A Review of Membrane-Based Desalination Systems Powered by Renewable Energy Sources

Abstract

:1. Introduction

2. Renewable Energies and Desalination

2.1. Solar Energy

2.2. Wind Energy

2.3. Wave Energy

2.4. Geothermal Energy

2.5. Nuclear Energy

2.6. Blue Energy

3. Membrane-Based Desalination Processes Coupled with Renewable Energy

3.1. RO-Based Desalination Systems Driven by Renewable Energy Sources

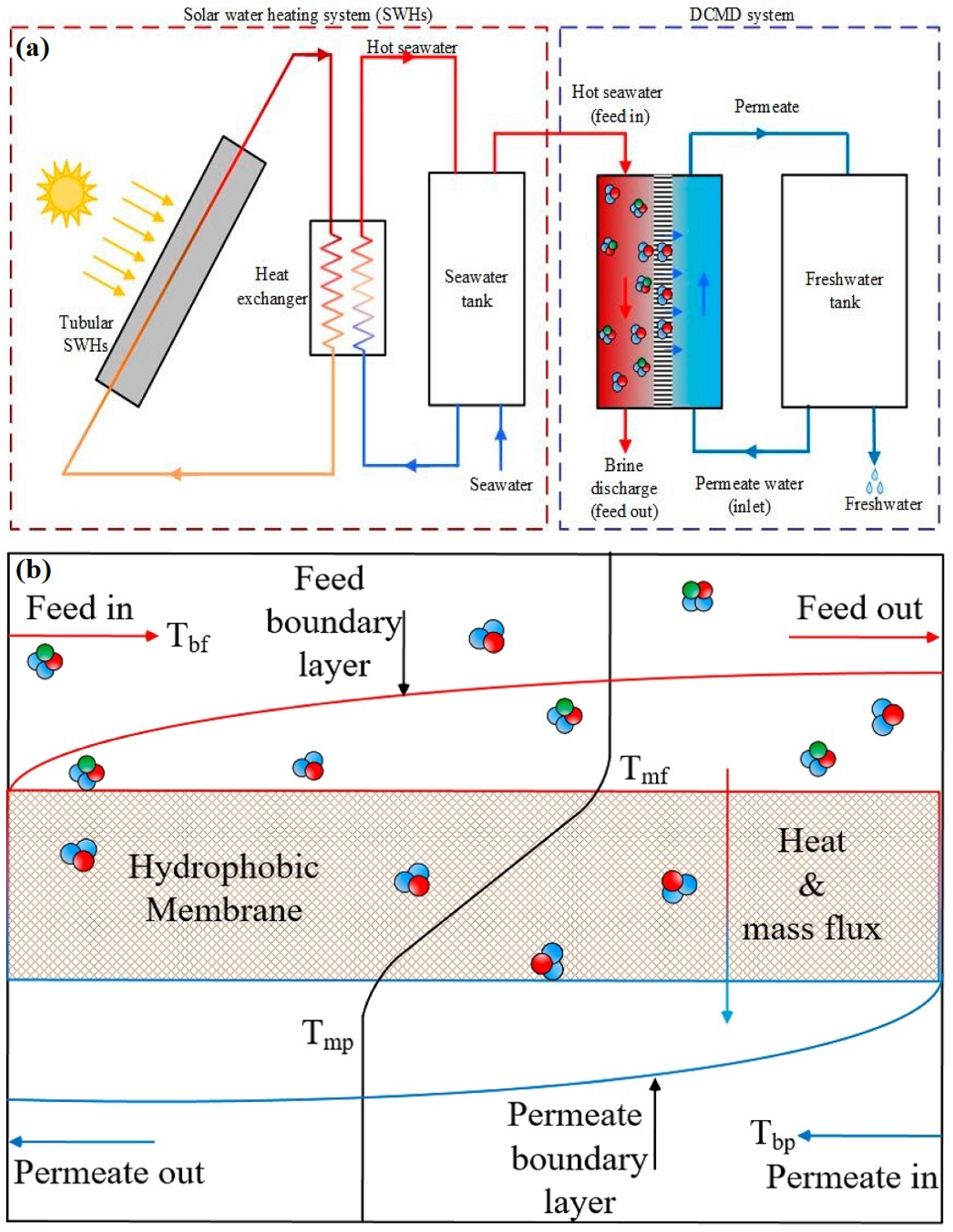

3.2. MD-Based Desalination Systems Driven by Renewable Energy Sources

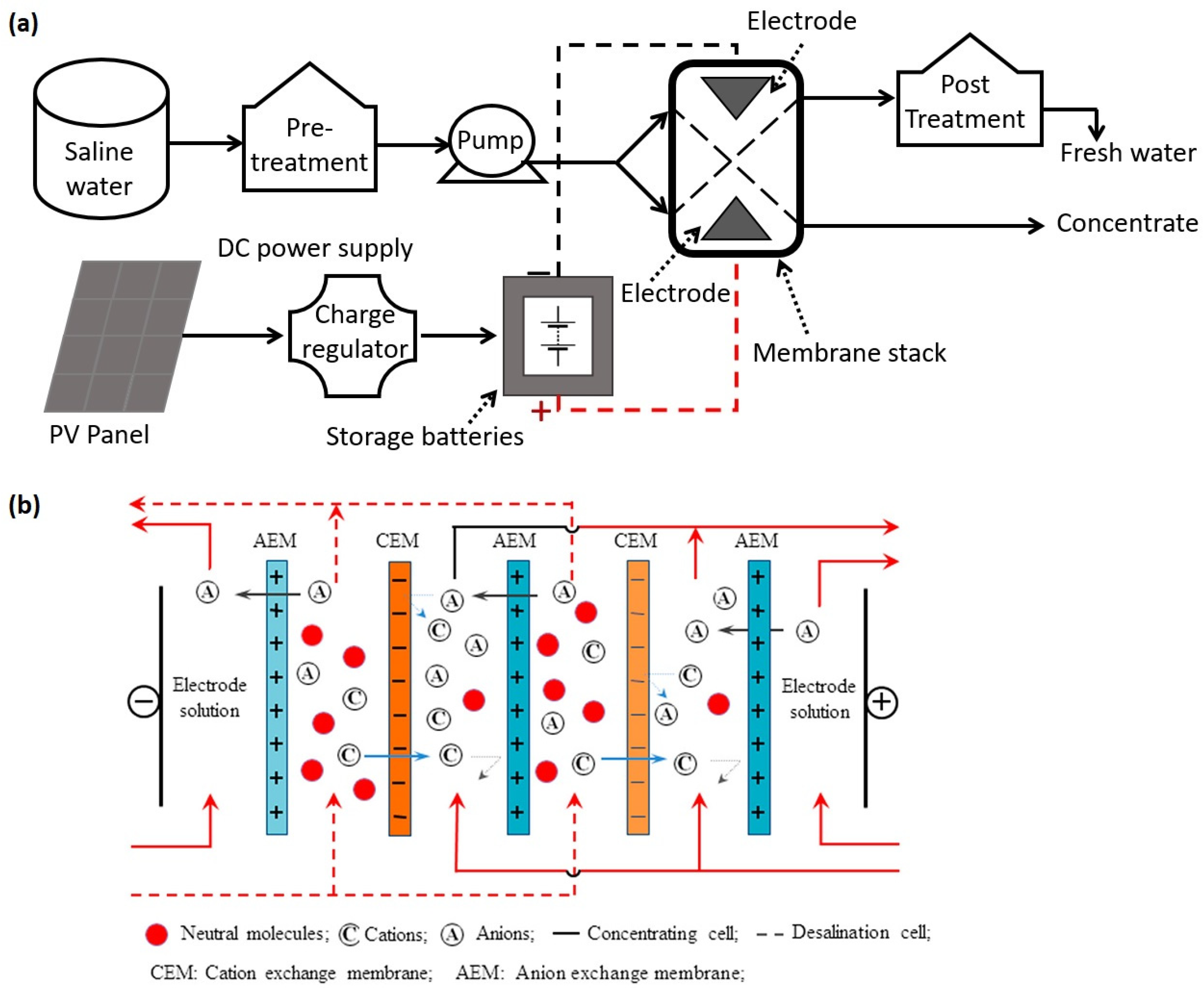

3.3. ED-Based Desalination Systems Driven by Renewable Energy Sources

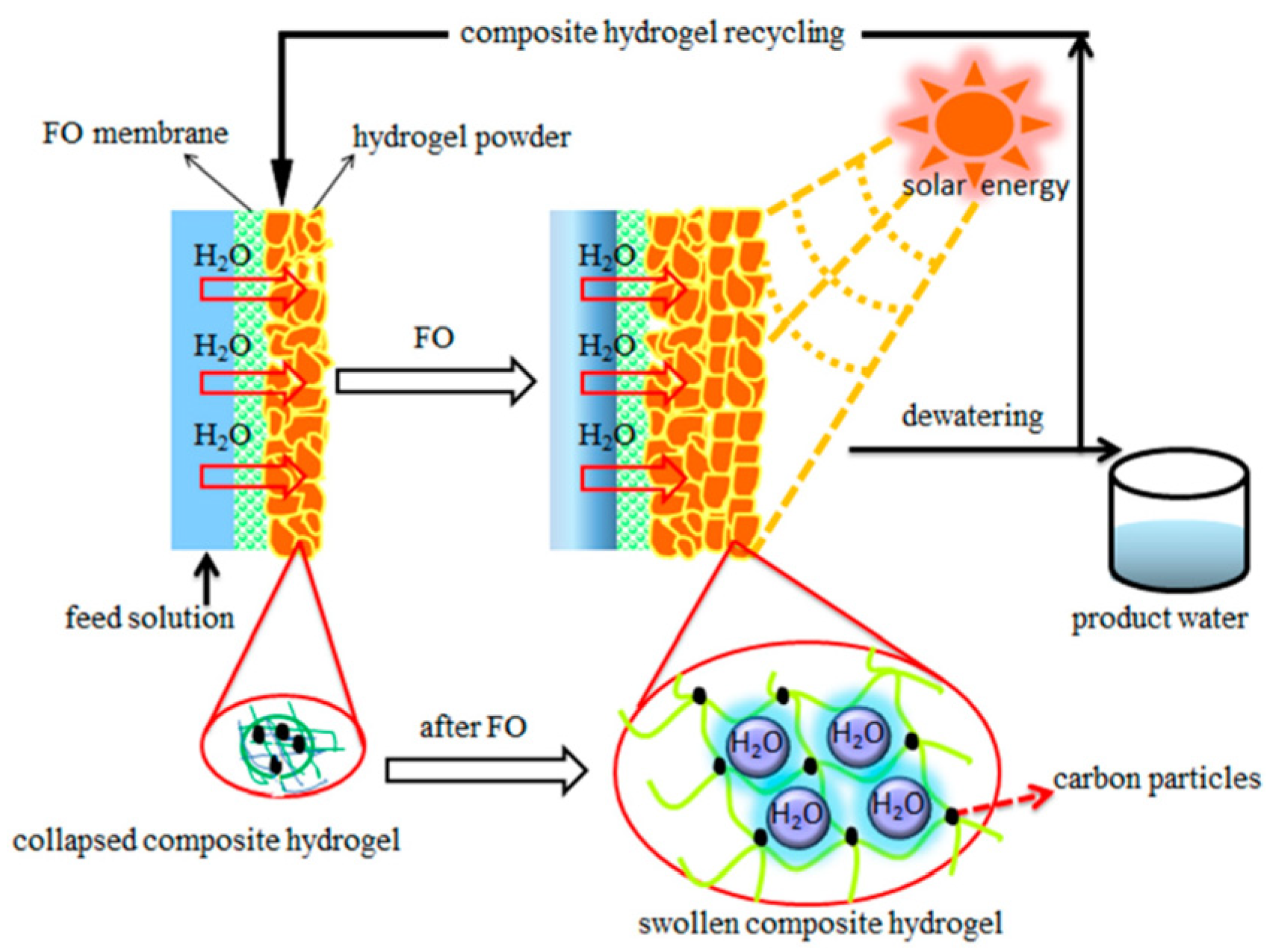

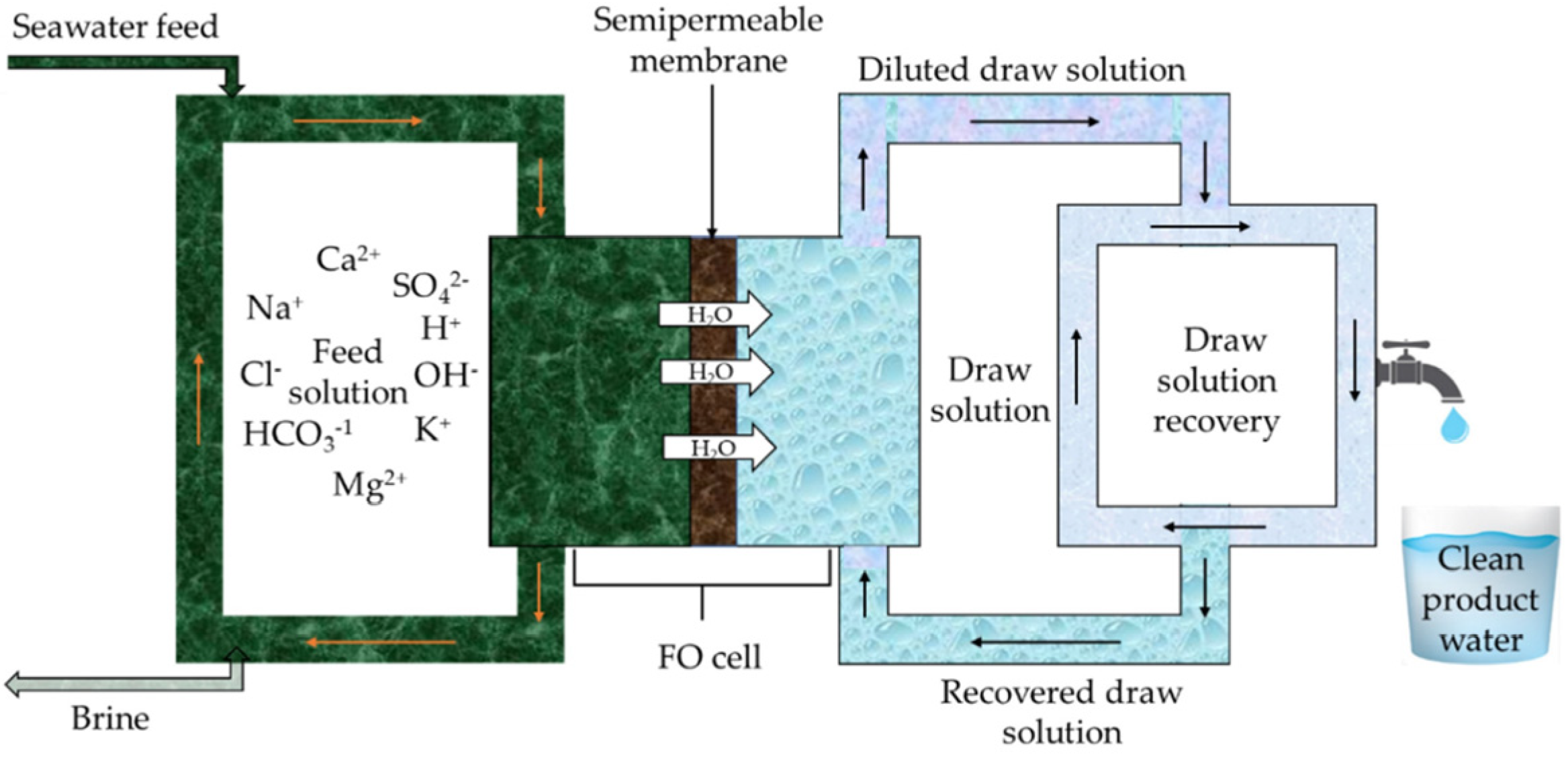

3.4. FO-Based Desalination Systems Driven by Renewable Energy Sources

4. Limitations and Future Perspectives

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shahid, M.K.; Pyo, M.; Choi, Y. Carbonate Scale Reduction in Reverse Osmosis Membrane by CO2 in Wastewater Reclamation. Membr. Water Treat. 2017, 8, 125–136. [Google Scholar] [CrossRef]

