Coupling AnMBR, Primary Settling and Anaerobic Digestion to Improve Carbon Fate When Treating Sulfate-Rich Wastewater

Abstract

:1. Introduction

2. Materials and Methods

2.1. Demonstration-Scale AnMBR Plant

2.2. Influent Wastewater Characterization

2.3. AnMBR Plant Operation and Experimental Design

2.4. Analytical Methods

2.4.1. Biogas Composition and Dissolved Methane

2.4.2. Anaerobic Biodegradability and Digestibility Tests

2.4.3. Carbon Footprint and Energy Calculations

3. Results and Discussion

3.1. Impact of Wastewater Clarification on AnMBR Influent Features

- ▪

- Complete dissimilatory sulfate reduction takes place.

- ▪

- The biodegradable COD left from dissimilatory sulfate reduction is available for MA.

- ▪

- Methane partition between liquid and gas phases takes place according to the equilibrium.

3.2. AnMBR Performance

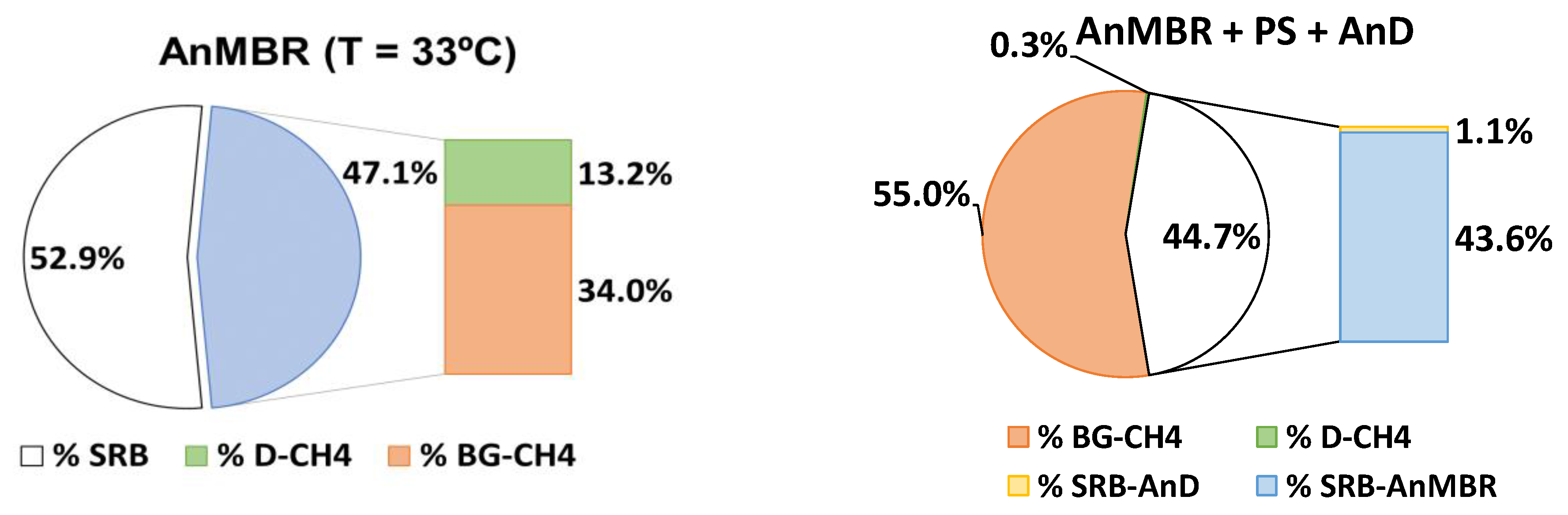

3.2.1. COD and TS Evolution

3.2.2. Waste Sludge Production and Characterization

