Evaporation-Assisted Humidification–Dehumidification Cycles for Desalination Application in Tropical and Subtropical Regions

Abstract

1. Introduction

2. Evaporation-Assisted HDH Desalination Cycles

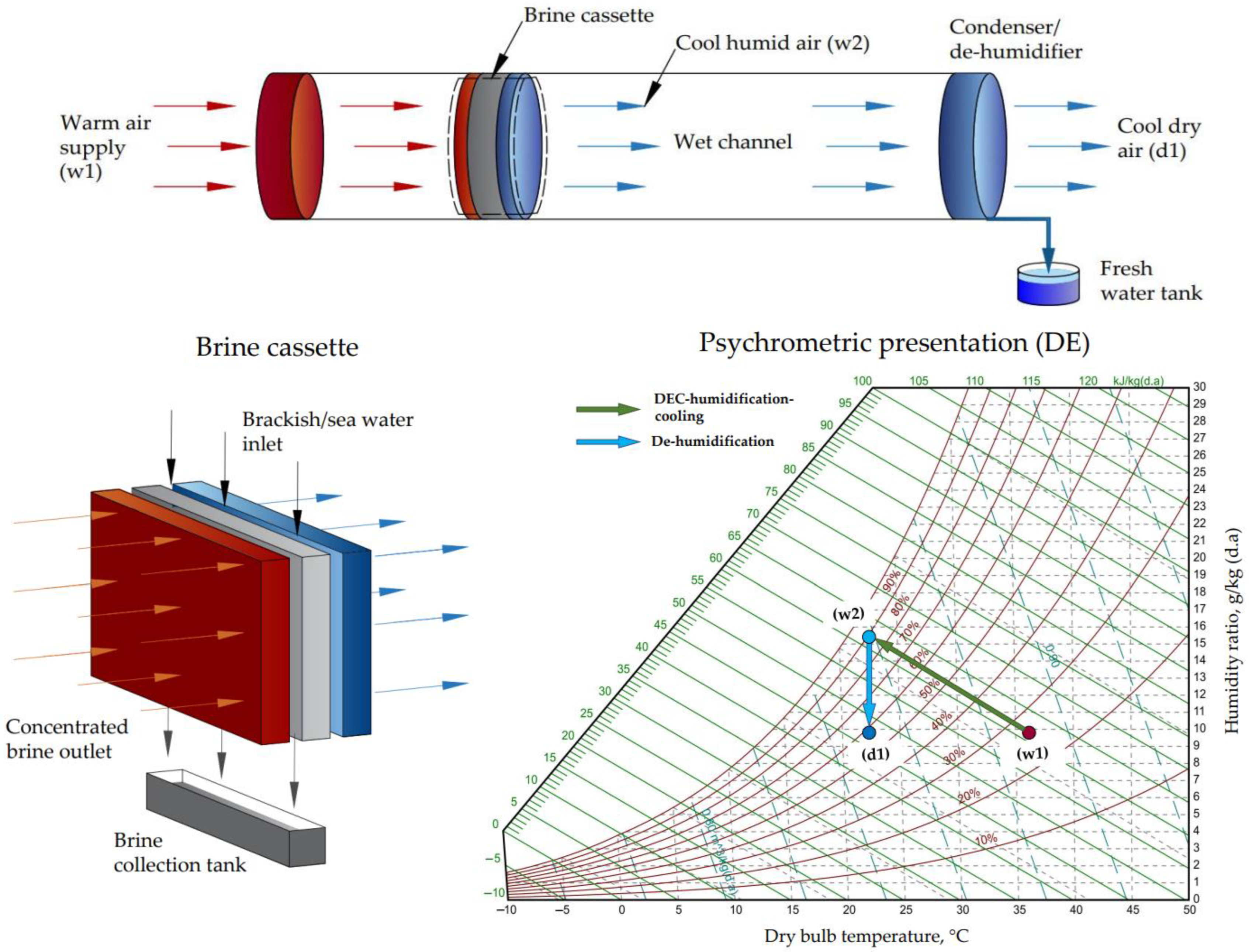

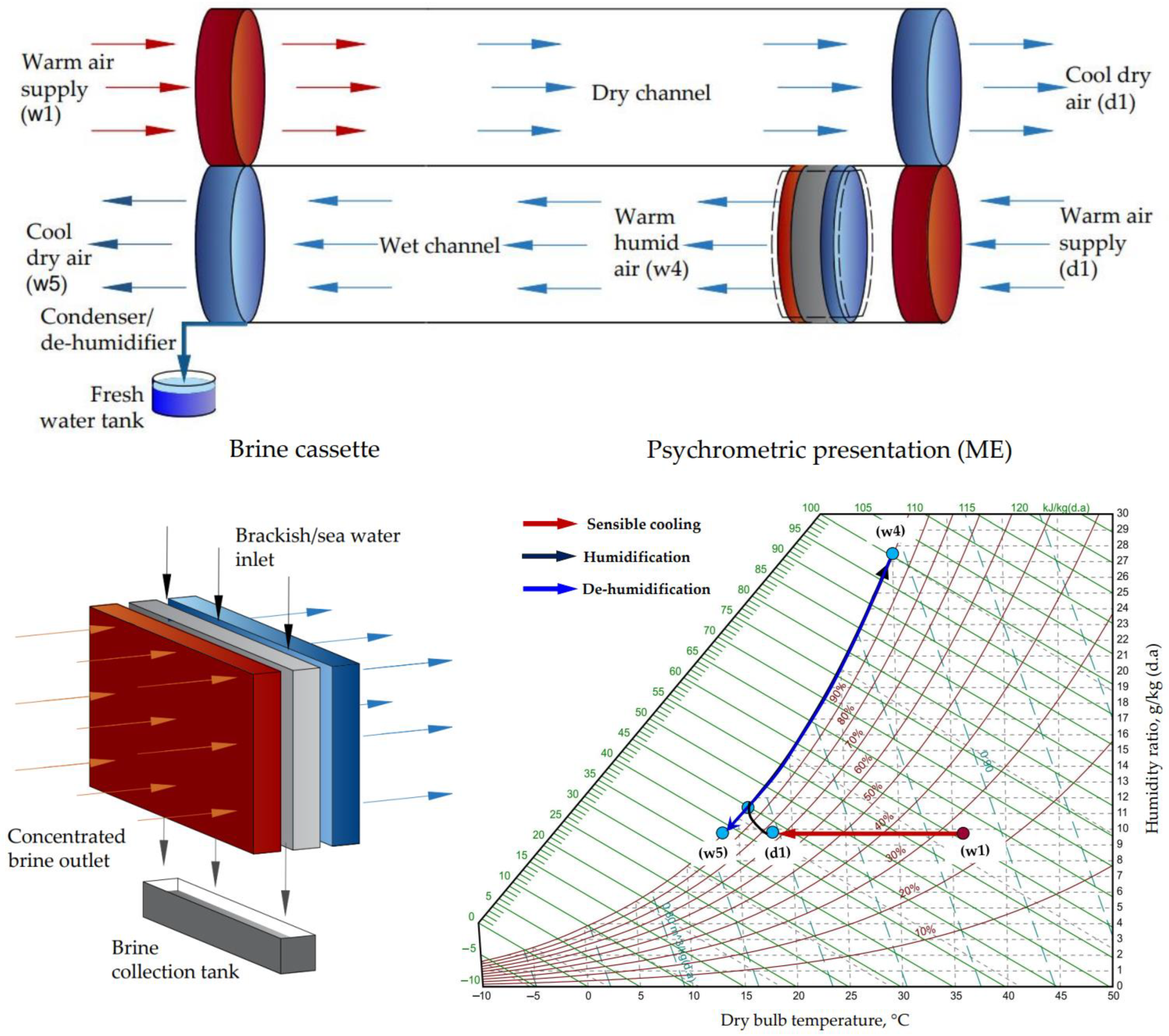

2.1. Direct Evaporative (DE-HDH)

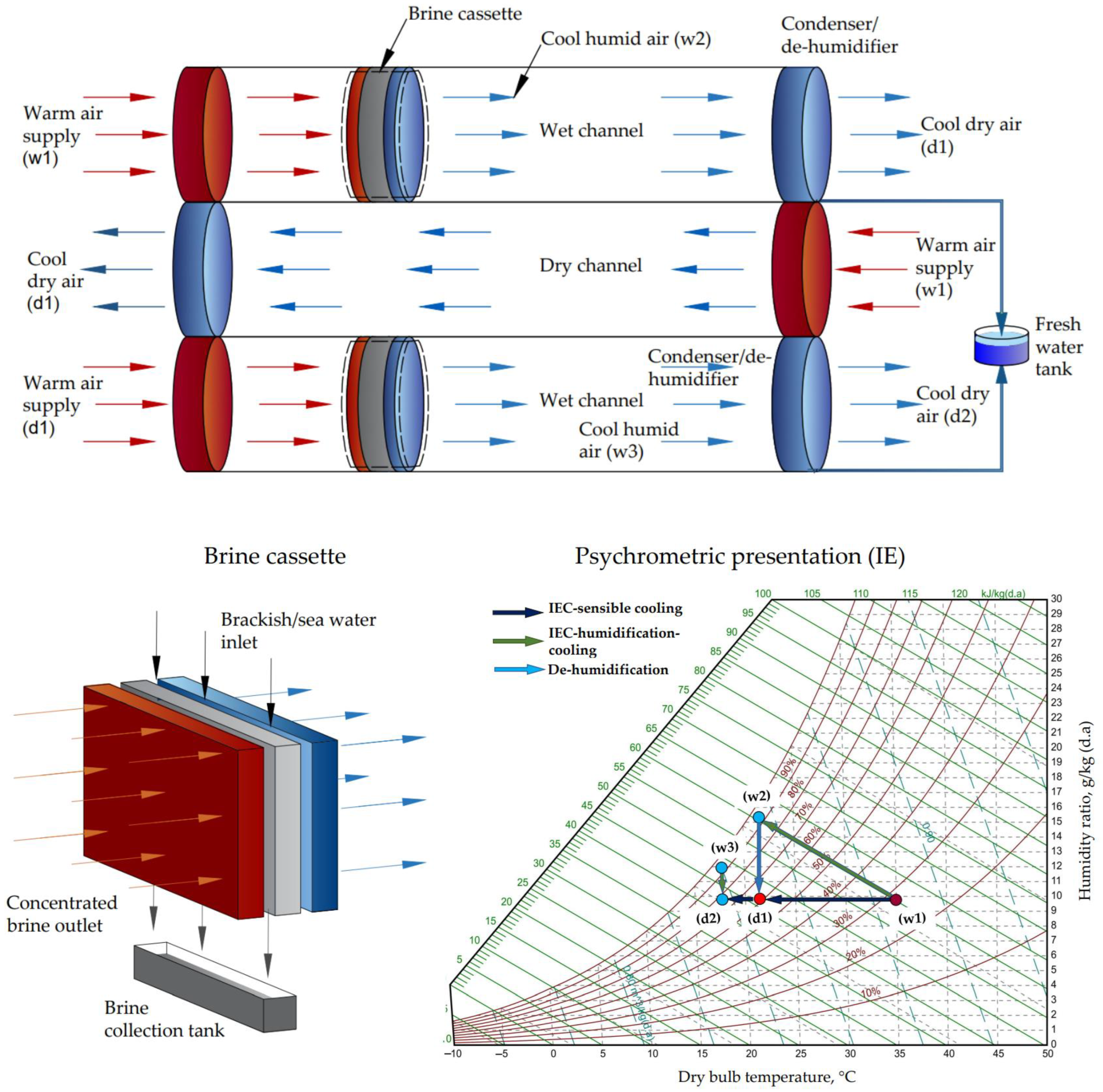

2.2. Indirect Evaporative (IE-HDH)

2.3. Maisotsenko Evaporative (ME-HDH)

3. Methodology

