Anaerobic Co-Digestion of Food Waste with Sewage Sludge: Simulation and Optimization for Maximum Biogas Production

Abstract

:1. Introduction

2. Materials and Methods

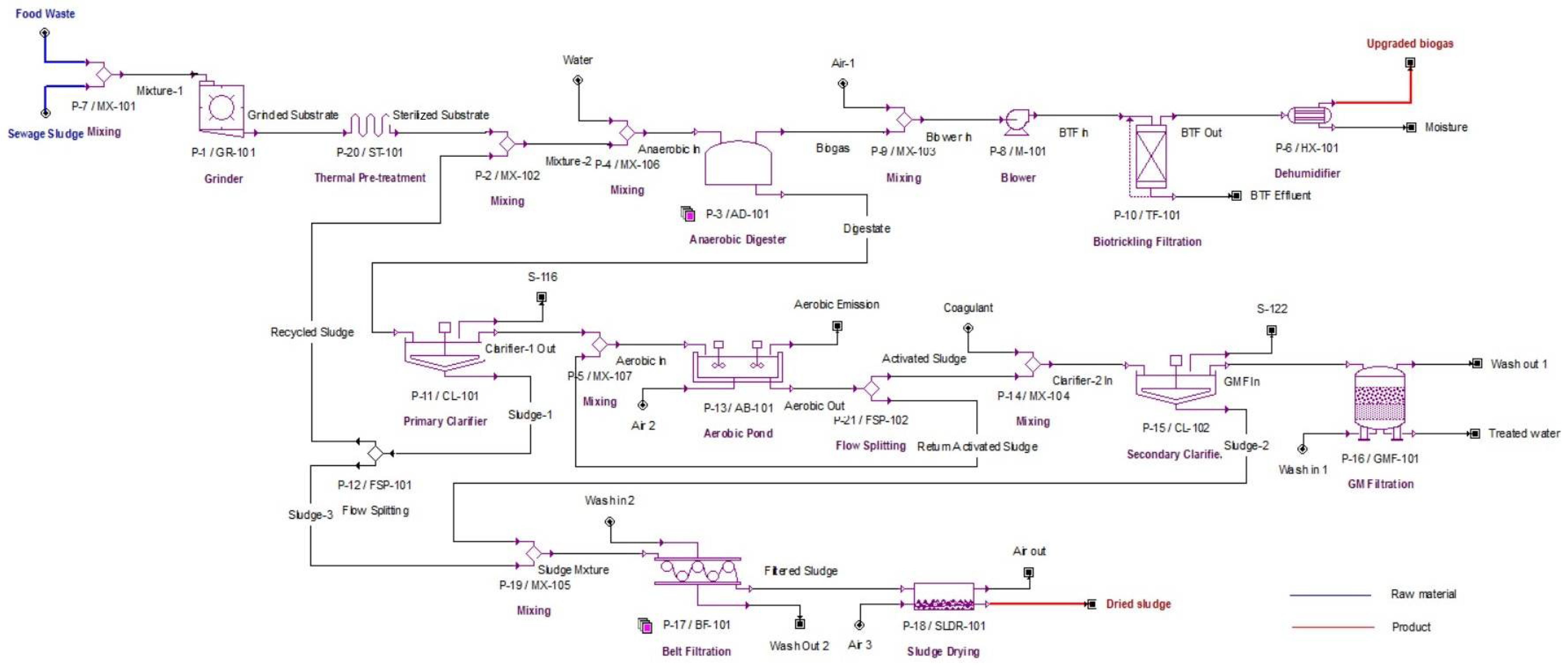

2.1. SuperPro Simulation Model for Anaerobic Co-Digestion of Food Waste and Sewage Sludge

2.2. Process Optimisation

3. Results and Discussions

