Simulation Study on the Environmental Impact of Rare Earth Ore Development on Groundwater in Hilly Areas: A Case Study in Nuodong, China

Abstract

:1. Introduction

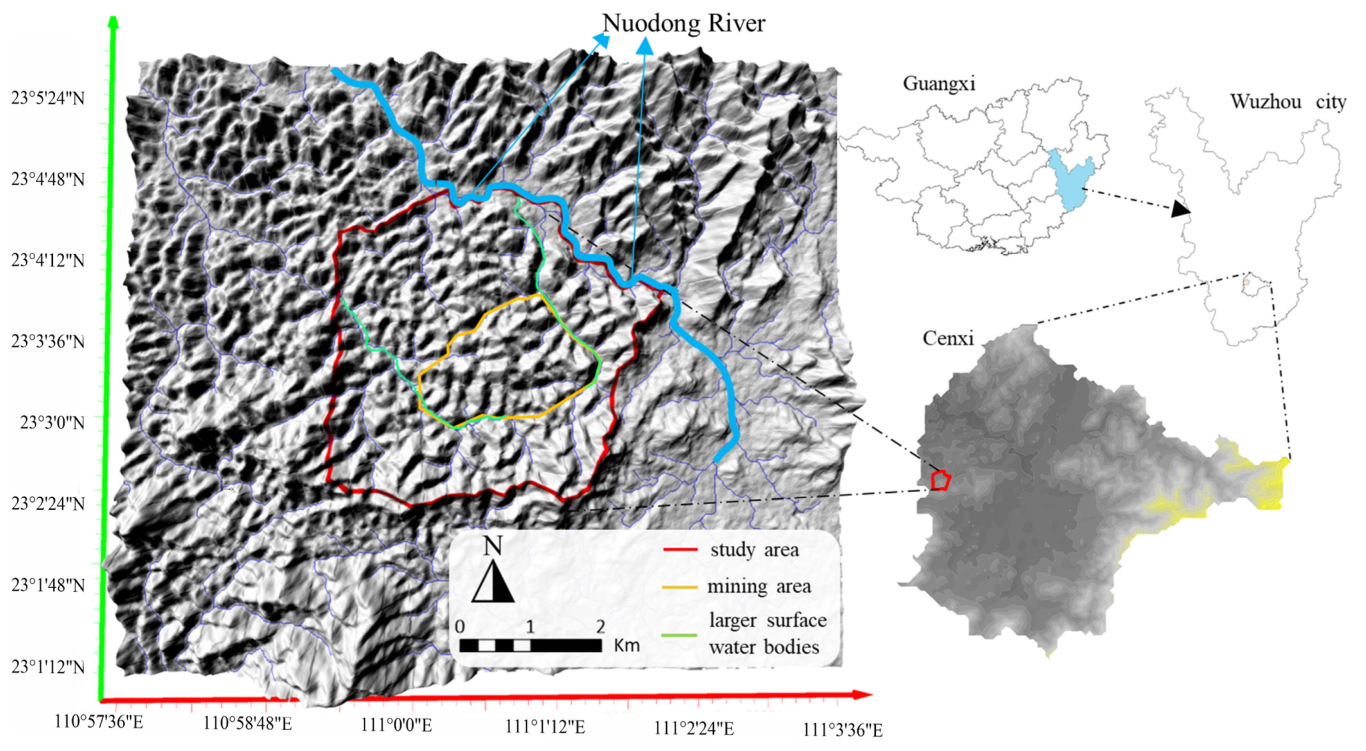

2. Study Area

3. Model Construction

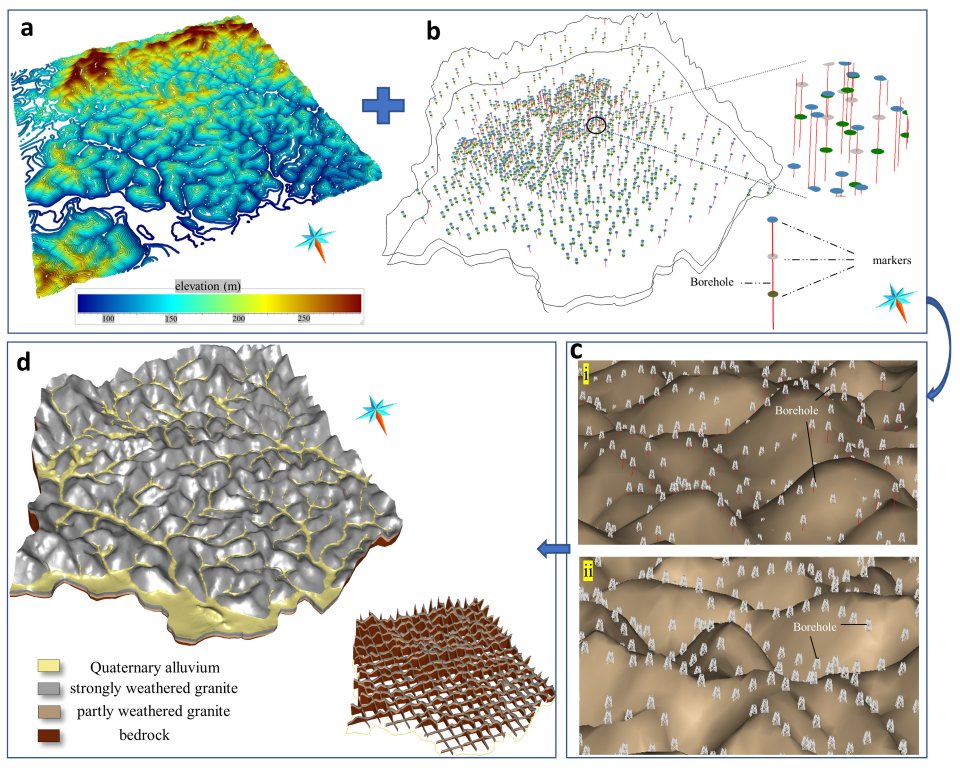

3.1. Geological Model

- The 1:5000 hydrogeological map contours (contour line spacing of 5 m) are extracted using MapGIS software (version 6.7) and integrated into GOCAD as the model surface elevation (Figure 2a);

