Modifying Natural Zeolites to Improve Heavy Metal Adsorption

Abstract

1. Introduction

2. Materials and Methods

- Zeolite samples were prepared by grinding and sieving to obtain a size fraction of 0.2–3.0 mm diameter. The sieved raw material was washed from impurities by distilled boiled water and water vapor at a temperature of 100–120 °C and dried in an oven at a temperature not exceeding 105 °C. The Shankanay zeolite belongs to the heulandite–clinoptilolite group and includes impurities such as quartz, feldspar, and montmorillonite [27].

- The samples were then demineralized through acid treatment. The acid treatment changes the structure of the zeolites by increasing the volume of effective pores, leading to an increase in sorption capacity. The zeolite samples were placed in glass containers covered with lids and filled with a mixture of 20% nitric acid (ratio 1:2). The mixture was boiled for 60 min and after boiling the mixture was left overnight for more complete demineralization. After this, the used nitric acid was drained by decantation and the demineralized sorbent was transferred to another container and washed several times by boiling to establish a neutral environment. The activated sorbents were dried under normal conditions in an oven.

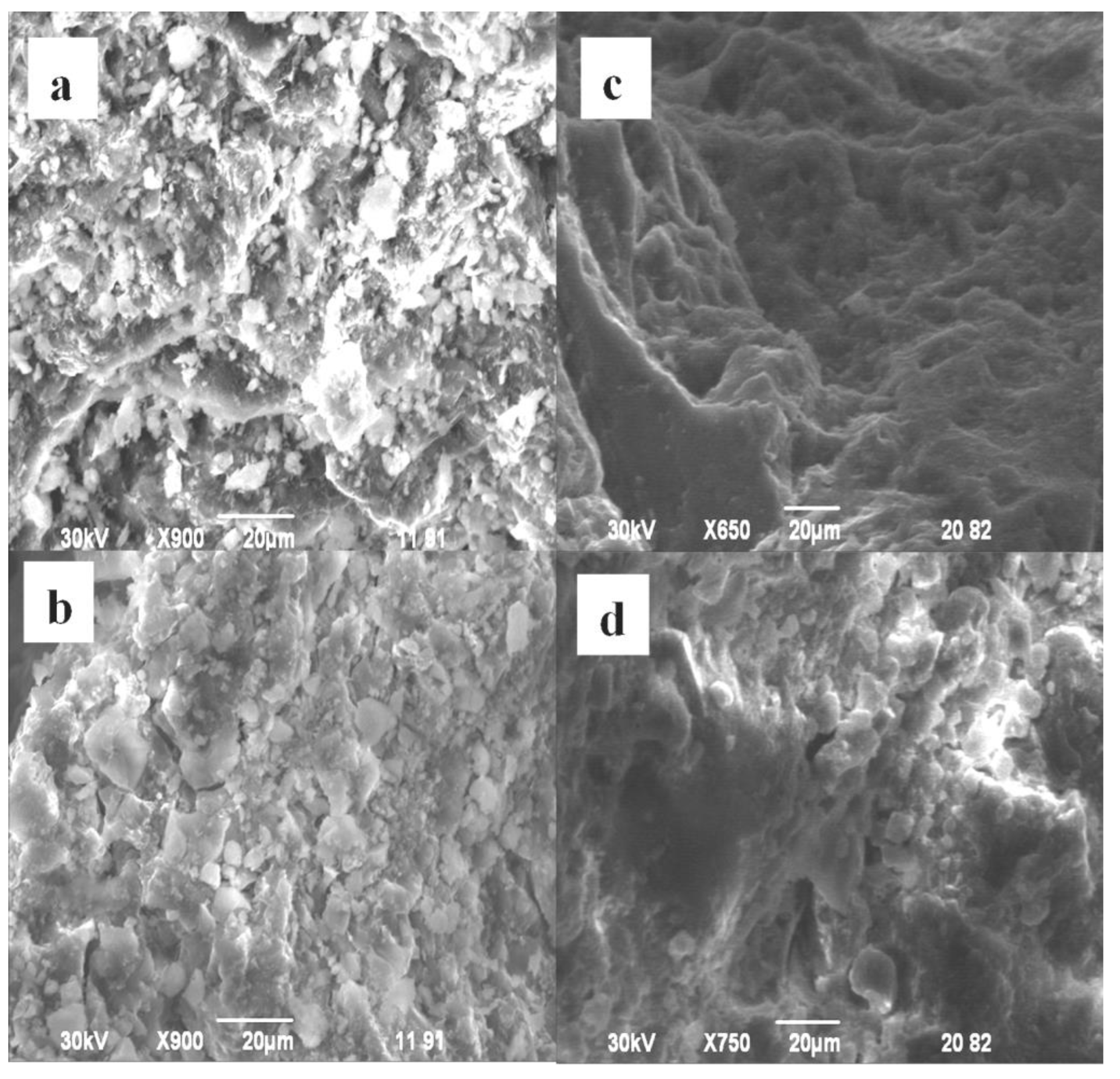

- Prepared sample sorbents were dosed on a dosing scale and loaded into a heat treatment reactor in an argon environment. The argon feed rate (5 L/min) was controlled depending on the weight of the zeolite and the temperature (450–600 °C). The samples were subjected to constant movement along the reactor. The thermal treatment volatilizes and/or oxidizes adsorbed molecules. Thus, heat treatment changes the morphological properties of the zeolite as well as the adsorption properties.

3. Results and Discussion

4. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pandi, M.; Paudel, K.P. Water pollution and income relationships; a seemingly unrelated partially linear analysis. Water Res. 2006, 52, 7668. [Google Scholar] [CrossRef]

