1. Introduction

Debris flow gullies in earthquake-affected areas and mountain areas vary, with differences in the micro-geomorphic conditions, loose material conditions and hydrological conditions [

1]. High potential energy debris flow is a type of debris flow which has a steep topography in the longitudinal direction and a narrow topography in the transverse direction, and its activity characteristics and mitigation measures are distinct from others [

2]. According to relevant research [

3], there was a considerable amount of debris flow in the area affected by the Wenchuan MS 8.0 earthquake which occurred on 12 May 2008, which was observed in a large gradient gully with a watershed area of F ≤ 5 km

2, a gully bed with an average longitudinal slope of I ≥ 300‰ and a basin integrity coefficient of δ ≤ 0.4 (a parameter representing the shape of a basin, which can be calculated by dividing the watershed area by the square of the length of the gully [

4]). Such debris flows are defined as ”narrow-steep“ debris flows. Compared with ordinary debris flow gullies, such debris flow gullies feature a higher longitudinal gradient, a larger amount of material source per square kilometer, a reduced critical rainfall for triggering debris flow and a high frequency and group occurrence of debris flow events. Typical cases are the mass debris flows which occurred on 13 August 2010 in Northwest Sichuan, China [

5], the mass debris flows which occurred on 17 August 2012 in Mianzhu City, and the debris flows which occurred on 20 August 2019 in Wenchuan County, resulting in greater damage, loss and environmental impacts than those which occurred before the earthquake [

6].

In terms of the mitigation strategies for debris flows with a high potential energy, the engineering measures are also different from those of common debris flows [

7]. A reasonable drainage gradient of a conventional debris flow is generally 30‰ to 100‰ (dilute debris flow) or 50‰ to 180‰ (viscous debris flow) [

8], while the average longitudinal slope of a high potential debris flow is generally more than 300‰. Large altitude differences in the catchment area have two consequences: one is the high flow velocity of the debris flow, some of which can be as high as 8.0m/s; and the other is the strong carrying capacity, by which it can carry a large quantity of large-sized boulders (generally with a grain size ≥ 1.0 m). For example, the largest boulder found in the Sanyanyu debris flow gully was 12.9 m × 8.6 m × 7.2 m [

7]. Therefore, the debris flow’s ability to abrade is significant for the movement process. In projects for debris flow prevention and control, the limit velocity of the abrasion resistance of masonry material is 8–10 m/s and that of concrete material is 10–12 m/s [

8]. If the velocity of the debris flow exceeds this limit, the structure will suffer serious abrasion, which will affect its normal operation, even reducing its service life.

The need to effectively reduce the abrasion damage of the debris flow to the bottom plate and side wall of the drainage channel and to ensure the set service life of the drainage channel are important issues in the design of drainage channels with large gradients (DCLG) [

3,

9]. From the perspective of engineering applications, the possible solutions can be summarized as follows [

10]: (1) the approach of optimizing the structural design so as to dissipate energy at the channel bottom; (2) the measure of improving the construction material’s performance, such as improving the concrete grade and adding admixtures; (3) the measure of adding auxiliary structures, such as laying formed steel structures on the channel bottom. A series of experimental studies were carried out using a new type of drainage channel with an energy dissipation structure [

11,

12,

13,

14], as well as different types and energy dissipation characteristics of debris flow deceleration baffles [

15]. Chen [

16] proposed a debris flow drainage channel with a step-pool configuration. Zhou [

17] analyzed the erosion mechanism and stress of a debris flow slurry on the drainage channel, but this study was insufficiently supported by quantitative data. In terms of the use of auxiliary materials to improve the wear resistance of concrete, the current research mainly focuses on the wear resistance of the structural concrete of hydraulic structures, such as spillways, discharge holes and ship locks. Steel fibers, epoxy resin, steel rail and steel plate are added to the concrete as auxiliary measures [

18,

19,

20,

21]. For example, silicon powder with high hardness is suitable for micro-cutting wear, while polypropylene fibers and steel fibers with high flexibility and integrity are suitable for mitigating the impact of deformation wear [

22].

However, most of the current research is focused upon model experimentation and numerical simulation, which have not been applied and efficiency-tested in engineering practice. It is necessary to further study the abrasion characteristics, energy dissipation and anti-wear technical measures of the DCLG for steep gullies. The influencing factors of debris flow abrasion capacity, the composition of the abrasion system and features of abrasion morphology, the regulating effects of energy dissipation and anti-wear measures of the drainage channel and the design and construction methods should be included so as to expand the applicable range of the use of drainage channels as a mitigation measure and improve the service life and operational uses of drainage channels.

