Numerical Modeling and Simulation of Fractured-Vuggy Reservoirs Based on Field Outcrops

Abstract

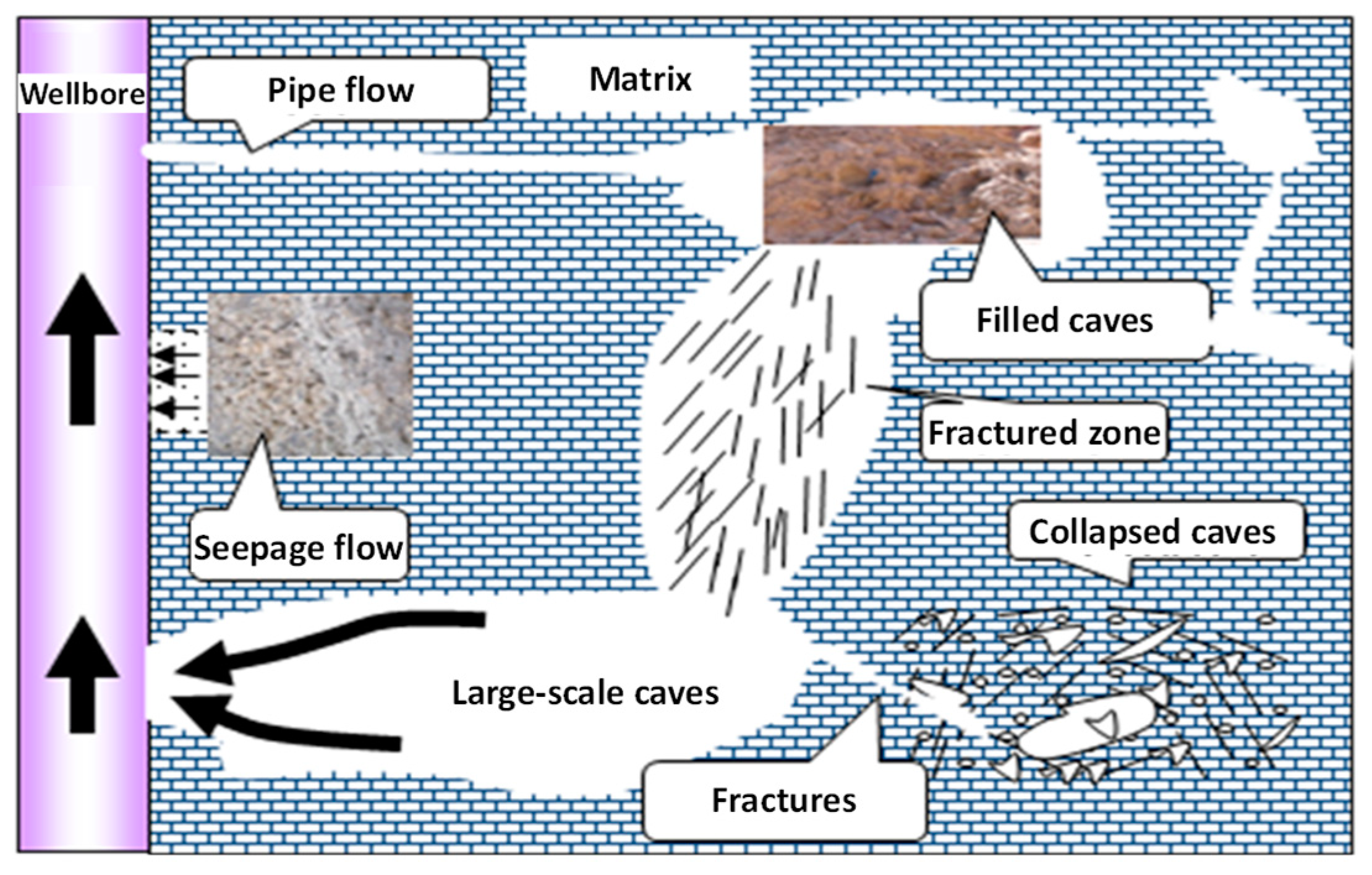

:1. Introduction

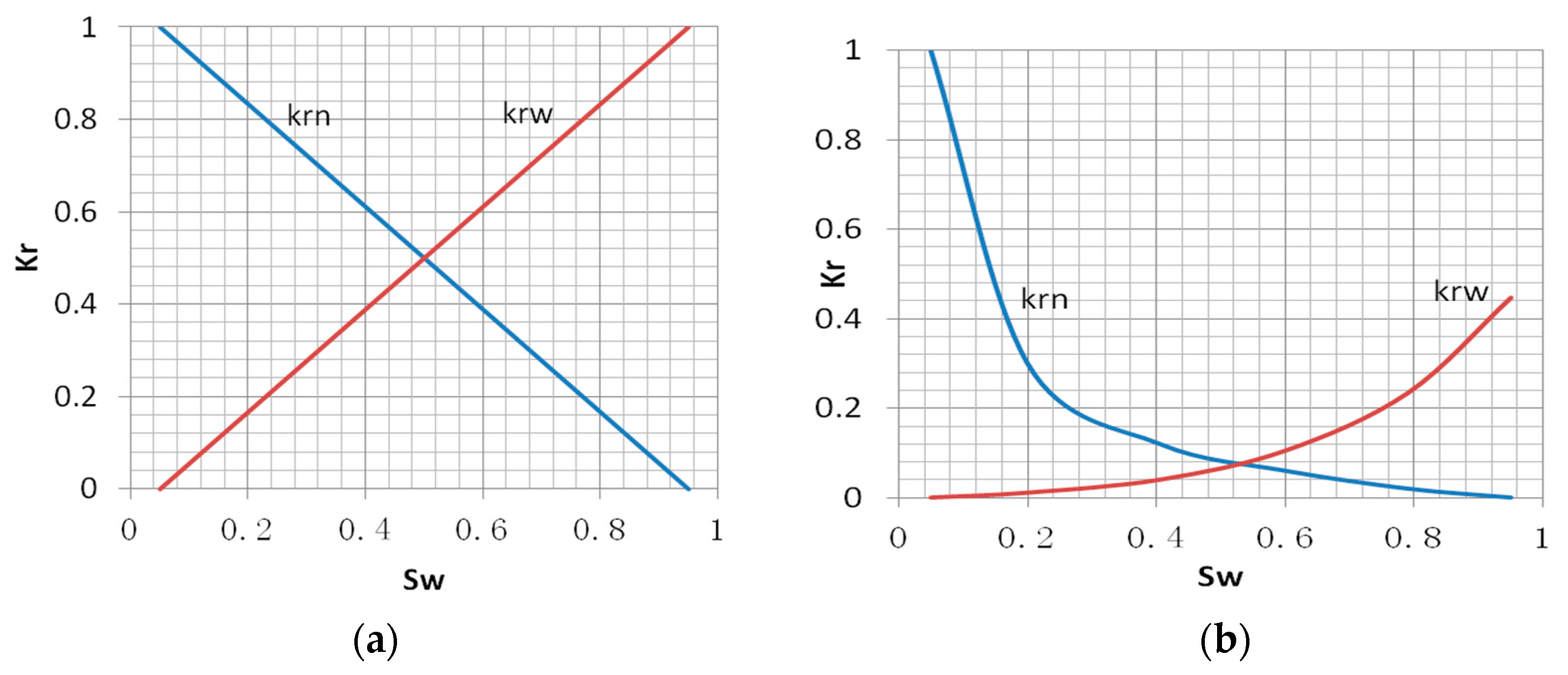

2. Methods

2.1. Basic Assumptions

- Assuming that the system consists of three phases—oil, gas, and water—with each phase containing multiple components, they are treated as a single “pseudo component” with average fluid properties, and the two liquid components of oil and water only exist in the accompanying phase; gases not only exist in the gas phase but can also be dissolved in oil;

- The fractured vuggy reservoir is considered an isothermal medium system without considering the impact of heat exchange;

- Heat transport through the porous media is neglected in this study;

- The caves studied in this work are assumed to be filled-type, such that Darcy’s law is satisfactory in describing the flow behaviors in the cave;

- Geomechanical and geochemical effects on the rock porosity and permeability are not considered in this study;

- The influence of capillary force is not considered in fractures;

- Fractures and karst caves are the main storage spaces, while fractures also serve as connecting channels, neglecting the self-absorption and oil drainage effect of the matrix.

