Integrated Smart Management in WDN: Methodology and Application

Abstract

1. Introduction

- -

- Section 2 presents the fundamentals, the methodological approach and the model development;

- -

- Section 3 presents the description of the case study and the characterization of the analyzed system in terms of water consumption. Moreover, different hydropower solutions are considered and compared in terms of leakage reduction and energy recovery. Finally, an economic analysis is carried out in order to assess the viability of the proposed solutions;

- -

- Section 4 presents the conclusive remarks of the proposed work.

2. Materials and Methods

2.1. Fundamentals

2.2. Methods

- Opening of closed PRVs;

- Setting the minimum pressure downstream of the existing PRVs, with the criterion of verifying the minimum regulatory pressure at the critical points of the network.

- Implementation of two new PRVs, in a strategic location, in order to control pressure on the network and simultaneously study their possible energy use.

- Evaluation of the network leakage simulation.

2.2.1. Model Restrictions

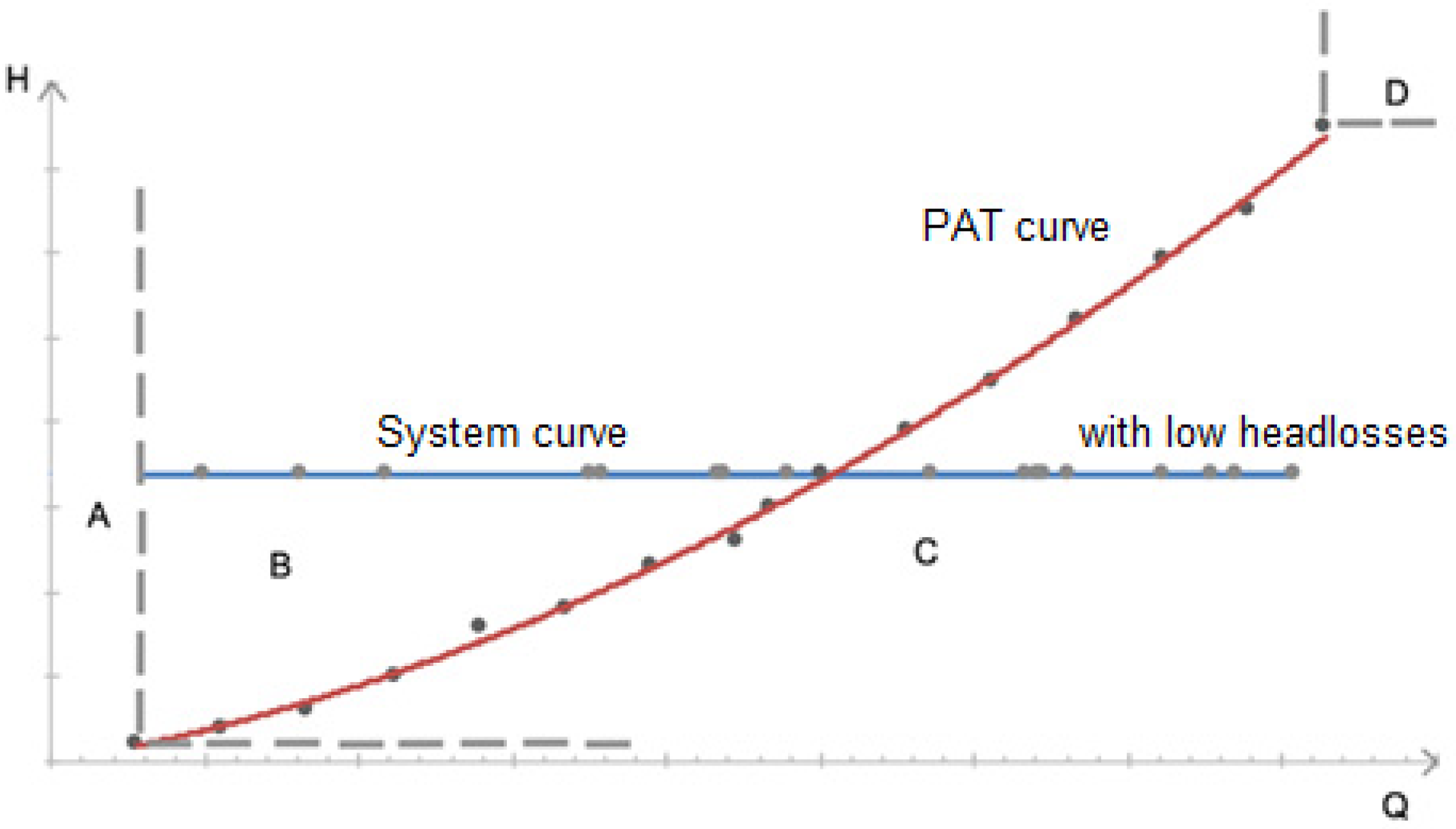

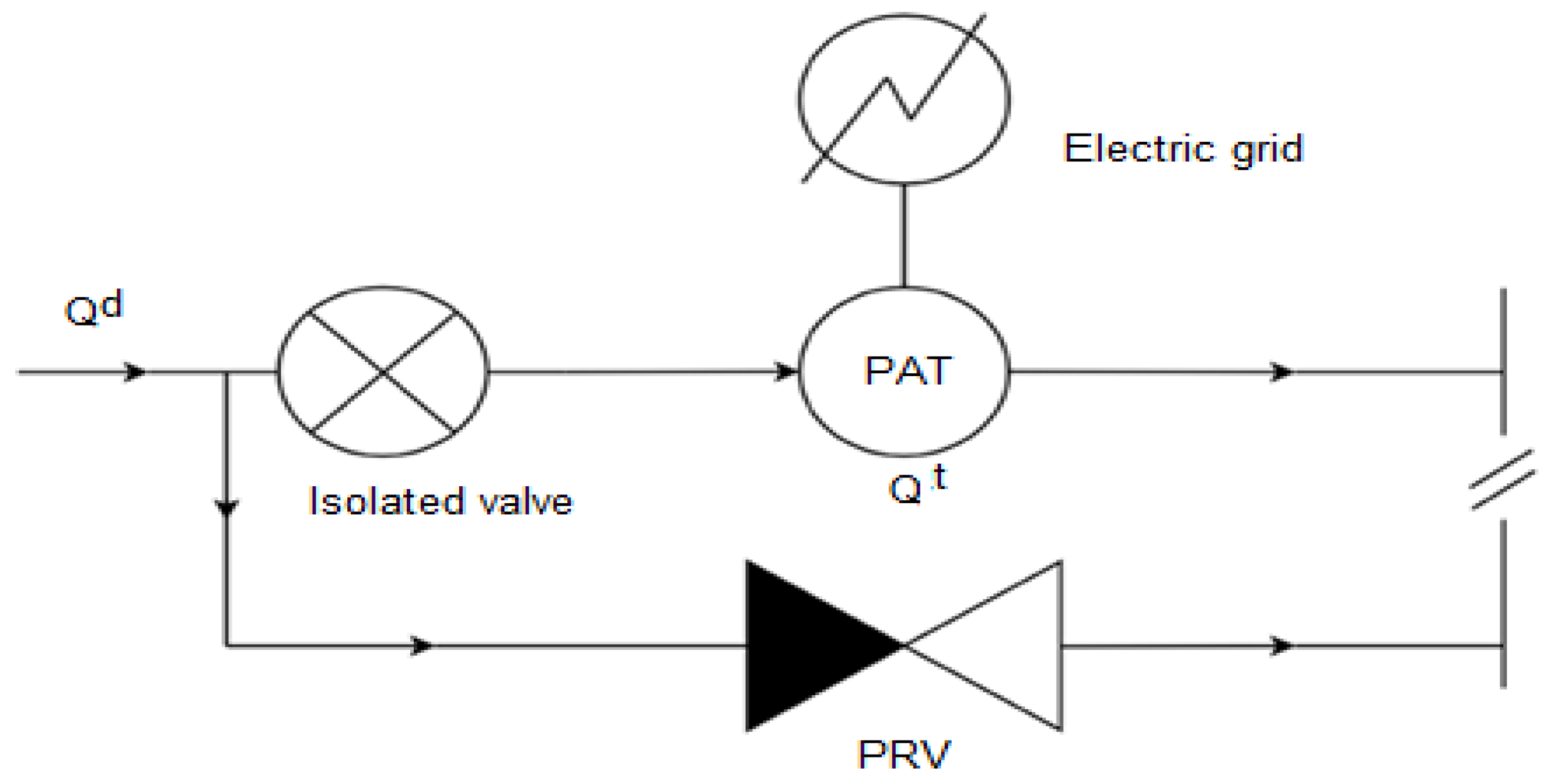

2.2.2. Hydraulic-Energy Simulator Model

2.2.3. Potential Energy Model

2.2.4. Economic Model

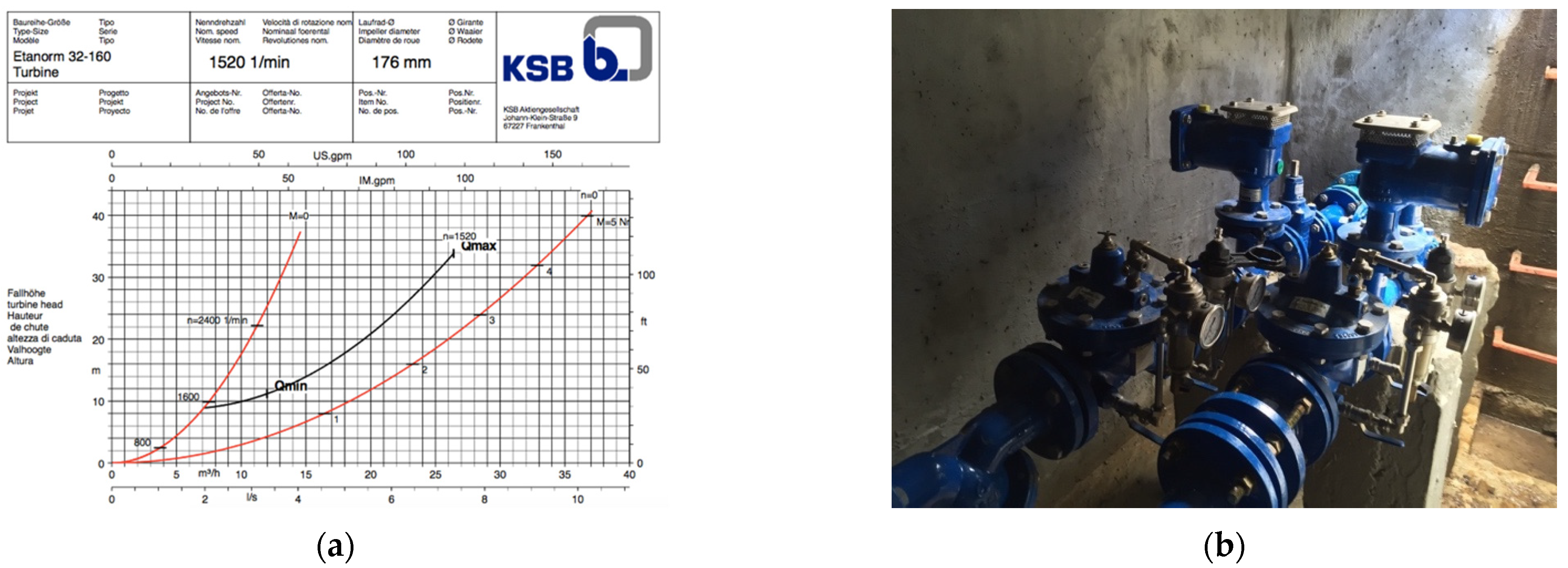

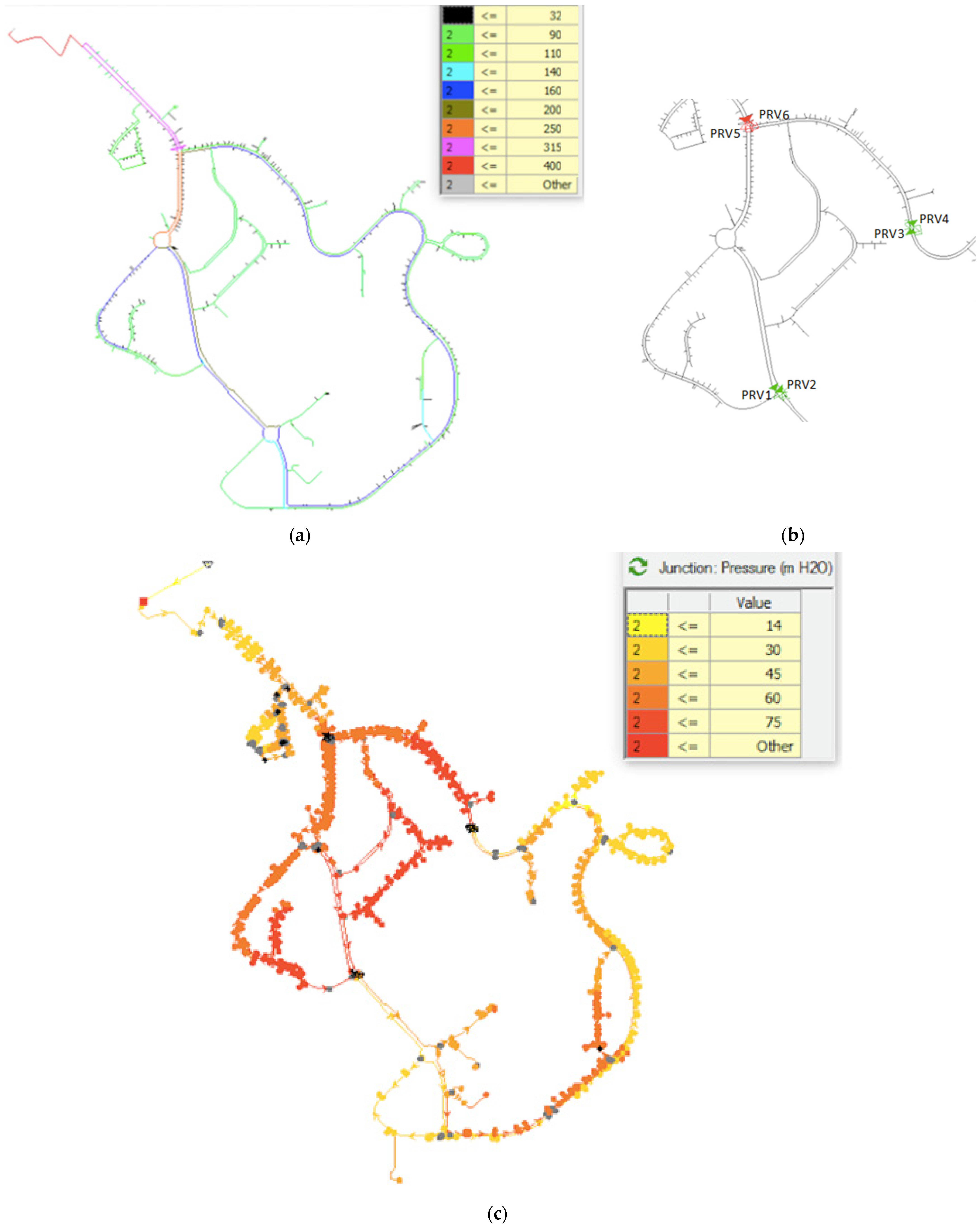

3. Case Study

3.1. Brief Description

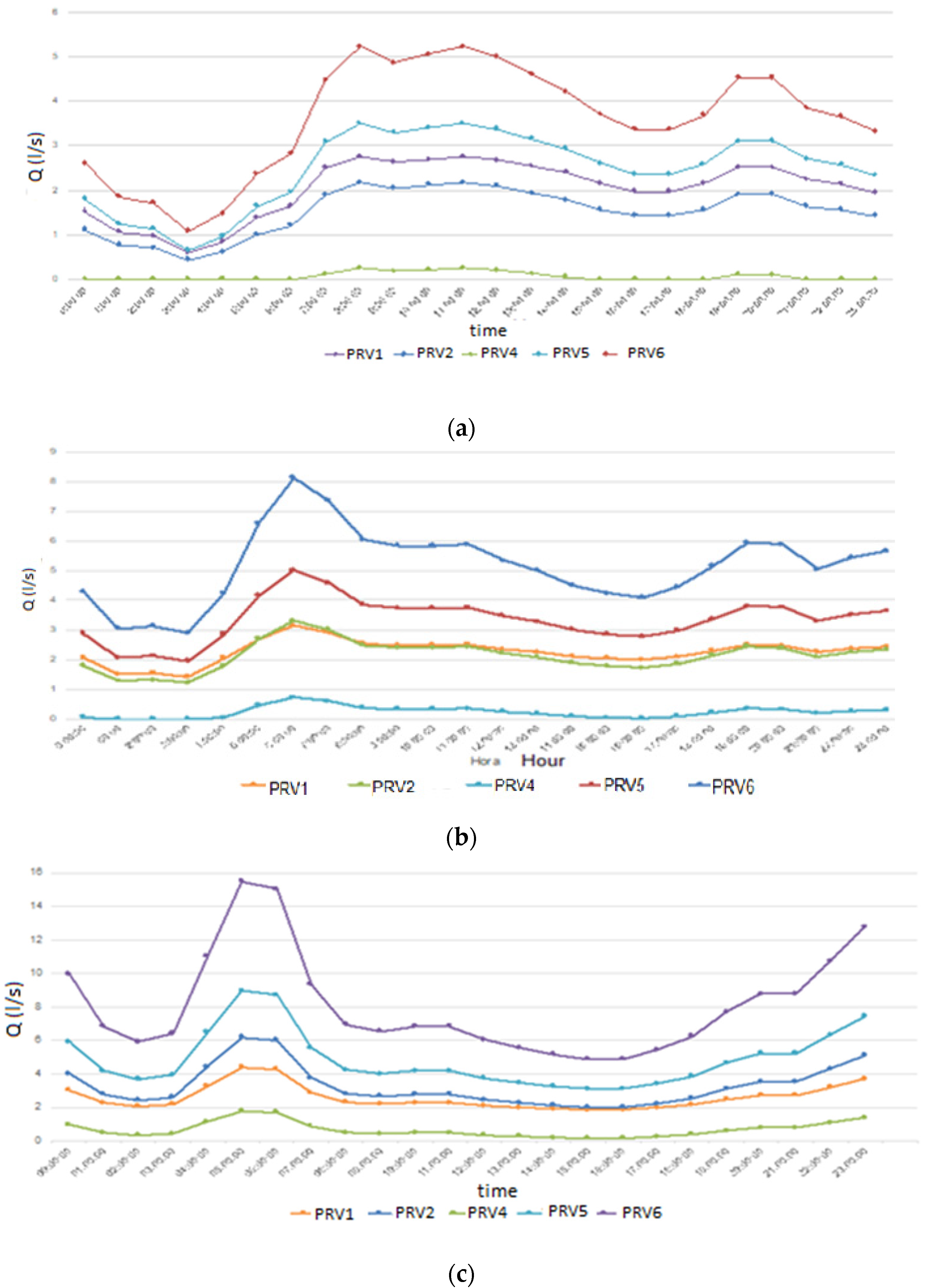

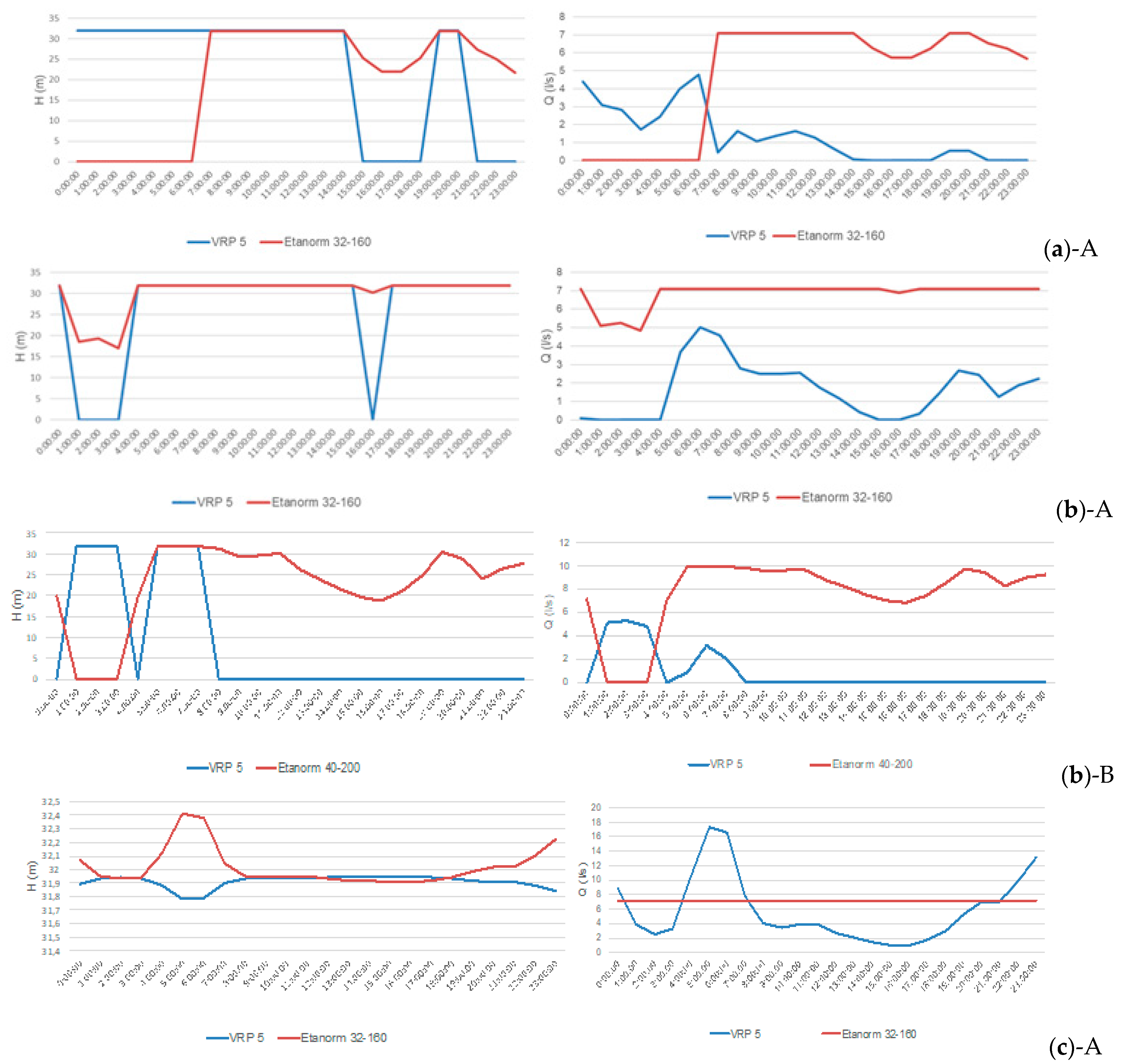

3.2. Results