2. Materials and Methods

2.1. Study Site Description

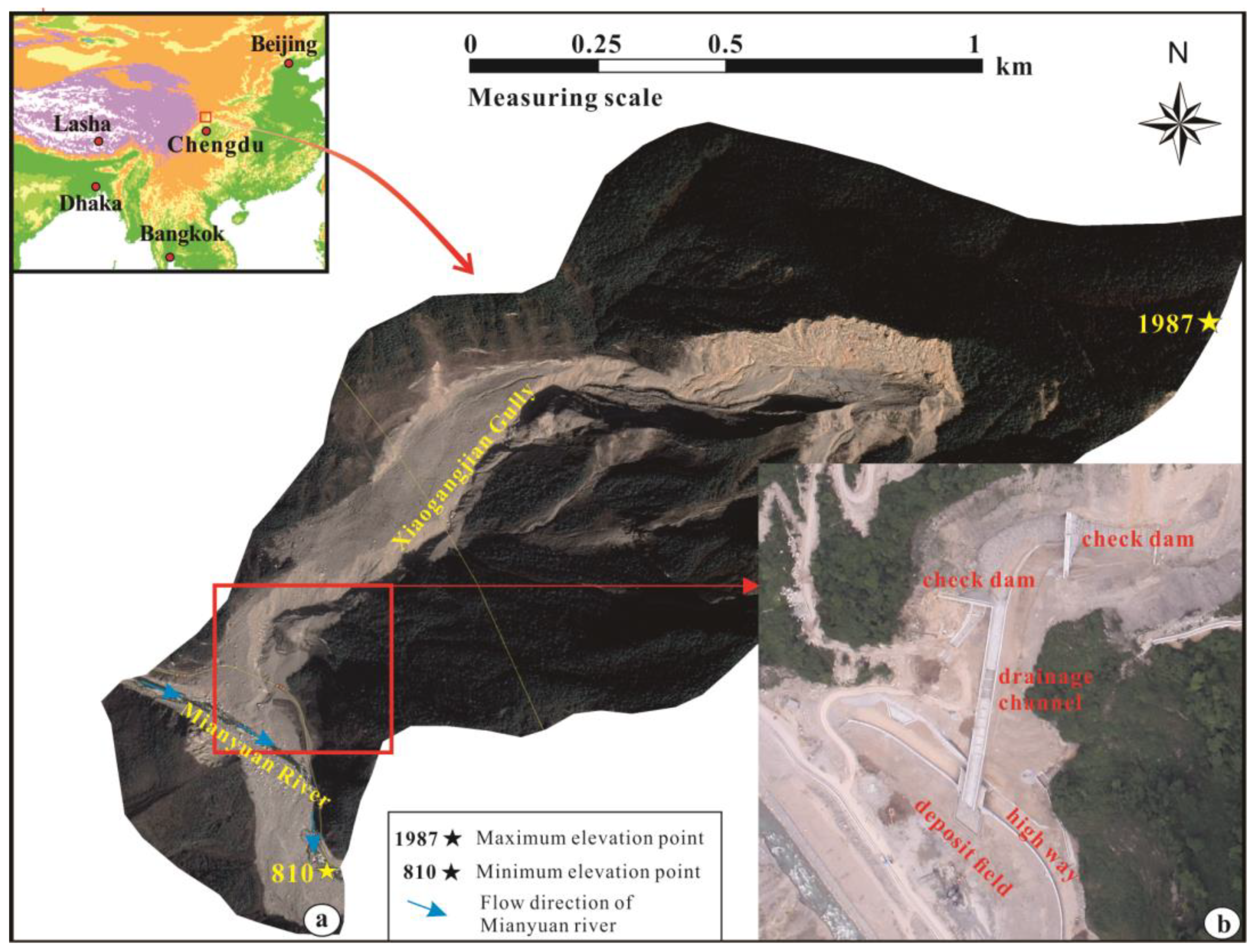

This study takes the Wenchuan earthquake zone, a representative area in the high mountain region of Southwest China, as the research area, and focuses on the Xiaogangjian debris flow drainage channel as an example in order to analyze the characteristics of abrasion and anti-wear measures. The Xiaogangjian gully is located in the town of Qingping, Mianzhu City, Sichuan Province. It is on the right side of the road from Mianzhu to Maoxian and on the left bank of the Mianyuan River. The coordinates of the gully fan are N 31°30′14.75″ and E 104°07′44.55″. The horizontal form of the watershed is shaped like a salix leaf (

Figure 1), and the area of land sloping by more than 25° in the gully accounts for 85.29% of the total basin area. Moreover, the free face has become formed of loose deposits, which provides favorable conditions for the rapid collection of rainfall runoff and the development of adverse geological phenomena such as collapse, landslide and unstable slopes, as well as the transportation of a loose solid source of debris flow.

