Implementation of FeSO4·H2O as an Eco-Friendly Coagulant for the Elimination of Organic Pollutants from Tertiary Palm Oil Mill Effluent: Process Optimization, Kinetics, and Thermodynamics Studies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Procedure of Coagulation–Flocculation

2.2. Design of Experiments

2.3. Kinetics and Thermodynamics Modeling

2.4. Characterization

3. Results and Discussion

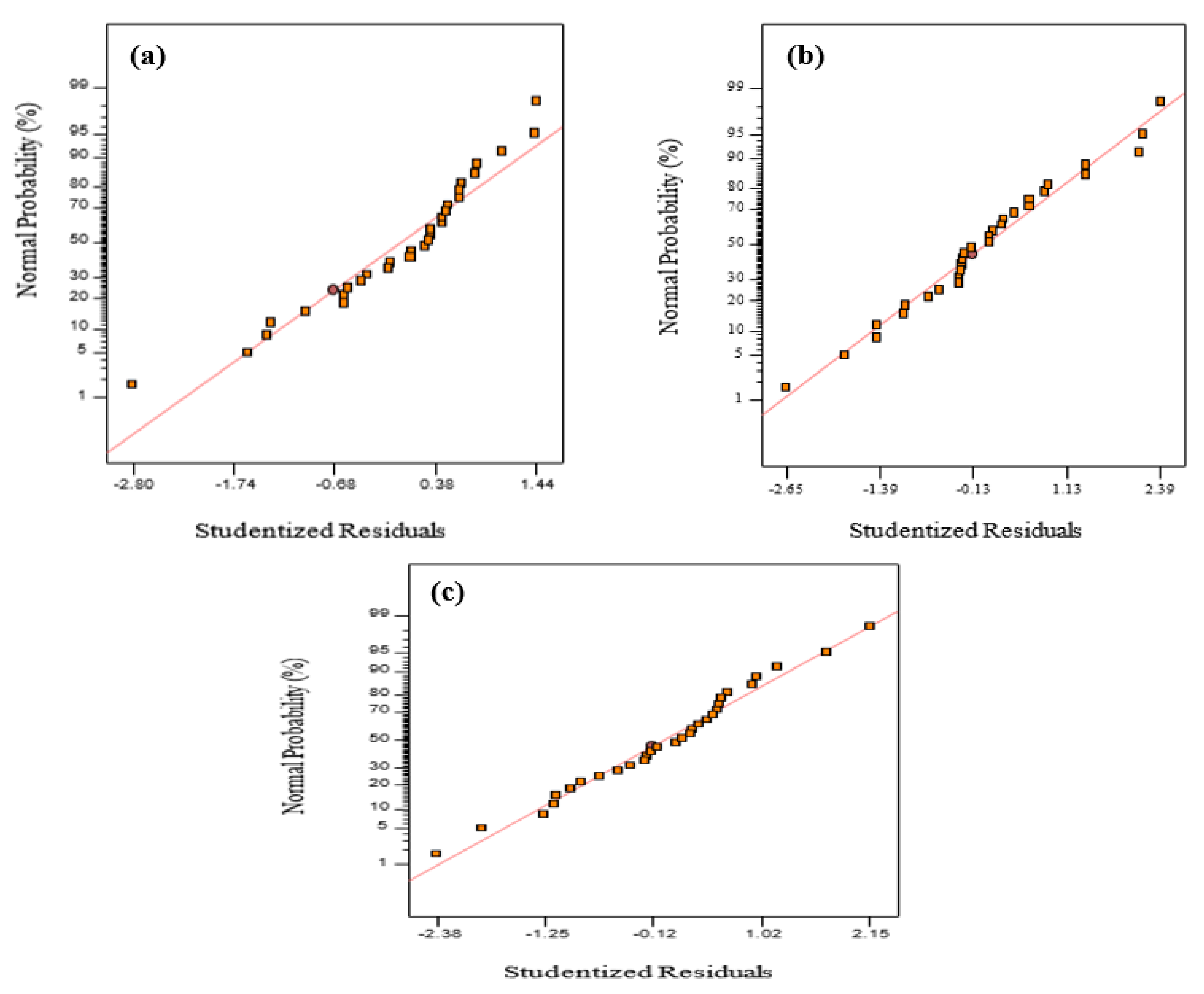

3.1. Regression Model of Response

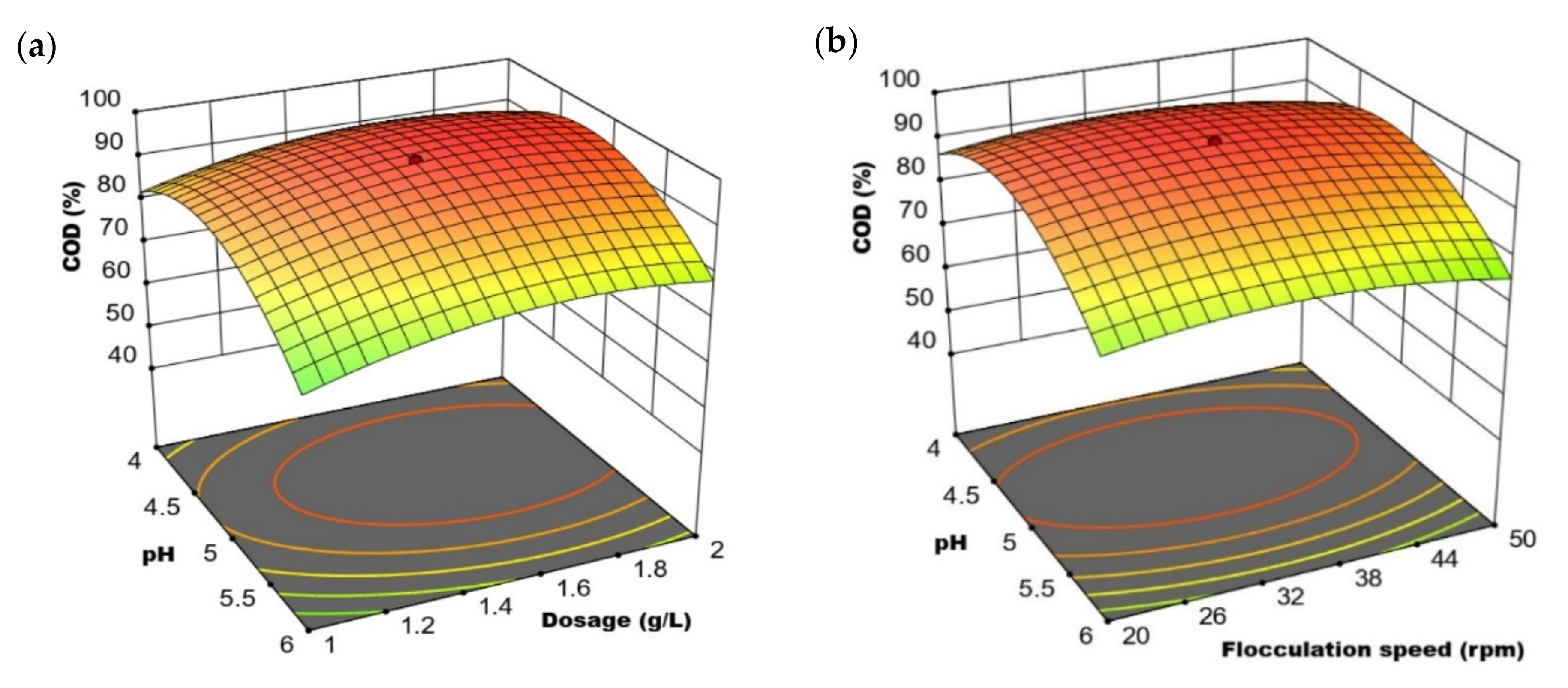

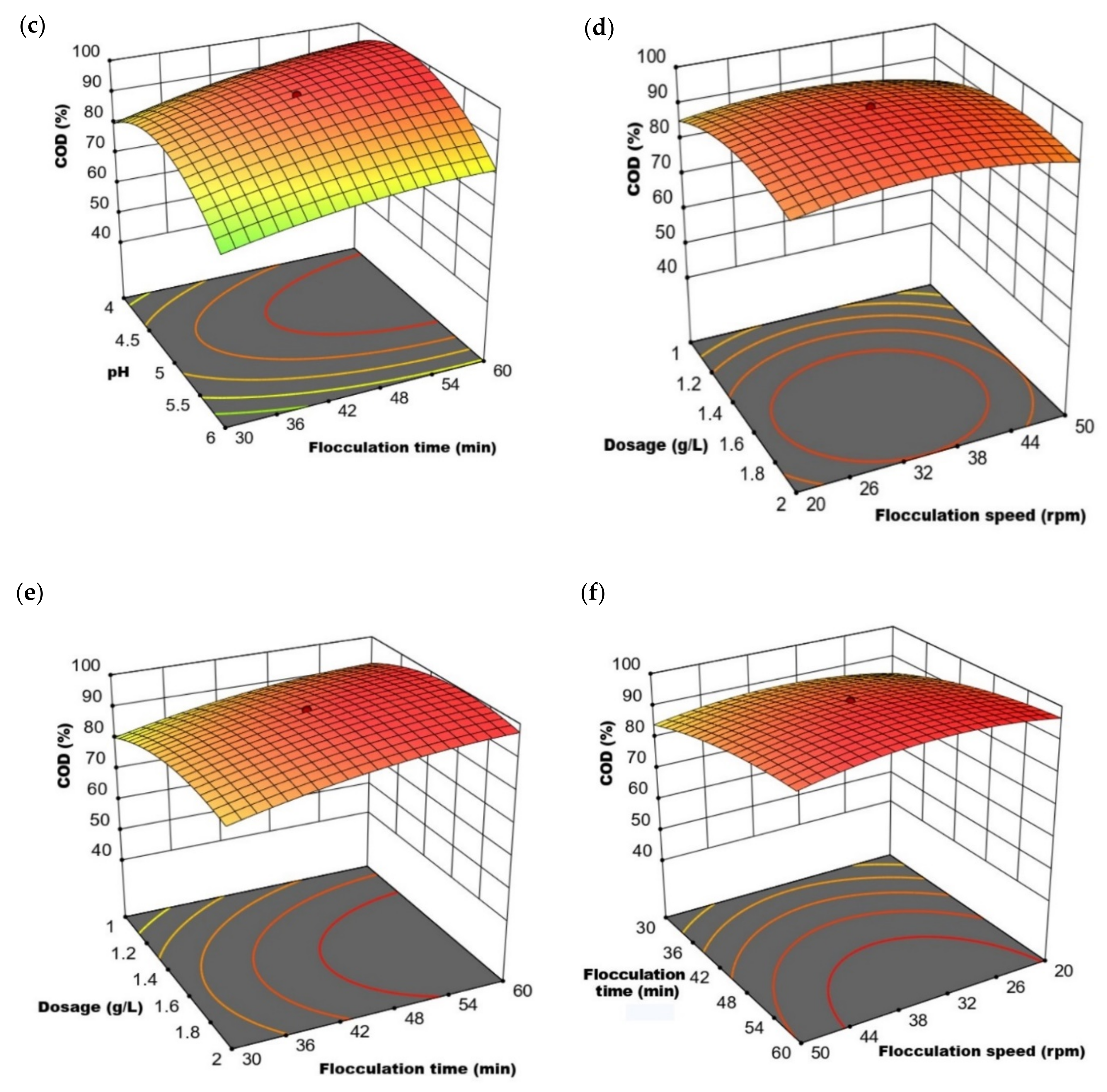

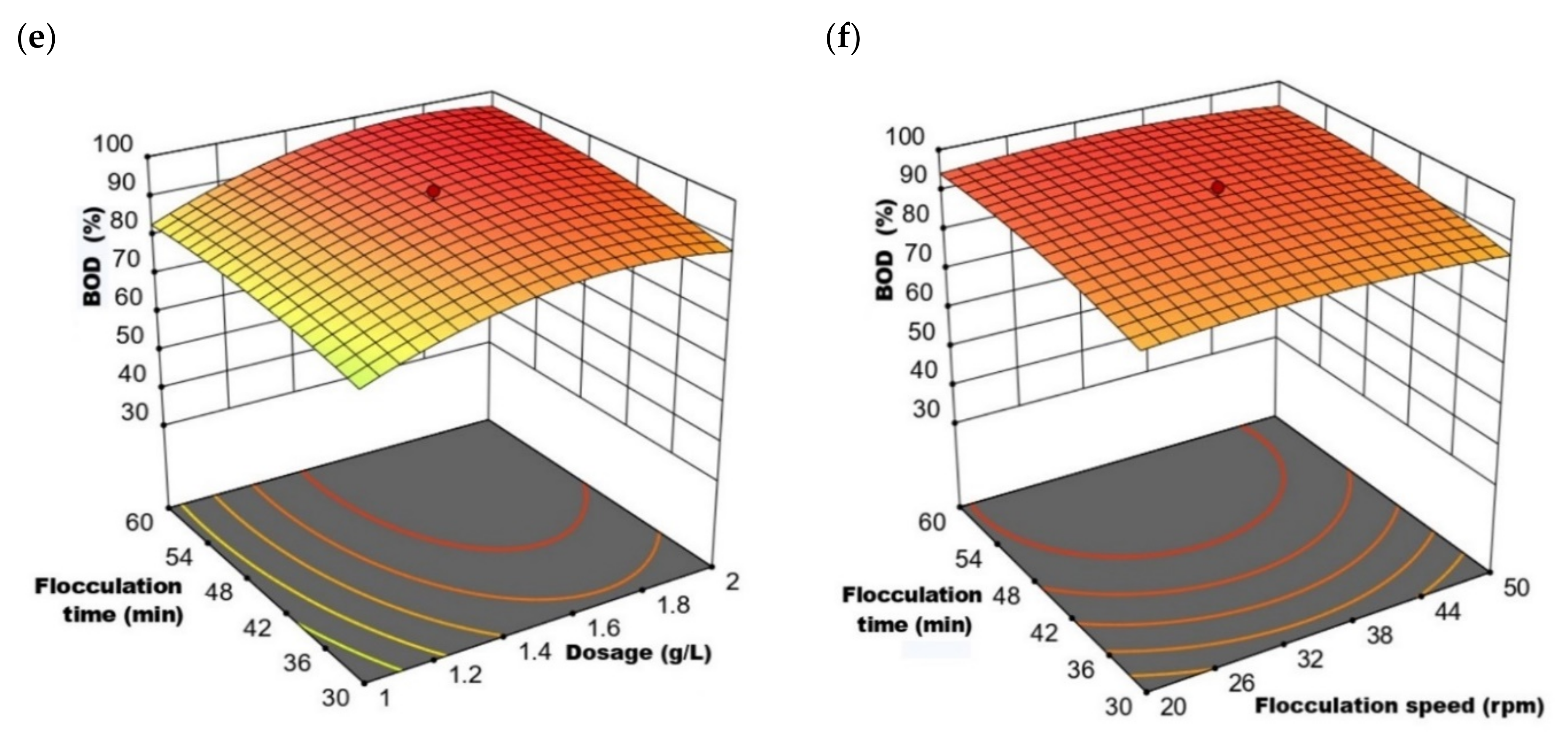

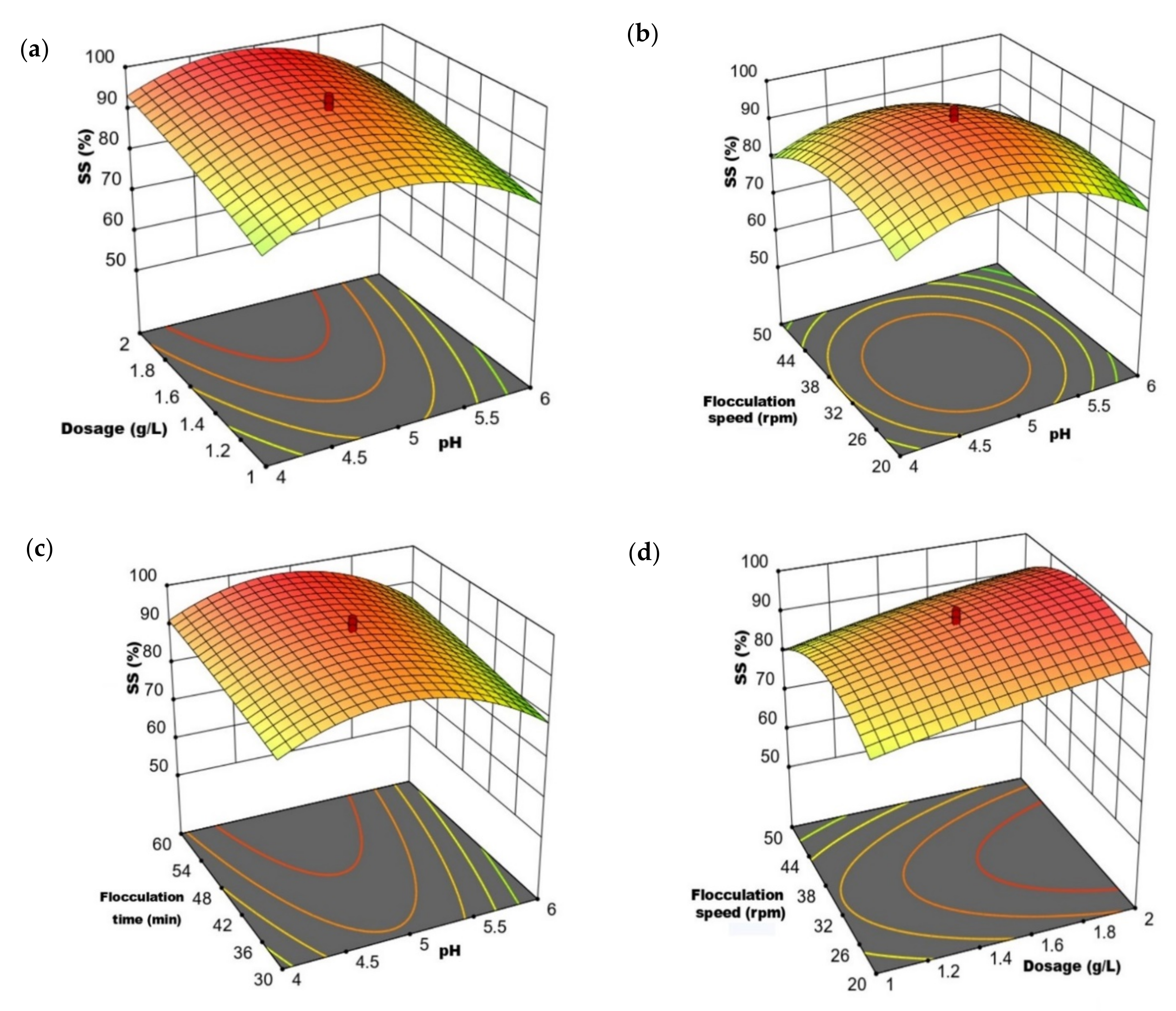

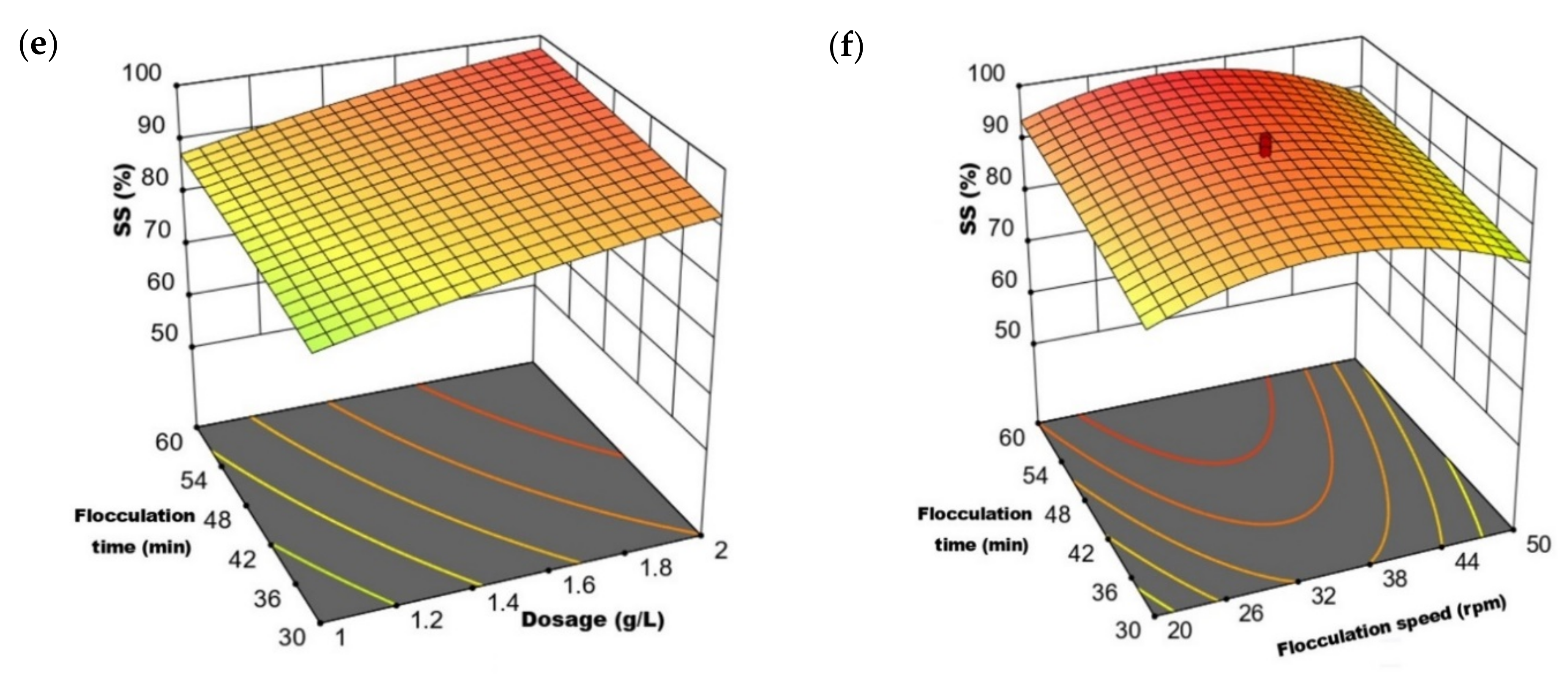

3.2. Response Surface Analyses

3.3. Process Optimization and Validation

3.4. Kinetics and Thermodynamics Modeling

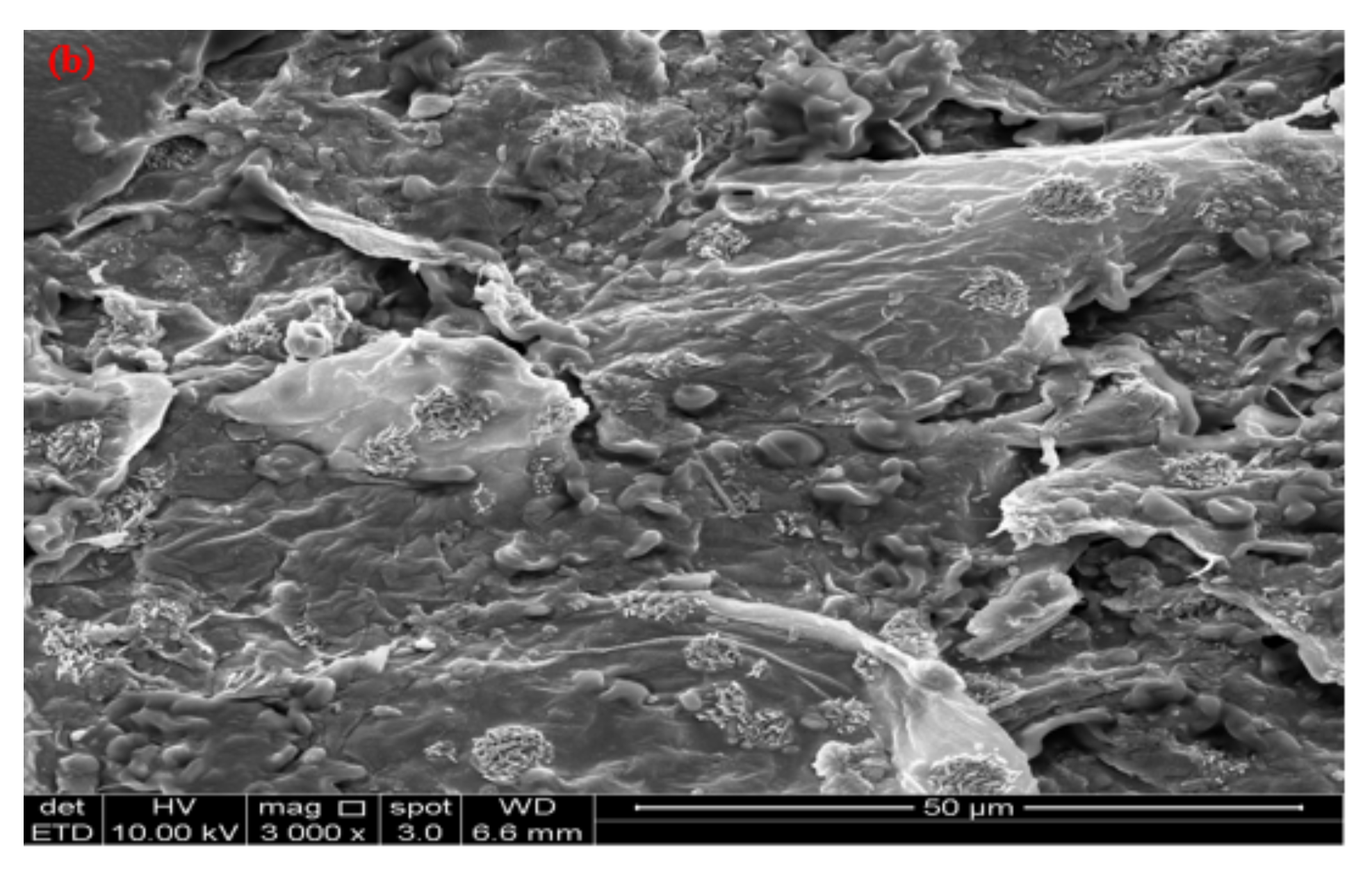

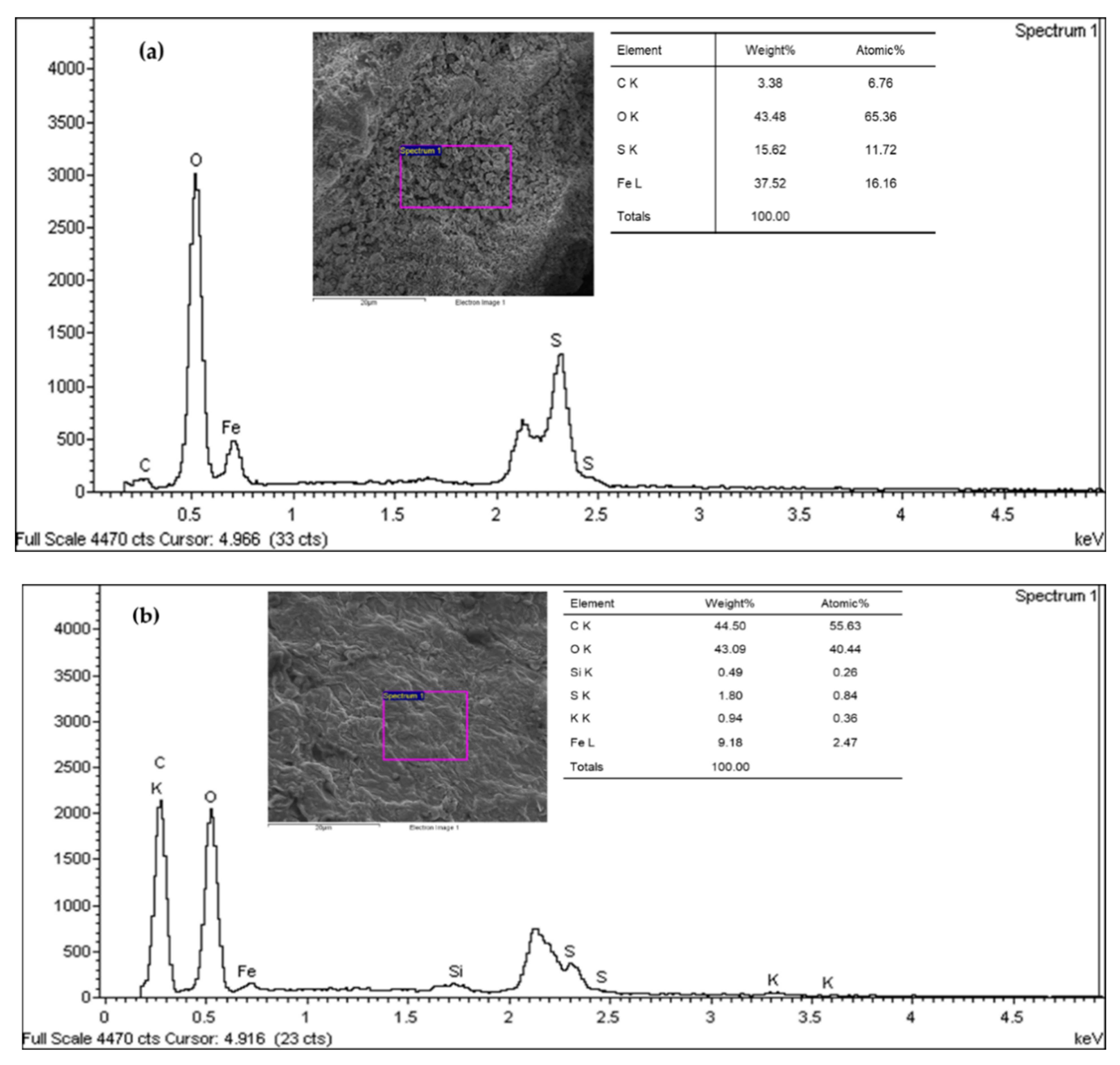

3.5. Assessment Post-Treatment of POME Using FeSO4·H2O as a Coagulant