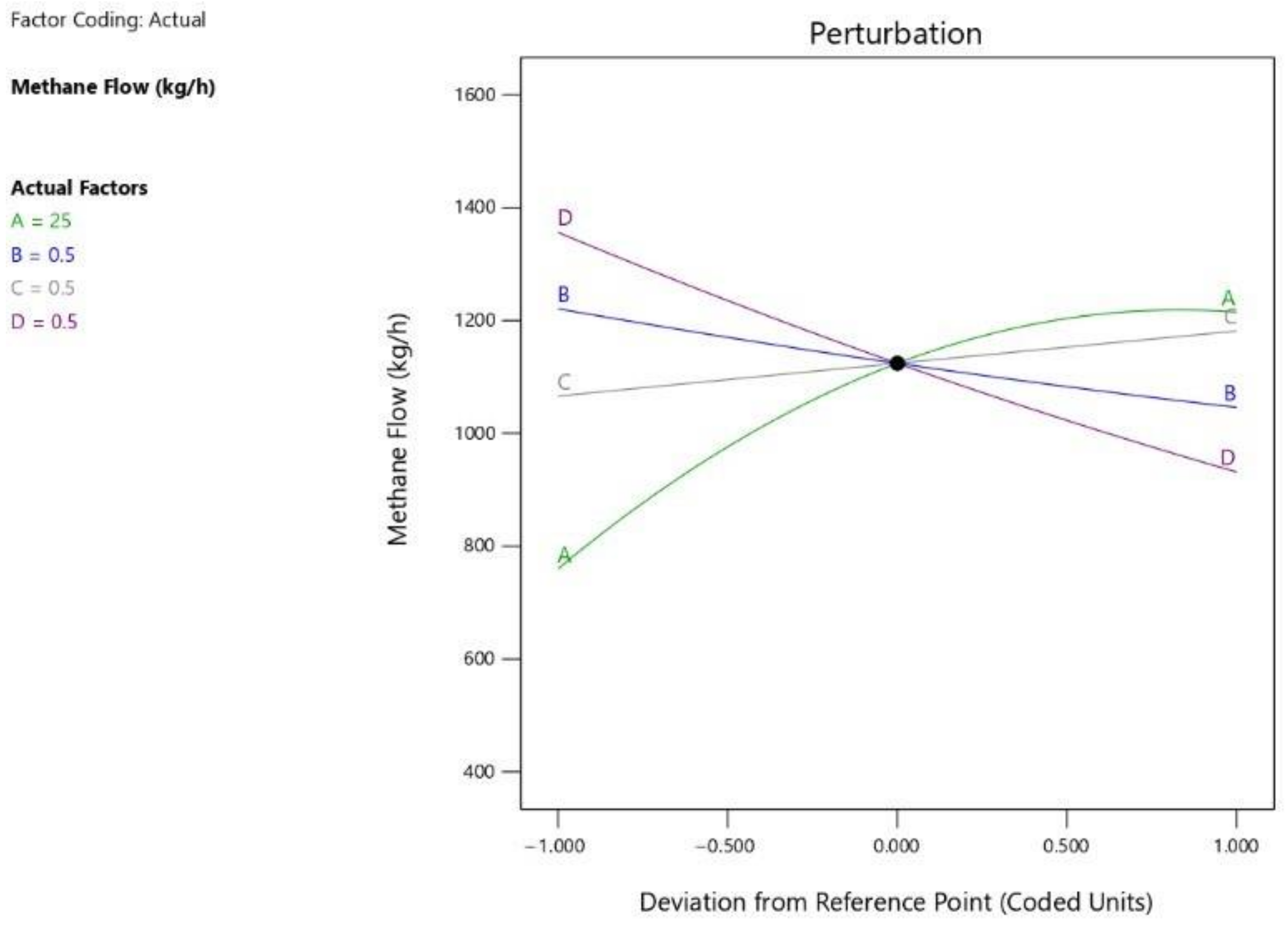

3.1. Effect of HRT, Water to Feed Ratio (kg/kg), Sludge Recycle Ratio and the SS to FW Ratio (kg/kg) on Methane Flow

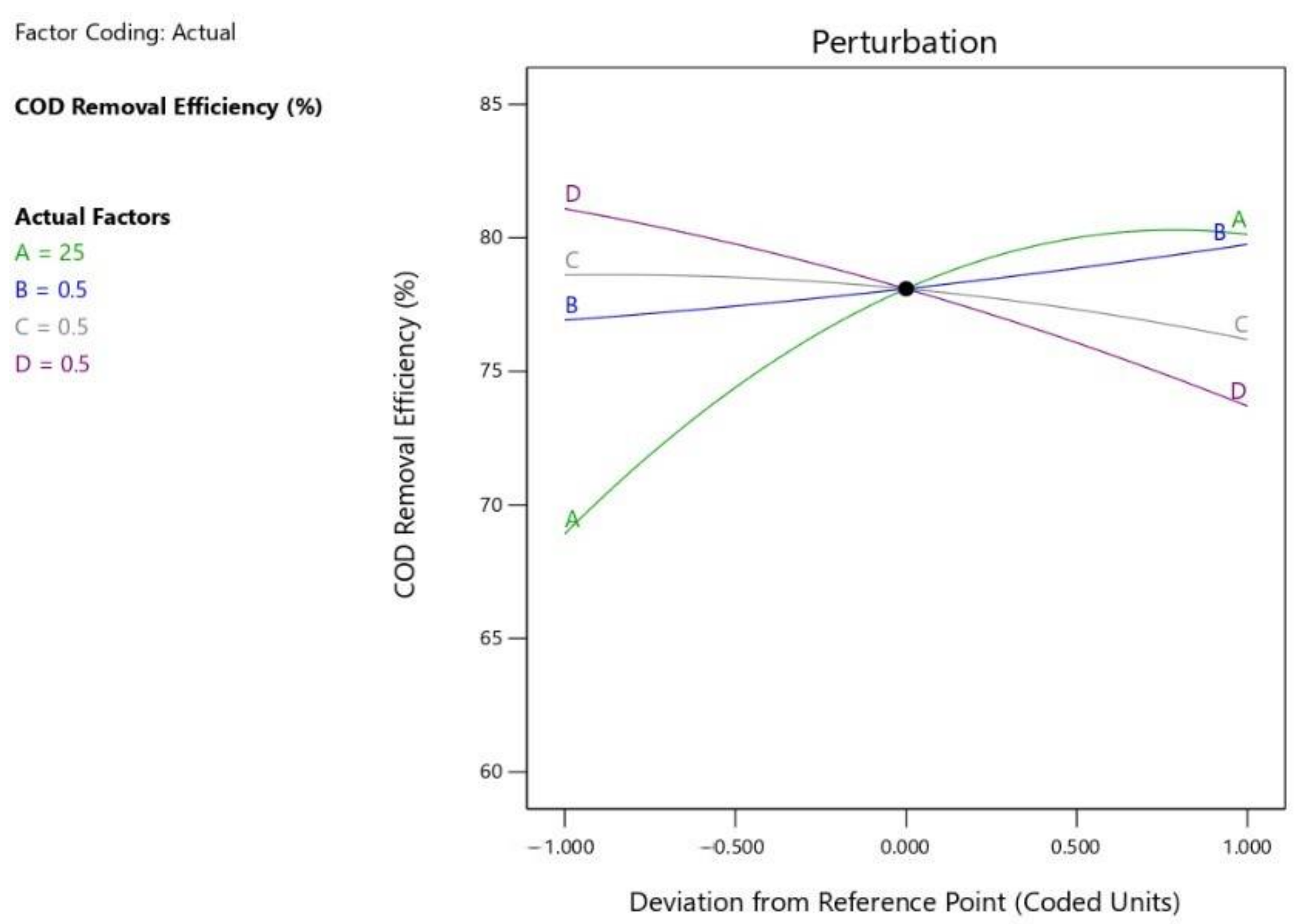

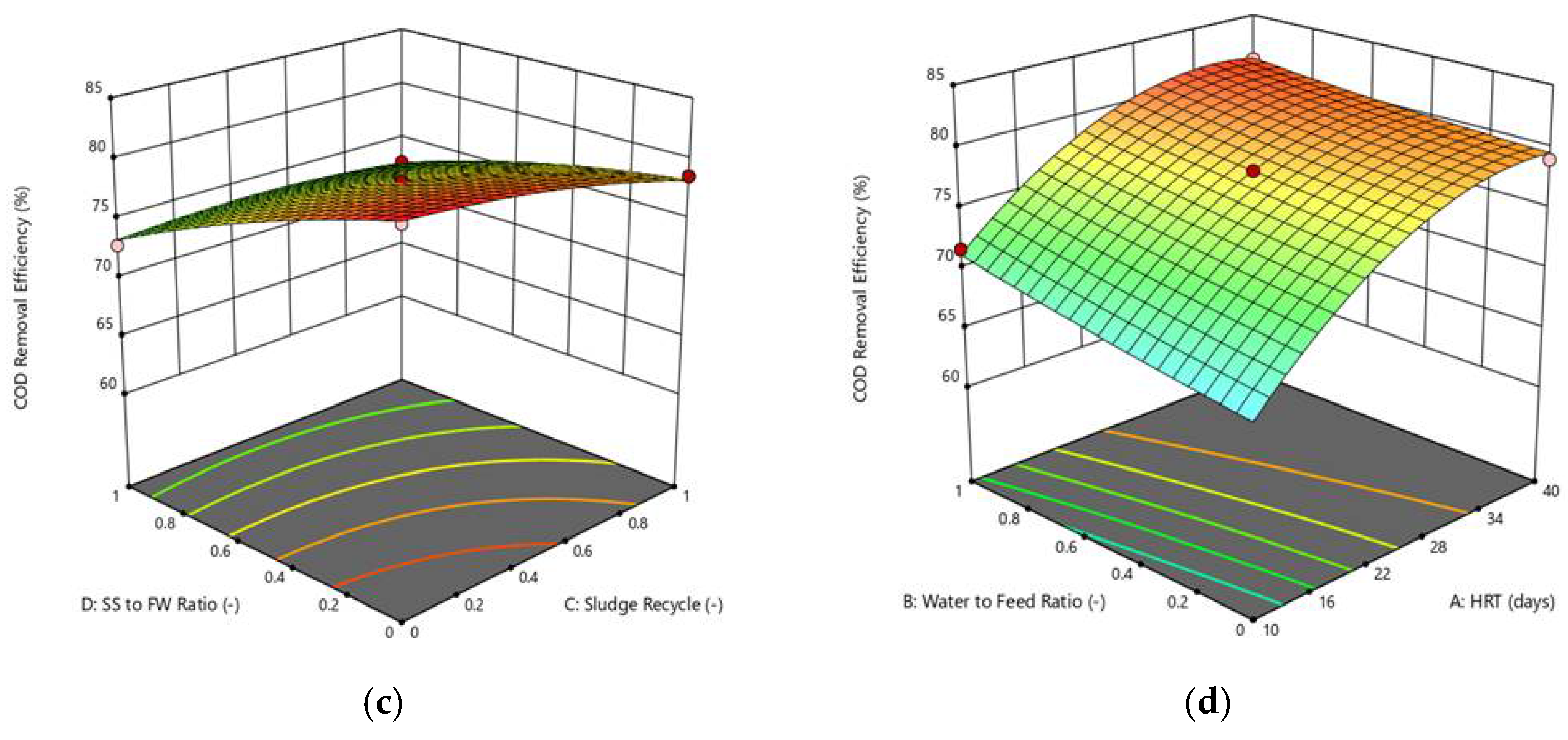

3.2. Effect of HRT, Water to Feed Ratio (kg/kg), Sludge Recycle Ratio and the SS to FW Ratio (kg/kg) on Chemical Oxygen Demand (COD) Removal Efficiency