The Xiaogangjian gully is a typical debris flow with a high potential energy, due to a longitudinal slope of 506‰ in the formation area. The cross-section of the gully is of a deep “V” shape. The longitudinal gradient of the outlet section of the gully is 337.8‰, and on the left bank, there is a loose accumulation with a volume of 2.26 × 10

5 m

3 and a slope of 42°~70°. There was no ditch developed before the “5.12” earthquake. After the earthquake, the topographic and hydrodynamic conditions of the gully were facilitated, and it was eroded intensely. Then, the gully developed a high susceptibility and high frequency of occurrence. From 12 May 2008 to 5 September 2011, 10 debris flows with a total volume of more than 5 × 10

4 m

3 occurred, resulting in the gully being cut into a deep trench with a depth of 30–45 m and a width of 48–65 m. The debris flow burst out of the gully and rushed into the Mianyuan River. It not only buried the highway several times but also blocked the river, forming a barrier lake upstream of the accumulation fan. The geomorphological parameters of the gully are listed in

Table 1.

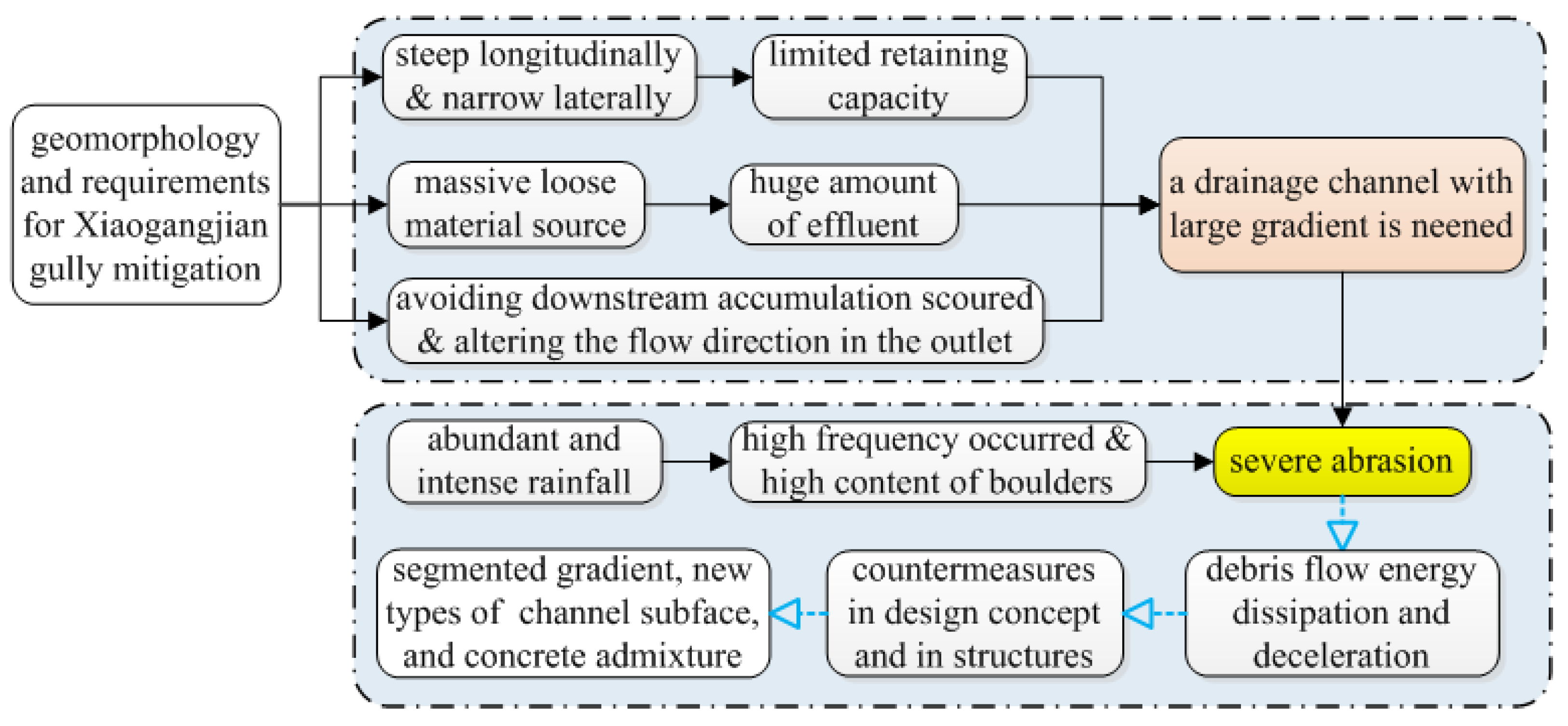

2.2. Disaster Mitigation Needs

For this kind of debris flow mitigation, there is a significant disparity between the large amount of loose material sources and the limited retaining conditions. According to a geological survey, there is, in total, 3.343 × 10

6 m

3 of loose material in the Xiaogangjian gully, and the possible dynamic reserve involved in the debris flow activities measures 1.568 × 10

6 m

3. The calculated loose sources per km

2 are 2.458 × 10

6 m

3/km

2, which indicates that the debris flow was controlled by the transport of material in the 5–10 years following the earthquake [

23].

However, because of the narrow and steep terrain conditions, the effective intervention area for retaining works, such as checking dams, is limited to only 15% of the total area of the basin. Moreover, the width–depth ratio of the ditch is only 1.0~1.5, so the dam locations that are suitable for construction and the reservoir capacity are very limited. Once debris flow occurs in the upper reaches, the old loose deposits in the lower reaches of the basin will be cut through in order to increase the supply sources along the gully and increase the scale of the debris flow.

From above, due to the need to prevent the formation of loose deposits at the terminus of the gully and to protect the highway on the fan and change the angle of the debris flow entering the Mianyuan River, it is necessary to build a drainage channel in order to quickly drain the rush-out materials from the middle regions to the outside of the gully (

Figure 2). The channel will pass over the highway and enter the desilting field. Therefore, a DCLG must be adopted.

