Analytical Framework for Understanding the Differences between Technical Standards Originating from Various Regions to Improve International Hydropower Project Delivery

Abstract

1. Introduction

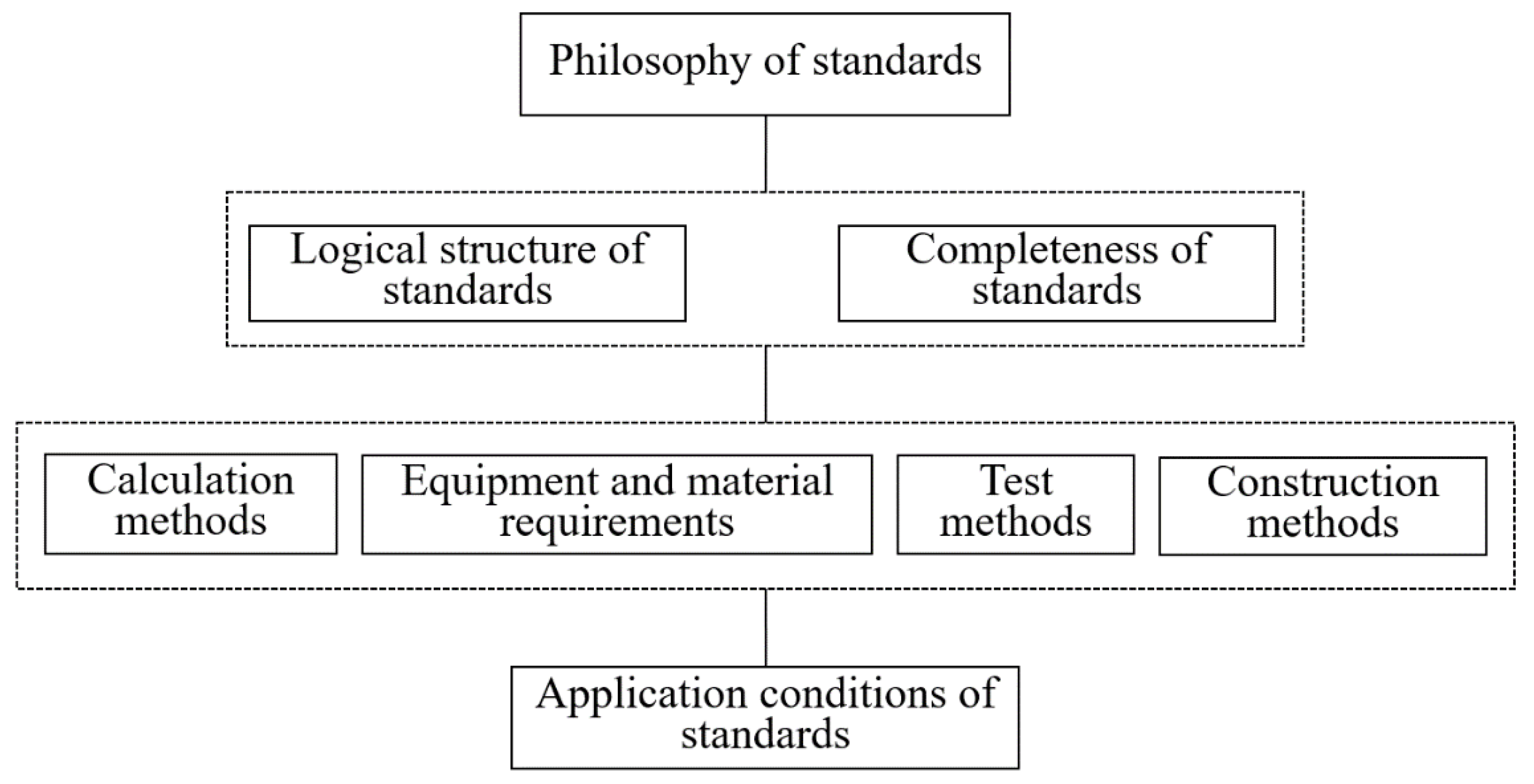

2. Analytical Framework for Understanding the Differences between Domestic and International Technical Standards

- What is the frequency of using various technical standards in international hydropower projects?