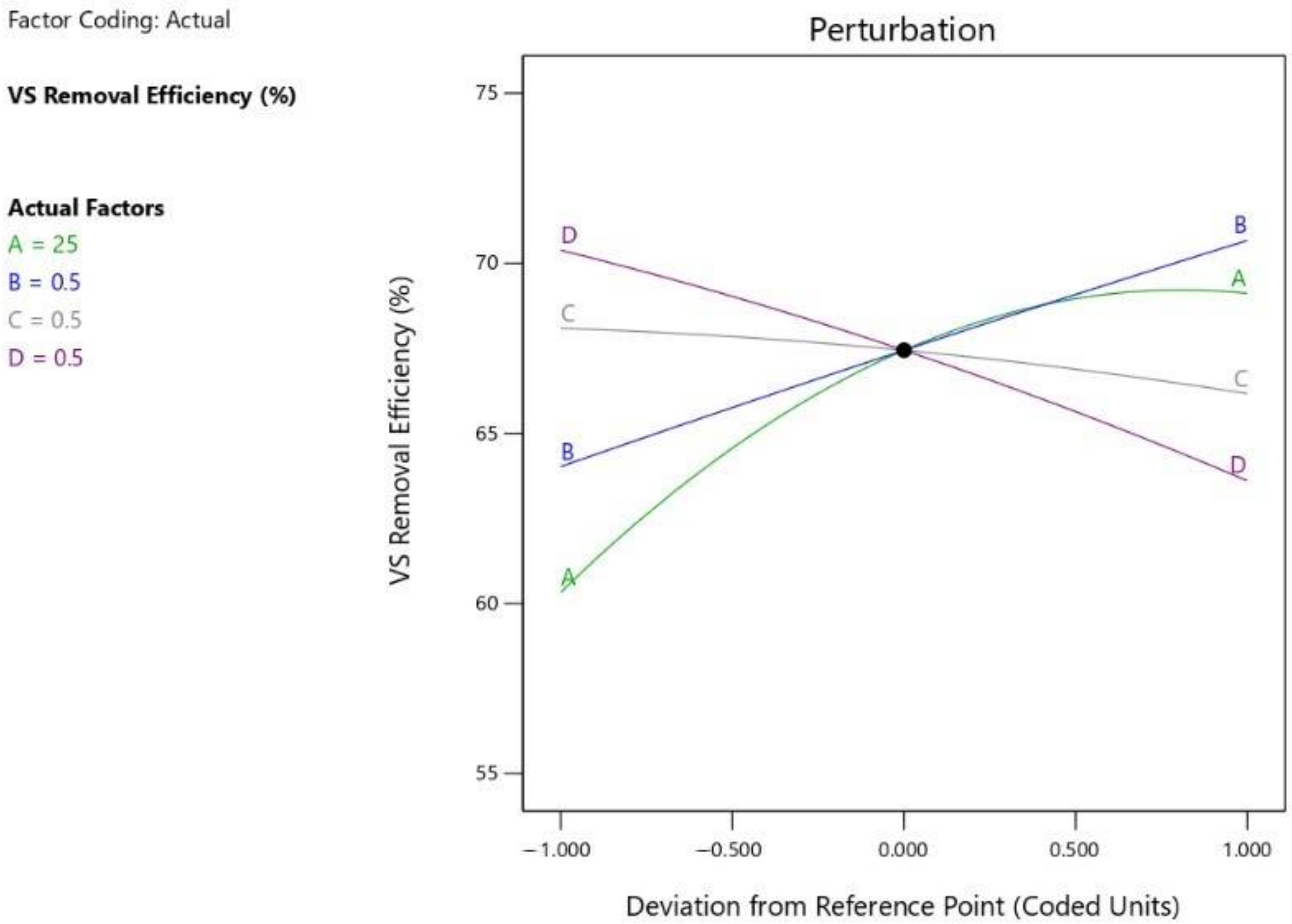

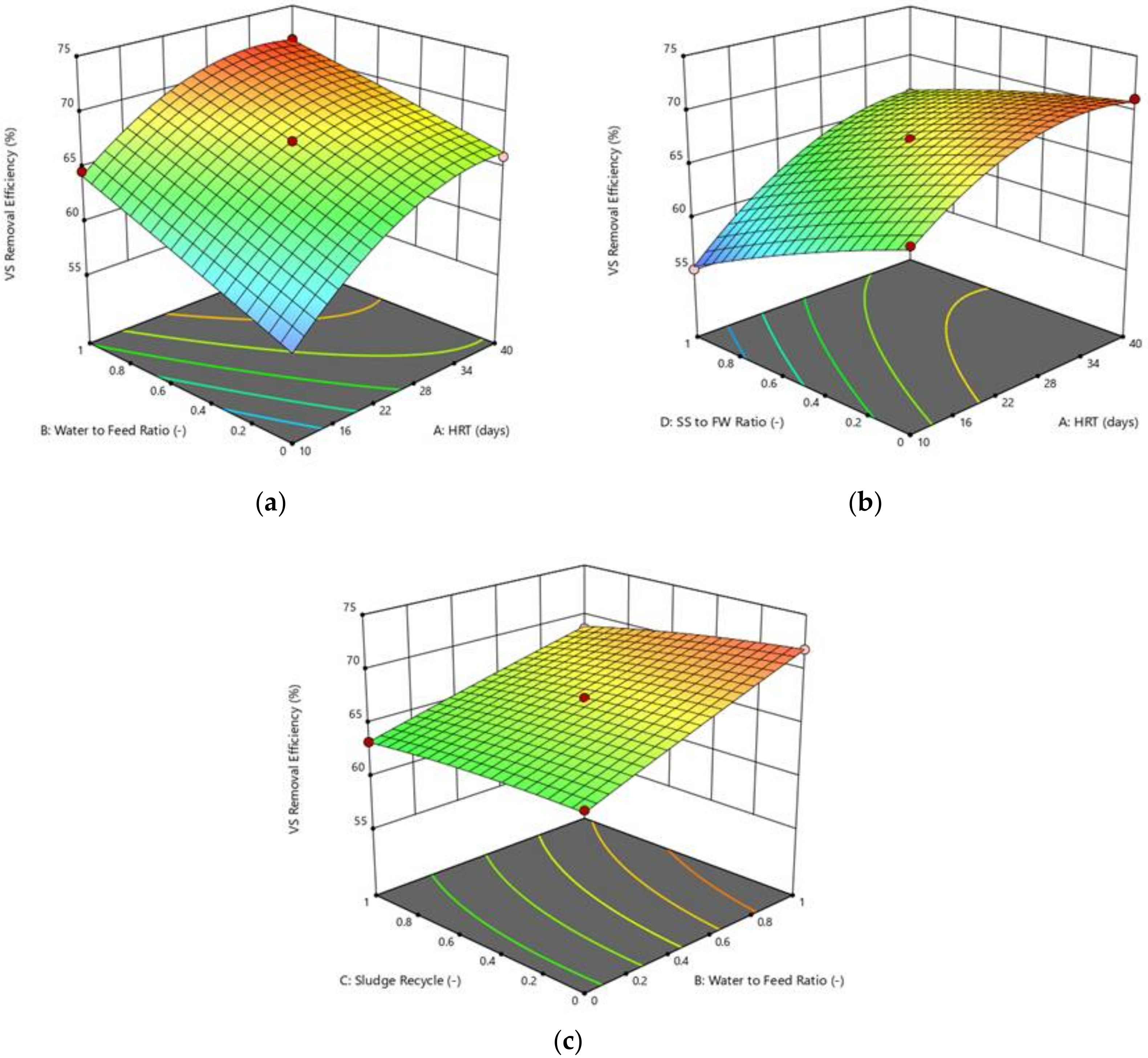

3.3. Effect of HRT, Water to Feed Ratio (kg/kg), Sludge Recycle Ratio and the SS to FW Ratio (kg/kg) on Volatile Solids (VS) Removal Efficiency

