Performance of Various Filtering Media for the Treatment of Cow Manure from Exercise Pens—A Laboratory Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Setup and Design

2.2. Application of Synthetic Dairy Cow Manure and Rainwater

2.3. Physicochemical Analyses of Effluents

2.4. Statistical Analyses

3. Results and Discussion

3.1. Synthetic Dairy Cow Manure

3.2. Effluent pH

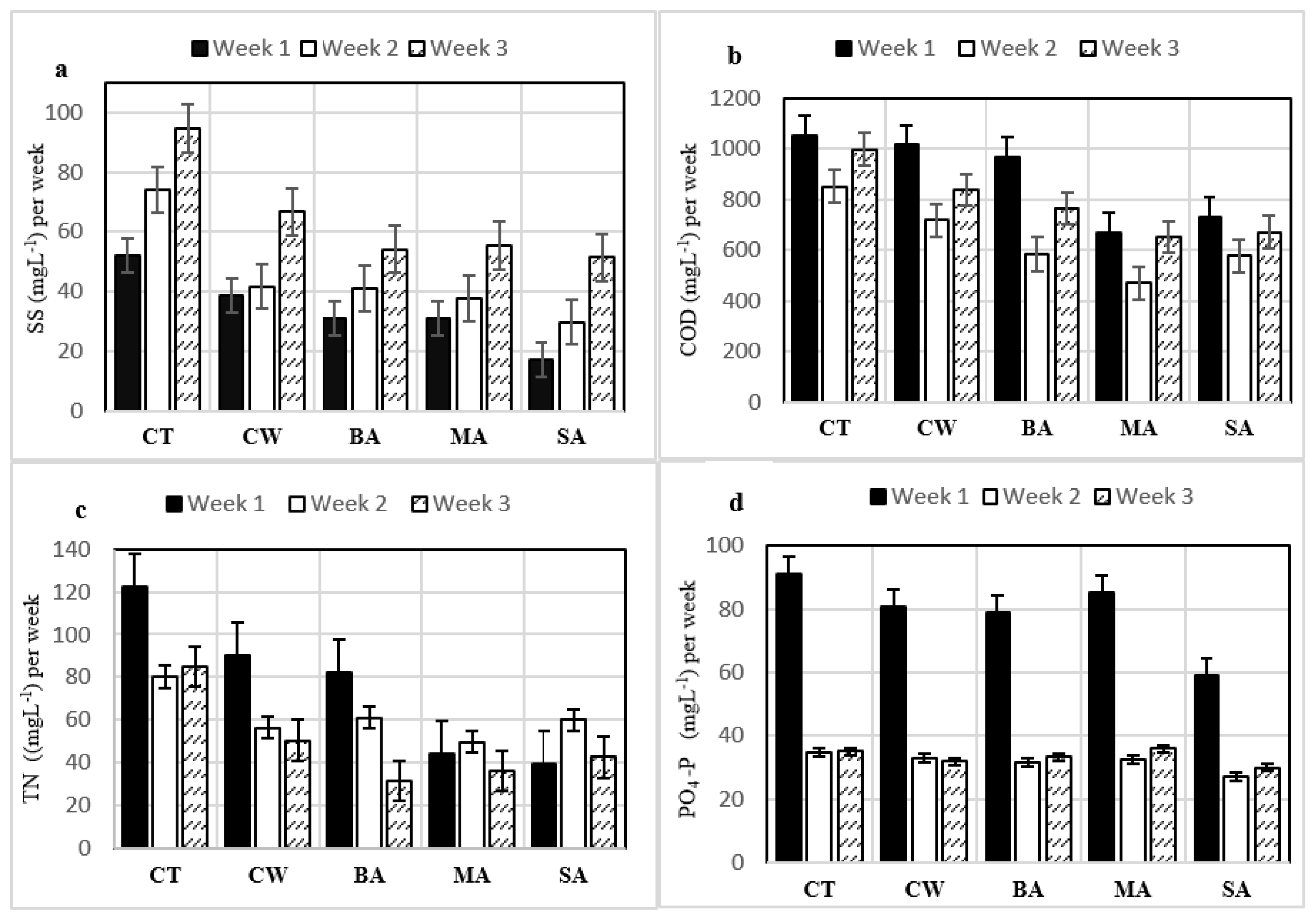