- What are the differences between domestic and international technical standards regarding the factors of philosophy of standards, logical structure, completeness, equipment and material requirements, calculation methods, construction methods, test methods, and application conditions of standards?

- What are the impacts of unfamiliarity with the differences between domestic and international technical standards on delivering international hydropower projects?

3. Research Methodology

3.1. Reason for Choosing Chinese Contractors

3.2. Data Collection

3.3. Data Analysis

4. Results and Analysis

4.1. Frequency of Using Different Technical Standards

4.2. The Differences between Chinese and International Technical Standards

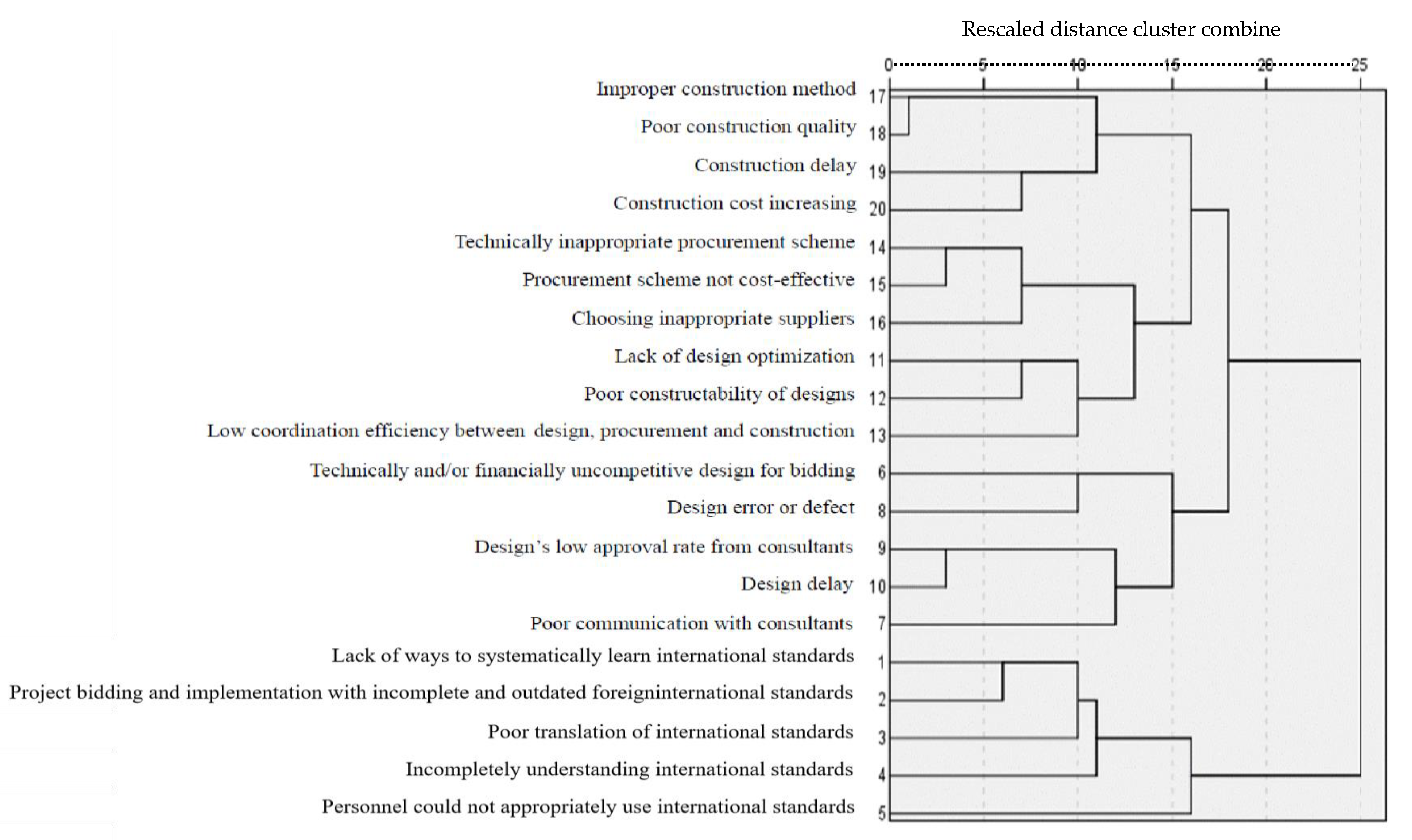

4.3. Problems Related to Unfamiliarity with Differences between Chinese and International Standards in International Hydropower Project Delivery

5. Application of the Analytical Framework: A Case Study from Nadarivatu Renewable Power Project in Fiji

6. Discussion

- (1)

- The survey results (see Figure 3) demonstrate that there are differences in all aspects between international and Chinese standards, and there is a need to compare the standards originating from different countries/regions. Understanding philosophies of different standards can help identify the trends for the development of standards by optimally balancing safety, economic, environmentally-friendly, and applicability principles. Contrasting the logic structure of different standards can assist in examining the completeness of the standards, and this can facilitate mutual recognition of the standards from various countries/regions, thereby maximizing the effectiveness of global resources such as expertise, technologies, methods, and products. Comparing different standards on calculation methods, equipment and material requirements, test methods, and construction methods can help in learning the features, strengths, and weaknesses of the standards, and then in the appropriate application of the standards in matching with local conditions to fulfill design, procurement, and construction tasks in international hydropower project delivery.

- (2)

- As the problem of applying international standards is a critical issue (see Figure 5), and is closely related to all aspects of international hydropower project delivery (see Figure 4), it is essential to improve the contractors’ capability of using international standards. Conducting comparative studies between Chinese and international standards, case studies on using international standards, transferring tacit knowledge into explicit knowledge on standards, and training activities are necessary to enhance both organizational and individual capabilities in applying international standards.

- (3)