- Shahid, M.K.; Kashif, A.; Pathak, P.; Choi, Y.; Rout, P.R. Water Reclamation, Recycle, and Reuse. In Clean Energy and Resource Recovery; Elsevier Inc.: Amsterdam, The Netherlands, 2021; pp. 39–49. ISBN 978-0-323-90178-9. [Google Scholar]

- Dayarathne, H.N.P.; Angove, M.J.; Shahid, M.K.; Paudel, S.R.; Aryal, R.; Mainali, B. Characterisation of Bushfire Residuals in Source Water and Removal by Coagulation. Sci. Total Environ. 2023, 862, 160800. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.A.; Morton, D.W.; Johnson, B.B.; Mainali, B.; Angove, M.J. Manganese Oxides and Their Application to Metal Ion and Contaminant Removal from Wastewater. J. Water Process Eng. 2018, 26, 264–280. [Google Scholar] [CrossRef]

- Shahid, M.K.; Kashif, A.; Fuwad, A.; Choi, Y. Current Advances in Treatment Technologies for Removal of Emerging Contaminants from Water–A Critical Review. Coord. Chem. Rev. 2021, 442, 213993. [Google Scholar] [CrossRef]

- Rout, P.R.; Shahid, M.K.; Dash, R.R.; Bhunia, P.; Liu, D.; Varjani, S.; Zhang, T.C.; Surampalli, R.Y. Nutrient Removal from Domestic Wastewater: A Comprehensive Review on Conventional and Advanced Technologies. J. Environ. Manag. 2021, 296, 113246. [Google Scholar] [CrossRef] [PubMed]

- Meran, G.; Siehlow, M.; von Hirschhausen, C. (Eds.) Water Availability: A Hydrological View. In The Economics of Water: Rules and Institutions; Springer International Publishing: Cham, Switzerland, 2021; pp. 9–21. ISBN 978-3-030-48485-9. [Google Scholar]

- Khilchevskyi, V.; Karamushka, V. Global Water Resources: Distribution and Demand. In Clean Water and Sanitation. Encyclopedia of the UN Sustainable Development Goals; Leal Filho, W., Azul, A.M., Brandli, L., Lange Salvia, A., Wall, T., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–11. ISBN 978-3-319-70061-8. [Google Scholar]

- Seman, H.; Ali, G.A.; Gökçeku, H.; Kassem, Y. Review on Waste Water Reuse for Irrigation towards Achieving Environmental Sustainability. Int. J. Eng. Appl. Phys. 2023, 3, 678–688. Available online: https://n2t.net/ark:/15735/IJEAP.v3i1.115 (accessed on 1 January 2023).

