Abstract

The settlement behavior of composite foundations plays an important role in the serviceability and stability of the subgrade or other infrastructures supporting the foundation. However, in water-rich flood plains, due to the complexity of the soft soil properties, the settlement behavior has not been well understood. The objective of this study is to investigate the effects of various key factors on the settlement behavior of composite foundations with deep mixed piles supporting highway subgrade in water-rich flood plains. The investigated subgrade is in operation, and the vehicle load is taken into account. The G347AH Project is considered in this study. Several typical models for predicting composite foundation settlements are discussed. By performing three-dimensional finite difference analysis, a comparison is made between the settlement behavior of the natural foundation and the composite foundation with deep mixed piles. Based on the single factor sensitivity analysis and the multi-factor orthogonal experimental design, the effects of pile length, pile diameter, pile spacing, pile elasticity modulus, cushion elasticity modulus, and cushion thickness on the composite foundation settlement are captured. It is found that among these factors, the degree of influence of pile length is superior. The composite foundation settlements predicted by the models agree well with the field-monitoring data, with the error being about 8.42% and 6.38%, respectively, at two monitoring sections. The research conducted in this paper can effectively reduce the probability of various settlement-related disasters occurring on highway subgrades in water-rich flood plains. Moreover, the research has important theoretical guidance for design optimization in terms of settlement control of highway subgrades in soft soil areas.

1. Introduction

In recent years, there has been a rapid development of transportation engineering construction thanks to persistently growing economics. When constructing a highway in water-rich soft soil areas, specific countermeasures need to be taken to improve the strength and deformation behavior of the ground. As an effective ground improvement alternative, the composite foundation technique has been widely applied for constructing various infrastructures, such as railways, ports, and highway subgrades [1,2,3,4,5]. In water-rich flood plains, the soft soil within the ground exhibits unsatisfactory engineering properties, including high compressibility, low bearing capacity, etc. In this case, if the ground improvement measures taken at the site are not effective, disasters such as road collapses and pavement cracking can occur [6,7,8,9,10]. Therefore, it is important to investigate the settlement behavior of composite foundations with deep mixed piles supporting operating highway subgrades in water-rich flood plains.

A review of the literature indicates that previous studies on settlement behavior of composite foundations are mainly focused on two aspects: the mechanism of composite foundation settlements, and models for predicting composite foundation settlements. By using a theoretical method, Chen et al. [11] calculated the settlement of flexible pile under a subgrade load and analyzed the influence of critical pile length and neutral surfaces on the pile settlement. Zheng et al. [12] investigated the influence of pile length, pile diameter, and cushion thickness on the stress distribution between pile and soil. By performing staged load tests, Yang et al. [13] analyzed the characteristics of the settlement of the pile composite foundation in soft soils and obtained the variational behavior of settlement with time. On the basis of the shear displacement method, Qiu and Zhu [14] discussed the distributions of the pile top settlement, pile shaft stress, pile side friction, and neutral surface. Zhao et al. [15] investigated the deformation mechanism of gravel pile composite foundations under flexible bases and deduced the differential equation controlling the pile bulging deformation. Based on a combination of centrifuge model tests and finite element analysis, Jiang et al. [16] investigated the pile–soil stress measuring method and the stress distribution characteristics. A theoretical model describing the consolidation settlement and axial stress transfer of the axially loaded pile group in multilayered porous elastic soils was established by Senjuntichai et al. [17]. By performing finite element analysis, Hamderi [18] established an equation for calculating the settlement of the pile group. Cho et al. [19] investigated the settlement behavior of square pile raft plates in cohesive soils, considering various parameters including pile position, pile amount, pile length, and load type. Duba et al. [20] proposed a settlement calculation method considering the soil structural strength. By adopting the finite element method, field monitoring, and the analytical method, Yang and Zhang [21] analyzed the mechanism of long–short composite-piled foundations.

In addition to the settlement behavior of the composite foundation, design optimization of the composite foundation for reducing settlements is also beneficial for real engineering practices. Significant achievements have been made in terms of composite foundation design optimization. Based on the settlement control standard, Li et al. [22] performed a finite element analysis of the effects of different parameters on the settlement of deep mixed piles and obtained the optimum parameters corresponding to the minimum settlement. By performing a parametric analysis, Rui et al. [23] established the relationship between the influencing factors and the axial stress-settlement response of the soil–pile-subgrade system. Chen et al. [24] proposed a design optimization method for composite foundations. Based on the response surface methodology, Chen et al. [25] proposed a design optimization method for composite foundations with deep mixed piles in thick–soft soil areas. Li and Gong [26] established an analytical method for predicting the bearing behavior of pile groups consisting of newly installed piles and existing displacement piles. By virtue of a finite element analysis, Xiong et al. [27] captured the influence of pile lengths, pile spacing, and pile elasticity modulus on the settlement and horizontal displacement behavior of the widened subgrade. Sun and Zhang [28] conducted static pressure tests and field static load tests, pointing out that loess foundations can be prevented from collapsing by applying dynamic compaction on cement columns when the compressive pressure ranges between 200 and 500 kPa. Mu and Gao [29] proposed a non-probabilistic reliability analysis method for composite foundations with deep mixed piles. Tong et al. [30] investigated the relationship between the pile thickness-diameter ratio and the bearing capacity of soil among piles. They then proposed a design method for determining the pile thickness-diameter ratio of long–short composite piled foundations. Tan and Wang [31] performed a finite element analysis of the effects of cushion elasticity modulus as well as the ratio of pile tip soil elasticity modulus to pile-side soil elasticity modulus on the bearing capacity of the composite foundation with flexible piles.