- Since design problems, such as low approval rates of design products, design delays, design errors/defects, and design options being not cost-effective, are strongly related to unfamiliarity with the differences of standards (see Figure 4 and Figure 5), the contractors should cooperate with both project consultants and experienced international designers. Open communication is essential to ensure that the requirements of consultants, and the intentions of contractors, can be accurately and quickly circulated without being misunderstood. To meet the key design challenges in using international standards, the contractors can hire experienced international design subcontractors, and collaboratively fulfill technically and financially feasible designs. The interviewed managers confirmed that, although experienced international designers may charge more than Chinese designers, their expertise on using international standards and their familiarity with local project environments can bring more cost-effective design options, leading to significant project cost reductions.

- (4)

- To avoid the procurement problems (see Figure 5), contractors should clearly understand the requirements of both international and Chinese standards. In preparing procurement schemes, contractors should take worldwide suppliers into consideration, as long as their equipment and material can meet project requirements, and then choose suitable suppliers to achieve cost-effective procurement.

- (5)

- To avoid construction problems, such as improper construction methods, construction costs increasing, construction delays, and poor construction quality (see Figure 5), on one hand, contractors need to understand the key differences between international and Chinese construction standards, and, on the other hand, they should take full advantage of the expertise accumulated from Chinese projects, thereby improving the efficacy of construction.

- (6)

- As integrated project management is a key issue arising from the problems of applying international standards (see Figure 4 and Figure 5), contractors should emphasize the coordination among standards of design, procurement, and construction. For instance, in the design process, contractors need to appropriately consider equipment functional requirements, material processing restrictions, and constructability in accordance with relevant international standards, thereby achieving optimum designs.

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Organization for Standards. ISO Standards Are Internationally Agreed by Experts; Springer: Cham, Switzerland, 2020; Available online: https://www.iso.org/standards.html (accessed on 29 January 2022).

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GB/T 20000 Guidelines for Standardization; Standards Press of China: Beijing, China, 2014. [Google Scholar]

- Tassey, G. Standardization in technology-based markets. Res. Policy 2000, 29, 587–602. [Google Scholar] [CrossRef]

- Engineering News Record. ENR’s 2020 Top 250 International Contractors. Available online: https://www.enr.com/articles/49907-top-250-international-contractors-struggling-with-covid-19 (accessed on 25 October 2021).