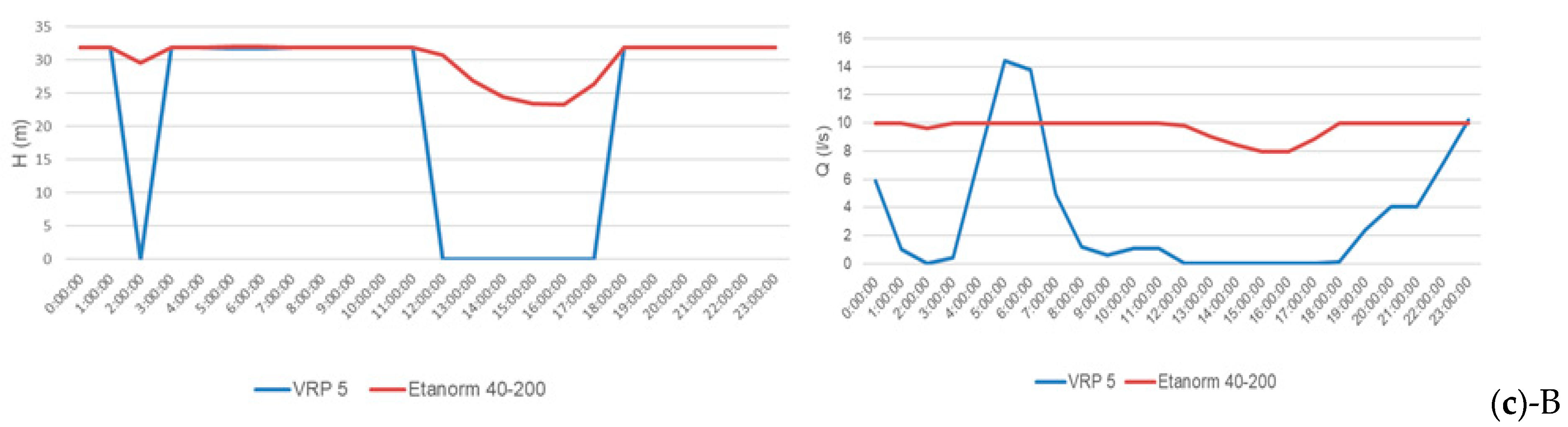

3.2.1. Different Types of Demand Pattern

3.2.2. Water Losses Evaluation

3.2.3. Operating Conditions

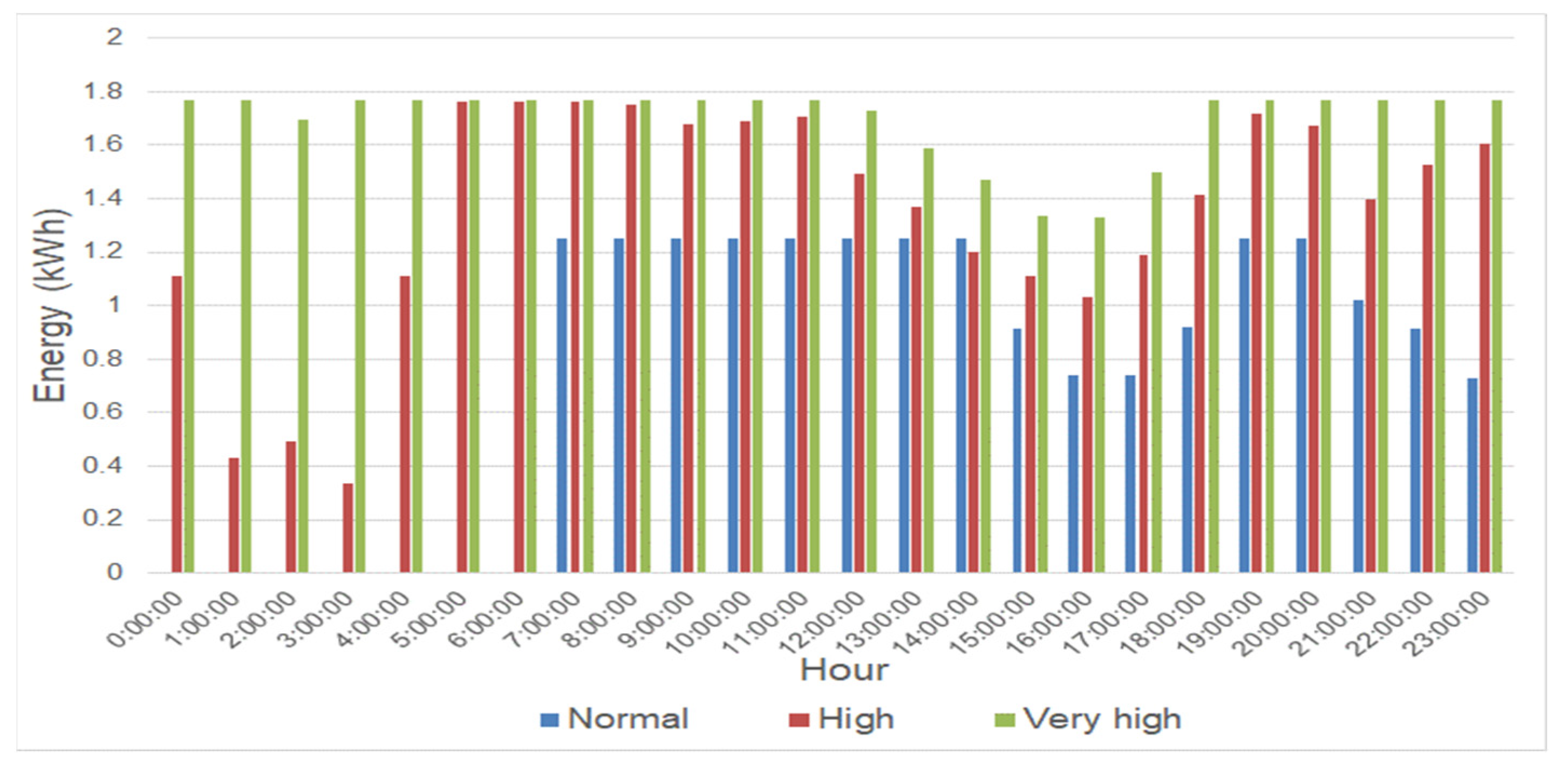

3.2.4. Average Weekly Recovery Energy and System Efficiency

3.2.5. Energetic and Economic Evaluation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| BEP | Best Efficiency Point |

