposed objective that will provide the utility operator with a set of strategies to choose from, depending on how resilient the system is desired to be during potential failures. Another way to upgrade the framework would be adding more constraints to the single objective model, such as minimizing the number of pump switches and minimum operational resilience to keep the advantage of obtaining single optimal settings for each time step, especially in the case of automated operational control management. Additionally, the proposed control framework could be extended to achieve other system-level goals, such as leakage minimization and water quality control. Lastly, future work might include studying the relationship between pumping, tank level variation, water quality, and leakage in order to upgrade the WDS operation practices.

There are limitations of this study that may be addressed in the future. Firstly, the exclusion of real-world energy pricing considerations, such as time-of-day pricing and peak energy demand charges, when estimating the pumps’ operation cost. In future work, it is possible to adapt the proposed approach to include a hybrid control scheme, where the optimization also considers the operational horizon to attempt to minimize the cost based on a time of use (TOU) energy pricing scheme. Secondly, in this study, a constant efficiency of 75% was assumed for the pumps over the full range of operating conditions, which ignored the fact that pump efficiency varies with the flow.

4. Conclusions

A framework for optimized near real-time scheduling for the operation and control of WDSs is proposed and demonstrated in this paper. The operation and speed of pressure-reducing valves (PRVs) and pumps are jointly controlled based on an evolutionary optimization algorithm that is driven by near real-time system monitoring data (e.g., the system’s hydraulic data, tank level, etc.). Energy minimization is considered to be the goal while maintaining minimum pressure and minimum tank levels, as well as real-world tank level considerations as constraints. Dynamic operational control time steps of 60, 30, and 15 min are investigated and compared to the conventional hourly rule-based control for a small-sized WDS benchmark. The results revealed that real-time control schemes reduce the operational costs of the selected WDS between 17.1% and 17.8%, with the shortest time step scheme (15 min) offering the most reduction in operational expenses, at the cost of more computational expensiveness. Furthermore, the sensitivity analyses conducted on the single benchmark water distribution system revealed that the real-time control scheme was not greatly sensitive to the incremental changes in minimum tank levels or actual water demand variations. However, the findings suggested a somewhat direct correlation between minimum tank levels and energy conservation. Moreover, the system’s actual water demand variations due to the uncertainty in the system were found to play an insignificant role in the presented energy conservation scheme. It was also observed that shifting from static, conservative operations of components in a water distribution system to a real-time, dynamic approach provides more energy conservation, real-time knowledge of the system, and thus more flexibility and awareness to interact with the system than merely reducing the time steps to minutes. Lastly, it was found that the average computational time for each run in the shortest real-time control time step of 15 min is less than 11 min, if run on cluster parallel computing nodes.