3.3. Weekly Effluent Concentrations

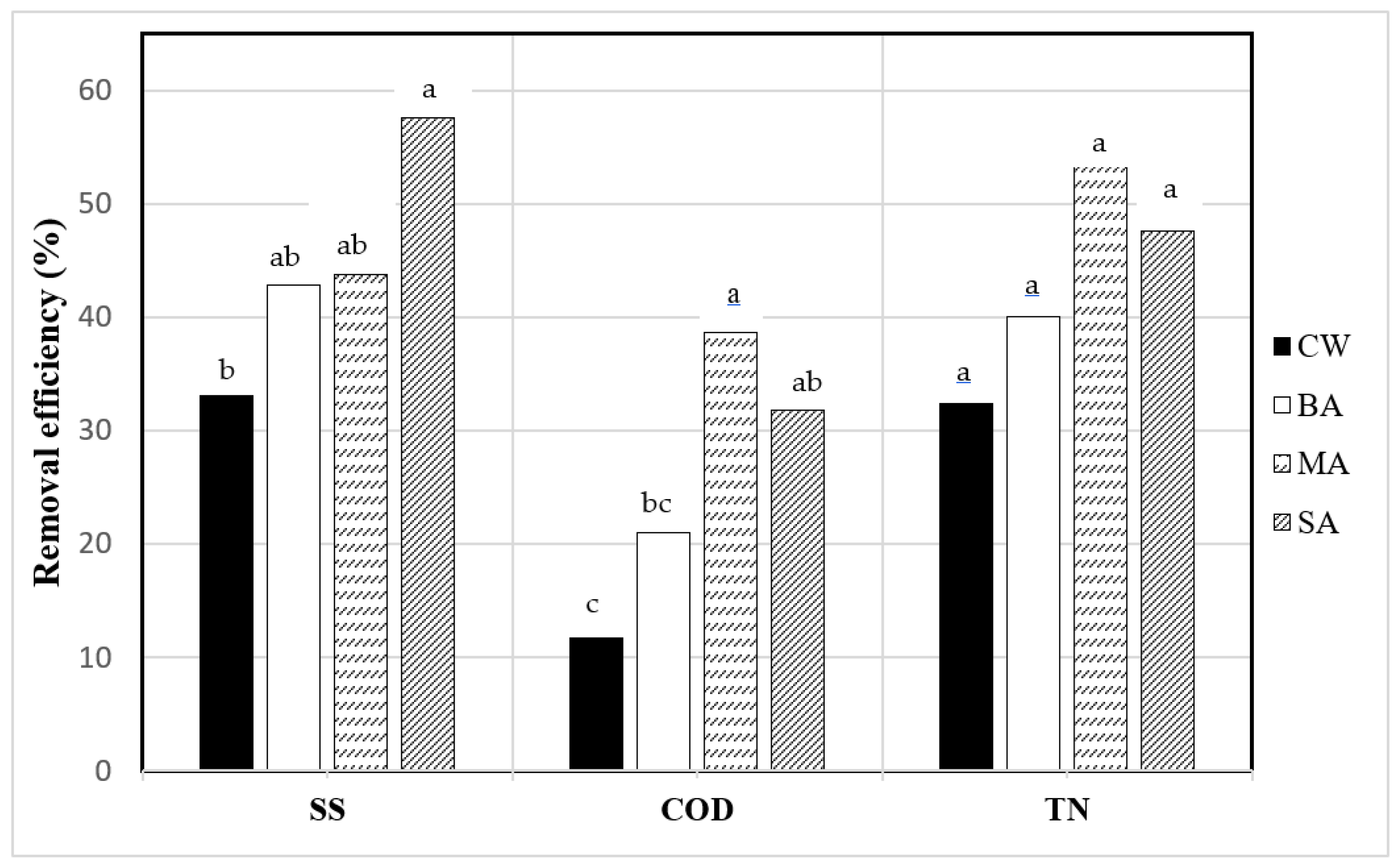

3.4. Contaminant Removal Efficiencies

3.4.1. Suspended Solids (SS) and Turbidity (Tb)

3.4.2. Removal of Organic Matter (COD)

3.4.3. Total Nitrogen (TN) and Nitrates (NO3-N)

3.4.4. Phosphates (PO4-P)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- PLQ. 2021. Available online: https://lait.org/la-ferme-en-action/sur-la-ferme/ (accessed on 7 June 2022).