In recent years, many scholars have studied the reinforcing effect of rigid piles and flexible piles in soft foundations in terms of settlement characteristics of composite foundations. Among these studies, a series of settlement calculation formulas were proposed; they varied in degrees of accuracy based on different basic assumptions. In addition, in order to optimize the design of composite foundations for road foundations in soft soil areas, the influence of the pile parameters, along with the cushion parameters on the settlement characteristics of road foundations, was analyzed. Furthermore, the weighting factors for different parameters were investigated. They shed light on the designing optimization of the composite foundations in different directions. It is well-known that there are many parameters affecting the settlement of composite foundations in thick soft–soil areas. However, a review of the literature presented above indicates that the effects of several key parameters, such as pile length, pile diameter, and pile spacing on the settlement behavior of composite foundations with deep mixed piles in water-rich flood plains, have not been fully investigated. Moreover, reliable parameters that can be used in the design optimization of composite foundations with deep mixed piles in water-rich flood plains still remain lacking, which restricts the sustainable development of this ground improvement technique in water-rich flood plains.

Based on an actual highway reconstruction and expansion project in the middle and lower reaches of the Changjiang River, this paper investigates the settlement behavior of composite foundations with deep mixed piles supporting highway subgrades in water-rich flood plains. To this end, the models for predicting composite foundation settlements are described. A series of three-dimensional finite difference analyses are performed to capture the effects of pile length, pile diameter, pile spacing, pile elasticity modulus, cushion thickness, and cushion elasticity modulus on the settlement behavior of composite foundations. On this basis, the orthogonal experiment optimization design method is used for reducing the composite foundation settlement, which reveals the degree of influence of these considered parameters.

This study proposes a new optimization design for controlling the settlement of composite foundations based on a comprehensive and systematic theoretical analysis. The numerical simulation is conducted to capture the main characteristics of the behaviour of composite foundations of deep mixed piles. In addition, the applicability and effectiveness of the designed composite foundations of deep mixed piles are demonstrated by a case study on soft soil highway subgrades in water-rich plain areas. This study is helpful to better understand the interaction between soil and piles, and then design a safe and effective composite foundation. Meanwhile, it can serve as a reference for further investigation and engineering implementation.

2. Theory of Composite Foundation Settlement

2.1. Mechanism of Composite Foundation Settlement

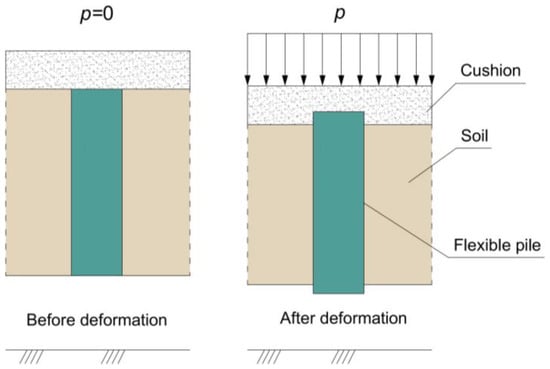

For a foundation with deep soft soil, the composite foundation technique is generally adopted to improve the bearing capacity and reduce the settlement of the foundation. The essential difference between a pile foundation or shallow foundation and a composite foundation is that, in the latter the load, it is shared directly by the piles and the soil between piles [32]. Obviously, the mechanism of composite foundation settlement differs from that of the natural foundation (i.e., without any treatment). Figure 1 shows the schematic of a composite foundation settlement under the upper load. For a composite foundation supporting highway subgrades, the upper load comes from the dead weight of the subgrade and the traffic load. Under this loading, the surface settlement of the soil between piles is greater than the pile top settlement, which will induce a downward frictional force on the pile shaft. Because of this frictional force, the upper load bore by the soil between piles will be gradually transferred to the pile top, followed by the penetration of the pile top into the cushion and by the penetration of the pile bottom into the underlying stratum.

Figure 1.

Schematic of composite foundation settlement under upper load.

2.2. Typical Models for Predicting Composite Foundation Settlement

Several typical models for predicting composite foundation settlements are introduced in this paper, which will be used for validating the three-dimensional numerical simulations. The models that will be used in this study are the hyperbolic prediction model, the exponential curve prediction model, and the Poisson curve prediction model. A brief description of these three models is presented below.

In the hyperbolic prediction model, the relationship between the composite foundation settlement and time is described using a hyperbolic function of the following form

where St is the composite foundation settlement at the moment of t, S0 is the initial composite foundation settlement when t equals zero, t0 is the initial time for predicting the composite foundation settlement, and a and b are the empirical coefficients obtained by the linear fitting of in-situ monitoring data.

In the exponential curve prediction model, it is assumed that the degree of foundation consolidation at the moment of t, Ut can be expressed as

where α and β are the consolidation parameters.

According to the consolidation theory, Ut can be also calculated as

where is the final settlement of the composite foundation.

By substituting Equation (3) into Equation (2), the final form of the expression describing the relationship between St and t is obtained as

The Poisson curve prediction model is highly precise in predicting the settlement of soft soil foundations. This model uses the settlement–time data to fit and calculate. The derived equation has the form of

where yt is the predicted foundation settlement at the moment of t, and a, b, and k are the undetermined parameters that need to be calculated using the time series.

3. Three-Dimensional Finite Difference Simulations

3.1. Basic Assumptions

The finite difference model, FLAC3D, is used herein to simulate the settlement behavior of composite foundations with deep mixed piles supporting operating highway subgrades in water-rich flood plains. To enable this simulation, several basic assumptions need to be made. First, it is assumed that the soil layers are isotropic, homogenous, and distributed horizontally. Second, the effect of groundwater on the settlement of composite foundations with deep mixed piles is neglected. Third, the deep mixed piles are assumed to be a homogeneous material consisting of cement paste and soil particles.

The study focuses on the supporting effect of composite foundations with deep mixed piles on highway subgrades. These assumptions are recommended for consideration when studying the performance of the monopile.