- Engineering News Record. 2010, ENR’s 2010 top 225 International Contractors. Available online: https://www.enr.com/articles/930-the-top-225-international-contractors (accessed on 25 October 2021).

- Zhao, Z.; Yao, J.; Tang, C. Chinese contractors in the international market: Business distribution and competitive situation. In Proceedings of the 20th International Symposium on Advancement of Construction Management and Real Estate, Hangzhou, China, 23–25 October 2015; pp. 1261–1277. [Google Scholar]

- Mahalingam, A. Understanding and Mitigating Institutional Costs on Global Projects. Doctoral Dissertation, Stanford University, Stanford, CA, USA, 2006. [Google Scholar]

- Javernick-will, A.N.; Scott, W.R. Who needs to know what? Institutional knowledge and global projects. J. Constr. Eng. Manag. 2010, 136, 546–557. [Google Scholar] [CrossRef]

- Shen, W.; Tang, W.; Wang, S.; Duffield, C.F.; You, R. Enhancing trust-based interface management in international engineering-procurement-construction projects. J. Constr. Eng. Manag. 2017, 143, 04017061. [Google Scholar] [CrossRef]

- Lei, Z.; Tang, W.; Duffield, C.; Zhang, L.; Hui, F.K.P. The impact of technical standards on international project performance: Chinese contractors’ experience. Int. J. Proj. Manag. 2017, 35, 1597–1607. [Google Scholar] [CrossRef]

- Zhang, Q.; Tang, W.; Duffield, C.F.; Hui, F.; Zhang, L.; Zhang, X. Improving design performance by alliance between contractors and designers in international hydropower epc projects from the perspective of chinese construction companies. Sustainability 2018, 10, 1171. [Google Scholar] [CrossRef]

- Foucart, R.; Li, Q. The role of technology standards in product innovation: Theory and evidence from UK manufacturing firms. Res. Policy 2021, 50, 104157. [Google Scholar] [CrossRef]

- Yates, J.K.; Aniftos, S. Engineering and construction industry standards developers. J. Manag. Eng. 1997, 13, 31–39. [Google Scholar] [CrossRef]

- Chua, D.K.H.; Wang, Y.; Tan, W.T. Impacts of obstacles in East Asian cross-border construction. J. Constr. Eng. Manag. 2003, 129, 131–141. [Google Scholar] [CrossRef]

- Javernick-will, A.N.; Levitt, R.E. Mobilizing institutional knowledge for international projects. J. Constr. Eng. Manag. 2009, 136, 430–441. [Google Scholar] [CrossRef]

- Orr, R.J.; Scott, W.R. Institutional exceptions on global projects: A process model. J. Int. Bus. Stud. 2008, 39, 562–588. [Google Scholar] [CrossRef]

- Kwon, D.K.; Kareem, A. Comparative study of major international wind codes and standards for wind effects on tall buildings. Eng. Struct. 2013, 51, 23–35. [Google Scholar] [CrossRef]

- Lee, J.H.; Huh, J.; Lee, J.J. A comparative study on wind loads between design standards for the design of pipe-rack structures. KSCE J. Civ. Eng. 2016, 20, 293–300. [Google Scholar] [CrossRef]

- Lane, C. The social regulation of inter-firm relations in Britain and Germany: Market rules, legal norms and technical standards. Camb. J. Econ. 1997, 21, 197–215. [Google Scholar] [CrossRef]

- Blayse, A.M.; Manley, K. Key influences on construction innovation. Constr. Innov. 2004, 4, 143–154. [Google Scholar] [CrossRef]

- Mangelsdorf, A. The role of technical standards for trade between China and the European Union. Tech. Anal. Strat. Manag. 2011, 23, 725–743. [Google Scholar] [CrossRef]