- CDIC. 2021. Available online: https://agriculture.canada.ca/en/canadas-agriculture-sectors/animal-industry/canadian-dairy-information-centre/dairy-statistics-and-market-information/farm-statistics/dairy-barns-type (accessed on 5 June 2022).

- Galama, P.; Ouweltjes, W.; Endres, M.; Sprecher, J.; Leso, L.; Kuipers, A.; Klopčič, M. Symposium review: Future of housing for dairy cattle. J. Dairy Sci. 2020, 103, 5759–5772. [Google Scholar] [CrossRef] [PubMed]

- Popescu, S.; Borda, C.; Diugan, E.A.; Spinu, M.; Groza, I.S.; Sandru, C.D. Dairy cows welfare quality in tie-stall housing system with or without access to exercise. Acta Vet. Scand. 2013, 5, 43. [Google Scholar] [CrossRef] [PubMed]

- Beaver, A.; Weary, D.M.; von Keyserlingk, M.A. Invited review: The welfare of dairy cattle housed in tiestalls compared to less-restrictive housing types: A systematic review. J. Dairy Sci. 2021, 104, 9383–9417. [Google Scholar] [CrossRef] [PubMed]

- Nalon, E.; Stevenson, P. Protection of dairy cattle in the EU: State of play and directions for policymaking from a legal and animal advocacy perspective. Animals 2019, 9, 1066. [Google Scholar] [CrossRef]

- Werema, C.W.; Yang, D.A.; Laven, L.J.; Mueller, K.R.; Laven, R.A. Evaluating Alternatives to Locomotion Scoring for Detecting Lameness in Pasture-Based Dairy Cattle in New Zealand: In-Parlour Scoring. Animals 2022, 12, 703. [Google Scholar] [CrossRef]

- NFACC. Available online: https://www.nfacc.ca/codes-of-practice/dairy-cattle (accessed on 10 June 2022).

- Labelle, F. Solutions Pratiques Pour Offrir de L’exercice Aux Bovins Laitiers Biologiques Pendant L’hiver; Valacta: Québec, QC, Canada, 2016; p. 45. [Google Scholar]

- Shepley, E.; Bergeron, R.; Bécotte, F.; Vasseur, E. Dairy cow preference for outdoor access during winter under Eastern Canada climatic conditions. Can. J. Anim. Sci. 2016, 97, 1–5. [Google Scholar] [CrossRef]

- Charlton, G.L.; Rutter, S.M.; East, M.; Sinclair, L.A. Preference of dairy cows: Indoor cubicle housing with access to a total mixed ration vs. access to pasture. Appl. Anim. Behav. Sci. 2011, 130, 1–9. [Google Scholar] [CrossRef]

- Mandel, R.; Whay, H.R.; Klement, E.; Nicol, C.J. Invited review: Environmental enrichment of dairy cows and calves in indoor housing. J. Dairy Sci. 2016, 99, 1695–1715. [Google Scholar] [CrossRef]

- Pelletier, F.; Godbout, S.; Georg, H.; Brassard, P.; Fournel, S.; Sporkmann, K.; Chrétien, F.; Joncas, R. Environmental issues and wintering pen for cow-calf: 15th years of research. In Proceedings of the 2016 Canadian Society for Bioengineering (CSBE) Annual General Meeting and Technical Conference, Halifax, NS, Canada, 24–27 July 2016. [Google Scholar]

- Smith, K.; Chadwick, D.; Dumont, P.; Grylls, J.; Sagoo, E. Woodchip Pads for Out-Wintering Cattle-Technical Review of Environmental Aspects; Report LK0676. Available online: https://meatpromotion.wales/images/resources/Woodchip_pad_review_fin_May-10-1.pdf (accessed on 5 June 2022).

- Basden, T. Wood Chip Pad Winter Feeding Area as a New Livestock Manure Management System. In Paper Presented at the Waste to Worth: Spreading Science and Solutions; USDA National Institute of Food and Agriculture: Washington, DC, USA, 2015. Available online: https://lpelc.org/wood-chip-pad-winter-feeding-area-as-a-new-livestock-manure-management-system/ (accessed on 5 June 2022).