4. Results and Discussion

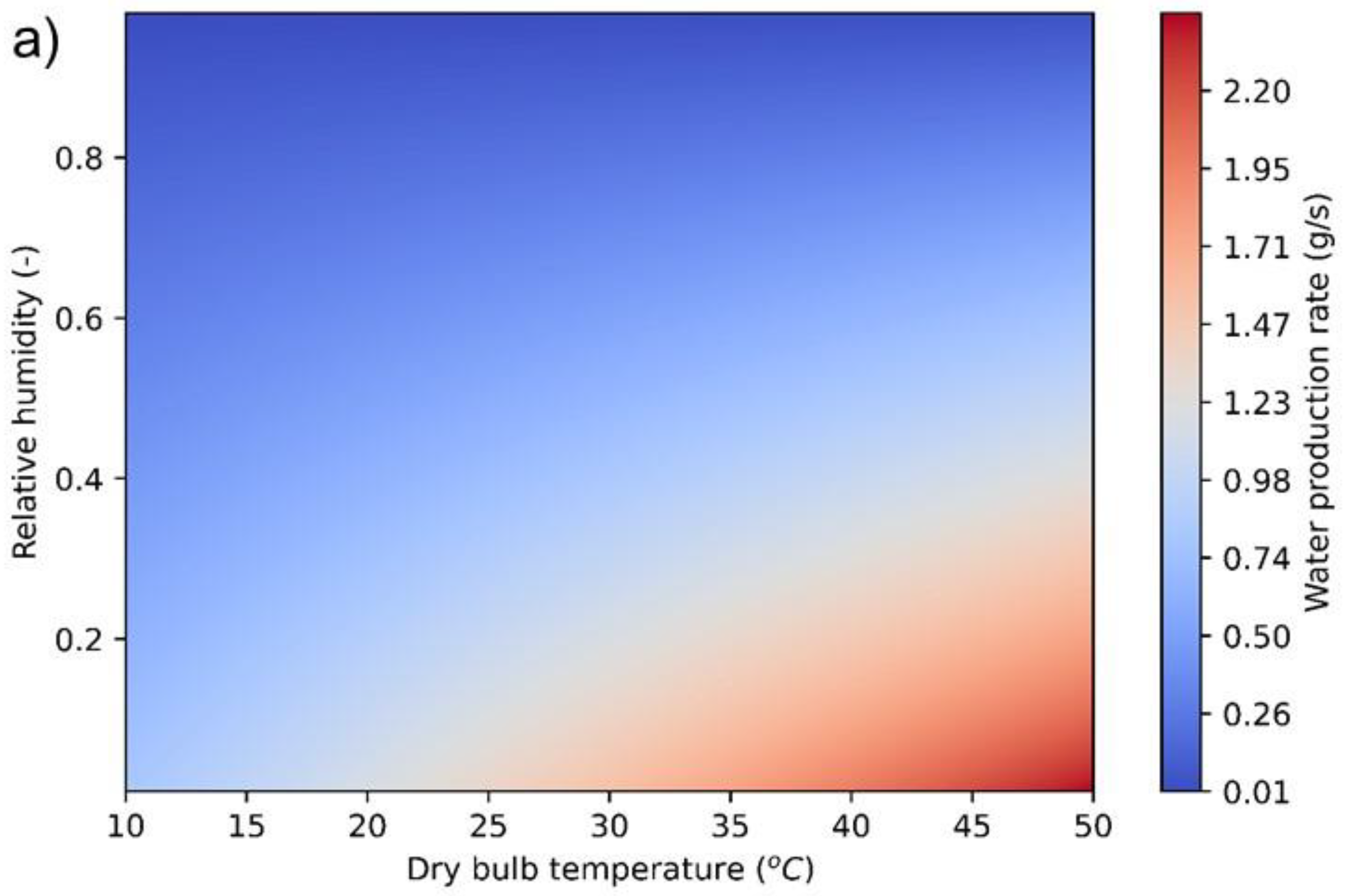

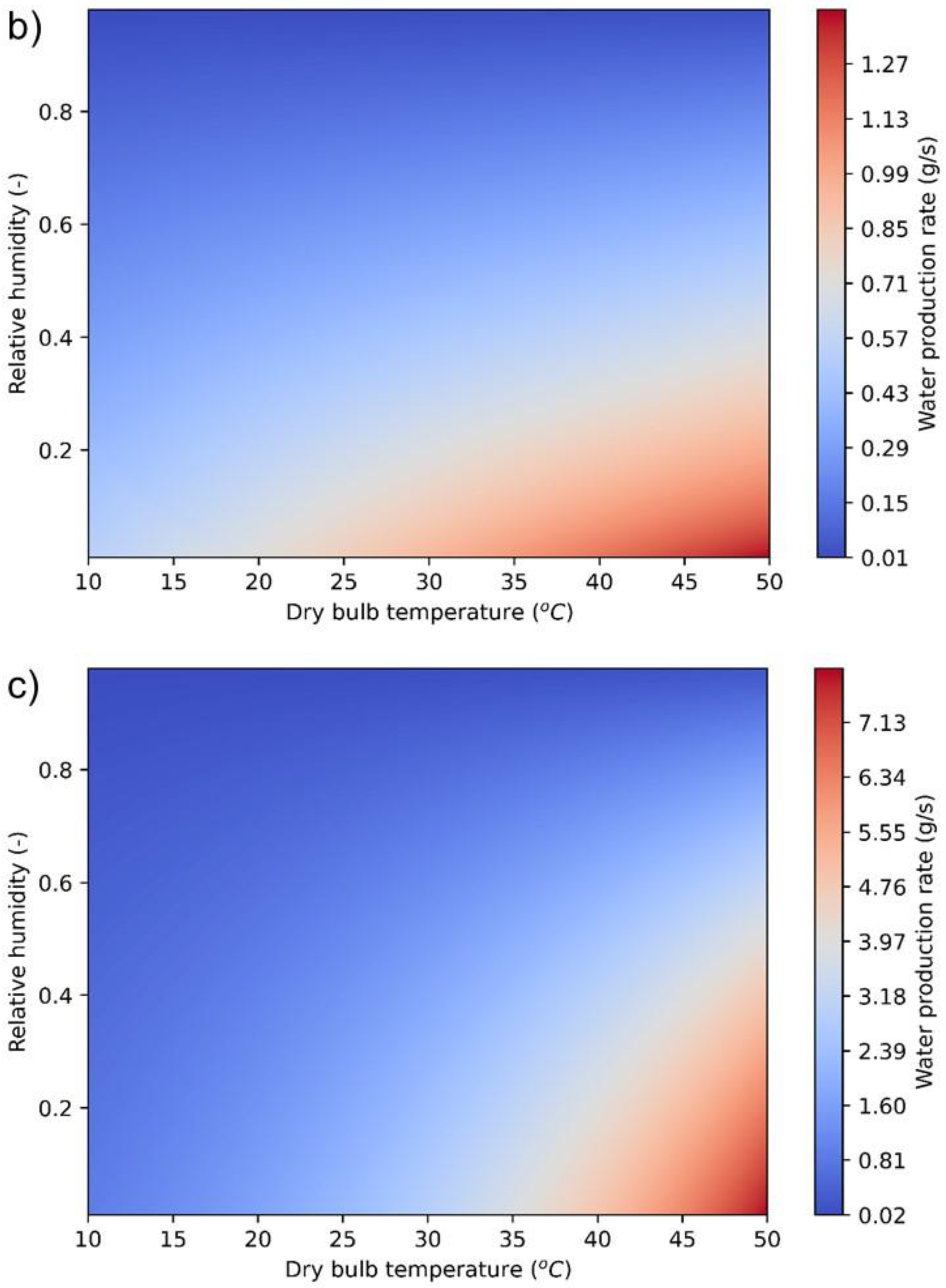

4.1. Water Production Rate

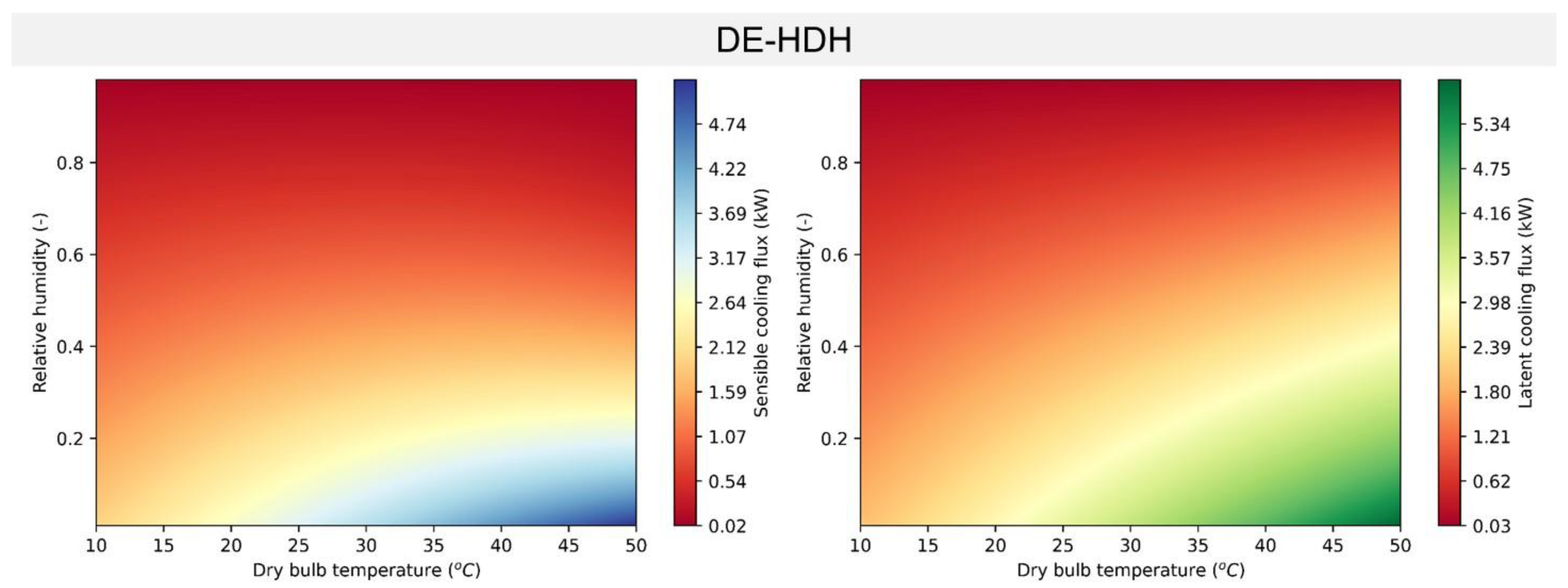

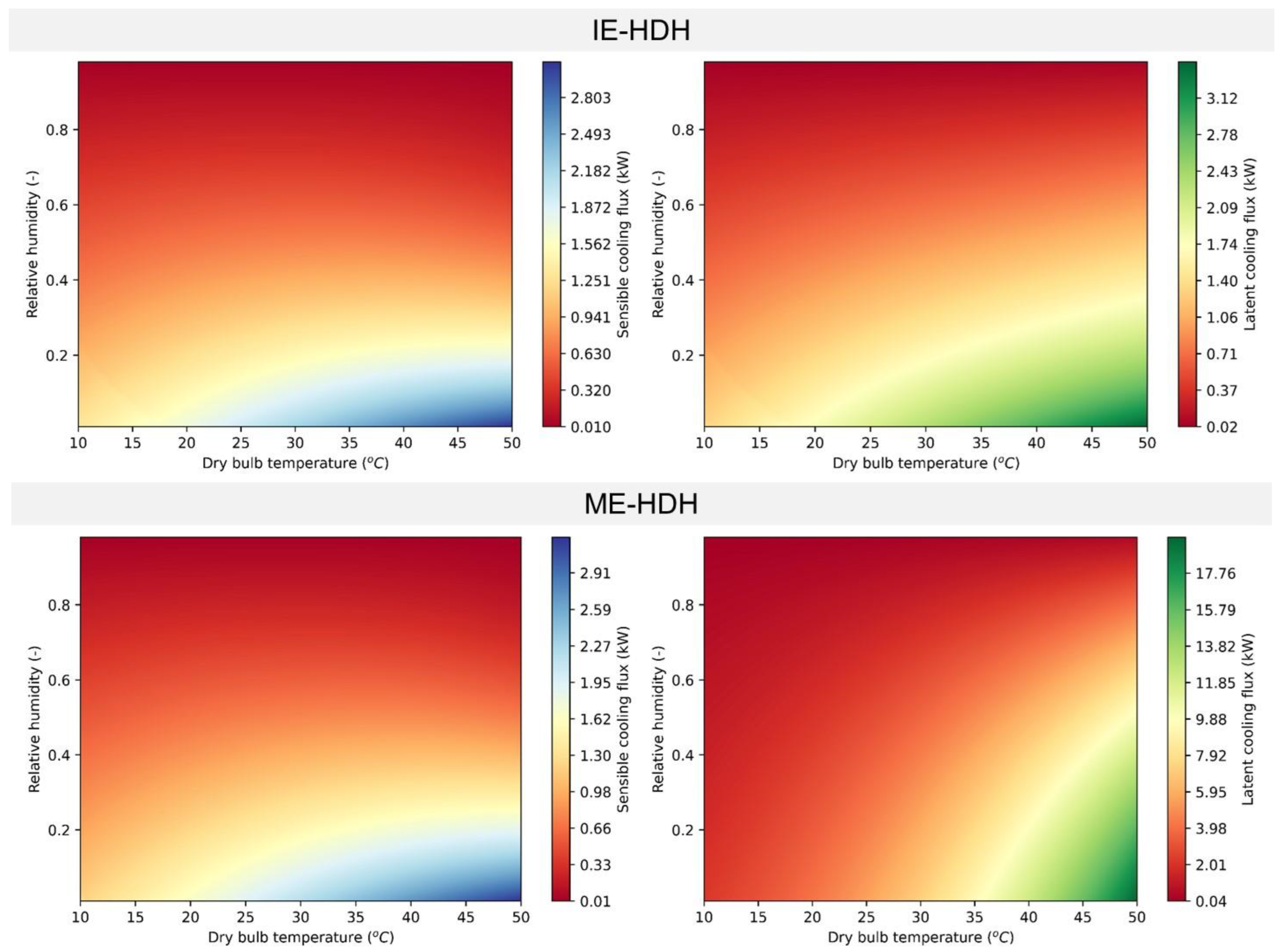

4.2. Sensible and Latent Cooling Fluxes

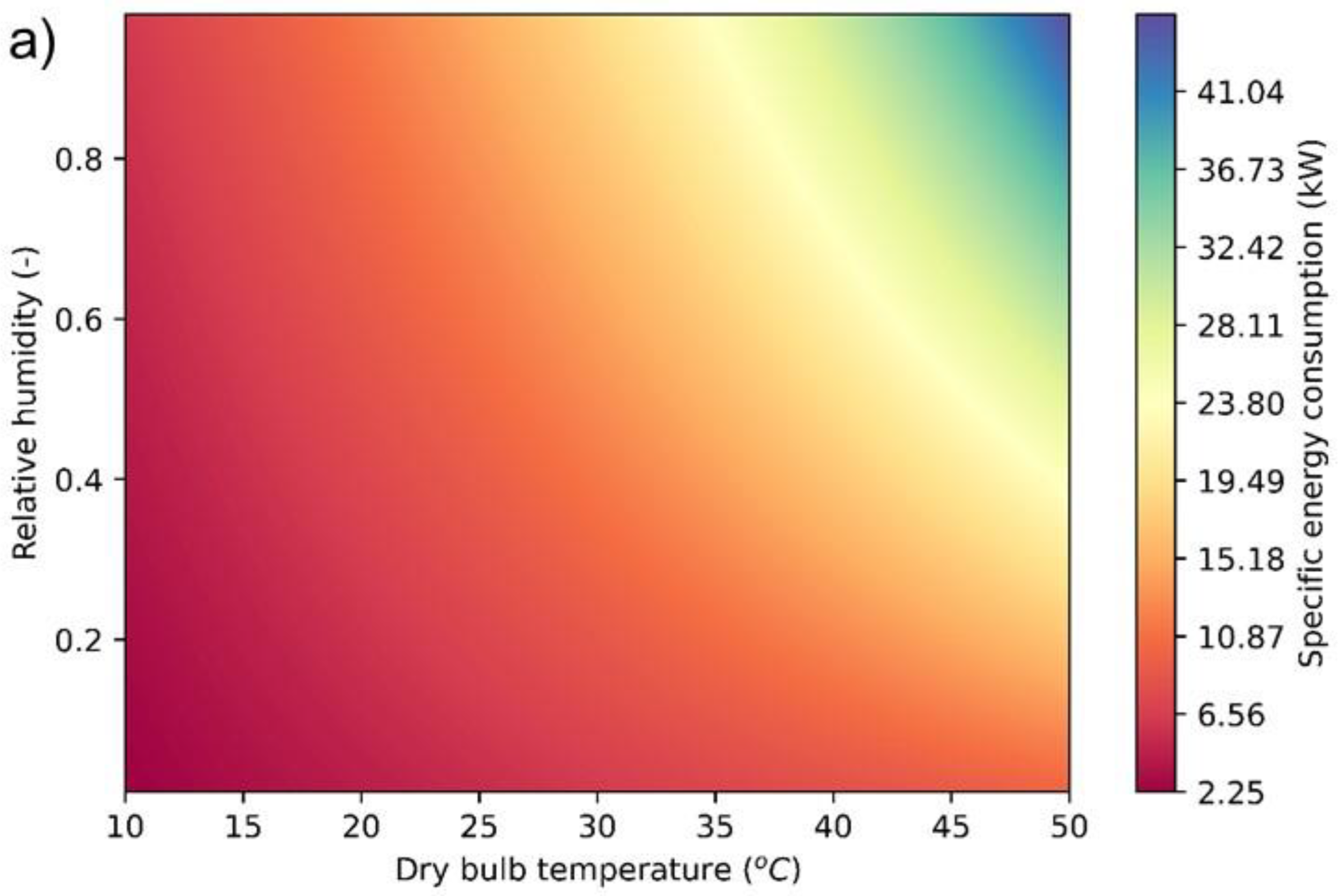

4.3. Specific Energy Consumption

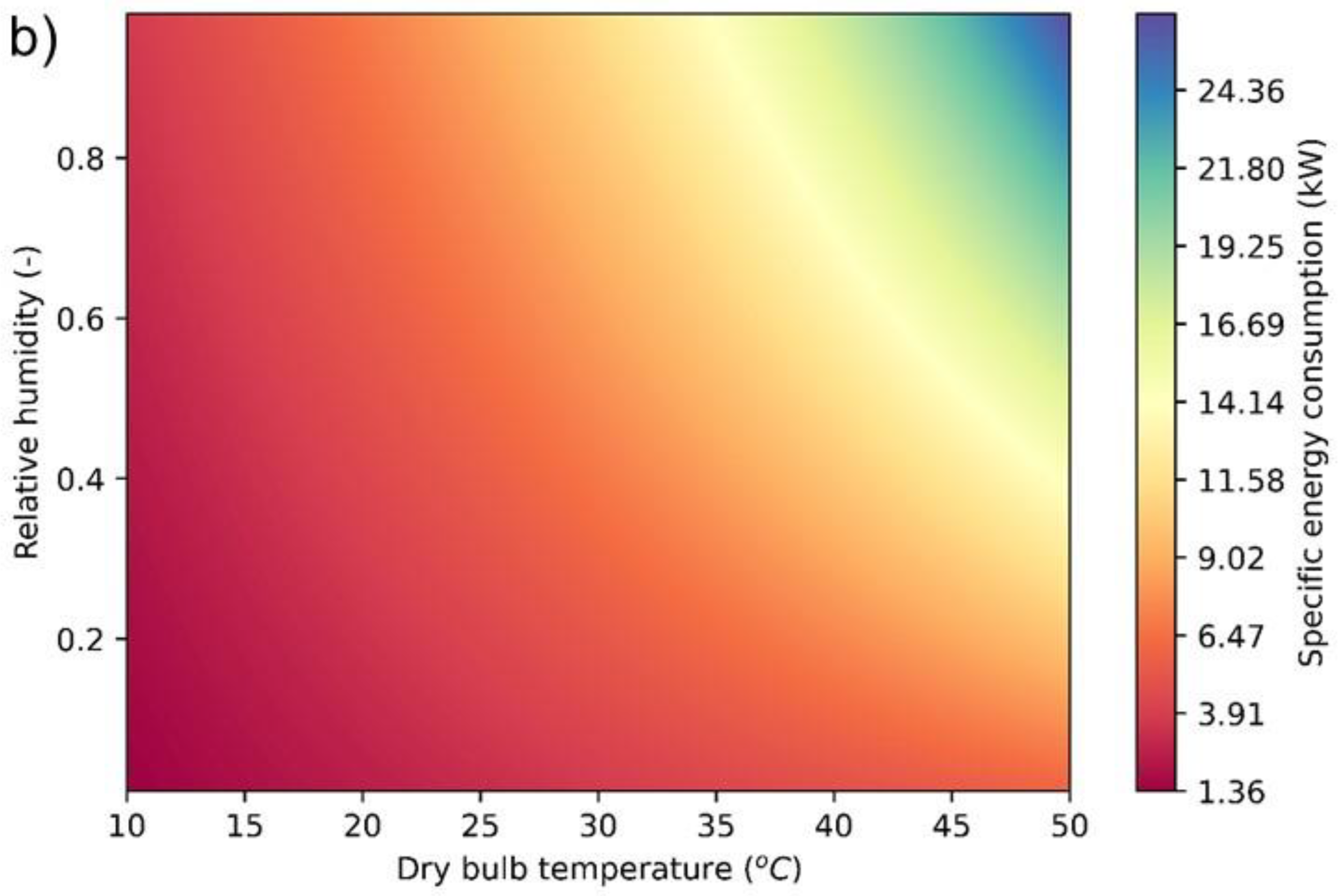

4.4. Sensible and Latent Heat Factors

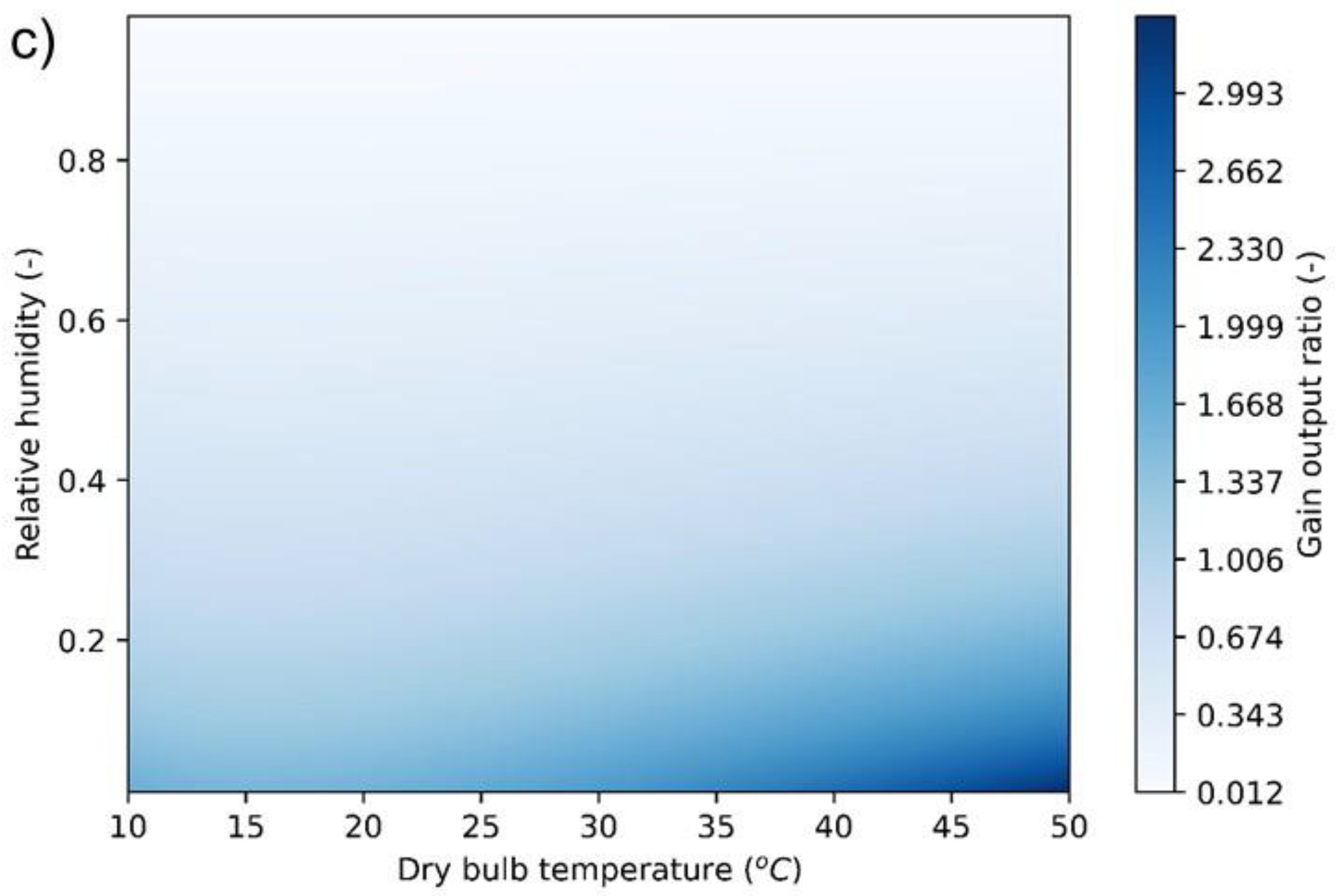