2.3. The Abrasion Behavior of DCLG

Abrasion phenomena are caused by the local jet or circulation which is formed at the bottom of the structural plane by the turbulent flow of fluid with high kinetic energy, which drives the repeated impact and scour of the block stone and gravel. Abrasion behavior varies due to the changes in fluid properties, movement characteristics and channel characteristics. Debris flows with high bulk density and high viscosity have the characteristics of wide gradation, huge particles, complex interactions and energy exchange between solid and liquid phases. As a result, the abrasion mechanism of a debris flow drainage channel is also very complex, and it is obviously different from other types of abrasion behavior such as mechanical friction, wind sand flow, high sediment flow and so on. Under the combined action of debris flow slurry erosion and coarse particle impact, the lining surface of the drainage channel shows the process of ”shear or impact → strength weakening → crack generation and expansion → local stress concentration producing eddy current → gravel abrasion → gradual wear expansion and deepening → bottom stripping, cutting groove or potholes“. It could eventually cause the entirety of the bottom of the channel to be damaged, maybe even causing the side wall to overturn or wear through the bottom, thus losing the drainage function.

2.3.1. Characteristics of Abrasion Morphology (AM)

According to field investigation in the study area, the AM of debris flow on structures is mainly divided into four categories (

Figure 3): (a) Relatively uniform surface peeling (USP); that is, the scraping on the surface is basically flat and creates a smooth layer by layer thinning, which appears on the bottom surface of the drainage channel and the inner faces of the side walls, when the particles in the fluid are relatively uniform and the flow state is stable; (b) Plowing groove along the streamline direction (PG), which generally appears at the bottom of a fully lined drainage channel, which is steep and long, with the fluid viscous, the bulk density high and the fluid composed of hard and angular block stones; (c) Jumping erosion pits (JEP), which are similar to the “potholes” developed on the bed rock of the high sandy rivulets and rivers in mountain areas [

24], which mainly occur on the bottom of a fully lined channel with a large longitudinal slope or under the drop-sills—the flow is turbulent and easily forms eddy currents; (d) Surface wear of the ground sills (SWGS), mainly in the middle of the rib sill, forming a transverse slope from both sides to the middle.

In field investigations, several forms of AM usually exist at the same time. With a change in working conditions, different forms of wear have different primary and secondary causes.