2.2. Governing Equations

2.3. Control Volume Finite-Difference Method

2.4. Treatments of Boundary Conditions

2.4.1. First Type of Boundary Conditions

2.4.2. Second Type of Boundary Conditions

2.4.3. Well Boundary Conditions

2.5. Solution Methodology

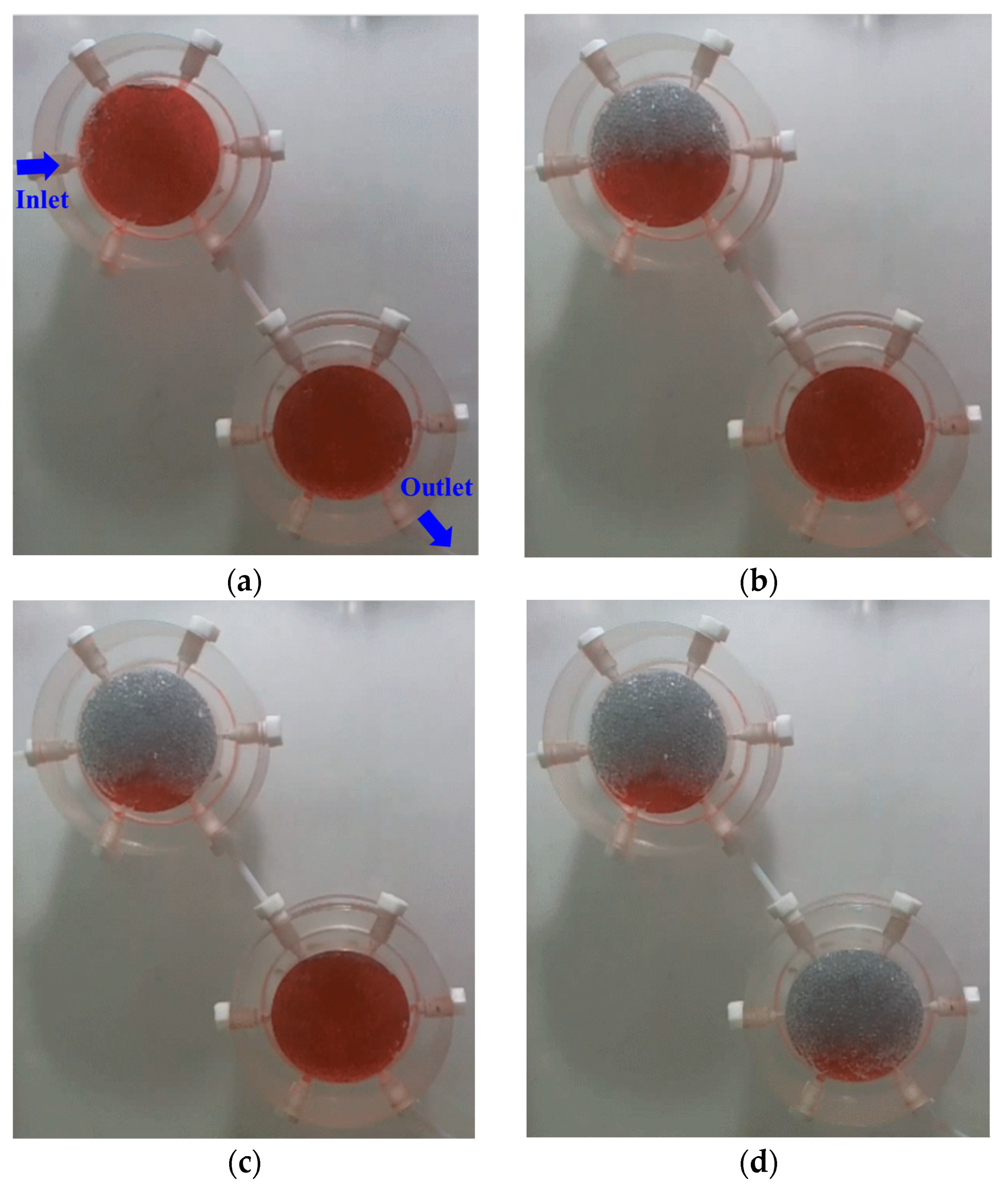

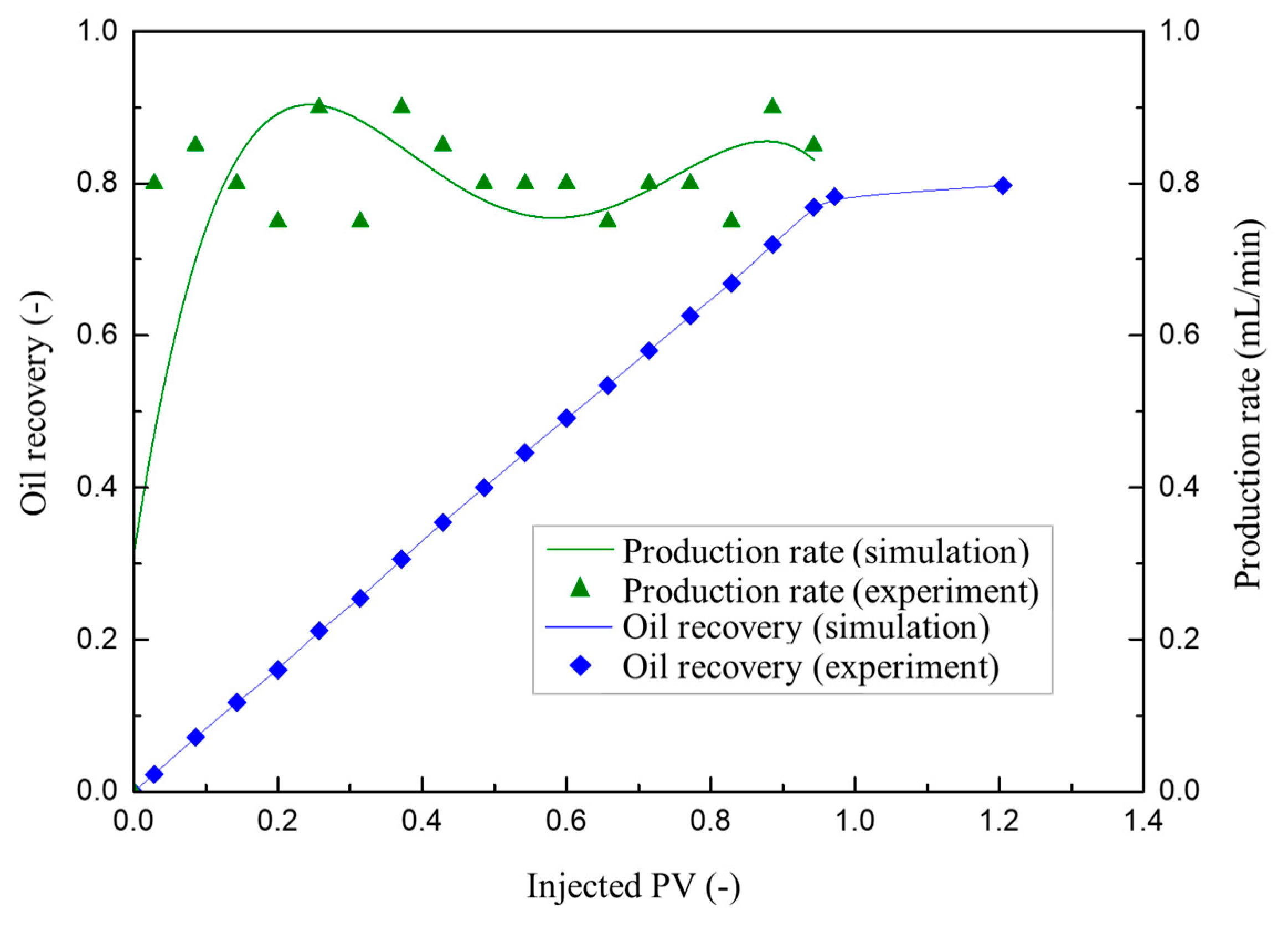

3. Model Validation

4. Numerical Results

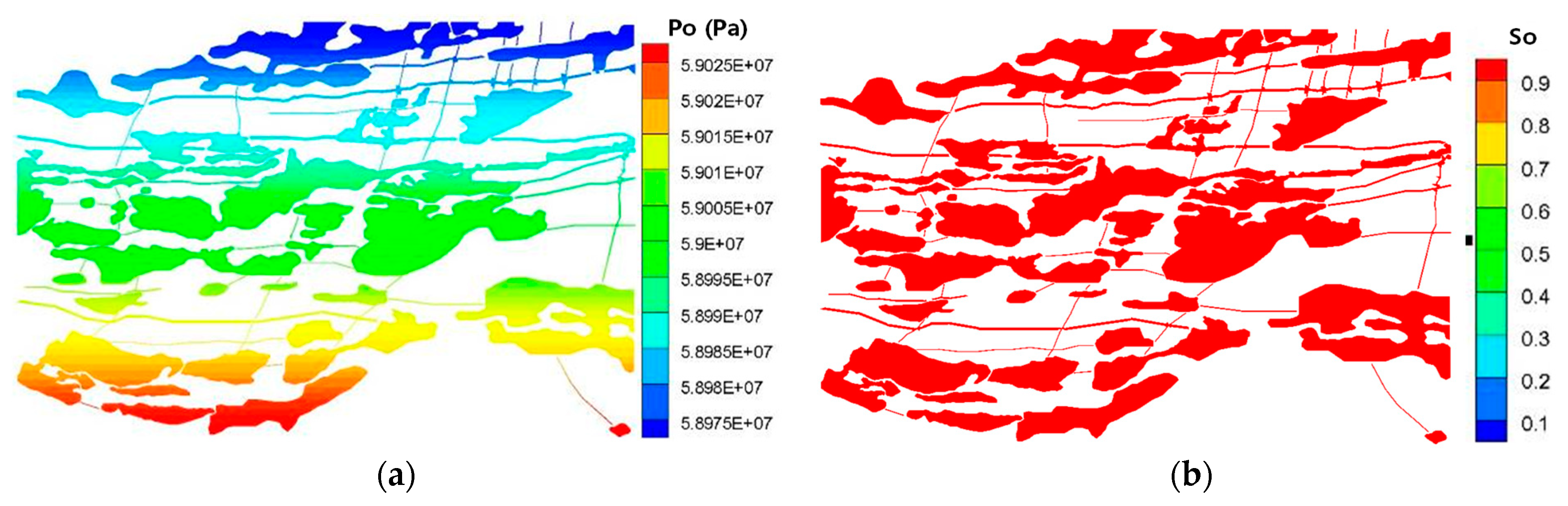

4.1. Discretization of Field Outcrop of Fractured-Vuggy Reservoirs

4.2. Numerical Results and Discussion

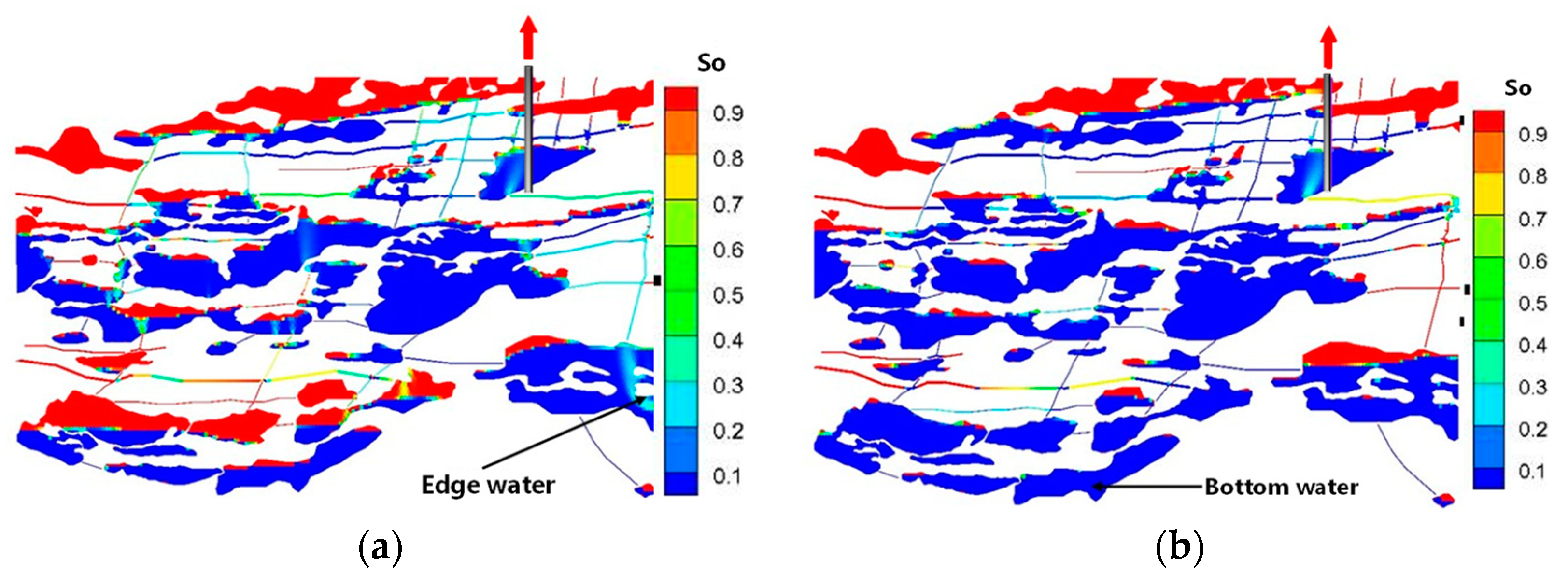

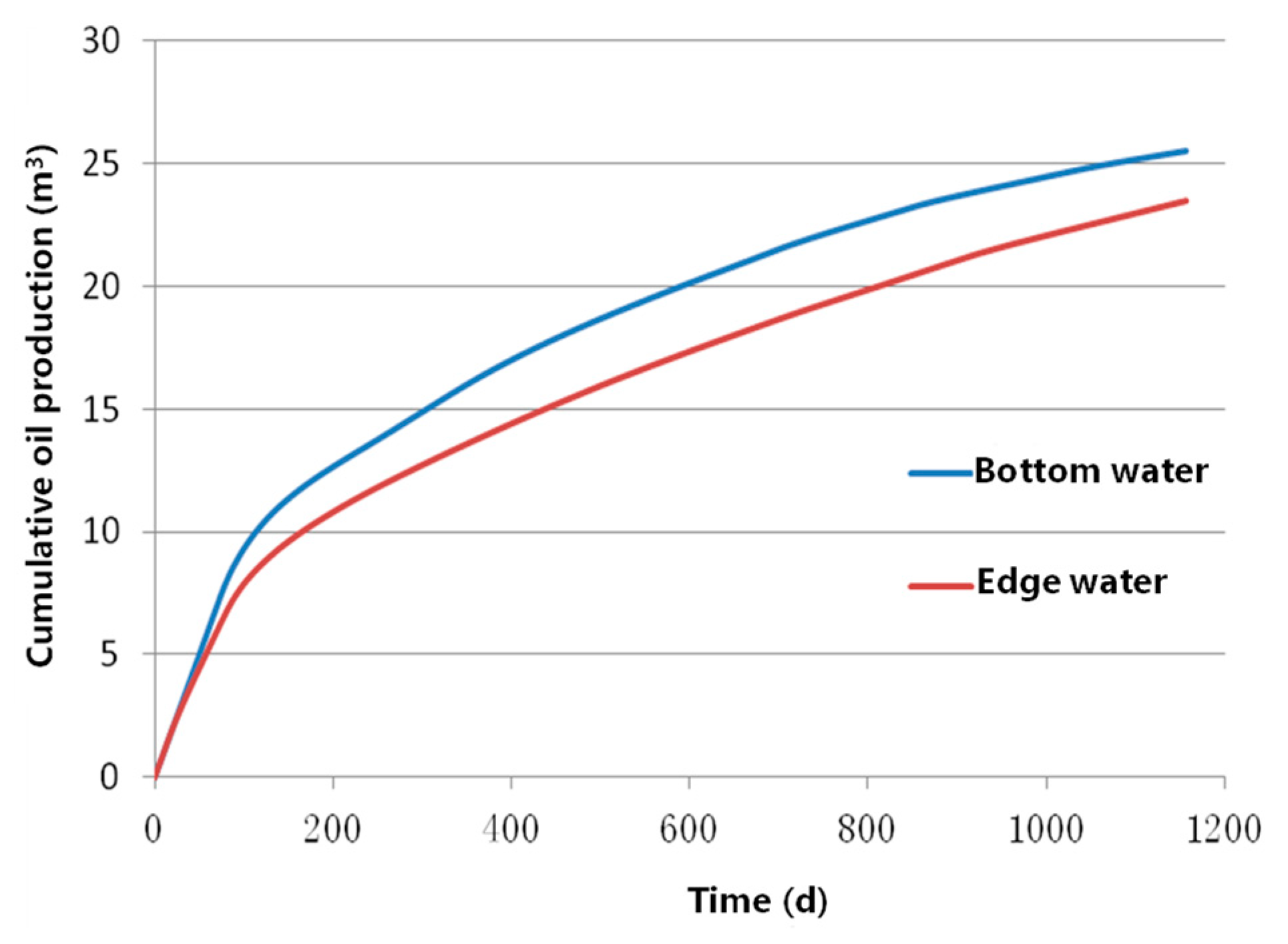

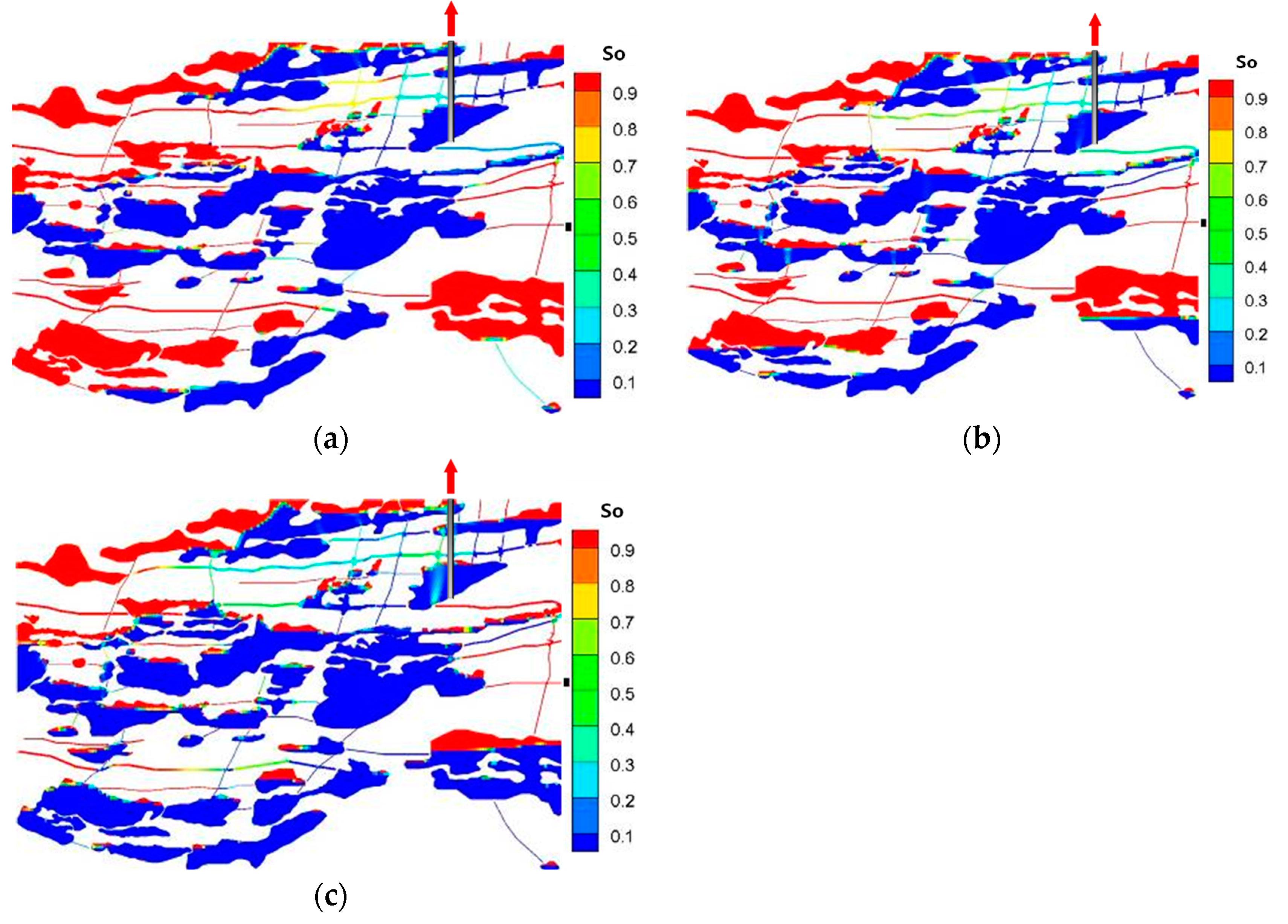

4.2.1. The Impact of the Location of Natural Water Bodies on Oil Recovery Efficiency

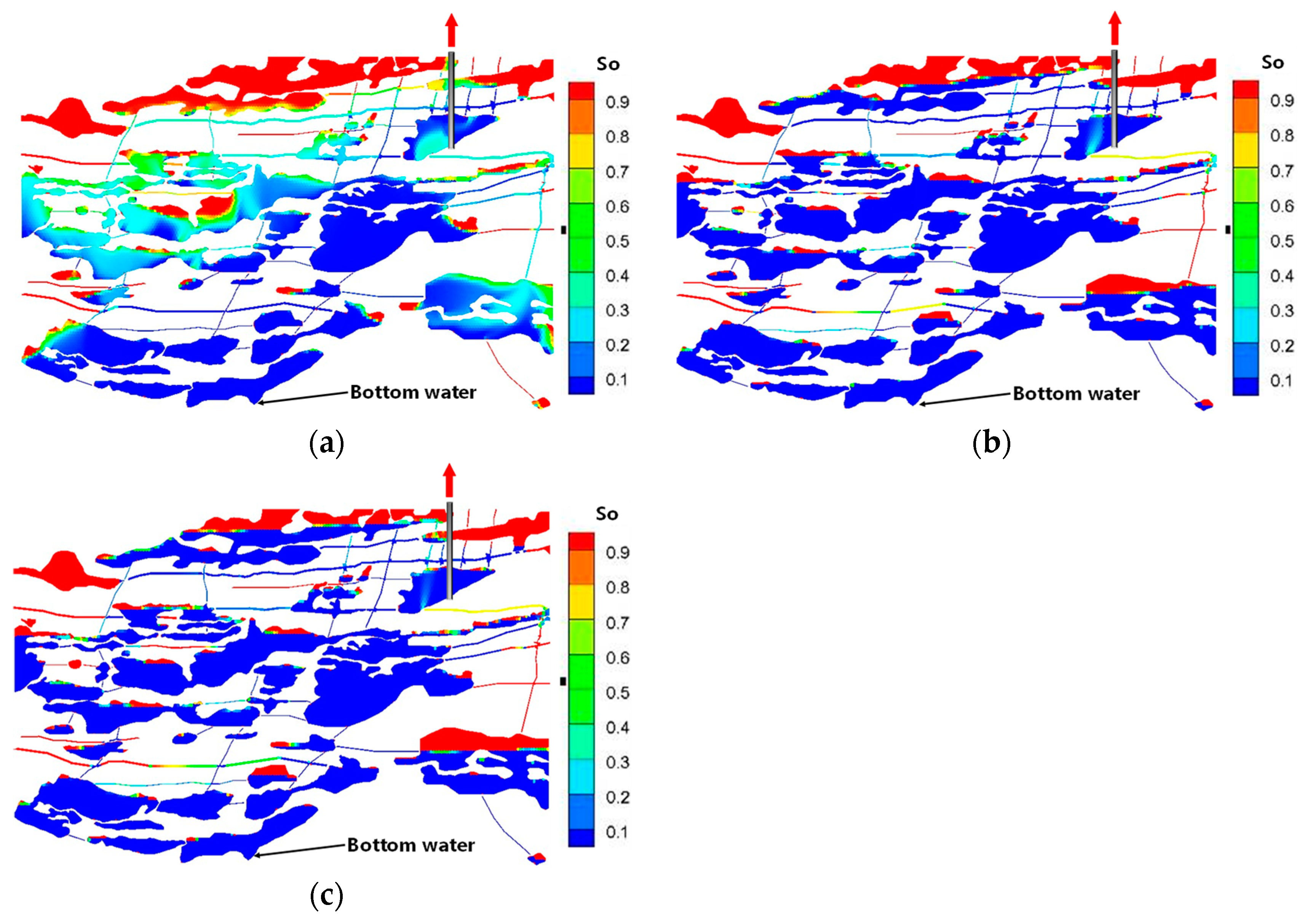

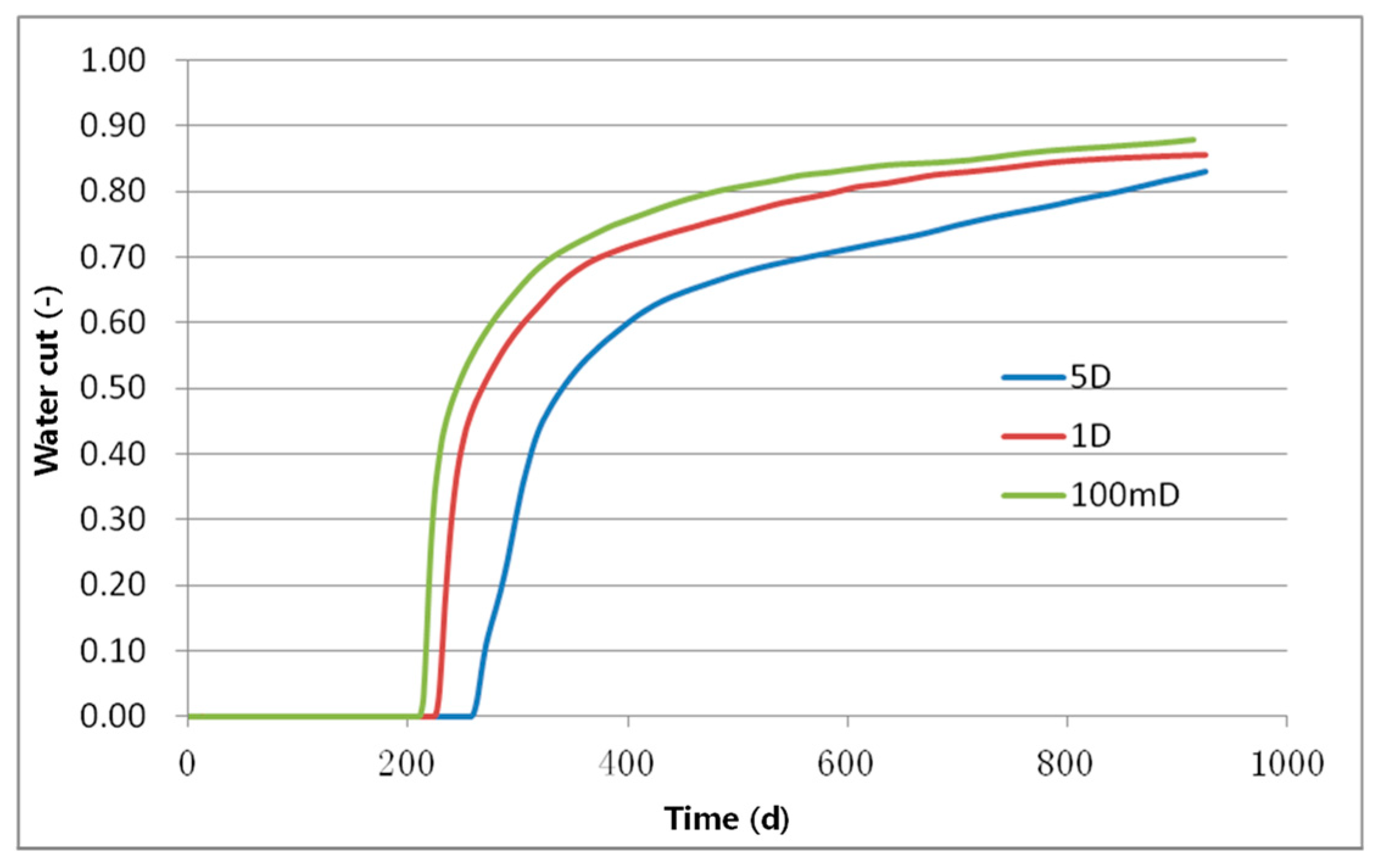

4.2.2. The Influence of the Cave Permeability on Oil Recovery Efficiency

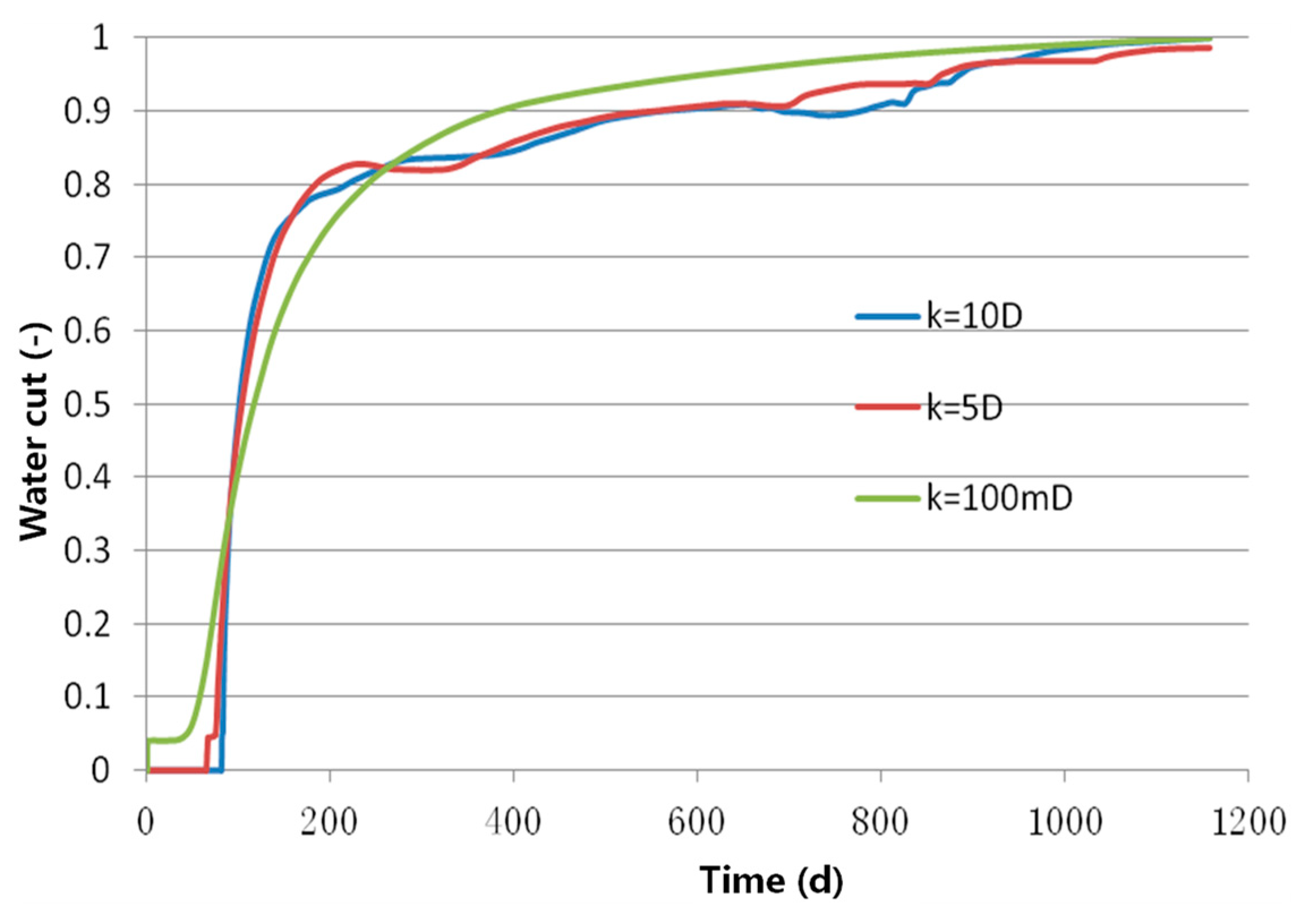

4.2.3. The Influence of the Fracture Permeability on Oil Recovery Efficiency