- Dairy, N.Z. Stand-off Pads (Your Essential Guide to Planning, Design and Management). 2021. Available online: https://www.dairynz.co.nz/media/5787814/stand-off_pads_booklet_june-2017_dnz40_050_web.pdf (accessed on 5 June 2022).

- Luo, J.; Donnison, A.; Ross, C.; Ledgard, S.; Longhurst, B. Control of pollutants using stand-off pads containing different natural materials. Proc. N. Z. Grassl. Assoc. 2006, 68, 315–320. [Google Scholar] [CrossRef]

- Mažeikienė, A. Improving small-scale wastewater treatment plant performance by using a filtering tertiary treatment unit. J. Environ. Manag. 2019, 232, 336–341. [Google Scholar] [CrossRef]

- Ruane, E.M.; Murphy, P.N.; Clifford, E.; O’Reilly, E.; French, P.; Rodgers, M. Performance of a woodchip filter to treat dairy soiled water. J. Environ. Manag. 2012, 95, 49–55. [Google Scholar] [CrossRef] [PubMed]

- Jackson, D.; Chadwick, D.; Crookes, M.; Sagoo, E.; Smith, K. Impact of hydrology and effluent quality on the management of woodchip pads for overwintering cattle. II. Effluent analysis and nutrient balance. J. Agric. Sci. 2013, 151, 279–286. [Google Scholar] [CrossRef]

- Maurya, A.; Singh, M.K.; Kumar, S. Biofiltration technique for removal of waterborne pathogens. Waterborne Pathog. 2020, 123–141. [Google Scholar] [CrossRef]

- Al-Marashdeh, O.; Cameron, K.C.; Bryant, R.H.; Chen, A.; McGowan, B.; Gillé-Perrier, C.; Carey, P.; Chrystal, J.; Hodge, S.; Edwards, G.R. Effects of surface type in an uncovered stand-off pad system on comfort and welfare of non-lactating dairy cows during winter. Appl. Anim. Behav. Sci. 2019, 211, 17–24. [Google Scholar] [CrossRef]

- Bock, E.; Smith, N.; Rogers, M.; Coleman, B.; Reiter, M.; Benham, B.; Easton, Z.M. Enhanced nitrate and phosphate removal in a denitrifying bioreactor with biochar. J. Environ. Qual. 2015, 44, 605–613. [Google Scholar] [CrossRef]

- Mohanty, S.K.; Valenca, R.; Berger, A.W.; Iris, K.; Xiong, X.; Saunders, T.M.; Tsang, D.C. Plenty of room for carbon on the ground: Potential applications of biochar for stormwater treatment. Sci. Total Environ. 2018, 625, 1644–1658. [Google Scholar] [CrossRef]

- Erickson, A.J.; Kozarek, J.L.; Kramarczuk, K.A.; Lewis, L. Biofiltration Media Optimization–Phase I Final Report. 2021. Available online: https://conservancy.umn.edu/handle/11299/218193 (accessed on 5 June 2022).

- Hemmati, F.; Norouzbeigi, R.; Sarbisheh, F.; Shayesteh, H. Malachite green removal using modified sphagnum peat moss as a low-cost biosorbent: Kinetic, equilibrium and thermodynamic studies. J. Taiwan Inst. Chem. Eng. 2016, 58, 482–489. [Google Scholar] [CrossRef]

- Abu Al–Roos, B.K.A.; Lubbad, S.H.; Abu–Saqer, K.K. Assessment of thermally treated sphagnum peat moss sorbents for removal of phenol red, bromothymol blue and malachite green from aqueous solution. Int. J. Environ. Stud. 2019, 76, 861–872. [Google Scholar] [CrossRef]

- Taskila, S.; Särkelä, R.; Tanskanen, J. Valuable applications for peat moss. Biomass Convers. Biorefinery 2016, 6, 115–126. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, J.; Huang, L.; Yuan, Z.; Li, Z.; Liu, M. Removal of Cd and Pb with biochar made from dairy manure at low temperature. J. Integr. Agric. 2019, 18, 201–210. [Google Scholar] [CrossRef]

