Gas Loss Mechanism in the High-Pressure Air Cushion Surge Chamber of Hydropower Station for Transient Process

Abstract

1. Introduction

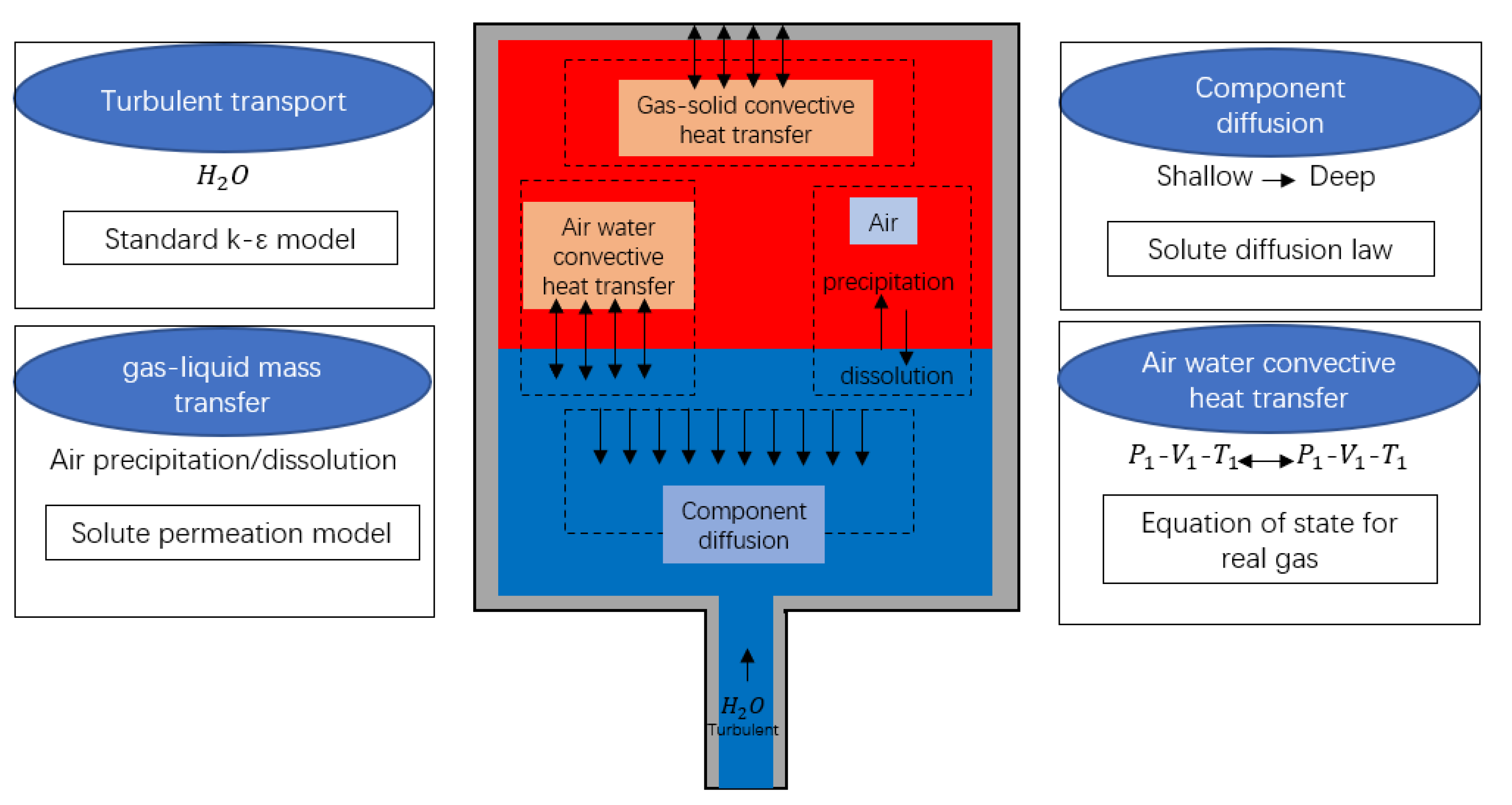

2. Water–Air Two-Phase Flow Model

2.1. VOF Model

2.2. Heat Transfer Model

2.3. Mass Transfer Model

3. Example Simulation and Analysis

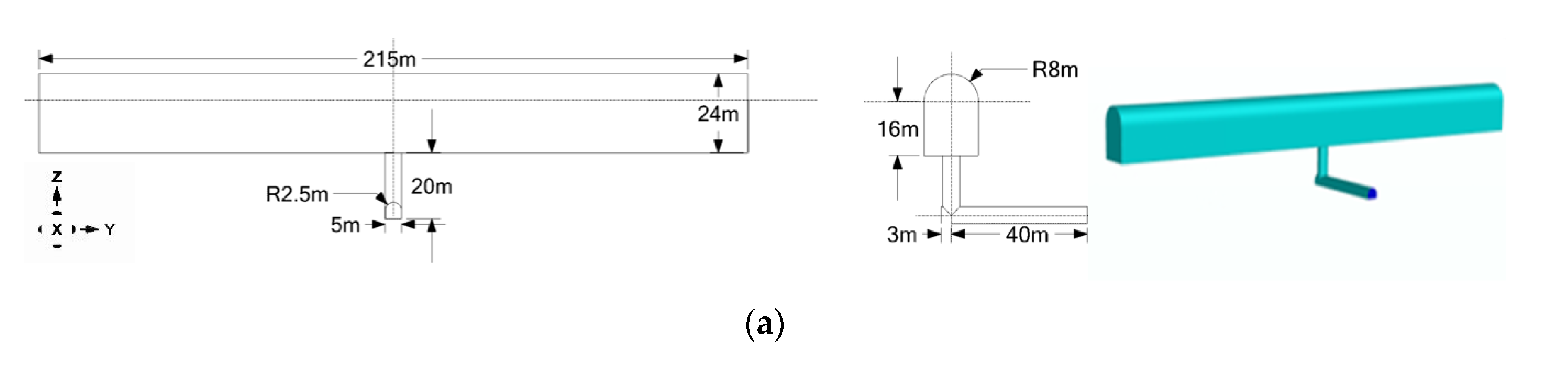

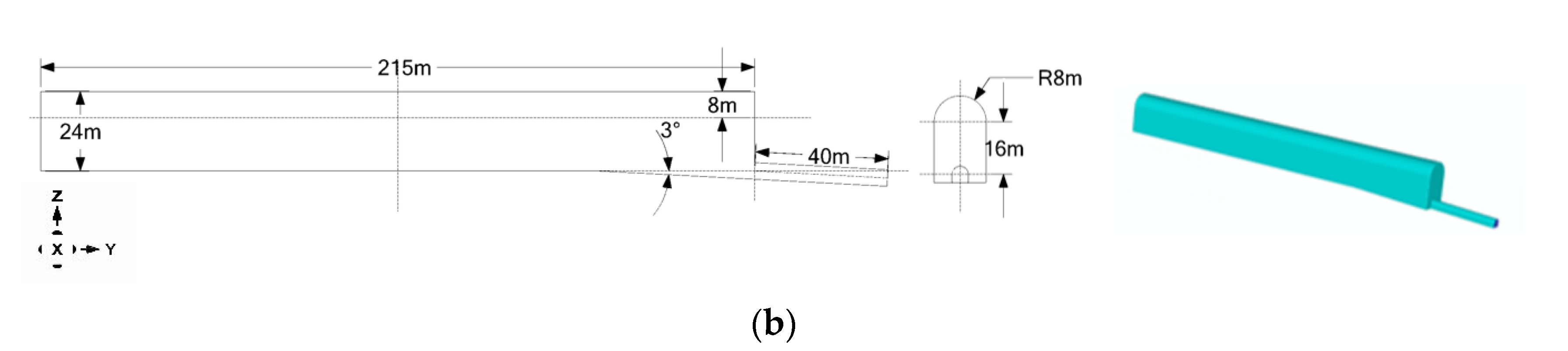

3.1. Surge Chamber Structure

3.2. Hydraulic Boundary Conditions

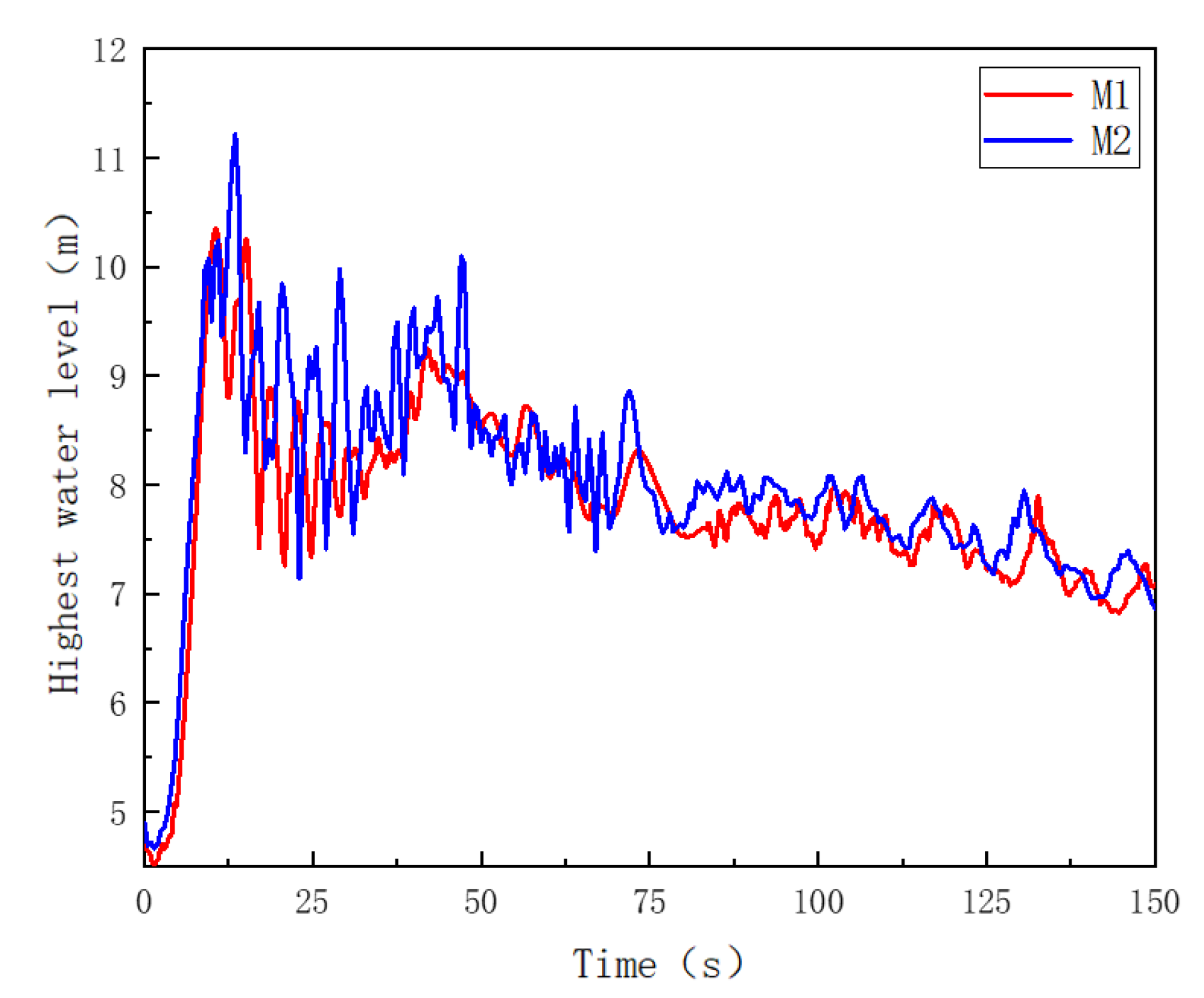

3.3. Grid Sensitivity Analysis

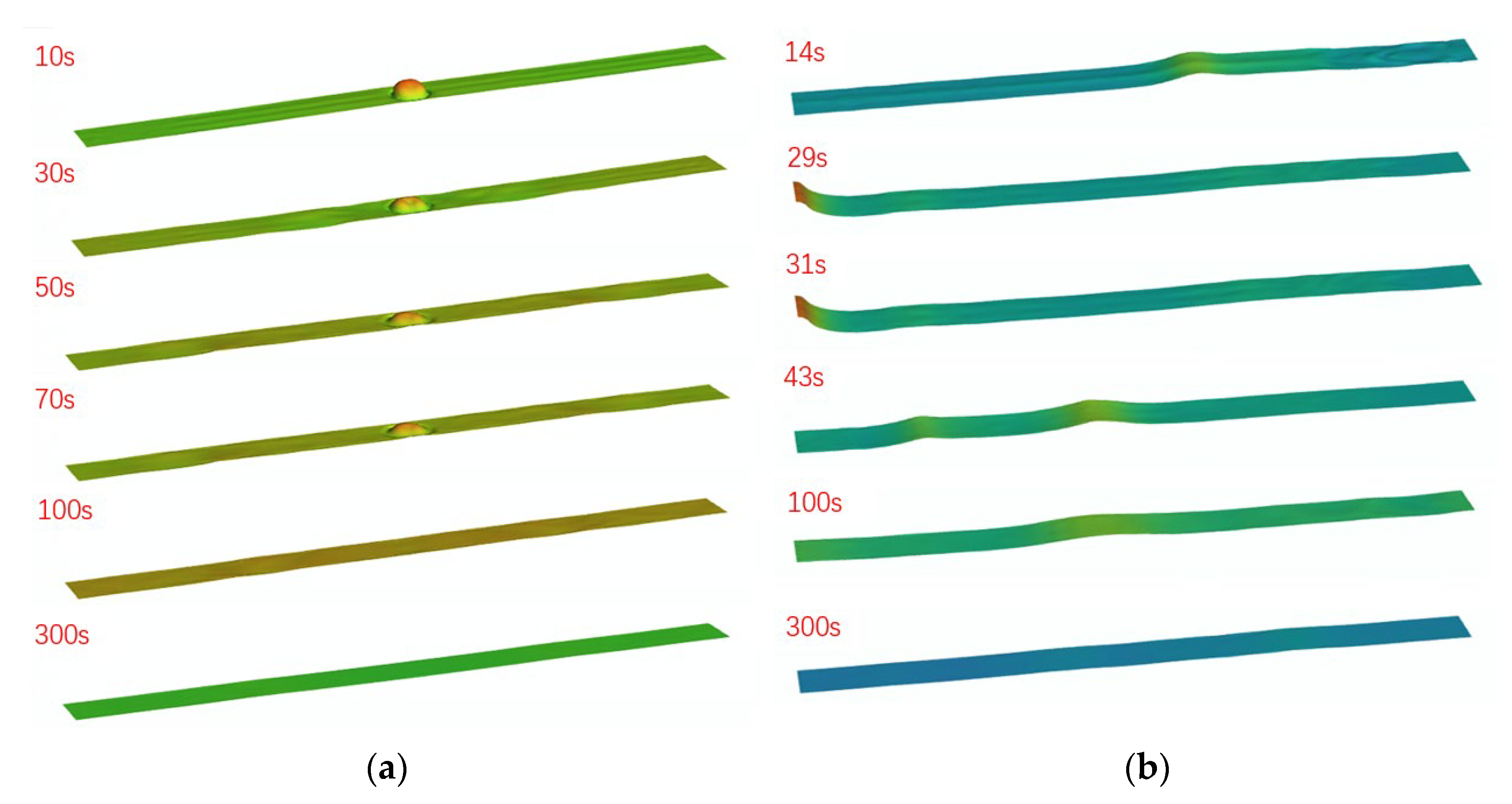

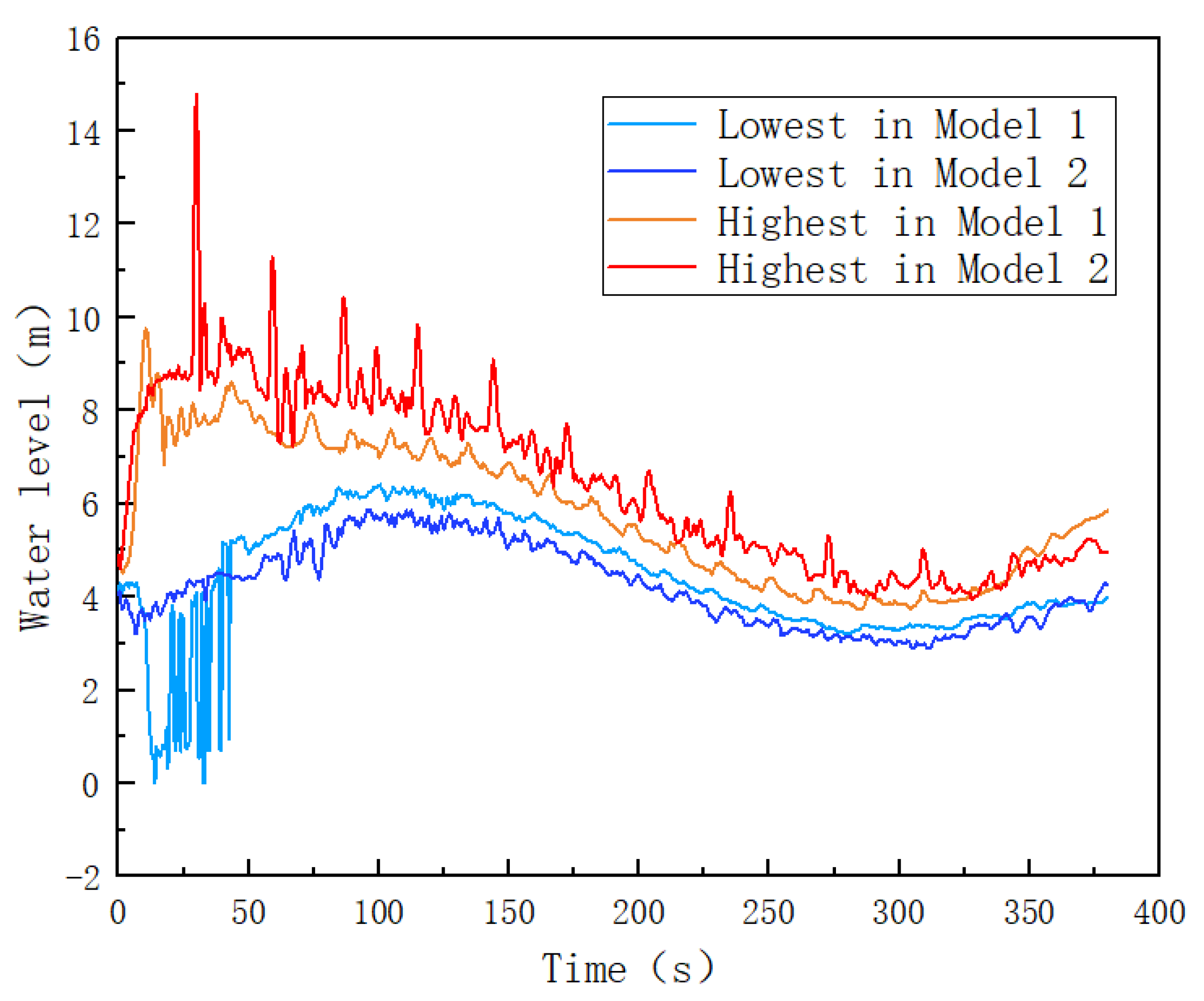