- A borehole database is established using 742 geological boreholes in the study area, and the thickness of each rock layer in the model is constrained based on the stratigraphic markers corresponding to the boreholes (Figure 2b);

- The borehole and ground elevation data is corrected to ensure that the borehole elevation closely follows the topographic surface prevents errors from different data sources. In the case of the groundwater model, water levels of the observation wells, evaporation, and rainfall infiltration are closely related to the surface elevation (Figure 2c);

- A stratigraphic geological model is constructed using the structural and stratigraphic workflow of GOCAD. To ensure more accurate and intuitive simulation results of groundwater flow and contaminant transport according to different permeability properties, the order of stratum is divided into the following strata from top to bottom: quaternary alluvium, strongly weathered granite, partly weathered granite, and bedrock (Figure 2d). Specifically, the quaternary is mainly distributed in the low-lying areas in front of the mountains on both sides of the river valley. Weathered granite is dominated by fracture water of the weathering zone network state, which is widely distributed, and mining injection holes fall on top of this aquifer.

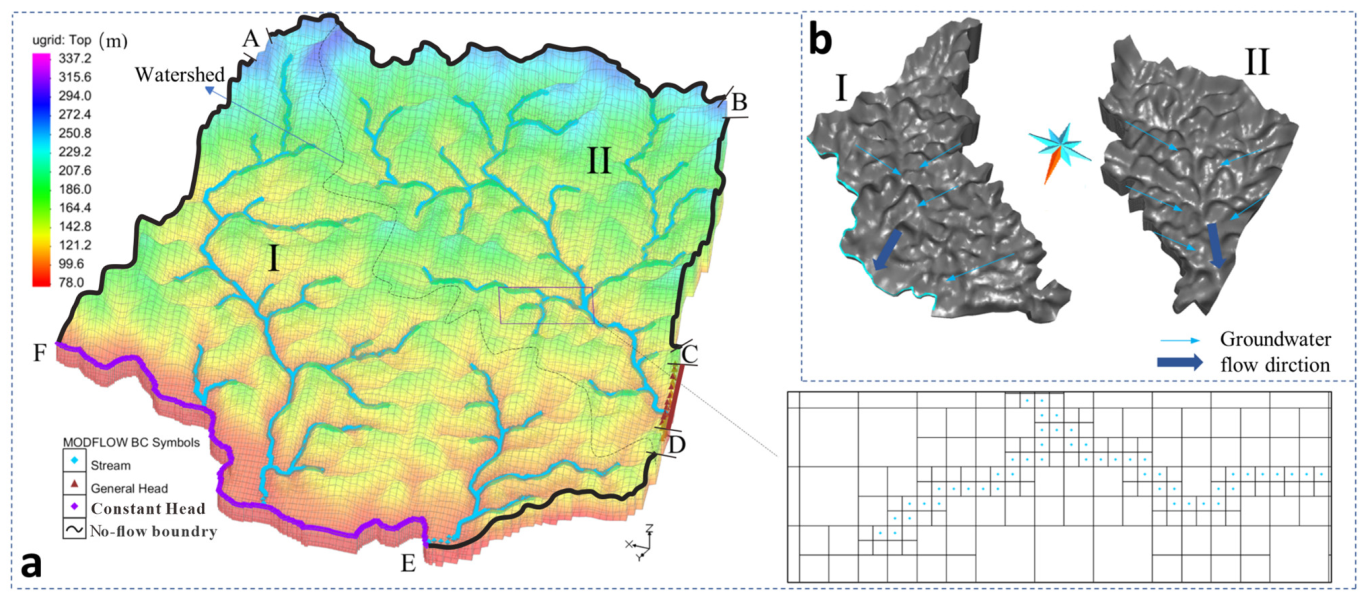

3.2. Groundwater Flow Model

3.2.1. Boundary Condition

3.2.2. Mesh Profile

3.2.3. Hydrogeological Parameters

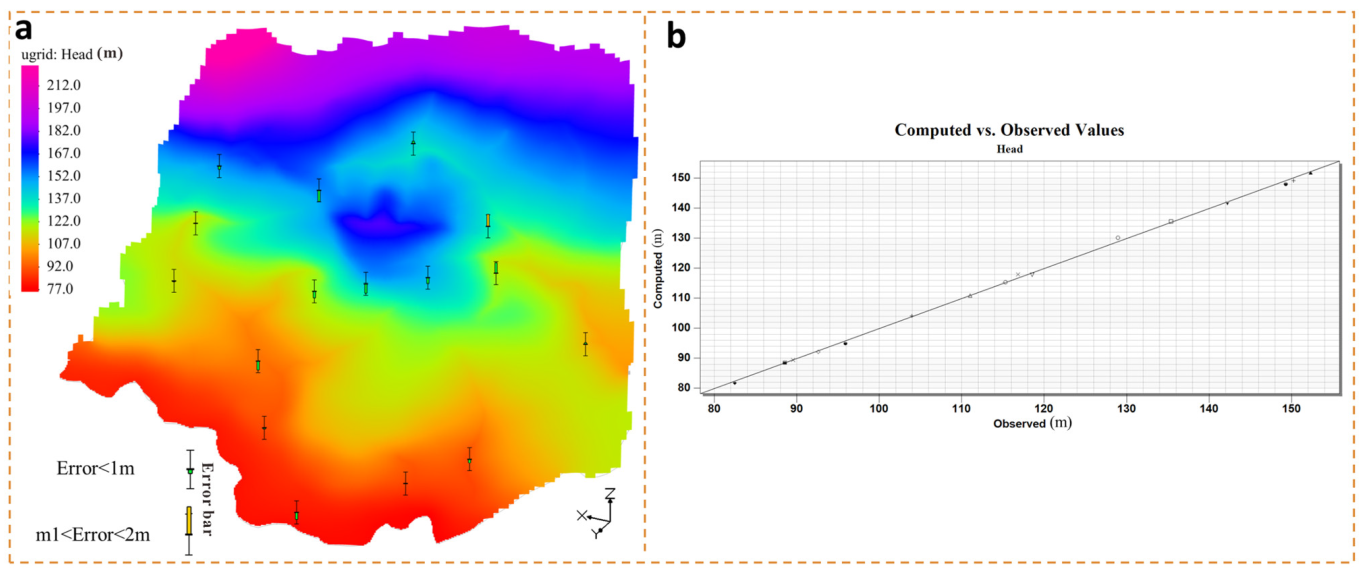

3.2.4. Model Calibration

3.3. Solute-Transport Model

4. Simulation Results and Discussion

4.1. Characteristics of Groundwater Flow Field

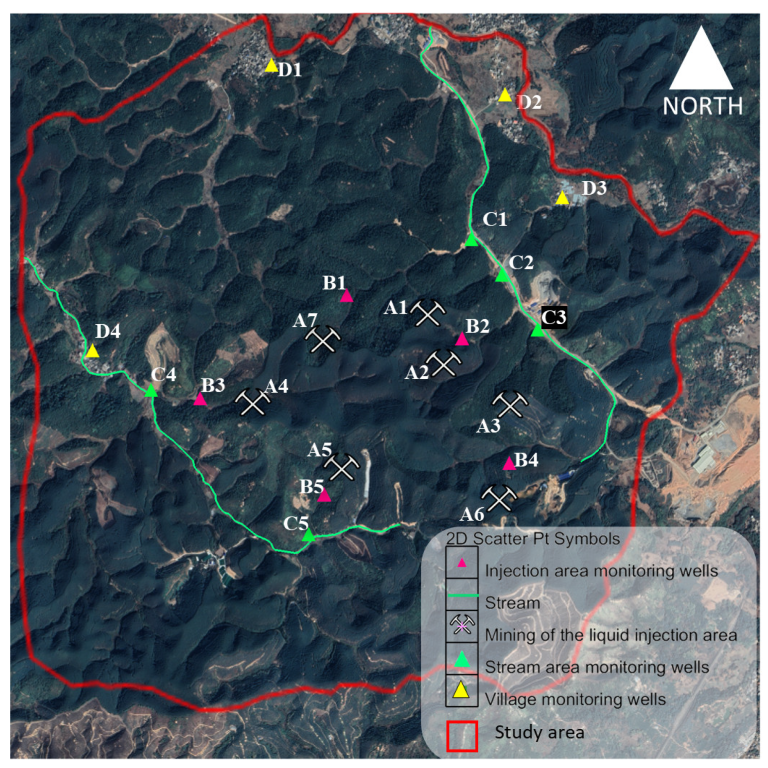

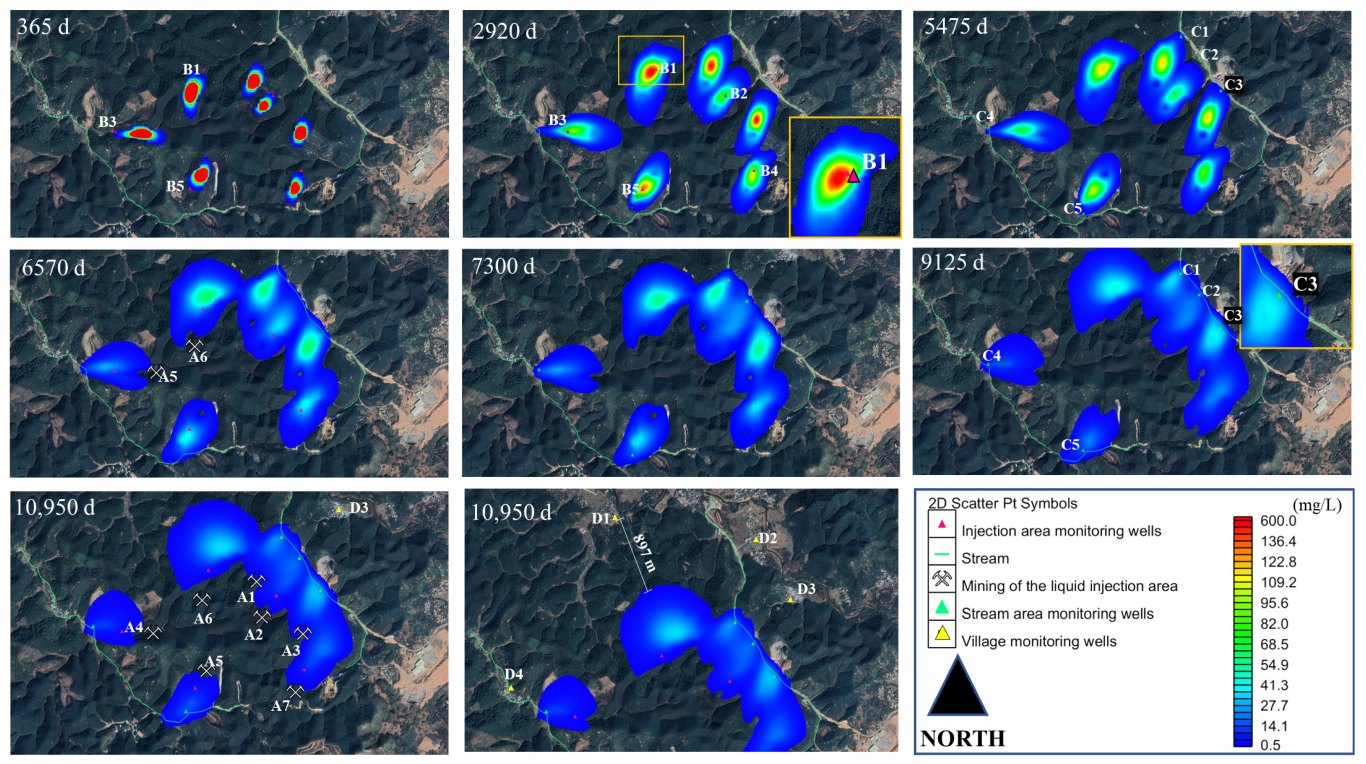

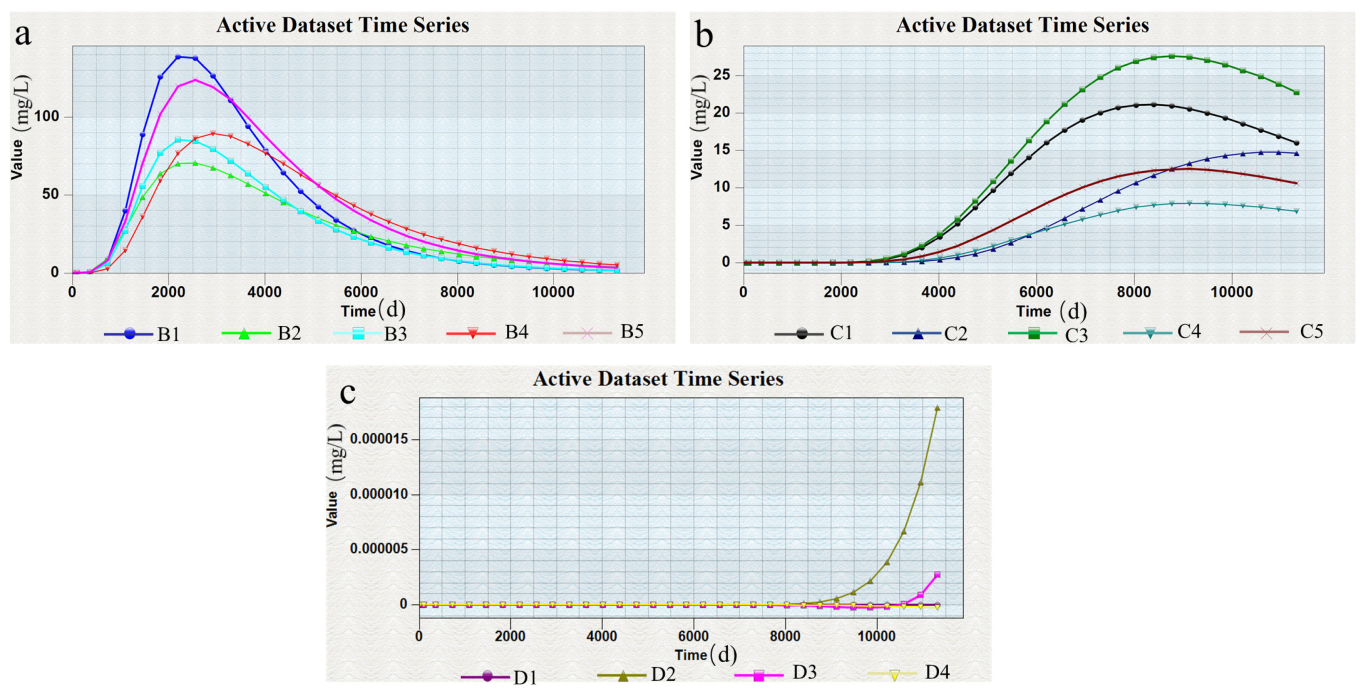

4.2. Characteristics of Solute Transport in the Liquid Injection Areas

4.3. Characteristics of Solute Transport in the Stream Area

4.4. Characteristics of Solute Transport in the Village Area

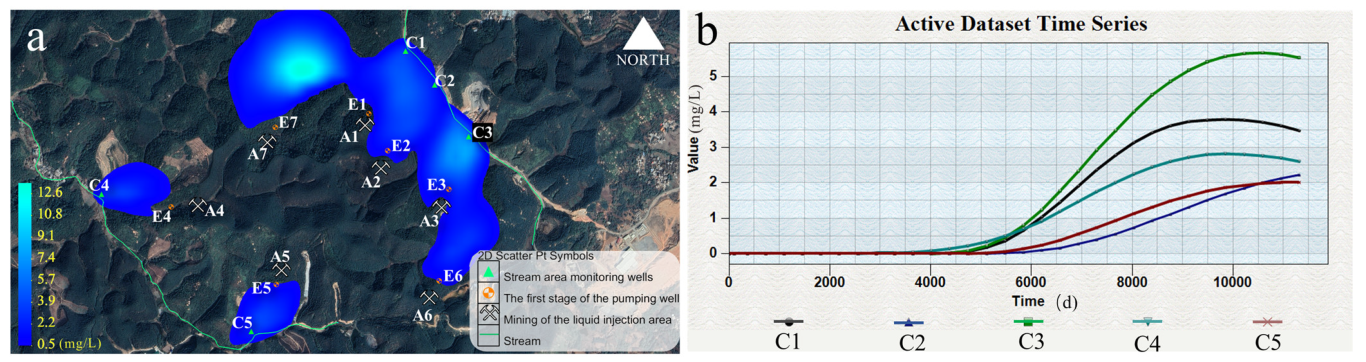

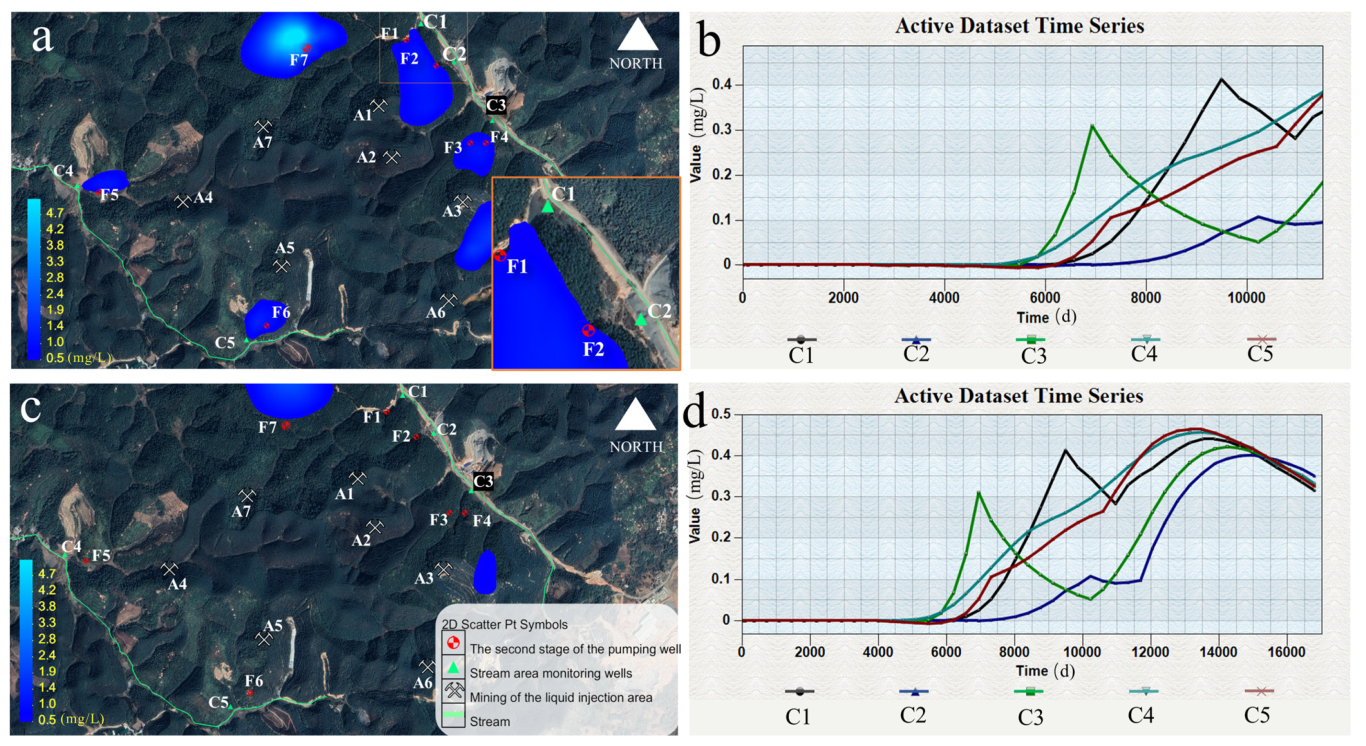

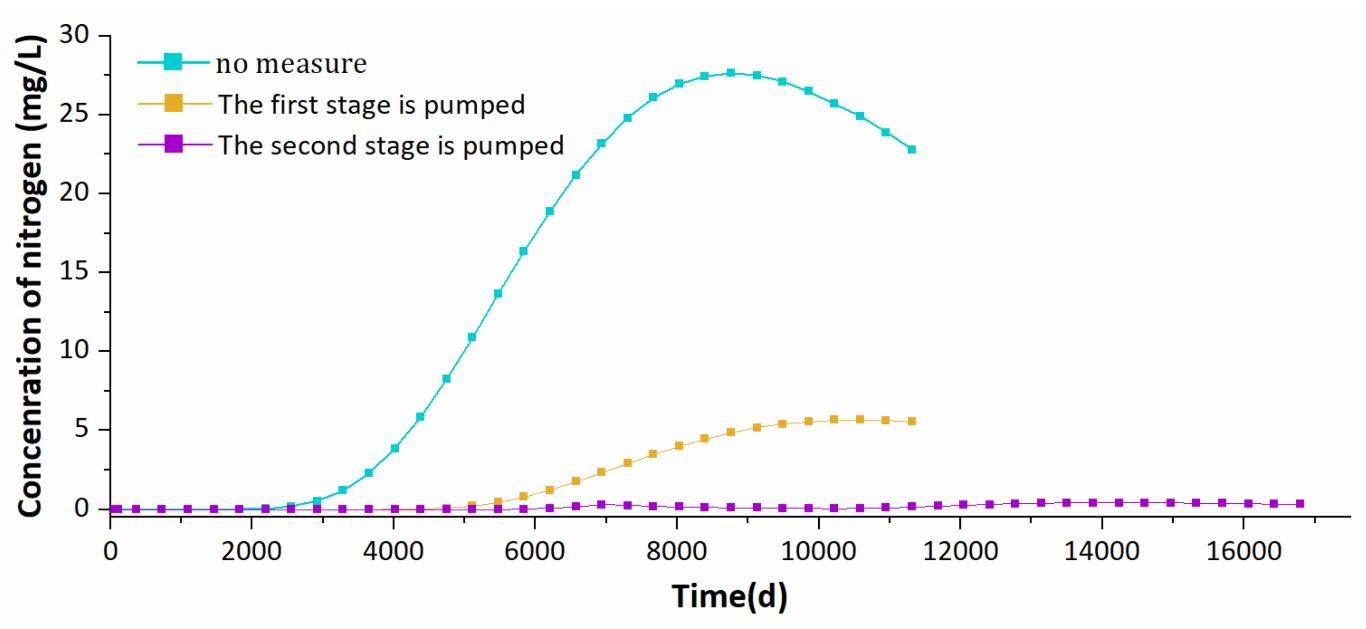

4.5. Groundwater Protection Measures and Effects

5. Conclusions

- (1)