4.5. Gain Output Ratio

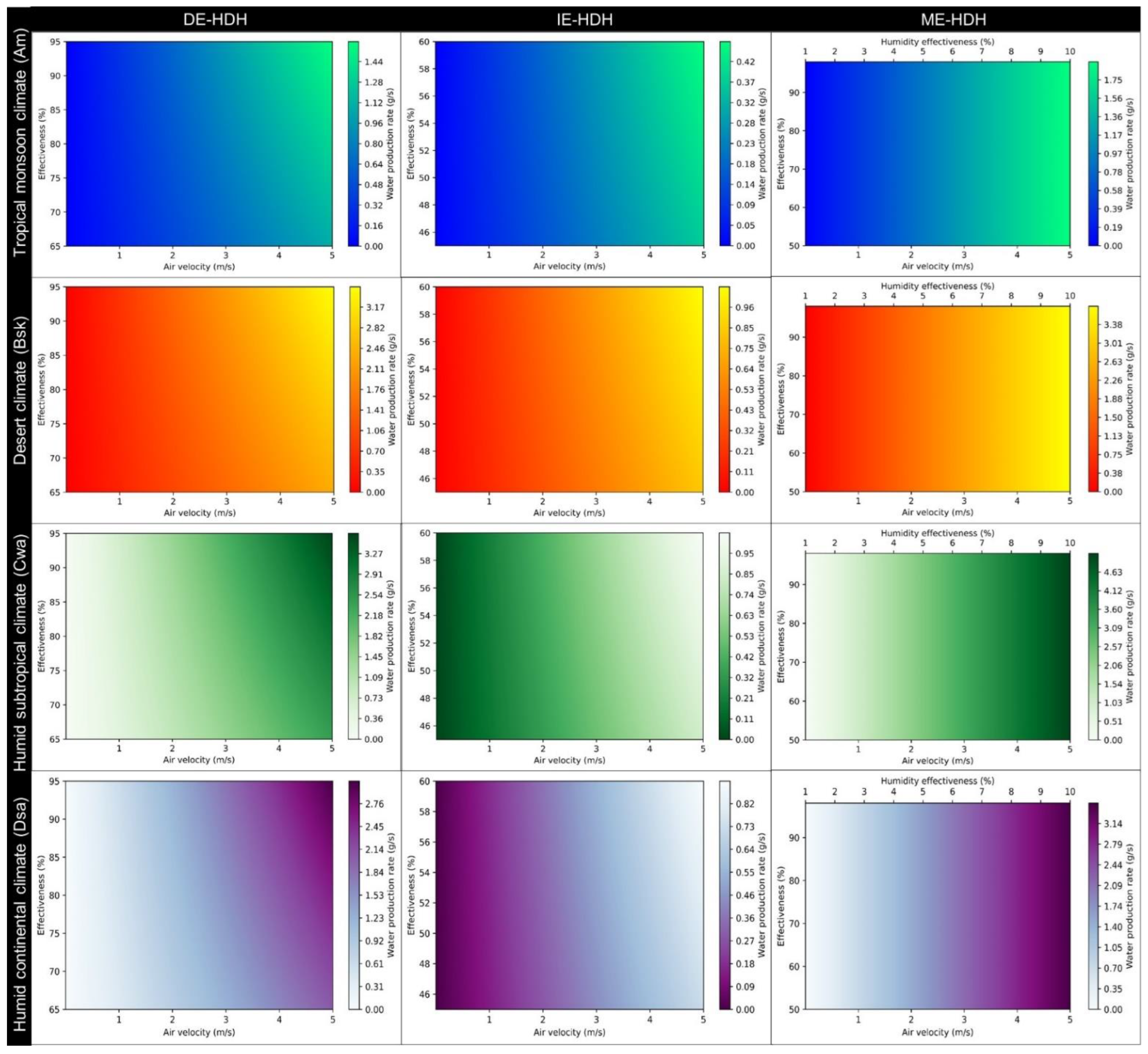

4.6. Effect of Velocity and E-HDH System Effectiveness

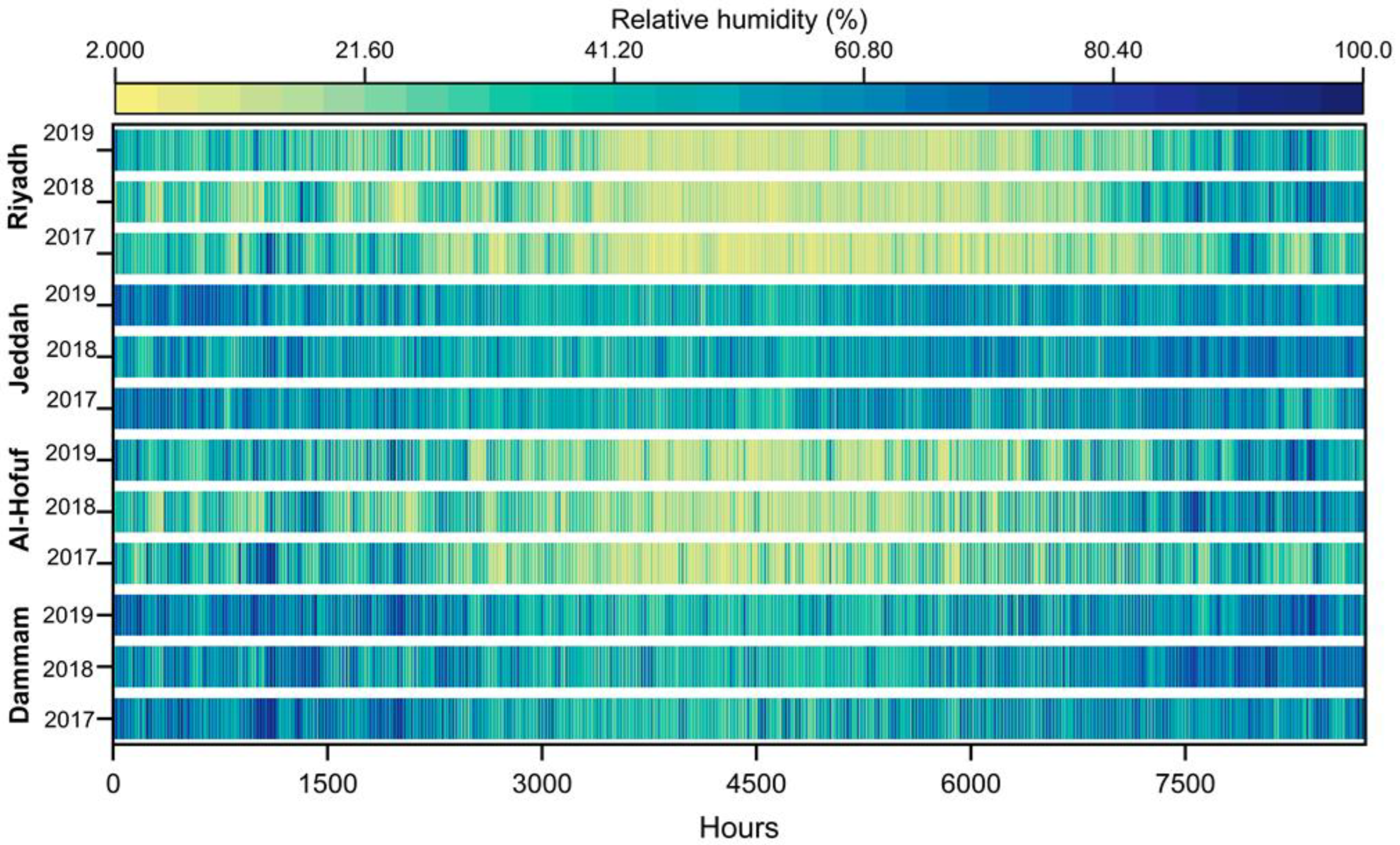

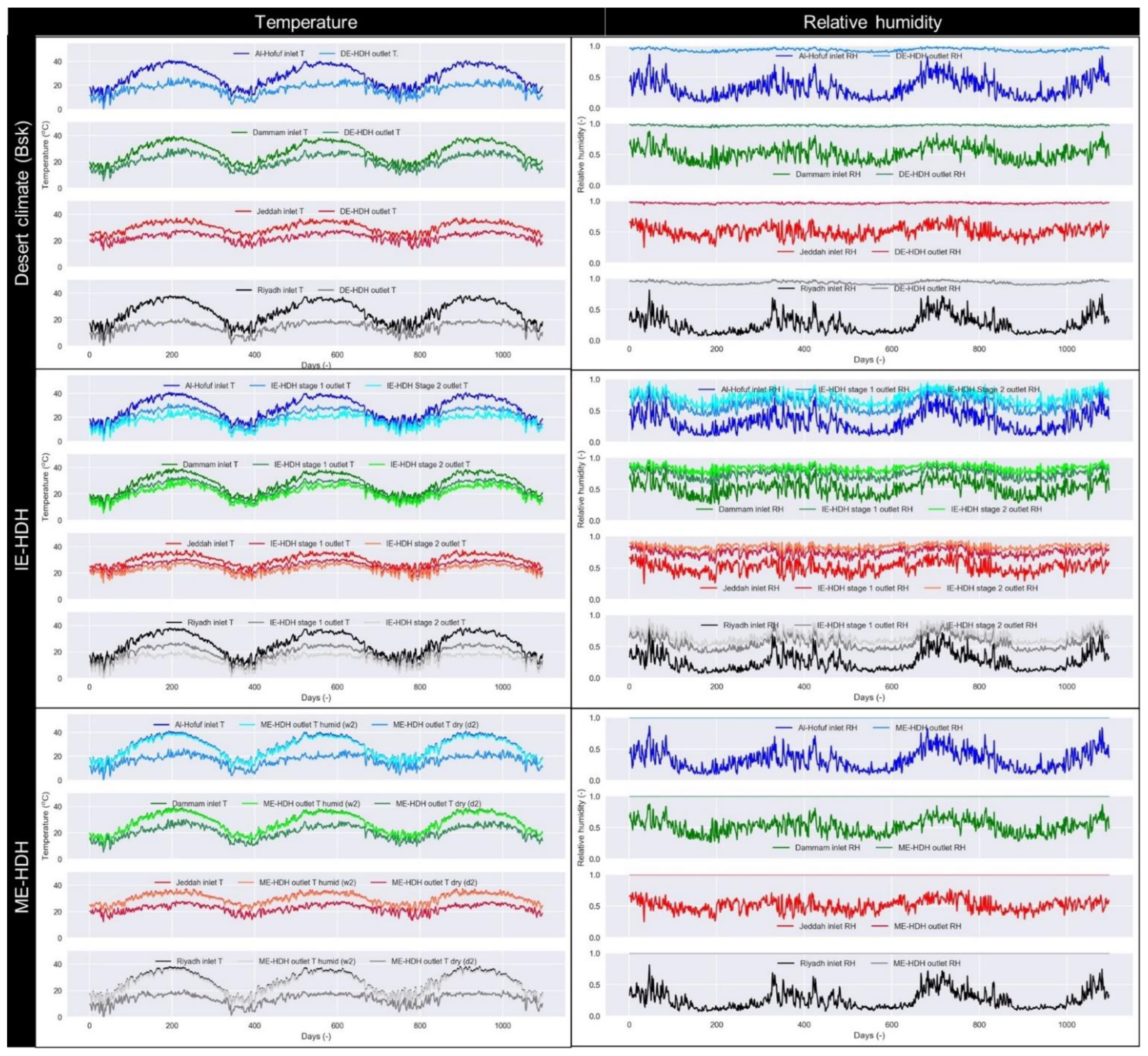

4.7. Performance Comparison against Climatic Conditions of Saudi Arabia

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| mass flow rate, (kg/s) | |

| cp | specific heat capacity, (J/kg.K) |

| DE-HDH | direct evaporative HDH |