3.2. Meshing and Boundary Conditions

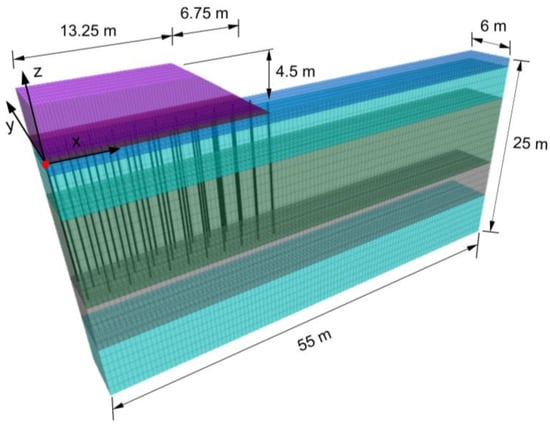

Taking into consideration the symmetry of the highway subgrade investigated in this study, half of the actual subgrade is numerically modeled. As depicted in Figure 2, in an attempt to eliminate the boundary effect, the overall length of the numerical model in x direction is taken as 55 m, and the overall width in y direction is taken as 6 m. In z direction, the height of the meshing for the ground below the subgrade is 25 m. The subgrade is of 13.25 m in top surface width and 4.5 m in height. On the right side of the subgrade, the slope ratio of the subgrade is 1:1.5. A cushion lies between the subgrade and the ground with a thickness of 0.5 m. The numerical model is divided into 110 meshes in the x-direction, six meshes in the y-direction, and 25 meshes in the z-direction. During the construction, the subgrade is filled in four layers. The deep mixed piles are 14 m in length, 0.6 m in diameter. The piles completely penetrate the soft soil layers, with their bottoms being in the hard clay layer. The arrangement of the deep mixed piles is triangular, with a distance of 2 m between two adjacent piles. In the finite difference analysis, the structural pile elements are used to simulate the deep mixed piles. Elasticity modulus and the unit weight of the deep mixed piles are, respectively, 400 MPa and 25 kN/m3. In FLAC numerical calculation software, the maximum unbalanced force in all nodes can measure the convergence of mesh. If the mesh of the model has zero force in the calculation, this means that the numerical calculation has reached equilibrium. In other words, the closer the maximum unbalance force is to zero, the better the convergence of the model. In this model, the maximum unbalanced force ratio value is set up to 1 × 10−5, and the computational convergence meets this criterion.

Figure 2.

Size and meshing of the finite difference analysis model.

Boundary conditions of the finite difference model are as follows. A full constraint is applied to the bottom surface of the model. In other words, no displacement is allowed for the model bottom surface. The four vertical side surfaces of the model are applied with the constraint of normal displacements. The top surface of the model is left to be free. By using the FISH language built in the FLAC3D, the calculated displacement results during the filling of each layer of the subgrade are regarded as the displacement boundary condition for the next filling of layer of the subgrade. This method allows for the consideration of the effect of subgrade filling on the settlement of the composite foundation.

A combination of the dead weight of the pavement structure layer and the traffic load during the operational period of the highway is simulated by the application of a uniformly distributed load with a magnitude of 20 kPa on the top surface of the subgrade. During the subgrade filling period, the Mohr–Coulomb model is used to simulate the constitutive behavior of the ground. During the operational period of the highway, the Maxwell creep model is used for simulating the behavior of the mucky clay and the subgrade filling material. The Maxwell creep model is a constitutive model capable of concurrently describing two deformation features: elastic and viscous deformation. Therefore, it is suitable to be used for simulating the creep process of geotechnical materials. In this study, the viscosity constant η is taken as 7.16 × 106 [33]. The calculation period is set to be one year. The soft soil layer of the foundation is muddy clay. Table 1 summarizes the material parameters required for the finite difference analysis.

Table 1.

Material parameters.

4. Settlement Behavior of Composite Foundation with Deep Mixed Piles

4.1. Comparison of Settlement Behavior between Natural and Composite Foundations

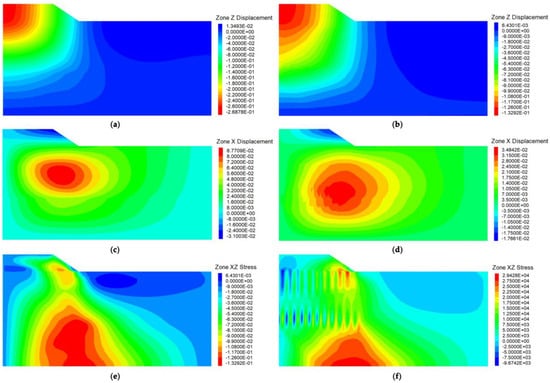

A comparison of the settlement contours (i.e., z displacement contours) between the natural foundation and the composite foundation with deep mixed piles is shown in Figure 3a,b. It can be indicated that the maximum settlements of the two foundations occur consistently at the middle of the subgrade. In addition, it can also be noted that the maximum region within which the main foundation settlements occur is located at the soft soil layer below the subgrade. Table 2 compares the settlement behavior after one year of operation between the natural and composite foundations. The comparison is made in terms of three parameters: the maximum settlement on foundation surface, Smax; the compression of soft soil layer, h; and the ratio of the compression of soft soil layer to the maximum settlement on foundation surface, h/Smax.

Figure 3.

Contours of: (a) Z displacement for natural foundation (m); (b) Z displacement for composite foundation (m); (c) X displacement for natural foundation (m); (d) X displacement for composite foundation (m); (e) XZ stress for natural foundation (Pa); (f) XZ stress for composite foundation (Pa).

Table 2.

Comparison of settlement behavior after one year operation between natural and composite foundations.