- Gu, L.; Zhang, Y.R.; Wang, Y.F. Comparison of energy efficiency standards in the public building of China, the US, the UK. Adv. Mater. Res. 2014, 869–870, 389–392. [Google Scholar] [CrossRef]

- Han, S.H.; Park, S.H.; Kim, H.; Kang, Y.W. Causes of bad profit in overseas construction projects. J. Constr. Eng. Manag. 2007, 133, 932–943. [Google Scholar] [CrossRef]

- Su, J.; Hai, T.; Li, X.; Deeks, A.; Li, S. Development length comparison between Australian codes and Chinese code on 500 mpa steel bars. Appl. Mech. Mater. 2014, 584–586, 889–893. [Google Scholar] [CrossRef]

- Jiang, H.; Liu, W.; Jia, L. How humble leadership influences the innovation of technology standards: A moderated mediation model. Sustainability 2019, 11, 5448. [Google Scholar] [CrossRef]

- Fladvad, M.; Ulvik, A. Large-size aggregates for road construction—A review of standard specifications and test methods. Bull. Eng. Geol. Environ. 2019, 80, 8847–8859. [Google Scholar] [CrossRef]

- Du, L.; Tang, W.; Liu, C.; Wang, S.; Wang, T.; Shen, W.; Huang, M.; Zhou, Y. Enhancing engineer–procure–construct project performance by partnering in international markets: Perspective from Chinese construction companies. Int. J. Proj. Manag. 2016, 34, 30–43. [Google Scholar] [CrossRef]

- Ling, F.Y.; Low, S.P. Legal risks faced by international architectural, engineering, and construction firms in China. J. Prof. Issues Eng. Educ. Pract. 2007, 133, 238–245. [Google Scholar] [CrossRef]

- Kano, S. Technical innovations, standardization and regional comparison—A case study in mobile communications. Telecommun. Policy 2000, 24, 305–321. [Google Scholar] [CrossRef]

- Duan, K. Comparison between Chinese and international standards on the provisions of welding material storage and Re-drying. Press. Ves. T. 2019, 36, 62–67. [Google Scholar]

- Bashor, R.; Kareem, A. Comparative study on major international standards. In Proceedings of the 7th Asia-Pacific Conference on Wind Engineering, Taipei, China, 8–12 November 2009. [Google Scholar]

- Wigle, R. Quantifying the impact of technical barriers to trade: Can it be done? J. Econ. Lit. 2003, 40, 596–597. [Google Scholar]

- Marette, S.; Beghin, J. Are standards always protectionist? Rev. Int. Econ. 2010, 18, 179–192. [Google Scholar] [CrossRef][Green Version]

- Shen, W.; Huang, M. Enhancing design management by partnering in delivery of international epc projects: Evidence from chinese construction companies. J. Constr. Eng. Manag. 2015, 142, 04015099. [Google Scholar] [CrossRef]

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimen. ASTM International: West Conshohocken, PA, USA, 2018.

- Love, P.D.; Holt, G.D.; Li, H. Triangulation in construction management research. Eng. Constr. Archit. Manag. 2002, 9, 294–303. [Google Scholar] [CrossRef]

- Thomas, R. Surveys. Research Methods: Guidance for Postgraduates; Arnold: London, UK, 1996; pp. 115–124. [Google Scholar]

- Sharma, S. Applied Multivariate Techniques; Jhon Wiley and Sons: New York, NY, USA, 1996. [Google Scholar]

- Tang, W.; Duffield, C.; Young, D. Partnering mechanism in construction: An empirical study on the chinese construction industry. J. Constr. Eng. Manag. 2006, 132, 217–229. [Google Scholar] [CrossRef]

- GB/T 28001; Occupational Health and Safety Management Systems-Requirements. Standards Press of China: Beijing, China, 2011.

- BS OHSAS 18001; Occupational Health and Safety Assessment Series. British Standards Institution: London, UK, 2007.

- ISO 45001; Occupational Health and Safety Occupational Health and Safety Management Systems-Requirements With Guidance For Use. ISO/TC 283 Occupational Health and Safety Management: London, UK, 2018.