- Govender, T.; Barnes, J.M.; Pieper, C.H. Contribution of water pollution from inadequate sanitation and housing quality to diarrheal disease in low-cost housing settlements of Cape Town, South Africa. Am. J. Public Health 2011, 101, e4–e9. [Google Scholar] [CrossRef] [PubMed]

- Smith, L.E.D.; Siciliano, G. A Comprehensive review of constraints to improved management of fertilizers in China and mitigation of diffuse water pollution from agriculture. Agric. Ecosyst. Environ. 2015, 209, 15–25. [Google Scholar] [CrossRef]

- Tadkaew, N.; Hai, F.I.; Mcdonald, J.A.; Nghiem, L. Removal of trace organics by MBR treatment; the role of molecular properties. Water Res. 2011, 45, 2439–2451. [Google Scholar] [CrossRef]

- Walker, M.; Iyer, K.; Heaven, S.; Banks, C.J. Ammonia removal in anaerobic digestion by biogas stripping: An evaluation of process alternatives using a first order rate model based on experimental findings. Chem. Eng. J. 2011, 178, 138–145. [Google Scholar] [CrossRef]

- Gollavelli, G.; Chang, C.C.; Ling, Y.C. Facile synthesis of smart magnetic graphene for safe drinking water. ACS Sustain. Chem. Eng. 2013, 1, 462–472. [Google Scholar] [CrossRef]

- Pirsaheb, M.; Mohamadi, M.; Mansouri, A.M.; Zinatizadeh, A.A.L.; Sumathi, S.; Sharafi, K. Process modeling and optimization of biological removal of carbon, nitrogen and phosphorus from hospital wastewater in a continuous feeding & intermittent discharge (CFID) bioreactor. Korean J. Chem. Eng. 2015, 32, 1340–1353. [Google Scholar]

- Zhu, S.; Khan, M.A.; Wang, F.; Bano, Z.; Xia, M. Exploration of adsorption mechanism of 2-phosphonobutane-1,2,4-tricarboxylic acid onto kaolinite and montmorillonite via batch experiment and theoretical studies. J. Hazard. Mater. 2021, 403, 123810. [Google Scholar] [CrossRef]

- Zhu, S.; Chen, Y.; Khan, M.A.; Xu, H.; Wang, F.; Xia, M. In-depth study of heavy metal removal by an etidronic acid-functionalized layered double hydroxide. ACS Appl. Mater. Interfaces 2022, 14, 7450–7463. [Google Scholar] [CrossRef]

