A Geological Site Selection Method of a Coal Mine Underground Reservoir and Its Application

Abstract

1. Introduction

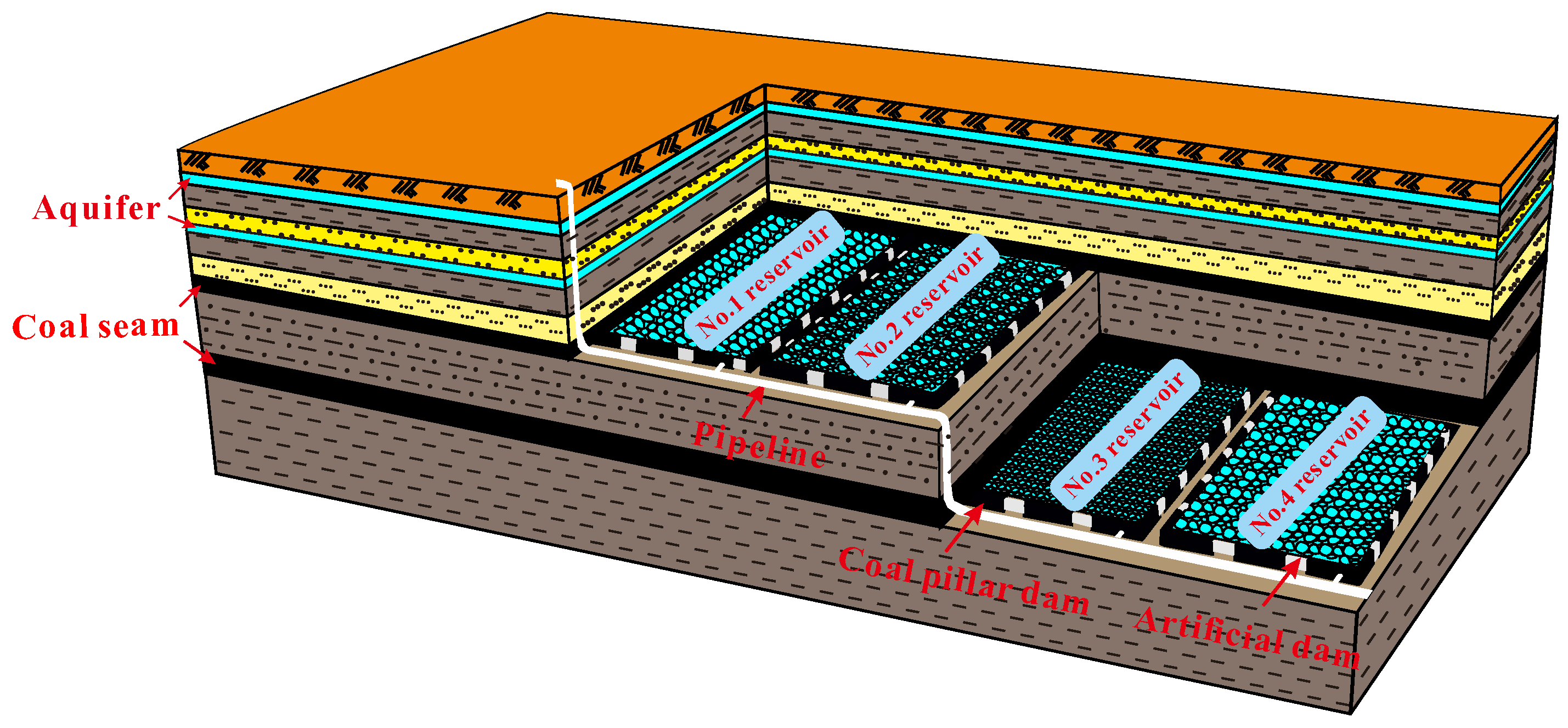

2. Site Selection Model of Coal Mine Underground Reservoir

2.1. Geological Influences of Water Storage Capacity of an Underground Reservoir

2.2. Development of a Model of Water Storage Coefficient

2.3. Effective Safe Thickness from Underlying Coal Seam

- (1)

- Calculate the height of the key layer position from the mining coal seam. If the height is greater than (7~10) M, the mining-induced fractures do not cut through the key layer; if the height is less than (7~10) M, the fracture will cut through the key layer. M is the thickness of coal seam, m;

- (2)

- Predict the height of water flowing fractured zone. When the main key layer of overlying strata is located above the critical height (7~10) M, the water flowing fracture will develop to the bottom of the nearest key stratum above the critical height (7~10) M, and the height of the water flowing fracture zone is equal to the height of the key layer from the mining coal seam (Figure 3a). When the main key layer of overlying strata is located within the critical height (7~10) M, the water flowing fracture will extend to the top of the bedrock (Figure 3b).