3.4. Numerical Optimization Results

3.5. Simulation Results

3.6. Economic Analysis

3.6.1. Economic Analysis Results

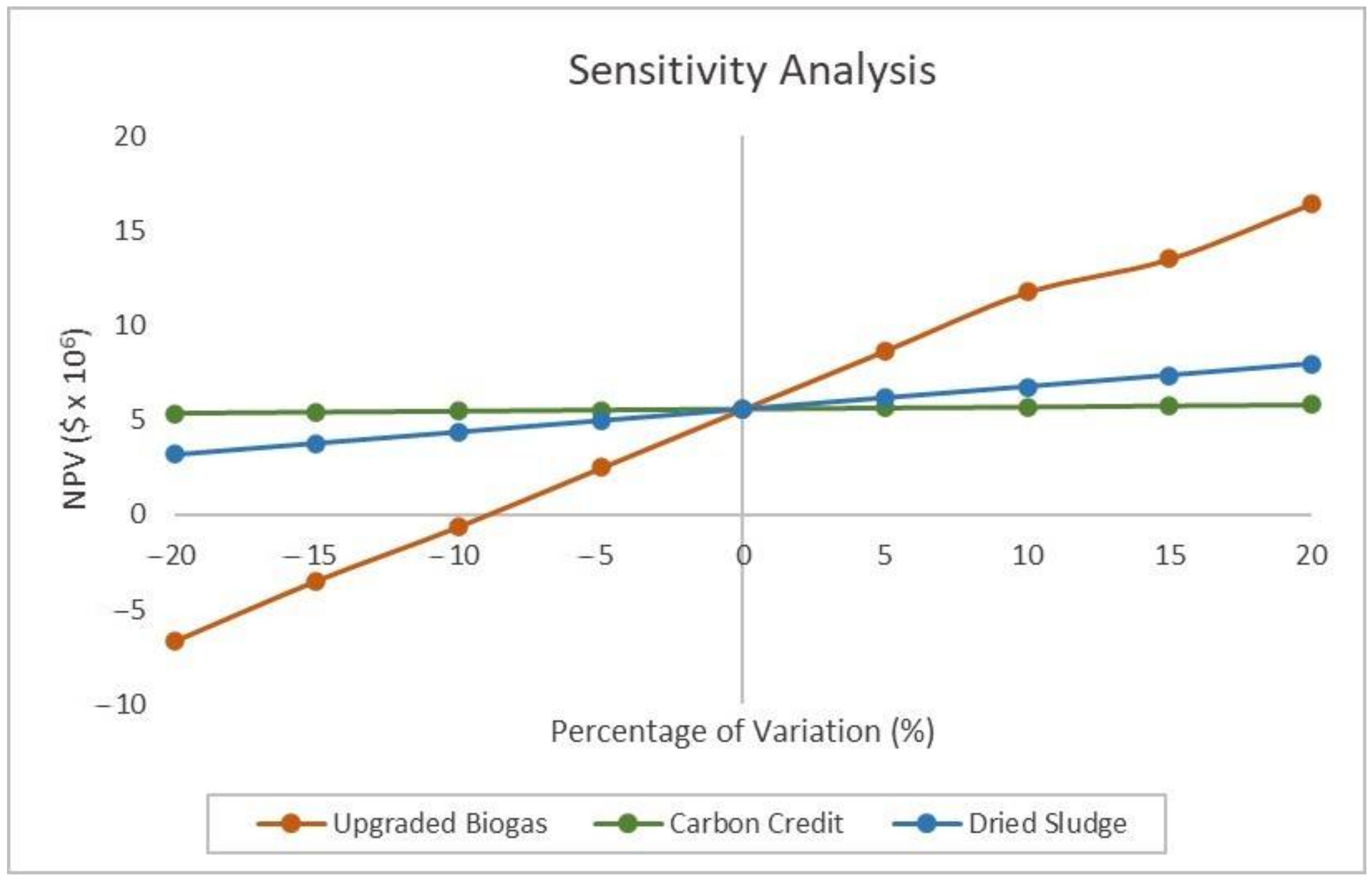

3.6.2. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Component | Food Waste | Sewage Sludge | ||

|---|---|---|---|---|

| Mass Flow (kg/h) | Composition (wt %) | Mass Flow (kg/h) | Composition (wt %) | |

| Moisture | 19,221.92 | 80.3 | 890.30 | 83.80 |

| Ash | 454.82 | 1.90 | 40.37 | 3.80 |

| Carbohydrates | 2576.36 | 10.76 | 10.04 | 0.95 |

| Proteins | 939.22 | 3.92 | 101.62 | 9.56 |

| Lipids | 676.41 | 2.83 | 20.08 | 1.89 |

| Biomass | 68.94 | 0.29 | 0.00 | 0.00 |

| Total | 23,937.64 | 100.00 | 1062.41 | 100.00 |

| Equipment | Parameter | Unit | Value | Source |

|---|---|---|---|---|

| Sterilizer | Sterilization temperature | °C | 121 | [29] |

| Anaerobic digester | Operating temperature | °C | 35 | [31] |

| Retention time | h | 931.2 | Optimisation | |

| Dehumidifier | Operating temperature | °C | 5 | [68] |

| Aerobic pond | Retention time | h | 48 | [39] |

| Secondary clarifier | Coagulant flowrate | kg/h | 40.4 | [69] |

| Run | A: HRT (Days) | B: Water to Feed Ratio | C: Sludge Recycle Ratio | D: Sewage Sludge to Food Waste Ratio |