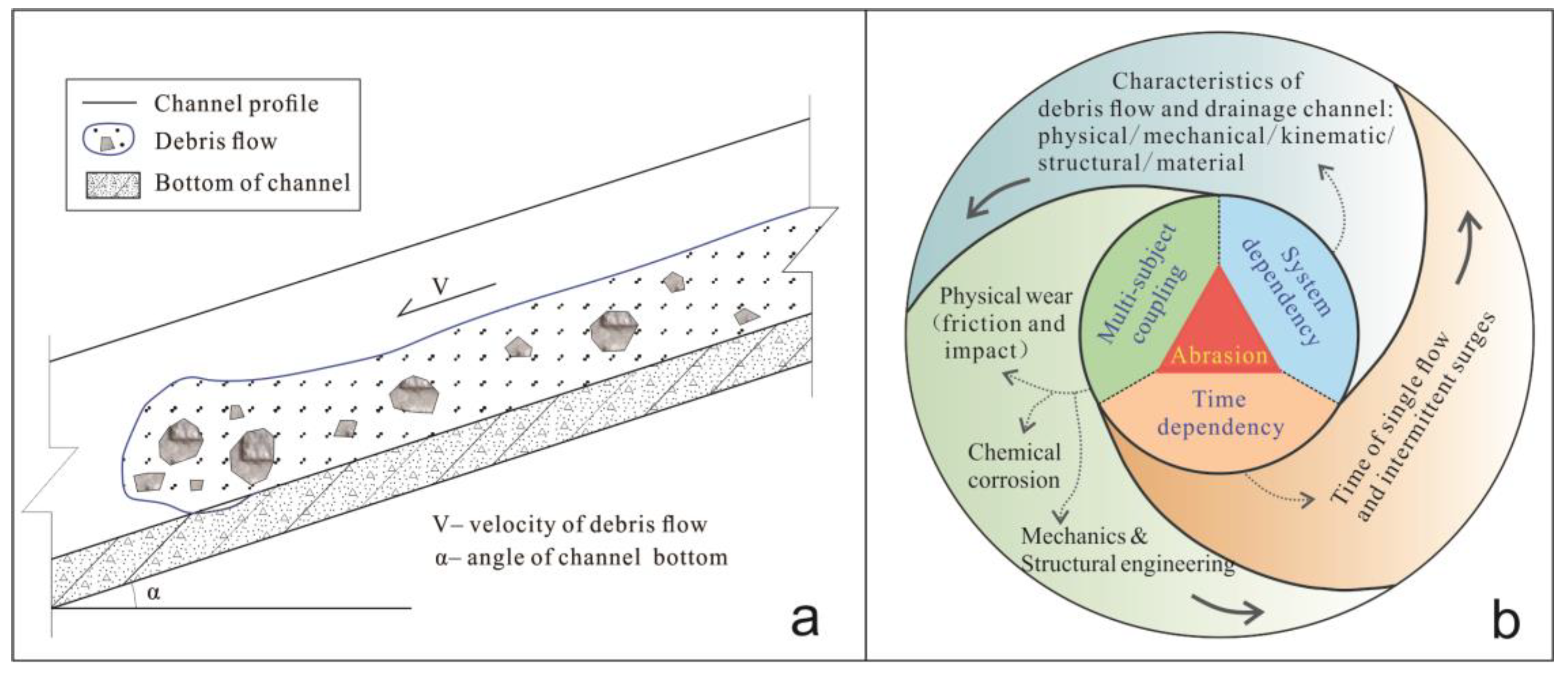

2.3.2. Composition and Influencing Factors of Abrasion System

From the perspective of tribology, the debris flow and channel surface can be regarded as a tribological system [

25] (

Figure 4a). The abrasive process has both sliding friction properties and rolling friction and micro-corrosion friction properties [

26]. As a multiphase and multi-ingredient fluid, debris flow should be considered as a structural fluid composed of slurry and coarse particles [

27,

28]. Special friction pairs are formed by debris flow and the structural surface of a drainage channel, forming the macro-phenomenon of scour, abrasion or deposition upon the structural surface.

As a tribological system, abrasion can be studied from the effects of system dependence, time dependence and multi-disciplinary coupling (shown in

Appendix A) [

29]. The abrasion behavior is system dependent, and the characteristics of its elements are time dependent. The elements of the abrasion system of the DCLG are shown in

Figure 4b. In the abrasion system, relative motion and interaction occur between the debris flow and the structure surface, and the two friction pairs have their own properties. The attributes of debris flow include the physical, mechanical and kinematic properties, and the attributes of a drainage channel are the structure types and materials. In terms of the disciplinary properties, these include the physical wear effects of sliding, impinging and friction on the bottom surface of the drainage channel by the block stones in the debris flow that occurred during the abrasion process, as well as the chemical corrosion between the slurry and concrete. Moreover, the abrasion is also closely related to the disciplines of mechanics (fluid mechanics, solid mechanics, and so on) and structural engineering. These attributes and behaviors are concentrated and coupled in the system, and they vary with the system’s state and time.