- Meng, S.; Li, Y.; Zhang, T.; Chen, J.Z.; Xu, P.; Song, C.; Fan, L.M.; Qiu, L.P. Influences of environmental factors on lanthanum/aluminum-modified zeolite adsorbent (La/Al-ZA) for phosphorus adsorption from wastewater. Water Air Soil Poll. 2013, 224, 1–8. [Google Scholar] [CrossRef]

- Ghasemi, Z.; Sourinejad, I.; Kazemian, H.; Rohani, S. Application of zeolites in aquaculture industry; a review. Rev. Aquacult. 2016, 10, 75–95. [Google Scholar] [CrossRef]

- Syafalni, S.; Sing, S.R.B.; Zawawi, M.H. Sorption of dye wastewater by using natural zeolite, anionic-cationic surfactant modified zeolite and cationic surfactant modified zeolite. World Appl. Sci. J. 2014, 32, 818–824. [Google Scholar]

- Dionisiou, N.S.; Matsi, T.; Misopolinos, N.D. Phosphorus adsorption–desorption on a surfactant-modified natural zeolite; a laboratory study. Water Air Soil Poll. 2013, 224, 1362. [Google Scholar] [CrossRef]

- Dionisiou, N.S.; Matsi, T.; Misopolinos, N.D. Removal of boron by surfactant modified zeolitic tuff from northeastern Greece. Indian J. Agric. Sci. 2013, 5, 94–99. [Google Scholar] [CrossRef]

- Hammond, K.D.; Gharibeh, M.; Tompsett, G.A.; Dogan, F.; Brown, A.V.; Grey, C.P.; Auerbach, S.M.; Conner, W.C. Optimizing the synthesis of nitrogen-substituted zeolites. Chem. Mater. 2010, 22, 130–142. [Google Scholar] [CrossRef]

- Velarde, L.; Nabavi, M.S.; Escalera, E.; Marta-Lena Antti, M.-L.; Akhtar, F. Adsorption of heavy metals on natural zeolites; A review. Chemosphere 2023, 328, 138508. [Google Scholar] [CrossRef]

- Wang, S.; Peng, Y. Natural zeolites as effective adsorbents in water and wastewater treatment. Chem. Eng. J. 2010, 156, 11–24. [Google Scholar] [CrossRef]

- Kinoti, I.K.; Ogunah, J.; M’Thiruaine, C.M.; Marangu, J.M. Adsorption of heavy metals in contaminated water using zeolite derived from agro-wastes and clays: A review. J. Chem. 2022, 2022, 4250299. [Google Scholar] [CrossRef]

- Ahmad, K.; Shah, H.-R.; Khan, M.S.; Iqbal, A.; Potrich, E.; Amaral, L.S.; Rasheed, S.; Nawaz, H.; Ayub, A.; Naseem, K.; et al. Lead In drinking water; Adsorption method and role of zeolitic imidazolate frameworks for its remediation: A review. J. Clean. Prod. 2022, 368, 133010. [Google Scholar] [CrossRef]

- Inglezakis, V.J.; Azat, S.; Tauanov, Z.; Mikhalovsky, S.V. Functionalization of biosourced silica and surface reactions with mercury in aqueous solutions. Chem. Eng. J. 2021, 423, 1385–8947. [Google Scholar] [CrossRef]

- Javanbakht, V.; Alavi, S.A.; Zilouei, H. Mechanisms of heavy metal removal using microorganisms as biosorbent. Water Sci. Technol. 2014, 69, 1775–1787. [Google Scholar] [CrossRef]

- Sakr, A.K.; Abdel Aal, M.M.; Abd El-Rahem, K.A.; Allam, E.M.; Abdel Dayem, S.M.; Elshehy, E.A.; Hanfi, M.Y.; Alqahtani, M.S.; Cheira, M.F. Characteristic Aspects of Uranium(VI) Adsorption Utilizing Nano-Silica/Chitosan from Wastewater Solution. Nanomaterials 2022, 12, 3866. [Google Scholar] [CrossRef]