| E-HDH | evaporation-assisted HDH |

| GOR | gain output ratio, (-) |

| GOR | gain output ratio, (-) |

| HDH | humidification–dehumidification |

| IE-HDH | indirect evaporative HDH |

| LHF | latent heat factor, (-) |

| ME-HDH | Maisotsenko evaporative HDH |

| Qc | sensible cooling flux, (kW) |

| Qf | energy consumed by fan, (kW) |

| Qh | sensible heat supplied, (kJ/s) |

| Qlat | latent cooling flux, (kW) |

| Qp | energy consumed by pump, (kW) |

| RH | relative humidity, (-) |

| SEC | specific energy consumption, (kW) |

| SHF | sensible heat factor, (-) |

| T | temperature, (K) |

| WPR | water production rate, (g/s) |

| humidity ratio, (kg/kg) | |

| system effectiveness, (-) | |

| Subscript | |

| d1, d2 | cool dry air |

| db | dry-bulb |

| dp | dew-point |

| in | inlet |

| out | outlet |

| w1 | warm air supply |

| w2, w3 | cool humid air |

| w4 | warm humid air |

| w5 | cool dry air |

| wb | wet-bulb |

Appendix A

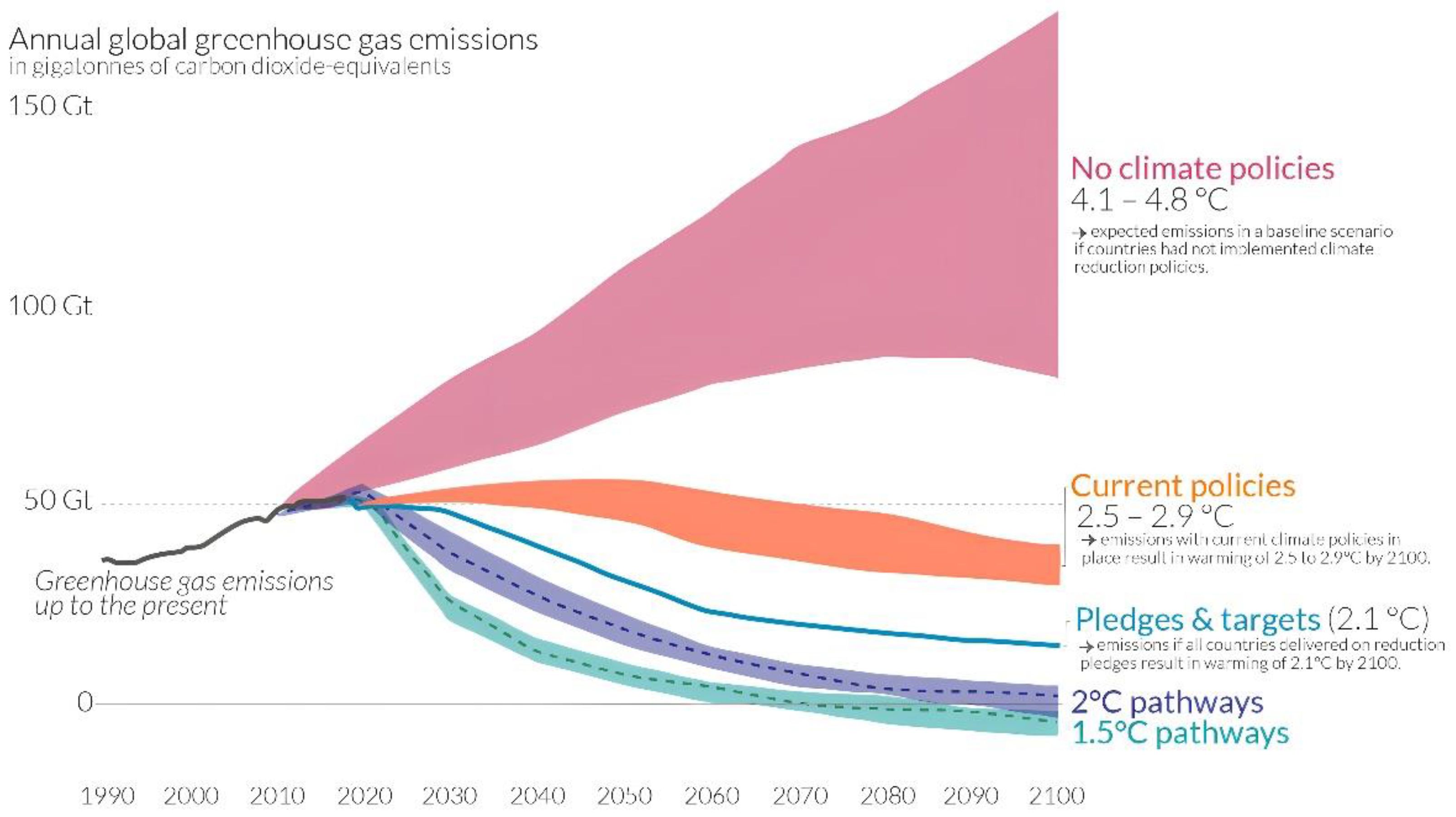

References

- The Distribution of Water on, in, and above the Earth|U.S. Geological Survey. Available online: https://www.usgs.gov/media/images/distribution-water-and-above-earth (accessed on 5 March 2023).

- UNESCO, UN-Water, 2020; The United Nations World Water Development Report 2020: WATER AND CLIMATE CHANGE; UNESCO: Paris, France, 2020.