2.4. Site Selection Assessment Method of a Coal Mine Underground Reservoir

2.4.1. Site Selection Evaluation Parameters

2.4.2. Determination of the Weight of Parameters Based on an Entropy Weight Method

2.4.3. Grey Relational Analysis

- (1)

- Determine the analysis sequence and pre-treat the variables.

- (2)

- Find the grey correlation coefficient y (x0(k), xj (k)) and correlation degree ri.

2.4.4. Implementation Procedure

- First, determine the thickness of main coal seam (M), the elevation of coal seam floor (Z), the sand ratio of roof (R), and the sand ratio of floor (F) according to the drilling data of the mine field;

- Second, calculate the water storage coefficient Q according to the size of the working face, the buried depth of the coal seam, the density of the overlying strata, and the mechanical parameters of the rock mass;

- Third, estimate the effective safety thickness (D), according to the distance between the target coal seam and the underlying coal seam, the depth of the floor fracture zone, and the height of the roof water-conducting fracture zone of the underlying coal seam;

- Fourth, determine the weight (Wj) of each index based on an entropy weight method;

- Fifth, calculate the suitability evaluation index SI of coal mine underground reservoir;

- Sixth, which is optional, analyze the correlation degree rj between each index and SI based on a grey relational analysis method.

3. A Case Study from a Coal Mine in the Shendong Coal-Mining Area

3.1. Geological Setting

3.2. Site Selection Assessment Results

- (1)

- The contour map of the elevation of No. 2−2 coal seam floor was obtained based on the statistical analysis of the drilling data in the study area (Figure 6). On the whole, from the northwest to the southeast of the mine field, the floor elevation of No. 2−2 coal seam showed a gradually increasing trend. The floor elevation of No. 36 borehole in the north was the lowest, which was 1053 m, and the floor elevation of No. 242 borehole in the southeast was the highest, which was 1118.4 m. The northwest of the connection line of H15, H40, and 247 boreholes, that is, the whole area of area A, area B, and area D, as well as C-1 and C-2 working faces, was more conducive to the realization of the self-flow supply of mine water and suitable for the construction of underground reservoirs.

- (2)

- The distribution map of coal thickness in the mine field was obtained based on the statistics of the thickness of No. 2−2 coal seam in the study area, (Figure 7). The average coal thickness in the southeast area of the borehole H15 to the H17 connection line was below 4m, and the thickness of No. 2−2 coal was only about 1.5m around the No. 242 borehole in the southeastern edge of the mine field. The coal thickness in the northwest was large, was above 5 m in the borehole No. H86, well H63 and H40. The thickness of No. 2−2 coal seam was larger in the northwest and smaller in the southeast. That is, the effective water storage space was relatively large if the underground reservoirs were located in the A, B, C, D areas and G-1, G-2, and G-3 working faces in the northwest of the mine field.

- (3)

- The height of the caving zone of No. 2−2 coal seam can be calculated according to Equation (1). Set the crushing expansion coefficient k = 1.4. At the same time, the thickness of sandstone in the height range of the caving zone was counted, and the contour map of the sand ratio of roof R can be obtained (Figure 8). Due to the great variation of sandstone thickness in the caving zone on plane, there was no obvious distribution law of R. The general trend was that the R value in the south of H127 was mostly below 0.5; the R value was close to 1 in the northeast and northwest. In the whole area of A and C areas, the east of B-1, B-2, B-3 working faces in B area and G-1, G-2, G-3 working faces in G area, it was conducive to water storage and flow and the construction of underground reservoirs. The R value was as low as 0.2 in the H49 and H40 boreholes of the central area where the thickness of roof sandstone was small, and the thickness of mudstone and other strata with good water-proof effect was relatively large, which is not conducive to the construction of underground reservoirs.