- Weshahy, A.R.; Sakr, A.K.; Gouda, A.A.; Atia, B.M.; Somaily, H.H.; Hanfi, M.Y.; Sayyed, M.I.; El Sheikh, R.; El-Sheikh, E.M.; Radwan, H.A.; et al. Selective Recovery of Cadmium, Cobalt, and Nickel from Spent Ni–Cd Batteries Using Adogen® 464 and Mesoporous Silica Derivatives. Int. J. Mol. Sci. 2022, 23, 8677. [Google Scholar] [CrossRef] [PubMed]

- Tran, H.N.; You, S.-J.; Hosseini-Bandegharaei, A.; Chao, H.-P. Mistakes and inconsistencies regarding adsorption of contaminants from aqueous solutions: A critical review. Water Res. 2017, 120, 88–116. [Google Scholar] [CrossRef] [PubMed]

- Sprynskyy, M.; Buszewski, B.; Terzyk, A.P.; Namiesnik, J. Study of the selection mechanism of heavy metal (Pb2+, Cu2+, Ni2+, and Cd2+) adsorption on clinoptilolite. J. Colloid Interface Sci. 2006, 304, 21–28. [Google Scholar] [CrossRef]

- Mirbaloochzehi, M.R.; Rezvani, A.; Samimi, A.; Shayesteh, M. Application of a novel surfactant-modified natural nano-zeolite for removal of heavy metals from drinking water. Adv. J. Chem. Sect. A 2020, 3, S612–S620. [Google Scholar]

- Sultanbayeva, G.S.; Holze, R.; Chernyakova, R.M.; Jussipbekov, U.Z. Removal of Fe2+-, Cu2+-, Al3+- and Pb2+-ions from phosphoric acid by sorption on carbonate-modified natural zeolite and its mixture with bentonite. Microporous Mesoporous Mater. 2013, 170, 173–180. [Google Scholar] [CrossRef]

- Kenzhaliyev, B.K.; Surkova, T.Y.; Berkinbayeva, A.N.; Dosymbayeva, Z.D.; Abdikerim, B.E. Revisiting the Kazakhstan natural sorbents modification. Metalurgija 2020, 59, 117–120. [Google Scholar]

- Khamzina, Z.B.; Belopukhov, S.L. Efficiency of using the Kazakhstan zeolites for the purification of water from iron ions. In AgroINNOVATION, IOP Conference Series: Earth and Environmental Science, Volgograd, Russia, 12–14 May 2021; IOP Publishing: Bristol, UK, 2022; Volume 965, p. 012010. [Google Scholar] [CrossRef]

- Cruciani, G.; Gualtieri, A. Dehydration dynamics of analcime by in situ synchrotron powder diffraction. Am. Mineral. 1999, 84, 112–119. [Google Scholar] [CrossRef]

- Bish, D.L.; Carey, J.W. Thermal behavior of natural zeolites. In Natural Zeolites: Occurrence, Properties, Applications (Reviews in Mineralogy and Geochemistry); Bish, D.L., Ming, D.W., Eds.; Volume Mineralogical Society of America: Washington, DC, USA, 2001; Volume 45, pp. 403–452. [Google Scholar]

- Malamis, S.; Katsou, E. A review on zinc and nickel adsorption on natural and modified zeolite, bentonite and vermiculite: Examination of process parameters, kinetics and isotherms. J. Hazard. Mater. 2013, 252, 428–461. [Google Scholar] [CrossRef]