- Mahmud, I.; Kaiser, S. Recent Progress in Waterless Textile Dyeing. J. Text. Sci. Eng. 2020, 10, 1–3. Available online: https://www.hilarispublisher.com/open-access/recent-progress-in-waterless-textile-dyeing-51894.html (accessed on 1 January 2023).

- He, K.; Hwang, H.J.; Woo, M.W.; Moon, I.S. Production of Drinking Water from Saline Water by Direct Contact Membrane Distillation (DCMD). J. Ind. Eng. Chem. 2011, 17, 41–48. [Google Scholar] [CrossRef]

- Greenlee, L.F.; Lawler, D.F.; Freeman, B.D.; Marrot, B.; Moulin, P. Reverse Osmosis Desalination: Water Sources, Technology, and Today’s Challenges. Water Res. 2009, 43, 2317–2348. [Google Scholar] [CrossRef]

- Ramasamy, R.; Surendran, S.N.; Jude, P.J.; Dharshini, S.; Vinobaba, M. Larval Development of Aedes Aegypti and Aedes Albopictus in Peri-Urban Brackish Water and Its Implications for Transmission of Arboviral Diseases. PLoS Negl. Trop. Dis. 2011, 5, e1369. [Google Scholar] [CrossRef] [Green Version]

- Shahid, M.K.; Choi, Y. CO2 as an Alternative to Traditional Antiscalants in Pressure-Driven Membrane Processes: An Experimental Study of Lab-Scale Operation and Cleaning Strategies. Membranes 2022, 12, 918. [Google Scholar] [CrossRef] [PubMed]

- Ayaz, M.; Namazi, M.A.; Din, M.A.; Ershath, M.I.M.; Mansour, A.; Aggoune, H.M. Sustainable Seawater Desalination: Current Status, Environmental Implications and Future Expectations. Desalination 2022, 540, 116022. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Burhan, M.; Ang, L.; Ng, K.C. Energy-Water-Environment Nexus Underpinning Future Desalination Sustainability. Desalination 2017, 413, 52–64. [Google Scholar] [CrossRef]

- Charcosset, C. Classical and Recent Developments of Membrane Processes for Desalination and Natural Water Treatment. Membranes 2022, 12, 267. [Google Scholar] [CrossRef] [PubMed]

- Prajapati, M.; Shah, M.; Soni, B. A Comprehensive Review of the Geothermal Integrated Multi-Effect Distillation (MED) Desalination and Its Advancements. Groundw. Sustain. Dev. 2022, 19, 100808. [Google Scholar] [CrossRef]

- Lawal, D.U.; Antar, M.A.; Ismaila, K.G.; Khalifa, A.; Alawad, S.M. Hybrid Multi-Stage Flash (MSF) and Membrane Distillation (MD) Desalination System for Energy Saving and Brine Minimization. Desalination 2023, 548, 116231. [Google Scholar] [CrossRef]

- Lin, B.; Malmali, M. Energy and Exergy Analysis of Multi-Stage Vacuum Membrane Distillation Integrated with Mechanical Vapor Compression. Sep. Purif. Technol. 2023, 306, 122568. [Google Scholar] [CrossRef]

- Abidin, M.N.Z.; Nasef, M.M.; Veerman, J. Towards the Development of New Generation of Ion Exchange Membranes for Reverse Electrodialysis: A Review. Desalination 2022, 537, 115854. [Google Scholar] [CrossRef]

- Shahid, M.K.; Pyo, M.; Choi, Y.-G. Inorganic Fouling Control in Reverse Osmosis Wastewater Reclamation by Purging Carbon Dioxide. Environ. Sci. Pollut. Res. 2019, 26, 1094–1102. [Google Scholar] [CrossRef]

- Manesh, M.H.K.; Kabiri, S.; Yazdi, M. Integration of MED-RO and MSF-RO Desalination with a Combined Cycle Power Plant. Desalin. Water Treat. 2020, 179, 106–129. [Google Scholar] [CrossRef]

- Kokabian, B.; Gude, V.G. Microbial Desalination Systems for Energy and Resource Recovery. In Biomass, Biofuels and Biochemicals; Mohan, S.V., Varjani, S., Pandey, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 999–1020. ISBN 978-0-444-64052-9. [Google Scholar]

- Ilechukwu, N.; Lahiri, S. Renewable-Energy Consumption and International Trade. Energy Rep. 2022, 8, 10624–10629. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, C. Promoting Renewable Energy through National Energy Legislation. Energy Econ. 2023, 118, 106504. [Google Scholar] [CrossRef]

- Shahid, M.K.; Batool, A.; Kashif, A.; Nawaz, M.H.; Aslam, M.; Iqbal, N.; Choi, Y. Biofuels and Biorefineries: Development, Application and Future Perspectives Emphasizing the Environmental and Economic Aspects. J. Environ. Manag. 2021, 297, 113268. [Google Scholar] [CrossRef] [PubMed]

- Kumar, C.M.S.; Singh, S.; Gupta, M.K.; Nimdeo, Y.M.; Raushan, R.; Deorankar, A.V.; Kumar, T.M.A.; Rout, P.K.; Chanotiya, C.S.; Pakhale, V.D.; et al. Solar Energy: A Promising Renewable Source for Meeting Energy Demand in Indian Agriculture Applications. Sustain. Energy Technol. Assess. 2023, 55, 102905. [Google Scholar] [CrossRef]

- Elsayed-Ali, H.E. Elevation-Distributed Multistage Reverse Osmosis Desalination with Seawater Pumped Storage. Appl. Water Sci. 2022, 13, 48. [Google Scholar] [CrossRef]