- Christianson, L.; De Vallance, D.; Faulkner, J.; Basden, T. Scientifically advanced woody media for improved water quality from livestock woodchip heavy-use areas. Front. Environ. Sci. Eng. 2017, 11, 2. [Google Scholar] [CrossRef]

- Murnane, J.G.; Brennan, R.; Healy, M.G.; Fenton, O. Assessment of intermittently loaded woodchip and sand filters to treat dairy soiled water. Water Res. 2016, 103, 408–415. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.Y.A.; Cooper, R.; Truong, N.; Ergas, S.J.; Nachabe, M.H. Water quality and hydraulic performance of biochar amended biofilters for management of agricultural runoff. Chemosphere 2021, 283, 130978. [Google Scholar] [CrossRef] [PubMed]

- Minogue, D.; French, P.; Bolger, T.; Murphy, P.N. Characterisation of dairy soiled water in a survey of 60 Irish dairy farms. Ir. J. Agric. Food Res. 2015, 54, 1–16. [Google Scholar] [CrossRef][Green Version]

- Healy, M.; Rodgers, M.; Mulqueen, J. Recirculating sand filters for treatment of synthetic dairy parlor washings. J. Environ. Qual. 2004, 33, 713–718. [Google Scholar] [CrossRef]

- Québec, G.D. Guide de Conception des Installations de Production d eau Potable. Volume 1, Modifiés le 4 Décembre. 2008. Available online: https://www.environnement.gouv.qc.ca/eau/potable/guide/index.htm (accessed on 5 June 2022).

- Quebec, L. Règlement sur L’évacuation et le Traitement des Eaux Usées des Résidences Isolées. Available online: https://www.legisquebec.gouv.qc.ca/fr/document/rc/Q-2,%20r.%2022 (accessed on 5 June 2022).

- Lee, S.-Y.; Kim, E.-G.; Park, J.-R.; Ryu, Y.-H.; Moon, W.; Park, G.-H.; Ubaidillah, M.; Ryu, S.-N.; Kim, K.-M. Effect on chemical and physical properties of soil each peat moss, elemental sulfur, and sulfur-oxidizing bacteria. Plants 2021, 10, 1901. [Google Scholar] [CrossRef]

- Ji, Y.; Wang, Y.; Sun, J.; Yan, T.; Li, J.; Zhao, T.; Yin, X.; Sun, C. Enhancement of biological treatment of wastewater by magnetic field. Bioresour. Technol. 2010, 101, 8535–8540. [Google Scholar] [CrossRef]

- Kõiv, M.; Vohla, C.; Mõtlep, R.; Liira, M.; Kirsimäe, K.; Mander, U.L. The performance of peat-filled subsurface flow filters treating landfill leachate and municipal wastewater. Ecol. Eng. 2009, 35, 204–212. [Google Scholar] [CrossRef]

- Ahmad, T.; Aadil, R.M.; Ahmed, H.; ur Rahman, U.; Soares, B.C.; Souza, S.L.; Pimentel, T.C.; Scudino, H.; Guimarães, J.T.; Esmerino, E.A. Treatment and utilization of dairy industrial waste: A review. Trends Food Sci. Technol. 2019, 88, 361–372. [Google Scholar] [CrossRef]

- Kaetzl, K.; Lübken, M.; Gehring, T.; Wichern, M. Efficient low-cost anaerobic treatment of wastewater using biochar and woodchip filters. Water 2018, 10, 818. [Google Scholar] [CrossRef]

- Achak, M.; Mandi, L.; Ouazzani, N. Removal of organic pollutants and nutrients from olive mill wastewater by a sand filter. J. Environ. Manag. 2009, 90, 2771–2779. [Google Scholar] [CrossRef] [PubMed]

- Berger, A.W.; Valenca, R.; Miao, Y.; Ravi, S.; Mahendra, S.; Mohanty, S.K. Biochar increases nitrate removal capacity of woodchip biofilters during high-intensity rainfall. Water Res. 2019, 165, 115008. [Google Scholar] [CrossRef] [PubMed]