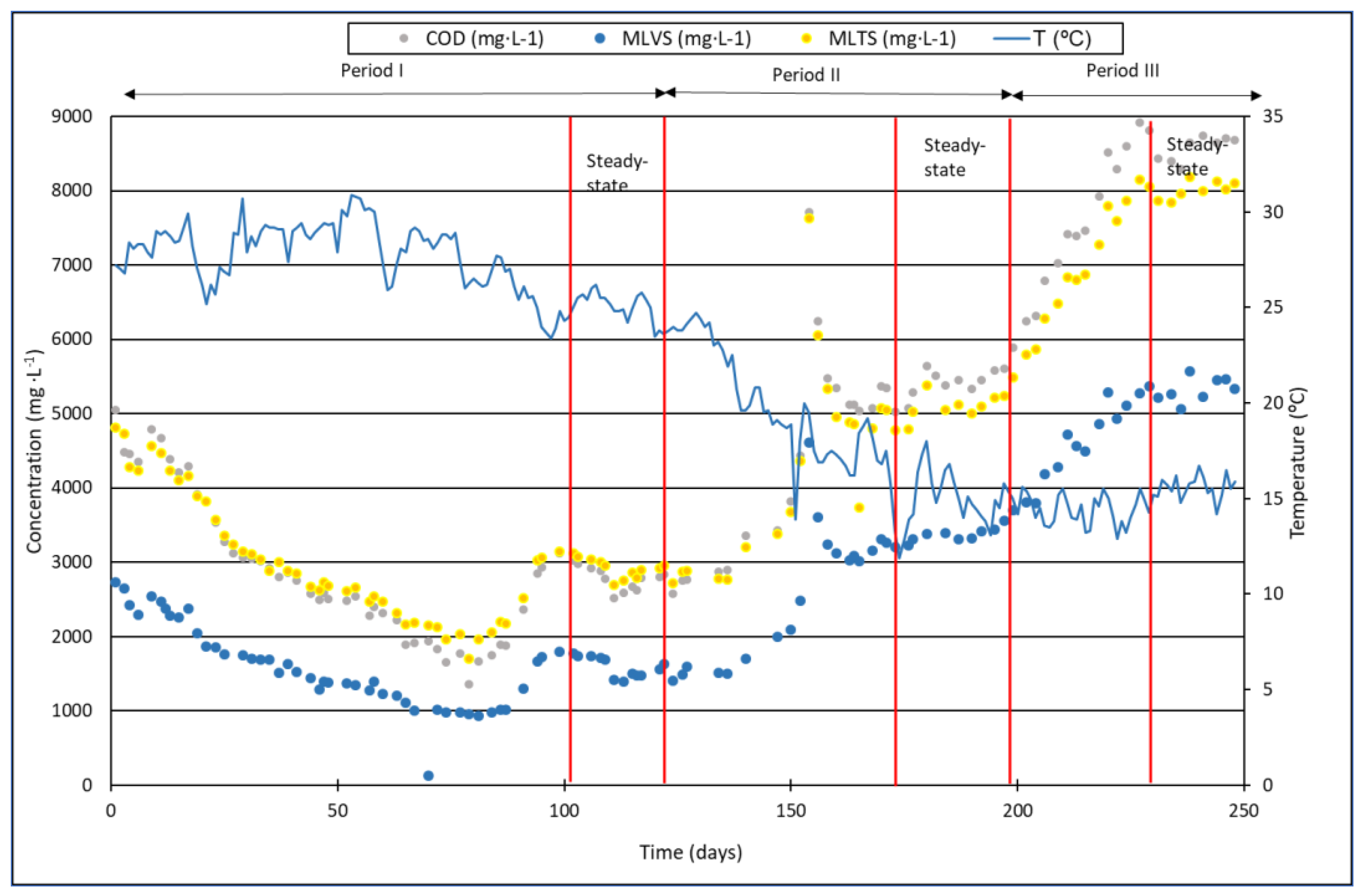

3.2.3. Effluent Characterization

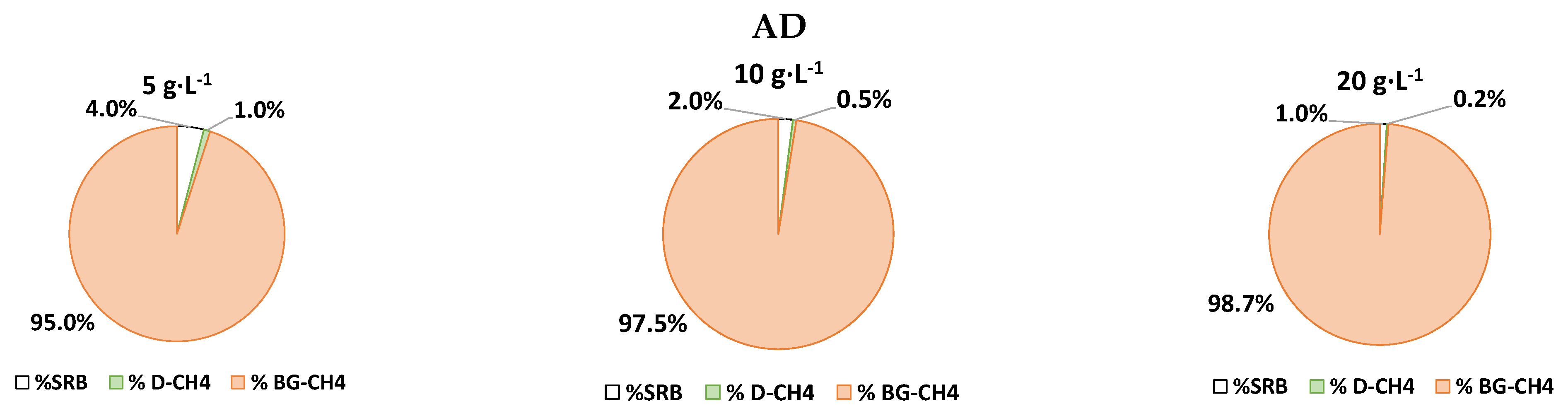

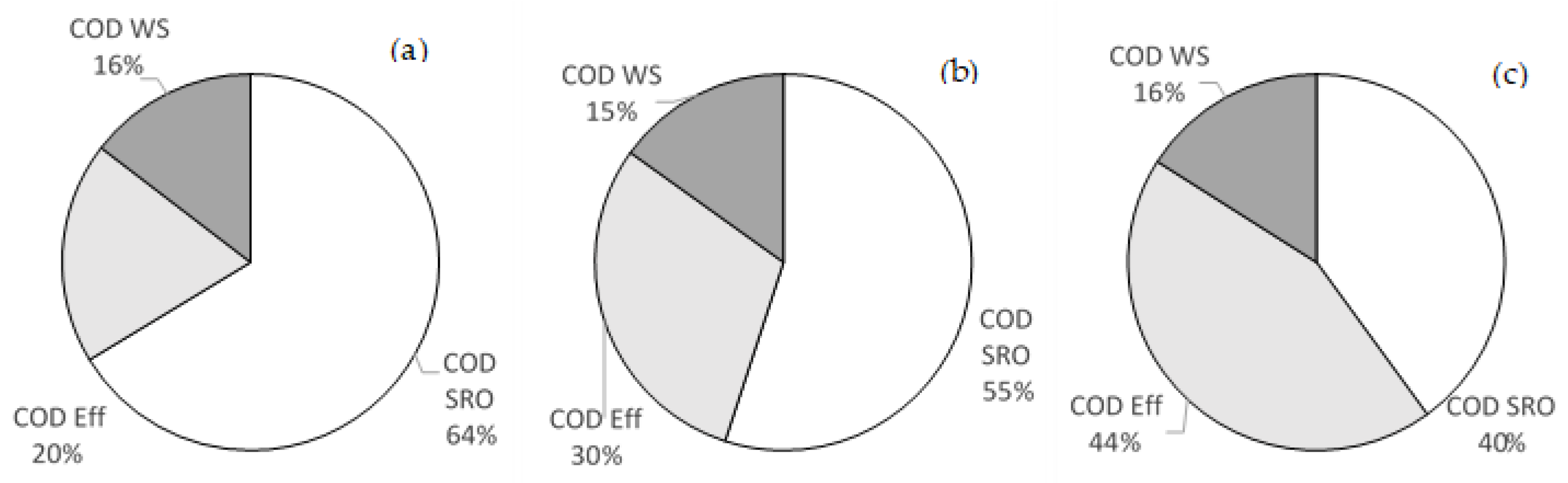

3.2.4. COD Mass Balance

3.3. Potential Benefits of the Proposed Alternative

4. Conclusions

- -

- An innovative treatment scheme combining primary settling, AnMBR technology and anaerobic digestion was successfully evaluated in a demonstration-scale AnMBR plant operating for over 8 months.