|---|---|---|---|---|

| 1 | 25 | 0 | 1 | 0.5 |

| 2 | 25 | 0.5 | 1 | 0 |

| 3 | 40 | 0.5 | 0 | 0.5 |

| 4 | 25 | 0 | 0.5 | 1 |

| 5 | 40 | 0.5 | 0.5 | 1 |

| 6 | 40 | 1 | 0.5 | 0.5 |

| 7 | 25 | 0.5 | 0.5 | 0.5 |

| 8 | 25 | 0.5 | 0.5 | 0.5 |

| 9 | 10 | 0.5 | 1 | 0.5 |

| 10 | 40 | 0.5 | 1 | 0.5 |

| 11 | 40 | 0 | 0.5 | 0.5 |

| 12 | 25 | 1 | 0.5 | 1 |

| 13 | 25 | 0.5 | 1 | 1 |

| 14 | 25 | 0.5 | 0.5 | 0.5 |

| 15 | 10 | 0.5 | 0.5 | 1 |

| 16 | 25 | 1 | 0.5 | 0 |

| 17 | 10 | 0.5 | 0.5 | 0 |

| 18 | 25 | 1 | 0 | 0.5 |

| 19 | 25 | 0.5 | 0.5 | 0.5 |

| 20 | 25 | 0.5 | 0 | 1 |

| 21 | 25 | 0 | 0 | 0.5 |

| 22 | 25 | 0.5 | 0 | 0 |

| 23 | 25 | 1 | 1 | 0.5 |

| 24 | 40 | 0.5 | 0.5 | 0 |

| 25 | 10 | 0 | 0.5 | 0.5 |

| 26 | 10 | 1 | 0.5 | 0.5 |

| 27 | 25 | 0.5 | 0.5 | 0.5 |

| 28 | 25 | 0 | 0.5 | 0 |

| 29 | 10 | 0.5 | 0 | 0.5 |

| Component | Composition (vol %) | |

|---|---|---|

| Literature | Simulations | |

| Methane | 55–65 | 59.16 |

| Carbon dioxide | 35–45 | 35.02 |

| Hydrogen sulfide | 0–1 | 0.74 |

| Moisture | 1–5 | 3.59 |

| Equipment | Capacity Measure | Unit Capacity | Unit Cost ($) | Source |

|---|---|---|---|---|

| Anaerobic digester | Vessel volume (L) | 14,162,231.27 | 1,696,000 | [70] |

| Bio-trickling filter | Surface area (m2) | 0.219 | 113,000 | [32] |

| Dehumidifier | Condensation area (m2) | 7.96 | 45,000 | Simulations |

| Primary clarifier | Surface area (m2) | 61.45 | 73,000 | [32] |

| Secondary clarifier | Surface area (m2) | 57.41 | 73,000 | [32] |

| Aerobic pond | Vessel volume (L) | 1,132,596.36 | 272,000 | [70] |

| Granular media filter | Volume (L) | 0.42 | 13,000 | [32] |

| Belt press filter | Belt width (m) | 2.37 | 75,000 | [32] |

| Sludge dryer | Evaporative capacity (kg/h) | 1980.33 | 42,000 | Simulations |

| Unlisted equipment | - | 374,000 | Simulations |

References

- Jeong, Y.; Hermanowicz, S.W.; Park, C. Treatment of food waste recycling wastewater using anaerobic ceramic membrane bioreactor for biogas production in mainstream treatment process of domestic wastewater. Water Res. 2017, 123, 86–95. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, S.K.; Suja, F.B.; Porhemmat, M.; Pramanik, B.K. Performance and Kinetic Model of a Single-Stage Anaerobic Digestion System Operated at Different Successive Operating Stages for the Treatment of Food Waste. Processes 2019, 7, 600. [Google Scholar] [CrossRef] [Green Version]

- Martin-Rios, C.; Demen-Meier, C.; Gössling, S.; Cornuz, C. Food waste management innovations in the foodservice industry. Waste Manag. 2018, 79, 196–206. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Green Technology Master Plan Malaysia 2017–2030, Ministry of Energy, Green Technology and Water (KeTTHA), 12 October 2017. Available online: https://www.pmo.gov.my/wp-content/uploads/2019/07/Green-Technology-Master-Plan-Malaysia-2017-2030.pdf (accessed on 7 May 2021).

- Aday, S.; Aday, M.S. Impact of COVID-19 on the food supply chain. Food Qual. Saf. 2020, 4, 167–180. [Google Scholar] [CrossRef]

- Lim, J.S.; Manan, Z.A.; Alwi, S.R.W.; Hashim, H. A review on utilisation of biomass from rice industry as a source of renewable energy. Renew. Sustain. Energy Rev. 2012, 16, 3084–3094. [Google Scholar] [CrossRef]

- Deepanraj, B.; Sivasubramanian, V.; Jayaraj, S. Experimental and kinetic study on anaerobic digestion of food waste: The effect of total solids and pH. J. Renew. Sustain. Energy 2015, 7, 063104. [Google Scholar] [CrossRef]

- Xu, F.; Li, Y.; Ge, X.; Yang, L.; Li, Y. Anaerobic digestion of food waste—Challenges and opportunities. Bioresour. Technol. 2018, 247, 1047–1058. [Google Scholar] [CrossRef]

- Tahri, A.; Kalloum, S.; Baba Amer, Z. Optimization of Hydraulic Retention Time for the Methanisation of Household Waste in the Town of Adrar (the south-west of Algeria). 2018. Available online: https://sphinxsai.com/2018/ch_vol11_no1/1/(75-82)V11N01CT.pdf (accessed on 21 January 2022).

- Smith, A.L.; Stadler, L.B.; Cao, L.; Love, N.G.; Raskin, L.; Skerlos, S.J. Navigating Wastewater Energy Recovery Strategies: A Life Cycle Comparison of Anaerobic Membrane Bioreactor and Conventional Treatment Systems with Anaerobic Digestion. Environ. Sci. Technol. 2014, 48, 5972–5981. [Google Scholar] [CrossRef]

- Cha, M.; Kim, S.; Park, C. Recent advances and future potential of anaerobic ceramic membrane bioreactors for wastewater treatment: A review. Membr. Water Treat. 2020, 11, 31–39. [Google Scholar]

- Capson-Tojo, G.; Rouez, M.; Crest, M.; Steyer, J.-P.; Delgenès, J.-P.; Escudié, R. Food waste valorization via anaerobic processes: A review. Rev. Environ. Sci. BioTechnol. 2016, 15, 499–547. [Google Scholar] [CrossRef]

- Pramanik, S.K.; Suja, F.B.; Zain, S.M.; Pramanik, B.K. The anaerobic digestion process of biogas production from food waste: Prospects and constraints. Bioresour. Technol. Rep. 2019, 8, 100310. [Google Scholar] [CrossRef]

- Mehariya, S.; Patel, A.K.; Obulisamy, P.K.; Punniyakotti, E.; Wong, J.W. Co-digestion of food waste and sewage sludge for methane production: Current status and perspective. Bioresour. Technol. 2018, 265, 519–531. [Google Scholar] [CrossRef] [PubMed]

- Prabhu, M.; Mutnuri, S. Anaerobic co-digestion of sewage sludge and food waste. Waste Manag. Res. 2016, 34, 307–315. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Huang, T.; Li, X.; Huang, J.; Peng, D.; Maurer, C.; Kranert, M. Experiments and Modeling for Flexible Biogas Production by Co-Digestion of Food Waste and Sewage Sludge. Energies 2020, 13, 818. [Google Scholar] [CrossRef] [Green Version]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anaerobic Co-Digestion of Wastewater Sludge: A Review of Potential Co-Substrates and Operating Factors for Improved Methane Yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.-Q.; Koike, Y.; Liu, K.; An, M.-Z.; Morimura, S.; Wu, X.-L.; Kida, K. Ethanol production from kitchen waste using the flocculating yeast Saccharomyces cerevisiae strain KF-7. Biomass Bioenergy 2008, 32, 1037–1045. [Google Scholar] [CrossRef]

- Inoue, S.; Sawayama, S.; Ogi, T.; Yokoyama, S.-Y. Organic composition of liquidized sewage sludge. Biomass Bioenergy 1996, 10, 37–40. [Google Scholar] [CrossRef]

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimisation of the anaerobic digestion of agricultural resources. Bioresour. Technol. 2008, 99, 7928–7940. [Google Scholar] [CrossRef]

- Al Naami, A. Techno-economic Feasibility Study of a Biogas Plant for Treating Food Waste Collected from Households in Kartamantul Region, Yogyakarta. Master’s Thesis, KTH School of Industrial Engineering and Management, Sweden, 2017. Available online: https://kth.diva-portal.org/smash/get/diva2:1209090/FULLTEXT02.pdf (accessed on 21 January 2022).