- Nasrollahi, M.; Motevali, A.; Banakar, A.; Montazeri, M. Comparison of Environmental Impact on Various Desalination Technologies. Desalination 2023, 547, 116253. [Google Scholar] [CrossRef]

- Zhang, Y.; Anoopkumar, A.N.; Aneesh, E.M.; Pugazhendhi, A.; Binod, P.; Kuddus, M.; Pandey, A.; Kumar Awasthi, M.; Sindhu, R. Advancements in the Energy-Efficient Brine Mining Technologies as a New Frontier for Renewable Energy. Fuel 2023, 335, 127072. [Google Scholar] [CrossRef]

- Bhattarai, T.N.; Ghimire, S.; Mainali, B.; Gorjian, S.; Treichel, H.; Paudel, S.R. Applications of Smart Grid Technology in Nepal: Status, Challenges, and Opportunities. Environ. Sci. Pollut. Res. 2022, 1–25. [Google Scholar] [CrossRef]

- Sikiru, S.; Oladosu, T.L.; Amosa, T.I.; Kolawole, S.Y.; Soleimani, H. Recent Advances and Impact of Phase Change Materials on Solar Energy: A Comprehensive Review. J. Energy Storage 2022, 53, 105200. [Google Scholar] [CrossRef]

- Azizi, N.; Esmaeilion, F.; Moosavian, S.F.; Yaghoubirad, M.; Ahmadi, A.; Aliehyaei, M.; Soltani, M. Critical Review of Multigeneration System Powered by Geothermal Energy Resource from the Energy, Exergy, and Economic Point of Views. Energy Sci. Eng. 2022, 10, 4859–4889. [Google Scholar] [CrossRef]

- Khojasteh, D.; Lewis, M.; Tavakoli, S.; Farzadkhoo, M.; Felder, S.; Iglesias, G.; Glamore, W. Sea Level Rise Will Change Estuarine Tidal Energy: A Review. Renew. Sustain. Energy Rev. 2022, 156, 111855. [Google Scholar] [CrossRef]

- Abedi, M.; Tan, X.; Klausner, J.F.; Bénard, A. Solar Desalination Chimneys: Investigation on the Feasibility of Integrating Solar Chimneys with Humidification–Dehumidification Systems. Renew. Energy 2023, 202, 88–102. [Google Scholar] [CrossRef]

- Gabrielli, P.; Mazzotti, M. Solar-Driven Humidification–Dehumidification Process for Water Desalination Analyzed and Optimized via Equilibrium Theory. Ind. Eng. Chem. Res. 2019, 58, 15244–15261. [Google Scholar] [CrossRef] [Green Version]

- Elgendi, M.; Kabeel, A.E.; Essa, F.A. Improving the Solar Still Productivity Using Thermoelectric Materials: A Review. Alex. Eng. J. 2022, 65, 963–985. [Google Scholar] [CrossRef]

- Ašmontas, S.; Čerškus, A.; Gradauskas, J.; Grigucevičienė, A.; Juškėnas, R.; Leinartas, K.; Lučun, A.; Petrauskas, K.; Selskis, A.; Staišiūnas, L.; et al. Photoelectric Properties of Planar and Mesoporous Structured Perovskite Solar Cells. Materials 2022, 15, 4300. [Google Scholar] [CrossRef]

- Wang, W.; Shi, Y.; Zhang, C.; Hong, S.; Shi, L.; Chang, J.; Li, R.; Jin, Y.; Ong, C.; Zhuo, S.; et al. Simultaneous Production of Fresh Water and Electricity via Multistage Solar Photovoltaic Membrane Distillation. Nat. Commun. 2019, 10, 3012. [Google Scholar] [CrossRef] [Green Version]

- Jafaripour, M.; Roghabadi, F.A.; Soleimanpour, S.; Sadrameli, S.M. Barriers to Implementation of Phase Change Materials within Solar Desalination Units: Exergy, Thermal Conductivity, Economic, and Environmental Aspects Review. Desalination 2023, 546, 116191. [Google Scholar] [CrossRef]

- Chiu, C.-H.; Lung, S.-C.C.; Chen, N.; Hwang, J.-S.; Tsou, M.-C.M. Effects of Low-Frequency Noise from Wind Turbines on Heart Rate Variability in Healthy Individuals. Sci. Rep. 2021, 11, 17817. [Google Scholar] [CrossRef]

- Teff-Seker, Y.; Berger-Tal, O.; Lehnardt, Y.; Teschner, N. Noise Pollution from Wind Turbines and Its Effects on Wildlife: A Cross-National Analysis of Current Policies and Planning Regulations. Renew. Sustain. Energy Rev. 2022, 168, 112801. [Google Scholar] [CrossRef]

- Oerlemans, S.; Sijtsma, P.; Méndez López, B. Location and Quantification of Noise Sources on a Wind Turbine. J. Sound Vib. 2007, 299, 869–883. [Google Scholar] [CrossRef]

- Deshmukh, S.; Bhattacharya, S.; Jain, A.; Paul, A.R. Wind Turbine Noise and Its Mitigation Techniques: A Review. Energy Procedia 2019, 160, 633–640. [Google Scholar] [CrossRef]

- Shabara, M.A.; Abdelkhalik, O. Dynamic Modeling of the Motions of Variable-Shape Wave Energy Converters. Renew. Sustain. Energy Rev. 2023, 173, 113070. [Google Scholar] [CrossRef]

- Del Río-Gamero, B.; Lis Alecio, T.; Schallenberg-Rodríguez, J. Performance Indicators for Coupling Desalination Plants with Wave Energy. Desalination 2022, 525, 115479. [Google Scholar] [CrossRef]

- Prajapati, M.; Shah, M.; Soni, B.; Parikh, S.; Sircar, A.; Balchandani, S.; Thakore, S.; Tala, M. Geothermal-Solar Integrated Groundwater Desalination System: Current Status and Future Perspective. Groundw. Sustain. Dev. 2021, 12, 100506. [Google Scholar] [CrossRef]

- Prajapati, M.; Shah, M.; Soni, B. A Review of Geothermal Integrated Desalination: A Sustainable Solution to Overcome Potential Freshwater Shortages. J. Clean. Prod. 2021, 326, 129412. [Google Scholar] [CrossRef]