Analyzing in terms of energy, when the debris flow passes through the drainage channel, it overcomes the shear resistance of the structural surface, and some of the energy is dissipated [

30]. At the same time, some of the energy will be dissipated when the fluid collides with the structure’s surface and with the particles inside the fluid. Therefore, the abrasion power of the debris flow is mainly related to such factors as bulk density, velocity, particle composition, duration, mud depth and scouring angle [

28,

31,

32], while the abrasion resistance of the drainage channel is related to section type, material strength (shear strength, compressive strength), aggregate grading and hardness.

Based on the influencing factors, the abrasion quantity could be expressed as follows:

where

γ,

ν,

τ0,

μ and

FD respectively represent the density, velocity, initial shear force, viscosity coefficient and drag force;

d90 and

d10 represent the particle size of the debris flow, which refers to the particle size of a sample when the cumulative percentage of particle size distribution reaches 90% and 10%;

σ,

α and

E respectively represent the positive pressure, scouring angle and elastic modulus of the channel bottom.

2.3.3. Dynamic Source of the Abrasion

The dynamic source of the abrasion is the high potential energy of the debris flow. As they originate on high and steep hillsides, the longitudinal slopes of debris gullies are far larger than those of common rivers (

Figure 5). With the high potential energy caused by the large height difference, debris flow washes against the DCLG, and the potential energy is rapidly converted into kinetic energy, with the flow velocity increasing along the path. The large particles contained in the fluid also move and jump rapidly under the action of gravity and drag force, which causes the impact, peeling and furrowing of grooves on the drainage structure.

According to the analysis of the debris flow activities in the Xiaogangjian gully from 2009 to 2013, the formation process is shown in

Figure 5. The gully was covered by a layer of very thick loose overburden, and a free surface developed. Once the debris flow is formed under the action of a rainstorm, it will rapidly drain along the steep gully, which is easily cut and eroded. The most important process is the conversion of the high potential energy into high kinetic energy.

2.3.4. Calculation Method of Debris Flow Abrasion

The abrasion behavior of debris flow on the concrete of a drainage channel is as follows: a bed load with a large particle size acts on the surface of the structure by rolling friction, jumping impact, sliding friction, etc., and the suspended sediment scours the surface with the flow fluctuation, which is similar to the abrasion effect of sand in high-speed sand flow on a hydroelectric spillway. According to the theory of abrasive wear energy in sediment laden flow [

33], the function of the bed load and suspended load is expressed in a unified way and the bulk density of the debris flow is considered. The simplified expression can be written as follows:

where

Iα is the concrete weight loss rate of abrasion (%);

α is the scouring angle (°);

αs is the critical angle of abrasion (°);

Vs is the velocity of the large particles in the debris flow (m/s);

γ,

γs and

γw are the bulk density of the debris flow, solid particles and water (g/cm

3);

K, ε,

φ and

n are the critical velocity (m/s), the energy consumption factor of the impact wear (kg·m

2/g·s

2), the energy factor of the micro-cutting wear (kg·m

2/g·s

2) and the horizontal resilience factor (dimensionless), which can be determined by the concrete wear resistance experiment.

2.4. Research Procedures

Theoretical analysis, field investigation, engineering practice and ongoing status observations were addressed in this study. Firstly, based on the investigation of the landform conditions and source distribution of the Xiaogangjian debris flow, the design parameters were put forward and the design concept of the DCLG was presented. Secondly, cases of drainage channels with similar natural geographical environments in the study area were investigated in order to determine the influencing factors of the abrasion. Then, the anti-wear countermeasures and details of the structure were designed and constructed. Finally, field observation was carried out during the debris flow’s outbreak period, including the abrasion development process, wear morphology and the distribution and amount of damage to the lining structure caused by the debris flow’s scour. Moreover, the response characteristics of the anti-wear measures of the DCLG were analyzed.

4. Observation and Discussion

After the completion of the mitigation project, the Xiaogangjian gully encountered heavy rainfall on many occasions during the flood season of 2012–2015, which led to eight debris flows, including four flows with a scale of more than 1 × 104 m3, and a total scale of more than 2.2 × 105 m3 of deposited sediment.