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Omar, A.K.M.; Norsalwani, T.L.T.; Asmah, M.S.; Badrulhisham, Z.Y.; Easa, A.M.; Omar, F.M.; Hossain, M.S.; Zuknik, M.H.; Norulaini, N.A.N. Implementation of the supercritical carbon dioxide technology in oil palm fresh fruits bunch sterilization: A review. J. CO2 Util. 2018, 25, 205–215. [Google Scholar] [CrossRef]

- Lee, M.D.; Lee, P.S. Performance of Chitosan and Polyglutamic Acid in Palm Oil Mill Effluent Treatment. In Handbook of Research on Waste Diversion and Minimization Technologies for the Industrial Sector; IGI Global: Hershey, PA, USA, 2021; pp. 147–173. [Google Scholar]

- Wee, A.N.C.H.; Erison, A.E.; Anyek, E.H.E.; Pakpahan, G.R.; Lim, J.R.; Tiong, A.N.T. Techno-economic assessment of hydrogen production via steam reforming of palm oil mill effluent. Sustain. Energy Technol. Assess. 2022, 53, 102575. [Google Scholar] [CrossRef]

- Ratnasari, A.; Syafiuddin, R.; Boopathy, S.; Malik, M.; Mehmood, R.A.; Amalia, D.; Prastyo, N.D.; Zaidi, S. Advances in pretreatment technology for handling the palm oil mill effluent: Challenges and prospects. Bioresour. Technol. 2022, 344, 126239. [Google Scholar] [CrossRef] [PubMed]

- Loh, S.K.; Nasrin, A.B.; Azri, S.M.; Adela, B.N.; Muzzammil, N.; Jay, T.D.; Eleanor, R.A.S.; Lim, W.S.; Choo, Y.M.; Kaltschmitt, M. First Report on Malaysia’s experiences and development in biogas capture and utilization from palm oil mill effluent under the Economic Transformation Programme: Current and future perspectives. Renew. Sustain. Energy Rev. 2017, 74, 1257–1274. [Google Scholar]

- DoE. Environmental Quality Act 1974, Environmental Quality (Industrial Effluent) Regulations 2009; Department of Environment, Ministry of Science, Technology and the Environment: Kuala Lumpur, Malaysia, 2009. [Google Scholar]

- Madaki, Y.S.; Seng, L. Pollution control: How feasible is zero discharge concepts in Malaysia palm oil mills. Am. J. Eng. Res. 2013, 2, 239–252. [Google Scholar]