- Bester, K.; Banzhaf, S.; Burkhardt, M.; Janzen, N.; Niederstrasser, B.; Scheytt, T. Activated soil filters for removal of biocides from contaminated run-off and waste-waters. Chemosphere 2011, 85, 1233–1240. [Google Scholar] [CrossRef] [PubMed]

- Tirpak, R.A.; Afrooz, A.N.; Winston, R.J.; Valenca, R.; Schiff, K.; Mohanty, S.K. Conventional and amended bioretention soil media for targeted pollutant treatment: A critical review to guide the state of the practice. Water Res. 2021, 189, 116648. [Google Scholar] [CrossRef]

- Bock, E.M.; Coleman, B.; Easton, Z.M. Effect of Biochar on Nitrate Removal in a Pilot-Scale Denitrifying Bioreactor. J. Environ. Qual. 2016, 45, 762–771. [Google Scholar] [CrossRef]

- Corley, M.; Rodgers, M.; Mulqueen, J.; Clifford, E. The performance of fibrous peat biofilters in treating domestic strength wastewater. J. Environ. Sci. Health Part A 2006, 41, 811–824. [Google Scholar] [CrossRef] [PubMed]

- Vohla, C.; Kõiv, M.; Bavor, H.J.; Chazarenc, F.; Mander, Ü. Filter materials for phosphorus removal from wastewater in treatment wetlands—A review. Ecol. Eng. 2011, 37, 70–89. [Google Scholar] [CrossRef]

- Rout, P.R.; Shahid, M.K.; Dash, R.R.; Bhunia, P.; Liu, D.; Varjani, S.; Zhang, T.C.; Surampalli, R.Y. Nutrient removal from domestic wastewater: A comprehensive review on conventional and advanced technologies. J. Environ. Manag. 2021, 296, 113246. [Google Scholar] [CrossRef]

| Treatment | Composition | ||||

|---|---|---|---|---|---|

| Section | Material | Depth (mm) | Grading (mm) | Quantity (g) | |

| Control (CT) | Top | Gravel | 500 | 25–50 | 1034 |

| Conventional wood (CW) | Top | Woodchips | 300 | 10–20 | 190 |

| Bottom | Gravel | 200 | 25 | 580 | |

| Biochar alternative (BA) | Top | Woodchips/biochar (20% v/v) | 300 | 10–20/<5 | 115/16.9 |

| Bottom | Gravel | 200 | 25–50 | 580 | |

| Sphagnum alternative (MA) | Top | Woodchips/sphagnum peat moss (80% v/v) | 300 | 10–20/0–20 | 28/230 |

| Bottom | Gravel | 200 | 25–50 | 580 | |

| Sand alternative (SA) | Top | Woodchips | 200 | 10–20 | 94 |

| Middle | Sand | 100 | 0.25–1.2 | 290 | |

| Bottom | Gravel | 200 | 25–50 | 580 | |

| Components | Amounts (g) |

|---|---|

| Glucose | 87 |

| Yeast | 13 |

| Dried milk | 8.6 |

| Urea | 10 |

| NH4Cl | 21 |

| Na2PO4 12H2O | 33 |

| KHCO3 | 22 |

| NaHCO3 | 57 |

| MgSO4·7H2O | 22 |

| FeSO4·7H2O | 0.9 |

| MnSO4·H2O | 0.9 |

| CaCl·6H2O | 0.2 |

| Bentonite | 18 |

| Equipment | Parameter | Method | Québec’s Environmental Regulation [35,36] |

|---|---|---|---|

| Multi-parameter Hanna (model: HAHI991301) | pH, Conductivity | Electrometric method | 6.5–8.5, <1500 µS/cm |

| DR900 Colorimeter HACH | Turbidity (Tb; 21 to 1000 FAU) | Absorptometric method 8237 HACH | 5 (NTU) |

| Suspended solids (SS; mg L−1) | Photometric method 8006 HACH (5–750 mg L−1) | 15 mg L−1 | |

| Chemical oxygen demand (COD), low (3–150 mg L−1) and high (20–1500 mg L−1) range | Colorimetric method 8000 HACH: method 410.4 EPA | ||

| Total nitrogen (NT; 2–150 mg L−1) | Persulfate digestion method, method 10072 HACH | ||

| Nitrates (NO3-N; 0.2 to 30.0 mg L−1) | Chromotropic acid method 10020 HACH | ||