- Tyagi, V.K.; Khan, A.A.; Jern, N.W.; Khursheed, A.; Kazmi, A.A. Post Treatments of Anaerobically Treated Effluents; IWA Publishing: London, UK, 2019. [Google Scholar]

- Kang, A.J.; Yuan, Q. Enhanced Anaerobic Digestion of Organic Waste. In Solid Waste Management in Rural Areas; InTech: Vienna, Austria, 2017. [Google Scholar]

- Jiang, J.; He, S.; Kang, X.; Sun, Y.; Yuan, Z.; Xing, T.; Guo, Y.; Li, L. Effect of Organic Loading Rate and Temperature on the Anaerobic Digestion of Municipal Solid Waste: Process Performance and Energy Recovery. Front. Energy Res. 2020, 8, 89. [Google Scholar] [CrossRef]

- Aguilar, M.C.; Wang, Y.; Roskilly, T.; Pathare, P.B.; Lamidi, R.O. Biogas from anaerobic co-digestion of food waste and primary sludge for cogeneration of power and heat. Energy Procedia 2017, 142, 70–76. [Google Scholar] [CrossRef]

- Ismail, M.H.; Ghazi, T.I.M.; Hamzah, M.H.; Manaf, L.A.; Tahir, R.M.; Nasir, A.M.; Omar, A.E. Impact of Movement Control Order (MCO) due to Coronavirus Disease (COVID-19) on Food Waste Generation: A Case Study in Klang Valley, Malaysia. Sustainability 2020, 12, 8848. [Google Scholar] [CrossRef]

- Ren, Y.; Yu, M.; Wu, C.; Wang, Q.; Gao, M.; Huang, Q.; Liu, Y. A comprehensive review on food waste anaerobic digestion: Research updates and tendencies. Bioresour. Technol. 2018, 247, 1069–1076. [Google Scholar] [CrossRef] [PubMed]

- Izumi, K.; Okishio, Y.-K.; Nagao, N.; Niwa, C.; Yamamoto, S.; Toda, T. Effects of particle size on anaerobic digestion of food waste. Int. Biodeterior. Biodegrad. 2010, 64, 601–608. [Google Scholar] [CrossRef]

- Lee, B.; Park, J.-G.; Shin, W.-B.; Kim, B.-S.; Byun, B.-S.; Jun, H.-B. Maximizing biogas production by pretreatment and by optimizing the mixture ratio of co-digestion with organic wastes. Environ. Eng. Res. 2019, 24, 662–669. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Duong, T.H.; Smits, M.; Verstraete, W.; Carballa, M. Enhanced biomethanation of kitchen waste by different pre-treatments. Bioresour. Technol. 2011, 102, 592–599. [Google Scholar] [CrossRef]

- Kondusamy, D.; Kalamdhad, A.S. Pre-treatment and anaerobic digestion of food waste for high rate methane production-A review. J. Environ. Chem. Eng. 2014, 2, 1821–1830. [Google Scholar] [CrossRef]

- Lok, X.; Chan, Y.J.; Foo, D.C. Simulation and optimisation of full-scale palm oil mill effluent (POME) treatment plant with biogas production. J. Water Process. Eng. 2020, 38, 101558. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Tsapekos, P.; Alfaro, N.; Diaz, I.; Fdz-Polanco, M.; Rafiee, S.; Angelidaki, I. A review on prospects and challenges of biological H2S removal from biogas with focus on biotrickling filtration and microaerobic desulfurization. Biofuel Res. J. 2017, 16, 741–750. [Google Scholar] [CrossRef] [Green Version]

- Syed, M.; Soreanu, G.; Falletta, P.; Béland, M. Removal of hydrogen sulfide from gas streams using biological processes-a review. Can. Biosyst. Eng. 2006, 48, 2. [Google Scholar]

- Huertas, J.K.; Quipuzco, L.; Hassanein, A.; Lansing, S. Comparing Hydrogen Sulfide Removal Efficiency in a Field-Scale Digester Using Microaeration and Iron Filters. Energies 2020, 13, 4793. [Google Scholar] [CrossRef]

- Petersson, A.; Wellinger, A. Biogas upgrading technologies-developments and innovations Task 37-Energy from biogas and landfill gas. IEA Bioenergy 2009, 20, 1–19. [Google Scholar]

- Sri, A.; Karsiwulan, D.; Yuwono, H.; Trisnawati, I.; Mulyasari, S.; Rahardjo, H.; Hokermin, S.; Paramita, V. Handbook POME-to-Biogas Project Development in Indonesia; Winlock International: Jakarta, Indonesia, 2015; Available online: https://winrock.org/wp-content/uploads/2016/05/CIRCLE-Handbook-2nd-Edition-EN-25-Aug-2015-MASTER-rev02-final-new02-edited.pdf (accessed on 21 January 2022).

- Metcalf, I.; Eddy, T.; George, L.B.; Franklin, H.D.; Franklin, B. Wastewater Engineering: Treatment and Reuse, 4th ed.; McGraw-Hill Education: Berkshire, UK, 2003. [Google Scholar]

- Butler, E.B.; Hung, Y.-T.; Al Ahmad, M.S.; Yeh, R.Y.-L.; Liu, R.L.-H.; Fu, Y.-P. Oxidation pond for municipal wastewater treatment. Appl. Water Sci. 2017, 7, 31–51. [Google Scholar] [CrossRef] [Green Version]

- Wang, N.-X.; Lu, X.-Y.; Tsang, Y.-F.; Mao, Y.; Tsang, C.-W.; Yueng, V.A. A comprehensive review of anaerobic digestion of organic solid wastes in relation to microbial community and enhancement process. J. Sci. Food Agric. 2019, 99, 507–516. [Google Scholar] [CrossRef] [PubMed]

- Liwarska-Bizukojc, E.; Bizukojc, M.; Ledakowicz, S. Kinetics of the aerobic biological degradation of shredded municipal solid waste in liquid phase. Water Res. 2002, 36, 2124–2132. [Google Scholar] [CrossRef]

- Environmental Quality (Sewage) Regulations 2009. 2009. Available online: https://www.doe.gov.my/portalv1/wp-content/uploads/2015/01/Environmental_Quality_Sewage_Regulations_2009_-_P.U.A_432-2009.pdf (accessed on 8 May 2021).

- Said, K.A.M.; Amin, M.A.M. Overview on the Response Surface Methodology (RSM) in Extraction Processes. J. Appl. Sci. Process. Eng. 2016, 2, 8–17. [Google Scholar]

- Raghupathy, R.; Amirthagadeswaran, K.S. Optimization of casting process based on box behnken design and response surface methodology. Int. J. Qual. Res. 2014, 8, 569–582. [Google Scholar]

- Thenabadu, M. Anaerobic Digestion of Food and Market Waste; Waste Characterisation, Biomethane Potential and Bio Reactor Design: A Case Study in Sri Lanka. Master’s Thesis, University of Gavle, Sweden, 2010. Available online: https://www.diva-portal.org/smash/get/diva2:854121/FULLTEXT02 (accessed on 21 January 2022).

- Liu, X.; Khalid, H.; Amin, F.R.; Ma, X.; Li, X.; Chen, C.; Liu, G. Effects of hydraulic retention time on anaerobic digestion performance of food waste to produce methane as a biofuel. Environ. Technol. Innov. 2018, 11, 348–357. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dzienis, L.; Dębowski, M.; Zieliński, M. Optimisation of methane fermentation as a valorisation method for food waste products. Biomass Bioenergy 2021, 144, 105913. [Google Scholar] [CrossRef]

- Magdalena, J.A.; Greses, S.; González-Fernández, C. Impact of Organic Loading Rate in Volatile Fatty Acids Production and Population Dynamics Using Microalgae Biomass as Substrate. Sci. Rep. 2019, 9, 18374. [Google Scholar] [CrossRef]

- Jain, S.; Singh, V.P. Chapter 13 Water quality modeling. In Developments in Water Science; Elsevier: Amsterdam, The Netherlands, 2003; Volume 51, pp. 743–786. [Google Scholar]

- Hallaji, S.M.; Kuroshkarim, M.; Moussavi, S.P. Enhancing methane production using anaerobic co-digestion of waste activated sludge with combined fruit waste and cheese whey. BMC Biotechnol. 2019, 19, 19. [Google Scholar] [CrossRef]

- Tak, B.-Y.; Tak, B.-S.; Kim, Y.-J.; Park, Y.-J.; Yoon, Y.-H.; Min, G.-H. Optimization of color and COD removal from livestock wastewater by electrocoagulation process: Application of Box–Behnken design (BBD). J. Ind. Eng. Chem. 2015, 28, 307–315. [Google Scholar] [CrossRef] [Green Version]