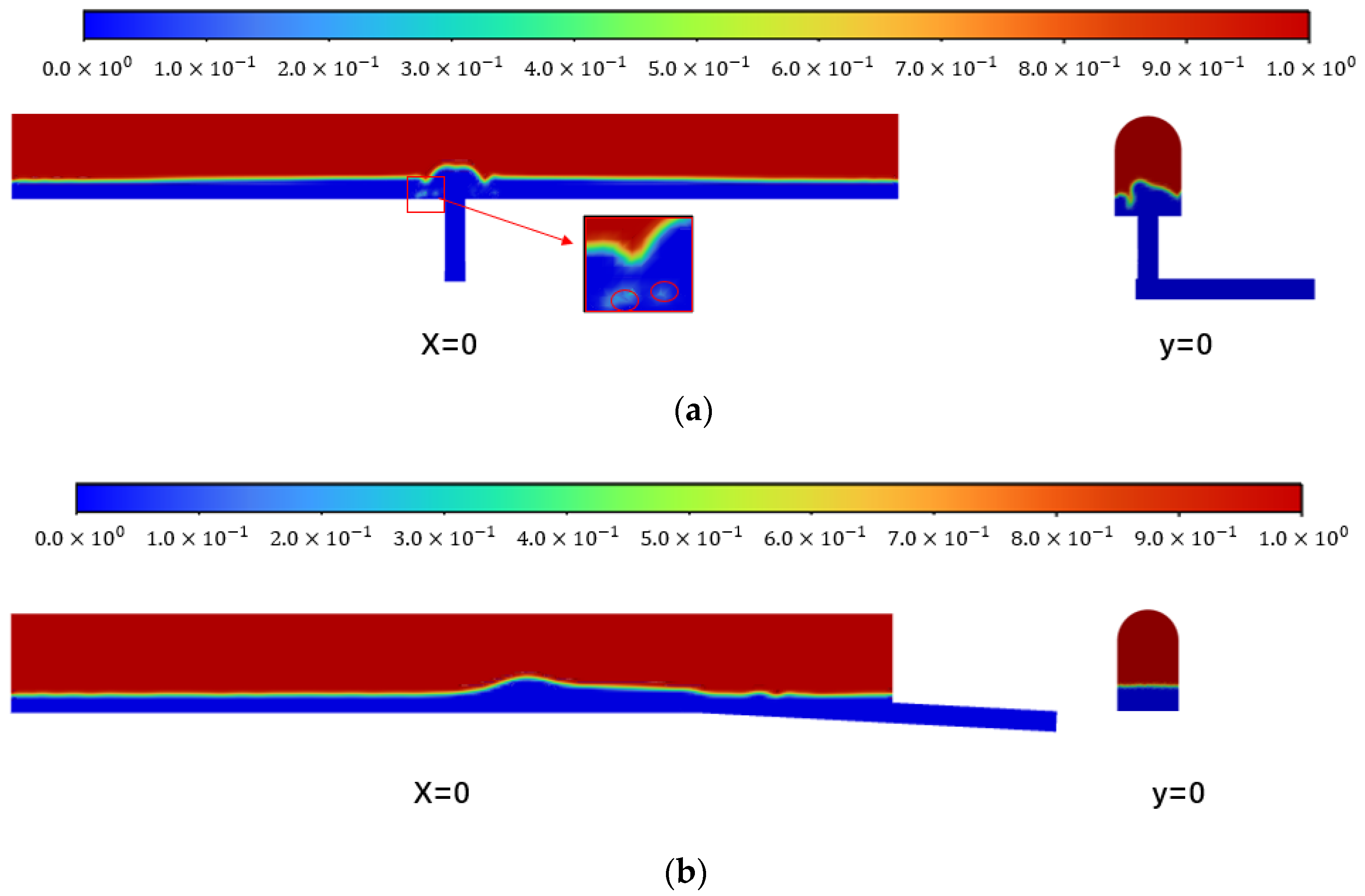

3.4. Analysis of Flow State Structure of Air Cushion Surge Chamber

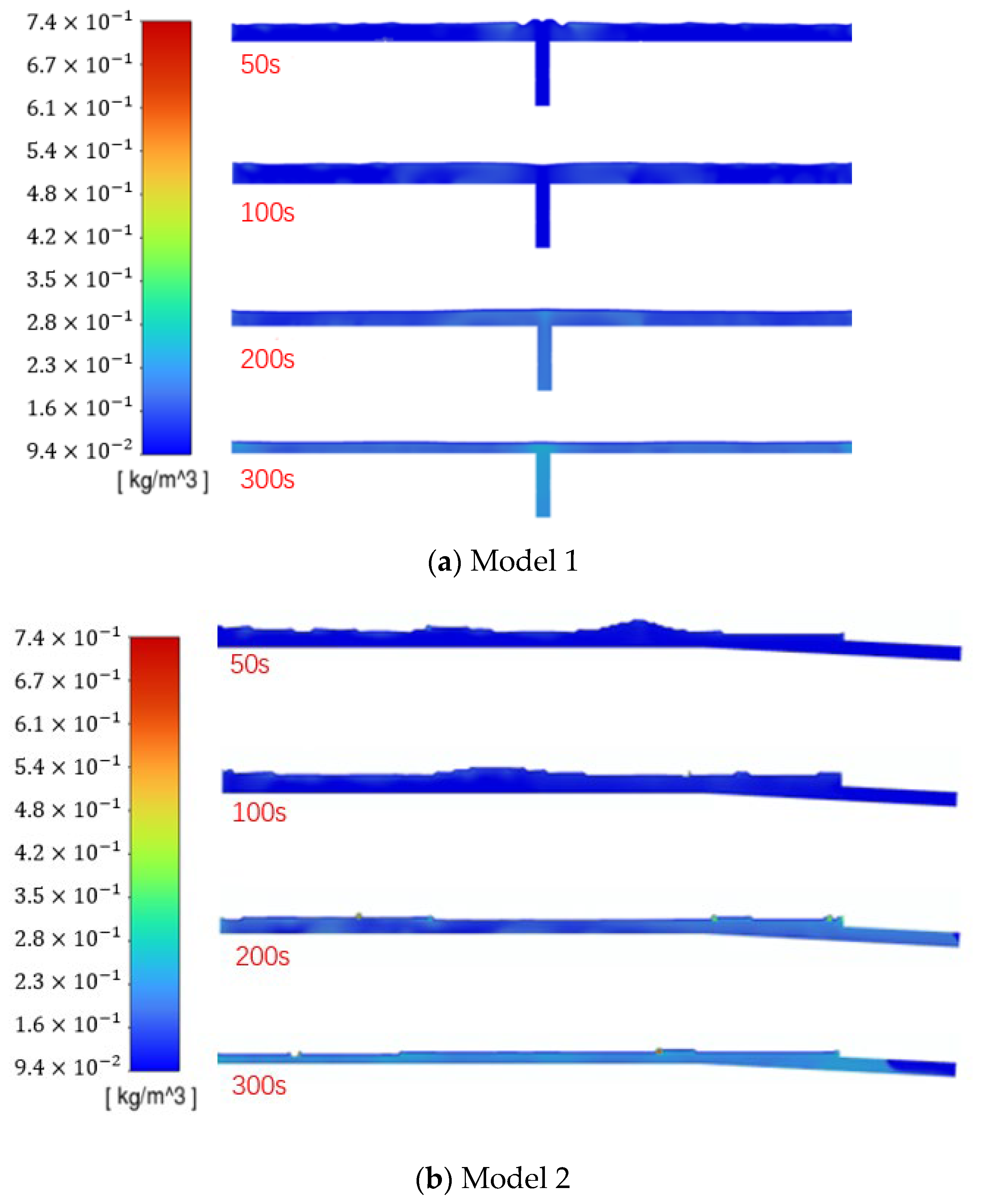

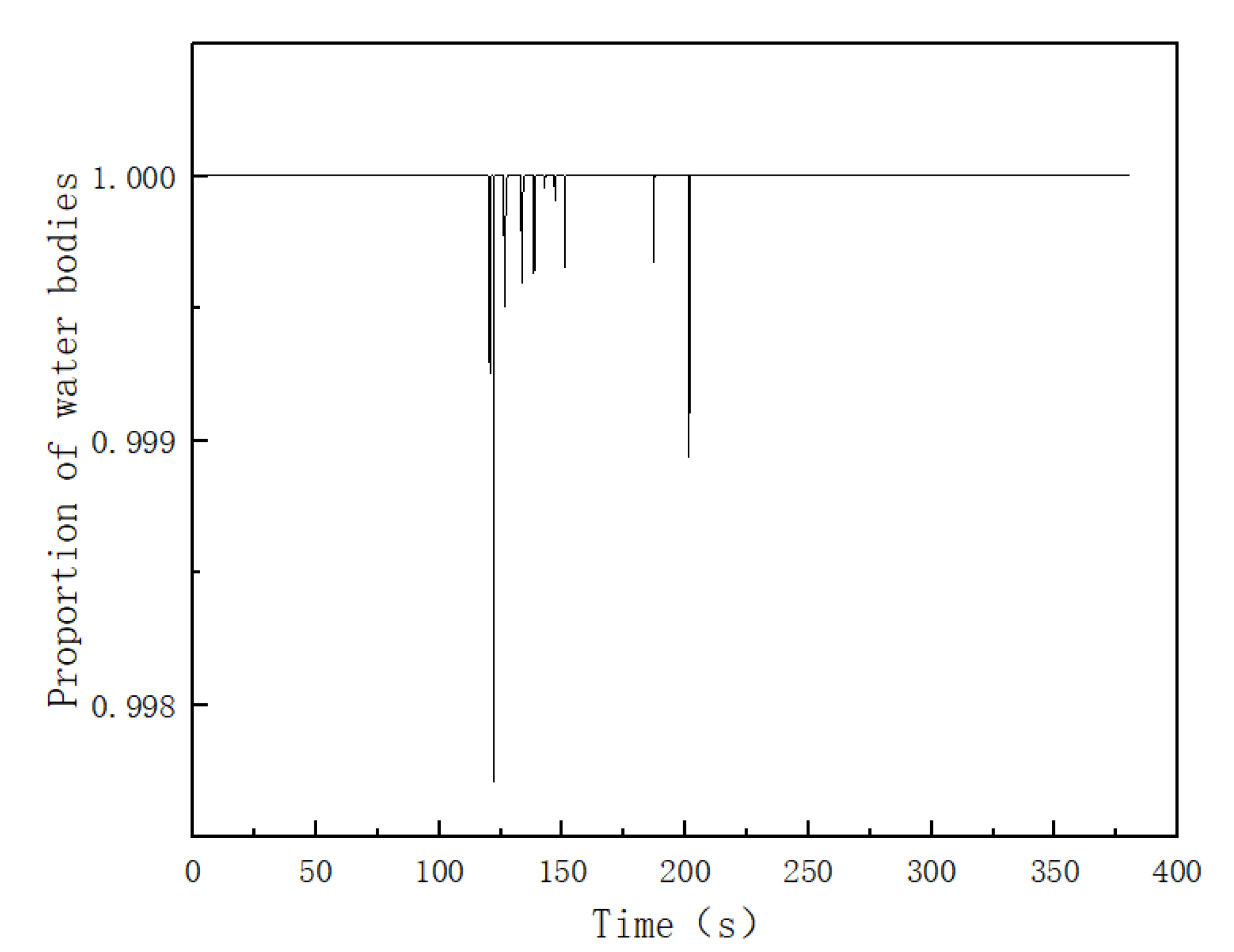

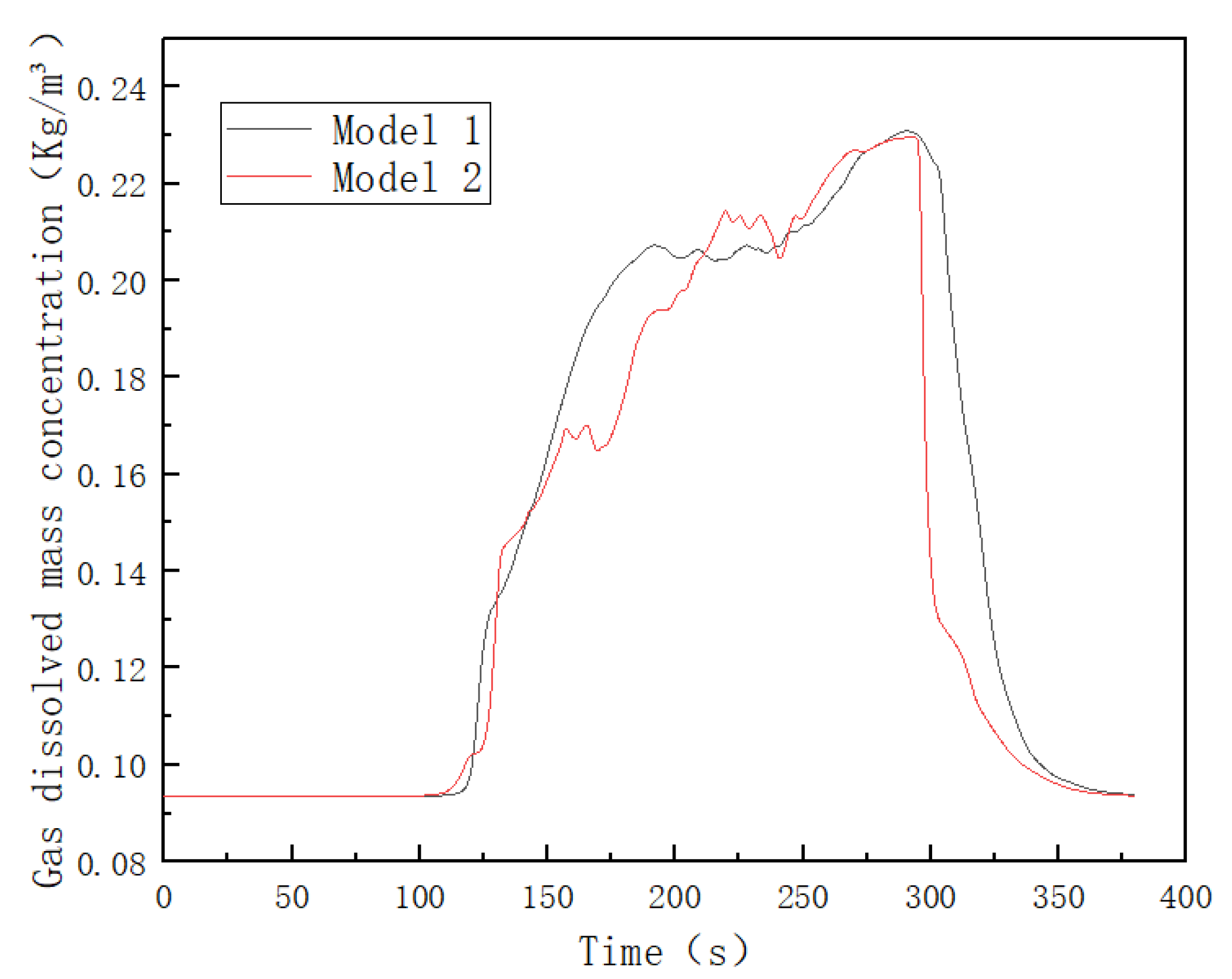

3.5. Heat and Mass Transfer in Air Cushion Surge Chamber

4. Conclusions

- A large amount of gas will be rolled into the water in the process of hydraulic fluctuation. There will be gathered air mass, mass transfer through the formation of high gas content water, and the main gas–liquid mass transfer process generally occurs in the turbulent area.