- Alsaleh, M.; Yang, Z.; Chen, T.; Wang, X.; Abdul-Rahim, A.S.; Mahmood, H. Moving toward Environmental Sustainability: Assessing the Influence of Geothermal Power on Carbon Dioxide Emissions. Renew. Energy 2023, 202, 880–893. [Google Scholar] [CrossRef]

- Al-Othman, A.; Darwish, N.N.; Qasim, M.; Tawalbeh, M.; Darwish, N.A.; Hilal, N. Nuclear Desalination: A State-of-the-Art Review. Desalination 2019, 457, 39–61. [Google Scholar] [CrossRef]

- Brogioli, D.; Zhao, R.; Biesheuvel, P.M. A Prototype Cell for Extracting Energy from a Water Salinity Difference by Means of Double Layer Expansion in Nanoporous Carbon Electrodes. Energy Environ. Sci. 2011, 4, 772–777. [Google Scholar] [CrossRef] [Green Version]

- Jia, Z.; Wang, B.; Song, S.; Fan, Y. Blue Energy: Current Technologies for Sustainable Power Generation from Water Salinity Gradient. Renew. Sustain. Energy Rev. 2014, 31, 91–100. [Google Scholar] [CrossRef]

- Rath, R.; Dutta, D.; Kamesh, R.; Sharqawy, M.H.; Moulik, S.; Roy, A. Rational Design of High Power Density “Blue Energy Harvester” Pressure Retarded Osmosis (PRO) Membranes Using Artificial Intelligence-Based Modeling and Optimization. Energy Convers. Manag. 2022, 253, 115160. [Google Scholar] [CrossRef]

- Abdullah Shah, S.; Haider, Z.; Shahbabaei, M.; Kim, D. Development of an Efficient System for Blue Energy Production Based on Reverse Electrodialysis (RED) by Optimizing Electrolyte Composition: Experimental and Theoretical Simulations. Energy Fuels 2022, 36, 6353–6361. [Google Scholar] [CrossRef]

- Shahid, M.K.; Kashif, A.; Rout, P.R.; Aslam, M.; Fuwad, A.; Choi, Y.; Park, J.H.; Kumar, G. A Brief Review of Anaerobic Membrane Bioreactors Emphasizing Recent Advancements, Fouling Issues and Future Perspectives. J. Environ. Manag. 2020, 270, 110909. [Google Scholar] [CrossRef] [PubMed]

- Shahid, M.K.; Choi, Y. Sustainable Membrane-Based Wastewater Reclamation Employing CO2 to Impede an Ionic Precipitation and Consequent Scale Progression onto the Membrane Surfaces. Membranes 2021, 11, 688. [Google Scholar] [CrossRef] [PubMed]

- Subramani, A.; Badruzzaman, M.; Oppenheimer, J.; Jacangelo, J.G. Energy Minimization Strategies and Renewable Energy Utilization for Desalination: A Review. Water Res. 2011, 45, 1907–1920. [Google Scholar] [CrossRef] [PubMed]

- Alqaed, S.; Mustafa, J.; Almehmadi, F.A. Design and Energy Requirements of a Photovoltaic-Thermal Powered Water Desalination Plant for the Middle East. Int. J. Environ. Res. Public Health 2021, 18, 1001. [Google Scholar] [CrossRef] [PubMed]

- Herold, D.; Neskakis, A. A Small PV-Driven Reverse Osmosis Desalination Plant on the Island of Gran Canaria. Desalination 2001, 137, 285–292. [Google Scholar] [CrossRef]

- Mohamed, E.S.; Papadakis, G.; Mathioulakis, E.; Belessiotis, V. A Direct Coupled Photovoltaic Seawater Reverse Osmosis Desalination System toward Battery Based Systems—A Technical and Economical Experimental Comparative Study. Desalination 2008, 221, 17–22. [Google Scholar] [CrossRef]

- Manolakos, D.; Mohamed, E.S.; Karagiannis, I.; Papadakis, G. Technical and Economic Comparison between PV-RO System and RO-Solar Rankine System. Case Study: Thirasia Island. Desalination 2008, 221, 37–46. [Google Scholar] [CrossRef]

- Soleimanzade, M.A.; Sadrzadeh, M. Deep Learning-Based Energy Management of a Hybrid Photovoltaic-Reverse Osmosis-Pressure Retarded Osmosis System. Appl. Energy 2021, 293, 116959. [Google Scholar] [CrossRef]

- Carta, J.A.; González, J.; Cabrera, P.; Subiela, V.J. Preliminary Experimental Analysis of a Small-Scale Prototype SWRO Desalination Plant, Designed for Continuous Adjustment of Its Energy Consumption to the Widely Varying Power Generated by a Stand-Alone Wind Turbine. Appl. Energy 2015, 137, 222–239. [Google Scholar] [CrossRef]

- Carta, J.A.; Cabrera, P. Optimal Sizing of Stand-Alone Wind-Powered Seawater Reverse Osmosis Plants without Use of Massive Energy Storage. Appl. Energy 2021, 304, 117888. [Google Scholar] [CrossRef]

- Rashidi, M.M.; Mahariq, I.; Murshid, N.; Wongwises, S.; Mahian, O.; Alhuyi Nazari, M. Applying Wind Energy as a Clean Source for Reverse Osmosis Desalination: A Comprehensive Review. Alex. Eng. J. 2022, 61, 12977–12989. [Google Scholar] [CrossRef]

- Rosales-Asensio, E.; Borge-Diez, D.; Pérez-Hoyos, A.; Colmenar-Santos, A. Reduction of Water Cost for an Existing Wind-Energy-Based Desalination Scheme: A Preliminary Configuration. Energy 2019, 167, 548–560. [Google Scholar] [CrossRef]

- Shahid, M.K.; Pyo, M.; Choi, Y.-G. The Operation of Reverse Osmosis System with CO2 as a Scale Inhibitor: A Study on Operational Behavior and Membrane Morphology. Desalination 2017, 426, 11–20. [Google Scholar] [CrossRef]

- Prado de Nicolás, A.; Molina-García, A.; García-Bermejo, J.T.; Vera-García, F. Reject Brine Management: Denitrification and Zero Liquid Discharge (ZLD)—Current Status, Challenges and Future Prospects. J. Clean. Prod. 2022, 381, 135124. [Google Scholar] [CrossRef]