On one hand, as summarized in Table 2, when the highway operation time is one year, the maximum compression of soft soil layer under the natural foundation is 148.36 mm, whereas the maximum compression of soft soil layer under the composite foundation with deep mixed piles is merely 37.74 mm. This implies a reduction of approximately 74.6% in the maximum compression of the soft soil layer can be achieved by using the composite foundation with deep mixed piles. On the other hand, when the highway operation time is one year, the maximum settlement on the surface of the natural foundation is 263.86 mm. This value can be reduced by about 51.9% if the composite foundation with deep mixed piles is used where the maximum settlement is only 127.05 mm. When there is a horizontal deviation from the middle of the subgrade, the rate of reduction in the settlement on the composite foundation surface increases sharply.

Figure 3c,d show the horizontal displacement contours for the natural and composite foundations. It can be seen that the maximum horizontal displacement of natural foundations is 87.7 mm, while this value is reduced to 34.84 mm for the composite foundation with deep mixed piles, corresponding to a reduction of 60.32%. Moreover, the maximum horizontal displacements beneath the subgrade slope toe occur within the soft soil layer, both for the natural foundation and the composite foundation with deep mixed piles; their cover depths occur at 11 and 8 m, respectively. In other words, a reduction of 3 m in the cover depth of the maximum horizontal displacement can be achieved by using the composite foundation. The composite foundation with deep mixed piles provides significant reinforcement to the soft soil layers of the highway subgrade. Therefore, the application of the composite foundation with deep mixed piles can effectively enhance the stability of the subgrade.

Figure 3e,f show the shear stress contours for the natural and composite foundations. For the natural foundation under upper loading, the maximum positive shear stress occurs within the bottom soil layer below the subgrade slope toe and on the surface of the foundation below the subgrade shoulder. In these two areas, a connection zone of shear stress is formed. Furthermore, the maximum negative shear stress for the natural foundation occurs on the foundation surface in the middle of the subgrade and within the shallow layer of the ground at 10 m outside of the subgrade toe. This phenomenon may easily cause the occurrence of subgrade instability. In contrast, for the composite foundation with deep mixed piles, the cover depth of the maximum shear stress within the bottom soil layer is larger than that of the natural foundation, which is primarily attributed to the effect of the deep mixed piles. Moreover, the connection zone of shear stress does not appear for the composite foundation due to the obstructing effect of the deep mixed piles. Therefore, the stability of the composite foundation is higher than the natural foundation.

4.2. Parametric Analysis

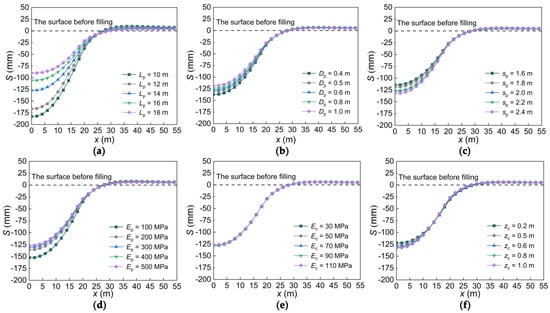

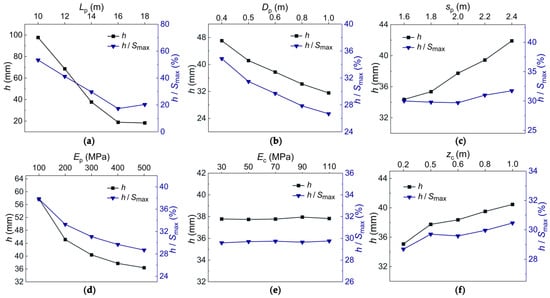

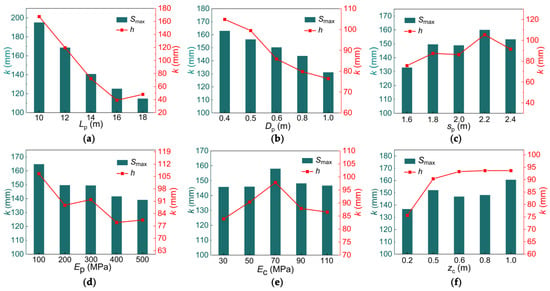

A parametric analysis is made in this section to capture the effects of key parameters related to columns and cushion on the settlement behavior of the composite foundation with deep mixed piles supporting highway subgrades in water-rich flood plains. The considered key parameters include pile length Lp, pile diameter Dp, pile spacing sp, pile elasticity modulus Ep, cushion elasticity modulus Ec, and cushion thickness zc. The results of the settlement behavior are presented in three aspects: the variations of composite foundation settlement (i.e., S) with these parameters, the variations of the maximum compression of the soft soil layer (i.e., h), and the ratio of maximum compression of soft soil layer to maximum composite foundation settlement (i.e., h/Smax) with these parameters, as shown in Figure 4 and Figure 5.

Figure 4.

Variations of composite foundation settlements (i.e., S) with parameters related to piles and cushion: (a) Lp; (b) Dp; (c) sp; (d) Ep; (e) Ec; (f) zc.

Figure 5.

Variations of the maximum compression of soft soil layer (i.e., h) and the ratio of maximum compression of soft soil layer to maximum composite foundation settlement (i.e., h/Smax) with parameters related to columns and cushion: (a) Lp; (b) Dp; (c) sp; (d) Ep; (e) Ec; (f) zc.

The effect of pile length on the composite foundation settlement and on the maximum compression of soft soil layer can be indicated from Figure 4a and Figure 5a. It is indicated that the greater the pile length is, the lower the composite foundation settlement and the maximum compression of soft soil layer are. The compression of soft soil layer peaks at the midpoint of the subgrade. When the pile length increases from 12 to 14 m, the reductions in the maximum composite foundation settlement, and in the compression of soft soil layers, are, respectively, 39.33 and 30.83 mm.