| B/C | Benefit/Cost ratio |

| CC | Characteristic Curve |

| DMA | District Metering Area |

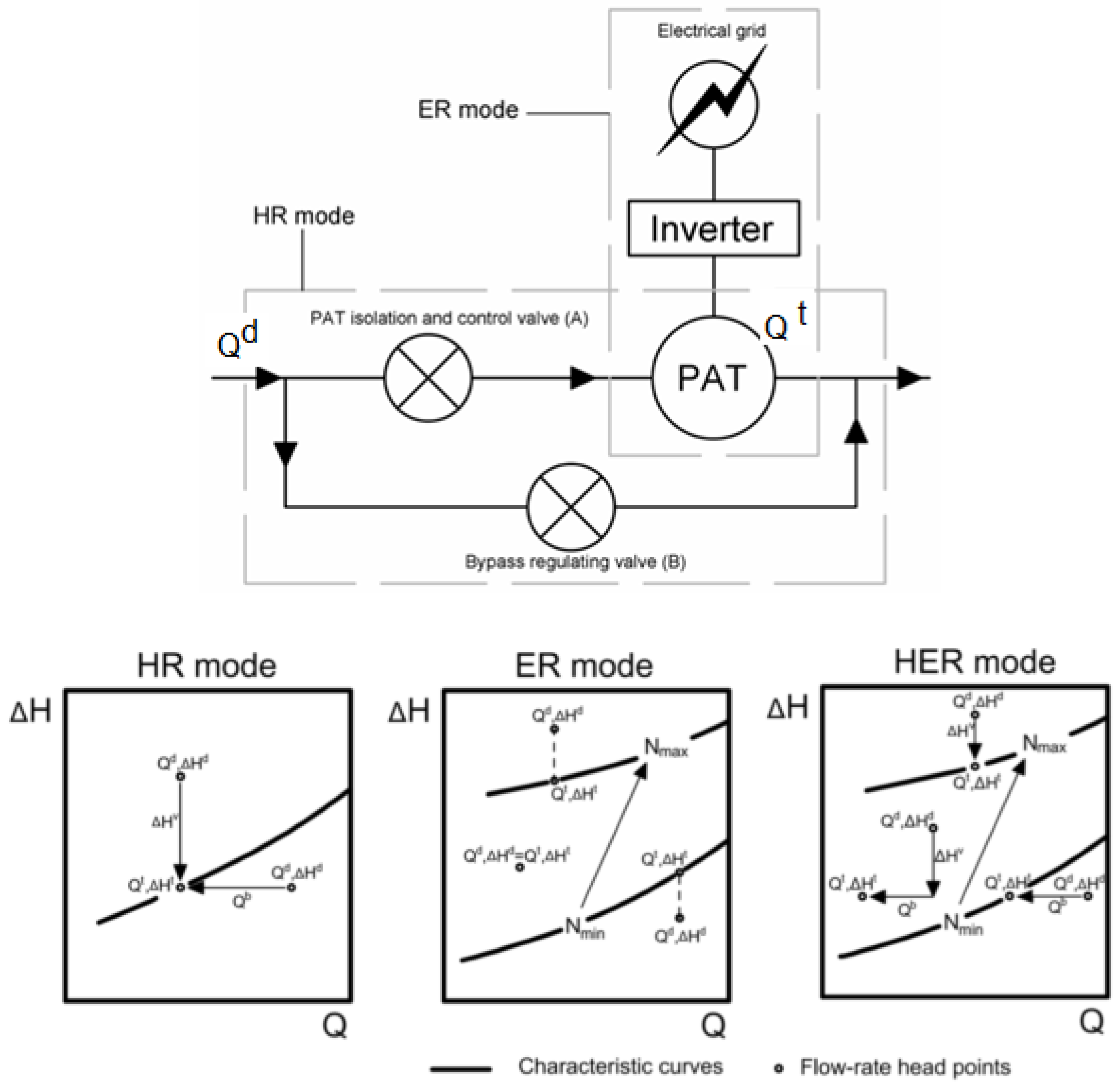

| ER | Electrical Regulation |

| HER | Hydraulic and Electrical Regulation |

| HR | Hydraulic Regulation |

| IRR | Internal Rate of Return |

| MFT | Mean failure Time |

| NPV | Net Present Value |

| PAT | Pumps as Turbines |

| PRV | Pressure Reduction Valve |

| SWG | Smart Water Grid |

| PBT | Payback Period |

| WDN | Water Distribution Network |

Notations/Symbols

| Backpressure | |

| Capital costs | |

| Effectiveness | |

| Energy produced | |

| Nodal head | |

| Available head in the system | |

| Available head | |

| Head delivered by the turbine | |

| Rated head | |

| Head loss | |

| Coefficient based on demand | |

| Number of floors above the ground level or years | |

| Rated turbine speed | |

| Operation costs | |

| Reposition costs | |

| Engine or mechanical power | |

| Hydraulic power | |

| Rated power | |

| Discharge | |

| Bypass discharge | |

| Discharge delivered by the turbine | |

| Rated flow | |

| Turbine discharge | |

| Total peak flow | |

| Revenues | |

| Discount rate | |

| Time interval | |

| Specific weight of the fluid | |

| Failure rate | |

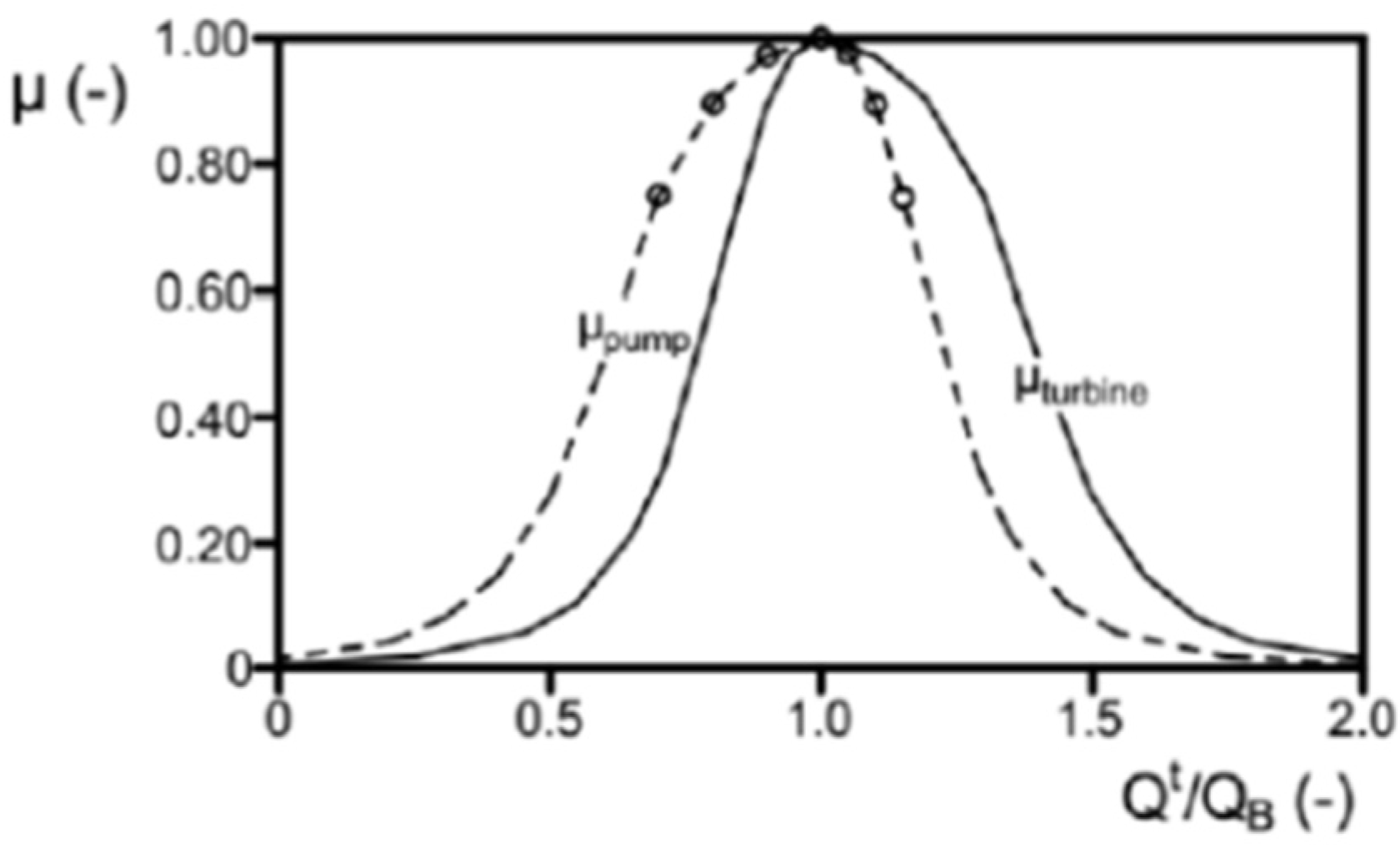

| Efficiency | |

| Capability | |

| Turbine efficiency | |

| Reliability | |

| Mass density of the fluid | |

| Flexibility | |

| Sustainability |

References

- United Nations World Water Assessment Programme (WWAP). The United Nations World Water Development Report 2019: Water for a Sustainable World; UNESCO: Paris, France, 2019. [Google Scholar]

- Ramos, H.M.; Morani, M.C.; Carravetta, A.; Fecarrotta, O.; Adeyeye, K.; López-Jiménez, P.A.; Pérez-Sánchez, M. New Challenges towards Smart Systems’ Efficiency by Digital Twin in Water Distribution Networks. Water 2022, 14, 1304. [Google Scholar] [CrossRef]

- Pérez-Sénchez, M.; Sénchez-Romero, F.J.; Ramos, H.M.; López-Jiménez, P.A. Energy Recovery in Existing Water Networks: Towards Greater Sustainability. Water 2017, 9, 97. [Google Scholar] [CrossRef]

- Carravetta, A.; Giudice, G.D.; Fecarotta, O.; Ramos, H.M. Pump as turbine (PAT) design in water distribution network by system effectiveness. Water 2013, 5, 1211–1225. [Google Scholar] [CrossRef]