- The gas solubility decreases with the water depth, and the gas diffusion depth is limited in the steady state. But in the transition process, some air masses and a large amount of high gas content water enter the pipeline through the water outlet.

- In this paper, a gas loss model in an air cushion surge chamber was established. In a set period of a transition process, the gas escape amount in the form of air mass is 33.93 kg in Model 1, and the corresponding gas volume under standard atmospheric pressure is 28.75 m3. The dissolved air volume of the model is 1090.35 kg (923.89 m3).

- Considering different structures of air cushion surge chambers, Model 2 (water inlet on the right side of the air chamber) did not detect any air mass escaping, and the dissolved gas volume was 1008.08 kg (854.18 m 3). There was a lower gas loss volume compared to Model 1(water inlet in the middle of the air chamber).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclatures

| the volume fraction of water phase | the effective heat conduction coefficient | ||

| the volume fraction of gas phase | the enthalpy of gas in water phase | ||

| the mass of material transfer from gas to water phase | the diffusion flux of gas in water phase | ||

| the mass of material transfer from water to gas phase | the diffusion coefficient of solute A in solvent B | ||

| the velocity components in x, y, z and three directions | the turbulent kinetic energy dissipation rate | ||

| the coordinate components in x, y, z and three directions | the dynamic viscosity of the liquid phase | ||

| the average density of each cell | the specific surface area of the gas-liquid boundary | ||

| the gravitational volume force in the direction of i | the molar mass of solvent B | ||

| the stress tensor | the molecular volume of solute A at the normal boiling point | ||

| the static pressure strength | the saturation solubility in water | ||