- (4)

- Calculate the sand ratio of floor (F) of No. 2−2 coal seam. The depth of the floor fracture zone of No. 2−2 coal seam was determined by Equation (2). Because No. 2−2 coal was a nearly horizontal coal seam, the dip angle α of the coal seam was 0, and the remaining parameters can be determined by the geological data of the mine field. The contour map of F of the floor was obtained (Figure 9). The F value was larger in the northeast than in the southwest within the mine field, and the peak of greater than o.6 was located at the boreholes H70 and H15 in the northeast, indicating that the sandstone in the floor fracture zone accounted for a large proportion, and the water insulation was poor, which was prone to leakage, which is not conducive to the effective storage of water in the underground reservoir. The F value was close to 0 near the H49 borehole, and near the No. 36 borehole in the northwest, indicating that the lithology of floor fracture zones was mostly mudstone with a good water-resisting property in these two places (A, C and D-1, D-2 areas), which is the favorable condition for the construction of the underground reservoir.

- (5)

- According to Equation (23), the water storage coefficient Q of No. 2−2 coal goaf in each region was determined. The elastic modulus of the overlying strata after mining disturbance was about 0.5 times of the original; the buried depth of No. 2−2 coal seam was obtained by drilling data, and the parameters used are shown in Table 1. The initial water storage coefficient Q0 of fractured rock mass can be calculated in terms of Equation (12). The water storage coefficient Q of each region was calculated and the contour map of Q in the study area was drawn (Figure 10).

- (6)

- To calculate the effective safety thickness D, the distance between No. 2−2 coal seam and No. 5−2 coal seam (l), the depth of the fracture zone of No. 2−2 coal seam floor (h2), and the height of the water-conducting fracture zone of No. 5−2 coal seam roof (h3) should be determined.

- (7)

3.3. Correlation Analysis

4. Conclusions

- (1)

- A mathematical model of water storage coefficient was established and a geological site selection method of a coal mine underground reservoir was proposed. The major evaluation indexes include the elevation of the coal seam floor Z, the coal seam thickness M, the sandstone ratio of the roof R, the sandstone ratio of the floor F, the water storage coefficient Q, and the effective safety thickness D. An entropy weight method was used to obtain the weight of the evaluation indexes.

- (2)

- The water storage capacity of coal mine underground reservoir was positively correlated with the coal thickness, sandstone ratio of the roof, water storage coefficient, and effective safety thickness, and was negatively correlated with the elevation of the coal seam floor and the sandstone ratio of the floor.

- (3)

- With an HJT mine field in the Shendong coal mining area as an example, the site selection suitability index (SI) was estimated. The maximum value appeared at boreholes H63 (0.387) and H70 (0.365), which was at a good level of suitability for underground reservoir construction. Combined with the distribution of No. 2−2 coal seam working face in the mine field, the suitable locations for the construction of underground reservoirs included: B-3 and B-4 working faces in the north; the E-1, E-2, H-1, and H-2 working faces in the east; the G-1 and G-2 working faces in the center.

- (4)

- The grey correlation degree between each evaluation index and site selection suitability index (SI) was analyzed. Six variables can be arranged in a descending order of grey correlation degree: sand ratio of floor F (0.809) > sand ratio of roof R (0.746) > floor elevation Z (0.735) > water storage coefficient Q (0.734) > coal seam thickness M (0.717) > effective safety thickness D (0.663) in this study area. The predicted results were consistent with the actual situation. The outcomes of this research may benefit the construction of coal mine underground reservoirs in water deficient coal mining areas.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fan, L.M.; Ma, X.D. A review on investigation of water-preserved coal mining in western China. Int. J. Coal Sci. Technol. 2018, 5, 411–416. [Google Scholar] [CrossRef]

- Hu, Z.Q.; Fu, Y.H.; Xiao, W.; Zhao, Y.L.; Wei, T.T. Ecological restoration plan for abandoned underground coal mine site in Eastern China. Int. J. Min. Reclam. Environ. 2015, 4, 316–330. [Google Scholar] [CrossRef]

- Zhang, B.; Cao, Z.G.; Chi, M.B.; Wu, B.Y.; Zhang, X.B.; Zhang, Y. Adaptive condition of construction and design system of coal mine underground reservoir. Saf. Coal Mines 2022, 53, 93–98, (In Chinese with English Abstract). [Google Scholar]