- Mohammad, S.; Baidurah, S.; Kobayashi, T.; Ismail, N.; Leh, C.P. Palm Oil Mill Effluent Treatment Processes—A Review. Processes 2021, 9, 739. [Google Scholar] [CrossRef]

- Soo, P.L.; Bashir, M.J.K.; Wong, L.-P. Recent advancements in the treatment of palm oil mill effluent (POME) using anaerobic biofilm reactors: Challenges and future perspectives. J. Environ. Manag. 2022, 320, 115750. [Google Scholar] [CrossRef]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W.; Thomaidis, N.S.; Xu, J. Progress in the biological and chemical treatment technologies for emerging contaminant eliminationfrom wastewater: A critical review. J. Hazard. Mater. 2017, 323, 274–298. [Google Scholar] [CrossRef]

- Adeleke, O.A.; Latiff, A.A.A.; Saphira, M.R.; Daud, Z.; Ismail, N.; Ahsan, A.; Aziz, N.A.A.; Ndah, M.; Kumar, V.; Adel, A.-G.; et al. 2—Locally Derived Activated Carbon from Domestic, Agricultural and Industrial Wastes for the Treatment of Palm Oil Mill Effluent. In Nanotechnology in Water and Wastewater Treatment; Ahsan, A., Ismail, A.F., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 35–62. [Google Scholar]

- Charles, A.; Cheng, C.K. Photocatalytic treatment of palm oil mill effluent by visible light-active calcium ferrite: Effects of catalyst preparation technique. J. Environ. Manag. 2019, 234, 404–411. [Google Scholar] [CrossRef]

- Mujeli, M.; Hussain, S.A.; Ismail, M.H.S.; Biak, D.R.A.; Jami, M.S. Screening of electrocoagulation process parameters for treated palm oil mill effluent using minimum-runs resolution IV design. Int. J. Environ. Sci. Technol. 2019, 16, 811–820. [Google Scholar] [CrossRef]

- Bashir, M.J.K.; Lim, J.H.; Amr, S.S.A.; Wong, L.P.; Sim, Y.L. Post treatment of palm oil mill effluent using electro-coagulation-peroxidation (ECP) technique. J. Clean. Prod. 2019, 208, 716–727. [Google Scholar] [CrossRef]