- -

- The feasibility of a primary settler in combination with AnMBR technology to remove organic matter from sulfate-rich urban wastewater was also demonstrated. Sulfate-reducing bacteria (SRB) effectively removed organic matter while meeting the European Directive criteria on effluents by using influent sulfate as an electron acceptor. No methane production was observed.

- -

- Temperature had a significant impact on the hydrolysis and fermentation rates, with lower temperatures leading to slower biological processes.

- -

- The low suspended solid concentration in settled wastewater allowed for shorter hydraulic retention times (HRTs) in the AnMBR system compared to the typical values for AnMBR systems fed with pretreated wastewater. Organic matter removal was achieved with an HRT of 12 h at 15 °C. When the HRT was further reduced to 8.5 h, the acidogenic bacteria were affected and the production of volatile fatty acids (VFAs) was insufficient to remove influent organic matter.

- -

- Future research is needed to optimize the operating conditions, including SRT and HRT at different temperatures.

- -

- Life cycle cost and life cycle analysis should also be conducted to quantify the advantages of the proposed treatment scheme under different operating conditions.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Puyol, D.; Batstone, D.J.; Hülsen, T.; Astals, S.; Peces, M.; Krömer, J.O. Resource Recovery from Wastewater by Biological Technologies: Opportunities, Challenges, and Prospects. Front. Microbiol. 2017, 7, 2106. [Google Scholar] [CrossRef]

- Hernández-Chover, V.; Castellet-Viciano, L.; Fuentes, R.; Hernández-Sancho, F. Circular economy and efficiency to ensure the sustainability in the wastewater treatment plants. J. Clean. Prod. 2023, 384, 135563. [Google Scholar] [CrossRef]

- Donoso-Bravo, A.; Olivares, D.; Lesty, Y.; Bossche, H.V. Exploitation of the ADM1 in a XXI century wastewater resource recovery facility (WRRF): The case of codigestion and thermal hydrolysis. Water Res. 2020, 175, 115654. [Google Scholar] [CrossRef]

- Shahid, M.K.; Kashif, A.; Rout, P.R.; Aslam, M.; Fuwad, A.; Choi, Y.; Banu, R.J.; Park, J.H.; Kumar, G. A brief review of anaerobic membrane bioreactors emphasizing recent advancements, fouling issues and future perspectives. J. Environ. Manag. 2020, 270, 110909. [Google Scholar] [CrossRef]

- Martin, I.; Pidou, M.; Soares, A.; Judd, S.; Jefferson, B. Modelling the energy demands of aerobic and anaerobic membrane bioreactors for wastewater treatment. Environ. Technol. 2011, 32, 921–932. [Google Scholar] [CrossRef] [PubMed]

- Anjum, F.; Khan, I.M.; Kim, J.; Aslam, M.; Blandin, G.; Heran, M.; Lesage, G. Trends and progress in AnMBR for domestic wastewater treatment and their impacts on process efficiency and membrane fouling. Environ. Technol. Innov. 2021, 21, 101204. [Google Scholar] [CrossRef]

- Chen, Y.; Jay, J.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef] [PubMed]

- Lens, P.; Pol, L.H. Environmental Technologies to Treat Sulfur Pollution—Principles and Applications; IWA Publishing: London, UK, 2015; ISBN 9781789060966. [Google Scholar]