- Meng, Z.P.; Shi, X.C.; Li, G.Q. Deformation, failure and permeability of coal-bearing strata during longwall mining. Eng. Geol. 2016, 208, 69–80. [Google Scholar] [CrossRef]

- Chi, M.B.; Li, Q.S.; Cao, Z.G.; Fang, J.; Wu, B.Y.; Zhang, Y.; Wei, S.R.; Liu, X.Q.; Yang, Y.M. Evaluation of water resources carrying capacity in ecologically fragile mining areas under the influence of underground reservoirs in coal mines. J. Clean. Prod. 2022, 379, 134449. [Google Scholar] [CrossRef]

- Qian, M.G.; Xu, J.L.; Miao, X.X. Green coal mining technology. J. China Univ. Min. Technol. 2003, 4, 5–10, (In Chinese with English Abstract). [Google Scholar]

- Shi, X.C. Research progress and prospect of underground mines in coal mine. Coal Sci. Technol. 2022, 10, 216–225, (In Chinese with English Abstract). [Google Scholar]

- Gu, D.Z. Theory framework and technological system of coal mine underground reservoir. J. China Coal Soc. 2015, 40, 239–246, (In Chinese with English Abstract). [Google Scholar]

- Ma, L.Q.; Zhang, D.S.; Li, X.; Fan, G.W.; Zhao, Y.F. Technology of groundwater reservoir construction in goafs of shallow coalfields. Min. Sci. Technol. 2009, 19, 0730–0735. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, F.T.; Bai, Q.S. Underground space utilization of coalmines in China: A review of underground water reservoir construction. Tunn. Undergr. Sp. Tech. 2021, 107, 103657. [Google Scholar] [CrossRef]

- Chen, L.W.; Feng, X.Q.; Xie, W.P.; Zeng, W.; Zheng, Z.Y. Using a fluid–solid coupled numerical simulation to determine a suitable size for barrier pillars when mining shallow coal seams beneath an unconsolidated, confined aquifer. Mine Water Environ. 2017, 36, 67–77. [Google Scholar] [CrossRef]

- Yao, Q.L.; Tang, C.J.; Xia, Z.; Liu, X.; Chong, Z.H. Mechanisms of failure in coal samples from underground water reservoir. Eng. Geol. 2020, 267, 105494. [Google Scholar] [CrossRef]

- Chu, T.X.; Yu, M.G.; Jiang, D.Y. Experimental Investigation on the permeability evolution of compacted broken coal. Transp. Porous Med. 2016, 116, 847–868. [Google Scholar] [CrossRef]

- Fan, J.Y.; Xie, H.P.; Chen, J.; Jiang, D.Y.; Li, C.B.; William, N.T.; Julien, A. Preliminary feasibility analysis of a hybrid pumped-hydro energy storage system using abandoned coal mine goafs. Appl. Energ. 2020, 258, 114007. [Google Scholar] [CrossRef]

- Chen, S.S.; Huang, Q.X.; Xue, G.; Li, R.Q. Technology of underground reservoir construction and water resource utilization in Daliuta Coal Mine. Coal Sci. Technol. 2016, 8, 21–28, (In Chinese with English Abstract). [Google Scholar]

- Li, Q.C.; Zhang, C.; Yang, Y.D.; Ubedullah, A.; Han, Y.; Li, X.Z.; Cheng, Y.F. Preliminary experimental investigation on long-term fracture conductivity for evaluating the feasibility and efficiency of fracturing operation in offshore hydrate-bearing sediments. Ocean Eng. 2023, 281, 114949. [Google Scholar] [CrossRef]

- Li, Q.C.; Zhao, D.F.; Yin, J.K.; Zhou, X.Y. Sediment instability caused by gas production from hydrate-bearing sediment in Northern South China Sea by horizontal wellbore: Evolution and mechanism. Nat. Resour. Res. 2023, 32, 1595–1620. [Google Scholar] [CrossRef]

- Wang, F.L.; Liu, X.; Jiang, B.H.; Zhou, H.Y.; Chen, W.M. Low-loading Pt nanoparticles combined with the atomically dispersed FeN4 sites supported by FeSA-N-C for improved activity and stability towards oxygen reduction reaction/hydrogen evolution reaction in acid and alkaline media. J. Colloid Interface Sci. 2023, 635, 514–523. [Google Scholar] [CrossRef]