- Shahid, M.K.; Choi, Y.-G. The Comparative Study for Scale Inhibition on Surface of RO Membranes in Wastewater Reclamation: CO2 Purging versus Three Different Antiscalants. J. Memb. Sci. 2017, 546, 61–69. [Google Scholar] [CrossRef]

- Hoek, E.M.V.; Weigand, T.M.; Edalat, A. Reverse Osmosis Membrane Biofouling: Causes, Consequences and Countermeasures. Clean Water 2022, 5, 45. [Google Scholar] [CrossRef]

- Jang, Y.; Lee, J.-G.; Fortunato, L.; Lee, J.; Lee, Y.; An, A.K.; Ghaffour, N.; Lee, S.; Jeong, S. Colloidal Silica Fouling Mechanism in Direct-Contact Membrane Distillation. Desalination 2022, 527, 115554. [Google Scholar] [CrossRef]

- Feng, H.; Li, H.; Li, M.; Zhang, X. Construction of Omniphobic PVDF Membranes for Membrane Distillation: Investigating the Role of Dimension, Morphology, and Coating Technology of Silica Nanoparticles. Desalination 2022, 525, 115498. [Google Scholar] [CrossRef]

- Bonyadi, E.; Niknejad, A.S.; Ashtiani, F.Z.; Bazgir, S.; Kargari, A. A Well-Designed Polystyrene/Polycarbonate Membrane for Highly Saline Water Desalination Using DCMD Process. Desalination 2022, 528, 115604. [Google Scholar] [CrossRef]

- Alsebaeai, M.K.; Ahmad, A.L. Membrane Distillation: Progress in the Improvement of Dedicated Membranes for Enhanced Hydrophobicity and Desalination Performance. J. Ind. Eng. Chem. 2020, 86, 13–34. [Google Scholar] [CrossRef]

- Bouguecha, S.T.; Aly, S.E.; Al-Beirutty, M.H.; Hamdi, M.M.; Boubakri, A. Solar Driven DCMD: Performance Evaluation and Thermal Energy Efficiency. Chem. Eng. Res. Des. 2015, 100, 331–340. [Google Scholar] [CrossRef]

- Chen, Y.-H.; Hung, H.-G.; Ho, C.-D.; Chang, H. Economic Design of Solar-Driven Membrane Distillation Systems for Desalination. Membranes 2021, 11, 15. [Google Scholar] [CrossRef]

- Soomro, M.I.; Kumar, S.; Ullah, A.; Shar, M.A.; Alhazaa, A. Solar-Powered Direct Contact Membrane Distillation System: Performance and Water Cost Evaluation. Sustainability 2022, 14, 16616. [Google Scholar] [CrossRef]

- Tomaszewska, B.; Bundschuh, J.; Pająk, L.; Dendys, M.; Delgado Quezada, V.; Bodzek, M.; Armienta, M.A.; Muñoz, M.O.; Kasztelewicz, A. Use of Low-Enthalpy and Waste Geothermal Energy Sources to Solve Arsenic Problems in Freshwater Production in Selected Regions of Latin America Using a Process Membrane Distillation–Research into Model Solutions. Sci. Total Environ. 2020, 714, 136853. [Google Scholar] [CrossRef]

- Bundschuh, J.; Kaczmarczyk, M.; Ghaffour, N.; Tomaszewska, B. State-of-the-Art of Renewable Energy Sources Used in Water Desalination: Present and Future Prospects. Desalination 2021, 508, 115035. [Google Scholar] [CrossRef]

- Mohammadi, M.H.; Abbasi, H.R.; Ghodrat, M. Optimal Design of a Hybrid Thermal- and Membrane-Based Desalination Unit Based on Renewable Geothermal Energy. Energy Convers. Manag. X 2021, 12, 100124. [Google Scholar] [CrossRef]

- Sarbatly, R.; Chiam, C.-K. Evaluation of Geothermal Energy in Desalination by Vacuum Membrane Distillation. Appl. Energy 2013, 112, 737–746. [Google Scholar] [CrossRef]

- Ozbey-Unal, B.; Imer, D.Y.; Keskinler, B.; Koyuncu, I. Boron Removal from Geothermal Water by Air Gap Membrane Distillation. Desalination 2018, 433, 141–150. [Google Scholar] [CrossRef]

- Tomaszewska, B.; Akkurt, G.G.; Kaczmarczyk, M.; Bujakowski, W.; Keles, N.; Jarma, Y.A.; Baba, A.; Bryjak, M.; Kabay, N. Utilization of Renewable Energy Sources in Desalination of Geothermal Water for Agriculture. Desalination 2021, 513, 115151. [Google Scholar] [CrossRef]

- Arana Juve, J.-M.; Christensen, F.M.S.; Wang, Y.; Wei, Z. Electrodialysis for Metal Removal and Recovery: A Review. Chem. Eng. J. 2022, 435, 134857. [Google Scholar] [CrossRef]

- Gurreri, L.; Tamburini, A.; Cipollina, A.; Micale, G. Electrodialysis Applications in Wastewater Treatment for Environmental Protection and Resources Recovery: A Systematic Review on Progress and Perspectives. Membranes 2020, 10, 146. [Google Scholar] [CrossRef] [PubMed]

- AlMadani, H.M.N. Water Desalination by Solar Powered Electrodialysis Process. Renew. Energy 2003, 28, 1915–1924. [Google Scholar] [CrossRef]

- Ortiz, J.M.; Expósito, E.; Gallud, F.; García-García, V.; Montiel, V.; Aldaz, A. Electrodialysis of Brackish Water Powered by Photovoltaic Energy without Batteries: Direct Connection Behaviour. Desalination 2007, 208, 89–100. [Google Scholar] [CrossRef]

- Khan, M.I.; Luque, R.; Akhtar, S.; Shaheen, A.; Mehmood, A.; Idress, S.; Buzdar, S.A.; Rehman, A.U. Design of Anion Exchange Membranes and Electrodialysis Studies for Water Desalination. Materials 2016, 9, 365. [Google Scholar] [CrossRef] [Green Version]