- Seco, A.; Mateo, O.; Zamorano-López, N.; Sanchis-Perucho, P.; Serralta, J.; Martí, N.; Borrás, L.; Ferrer, J. Exploring the limits of anaerobic biodegradability of urban wastewater by AnMBR technology. Environ. Sci. Water Res. Technol. 2018, 4, 1877–1887. [Google Scholar] [CrossRef]

- Robles, Á.; Jiménez-Benítez, A.; Giménez, J.B.; Durán, F.; Ribes, J.; Serralta, J.; Ferrer, J.; Rogalla, F.; Seco, A. A semi-industrial scale AnMBR for municipal wastewater treatment at ambient temperature: Performance of the biological process. Water Res. 2022, 215, 118249. [Google Scholar] [CrossRef]

- Pretel, R.; Durán, F.; Robles, A.; Ruano, M.V.; Ribes, J.; Serralta, J.; Ferrer, J. Designing an AnMBR-based WWTP for energy recovery from urban wastewater: The role of primary settling and anaerobic digestion. Sep. Purif. Technol. 2015, 156, 132–139. [Google Scholar] [CrossRef]

- Giménez, J.B.; Martí, N.; Ferrer, J.; Seco, A. Methane recovery efficiency in a submerged anaerobic membrane bioreactor (SAnMBR) treating sulphate-rich urban wastewater: Evaluation of methane losses with the effluent. Bioresour. Technol. 2012, 118, 67–72. [Google Scholar] [CrossRef] [PubMed]

- Robles, Á.; Durán, F.; Ruano, M.V.; Ribes, J.; Rosado, A.; Seco, A.; Ferrer, J. Instrumentation, control, and automation for submerged anaerobic membrane bioreactors. Environ. Technol. 2015, 36, 1795–1806. [Google Scholar] [CrossRef]

- Moñino, P.; Jiménez, E.; Barat, R.; Aguado, D.; Seco, A.; Ferrer, J. Potential use of the organic fraction of municipal solid waste in anaerobic co-digestion with wastewater in submerged anaerobic membrane technology. Waste Manag. 2016, 56, 158–165. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater; Rice, E.W., Bridgewater, L., American Public Health Association, Eds.; APHA: Washington, DC, USA, 2012; p. 1496. [Google Scholar]

- Moosbrugger, R.E.; Wentzel, M.C.; Ekama, G.A.; Marais, G.V.R. Simple Titration Procedures to Determine H2CO3* Alkalinity and Short-Chain Fatty Acids in Aqueous Solutions Containing Known Concentrations of Ammonium, Phosphate and Sulphide Weak Acid/Bases; Water Research Commission, Report No. TT; University of Cape Town: Cape Town, South Africa, 1992. [Google Scholar]

- Robles, Á.; Ruano, M.V.; Charfi, A.; Lesage, G.; Heran, M.; Harmand, J.; Seco, A.; Steyer, J.-P.; Batstone, D.J.; Kim, J.; et al. A review on anaerobic membrane bioreactors (AnMBRs) focused on modelling and control aspects. Bioresour. Technol. 2018, 270, 612–626. [Google Scholar] [CrossRef] [PubMed]

- Cookney, J.; Mcleod, A.; Mathioudakis, V.; Ncube, P.; Soares, A.; Jefferson, B.; McAdam, E. Dissolved methane recovery from anaerobic effluents using hollow fibre membrane contactors. J. Membr. Sci. 2016, 502, 141–150. [Google Scholar] [CrossRef]

- Crone, B.C.; Garland, J.L.; Sorial, G.A.; Vane, L.M. Significance of dissolved methane in effluents of anaerobically treated low strength wastewater and potential for recovery as an energy product: A review. Water Res. 2016, 104, 520–531. [Google Scholar] [CrossRef]

- Giménez, J.B.; Martí, N.; Robles, A.; Ferrer, J.; Seco, A. Anaerobic treatment of urban wastewater in membrane bioreactors: Evaluation of seasonal temperature variations. Water Sci. Technol. 2014, 69, 1581–1588. [Google Scholar] [CrossRef]