- Li, K. International Technical Standards and Application—Chapter 23 Comparison on Durability between Chinese and International Technical Standards; Tsinghua University Press: Beijing, China, 2019. [Google Scholar]

- DIN EN 206; Concrete—Specification, Performance, Production and Conformity. German Institute for Standardization: Berlin, Germany, 2017.

- GB/T 50081; Standard for Test Methods of Concrete Physical and Mechanical Properties. Standards Press of China: Beijing, China, 2019.

- Fry, J. The Strategic Industry Roadmap; ICOLD (International Commission on Large Dams): Paris, France, 2020; Available online: https://hydropower-europe.eu/ (accessed on 29 January 2022).

- Schletterer, M.; Reindl, R.; Thonhauser, S. Options for re-establishing river continuity, with an emphasis on the special solution ‘’fish lift’’: Examples from Austria. Rev. Eletrôn. Gest. Tecnol. Ambient. 2016, 4, 109. [Google Scholar] [CrossRef]

- European Investment Bank. Environmental and Social Standards. 2020. Available online: https://www.eib.org/attachments/strategies/environmental_and_social_practices_handbook_en.pdf (accessed on 29 January 2022).

- European Investment Bank. Environmental, Climate and Social Guidelines on Hydropower Development. 2020. Available online: https://www.eib.org/attachments/eib_guidelines_on_hydropower_development_en.pdf (accessed on 29 January 2022).

- NB/T 10347; Code for Environment Impact Assessment of Hydropower Projects. Standards Press of China: Beijing, China, 2019.

- EN 15804-2012; Sustainability of Construction Works, Environmental Product Declarations, Core Rules for the Product Category of Construction Products or Comparable Standards. CEN-CENELEC Management Centre: Brussels, Belgium, 2012.

- Chen, K.; Tao, J.; Chang, Z.; Cao, X.; Ge, H. Difficulties and prospects of fishways in China: An overview of the construction status and operation practice since 2000. Ecol. Eng. 2014, 70, 82–91. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, W.; Duffield, C.F.; Zhang, L.; Hui, F. Environment management of hydropower development: A case study. Energies 2021, 14, 2029. [Google Scholar] [CrossRef]

| Regions | Numbers of Projects Located in Different Countries/Regions |

|---|---|

| East Africa | 4 (Uganda), 3 (Ethiopia), 2 (Sudan), 1 (Kenya), 1 (Rwanda), 1 (Tanzania), 1 (Djibouti) |

| South Africa | 6 (Angola), 4 (Zambia), 2 (Mozambique), 2 (Zimbabwe), 1 (Namibia), 1 (Senegal) |

| West Africa | 3 (Guinea), 2 (Nigeria), 2 (Niger), 2 (Cote d’Ivoire), 1 (Benin), 1 (Gambia), 1 (Ghana), 1 (Liberia) |

| North Africa | 3 (Algeria) |

| Central Africa | 2 (Equatorial Guinea), 2 (Cameroon), 1 (Republic of the Congo), 1 (The Democratic Republic of the Congo) |

| East Asia | 1 (South Korea), 1 (Hong Kong China) |

| South East Asia | 6 (Malaysia), 5 (Indonesia), 4 (Laos), 3 (Myanmar), 3 (Vietnam), 2 (Cambodia), 1 (Thailand), 1 (Singapore), 1 (Timor-Leste) |

| South Asia | 4 (Pakistan), 3 (Nepal)2 (Sri Lanka), 1 (India) |

| Central Asia | 1 (Tajikistan) |

| Middle East | 4 (Qatar), 3 (Israel), 3 (Saudi Arabia), 2 (Kuwait), 2 (The United Arab Emirates) |

| America | 6 (Venezuela), 4 (Ecuador), 1 (Colombia), 1 (Costa Rica), 1 (Cuba), 2 (Trinidad and Tobago), 2 (Bolivia), 1 (Honduras) |