- Thornton, J.; Sturm, R.; Kunkel, G. Water Loss Control; McGraw-Hill Companies: New York, NY, USA, 2008. [Google Scholar]

- Arregui, F.J.; Cobacho, R.; Soriano, J.; Jimenez-Redal, R. Calculation Proposal for the Economic Level of Apparent Losses (ELAL) in a Water Supply System. Water 2018, 10, 1809. [Google Scholar] [CrossRef]

- Martyusheva, O. Smart Water Grid; Department of Civil and Enviromental Engineering, Colorado State University: Fort Collins, CO, USA, 2014. [Google Scholar]

- Đurin, B.; Margeta, J. Analysis of the possible use of solar photovoltaic energy in urban water supply systems. Water 2014, 6, 1546–1561. [Google Scholar] [CrossRef]

- Walski, T. Committee Report: Defining model calibration. J. Am. Water Works Assoc. 2013, 105, 60–63. [Google Scholar]

- PENSAAR. Uma Nova Estratégia Para o Setor de Abastecimento de águas e Saneamento de águas Residuais. 2020. Available online: https://apambiente.pt/agua/plano-estrategico-de-abastecimento-de-agua-e-saneamento-de-aguas-residuais (accessed on 10 April 2015).

- Fabbiano, L.; Vacca, G.; Dinardo, G. Smart water grid: A smart methodology to detect leaks in water distribution networks. Measurement 2020, 151, 107260. [Google Scholar] [CrossRef]

- Ramos, H.M.; McNabola, A.; López-Jiménez, P.A.; Pérez-Sánchez, M. Smart Water Management towards Future Water Sustainable Networks. Water 2020, 12, 58. [Google Scholar] [CrossRef]

- Galdiero, E.; De Paola, F.; Fontana, N.; Giugni, M.; Savic, D. Decision support system for the optimal design of district metered areas. J. Hydroinform. 2015, 18, 49–61. [Google Scholar] [CrossRef]

- Parra, S.; Krause, S.; Krönlein, F.; Günthert, F.W.; Klunke, T. Intelligent pressure management by pumps as turbines in water distribution systems: Results of experimentation. Water Sci. Technol. Water Supply 2018, 18, 778–789. [Google Scholar] [CrossRef]

- Conejos Fuertes, P.; Martínez Alzamora, F.; Hervás Carot, M.; Alonso Campos, J.C. Building and exploiting a Digital Twin for the management of drinking water distribution networks. Urban Water J. 2020, 17, 704–713. [Google Scholar] [CrossRef]

- Ulanicki, B.; Bounds, P.; Rance, J.; Reynolds, L. Open and closed loop pressure control for leakage reduction. Urban Water 2000, 2, 105–114. [Google Scholar] [CrossRef]