- The water level fitting results of the groundwater flow model show that the absolute error between the simulated and measured water levels of each observation well is 0.554 m. The number of observation wells with MA < 0.5 m accounts for 50% of the total, the number of observation wells between 0.5 and 0.8 m accounts for 31.2%, and the RMS error of each monitoring well is 0.693 m. The established model reflected the groundwater flow field in the study area.

- (2)

- After rare earth mining, the maximum peak concentration of pollutants in the monitoring wells in the injection area reached 139.15 mg/L, exceeding the Class III standard by nearly 280 times. The maximum concentration in the monitoring wells in the stream area is 27.9 mg/L, significantly lower than that in the liquid injection area, but still exceeding the Class III standard by nearly 56 times. The cumulative ammonia-nitrogen contamination area reached 1.95 km2, and the farthest migration distance of the contamination plume was approximately 981 m. During the model run (10,950 d), the ammonia-nitrogen concentration of all monitoring wells in the village area did not exceed the standard, and the impact of rare earth metal mining on the groundwater environment is limited. However, pollutants during mining seriously affect the streams and reservoirs in the area, which could threaten the safety of the water for residents.

- (3)

- After adopting the first-stage pumping measure, ammonia-nitrogen transport is effectively controlled, and the peak concentration of the monitoring wells decreased significantly, with the maximum peak concentration decreasing from 27.9 mg/L to 5.51 mg/L, a reduction of 80%. However, the low concentration of the ammonia-nitrogen control range was limited, and the contaminated area was only reduced by 0.4 km2. Based on these results, a second pumping stage was adopted. The model results showed that the peak concentration of ammonia-nitrogen pollutants discharged into the stream after natural attenuation was less than 0.5 mg/L and the ammonia-nitrogen pollutants in the mine area could be effectively controlled.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dutta, T.; Kim, K.H.; Uchimiya, M.; Kwon, E.E.; Jeon, B.-H.; Deep, A.; Yun, S.-T. Global demand for rare earth resources and strategies for green mining. Environ. Res. 2016, 150, 182–190. [Google Scholar] [CrossRef] [PubMed]