- Shin, C.; Bae, J. Current status of the pilot-scale anaerobic membrane bioreactor treatments of domestic wastewaters: A critical review. Bioresour. Technol. 2018, 247, 1038–1046. [Google Scholar] [CrossRef]

- Souza, T.S.O.; Foresti, E. Sulfide-Oxidizing Autotrophic Denitrification: An Evaluation for Nitrogen Removal from Anaerobically Pretreated Domestic Sewage. Appl. Biochem. Biotechnol. 2013, 170, 1094–1103. [Google Scholar] [CrossRef] [PubMed]

- Yue, X.; Koh, Y.K.K.; Ng, H.Y. Effects of dissolved organic matters (DOMs) on membrane fouling in anaerobic ceramic membrane bioreactors (AnCMBRs) treating domestic wastewater. Water Res. 2015, 86, 96–107. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Sosa, D.; Helmreich, B.; Netter, T.; Paris, S.; Bischof, F.; Horn, H. Anaerobic submerged membrane bioreactor (AnSMBR) for municipal wastewater treatment under mesophilic and psychrophilic temperature conditions. Bioresour. Technol. 2011, 102, 10377–10385. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-Benítez, A.; Ruiz-Martínez, A.; Robles, Á.; Serralta, J.; Ribes, J.; Rogalla, F.; Seco, A.; Ferrer, J. A semi-industrial AnMBR plant for urban wastewater treatment at ambient temperature: Analysis of the filtration process, energy balance and quantification of GHG emissions. J. Environ. Chem. Eng. 2023, 11, 109454. [Google Scholar] [CrossRef]

- Elmoutez, S.; Abushaban, A.; Necibi, M.C.; Sillanpää, M.; Liu, J.; Dhiba, D.; Chehbouni, A.; Taky, M. Design and operational aspects of anaerobic membrane bioreactor for efficient wastewater treatment and biogas production. Environ. Challenges 2023, 10, 100671. [Google Scholar] [CrossRef]