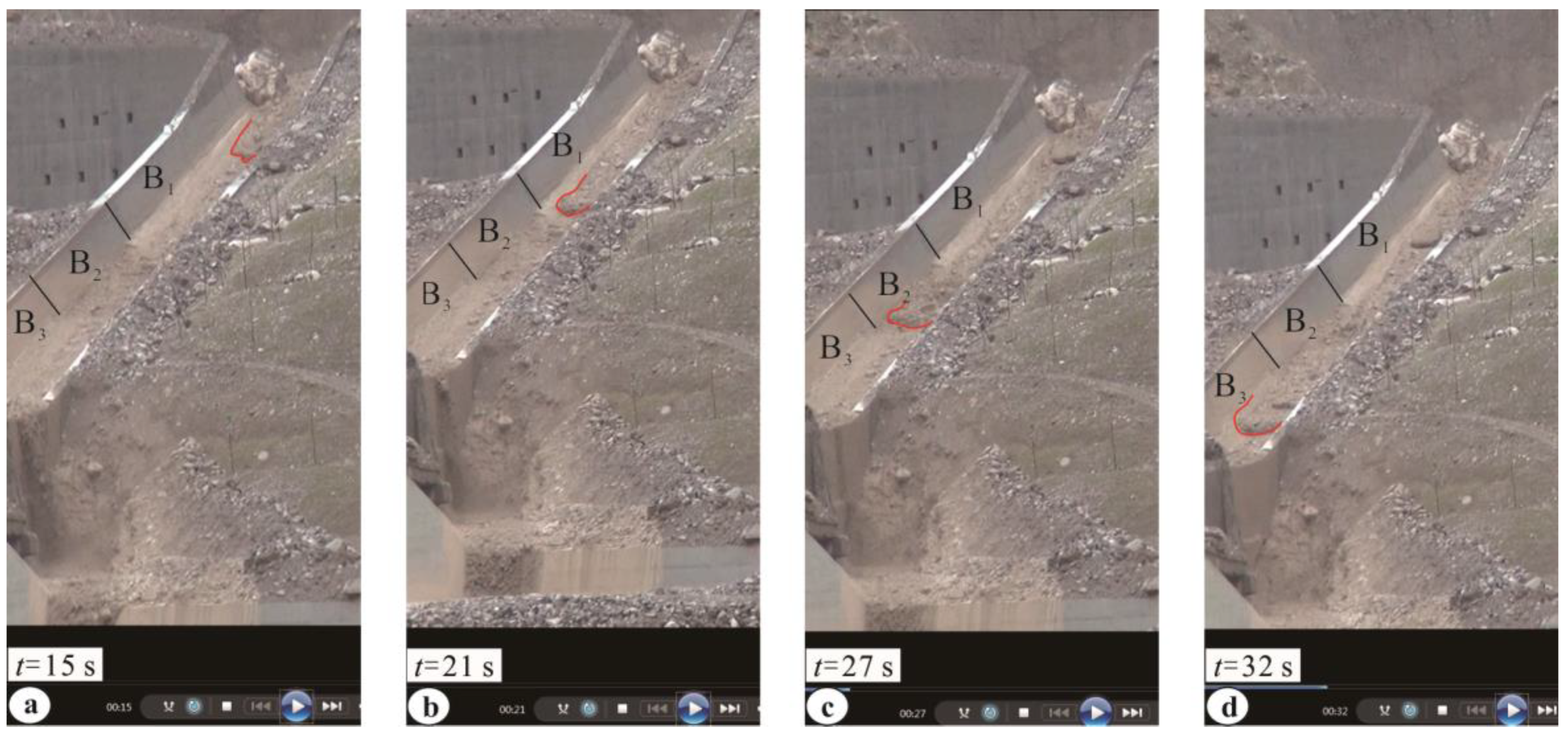

4.1. Observation and Analysis of ED Effect of PRC Boxes

From the field observation of the Xiaogangjian debris flow in 2012, the regulation effect on debris flow of the PRC boxes was mainly shown in two ways: (1) the velocity of debris flow before and after passing through the section B2; and (2) the concrete abrasion on the upstream and downstream baseplate of the section B2.