- Chastain, J.P.; Smith, W.B. Determination of the Anaerobic Volatile Solids Reduction Ratio of Animal Manure Using a Bench Scale Batch Reactor. In Proceedings of the 2015 ASABE International Meeting, New Orleans, LA, USA, 26–29 July 2015; p. 1. [Google Scholar]

- Lee, D.-J.; Lee, S.-Y.; Bae, J.-S.; Kang, J.-G.; Kim, K.-H.; Rhee, S.-S.; Park, J.-H.; Cho, J.-S.; Chung, J.; Seo, D.-C. Effect of Volatile Fatty Acid Concentration on Anaerobic Degradation Rate from Field Anaerobic Digestion Facilities Treating Food Waste Leachate in South Korea. J. Chem. 2015, 2015, 640717. [Google Scholar] [CrossRef] [Green Version]

- Chua, K.H.; Cheah, W.L.; Tan, C.F.; Leong, Y.P. Harvesting biogas from wastewater sludge and food waste. IOP Conf. Ser. Earth Environ. Sci. 2013, 16, 12118. [Google Scholar] [CrossRef] [Green Version]

- Kazimierowicz, J.; Zieliński, M.; Dębowski, M. Influence of the Heating Method on the Efficiency of Biomethane Production from Expired Food Products. Fermentation 2021, 7, 12. [Google Scholar] [CrossRef]

- Shoener, B.D.; Zhong, C.; Greiner, A.D.; Khunjar, W.O.; Hong, P.-Y.; Guest, J.S. Design of anaerobic membrane bioreactors for the valorization of dilute organic carbon waste streams. Energy Environ. Sci. 2016, 9, 1102–1112. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Lv, C.; Tong, J.; Liu, J.; Liu, J.; Yu, D.; Wang, Y.; Chen, M.; Wei, Y. Optimization and microbial community analysis of anaerobic co-digestion of food waste and sewage sludge based on microwave pretreatment. Bioresour. Technol. 2016, 200, 253–261. [Google Scholar] [CrossRef]

- Whiting, A.; Azapagic, A. Life cycle environmental impacts of generating electricity and heat from biogas produced by anaerobic digestion. Energy 2014, 70, 181–193. [Google Scholar] [CrossRef]

- Couper, J.R.; Penney, W.R.; Fair, J.R.; Walas, S.M. Introduction. In Chemical Process Equipment, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2012; pp. 1–16. [Google Scholar]

- Yousuf, A.; Khan, M.R.; Pirozzi, D.; Wahid, Z.A.; Atnaw, S.M. Economic and Market Value of Biogas Technology. In Waste Biomass Management–A Holistic Approach; Springer International Publishing: Cham, Switzerland, 2017; pp. 137–158. [Google Scholar]

- Yong, Z.J.; Bashir, M.J.; Hassan, M.S. Assessment of environmental, energy and economic prospective of anaerobic digestion of organic municipal solid waste in Malaysia. IOP Conf. Ser. Earth Environ. Sci. 2020, 463, 12054. [Google Scholar] [CrossRef]

- Rao, T.; Mustapa, S. A Review of Climate Economic Models in Malaysia. Sustainability 2021, 13, 325. [Google Scholar] [CrossRef]

- Gebbie, P. Earth Tech Engineering. 2006. Available online: http://wioa.org.au/conference_papers/06_qld/documents/PeterGebbie.pdf (accessed on 21 January 2022).

- Towler, G.; Sinnott, R. Chemical Engineering Design: Principles, Practice and Economics of Plant and Process Design, 2nd ed.; Elsevier Ltd.: Waltham, MA, USA, 2013. [Google Scholar]

- Chans, S. An Analysis of the Feasibility of Anaerobic Digestion on Small-Scale Dairies in Utah; Utah State University: Logan, UT, USA, 2016. [Google Scholar]

- Mohammed, M.; Egyir, I.; Donkor, A.; Amoah, P.; Nyarko, S.; Boateng, K.; Ziwu, C. Feasibility study for biogas integration into waste treatment plants in Ghana. Egypt. J. Pet. 2016, 26, 695–703. [Google Scholar] [CrossRef] [Green Version]

- Al Seadi, T. Biogas Handbook; University of Southern Denmark Esbjerg: Esbjerg, Denmark, 2008. [Google Scholar]

- De Arespacochaga, N.; Valderrama, C.; Mesa, C.; Bouchy, L.; Cortina, J.L. Biogas deep clean-up based on adsorption technologies for Solid Oxide Fuel Cell applications. Chem. Eng. J. 2014, 255, 593–603. [Google Scholar] [CrossRef]

- Rowe, J. Chemical Feed Calculations in Water Treatment Processes-Workforce LibreTexts. 2020. Available online: https://workforce.libretexts.org/Bookshelves/Water_Systems_Technology/Water_151%3A_Water_Treatment_Plant_and_Operation_Processes_II_(Rowe)/01%3A_Chapters/1.01%3A_Chemical_Feed_Calculations_In_Water_Treatment_Processes (accessed on 9 May 2021).

- Smith, R. Chemical Process: Design and Integration; John Wiley & Sons: New York, NY, USA, 2005. [Google Scholar]

| Component | Composition (%) | |

|---|---|---|

| Food Waste | Sewage Sludge | |

| Moisture | 80.3 | 83.8 |

| Total solids | 19.7 | 12.4 |

| Ash | 1.9 | 3.8 |

| Volatile solids | 18.8 | 9.7 |

| Carbohydrates | 59.8 | 3.3 |

| Protein | 21.8 | 33.4 |

| Lipids | 15.7 | 6.6 |

| Parameter | µMax (1/h) | Ks (mg/L) | Source |

|---|---|---|---|

| Anaerobic digestion | |||

| Carbohydrates | 0.052 | 465 | [40] |

| Protein | 0.033 | 465 | [40] |

| Lipids | 0.029 | 465 | [40] |

| Aerobic digestion | 0.126 | 21.23 | [41] |

| Independent Variables | Annotation | Unit | Lower Bound | Upper Bound |

|---|---|---|---|---|

| HRT | A | days | 10 | 40 |

| Water to feed ratio | B | - | 0 | 1 |

| Sludge recycle ratio | C | - | 0 | 1 |

| Sewage sludge to food waste ratio | D | - | 0 | 1 |

| Source | df | Sum of Squares | Mean Squares | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 14 | 1.17 × 106 | 83,277.40 | 18,008.96 | <0.0001 | Significant |