- Pastor, A.V.; Palazzo, A.; Havlik, P.; Biemans, H.; Wada, Y.; Obersteiner, M.; Kabat, P.; Ludwig, F. The global nexus of food–trade–water sustaining environmental flows by 2050. Nat. Sustain. 2019, 2, 499–507. [Google Scholar] [CrossRef]

- Fontana, N.; Giugni, M.; Portolano, D. Losses Reduction and Energy Production in Water-Distribution Networks. J. Water Resour. Plan. Manag. 2012, 138, 237–244. [Google Scholar] [CrossRef]

- Wu, H.; Jin, R.; Liu, A.; Jiang, S.; Chai, L. Savings and Losses of Scarce Virtual Water in the International Trade of Wheat, Maize, and Rice. Int. J. Environ. Res. Public Health 2022, 19, 4119. [Google Scholar] [CrossRef] [PubMed]

- Vilanova, M.R.N.; Balestieri, J.A.P. Energy and hydraulic efficiency in conventional water supply systems. Renew. Sustain. Energy Rev. 2014, 30, 701–714. [Google Scholar] [CrossRef]

- Carravetta, A.; Del Giudice, G.; Fecarotta, O.; Ramos, H.M. Energy production in water distribution networks: A PAT design strategy. Water Resour. Manag. 2012, 26, 3947–3959. [Google Scholar] [CrossRef]

- Fecarotta, O.; Aricó, C.; Carravetta, A.; Martino, R.; Ramos, H. Hydropower Potential in Water Distribution Networks: Pressure Control by PATs. Water Resour. Manag. 2014, 29, 699–714. [Google Scholar] [CrossRef]

- Carravetta, A.; Giudice, G.D.; Fecarotta, O.; Ramos, H.M. PAT design strategy for energy recovery in water distribution networks by electrical regulation. Energies 2013, 6, 411–424. [Google Scholar] [CrossRef]

- Carravetta, A.; Ferracotta, O.; Ramos, H. Energy production by PAT in small residential areas. Renew. Energy, 2016; 1–16, Submitted. [Google Scholar]

- Boyle, T.; Giurco, D.; Mukheibir, P.; Liu, A.; Moy, C.; White, S.; Stewart, R. Intelligent Metering for Urban Water: A Review. Water 2013, 5, 1052–1081. [Google Scholar] [CrossRef]

- Byeon, S.; Choi, G.; Maen, S.; Gourbesville, P. Sustainable water distribution strategy with smart water grid. Sustainability 2015, 7, 4240–4259. [Google Scholar] [CrossRef]

- Kenway, S.J.; Lant, P.A.; Priestley, A.; Daniels, P. The connection between water and energy in cities: A review. Water Sci. Technol. 2011, 63, 1983–1990. [Google Scholar] [CrossRef] [PubMed]

- Ministério das Obras Pêblicas, Transportes e Comunicações. Decreto Regulamentar nº 23/95, de 23 de Agosto, 36. 1995. Available online: https://dre.pt/dre/detalhe/decreto-regulamentar/23-1995-431873 (accessed on 10 April 2015).

- Wagner, J.M.; Shamir, U.; Marks, D.H. Water distribution reliability: Simulation metods. J. Water Resour. Plan. Manag. 1988, 114, 253–275. [Google Scholar] [CrossRef]

- Morosini, A.F.; Caruso, O.; Veltri, P. Management of water distribution systems in PDA conditions using isolation valves: Case studies of real networks. J. Hydroinform. 2020, 22, 681–690. [Google Scholar] [CrossRef]

- Bentley Systems. WaterGEMS User’s Guide; Bentley Systems: Exton, PA, USA, 2016. [Google Scholar]

- Du, J.; Yang, H.; Shen, Z.; Chen, J. Micro hydro power generation from water supply system in high rise buildings using pump as turbines. Energy 2017, 137, 431–440. [Google Scholar] [CrossRef]

- Ramos, H. (Ed.) Guidelines for Design of Small Hydropower Plants; WREAN (Western Regional Energy Agency and Network) and DED (Department of Economic Development—Energy Division): Belfast, North Ireland, 2000; ISBN 972-96346-4-5.

| PAT | |||||||

|---|---|---|---|---|---|---|---|

| Etanorm 32–160 | 3.33 | 7.31 | 11 | 34 | 5.55 | 21 | 0.6 |

| Etanorm 40–200 | 5.56 | 13.4 | 16 | 52.5 | 10 | 32 | 0.57 |

| Types Demand | Average Flow Distributed in the Period () | Daily Leakage Volume () | Total Leakage Volume in the Analyzed Period () | Yearly Total Leakage Volume () |

|---|---|---|---|---|

| Normal | 8.12 | 30.64 | 5576 | 11,623 |

| High | 11.74 | 30.99 | 1921 | |

| Very high | 18.28 | 33.82 | 4126 |

| Type of Demand |

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|

| Normal | 46.9 | 59.6 | 53.4 | 87.4 | 99.3 | 98.6 | 100 |

| High | 40.6 | 56.6 | 47.5 | 86.6 | 99.3 | 98.2 | 100 |

| Very high | 27.3 | 39.2 | 34.3 | 80 | 80 | 99.6 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramos, H.M.; Morani, M.C.; Pugliese, F.; Fecarotta, O. Integrated Smart Management in WDN: Methodology and Application. Water 2023, 15, 1217. https://doi.org/10.3390/w15061217

Ramos HM, Morani MC, Pugliese F, Fecarotta O. Integrated Smart Management in WDN: Methodology and Application. Water. 2023; 15(6):1217. https://doi.org/10.3390/w15061217

Chicago/Turabian StyleRamos, Helena M., Maria Cristina Morani, Francesco Pugliese, and Oreste Fecarotta. 2023. "Integrated Smart Management in WDN: Methodology and Application" Water 15, no. 6: 1217. https://doi.org/10.3390/w15061217

APA StyleRamos, H. M., Morani, M. C., Pugliese, F., & Fecarotta, O. (2023). Integrated Smart Management in WDN: Methodology and Application. Water, 15(6), 1217. https://doi.org/10.3390/w15061217