At a pile length shorter than 14 m, the pile is floating within the soft soil layer of poor mechanical properties. In this case, the pile tip resistance cannot be mobilized, which leads to larger composite foundation settlements and the compression of the soft soil layer. When the pile length is greater than 14 m, the pile tip is within the stratum of good mechanical properties. In this case, the fully mobilized pile tip resistance plays the dominant role in bearing the load, corresponding to a lower composite foundation settlement. The deep mixed piles provide excellent reinforcement to the soft soil layers in the highway subgrade foundation. In addition, when the pile length increases from 14 to 18 m, the rate of reduction in the composite foundation settlement gradually drops. Thus, it is inferred that an optimum range of pile length for reducing composite foundation settlement exists. Outside of this range, the method of increasing pile length for reducing composite foundation settlement is not economic.

The effect of the pile diameter on the composite foundation settlement, and on the maximum compression of the soft soil layer, can be indicated from Figure 4b and Figure 5b. It can be seen that a greater pile diameter corresponds to a lower composite foundation settlement and compression of soft soil layer. A slight difference in the maximum compression of soft soil layer is also observed among the cases of various pile diameters. The increase in pile diameter will lead to the reduction of the net spacing between piles, which indicates the reinforcement effect of deep mixing piles on soil is more significant. In this case, the load-bearing capacity of the composite foundation mainly arises from deep mixing piles under the combined effect of the gravity load of the subgrade and the vehicle load. This limits the reinforcement effectiveness of increasing the pile diameter in the case of the pile tip that is not within the stratum of good mechanical properties. This demonstrates the limitation of the controlling effect on the composite foundation settlement solely by changing the pile diameter.

The effect of pile spacing on the composite foundation settlement and on the maximum compression of soft soil layer can be indicated from Figure 4c and Figure 5c. The report indicates that the larger the pile spacing is, the greater the composite foundation settlement and the compression of soft soil layer are. Moreover, when deviating horizontally from the slope toe of the subgrade, the curves of the composite foundation settlement for various cases tend to coincide, demonstrating that the effect of changing pile spacing on controlling composite foundation settlement is limited. Additionally, this controlling effect diminishes horizontal deviation from the slope toe of the subgrade. As the pile spacing increases, the number of piles decreases in the same section area of the subgrade, causing a reduction in the extent of reinforcement of the soil layer by the piles.

Figure 4d and Figure 5d indicate the effect of pile elasticity modulus on the composite foundation settlement, and on the maximum compression of the soft soil layer. It is demonstrated that when the pile elasticity modulus increase from 100 to 200 MPa, the maximum composite foundation settlement and the maximum compression of the soft soil layer peak are reduced compared to other ranges of pile elasticity modulus. This demonstrates the existence of an optimum range of pile elasticity modulus for achieving the best controlling of the composite foundation settlement. The increase in the elastic modulus of the pile enhances the overall stiffness of the composite foundation, thus reducing the settlement of the composite foundation. Furthermore, the improvement will achieve a better performance when the pile tip is within the stratum of good mechanical properties.

The effect of cushion elasticity modulus on the composite foundation settlement and on the maximum compression of soft soil layer are demonstrated in Figure 4e and Figure 5e. The curves of the composite foundation settlement for various magnitudes of cushion elasticity modulus tend to coincide, and the curves for the ratio of maximum compression of the soft soil layer to the maximum composite foundation settlement tend to stabilize. This indicates that the controlling effect of solely changing the cushion elasticity modulus on the composite foundation settlement can be nearly neglected. Without the elasticity modulus of the cushion being raised, only the parameters of the pile are changed, and the synergy between the pile and the soil is improved. Thus, the settlement of the composite foundation does not decrease because the weak soil layer in the foundation is not reinforced.

The effect of cushion thickness on the composite foundation settlement, and on the maximum compression of the soft soil layer, can be indicated from Figure 4f and Figure 5f. It is demonstrated that the greater the cushion thickness is, the greater the composite foundation settlement and the compression of the soft soil layer. However, the rate of increase in the composite foundation settlement and the compression of the soft soil layer gradually decrease in the cushion thickness. Increasing cushion thickness on the settlement of composite foundations has a similar effect to enlarging the elasticity modulus of the cushion. In the case of highway subgrades in water-rich plains, the cushion parameters have a greater effect on composite foundation settlements when the pile parameters are set properly, especially the pile length. The settlement of composite foundations can only be effectively reduced if the soft soil layer is reinforced.

5. Optimization Design for Controlling Settlement of Composite Foundation

5.1. Orthogonal Experimental Design

The results of single-factor analysis presented above indicate that the controlling effect on composite foundation settlements differs among various parameters, including pile length, pile diameter, pile spacing, pile elasticity modulus, cushion elasticity modulus, and cushion thickness. In this section, by using the orthogonal experimental method, multiple-factor numerical analysis is performed to further capture the influence degree of these six factors on the composite foundation settlement.

The numerical analysis is carried out by using the finite difference software, FLAC3D. The model size, basic assumptions, material parameters, boundary conditions, and load applications adopted herein are identical with that in the above section. In this section, the indexes to be investigated are the maximum composite foundation settlement, Smax, and the maximum compression of soft soil layer, h. The considered factors and their serial numbers (presented in the brackets) are, respectively, pile length Lp (A), pile diameter Dp (B), pile spacing s (C), pile elasticity modulus Ep (D), cushion elasticity modulus Ec (E), and cushion thickness zc (F). Each factor has five levels, as summarized in Table 3. As this numerical analysis conforms to the orthogonal test with six factors of five levels, the L25 (65) orthogonal table is selected to design the orthogonal numerical analysis schemes. Table 4 summarizes the 25 orthogonal numerical analysis schemes and the obtained results.