| Phosphates (PO4-P; 0.3 to 45.0 mg L−1) | Molybdovanadate method 8114: method 4500-P-E | 1.0 mg L−1 |

| Parameter | Synthetic Manure | Healy, Rodgers [34] | Murnane [31] |

|---|---|---|---|

| pH | 7.7 | 7.9 | 7.22 ± 0.71 |

| Turbidity (Tb; FAU) | 79 ± 26 | - | - |

| Suspended solids (SS; mg L−1) | 78 ± 21 | 457 | 874 ± 614 |

| Chemical oxygen demand (COD; mg L−1) | 988 ± 104 | 1395 | 2798 ± 1503 |

| Total nitrogen (TN; mg L−1) | 96 ± 23 | 66 | 81.5 ± 34.1 |

| Nitrates (NO3-N; mg L−1) | 2.3 ± 2 | 12.5 | |

| Phosphates (PO4-P; mg L−1) | 50.4 ± 32 | 6.8 | 29.8 ± 14.4 |

| Treatment | Week | Parameter | |||||

|---|---|---|---|---|---|---|---|

| Tb | SS | COD | TN | PO4-P | NO3-N | ||

| CW | 1 | 25.1 | 26.1 | 3.49 | 26.4 | 11.2 | 73.6 |

| 2 | 29.6 | 43.5 | 15.6 | 29.8 | 5.61 | 68.8 | |

| 3 | 14.6 | 29.6 | 15.9 | 40.7 | 8.67 | 3.4 | |

| Avg | 23.1 | 33.1 | 11.7 | 32.3 | 8.51 | 48.6 | |

| BA | 1 | 25.4 | 40.9 | 8.11 | 32.9 | 13.5 | 90.5 |

| 2 | 31.4 | 44.7 | 31.4 | 24.0 | 4.18 | 13.1 | |

| 3 | 36.4 | 42.8 | 23.5 | 63.1 | 4.95 | 37.9 | |

| Avg | 31.1 | 42.8 | 21.0 | 40.0 | 7.56 | 47.2 | |

| MA | 1 | 11.5 | 40.4 | 36.4 | 64.0 | 6.36 | 0.0 |

| 2 | 25.0 | 49.2 | 44.7 | 38.1 | (3.5) | 84.0 | |

| 3 | 31.0 | 41.5 | 34.7 | 57.6 | (2.5) | 0.0 | |

| Avg | 22.5 | 43.8 | 38.6 | 53.3 | 0.07 | 28.0 | |

| SA | 1 | 65.0 | 67.1 | 30.3 | 67.5 | 34.9 | 13.7 |

| 2 | 55.4 | 59.7 | 32.2 | 25.3 | 17.2 | 84.4 | |

| 3 | 54.7 | 45.7 | 32.7 | 50.0 | 14.3 | 91.5 | |

| Avg | 58.4 | 57.5 | 31.7 | 47.6 | 22.2 | 63.0 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Álvarez-Chávez, E.; Godbout, S.; Rousseau, A.N.; Brassard, P.; Fournel, S. Performance of Various Filtering Media for the Treatment of Cow Manure from Exercise Pens—A Laboratory Study. Water 2022, 14, 1912. https://doi.org/10.3390/w14121912

Álvarez-Chávez E, Godbout S, Rousseau AN, Brassard P, Fournel S. Performance of Various Filtering Media for the Treatment of Cow Manure from Exercise Pens—A Laboratory Study. Water. 2022; 14(12):1912. https://doi.org/10.3390/w14121912

Chicago/Turabian StyleÁlvarez-Chávez, Elizabeth, Stéphane Godbout, Alain N. Rousseau, Patrick Brassard, and Sébastien Fournel. 2022. "Performance of Various Filtering Media for the Treatment of Cow Manure from Exercise Pens—A Laboratory Study" Water 14, no. 12: 1912. https://doi.org/10.3390/w14121912

APA StyleÁlvarez-Chávez, E., Godbout, S., Rousseau, A. N., Brassard, P., & Fournel, S. (2022). Performance of Various Filtering Media for the Treatment of Cow Manure from Exercise Pens—A Laboratory Study. Water, 14(12), 1912. https://doi.org/10.3390/w14121912