- Lawal, D.U.; Qasem, N.A.A. Humidification-dehumidification desalination systems driven by thermal-based renewable and low-grade energy sources: A critical review. Renew. Sustain. Energy Rev. 2020, 125, 109817. [Google Scholar] [CrossRef]

- Faegh, M.; Behnam, P.; Shafii, M.B. A review on recent advances in humidification-dehumidification (hdh) desalination systems integrated with refrigeration, power and desalination technologies. Energy Convers. Manag. 2019, 196, 1002–1036. [Google Scholar] [CrossRef]

- Eghtesad, A.; Salakhi, M.; Afshin, H.; Hannani, S.K. Numerical investigation and optimization of indirect freeze desalination. Desalination 2020, 481, 114378. [Google Scholar] [CrossRef]

- Quan, Q.; Liang, W.; Yan, D.; Lei, J. Influences of joint action of natural and social factors on atmospheric process of hydrological cycle in Inner Mongolia, China. Urban Clim. 2022, 41, 101043. [Google Scholar] [CrossRef]

- Wang, W.; Xie, S.; Pan, Q.; Dai, Y.; Wang, R.; Ge, T. Air-cooled adsorption-based device for harvesting water from island air. Renew. Sustain. Energy Rev. 2021, 141, 110802. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. Sustainability: Four billion people facing severe water scarcity. Sci. Adv. 2016, 1–6. [Google Scholar] [CrossRef]

- Santosh, R.; Lee, H.-S.; Kim, Y.-D. A comprehensive review on humidifiers and dehumidifiers in solar and low-grade waste heat powered humidification-dehumidification desalination systems. J. Clean. Prod. 2022, 347, 131300. [Google Scholar] [CrossRef]

- Wu, X.; Guo, S.; Qian, S.; Wang, Z.; Lai, C.; Li, J.; Liu, P. Long-range precipitation forecast based on multipole and preceding fluctuations of sea surface temperature. Int. J. Clim. 2022, 42, 8024–8039. [Google Scholar] [CrossRef]

- Ayaz, M.; Namazi, M.A.; Din, M.A.U.; Ershath, M.I.M.; Mansour, A.; Aggoune, E.-H.M. Sustainable Seawater Desalination: Current status, environmental implications and future expectations. Desalination 2022, 540, 116022. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.; Wu, X.; Xu, C.-Y.; Guo, S.; Chen, X. Toward Monitoring Short-Term Droughts Using a Novel Daily Scale, Standardized Antecedent Precipitation Evapotranspiration Index. J. Hydrometeorol. 2020, 21, 891–908. [Google Scholar] [CrossRef]

- Zhongming, Z.; Linong, L.; Xiaona, Y.; Wangqiang, Z.; Wei, L. Climate and Weather Related Disasters Surge Five-Fold over 50 Years, but Early Warnings Save Lives–WMO Report; United Nations: New York, NY, USA, 2021. [Google Scholar]

- Li, J.; Wang, Z.; Wu, X.; Zscheischler, J.; Guo, S.; Chen, X. A standardized index for assessing sub-monthly compound dry and hot conditions with application in China. Hydrol. Earth Syst. Sci. 2021, 25, 1587–1601. [Google Scholar] [CrossRef]

- Amy, G.; Ghaffour, N.; Li, Z.; Francis, L.; Linares, R.V.; Missimer, T.; Lattemann, S. Membrane-based seawater desalination: Present and future prospects. Desalination 2017, 401, 16–21. [Google Scholar] [CrossRef]

- Khawaji, A.D.; Kutubkhanah, I.K.; Wie, J.-M. Advances in seawater desalination technologies. Desalination 2008, 221, 47–69. [Google Scholar] [CrossRef]

- Ghaffour, N.; Missimer, T.M.; Amy, G.L. Technical review and evaluation of the economics of water desalination: Current and future challenges for better water supply sustainability. Desalination 2013, 309, 197–207. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Thu, K.; Kim, Y.d.; Ng, K.C. An experimental investigation on MEDAD hybrid desalination cycle. Appl. Energy 2015, 148, 273–281. [Google Scholar] [CrossRef]

- El-Dessouky, H.T.; Ettouney, H.M. Multi-Stage Flash Desalination. In Fundamentals of Salt Water Desalination; Elsevier Science: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Ng, K.C.; Thu, K.; Oh, S.J.; Ang, L.; Shahzad, M.W.; Bin Ismail, A. Recent developments in thermally-driven seawater desalination: Energy efficiency improvement by hybridization of the MED and AD cycles. Desalination 2015, 356, 255–270. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Ng, K.C.; Thu, K. Future sustainable desalination using waste heat: Kudos to thermodynamic synergy. Environ. Sci. Water Res. Technol. 2016, 2, 206–212. [Google Scholar] [CrossRef]

- Bataineh, K.M. Multi-effect desalination plant combined with thermal compressor driven by steam generated by solar energy. Desalination 2016, 385, 39–52. [Google Scholar] [CrossRef]

- Riaz, N.; Sultan, M.; Miyazaki, T.; Shahzad, M.W.; Farooq, M.; Sajjad, U.; Niaz, Y. A review of recent advances in adsorption desalination technologies. Int. Commun. Heat Mass Transf. 2021, 128, 105594. [Google Scholar] [CrossRef]

- Asfahan, H.M.; Sultan, M.; Farooq, M.; Ibrahim, S.M.; Imran, M.; Askalany, A.A.; Shahzad, M.W.; Zhou, Y.; Sajjad, U.; Feng, Y.-Q. Evaluating the emerging adsorbents for performance improvement of adsorption desalination cum cooling system. Int. Commun. Heat Mass Transf. 2023, 142, 106661. [Google Scholar] [CrossRef]

- Asfahan, H.M.; Sultan, M.; Miyazaki, T.; Saha, B.B.; Askalany, A.A.; Shahzad, M.W.; Worek, W. Recent development in adsorption desalination: A state of the art review. Appl. Energy 2022, 328, 120101. [Google Scholar] [CrossRef]

- Kucera, J. Desalination: Water from Water; John Wiley & Sons: Hoboken, NJ, USA, 2019; ISBN 1119407893. [Google Scholar]

- Gebel, J.; Yüce, S. An Engineer’s Guide to Desalination; VGB PowerTech Service GmbH Essen: Essen, Germany, 2008; ISBN 3868750002. [Google Scholar]

- Kalogirou, S.A. Seawater desalination using renewable energy sources. Prog. Energy Combust. Sci. 2005, 31, 242–281. [Google Scholar] [CrossRef]

- Alnajdi, O.; Wu, Y.; Calautit, J.K. Toward a sustainable decentralized water supply: Review of adsorption desorption desalination (ADD) and current technologies: Saudi Arabia (SA) as a case study. Water 2020, 12, 1111. [Google Scholar] [CrossRef]

- Tian, Y.; Yang, Z.; Yu, X.; Jia, Z.; Rosso, M.; Dedman, S.; Zhu, J.; Xia, Y.; Zhang, G.; Yang, J.; et al. Can we quantify the aquatic environmental plastic load from aquaculture? Water Res. 2022, 219, 118551. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M.; Rosado, P. CO2 and Greenhouse Gas Emissions. Our world in Data 2020. Published Online at OurWorldInData.org. Available online: https://ourworldindata.org/co2-and-greenhouse-gas-emissions (accessed on 5 March 2023).

- Panagopoulos, A.; Haralambous, K.-J. Minimal Liquid Discharge (MLD) and Zero Liquid Discharge (ZLD) strategies for wastewater management and resource recovery—Analysis, challenges and prospects. J. Environ. Chem. Eng. 2020, 8, 104418. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Saha, B.; Koyama, S. Steady-state investigation of water vapor adsorption for thermally driven adsorption based greenhouse air-conditioning system. Renew. Energy 2016, 86, 785–795. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Koyama, S. Optimization of adsorption isotherm types for desiccant air-conditioning applications. Renew. Energy 2018, 121, 441–450. [Google Scholar] [CrossRef]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S.; Maruyama, T.; Maeda, S.; Nakamura, T. Water vapor sorption kinetics of polymer based sorbents: Theory and experiments. Appl. Therm. Eng. 2016, 106, 192–202. [Google Scholar] [CrossRef]

- Bai, B.; Rao, D.; Chang, T.; Guo, Z. A nonlinear attachment-detachment model with adsorption hysteresis for suspension-colloidal transport in porous media. J. Hydrol. 2019, 578, 124080. [Google Scholar] [CrossRef]

- Dong, H.; Askalany, A.A.; Olkis, C.; Zhao, J.; Santori, G. Hydrothermal stability of water sorption ionogels. Energy 2019, 189, 116186. [Google Scholar] [CrossRef]

- Narayan, S.; Harrison, B.; Liang, S.; Evans, M.; Croll, L.; Smith, S. Sorption kinetic studies of water vapour on activated carbon beds. Carbon 2008, 46, 397–404. [Google Scholar] [CrossRef]

- Shabir, F.; Sultan, M.; Miyazaki, T.; Saha, B.B.; Askalany, A.; Ali, I.; Zhou, Y.; Ahmad, R.; Shamshiri, R.R. Recent updates on the adsorption capacities of adsorbent-adsorbate pairs for heat transformation applications. Renew. Sustain. Energy Rev. 2019, 119, 109630. [Google Scholar] [CrossRef]

- Qasem, N.A.A.; Zubair, S.M. Performance Evaluation of a novel hybrid humidification-dehumidification (Air-Heated) system with an adsorption desalination system. Desalination 2019, 461, 37–54. [Google Scholar] [CrossRef]