| the isobaric specific heat | the corresponding solubility in water at time t |

References

- Yu, X. Air cushion surge chamber of underground hydropower station. Northeast. Water Resour. Hydropower 1990, 4, 40–47. [Google Scholar]

- Jin, J. Air cushion surge chamber for underground hydropower stations in Norway. Sichuan Water Power 1991, 1, 43–47. [Google Scholar]

- Godard, D.C.; Gerhott, H.; Turkel, T.; Bloch, E. Air cushion surge chamber for underground hydropower stations. Hydropower Stn. Des. 1990, 2, 74–78. [Google Scholar]

- Liu, D.; Zhang, J.; Suo, L. Research progress on air cushion surge chamber. Hydroelectr. Energy Sci. 2000, 4, 1–5. [Google Scholar]

- Zhan, J.; Suo, L.; Zheng, Y.; Liu, D. Research on the dynamic characteristics of gas in air cushion pressure regulating room. J. Hydroelectr. Eng. 2004, 4, 97–101. [Google Scholar]

- Wu, J. Research on cavitation and erosion problems in water conservancy and hydropower engineering. In Proceedings of the 18th National Symposium on Hydrodynamics, Beijing, China, 23–27 June 2004; p. 18. [Google Scholar]

- Xia, L.-S.; Cheng, Y.-G.; Zhou, D.-Q. 3-D simulation of transient flow patterns in a corridor-shaped air-cushion surge chamber based on computational fluid dynamics. J. Hydrodyn. 2013, 25, 249–257. [Google Scholar] [CrossRef]