5. Conclusions

- The cave permeability has few impacts on the oil production, while the fracture permeability plays a significant role in determining the oil recovery;

- The higher the permeability of fractures, the longer the anhydrous oil recovery period and the higher the degree of recovery. When the permeability reaches a certain level, the impact of fracture permeability weakens;

- The location of the water body has a significant impact on the oil recovery effect. When the water body is close to the production well, it can easily form preferential channels, reduce the water body’s coverage, and thus, have a low oil recovery;

- The distribution of remaining oil is influenced by the connection mode of fractures and caves and the development scheme, usually distributed at the top and edges of the model, as well as at the top of single- and multiple-fracture connected caves.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, W.; Fu, S.; Li, A.; Xie, H.; Cui, S.; Nangendo, J. Experimental research on the mechanisms of improving water flooding in fractured-vuggy reservoirs. J. Pet. Sci. Eng. 2022, 213, 110383. [Google Scholar] [CrossRef]

- Li, Y.; Kang, Z.; Xue, Z.; Zheng, S. Theories and practices of carbonate reservoirs development in China. Pet. Explor. Dev. 2018, 45, 712–722. [Google Scholar] [CrossRef]

- Zhang, F.; An, M.; Yan, B.; Wang, Y. Modeling the depletion of fractured vuggy carbonate reservoir by coupling geomechanics with reservoir flow. In Proceedings of the SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 8–10 May 2017. [Google Scholar]

- Lu, A. Carbonate Fractured Vuggy Reservoir Engineering Method Research. Ph.D. Thesis, China University of Petroleum, Qingdao, China, 2007. [Google Scholar]

- Li, B.; Tan, X.; Wang, F.; Lian, P.; Gao, W.; Li, Y. Fracture and vug characterization and carbonate rock type automatic classification using X-ray CT images. J. Pet. Sci. Eng. 2017, 153, 88–96. [Google Scholar] [CrossRef]