- Golev, A.; Scott, M.; Erskine, P.D.; Ali, S.H.; Ballantyne, G.R. Rare earths supply chains: Current status, constraints and opportunities. Resour. Policy 2014, 41, 52–59. [Google Scholar] [CrossRef]

- Packey, D.J.; Kingsnorth, D. The impact of unregulated ionic clay rare earth mining in China. Resour. Policy 2016, 48, 112–116. [Google Scholar] [CrossRef]

- Deng, Z.X.; Qin, L.; Wang, G.S.; Luo, S.H.; Peng, C.L. Ammonia nitrogen pollution and rogress in its treatment of ionic rare earth mines. Chin. Rare Earths 2019, 40, 120–129. [Google Scholar]

- Zhou, F.; Liu, Q.; Feng, J.; Su, J.; Liu, X.; Chi, R. Role of initial moisture content on the leaching process of weathered crust elution-deposited rare earth ores. Sep. Purif. Technol. 2019, 217, 24–30. [Google Scholar] [CrossRef]

- Zhang, Z.; He, Z.; Yu, J.; Xu, Z.; Chi, R. Novel solution injection technology for in-situ leaching of weathered crust elution-deposited rare earth ores. Hydrometallurgy 2016, 164, 248–256. [Google Scholar] [CrossRef]