- Hossain, M.S.; Omar, F.; Asis, A.J.; Bachmann, R.T.; Sarker, M.Z.I.; Kadir, M.O.A. Effective treatment of palm oil mill effluent using FeSO4·H2O waste from titanium oxide industry: Coagulation adsorption isotherm and kinetics studies. J. Clean. Prod. 2019, 219, 86–98. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Idris, I.; Chan, C.Y.; Ismail, S. Reclamation from palm oil mill effluent using an integrated zero discharge membrane-based process. Pol. J. Chem. Technol. 2015, 17, 49–55. [Google Scholar]

- Gázquez, M.J.; Contreras, M.; Pérez-Moreno, S.M.; Guerrero, J.L.; Casas-Ruiz, M.; Bolívar, J.P. A Review of the Commercial Uses of Sulphate Minerals from the Titanium Dioxide Pigment Industry: The Case of Huelva (Spain). Minerals 2021, 11, 575. [Google Scholar] [CrossRef]

- Poblete, R.; Otal, E.; Vilches, L.F.; Vale, J.; Fernández-Pereira, C. Photocatalytic degradation of humic acids and landfill leachate using a solid industrial by-product containing TiO2 and Fe. Appl. Catal. B Environ. 2011, 102, 172–179. [Google Scholar] [CrossRef]

- Erdem, E.; Donat, R.; Esen, K.; Tunç, T. Eliminationof soluble Cr (VI) in cements by ferrous sulphate monohydrate, solid lignin and other materials. Ceram.-Silik. 2011, 55, 85–93. [Google Scholar]

- Rajniak, J.; Giehl, R.F.H.; Chang, E.; Murgia, I.; von Wirén, N.; Sattely, E.S. Biosynthesis of redox-active metabolites in response to iron deficiency in plants. Nat. Chem. Biol. 2018, 14, 442–450. [Google Scholar] [CrossRef]

- Mensah-Akutteh, H.; Buamah, R.; Wiafe, S.; Nyarko, K.B. Optimizing coagulation–flocculation processes with aluminium coagulation using response surface methods. Appl. Water Sci. 2022, 12, 188. [Google Scholar] [CrossRef]

- Ravikumar, K.; Krishnan, S.; Ramalingam, S.; Balu, K. Optimization of process variables by the application of response surface methodology for dye removal using a novel adsorbent. Dye. Pigment. 2007, 72, 66–74. [Google Scholar] [CrossRef]

- Siyar, M.; Lashkarbolooki, M. Evaluation of the interfacial tension of binary surfactant mixtures and crude oil using the response surface method. J. Mol. Liq. 2022, 366, 120253. [Google Scholar]

- Ilias, M.K.M.; Hossain, M.S.; Ngteni, R.; Al-Gheethi, A.; Ahmad, H.; Omar, F.M.; Naushad, M.; Pandey, S. Environmental Remediation Potential of Ferrous Sulfate Waste as an Eco-Friendly Coagulant for the Eliminationof NH3-N and COD from the Rubber Processing Effluent. Int. J. Environ. Res. Public Health 2021, 18, 12427. [Google Scholar] [CrossRef] [PubMed]

- Shadi, A.M.H.; Kamaruddin, M.A.; Niza, N.M.; Omar, F.M.; Hossain, M.S. Facile isotherms of iron oxide nanoparticles for the effectively removing organic and inorganic pollutants from landfill leachate: Isotherms, kinetics, and thermodynamics modelling. J. Environ. Chem. Eng. 2022, 10, 107753. [Google Scholar] [CrossRef]

- Moghaddam, S.S.; Moghaddam, M.R.A.; Arami, M. Coagulation/flocculation process for dye eliminationusing sludge from water treatment plant: Optimization through response surface methodology. J. Hazard. Mater. 2010, 175, 651–657. [Google Scholar] [CrossRef]

- Hossain, M.S.; Rahman, N.N.N.A.; Balakrishnan, V.; Alkarkhi, A.F.M.; Rajion, Z.A.; Kadir, M.O.A. Optimizing supercritical carbon dioxide in the inactivation of bacteria in clinical solid waste by using response surface methodology. Waste Manag. 2015, 38, 462–473. [Google Scholar] [PubMed]

- Kozak, M.; Piepho, H.-P. What’s normal anyway? Residual plots are more telling than significance tests when checking ANOVA assumptions. J. Agron. Crop Sci. 2018, 204, 86–98. [Google Scholar]

- Ngteni, R.; Hossain, M.S.; Kadir, M.O.A.; Asis, A.J.; Tajudin, Z. Kinetics and Isotherm Modeling for the Treatment of Rubber Processing Effluent Using Iron (II) Sulphate Waste as a Coagulant. Water 2020, 12, 1747. [Google Scholar]

- Muthusaravanan, S.; Sivarajasekar, N.; Vivek, J.S.; Paramasivan, T.; Naushad, M.; Prakashmaran, J.; Gayathri, V.; Al-Duaij, O.K. Phytoremediation of heavy metals: Mechanisms, methods and enhancements. Environ. Chem. Lett. 2018, 16, 1339–1359. [Google Scholar]

- Shadi, M.H.; Kamaruddin, M.A.; Niza, N.M.; Emmanuel, M.I.; Hossain, M.S.; Ismail, N. Electroflotation treatment of stabilized landfill leachate using titanium-based electrode. Int. J. Environ. Sci. Technol. 2021, 18, 2425–2440. [Google Scholar]

- Mohamad, N.A.; Hamzah, S.; Harun, M.H.C.; Ali, A.; Rasit, N.; Awang, M.; Rahman, W.R.W.A.; Azmi, A.A.A.R.; Habib, A.A.A.; Zahid, M.S.A.; et al. Integration of copperas and calcium hydroxide as a chemical coagulant and coagulant aid for efficient treatment of palm oil mill effluent. Chemosphere 2021, 281, 130873. [Google Scholar] [CrossRef]

- Sharma, G.; Thakur, B.; Kumar, A.; Sharma, S.; Naushad, M.; Stadler, F.J. Atrazine eliminationusing chitin-cl-poly(acrylamide-co-itaconic acid) nanohydrogel: Isotherms and pH responsive nature. Carbohydr. Polym. 2020, 241, 116258. [Google Scholar] [CrossRef]

- Nourani, M.; Baghdadi, M.; Javan, M.; Bidhendi, G.N. Production of a biodegradable flocculant from cotton and evaluation of its performance in coagulation-flocculation of kaolin clay suspension: Optimization through response surface methodology (RSM). J. Environ. Chem. Eng. 2016, 4, 1996–2003. [Google Scholar] [CrossRef] [Green Version]

- Rodrigues, C.S.D.; Madeira, L.M.; Boaventura, R.A.R. Treatment of textile dye wastewaters using ferrous sulphate in a chemical coagulation/flocculation process. Environ. Technol. 2013, 34, 719–729. [Google Scholar] [PubMed]

- Chung, C.Y.; Selvarajoo, A.; Sethu, V.; Koyande, A.K.; Arputhan, A.; Lim, Z.C. Treatment of palm oil mill effluent (POME) by coagulation flocculation process using peanut–okra and wheat germ-okra. Clean Technol. Environ. Policy 2018, 20, 1951–1970. [Google Scholar] [CrossRef]