- Khalil, A.; El-Agouz, S.A.; El-Samadony, Y.A.F.; Abdo, A. Solar water desalination using an air bubble column humidifier. Desalination 2015, 372, 7–16. [Google Scholar] [CrossRef]

- Wu, G.; Kutlu, C.; Zheng, H.; Su, Y.; Cui, D. A study on the maximum gained output ratio of single-effect solar humidification-dehumidification desalination. Solar Energy 2017, 157, 1–9. [Google Scholar] [CrossRef]

- Muthusamy, C.; Srithar, K. Energy saving potential in humidification-dehumidification desalination system. Energy 2017, 118, 729–741. [Google Scholar] [CrossRef]

- Müller-Holst, H. Solar Thermal Desalination Using the Multiple Effect Humidification (MEH)-Method. In Solar Desalination for the 21st Century; Springer: Berlin/Heidelberg, Germany, 2007; pp. 215–225. [Google Scholar]

- Abd ElKader, M.; Aref, A.; Moustafa, G.H.; ElHenawy, Y.A. Theoretical and experimental study for a humidification-dehumidification (HD) solar desalination unit. Eng. Res. J. 2010, 33, 119–130. [Google Scholar] [CrossRef]

- Sajjad, U.; Abbas, N.; Hamid, K.; Abbas, S.; Hussain, I.; Ammar, S.M.; Sultan, M.; Ali, H.M.; Hussain, M.; Rehman, T.U.; et al. A review of recent advances in indirect evaporative cooling technology. Int. Commun. Heat Mass Transf. 2021, 122, 105140. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Mahmood, M.H.; Khan, Z.M. Solar assisted evaporative cooling based passive air-conditioning system for agricultural and livestock applications. J. Eng. Sci. Technol. 2018, 13, 693–703. [Google Scholar]

- Aleem, M.; Hussain, G.; Sultan, M.; Miyazaki, T.; Mahmood, M.H.; Sabir, M.I.; Nasir, A.; Shabir, F.; Khan, Z.M. Experimental Investigation of Desiccant Dehumidification Cooling System for Climatic Conditions of Multan (Pakistan). Energies 2020, 13, 5530. [Google Scholar] [CrossRef]

- Asfahan, H.M.; Sajjad, U.; Sultan, M.; Hussain, I.; Hamid, K.; Ali, M.; Wang, C.-C.; Shamshiri, R.R.; Khan, M.U. Artificial Intelligence for the Prediction of the Thermal Performance of Evaporative Cooling Systems. Energies 2021, 14, 3946. [Google Scholar] [CrossRef]

- Vala, K.V.; Saiyed, F.; Joshi, D.C. Evaporative Cooled Storage Structures: An Indian Scenario. Trends in Post Harvest Technology, 2, 22–32.—Google Search. 2014. Available online: https://rb.gy/qwtnar (accessed on 5 March 2023).

- Raza, H.M.U.; Sultan, M.; Bahrami, M.; Khan, A.A. Experimental investigation of evaporative cooling systems for agricultural storage and livestock air-conditioning in Pakistan. Build. Simul. 2020, 14, 617–631. [Google Scholar] [CrossRef]

- Aziz, M.A.; Lin, J.; Mikšík, F.; Miyazaki, T.; Thu, K. The second law analysis of a humidification-dehumidification desalination system using M-cycle. Sustain. Energy Technol. Assess. 2022, 52, 102141. [Google Scholar] [CrossRef]

- Dizaji, H.S.; Hu, E.J.; Chen, L. A comprehensive review of the Maisotsenko-cycle based air conditioning systems. Energy 2018, 156, 725–749. [Google Scholar] [CrossRef]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T.; Koyama, S.; Maisotsenko, V.S. Overview of the Maisotsenko cycle—A way towards dew point evaporative cooling. Renew. Sustain. Energy Rev. 2016, 66, 537–555. [Google Scholar] [CrossRef]

- Raza, H.M.U.; Ashraf, H.; Shahzad, K.; Sultan, M.; Miyazaki, T.; Usman, M.; Shamshiri, R.R.; Zhou, Y.; Ahmad, R. Investigating Applicability of Evaporative Cooling Systems for Thermal Comfort of Poultry Birds in Pakistan. Appl. Sci. 2020, 10, 4445. [Google Scholar] [CrossRef]

- Çalişkan, H.; Hepbasli, A.; Dincer, I.; Maisotsenko, V. Thermodynamic performance assessment of a novel air cooling cycle: Maisotsenko cycle. Int. J. Refrig. 2011, 34, 980–990. [Google Scholar] [CrossRef]

- Hussain, G.; Aleem, M.; Sultan, M.; Sajjad, U.; Ibrahim, S.M.; Shamshiri, R.R.; Farooq, M.; Khan, M.U.; Bilal, M. Evaluating Evaporative Cooling Assisted Solid Desiccant Dehumidification System for Agricultural Storage Application. Sustainability 2022, 14, 1479. [Google Scholar] [CrossRef]

- Bell, I.H.; Wronski, J.; Quoilin, S.; Lemort, V. Pure and Pseudo-Pure Fluid Thermophysical Property Evaluation and the Open-Source Thermophysical Property Library Coolprop. Ind. Eng. Chem Res. 2014, 53, 2498–2508. [Google Scholar] [CrossRef]

- Maclaine-Cross, I.L.; Banks, P.J. A General Theory of Wet Surface Heat Exchangers and its Application to Regenerative Evaporative Cooling. J. Heat Transf. 1981, 103, 579–585. [Google Scholar] [CrossRef]

- Stoitchkov, N.J.; Dimitrov, G.I. Effectiveness of Crossflow plate heat exchanger for indirect evaporative cooling: Efficacité des échangeurs thermiques à plaques, à courants croises pour refroidissement indirect évaporatif. Int. J. Refrig. 1998, 21, 463–471. [Google Scholar] [CrossRef]

- Alonso, J.F.S.J.; Martíez, F.J.R.; Gómez, E.V.; Plasencia, M.A.A.G. Simulation model of an indirect evaporative cooler. Energy Build 1998, 29, 23–27. [Google Scholar] [CrossRef]

- Chidnovsky, Y.; Kozlov, A. Integrated Industrial Wastewater Reuse by Heat Recovery; State of California Energy Commission: Sacramento, CA, USA, 2015. [Google Scholar]

- Xu, H.; Jiang, S.; Xie, M.X.; Jia, T.; Dai, Y.J. Technical Improvements and perspectives on humidification-dehumidification desalination—A review. Desalination 2022, 541, 116029. [Google Scholar] [CrossRef]

- Campos, B.L.d.O.; Costa, A.O.S.d.; Costa Junior, E.F.d. Mathematical modeling and sensibility analysis of a solar humidification-dehumidification desalination system considering saturated air. Solar Energy 2017, 157, 321–327. [Google Scholar] [CrossRef]

- Rocchetti, A.; Socci, L. Theoretical and numerical assessment of an enhanced humidification-dehumidification desalination system based on indirect evaporative cooling and vapour compression refrigeration. Appl. Therm. Eng. 2022, 208, 118194. [Google Scholar] [CrossRef]

- Tariq, R.; Sheikh, N.A.; Xamán, J.; Bassam, A. An innovative air saturator for humidification-dehumidification desalination application. Appl. Energy 2018, 228, 789–807. [Google Scholar] [CrossRef]

| Parameters (Units) | DE-HDH | IE-HDH | ME-HDH |

|---|---|---|---|

| Width (m) | 0.25 | 0.127 | 0.127 |

| Height (m) | 0.2032 | 0.2032 | |

| Velocity (m/s) | 2.0 | 4.0 | |

| Tdb (°C) | 10 to 50 | ||

| RH (-) | 0.1 to 1.0 | ||

| Wet bulb effectiveness (%) | 95% | 58% | 98% |

| Fan (Qty) | 1.0 | 2.0 | 2.0 |

| Pump (Qty) | 1.0 | ||

| Fan power (W) | 15.0 | ||

| Pump power (W) | 10 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, M.; Alqahtani, N.K.; Asfahan, H.M.; Sultan, M. Evaporation-Assisted Humidification–Dehumidification Cycles for Desalination Application in Tropical and Subtropical Regions. Water 2023, 15, 1125. https://doi.org/10.3390/w15061125

Mohammed M, Alqahtani NK, Asfahan HM, Sultan M. Evaporation-Assisted Humidification–Dehumidification Cycles for Desalination Application in Tropical and Subtropical Regions. Water. 2023; 15(6):1125. https://doi.org/10.3390/w15061125

Chicago/Turabian StyleMohammed, Maged, Nashi K. Alqahtani, Hafiz M. Asfahan, and Muhammad Sultan. 2023. "Evaporation-Assisted Humidification–Dehumidification Cycles for Desalination Application in Tropical and Subtropical Regions" Water 15, no. 6: 1125. https://doi.org/10.3390/w15061125

APA StyleMohammed, M., Alqahtani, N. K., Asfahan, H. M., & Sultan, M. (2023). Evaporation-Assisted Humidification–Dehumidification Cycles for Desalination Application in Tropical and Subtropical Regions. Water, 15(6), 1125. https://doi.org/10.3390/w15061125