- Fernandez-Gonzalez, C.; Dominguez-Ramos, A.; Ibañez, R.; Irabien, A. Sustainability Assessment of Electrodialysis Powered by Photovoltaic Solar Energy for Freshwater Production. Renew. Sustain. Energy Rev. 2015, 47, 604–615. [Google Scholar] [CrossRef]

- Ali, M.T.; Fath, H.E.S.; Armstrong, P.R. A Comprehensive Techno-Economical Review of Indirect Solar Desalination. Renew. Sustain. Energy Rev. 2011, 15, 4187–4199. [Google Scholar] [CrossRef]

- Wright, N.C.; Winter, A.G. Justification for Community-Scale Photovoltaic-Powered Electrodialysis Desalination Systems for Inland Rural Villages in India. Desalination 2014, 352, 82–91. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; El Haj Assad, M.; Sayed, E.T.; Soudan, B. Recent Progress in the Use of Renewable Energy Sources to Power Water Desalination Plants. Desalination 2018, 435, 97–113. [Google Scholar] [CrossRef]

- Subiela-Ortín, V.J.; Peñate-Suárez, B.; de la Fuente-Bencomo, J.A. Main Technical and Economic Guidelines to Implement Wind/Solar-Powered Reverse-Osmosis Desalination Systems. Processes 2022, 10, 653. [Google Scholar] [CrossRef]

- Veza, J.; Peñate, B.; Castellano, F. Electrodialysis Desalination Designed for Off-Grid Wind Energy. Desalination 2004, 160, 211–221. [Google Scholar] [CrossRef]

- Zou, S.; Yuan, H.; Childress, A.; He, Z. Energy Consumption by Recirculation: A Missing Parameter When Evaluating Forward Osmosis. Environ. Sci. Technol. 2016, 50, 6827–6829. [Google Scholar] [CrossRef] [PubMed]

- Subramani, A.; Jacangelo, J.G. Emerging Desalination Technologies for Water Treatment: A Critical Review. Water Res. 2015, 75, 164–187. [Google Scholar] [CrossRef]

- Aende, A.; Gardy, J.; Hassanpour, A. Seawater Desalination: A Review of Forward Osmosis Technique, Its Challenges, and Future Prospects. Processes 2020, 8, 901. [Google Scholar] [CrossRef]

- Huayong, L.; Qin, W.; Tao, T.; Zhang, T.C.; Aijiao, Z. Performance of Strong Ionic Hydrogels Based on 2-Acrylamido-2-Methylpropane Sulfonate as Draw Agents for Forward Osmosis. J. Environ. Eng. 2014, 140, 4014044. [Google Scholar] [CrossRef]

- Alnaizy, R.; Aidan, A.; Qasim, M. Draw Solute Recovery by Metathesis Precipitation in Forward Osmosis Desalination. Desalin. Water Treat. 2013, 51, 5516–5525. [Google Scholar] [CrossRef]

- Li, D.; Zhang, X.; Yao, J.; Zeng, Y.; Simon, G.P.; Wang, H. Composite Polymer Hydrogels as Draw Agents in Forward Osmosis and Solar Dewatering. Soft Matter 2011, 7, 10048–10056. [Google Scholar] [CrossRef]

- Khayet, M.; Sanmartino, J.A.; Essalhi, M.; García-Payo, M.C.; Hilal, N. Modeling and Optimization of a Solar Forward Osmosis Pilot Plant by Response Surface Methodology. Sol. Energy 2016, 137, 290–302. [Google Scholar] [CrossRef] [Green Version]

- Long, Q.; Jia, Y.; Li, J.; Yang, J.; Liu, F.; Zheng, J.; Yu, B. Recent Advance on Draw Solutes Development in Forward Osmosis. Processes 2018, 6, 165. [Google Scholar] [CrossRef] [Green Version]

- Kiehbadroudinezhad, M.; Merabet, A.; Hosseinzadeh-Bandbafha, H.; Ghenai, C. Environmental Assessment of Optimized Renewable Energy-Based Microgrids Integrated Desalination Plant: Considering Human Health, Ecosystem Quality, Climate Change, and Resources. Environ. Sci. Pollut. Res. 2022, 1–21. [Google Scholar] [CrossRef]

- Kyriakarakos, G.; Papadakis, G.; Karavitis, C.A. Renewable Energy Desalination for Island Communities: Status and Future Prospects in Greece. Sustainability 2022, 14, 8176. [Google Scholar] [CrossRef]

- Ginsberg, M.; Zhang, Z.; Atia, A.A.; Venkatraman, M.; Esposito, D.V.; Fthenakis, V.M. Integrating Solar Energy, Desalination, and Electrolysis. Solar RRL 2022, 6, 2100732. [Google Scholar] [CrossRef]

| Desalination System | Capacity (m3/d) | Water Cost (USD/m3) |

|---|---|---|

| Wind-powered BWRO | 50–2000 | 6.6–9 |

| PV-powered SWRO | <100 | 11.7–15.6 |

| PV-powered SWRO | 250 | 3–4 |

| Wind-powered RO | 50–2000 | 2.0–5.2 |

| Wave energy-powered RO | 1000–3000 | 0.7–1.2 |

| Solar-powered MD | 0.15–10 | 10.4–19.5 |

| PV-powered ED | <100 | 10.4–11.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahid, M.K.; Mainali, B.; Rout, P.R.; Lim, J.W.; Aslam, M.; Al-Rawajfeh, A.E.; Choi, Y. A Review of Membrane-Based Desalination Systems Powered by Renewable Energy Sources. Water 2023, 15, 534. https://doi.org/10.3390/w15030534

Shahid MK, Mainali B, Rout PR, Lim JW, Aslam M, Al-Rawajfeh AE, Choi Y. A Review of Membrane-Based Desalination Systems Powered by Renewable Energy Sources. Water. 2023; 15(3):534. https://doi.org/10.3390/w15030534

Chicago/Turabian StyleShahid, Muhammad Kashif, Bandita Mainali, Prangya Ranjan Rout, Jun Wei Lim, Muhammad Aslam, Aiman Eid Al-Rawajfeh, and Younggyun Choi. 2023. "A Review of Membrane-Based Desalination Systems Powered by Renewable Energy Sources" Water 15, no. 3: 534. https://doi.org/10.3390/w15030534