- Bello, M.M.; Raman, A.A.A. Trend and current practices of palm oil mill effluent polishing: Application of advanced oxidation processes and their future perspectives. J. Environ. Manag. 2017, 198, 170–182. [Google Scholar] [CrossRef] [PubMed]

| Independent Factors | Units | Symbol | Coded Levels | ||

|---|---|---|---|---|---|

| Low (−1) | Intermediate (0) | High (+1) | |||

| pH | 4 | 5 | 6 | ||

| Coagulant dosage | g/L | 1.0 | 1.5 | 2.0 | |

| Slow mixing speed | rpm | 20 | 35 | 50 | |

| Flocculation time | min | 30 | 45 | 60 | |

| Run | X1 | X2 | X3 | X4 | Removal (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| COD | BOD | SS | ||||||||

| Observed | Predicted | Observed | Predicted | Observed | Predicted | |||||

| 1 | 4 | 1 | 20 | 30 | 64.46 | 68.48 | 64.59 | 64.13 | 71.28 | 72.57 |

| 2 | 6 | 1 | 20 | 30 | 60.87 | 60.41 | 63.32 | 62.94 | 69.86 | 69.8 |

| 3 | 4 | 2 | 20 | 30 | 72.67 | 72.94 | 76.89 | 76.99 | 85.46 | 84.08 |

| 4 | 6 | 2 | 20 | 30 | 68.6 | 67.01 | 64.43 | 64.25 | 76.91 | 77.15 |

| 5 | 4 | 1 | 50 | 30 | 67.61 | 67.13 | 61.62 | 61.49 | 70.63 | 71.09 |

| 6 | 6 | 1 | 50 | 30 | 58.59 | 60.06 | 60.28 | 58.67 | 67.58 | 67.53 |

| 7 | 4 | 2 | 50 | 30 | 71.95 | 72.55 | 78.41 | 80.48 | 84.26 | 84.09 |

| 8 | 6 | 2 | 50 | 30 | 66.18 | 67.61 | 66.38 | 66.11 | 75.28 | 76.36 |

| 9 | 4 | 1 | 20 | 60 | 84.94 | 83.21 | 66.31 | 66.52 | 82.92 | 81.5 |

| 10 | 6 | 1 | 20 | 60 | 69.26 | 69.51 | 72.28 | 71.23 | 78.46 | 78.77 |

| 11 | 4 | 2 | 20 | 60 | 88.5 | 87.87 | 79.64 | 82.27 | 92.28 | 92.47 |

| 12 | 6 | 2 | 20 | 60 | 76.12 | 76.3 | 75.36 | 75.43 | 86.37 | 85.57 |

| 13 | 4 | 1 | 50 | 60 | 77.51 | 79.95 | 62.41 | 63.61 | 76.54 | 76.44 |

| 14 | 6 | 1 | 50 | 60 | 67.8 | 67.23 | 66.85 | 66.69 | 71.89 | 72.92 |

| 15 | 4 | 2 | 50 | 60 | 85.4 | 85.56 | 85.19 | 85.5 | 89.17 | 88.89 |

| 16 | 6 | 2 | 50 | 60 | 78.16 | 74.98 | 75.54 | 77.02 | 82.35 | 81.2 |

| 17 | 5 | 1.5 | 35 | 45 | 96.5 | 94.75 | 91.42 | 93.13 | 96.34 | 96.94 |

| 18 | 5 | 1.5 | 35 | 45 | 96.5 | 94.75 | 96.83 | 93.13 | 97.69 | 96.94 |

| 19 | 5 | 1.5 | 35 | 45 | 93.1 | 94.75 | 91.26 | 93.13 | 95.99 | 96.94 |

| 20 | 5 | 1.5 | 35 | 45 | 95.1 | 94.75 | 96.84 | 93.13 | 96.92 | 96.94 |

| 21 | 3 | 1.5 | 35 | 45 | 62.7 | 60.65 | 52.55 | 50.06 | 59.52 | 60.13 |

| 22 | 7 | 1.5 | 35 | 45 | 40.5 | 42 | 38.87 | 40.4 | 50.07 | 49.67 |

| 23 | 5 | 0.5 | 35 | 45 | 74.14 | 71.94 | 57.17 | 58.84 | 80.36 | 79.53 |

| 24 | 5 | 2.5 | 35 | 45 | 82.5 | 84.15 | 84.67 | 82.04 | 98.29 | 99.33 |

| 25 | 5 | 1.5 | 5 | 45 | 83.37 | 83.49 | 88.41 | 88.42 | 67.51 | 68.23 |

| 26 | 5 | 1.5 | 65 | 45 | 81.49 | 80.82 | 88.35 | 87.38 | 62.9 | 62.39 |

| 27 | 5 | 1.5 | 35 | 15 | 79.37 | 77.01 | 80.38 | 81.29 | 85.52 | 84.72 |

| 28 | 5 | 1.5 | 35 | 75 | 97.3 | 99.11 | 96.47 | 94.6 | 97.49 | 98.5 |

| 29 | 5 | 1.5 | 35 | 45 | 96.2 | 97.1 | 94.36 | 95.8 | 95.27 | 93.48 |

| 30 | 5 | 1.5 | 35 | 45 | 95.81 | 97.1 | 93.42 | 95.8 | 92.51 | 93.48 |

| Term | Coefficient | Standard Error | T-Value | p-Value | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| COD | BOD | SS | COD | BOD | SS | COD | BOD | SS | COD | BOD | SS | |

| Constant | 95.926 | 94.47 | 95.209 | 0.978 | 1.01 | 0.506 | 98.07 | 93.09 | 188.14 | 0.000 | 0.000 | 0.000 |