| A-HRT | 1 | 3.07 × 105 | 3.07 × 105 | 66,292.88 | <0.0001 | Significant |

| B-Water to Feed Ratio | 1 | 74,351.11 | 16,078.63 | <0.0001 | Significant | |

| C-Sludge Recycle Ratio | 1 | 21,333.09 | 4613.34 | <0.0001 | Significant | |

| D- SS to FW Ratio | 1 | 4.36 × 105 | 94,185.27 | <0.0001 | Significant | |

| AB | 1 | 5.76 | 1.25 | 0.2904 | ||

| AC | 1 | 78.73 | 17.03 | 0.0021 | ||

| AD | 1 | 860.51 | 186.09 | <0.0001 | ||

| BC | 1 | 75.86 | 16.40 | 0.0023 | ||

| BD | 1 | 1.21 | 0.2617 | 0.6201 | ||

| CD | 1 | 112.34 | 24.29 | 0.0006 | ||

| A2 | 1 | 89,639.28 | 19,384.74 | <0.0001 | ||

| B2 | 1 | 441.80 | 95.54 | <0.0001 | ||

| C2 | 1 | 0.8471 | 0.1832 | 0.6777 | ||

| D2 | 1 | 2134.19 | 461.52 | <0.0001 |

| Source | Sum of Squares | Mean Squares | F-Value | p-Value | |

|---|---|---|---|---|---|

| Model | 602.82 | 43.06 | 143.38 | <0.0001 | Significant |

| A-HRT | 314.14 | 314.14 | 1046.07 | <0.0001 | Significant |

| B-Water to Feed Ratio | 20.15 | 20.15 | 67.11 | <0.0001 | Significant |

| C-Sludge Recycle Ratio | 17.44 | 17.44 | 58.07 | <0.0001 | Significant |

| D-SS to FW Ratio | 163.77 | 163.77 | 545.33 | <0.0001 | Significant |

| AB | 0.9708 | 0.9708 | 3.23 | 0.0974 | |

| AC | 2.91 | 2.91 | 9.68 | 0.0090 | |

| AD | 10.05 | 10.05 | 33.47 | <0.0001 | |

| BC | 0.1226 | 0.1226 | 0.4083 | 0.5348 | |

| BD | 0.7206 | 0.7206 | 2.40 | 0.1473 | |

| CD | 3.47 | 3.47 | 11.54 | 0.0053 | |

| A2 | 69.52 | 69.52 | 231.49 | <0.0001 | |

| B2 | 0.3212 | 0.3212 | 1.07 | 0.3214 | |

| C2 | 2.82 | 2.82 | 9.41 | 0.0098 | |

| D2 | 2.88 | 2.88 | 9.58 | 0.0093 |

| Source | Sum of Squares | Mean Squares | F-Value | p-Value | |

|---|---|---|---|---|---|

| Model | 469.64 | 33.55 | 338.62 | <0.0001 | Significant |

| A-HRT | 191.64 | 191.64 | 1934.49 | <0.0001 | Significant |

| B-Water to Feed Ratio | 109.60 | 109.60 | 1106.30 | <0.0001 | Significant |

| C-Sludge Recycle Ratio | 9.14 | 9.14 | 92.27 | <0.0001 | Significant |

| D- SS to FW Ratio | 113.95 | 113.95 | 1150.25 | <0.0001 | Significant |

| AB | 1.22 | 1.22 | 12.33 | 0.0043 | |

| AC | 0.7887 | 0.7887 | 7.96 | 0.0154 | |

| AD | 5.77 | 5.77 | 58.26 | <0.0001 | |

| BC | 1.24 | 1.24 | 12.50 | 0.0041 | |

| BD | 2.19 | 2.19 | 22.13 | 0.0005 | |

| CD | 0.6744 | 0.6744 | 6.81 | 0.0228 | |

| A2 | 41.28 | 41.28 | 416.72 | <0.0001 | |

| B2 | 0.0525 | 0.0525 | 0.5298 | 0.4807 | |

| C2 | 0.5517 | 0.5517 | 5.57 | 0.0361 | |

| D2 | 1.12 | 1.12 | 11.26 | 0.0057 |

| HRT (Days) | Water to Feed Ratio | Sludge Recycle Ratio | SS to FW Ratio | Methane Flow (kg/h) | COD Removal Efficiency (%) | VS Removal Efficiency (%) |

|---|---|---|---|---|---|---|

| 38.8 | 0.047 | 0.438 | 0.044 | 1495.25 | 81.8 | 69.2 |

| Parameter | Base Case | Optimized Case | Percentage Improvements (%) |

|---|---|---|---|

| Methane flow | 979.06 kg/h | 1494.23 kg/h | 52.6 |

| COD removal efficiency | 70.90% | 81.50% | 15.0 |

| VS removal efficiency | 59.40% | 69.20% | 16.5 |

| Methane yield | 0.25 L CH4/g COD removed | 0.29 L CH4/g COD removed | 16.0 |

| Component | Before Upgrading | After Upgrading | ||

|---|---|---|---|---|

| Mass Flow (kg/h) | Composition (wt %) | Mass Flow (kg/h) | Composition (wt %) | |

| Methane | 1494.23 | 37.51 | 1494.230 | 38.86 |

| Carbon dioxide | 2349.77 | 58.98 | 2349.770 | 61.11 |

| Hydrogen sulfide | 39.47 | 0.99 | 0.001 | 0.00 |

| Moisture | 100.62 | 2.52 | 1.080 | 0.03 |

| Total | 3984.08 | 100.00 | 3845.08 | 100.00 |

| Parameter | Unit | Value |

|---|---|---|

| Ammonia | kg/h | 39.47 |

| Ash | kg/h | 0.21 |

| Biomass | kg/h | 0.23 |

| Carbohydrates | kg/h | 0.00 |

| Dead biomass | kg/h | 0.33 |

| Fats | kg/h | 0.00 |

| Proteins | kg/h | 0.00 |

| COD | mg/L | 14.04 |

| BOD5 | mg/L | 8.78 |

| Item | Unit | Category | Values | Source |

|---|---|---|---|---|

| Upgraded biogas | $/kg | Revenue | 0.360 | [60] |

| Dried sludge | $/kg | Revenue | 0.132 | [61] |

| Carbon credit | $/kg | Revenue | 0.007 | [62] |

| Coagulant | $/kg | Operating Cost | 0.450 | [63] |

| Aqueous waste | $/kg | Operating Cost | 0.002 | [64] |

| Item | Unit | Values |

|---|---|---|

| Total capital investment | $ | 19,694,000 |

| Operating cost | $/yr | 11,062,000 |

| Total revenues | $/yr | 13,445,000 |

| Cost basis annual rate | kg MP/yr | 30,760,628 |

| Unit production cost | $/kg MP | 0.36 |

| Unit production revenue | $/kg MP | 0.44 |

| Gross margin | % | 17.72 |

| Return on investment (ROI) | % | 16.02 |

| Payback period | year | 6.24 |

| Internal rate of return (IRR) | % | 10.23 |

| Net present value (NPV) | $ | 5,283,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheong, W.L.; Chan, Y.J.; Tiong, T.J.; Chong, W.C.; Kiatkittipong, W.; Kiatkittipong, K.; Mohamad, M.; Daud, H.; Suryawan, I.W.K.; Sari, M.M.; et al. Anaerobic Co-Digestion of Food Waste with Sewage Sludge: Simulation and Optimization for Maximum Biogas Production. Water 2022, 14, 1075. https://doi.org/10.3390/w14071075

Cheong WL, Chan YJ, Tiong TJ, Chong WC, Kiatkittipong W, Kiatkittipong K, Mohamad M, Daud H, Suryawan IWK, Sari MM, et al. Anaerobic Co-Digestion of Food Waste with Sewage Sludge: Simulation and Optimization for Maximum Biogas Production. Water. 2022; 14(7):1075. https://doi.org/10.3390/w14071075

Chicago/Turabian StyleCheong, Wai Lin, Yi Jing Chan, Timm Joyce Tiong, Woon Chan Chong, Worapon Kiatkittipong, Kunlanan Kiatkittipong, Mardawani Mohamad, Hanita Daud, I. Wayan Koko Suryawan, Mega Mutiara Sari, and et al. 2022. "Anaerobic Co-Digestion of Food Waste with Sewage Sludge: Simulation and Optimization for Maximum Biogas Production" Water 14, no. 7: 1075. https://doi.org/10.3390/w14071075

APA StyleCheong, W. L., Chan, Y. J., Tiong, T. J., Chong, W. C., Kiatkittipong, W., Kiatkittipong, K., Mohamad, M., Daud, H., Suryawan, I. W. K., Sari, M. M., & Lim, J. W. (2022). Anaerobic Co-Digestion of Food Waste with Sewage Sludge: Simulation and Optimization for Maximum Biogas Production. Water, 14(7), 1075. https://doi.org/10.3390/w14071075