- Li, H.X.; Cao, Z.G.; Wu, B.Y.; Zhang, Y.; Wu, Y.; Wu, B. Calculation method and system for aquifer recharge in coal mine underground reservoirs. P. CN114111954A, 1 March 2022. (In Chinese with English Abstract). [Google Scholar]

- Ju, J.F.; Xu, J.L.; Zhu, W.B. Storage capacity of underground reservoir in the Chinese western water-short coalfield. J. China Coal Soc. 2017, 2, 381–387, (In Chinese with English Abstract). [Google Scholar]

- Pang, Y.H.; Li, P.; Zhou, B.J. Underground reservoir construction technical feasibility analysis in 8. 0m large mining height working face. Coal Eng. 2018, 2, 6–9+15, (In Chinese with English Abstract). [Google Scholar]

- Pang, Y.H.; Li, Q.S.; Cao, G.M.; Zhou, B.J. Analysis and calculation method of underground reservoir water storage space composition. J. China Coal Soc. 2019, 2, 557–566, (In Chinese with English Abstract). [Google Scholar]

- Song, H.Q.; Xu, J.J.; Fang, J. Potential for mine water disposal in coal seam goaf: Investigation of storage coefficients in the Shendong mining area. J. Clean. Prod. 2020, 244, 118646. [Google Scholar] [CrossRef]

- Li, Q.S.; Ju, J.F.; Cao, Z.G.; Gao, F.; Li, J.H. Suitability evaluation of underground reservoir technology based on the discriminant of the height of water conduction fracture zone. J. China Coal Soc. 2017, 8, 2116–2124, (In Chinese with English Abstract). [Google Scholar]

- Guo, Y.N.; Li, G.Q.; Wang, L.; Zhang, Z. Hydrochemical characteristics of mine water and their significance for the site selection of an underground reservoir in the Shendong coal mining area. Water 2023, 15, 1038. [Google Scholar] [CrossRef]

- Álvarez, R.; Ordóñez, A.; García, R.; Loredo, J. An estimation of water resources in flooded, connected underground mines. Eng. Geol. 2018, 232, 114–122. [Google Scholar] [CrossRef]

- Zhang, W.J.; Zhang, B.; Xu, H.G.; Zhao, Z.H. Study on the height of caving zone and fractured zone in No.3 coal seam of Xinyuan Coal Mine. Energy Technol. Manag. 2018, 1, 78–80, (In Chinese with English Abstract). [Google Scholar]

- Zhang, F.L.; He, Q.L. Determination of the height of the two zones of the overlying rock caving water flowing fracture on the working face. Miner. Eng. Res. 2012, 4, 66–70, (In Chinese with English Abstract). [Google Scholar]

- State Administration of Coal Industry of China. Specification for Coal Pillar Retention of Building, Water Body, Railway and Main Road-Way and Coal Mining under Pressure; State Administration of Coal Industry of China: Beijing, China, 2000; (In Chinese with English Abstract).

- Xiang, P.; Sun, L.H.; Ji, H.G.; Gao, Y.; Liu, Y.J.; Wu, Y.F. Dynamic distribution characteristics and determination method of caving zone in overburden strata with large mining height. J. Min. Saf. Eng. 2017, 5, 861–867, (In Chinese with English Abstract). [Google Scholar]

- Wang, Z.F.; Li, Q.S.; Yang, L.P.; Liu, J. Research on the height of caving zone of comprehensive top coal caving working face at Xiashijie coal mine. Saf. Coal Mines. 2007, 5, 13–15, (In Chinese with English Abstract). [Google Scholar]

- Chen, S.S. Research on Key Technology of Water Resources Recycling and Utilization in the Underground Goaf Reservoir in Shen Dong Mining Area. Ph.D. Thesis, Xi’an University of Science and Technology, Xi’an, China, 2016. (In Chinese with English Abstract). [Google Scholar]

- Zhang, C.; Han, P.H.; Wang, F.T.; He, X. The stability of residual coal pillar in underground reservoir with the effect of mining and water immersion. J. China Univ. Min. Technol. 2021, 2, 220–227+247, (In Chinese with English Abstract). [Google Scholar]