| X1 | −4.661 | −2.416 | −2.614 | 0.483 | 0.501 | 0.250 | −9.65 | −4.82 | −10.46 | 0.000 | 0.000 | 0.000 |

| X2 | 3.053 | 5.799 | 4.949 | 0.483 | 0.501 | 0.250 | 6.32 | 11.57 | 19.80 | 0.000 | 0.000 | 0.000 |

| X3 | −0.666 | −0.261 | −1.461 | 0.483 | 0.501 | 0.250 | −1.38 | −0.52 | −5.85 | 0.190 | 0.611 | 0.000 |

| X4 | 5.526 | 3.327 | 3.444 | 0.483 | 0.501 | 0.250 | 11.44 | 6.64 | 13.78 | 0.000 | 0.000 | 0.000 |

| X12 | −11.443 | −12.643 | −9.645 | 0.452 | 0.469 | 0.234 | −25.33 | −26.97 | −41.26 | 0.000 | 0.000 | 0.000 |

| X22 | −4.763 | −6.340 | −1.012 | 0.452 | 0.469 | 0.234 | −10.54 | −13.52 | −4.33 | 0.000 | 0.000 | 0.001 |

| X32 | −3.736 | −1.975 | −7.042 | 0.452 | 0.469 | 0.234 | −8.27 | −4.21 | −30.12 | 0.000 | 0.001 | 0.000 |

| X42 | −2.260 | −1.964 | −0.467 | 0.452 | 0.469 | 0.234 | −5.00 | −4.19 | −2.00 | 0.000 | 0.001 | 0.066 |

| X1X2 | 0.534 | −2.889 | −1.042 | 0.592 | 0.614 | 0.306 | 0.90 | −4.71 | −3.41 | 0.382 | 0.000 | 0.004 |

| X1X3 | 0.249 | −0.409 | −0.198 | 0.592 | 0.614 | 0.306 | 0.42 | −0.67 | −0.65 | 0.681 | 0.516 | 0.529 |

| X1X4 | −1.410 | 1.474 | 0.010 | 0.592 | 0.614 | 0.306 | −2.38 | 2.40 | 0.03 | 0.032 | 0.031 | 0.974 |

| X2 X 3 | 0.239 | 1.534 | 0.370 | 0.592 | 0.614 | 0.306 | 0.40 | 2.50 | 1.21 | 0.693 | 0.026 | 0.247 |

| X2X 4 | 0.050 | 0.724 | −0.137 | 0.592 | 0.614 | 0.306 | 0.08 | 1.18 | −0.45 | 0.934 | 0.258 | 0.660 |

| X3X 4 | −0.480 | −0.066 | −0.895 | 0.592 | 0.614 | 0.306 | −0.81 | −0.11 | −2.92 | 0.431 | 0.916 | 0.011 |

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Value | p-Value | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a COD | b BOD | c SS | COD | BOD | SS | COD | BOD | SS | COD | BOD | SS | ||

| Block | 1 | 36.72 | 47.62 | 80.04 | 36.72 | 47.62 | 80.04 | ||||||

| Model | 14 | 5479.52 | 6399.73 | 4668.36 | 391.39 | 457.12 | 333.45 | 69.89 | 75.83 | 222.45 | <0.0001 | <0.0001 | <0.0001 |

| Residual | 14 | 78.40 | 84.40 | 20.99 | 5.60 | 6.03 | 1.50 | ||||||

| Lack of fit | 10 | 70.56 | 53.75 | 15.52 | 7.06 | 5.37 | 1.55 | 3.60 | 0.7014 | 1.14 | 0.1142 | 0.7051 | 0.4907 |

| Pure error | 4 | 7.84 | 30.65 | 5.47 | 1.96 | 7.66 | 1.37 | ||||||

| Total | 29 | 5594.64 | 6531.74 | 4769.39 | |||||||||

| Parameters | Optimized Condition | Removal (%) | |||||

|---|---|---|---|---|---|---|---|

| COD | BOD | SS | |||||

| Predicted | Actual | Predicted | Actual | Predicted | Actual | ||

| pH | 4.7 | 97.73 | 96.21 ± 2.34 | 98.15 | 96.72 ± 1.85 | 97.58 | 96.97 ± 2.18 |

| Coagulant dosage (g/L) | 1.82 | ||||||

| Slow mixing speed (rpm) | 30 | ||||||

| Flocculation time (min) | 60 | ||||||

| Parameters | T (°C) | qe (Exp) (mg/mg) | Pseudo-1st-Order Kinetics | Pseudo-2nd-Order Kinetics | Thermodynamics | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| qe (mg/mg) | K1 (1/min) | R2 | qe (mg/mg) | K2 (mg/mg.min) | R2 | ΔGo (kJ/mol) | ΔHo (kJ/mol) | ΔSo (J/mol) | |||

| COD | 28 | 1.519 | 1.466 | 0.0531 | 0.9711 | 1.731 | 0.076 | 0.9953 | 8.622 | 8.426 | −5.372 |

| 40 | 1.526 | 1.342 | 0.0524 | 0.9687 | 1.703 | 0.093 | 0.9984 | 8.628 | |||

| 50 | 1.530 | 1.096 | 0.0444 | 0.9553 | 1.666 | 0.123 | 0.9991 | 8.635 | |||

| 60 | 1.551 | 1.022 | 0.0375 | 0.9951 | 1.660 | 0.142 | 0.9993 | 8.641 | |||

| 70 | 1.562 | 1.155 | 0.0481 | 0.9598 | 1.651 | 0.162 | 0.9997 | 8.648 | |||

| BOD | 28 | 0.767 | 0.746 | 0.0227 | 0.9987 | 0.854 | 0.148 | 0.9975 | 8.401 | 8.337 | −1.758 |

| 40 | 0.769 | 0.715 | 0.0217 | 0.9975 | 0.839 | 0.175 | 0.9955 | 8.403 | |||

| 50 | 0.771 | 0.686 | 0.0206 | 0.9864 | 0.841 | 0.183 | 0.9965 | 8.406 | |||

| 60 | 0.777 | 0.639 | 0.0173 | 0.9296 | 0.842 | 0.197 | 0.9971 | 8.408 | |||

| 70 | 0.778 | 1.306 | 0.0025 | 0.8981 | 0.830 | 0.240 | 0.9983 | 8.410 | |||

| SS | 28 | 3.525 | 1.330 | 0.0019 | 0.9711 | 3.824 | 0.039 | 0.9953 | 8.675 | 8.419 | −7.034 |

| 40 | 3.545 | 1.452 | 0.0258 | 0.9774 | 3.848 | 0.041 | 0.9948 | 8.684 | |||

| 50 | 3.554 | 1.459 | 0.0316 | 0.9568 | 3.854 | 0.048 | 0.9965 | 8.692 | |||

| 60 | 3.579 | 1.462 | 0.0347 | 0.9746 | 3.864 | 0.054 | 0.9984 | 8.701 | |||

| 70 | 3.587 | 1.377 | 0.0364 | 0.9779 | 3.797 | 0.074 | 0.9995 | 8.709 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hossain, M.S.; Rashdi, S.A.; Hamed, Y.; Al-Gheethi, A.; Omar, F.M.; Zulkifli, M.; Ahmad Yahaya, A.N. Implementation of FeSO4·H2O as an Eco-Friendly Coagulant for the Elimination of Organic Pollutants from Tertiary Palm Oil Mill Effluent: Process Optimization, Kinetics, and Thermodynamics Studies. Water 2022, 14, 3602. https://doi.org/10.3390/w14223602

Hossain MS, Rashdi SA, Hamed Y, Al-Gheethi A, Omar FM, Zulkifli M, Ahmad Yahaya AN. Implementation of FeSO4·H2O as an Eco-Friendly Coagulant for the Elimination of Organic Pollutants from Tertiary Palm Oil Mill Effluent: Process Optimization, Kinetics, and Thermodynamics Studies. Water. 2022; 14(22):3602. https://doi.org/10.3390/w14223602

Chicago/Turabian StyleHossain, Md. Sohrab, Shabib Al Rashdi, Yaman Hamed, Adel Al-Gheethi, Fatehah Mohd Omar, Muzafar Zulkifli, and Ahmad Naim Ahmad Yahaya. 2022. "Implementation of FeSO4·H2O as an Eco-Friendly Coagulant for the Elimination of Organic Pollutants from Tertiary Palm Oil Mill Effluent: Process Optimization, Kinetics, and Thermodynamics Studies" Water 14, no. 22: 3602. https://doi.org/10.3390/w14223602