- Wu, Y.-S.; Di, Y.; Kang, Z.; Fakcharoenphol, P. A multiple-continuum model for simulating single-phase and multiphase flow in naturally fractured vuggy reservoirs. J. Pet. Sci. Eng. 2011, 78, 13–22. [Google Scholar] [CrossRef]

- Yao, J.; Huang, Z.-Q. Fractured Vuggy Carbonate Reservoir Simulation; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Neale, G.H.; Nader, W.K. The permeability of a uniformly vuggy porous medium. Soc. Pet. Eng. J. 1973, 13, 69–74. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Y.; Du, H.; Liu, J.; Zhou, Z.; Wang, Z.; Huang, K.; Pan, B. Experimental study on fluid flow behaviors of waterflooding fractured-vuggy oil reservoir using two-dimensional visual model. Phys. Fluids 2023, 35, 062106. [Google Scholar]

- Ju, X.; Zhao, X.; Zhou, B.; Zhang, R.; Wu, X.; Guo, D. Identification of reservoir water-flooding degrees via core sizes based on a drip experiment of the Zhenwu Area in Gaoyou Sag, China. Energies 2023, 16, 608. [Google Scholar] [CrossRef]

- Lu, G.; Zhang, L.; Liu, Q.; Xu, Q.; Zhao, Y.; Li, X.; Deng, G.; Wang, Y. Experiment analysis of remaining oil distribution and potential tapping for fractured-vuggy reservoir. J. Pet. Sci. Eng. 2022, 208, 109544. [Google Scholar] [CrossRef]

- Lyu, X.; Liu, Z.; Hou, J.; Lyu, T. Mechanism and influencing factors of EOR by N2 injection in fractured-vuggy carbonate reservoirs. J. Nat. Gas Sci. Eng. 2017, 40, 226–235. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, H.; Shi, H. Experimental study on stress monitoring in fractured-vuggy carbonate reservoirs before and after fracturing. J. Pet. Sci. Eng. 2022, 218, 110958. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, D.; Lei, G. Experimental study on multiphase flow in fracture-vug medium using 3D printing technology and visualization techniques. J. Pet. Sci. Eng. 2020, 193, 107394. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, D. Experimental study on multiphase flow in 3D-printed heterogeneous, filled vugs. J. Pet. Sci. Eng. 2022, 208, 109497. [Google Scholar] [CrossRef]

- Li, S.; Zhang, D. Development of 3-D curved fracture swarms in shale rock driven by rapid fluid pressure buildup: Insights from numerical modeling. Geophys. Res. Lett. 2021, 48, e2021GL092638. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Jiang, Y.; Song, J.; Jia, M. New approach for the digital reconstruction of complex mine faults and its application in mining. Int. J. Coal Sci. Technol. 2022, 9, 43. [Google Scholar] [CrossRef]

- Chen, Y.; Zuo, J.; Liu, D.; Li, Y.; Wang, Z. Experimental and numerical study of coal-rock bimaterial composite bodies under triaxial compression. Int. J. Coal Sci. Technol. 2021, 8, 908–924. [Google Scholar] [CrossRef]

- Li, S.; Feng, X.-T.; Zhang, D.; Tang, H. Coupled thermo-hydro-mechanical analysis of stimulation and production for fractured geothermal reservoirs. Appl. Energy 2019, 247, 40–59. [Google Scholar] [CrossRef]