- Srdan, K.; Dragoslav, S.; Jovan, L.; Dragan, M.; Sreten, T.; Slavisa, T.; Slobodan, M. Forming a filter medium from zeolite modified with SDBAC for wastewater treatment process. Chem. Ind. Chem. Eng. 2014, 20, 361–369. [Google Scholar]

| No. | Indicator | Unit | Characteristics |

|---|---|---|---|

| 1. | Ocular appearance | Free-form granules with dark brown color without impurities | |

| 2. | Mass fraction of zeolite | % | 50–84 |

| 3. | Mineral type | Clinoptilolite | |

| 4. | Mohs hardness | 4.5 | |

| 5. | Associated minerals: | % | |

| clay | 3.0–6.0 | ||

| dolomite | 0.5–2.0 | ||

| 6. | Mass fraction of gelling agents | % | 0.9–1.8 |

| 7. | Organic content | % | 0 |

| 8. | Chemical composition: | % | |

| SiO2 | 60.0–74.0 | ||

| Al2O3 | 14.0–15.0 | ||

| TiO2 | 0.070–0.700 | ||

| Fe2O3 | 1.40–5.83 | ||

| MnO | 0.067–0.199 | ||

| MqO | 0–2.120 | ||

| CaO | 0.130–6.400 | ||

| Na2O | 0.610–5.450 | ||

| K2O | 0.660–4.030 | ||

| P2O5 | 0.012–0.173 | ||

| H2O | 0.0–4.090 | ||

| 9. | Ratio of SiO2/Al2O3 | 4.00–5.28 |

| Name | Characteristics | Processing Condition | S, m2/g |

|---|---|---|---|

| Modified natural zeolite | Brown color, size 3 mm | 400 °C, 120 min | 20.07 |

| Modified natural zeolite | Brown color, size 3 mm | 450 °C, 120 min | 19.60 |

| Modified natural zeolite | Brown color, size 3 mm | 550 °C, 120 min | 54.23 |

| Name | Characteristics | Processing Condition | S, m2/g |

|---|---|---|---|

| Modified natural zeolite | Brown color, size 3 mm | 550 °C, 60 min | 92.21 |

| Modified natural zeolite | Brown color, size 3 mm | 550 °C, 90 min | 85.24 |