- Li, P.; Lu, W.X.; Long, Y.Q.; Yang, Z.P.; Li, J. Seepage analysis in a fractured rock mass: The upper reservoir of Pushihe pumped-storage power station in China. Eng. Geol. 2008, 97, 53–62. [Google Scholar] [CrossRef]

- Bai, Q.S.; Tu, S.H. A General Review on Longwall Mining-Induced Fractures in Near-Face Regions. Geofluids 2019, 1–22. [Google Scholar] [CrossRef]

- Xu, J.L.; Wang, X.Z.; Liu, W.T.; Wang, Z.G. Effects of primary key stratum location on height of water flowing fracture zone. Chin. J. Rock Mech. Eng. 2009, 2, 380–385, (In Chinese with English Abstract). [Google Scholar]

- Xu, J.L.; Zhu, W.B.; Wang, X.Z. New method to predict the height of fractured water-conducting zone by location of key strata. J. China Coal Soc. 2012, 5, 762–769, (In Chinese with English Abstract). [Google Scholar]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Theoretical study of key strata in strata control. J. China Coal Soc. 1996, 3, 2–7, (In Chinese with English Abstract). [Google Scholar]

- Xu, J.L.; Qian, M.G. Discrimination method of key strata position of overburden rock. J. China Univ. Min. Technol. 2000, 5, 21–25, (In Chinese with English Abstract). [Google Scholar]

| Rock Type | ρ (kg/m3) | Bulk Modulus K (GPa) | Shear Modulus G (GPa) |

|---|---|---|---|

| sandy mudstone | 2420 | 5.12 | 3.5 |

| 5−2 coal seam | 1410 | 1.7 | 0.8 |

| No. 1 siltstone | 2460 | 7.2 | 4.9 |

| No. 2 siltstone | 2500 | 7.9 | 5.3 |

| fine sandstone | 2790 | 8 | 4.43 |

| mudstone | 2650 | 4.39 | 2.37 |

| feldspathic sandstone | 2560 | 5.4 | 4.05 |

| Coarse-grained feldspathic sandstone | 2620 | 5.6 | 4.15 |

| 2−2 coal seam | 1540 | 1.45 | 0.7 |

| eolian sand | 1960 | 0.25 | 0.28 |

| Variable | Weight (%) |

|---|---|

| M | 10.09 |

| Z | 11.93 |

| R | 19.61 |

| F | 26.53 |

| Q | 18.01 |

| D | 13.83 |

| Variable | Correlation Degree with SI | Order |

|---|---|---|

| F | 0.809 | 1 |

| R | 0.746 | 2 |

| Z | 0.735 | 3 |

| Q | 0.734 | 4 |

| M | 0.717 | 5 |

| D | 0.663 | 6 |

| Borehole Number | SI | Level |

|---|---|---|

| H63 | 0.387 | Good |

| H70 | 0.365 | |

| 247 | 0.298 | Average |

| H40 | 0.296 | |

| H86 | 0.263 | |

| H49 | 0.242 | |

| H127 | 0.218 | |

| H102 | 0.215 | |

| 238 | 0.211 | |

| H15 | 0.196 | |

| H72 | 0.176 | |

| 246 | 0.167 | |

| H65 | 0.156 | |

| 242 | 0.147 | |

| H17 | 0.015 | Poor |

| 36 | −0.052 | |

| 245 | −0.135 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Li, G.; Xing, Z.; Wang, L.; Zou, W. A Geological Site Selection Method of a Coal Mine Underground Reservoir and Its Application. Water 2023, 15, 2747. https://doi.org/10.3390/w15152747

Zhang H, Li G, Xing Z, Wang L, Zou W. A Geological Site Selection Method of a Coal Mine Underground Reservoir and Its Application. Water. 2023; 15(15):2747. https://doi.org/10.3390/w15152747

Chicago/Turabian StyleZhang, Hao, Guoqing Li, Zhenguo Xing, Lei Wang, and Weikun Zou. 2023. "A Geological Site Selection Method of a Coal Mine Underground Reservoir and Its Application" Water 15, no. 15: 2747. https://doi.org/10.3390/w15152747

APA StyleZhang, H., Li, G., Xing, Z., Wang, L., & Zou, W. (2023). A Geological Site Selection Method of a Coal Mine Underground Reservoir and Its Application. Water, 15(15), 2747. https://doi.org/10.3390/w15152747