- Zhang, Q.; Ren, F.; Li, F.; Chen, G.; Yang, G.; Wang, J.; Du, K.; Liu, S.; Li, Z. Ammonia nitrogen sources and pollution along soil profiles in an in-situ leaching rare earth ore. Environ. Pollut. 2020, 267, 115449. [Google Scholar] [CrossRef]

- Zhu, Y.B.; Zhou, L.B.; Li, Q. Water pollution prevention method for in-situ leach mining of ion-absorbed rare-earth mineral. Nonferrous Met. 2011, 6, 46–49. [Google Scholar]

- Wu, D.Y. Study on the stability of residual matter in southern ion rare earth mines. Master’s Thesis, China University of Geosciences, Beijing, China, 2018. [Google Scholar]

- Zhao, Y.H.; Zheng, T.; Cheng, X.X. Advance of ammonia nitrogen pollution and control techniques for soil and water environment in ion-adsorption rare earth mines. Chin. Rare Earths 2020, 41, 24–132. [Google Scholar]

- Feng, J.; Zhou, F.; Chi, R.; Liu, X.; Xu, Y.; Liu, Q. Effect of a novel compound on leaching process of weathered crust elution-deposited rare earth ore. Miner. Eng. 2018, 129, 63–70. [Google Scholar] [CrossRef]

- He, Q.; Qiu, J.; Chen, J.; Zan, M.; Xiao, Y. Progress in green and efficient enrichment of rare earth from leaching liquor of ion adsorption type rare earth ores. J. Rare Earths 2022, 40, 353–364. [Google Scholar] [CrossRef]

- Gong, R.; Ye, C.W.; Cheng, R. Resistance and control of ammonia nitrogen pollution of ionic rare earth ores with modified soil-bentonite barrier. Chin. J. Environ. Eng. 2020, 14, 1394–1403. [Google Scholar]

- Xiao, Y.F.; Feng, Z.Y.; Huang, X.W.; Huang, L.; Yingying, C.; Liangshi, W.; Zhiqi, L. Recovery of rare earths from weathered crust elution-deposited rare earth ore without ammonia-nitrogen pollution: I. leaching with magnesium sulfate. Hydrometallurgy 2015, 153, 58–65. [Google Scholar]

- Yan, H.S.; Liang, T.M.; Liu, Q.S.; Qiu, T.S.; Ai, G.H. Compound leaching behavior and regularity of ionic rare earth ore. Powder Technol. 2018, 333, 106–114. [Google Scholar] [CrossRef]

- Liu, L.; Liang, S.P.; Liu, H.C.; Tan, W.; Zhu, G.R. Migration of Cr2O72− and butanone in soil and groundwater system after the Tianjin port 8·12 Explosion. Trans. Tianjin Univ. 2018, 24, 522–531. [Google Scholar] [CrossRef]

- Liu, M.Z.; Chen, H.H.; Hu, L. Numerical modeling of transport of organic pollutants in shallow groundwater in a certain city of northern China. Geol. China 2005, 32, 507–511. [Google Scholar]

- Liu, S.L.; Wer, J.; Shen, Y.Y. Pollution risk evaluation of Dawu groundwater source site in Zibo City, Shandong. J. Saf. Environ. 2013, 13, 142–148. [Google Scholar]

- McDonald, M.G.; Harbaugh, A.W. A modular three-dimensional finite-difference ground-water flow model. In Open-File Report; US Geological Survey: Reston, VA, USA, 1984. [Google Scholar]

- Shen, T.T. Numerical simulation of solute transport in groundwater at a chemical plant. Environ. Sci. Technol. 2015, 38, 378–382. [Google Scholar]

- Li, X.; Du, J.; Cui, J.; Chai, L.; Di, Z.; Wang, X. Migration and prediction of groundwater organic contamination intypical region of Hunhe River alluvial fan. J. Cent. South Univ. 2014, 45, 2529–2537. [Google Scholar]

- Zhu, J.; Chen, C.; Li, T.; Zhang, A.M. Numerical simulation of groundwater flow characteristics and radionuclide migration in hilly area. J. Shanxi Univ. 2019, 42, 465–472. [Google Scholar]

- Zhu, J.; Li, T.; Chen, C.; Xie, T.; Zhang, A. Model calculation method of radionuclide groundwater release flux of offshore nuclear power plants. J. Jilin Univ. 2021, 51, 201–211. [Google Scholar]

- Woloszyn, I.; Merkel, B.; Stanek, K. 3D geological modeling of the transboundary Berzdorf–Radomierzyce basin in Upper Lusatia (Germany/Poland). Int. J. Earth Sci. 2016, 106, 1651–1663. [Google Scholar] [CrossRef]

- Ross, M.; Aitssi, L.; Martel, R.; Parent, M. From Geological to Groundwater Flow Models: An Example of Interoperability for Semi-regular Grids; Natural Resources Canada/CMSS/Information Management: Salt Lake City, UT, USA, 2006. [Google Scholar]

- Watson, C.; Richardson, J.; Wood, B.; Jackson, C.; Hughes, A. Improving geological and process model integration through TIN to 3D grid conversion. Comput. Geosci. 2015, 82, 45–54. [Google Scholar] [CrossRef] [Green Version]