| Modified natural zeolite | Brown color, size 3 mm | 550 °C, 120 min | 80.18 |

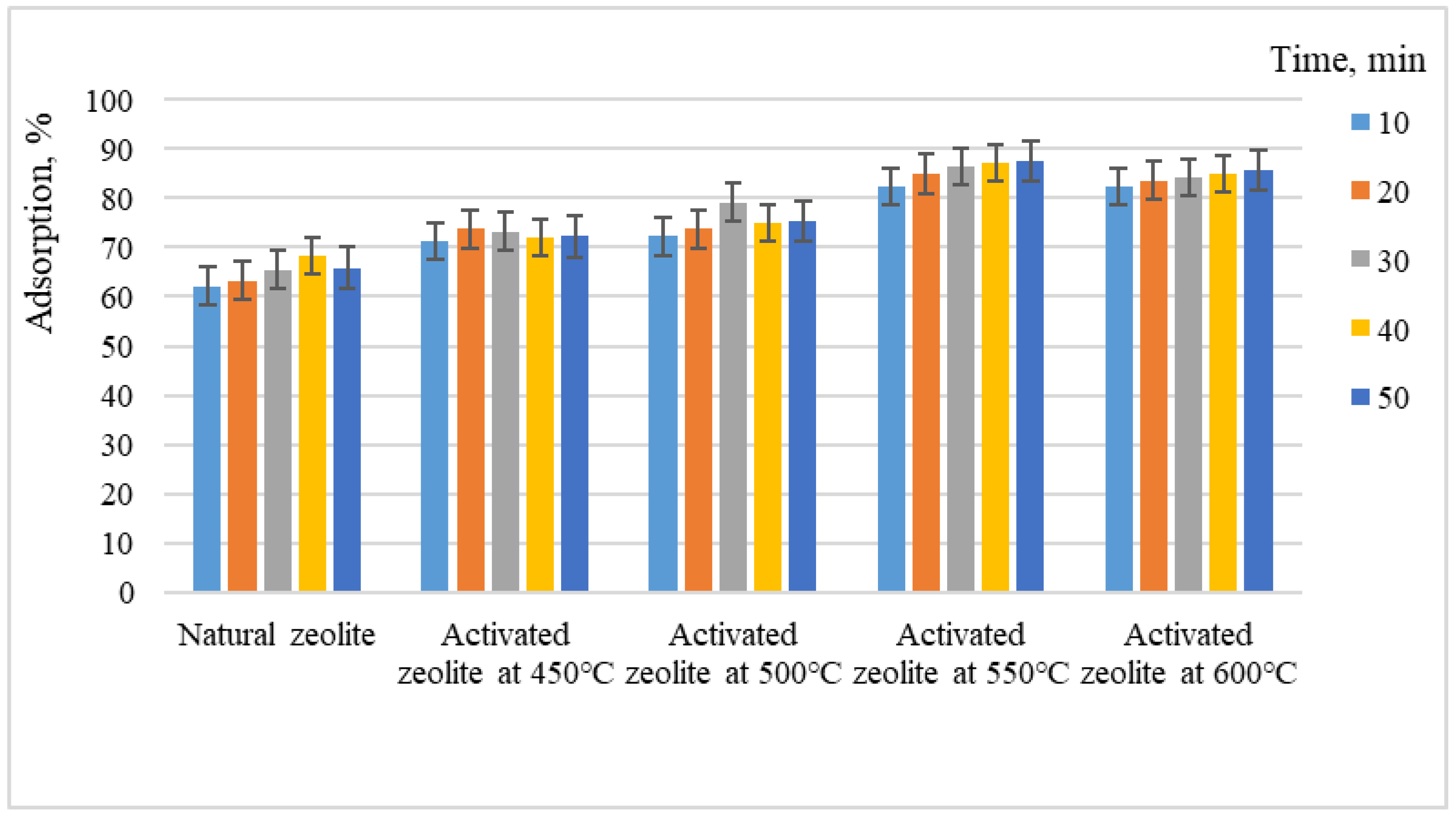

| Time, min | Adsorption, % | ||||

|---|---|---|---|---|---|

| Natural Zeolite | Activated Zeolite at 450 °C | Activated Zeolite at 500 °C | Activated Zeolite at 550 °C | Activated Zeolite at 600 °C | |

| 10 | 62.2 | 71.3 | 72.3 | 82.3 | 82.4 |

| 20 | 63.3 | 73.7 | 73.7 | 85.0 | 83.6 |

| 30 | 65.5 | 73.2 | 79.2 | 86.5 | 84.2 |

| 40 | 68.2 | 72.1 | 75.1 | 87.1 | 85.1 |

| 50 | 65.9 | 72.2 | 75.2 | 87.5 | 85.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuldeyev, E.; Seitzhanova, M.; Tanirbergenova, S.; Tazhu, K.; Doszhanov, E.; Mansurov, Z.; Azat, S.; Nurlybaev, R.; Berndtsson, R. Modifying Natural Zeolites to Improve Heavy Metal Adsorption. Water 2023, 15, 2215. https://doi.org/10.3390/w15122215

Kuldeyev E, Seitzhanova M, Tanirbergenova S, Tazhu K, Doszhanov E, Mansurov Z, Azat S, Nurlybaev R, Berndtsson R. Modifying Natural Zeolites to Improve Heavy Metal Adsorption. Water. 2023; 15(12):2215. https://doi.org/10.3390/w15122215

Chicago/Turabian StyleKuldeyev, Erzhan, Makpal Seitzhanova, Sandugash Tanirbergenova, Kairat Tazhu, Erlan Doszhanov, Zulkhair Mansurov, Seitkhan Azat, Ruslan Nurlybaev, and Ronny Berndtsson. 2023. "Modifying Natural Zeolites to Improve Heavy Metal Adsorption" Water 15, no. 12: 2215. https://doi.org/10.3390/w15122215

APA StyleKuldeyev, E., Seitzhanova, M., Tanirbergenova, S., Tazhu, K., Doszhanov, E., Mansurov, Z., Azat, S., Nurlybaev, R., & Berndtsson, R. (2023). Modifying Natural Zeolites to Improve Heavy Metal Adsorption. Water, 15(12), 2215. https://doi.org/10.3390/w15122215