| Europe | 2 (Belarus), 1 (Serbia), 1 (Russia), 1 (Macedonia) |

| Oceania | 2 (Fiji), 1 (Papua New Guinea), 1 (Vanuatu) |

| Total | 131 |

| Project Name | Contract Value (Million Dollars) | Mainly Applied Standards |

|---|---|---|

| Pakistan Gomal Zam Hydropower Project | 87 | ASTM, ACI, IEC, and other equivalent standard accepted by the client |

| Angola N’zeto-Soyo Highway Project | 605 | AASHTO, ACI, ASTM, BS, DIN, ISO, NF, and IBC |

| Qatar Luce CP1 Project | 1430 | BS, ISO, ASTM, and Qatar standards |

| Fiji Nadarivatu Renewable Power Project | 124 | AS/NZS, IEC, BS, ISO, ASCE, ASTM, ACI, and Fiji standards (FJS) |

| Mali Felu Hydropower Project | 170 | EN, USACE, ACI, IEC, ASTM, ISO, DIN |

| Zambia Itaiz Hydropower Project | 138 | BS, EN, ISO, USACE, USBR, ASTM, ACI, ASCE, and IEC |

| Ethiopia Tekeze Hydropower Project | 224 | ISO, IEC, ASTM, BS, and Chinese standards |

| Ghana Buvi Hydropower Project | 596 | USACE, Chinese standards, ASTM, BS, and ACI |

| Malaysia Bakun Hydropower Project | 813 | ASTM, Chinese standards, USBR, USACE, ACI, and BS |

| Ecuador Coca Codo Sinclair Hydropower Project | 1980 | ASTM, ACI, USBR, AASHTO, Chinese standards, and Ecuador standards |

| Technical Standards | Using Frequency (Represented by Percentage) | Rank |

|---|---|---|

| American Society for Testing and Materials (ASTM) | 52% | 1 |

| International Organization for Standardization (ISO) | 47% | 2 |

| Chinese Standards | 46% | 3 |

| American Concrete Institute (ACI) | 32% | 4 |

| European Norm (EN) | 31% | 5 |

| British Standard (BS) | 29% | 6 |

| International Electrotechnical Commission (IEC) | 20% | 7 |

| The American Society of Mechanical Engineers (ASME) | 19% | 8 |

| Institute of Electrical and Electronics Engineers (IEEE) | 17% | 9 |

| German Institute for Standardization (DIN) | 15% | 10 |

| The American Society of Civil Engineers (ASCE) | 14% | 11 |

| French Standards Association (NF) | 13% | 12 |

| American Association of State Highway and Transportation Officials (AASHTO) | 13% | 13 |

| United States Army Corps of Engineers (USACE) | 12% | 14 |

| United States Bureau of Reclamation (USBR) | 8% | 15 |

| International Telecommunication Union (ITU) | 6% | 16 |

| Australian Standards/New Zealand Standards (AS/NZS) | 4% | 17 |

| Indian standards | 2% | 18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, R.; Tang, W.; Duffield, C.F.; Zhang, L.; Hui, F.; Kang, Y. Analytical Framework for Understanding the Differences between Technical Standards Originating from Various Regions to Improve International Hydropower Project Delivery. Water 2022, 14, 662. https://doi.org/10.3390/w14040662

You R, Tang W, Duffield CF, Zhang L, Hui F, Kang Y. Analytical Framework for Understanding the Differences between Technical Standards Originating from Various Regions to Improve International Hydropower Project Delivery. Water. 2022; 14(4):662. https://doi.org/10.3390/w14040662

Chicago/Turabian StyleYou, Richun, Wenzhe Tang, Colin F. Duffield, Lihai Zhang, Felix Hui, and Yanling Kang. 2022. "Analytical Framework for Understanding the Differences between Technical Standards Originating from Various Regions to Improve International Hydropower Project Delivery" Water 14, no. 4: 662. https://doi.org/10.3390/w14040662

APA StyleYou, R., Tang, W., Duffield, C. F., Zhang, L., Hui, F., & Kang, Y. (2022). Analytical Framework for Understanding the Differences between Technical Standards Originating from Various Regions to Improve International Hydropower Project Delivery. Water, 14(4), 662. https://doi.org/10.3390/w14040662