- Lachaal, F.; Chekirbane, A.; Chargui, S.; Sellami, H.; Tsujimura, M.; Hezzi, H.; Faycel, J.; Mlayah, A. Water resources management strategies and its implications on hydrodynamic and hydrochemical changes of costal groundwater: Case of Grombalia shallow aquifer, NE Tunisia. J. Afr. Earth Sci. 2016, 124, 171–188. [Google Scholar] [CrossRef]

- Cui, W.Z.; Hao, Q.C. Comparing Q-Tree with nested grids for simulating managed river recharge of groundwater. Water 2020, 12, 3516. [Google Scholar] [CrossRef]

- Ezzeldin, M.M.; ElAlfy, K.S.; Gawad, H.A.A.; Elmaboud, M.E.A. Comparison between structured and unstructured MODFLOW for simulating groundwater flow in Three-Dimensional multilayer Quaternary aquifer of East Nile Delta, Egypt. Hydrol. Curr. Res. 2018, 9, 297. [Google Scholar] [CrossRef]

- Karan, S.; Jacobsen, M.; Kazmierczak, J.; Reyna-Gutiérrez, J.; Breum, T.; Engesgaard, P. Numerical representation of groundwater-surface water exchange and the effect on streamflow contribution estimates. Water 2021, 13, 1923. [Google Scholar] [CrossRef]

- Yuan, S.D.; Zhang, W.J.; Yuan, S.S. Dispersion values in solute migration tests. Rock Soil Mech. 2020, S2, 1–6. [Google Scholar]

- Anderson, M.P.; Woessner, W.W. The role of the postaudit in model validation. Adv. Water Resour. 1992, 15, 167–173. [Google Scholar] [CrossRef]

- Ju, X.L. Study on the Simulation Prediction of Groundwater Ammonia-Nitrogen Pollution in Rare Earth Area of Southern Jiangxi Province. Master’s Thesis, Liaoning Normal University, Dalian, China, 2015. [Google Scholar]

- Xu, S.T.; Xiang, Y.; Liu, Z.Y. Simulation and predication of ammonia nitrogen contamination of groundwater in ionic adsorption rare earth in-situ leaching mining. Nonferrous Met. Sci. Eng. 2016, 7, 140–146. [Google Scholar]

- Panday, S. Block-Centered Transport (BCT) process for MODFLOW-USG. In GSI Environmental; US Geological Survey: Reston, VA, USA, 2017. [Google Scholar]

- Song, K.; Ren, X.; Mohamed, A.K.; Liu, J.; Wang, F. Research on drinking-groundwater source safety management based on numerical simulation. Sci. Rep. 2020, 10, 15481. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.Q.; Zhang, Y.K. Twofold significance of groundwater pollution prevention in China’s water pollution control. Acta Sci. Circumstantiae 2009, 29, 474–481. [Google Scholar]

- Pu, M. Reviews on groundwater contaminants control and remediation technology: Rump and treat. Environ. Eng. 2017, 35, 6–10. [Google Scholar]

| NO. | Lithology | Kx (m/d) | Ky (m/d) | Kx/Kz |

|---|---|---|---|---|

| 1 | Quaternary alluvium | 2.39~3.54 | 2.39~3.54 | 5 |

| 2 | Strongly weathered granite | 0.09~2.359 | 0.09~2.359 | 5 |

| 3 | Partly fractionated granite | 0.018~0.47 | 0.018~0.47 | 5 |

| 4 | Bedrock | 0.005~0.009 | 0.005~0.009 | 5 |

| Well Number | Running Time (d) | Pumping Capacity (m3/d) | Location |

|---|---|---|---|

| F1 | 9490–10,585 | 200 | A1 pollution plume downstream |

| F2 | 9855–10,950 | 200 | A2 pollution plume downstream |

| F3 | 6935–10,220 | 200 | A3 pollution plume downstream |

| F4 | 6935–10,220 | 200 | A3 pollution plume downstream |

| F5 | 5475–7665 | 250 | A4 pollution plume downstream |

| F6 | 7300–10,220 | 200 | A5 pollution plume downstream |

| F7 | 7300–9490 | 200 | A7 pollution plume downstream |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, H.; Shan, H.; Mo, D.; Liu, Y.; Peng, S.; Cheng, Y.; Chen, M.; Yan, Z. Simulation Study on the Environmental Impact of Rare Earth Ore Development on Groundwater in Hilly Areas: A Case Study in Nuodong, China. Water 2023, 15, 263. https://doi.org/10.3390/w15020263

He H, Shan H, Mo D, Liu Y, Peng S, Cheng Y, Chen M, Yan Z. Simulation Study on the Environmental Impact of Rare Earth Ore Development on Groundwater in Hilly Areas: A Case Study in Nuodong, China. Water. 2023; 15(2):263. https://doi.org/10.3390/w15020263

Chicago/Turabian StyleHe, Hongqiu, Huimei Shan, Deke Mo, Yunquan Liu, Sanxi Peng, Yaping Cheng, Meng Chen, and Zhiwei Yan. 2023. "Simulation Study on the Environmental Impact of Rare Earth Ore Development on Groundwater in Hilly Areas: A Case Study in Nuodong, China" Water 15, no. 2: 263. https://doi.org/10.3390/w15020263

APA StyleHe, H., Shan, H., Mo, D., Liu, Y., Peng, S., Cheng, Y., Chen, M., & Yan, Z. (2023). Simulation Study on the Environmental Impact of Rare Earth Ore Development on Groundwater in Hilly Areas: A Case Study in Nuodong, China. Water, 15(2), 263. https://doi.org/10.3390/w15020263