- Deng, S.; Zhang, J.; Cheng, Y.; Wu, D. CFD analysis of flow pattern in a long corridor surge chamber and research on measures to eliminate suction vortices. J. Hydroelectr. Eng. 2009, 28, 130–136, 142. [Google Scholar]

- Ding, N.; Cai, F.; Gu, J.; Zhang, W. Research on the influence of upper chamber shape on surge tank surge wave based on 3D VOF method. J. Three Gorges Univ. 2017, 39, 7–10. [Google Scholar]

- Cai, F.; Cheng, Y.-G.; Xia, L.-S.; Jiang, Y. Mechanism of air-trapped vertical vortices in long-corridor-shaped surge tank of hydropower station and their elimination. J. Hydrodyn. 2017, 29, 845–853. [Google Scholar] [CrossRef]

- Xu, W.; Wang, W.; Tan, L.; Yang, Y. Numerical simulation of water air two-phase flow in hydraulic engineering. Res. Prog. Hydrodyn. Part A 2001, 2, 225–229. [Google Scholar]

- Li, Z. Numerical Simulation Study on Free Water Surface and Aeration in Hydraulic Engineering; Xi’an University of Technology: Xi’an, China, 2004. [Google Scholar]

- Hohermuth, B.; Schmocker, L.; Boes, R.M.; Vetsch, D.F. Numerical simulation of air entrainment in uniform chute flow. J. Hydraul. Res. 2020, 59, 378–391. [Google Scholar] [CrossRef]

- Liu, D.; Zhou, L.; Suo, L.; Wang, F. Simulation analysis of VOF model for the phenomenon of water flow impacting trapped air masses in pipelines. J. Comput. Mech. 2009, 26, 390–394. [Google Scholar]

- Ma, J.; Zhou, L.; Liu, D.; Wang, H.; Pan, T. Verification of CFD simulation method for impacting and detaining air masses in pipe water flow. Hydroelectr. Energy Sci. 2016, 34, 110–113. [Google Scholar]

- Lu, K.; Zhou, L.; Liu, J. Three dimensional numerical simulation of water flow impacting multiple trapped air masses. J. Drain. Irrig. Mach. Eng. 2021, 39, 264–269. [Google Scholar]

- Cheng, X.; Chen, Y.; Gao, Q.; Chen, Y. Analysis of supersaturated reaeration of three gorges reservoir dam body discharge. J. Hydroelectr. Eng. 2005, 6, 62–67. [Google Scholar]

- Cheng, X.; Chen, Y.; Chen, X. Numerical simulation of dissolved oxygen concentration in downstream water bodies of the Three Gorges Dam body discharge. Res. Prog. Hydrodyn. Part A 2009, 24, 761–767. [Google Scholar]

- Liu, M.; Hou, F.; Yan, K.; Ben, Y.; Wang, H.; Li, C. Research on high pressure dissolved gas problem in damless pumped storage system. J. Eng. Thermophys. 2020, 41, 609–614. [Google Scholar]

- Wei, W.-R.; Deng, J.; Zhang, F.-X.; Tian, Z. A numerical model for air concentration distribution in self-aerated open channel flows. J. Hydrodyn. 2015, 27, 394–402. [Google Scholar] [CrossRef]

- Bung, D.; Valero, D. Re-Aeration on stepped spillways with special consideration of entrained and entrapped air. Geosciences 2018, 8, 333. [Google Scholar] [CrossRef]

- Tan, S.; Zhao, F.; Li, S.; Gao, P. Conversion method between interface mass transfer and volume mass transfer in VOF model. J. Harbin Eng. Univ. 2015, 36, 317–321. [Google Scholar]

- Zhu, H. Study on Oscillating Flow and Heat Transfer Characteristics of Gas-Liquid Two Phase Flow; Beijing Institute of Technology: Beijing, China, 2015. [Google Scholar]

- Zhu, H.; Zhang, W.; Yuan, Y. The influence of improved VOF method on oscillatory flow and heat transfer calculation of gas-liquid two phase flow. J. Aerodyn. 2015, 30, 1040–1046. [Google Scholar]

- Zhang, Y. Mathematical Model and Numerical Simulation of Two-Phase Flow in Heat Pipes Based on CFD; South China University of Technology: Guangzhou, China, 2014. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, Y.; Wang, P.; Du, P.; Liu, Y.; Tang, B.; Li, X.; Zhou, L.; Liu, D. Gas Loss Mechanism in the High-Pressure Air Cushion Surge Chamber of Hydropower Station for Transient Process. Water 2023, 15, 2784. https://doi.org/10.3390/w15152784

Xia Y, Wang P, Du P, Liu Y, Tang B, Li X, Zhou L, Liu D. Gas Loss Mechanism in the High-Pressure Air Cushion Surge Chamber of Hydropower Station for Transient Process. Water. 2023; 15(15):2784. https://doi.org/10.3390/w15152784

Chicago/Turabian StyleXia, Yong, Pei Wang, Pengxia Du, Yue Liu, Bihua Tang, Xueyu Li, Ling Zhou, and Deyou Liu. 2023. "Gas Loss Mechanism in the High-Pressure Air Cushion Surge Chamber of Hydropower Station for Transient Process" Water 15, no. 15: 2784. https://doi.org/10.3390/w15152784

APA StyleXia, Y., Wang, P., Du, P., Liu, Y., Tang, B., Li, X., Zhou, L., & Liu, D. (2023). Gas Loss Mechanism in the High-Pressure Air Cushion Surge Chamber of Hydropower Station for Transient Process. Water, 15(15), 2784. https://doi.org/10.3390/w15152784