Table 3.

Orthogonal factor level.

Table 4.

Orthogonal numerical analysis schemes and results.

5.2. Results and Interpretation

The results presented in Table 4 indicate that the lowest magnitudes of the maximum composite foundation settlement, Smax, and the maximum compression of soft soil layer, h, are achieved in Scheme No. 25, where Smax = 77.10 mm and h = 7.22 mm. Therefore, the optimal combination of test schemes can be regarded as A5–B5–C5–D5–E5–F1.

The results of the range analysis are shown in Table 5. The variations of Smax and h with the levels of the six factors considered herein are depicted in Figure 6. From the results presented in Table 5 and Figure 6, it is demonstrated that the degree of influence of the factors on maximum composite foundation settlement Smax can be ranked from highest to lowest as: pile length (A) > pile diameter (B) > pile spacing (C) > pile elasticity modulus (D) > cushion thickness (F) > cushion elasticity modulus (E). In addition, the degree of influence of the factors on the maximum compression of soft soil layer h can be ranked from highest to lowest as: pile length (A) > pile spacing (C) > pile diameter (B) > pile elasticity modulus (D) > cushion thickness (F) > cushion elasticity modulus (E). Moreover, it can be also noted that the factor, pile length, is the dominant factor affecting the settlement behavior of the composite foundation in water-rich flood plains.

Table 5.

Range analysis of maximum settlement on foundation surface.

Figure 6.

Variations of the maximum composite foundation settlement (i.e., Smax) and the maximum compression of soft soil layer (i.e., h) with parameters related to columns and cushion: (a) Lp; (b) Dp; (c) sp; (d) Ep; (e) Ec; (f) zc.

6. Case Study

6.1. Project Overview

A case study is presented in this section. The actual project considered is a reconstruction and expansion project for a first-class highway, as shown in Figure 7. It is located at a water-rich flood plain around the middle and lower reaches of Changjiang River. At the project site, a soft soil layer of 0 to 9 m in cover depth is inhomogeneously distributed. The thickness of this soft soil layer ranges between 0 and 25 m. As the engineering property of the soft soil layer, characterized by a low-bearing capacity, high total settlement, and high differential settlement, it is unsatisfactory and a ground improvement technique needs to be implemented. In this project, the technique of composite foundations with deep mixed piles has been adopted. The monitoring positions of the subgrade sections in the project are the foundation surface in the center of the highway subgrade. The start time for settlement monitoring is one month after the completion of subgrade filling construction. In this section, the settlement described is the D-value between the ground surface settlement one year after the operation period and that after the completion of subgrade filling construction.

Figure 7.

Photos of the project site: (a) ground improvement; (b) highway widening.

6.2. Numerical Simulations

In this case study, two typical monitoring sections (i.e., MS 1 and MS 2) along the subgrade are selected as the object of numerical simulations. At MS 1, the ground consists of, from up to down, the plain fill layer, clay layer, mucky clay layer, clay layer, and silty clay layer. The thickness of these five soil layers are, respectively, 1, 4, 9, 5, and 6 m. At MS 2, the ground consists of, from up to down, the plain fill layer, mucky clay layer, clay layer, and silty clay layer. The thickness of these four soil layers are, respectively, 1, 16, 4, and 4 m. At these two monitoring sections, the technique of composite foundations with deep mixed piles is adopted to achieve ground improvement. The lengths of the piles at MS 1 and MS 2 are, respectively, 14 and 17 m.

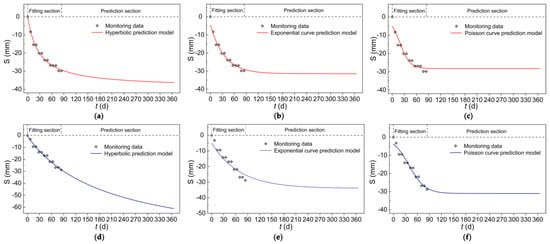

6.3. Result Analysis

Figure 8 shows the application of the three prediction models mentioned above in fitting the field monitored composite foundation settlements and predicting the long-term development of the composite foundation settlement with time. These three prediction models are the hyperbolic prediction model, exponential curve prediction model, and Poisson curve prediction model. The monitoring data are observed at two typical subgrade sections in the site for a period of 84 days. Based on the nonlinear fitting of the monitoring data using these three prediction models, the subsequent development of the composite foundation settlement within one year is predicted. From Figure 8, it can be demonstrated that the degree of fitting is high for these three models at MS 1. At MS 1, the final errors in the settlements predicted by using the hyperbolic prediction model, exponential curve prediction model, and Poisson curve prediction model are, respectively, 2, 11.5, and 20.6%. On the other hand, at MS 2, the final errors in the settlements predicted by using the hyperbolic prediction model, exponential curve prediction model, and Poisson curve prediction model are, respectively, 20.9, 20.1, and 33.9%.

Figure 8.

Fitting of the monitored settlements at two monitoring sections (MS) by using three different models: (a) hyperbolic prediction model for MS 1; (b)exponential curve prediction model for MS 1; (c) Poisson curve prediction model for MS 1; (d) hyperbolic prediction model for MS 2; (e) exponential curve prediction model for MS 2; (f) Poisson curve prediction model for MS 2.