| Operating Conditions | |||||

|---|---|---|---|---|---|

| Period | Flow Rate | SRT | HRT | Temperature | OLR |

| L·d−1 | d | h | °C | g COD·L−1·d−1 | |

| I | 2032 ± 27 | 70 ± 7 | 25.3 ± 4.2 | 25 ± 1 | 0.27 ± 0.04 |

| II | 4335 ± 43 | 68 ± 8 | 12.3 ± 3.4 | 15 ± 2 | 0.58 ± 0.07 |

| III | 5929 ± 31 | 69 ± 7 | 8.5 ± 3.4 | 15 ± 2 | 0.79 ± 0.06 |

| Parameter | Mean ± SD | |

|---|---|---|

| Pretreated WW | Settled WW * | |

| TSS (mg·L−1) | 315 ± 171 | 97 ± 10 |

| VSS (%) | 80.4 ± 8.0 | 78.4 ± 5.3 |

| CODT (mg COD·L−1) | 591 ± 249 | 279 ± 39 |

| CODS (mg COD·L−1) | 84.0 ± 22.2 | 98 ± 17 |

| BODT (mg BOD·L−1) | 390 ± 138 | 170 ± 14 |

| BODS (mg BOD·L−1) | 66.5 ± 33.0 | 50 ± 9 |

| VFA (mg COD·L−1) | 7.9 ± 10.2 | 13.4 ± 6.6 |

| Alkalinity (mg CaCO3·L−1) | 338 ± 65 | 486.7 ± 59.0 |

| SO4-S (mg S·L−1) | 101.7 ± 19.9 | 97.4 ± 10.3 |

| CODT/SO4-S (mg COD·mg−1 S) | 6.0 ± 2.9 | 2.6 ± 0.2 |

| TN (mg N·L−1) | 55.3 ± 12.2 | 48.9 ± 9.7 |

| TP (mg P·L−1) | 10.1 ± 3.5 | 5.5 ± 0.4 |

| NH4-N (mgN·L−1) | 33.1 ± 9.1 | 41.8 ± 7.5 |

| PO4-P (mg P·L−1) | 4.1 ± 1.6 | 3.5 ± 0.6 |

| Anaerobic biodegradability (%) | 68.5 ± 2.8 | 64.3 ± 1.8 |

| Aerobic biodegradability (%) | 63.1 ± 8.9 | 60.5 ± 1.3 |

| Parameter | Mean ± SD | ||

|---|---|---|---|

| Period I | Period II | Period III | |

| CODsludge (mg COD·L−1) | 2783 ± 172 | 5339 ± 182 | 8719 ± 147 |

| MLTS (mg·L−1) | 2941 ± 182 | 5061 ± 232 | 8061 ± 247 |

| MLVS (mg·L−1) | 1603 ± 172 | 3349 ± 231 | 5349 ± 236 |

| MLVS (%) | 54 ± 2 | 66 ± 2 | 66 ± 2 |

| Sludge production (g VSS·kg−1CODinf) | 79 ± 6 | 91 ± 8 | 96 ± 9 |

| Sludge production (g VSS·kg−1CODrem) | 101 ± 8 | 124 ± 9 | 176 ± 16 |

| Aerobic sludge digestibility (%) a | 49.0 ± 1.4 | 57 ± 1.2 | 59 ± 1.3 |

| Anaerobic sludge digestibility (%) b | 9.8 ± 1.2 | 25.0 ± 0.7 | 34.0 ± 0.7 |

| Parameter | Mean ± SD | ||

|---|---|---|---|

| Period I | Period II | Period III | |

| SO4-Sinf (mg S·L−1) | 92.6 ± 8.2 | 102 ± 7.5 | 98.5 ± 6.3 |

| SO4-Sef (mg S·L−1) | 5.2 ± 1.1 | 40.9 ± 3,2 | 73.2 ± 6.9 |

| S2−-Sef (mg S·L−1) | 88.9 ± 9.5 | 66 ± 2.1 | 37.5 ± 2.6 |

| Parameter | Units | Period I | Period II | Period III |

|---|---|---|---|---|

| Fermented COD | (mg·L−1) | 175 | 122 | 51 |

| (g·d−1) | 355 | 530 | 300 | |

| Hydrolyzed COD | (mg L−1) | 146 | 97 | 93 |

| (g·d−1) | 296 | 421 | 549 |

| Parameter | Mean ± SD | ||

|---|---|---|---|

| Period I | Period II | Period III | |

| CODrem (%) | 80 ± 2 | 70 ± 2 | 56 ± 2 |

| CODdeg (%) | 64 ± 1 | 55 ± 1 | 40 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mateo, O.; Sanchis-Perucho, P.; Giménez, J.B.; Robles, Á.; Martí, N.; Serralta, J.; Seco, A. Coupling AnMBR, Primary Settling and Anaerobic Digestion to Improve Carbon Fate When Treating Sulfate-Rich Wastewater. Water 2023, 15, 3574. https://doi.org/10.3390/w15203574

Mateo O, Sanchis-Perucho P, Giménez JB, Robles Á, Martí N, Serralta J, Seco A. Coupling AnMBR, Primary Settling and Anaerobic Digestion to Improve Carbon Fate When Treating Sulfate-Rich Wastewater. Water. 2023; 15(20):3574. https://doi.org/10.3390/w15203574

Chicago/Turabian StyleMateo, Oscar, Pau Sanchis-Perucho, Juan B. Giménez, Ángel Robles, Nuria Martí, Joaquín Serralta, and Aurora Seco. 2023. "Coupling AnMBR, Primary Settling and Anaerobic Digestion to Improve Carbon Fate When Treating Sulfate-Rich Wastewater" Water 15, no. 20: 3574. https://doi.org/10.3390/w15203574

APA StyleMateo, O., Sanchis-Perucho, P., Giménez, J. B., Robles, Á., Martí, N., Serralta, J., & Seco, A. (2023). Coupling AnMBR, Primary Settling and Anaerobic Digestion to Improve Carbon Fate When Treating Sulfate-Rich Wastewater. Water, 15(20), 3574. https://doi.org/10.3390/w15203574