- Li, S.; Zhang, D. Three-dimensional thermoporoelastic modeling of hydrofracturing and fluid circulation in hot dry rock. J. Geophys. Res. Solid Earth 2023, 128, e2022JB025673. [Google Scholar] [CrossRef]

- Fadlelmula, M.M.; Fraim, M.; He, J.; Killough, J.E. Discrete Fracture-vug Network Modeling in Naturally Fractured Vuggy Reservoirs Using Multiple-Point Geostatistics: A Micro-Scale Case; SPE: Kuala Lumpur, Malaysia, 2015. [Google Scholar]

- Lei, G.; Liao, Q.; Zhang, D. A new analytical model for flow in acidized fractured-vuggy porous media. Sci. Rep. 2019, 9, 8293. [Google Scholar] [CrossRef]

- Li, S.; Kang, Z.; Feng, X.T.; Pan, Z.; Huang, X.; Zhang, D. Three-dimensional hydrochemical model for dissolutional growth of fractures in karst aquifers. Water Resour. Res. 2020, 56, e2019WR025631. [Google Scholar] [CrossRef]

- Wu, Y.-S.; Ehlig-Economides, C.; Qin, G.; Kang, Z.; Zhang, W.; Ajayi, B.; Tao, Q. A Triple-Continuum Pressure-Transient Model for a Naturally Fractured Vuggy Reservoir; SPE: Kuala Lumpur, Malaysia, 2007. [Google Scholar]

- Kang, Z.; Wu, Y.-S.; Li, J.; Wu, Y.; Zhang, J.; Wang, G. Modeling Multiphase Flow in Naturally Fractured Vuggy Petroleum Reservoirs; SPE: Kuala Lumpur, Malaysia, 2006. [Google Scholar]

- Zhang, N.; Yao, J.; Xue, S.; Huang, Z. Multiscale mixed finite element, discrete fracture–vug model for fluid flow in fractured vuggy porous media. Int. J. Heat Mass Transf. 2016, 96, 396–405. [Google Scholar] [CrossRef]

- Wang, M.; Cheung, S.W.; Chung, E.T.; Vasilyeva, M.; Wang, Y. Generalized multiscale multicontinuum model for fractured vuggy carbonate reservoirs. J. Comput. Appl. Math. 2020, 366, 112370. [Google Scholar] [CrossRef]

- Guo, J.-C.; Nie, R.-S.; Jia, Y.-L. Dual permeability flow behavior for modeling horizontal well production in fractured-vuggy carbonate reservoirs. J. Hydrol. 2012, 464, 281–293. [Google Scholar] [CrossRef]

- Jing, W.; Huiqing, L.; Zhengfu, N.; Zhang, H.; Cheng, H. Experiments on water flooding in fractured-vuggy cells in fractured-vuggy reservoirs. Pet. Explor. Dev. 2014, 41, 74–81. [Google Scholar]

- Jing, W.; Huiqing, L.; Jie, X.; Zhang, H. Formation mechanism and distribution law of remaining oil in fracture-cavity reservoir. Pet. Explor. Dev. 2012, 39, 624–629. [Google Scholar]

- Pruess, K. A General Purpose Numerical Simulator for Multiphase Fluid and Heat; LBL-29400; Lawrence Berkeley National Lab: Berkeley, CA, USA, 1991. [Google Scholar]

- Narasimhan, T.; Witherspoon, P. An integrated finite difference method for analyzing fluid flow in porous media. Water Resour. Res. 1976, 12, 57–64. [Google Scholar] [CrossRef]

- Zhang, K.; Wu, Y.-S.; Pruess, K. User’s Guide for TOUGH2-MP-a Massively Parallel Version of the TOUGH2 Code; Ernest Orlando Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2008. [Google Scholar]

- Wu, Y.-S. A virtual node method for handling well bore boundary conditions in modeling multiphase flow in porous and fractured media. Water Resour. Res. 2000, 36, 807–814. [Google Scholar] [CrossRef]

- Wu, Y.-S. MSFLOW: Multiphase Subsurface Flow Model of Oil, Gas and Water in Porous and Fractured Media with Water Shut-Off Capability, Documentation and User’s Guide; Twange Int.: Houston, TX, USA; Walnut Creek, CA, USA, 1998. [Google Scholar]

- Huber, R.; Helmig, R. Multiphase flow in heterogeneous porous media: A classical finite element method versus an implicit pressure-explicit saturation-based mixed finite element-finite volume approach. Int. J. Numer. Methods Fluids 1999, 29, 899–920. [Google Scholar] [CrossRef]

- MacDonald, R. Methods for numerical simulation of water and gas coning. Soc. Pet. Eng. J. 1970, 10, 425–436. [Google Scholar] [CrossRef]

- Peaceman, D.W. A new method for representing multiple wells with arbitrary rates in numerical reservoir simulation. SPE Reserv. Eng. 1995, 10, 253–258. [Google Scholar] [CrossRef]

- Tian, Y.; Xiong, Y.; Wang, L.; Lei, Z.; Zhang, Y.; Yin, X.; Wu, Y.-S. A compositional model for gas injection IOR/EOR in tight oil reservoirs under coupled nanopore confinement and geomechanics effects. J. Nat. Gas Sci. Eng. 2019, 71, 102973. [Google Scholar] [CrossRef]

- Wu, Y.-S. Numerical simulation of single-phase and multiphase non-Darcy flow in porous and fractured reservoirs. Transp. Porous Media 2002, 49, 209–240. [Google Scholar] [CrossRef]

- Pan, L. User Information Document for WinGridder Version 3.0; Ernest Orlando Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2007. [Google Scholar]

- Li, S.; Zhang, K.; Wang, Y. Use WinGridder grid generator to achieve the fine description of complex geological features. Geotech. Investig. Surv. 2012, 40, 37–40. [Google Scholar]

- Li, S.; Zhang, D.; Li, X. A new approach to the modeling of hydraulic-fracturing treatments in naturally fractured reservoirs. SPE J. 2017, 22, 1064–1081. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Kang, Z.; Zhang, Y. Numerical Modeling and Simulation of Fractured-Vuggy Reservoirs Based on Field Outcrops. Water 2023, 15, 3687. https://doi.org/10.3390/w15203687

Li S, Kang Z, Zhang Y. Numerical Modeling and Simulation of Fractured-Vuggy Reservoirs Based on Field Outcrops. Water. 2023; 15(20):3687. https://doi.org/10.3390/w15203687

Chicago/Turabian StyleLi, Sanbai, Zhijiang Kang, and Yun Zhang. 2023. "Numerical Modeling and Simulation of Fractured-Vuggy Reservoirs Based on Field Outcrops" Water 15, no. 20: 3687. https://doi.org/10.3390/w15203687