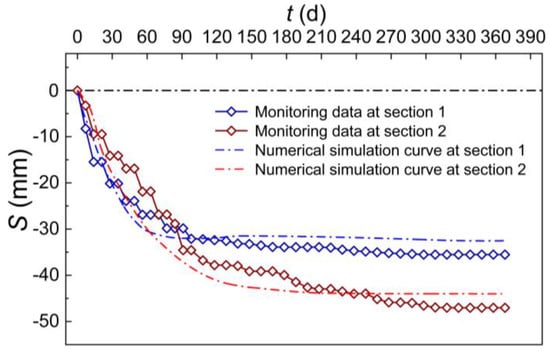

Figure 9 presents a comparison of the development of composite foundation settlements with time between the monitoring data and the numerical simulation results at two sections. A good agreement between the monitoring data and the numerical simulation results can be observed. The differences between the final settlement monitored in the field and the final settlement obtained from numerical simulations at MS 1 and MS 2 are, respectively, 8.42% and 6.38%. This demonstrates the effectiveness of the finite difference model adopted in this study for investigating the settlement behavior of composite foundation with deep mixed piles in water-rich flood plains.

Figure 9.

Comparison of settlements between monitoring data and results of numerical simulations.

7. Conclusions

The settlement behavior of composite foundations with deep mixed piles supporting operating highway subgrade in water-rich flood plains is systematically investigated considering various factors in terms of pile and cushion characteristics. Based on an actual project, parametric analysis is performed by using the finite difference method. The conclusions obtained from this study can be summarized as follows.

(1) The surface settlement of the composite foundation with deep mixed piles in water-rich flood plains and the compression of the soft soil layer within the composite foundation decrease with an increase in pile length, pile diameter, and pile elasticity modulus, while they increase with increasing pile spacing and cushion thickness. An increase in cushion elasticity modulus has little effect in reducing the composite foundation settlement and the compression of soft soil layer within the composite foundation. Due to the existence of the optimum range of pile length, it is recommended that a reasonable pile length should be selected during the design of the settlement control of composite foundation.

(2) In light of the degree of influence of various factors on the composite foundation settlement and compression of soft soil layer, the six factors considered in this study can be ranked from highest to lowest as: pile length, pile diameter, pile spacing, pile elasticity, cushion thickness, and cushion elasticity modulus. Therefore, in the design of settlement control of composite foundation, pile length can be adjusted first.

(3) A good agreement between the numerical simulation results and the monitoring data in the field is observed, demonstrating the applicability and reliability of the finite difference method with Maxwell creep model in the optimization design of the settlement control of composite foundation with deep mixed piles supporting operating highway subgrade in water-rich flood plain.

In future research, the effects of fluid—solid coupling can be considered in numerical models, which increases the accuracy of the results of the numerical calculations of pile-soil settlement and foundation soil deformation in composite foundations. In addition, the dynamic vehicle load transfer can be considered in the simulation of the vehicle load action on the subgrade surface, and the dynamic response of the foundation can be taken into account. These will provide helpful guidance on the analysis of settlements of composite foundations and the design of soft foundation treatment methods in water-rich flood plains.

Author Contributions

Conceptualization, P.G.; methodology, S.L.; software, S.L.; validation, S.L. and P.G.; formal analysis, P.G.; investigation, S.L.; resources, X.L.; data curation, S.L.; writing—original draft preparation, S.L.; writing—review and editing, P.G., X.L., Y.W., K.W. and R.T.; visualization, X.L., K.W. and R.T.; supervision, P.G.; project administration, P.G.; funding acquisition, P.G., Y.W. and X.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Nos. 42077249, 51774107), and the opening project of State Key Laboratory of Explosion Science and Technology (Beijing Institute of Technology) (Nos. KFJJ23-05M, KFJJ23-04M).

Data Availability Statement

All data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Loktev, A.; Ulanov, I.; Shishkina, I.; Savulidi, M.; Klekovkina, N.; Kuznetsov, A. Determination of settlement parameters of highway embankment and base consolidation time depending on soil characteristics. Transp. Res. Procedia 2022, 63, 946–955. [Google Scholar] [CrossRef]

- Guo, P.P.; Gong, X.N.; Wang, Y.X.; Lin, H.; Zhao, Y.L. Analysis of observed performance of a deep excavation straddled by shallowly buried pressurized pipelines and underneath traversed by planned tunnels. Tunn. Undergr. Space Technol. 2023, 132, 104946. [Google Scholar] [CrossRef]

- Mahdi, I.M.; Ebid, A.M.; Khallaf, R. Decision support system for optimum soft clay improvement technique for highway construction projects. Ain Shams Eng. J. 2020, 11, 213–223. [Google Scholar] [CrossRef]

- Ullah, A.; Kassim, A.; Ahmed, S.; Ullah, R.; Junaid, M.; Zia, M.D. Experimental analysis of embankment on soft soil improved with bottom ash columns. Transp. Geotech. 2022, 37, 100881. [Google Scholar] [CrossRef]

- Jerman, J.; Mašín, D. Evaluation of hypoplastic model for soft clays by modelling of Nicoll highway case history. Comput. Geotech. 2021, 134, 104053. [Google Scholar] [CrossRef]

- Guo, P.P.; Gong, X.N.; Wang, Y.X.; Lin, H.; Zhao, Y.L. Minimum cover depth estimation for underwater shield tunnels. Tunn. Undergr. Space Technol. 2021, 115, 104027. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Chen, Y.K.; Chen, W.X.; Wang, J.C.; Ren, C. The performance of T-shaped deep mixed soil cement column-supported embankments on soft ground. Constr. Build. Mater. 2023, 369, 130578. [Google Scholar] [CrossRef]

- Wang, X.S.; Kim, S.; Wu, Y.P.; Liu, Y.; Liu, T.Y.; Wang, Y.M. Study on the optimization and performance of GFC soil stabilizer based on response surface methodology in soft soil stabilization. Soils Found. 2023, 63, 101278. [Google Scholar] [CrossRef]

- Wu, T.Y.; Jin, H.X.; Guo, L.; Sun, H.L.; Tong, J.H.; Jiang, Y.C.; Wei, P.F. Predicting method on settlement of soft subgrade soil caused by traffic loading involving principal stress rotation and loading frequency. Soil Dyn. Earthq. Eng. 2022, 152, 107023. [Google Scholar] [CrossRef]

- Guo, P.P.; Gong, X.N.; Wang, Y.X. Displacement and force analyses of braced structure of deep excavation considering unsymmetrical surcharge effect. Comput. Geotech. 2019, 113, 103102. [Google Scholar] [CrossRef]

- Chen, S.Y.; Ye, H.Y.; Zhang, W.F. Settlement analysis of flexible pile composite foundation under embankment load. Rock Soil. Mech. 2020, 41, 3077–3086. [Google Scholar]

- Zheng, J.J.; Abusharar, S.W.; Wang, X.Z. Three-dimensional nonlinear finite element modeling of composite foundation formed by CFG-lime piles. Comput. Geotech. 2007, 35, 637–643. [Google Scholar] [CrossRef]

- Yang, P.; Hu, H.S.; Xu, J.F. Settlement characteristics of pile composite foundation under staged loading. Procedia Environ. Sci. 2012, 12, 1055–1062. [Google Scholar] [CrossRef]

- Qiu, L.; Zhu, N. Settlement analysis of composite foundation with rigid piles under flexible ground. Rock Soil. Mech. 2007, 28, 1964–1968. [Google Scholar]

- Zhao, M.H.; Niu, H.Y.; Liu, M. Pile-soil stress ratio and settlement of composite ground with gravel piles in flexible foundation. Chin. J. Geotech. Eng. 2017, 39, 1549–1556. [Google Scholar]

- Jiang, Y.B.; He, N.; He, B. Distribution of pile-soil stress in centrifugal modelling of composite foundation. Chin. J. Geotech. Eng. 2020, 42, 85–89. [Google Scholar]

- Senjuntichai, T.; Sornpakdee, N.; Keawsawasvong, S.; Phulsawat, B.; Rajapakse, R.K.N.D. Consolidation settlement of vertically loaded pile groups in multilayered poroelastic soils. Transp. Geotech. 2023, 38, 100904. [Google Scholar] [CrossRef]

- Hamderi, M. Comprehensive group pile settlement formula based on 3D finite element analyses. Soils Found. 2018, 58, 1–15. [Google Scholar] [CrossRef]

- Cho, J.; Lee, J.H.; Jeong, S.; Lee, J. The settlement behavior of piled raft in clay soils. Ocean Eng. 2012, 53, 153–163. [Google Scholar] [CrossRef]

- Duba, V.P.; Galashev, Y.V.; Osipova, O.N. More precisely defined methods of foundation-settlement calculation based on tray and in-situ experiments. Soil Mech. Found. Eng. 2011, 48, 114–120. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, J. Analysis of features of long and short pile composite foundation in high-rise buildings. Soil Mech. Found. Eng. 2022, 59, 92–101. [Google Scholar] [CrossRef]

- Li, M.Y.; Zeng, Q.J.; Mo, H.H. Optimum design of composite foundation according to settlement control for extension project of expressway. Rock Soil. Mech. 2008, 29, 535–540. [Google Scholar]

- Rui, R.; Han, J.; Zhang, L.; Zhai, Y.X.; Cheng, Z.; Chen, C. Simplified method for estimating vertical stress-settlement responses of piled embankments on soft soils. Comput. Geotech. 2020, 119, 103365. [Google Scholar] [CrossRef]

- Chen, C.F.; Qiu, L.Q.; Mao, F.S. Design optimization of pile-net composite foundation based on perturbation-weighted symbiotic organisms search (PWSOS) algorithm. Rock Soil. Mech. 2019, 40, 4477–4485. [Google Scholar]

- Chen, C.F.; Li, X.; Mao, F.S. Settlement-based optimization design on composite foundation in region with deep soft soils by orthogonal numerical tests. Highw. Eng. 2018, 43, 49–53. [Google Scholar]

- Li, L.; Gong, W.B. Prediction of nonlinear vertical settlement of a pile group consisting of new and existing displacement piles in clay strata. Soils Found. 2019, 59, 1336–1348. [Google Scholar] [CrossRef]

- Xiong, B.L.; Yang, G.Q.; Wang, X.S. Settlement analysis of widening subgrade in the highway considering technology parameter of composite foundation. Int. J. Earth Sci. 2016, 9, 1429–1433. [Google Scholar]

- Sun, H.J.; Zhang, S.Y. A field experimental study of composite foundation with rammed soil-cement pile in collapsible loess area. Adv. Mat. Res. 2014, 3470, 1030–1032. [Google Scholar] [CrossRef]

- Mu, H.S.; Gao, L. Finite element study of settlement of cement mixing composite foundation and non-probabilistic reliability analysis. Appl. Mech. Mater. 2014, 3489, 638–640. [Google Scholar] [CrossRef]

- Tong, J.X.; Sun, X.H.; Luo, P.F.; Jia, N.; Yang, X.H.; Yan, M.L. Study on the design method of different thickness-diameter ratios for composite foundation with rigid long and short piles. Appl. Mech. Mater. 2014, 3307, 580–583. [Google Scholar] [CrossRef]

- Tan, F.Y.; Wang, X.Z. Numerical analysis for bearing performance of flexible piles composite foundation influenced by modulus’ changes. Adv. Mat. Res. 2011, 1278, 261–263. [Google Scholar] [CrossRef]

- Gong, X.N. Generalized composite foundation theory and engineering application. Chin. J. Geotech. Eng. 2007, 29, 1–13. [Google Scholar]

- Yang, L.M.; Guo, J.J.; Han, Y.C. Study on effects of underlying goaf on the subgrade stability. J. Zhengzhou Univ. 2018, 39, 42–46. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).