4.1.1. Influence on the Velocity of Debris Flow before and after the ED Section

Using the debris flow video recorded in the flood season, the time of flow through each control section was found. According to the distance and the time intervals between the adjacent control sections, the average velocity of the debris flow on the plate of this section was accurately calculated (

Figure 9). The selected control sections were divided into four parts: the starting point of the steep channel (0 + 000 m), the starting point of the PRC box section (0 + 046 m), the starting point of the PRC box section (0 + 066 m) and the endpoint of the steep slope section (0 + 100.2 m). In total, the flow time data of 15 debris flows were given.

The change trend of the average velocity of each debris flow in the different channel sections showed that the process of the debris flow in the three sections was as follows: acceleration → deceleration → reacceleration. Except in the case of No.1, the debris flow was gradually slowed down by the roughening belts and lay on the bottom of section B

3 due to the small scale. The other data basically conformed to this change trend. By calculating the velocity attenuation in each section, the average velocity of the debris flow was reduced by 5.7~37.1% in the ED section lined with PRC boxes (

Figure 10). The attenuation rate (

Ra) of velocity in the ED section can be calculated by Equation (4):

where

Ra is the rate of velocity reduction in the ED section (sec. B

2), and

VB1 and

VB2 is the velocity of the debris flow in section B

1 and section B

2 (m/s).

Moreover, the change trend of the debris flow’s velocity in the channel could also be seen from the measurements of the mud depth.

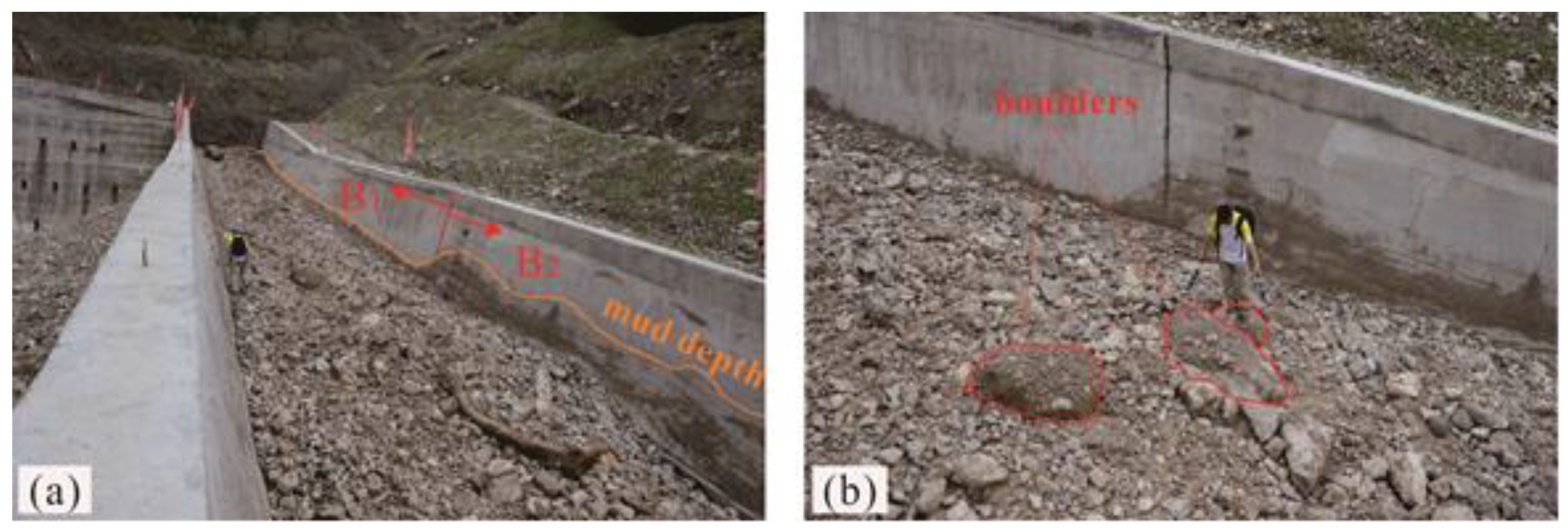

Figure 11a shows that the mud trace of the debris flow which occurred on 26 July 2012 suddenly became higher in the initiating terminal wall of the ED section and stayed higher, indicating that the velocity of the debris flow in this section became slower and the mud depth was greater.

Figure 11b shows that the boulders with larger particle sizes were concentrated and deposited in the ED section, which also shows that the flow velocity slowed down and the carrying capacity of the debris flow weakened. It could be seen that the flow pattern of the debris flow changed from flowing through normally to local deposition, which meant that the kinetic energy decreased.

4.1.2. Abrasion on Upstream and Downstream Baseplates of the ED Section

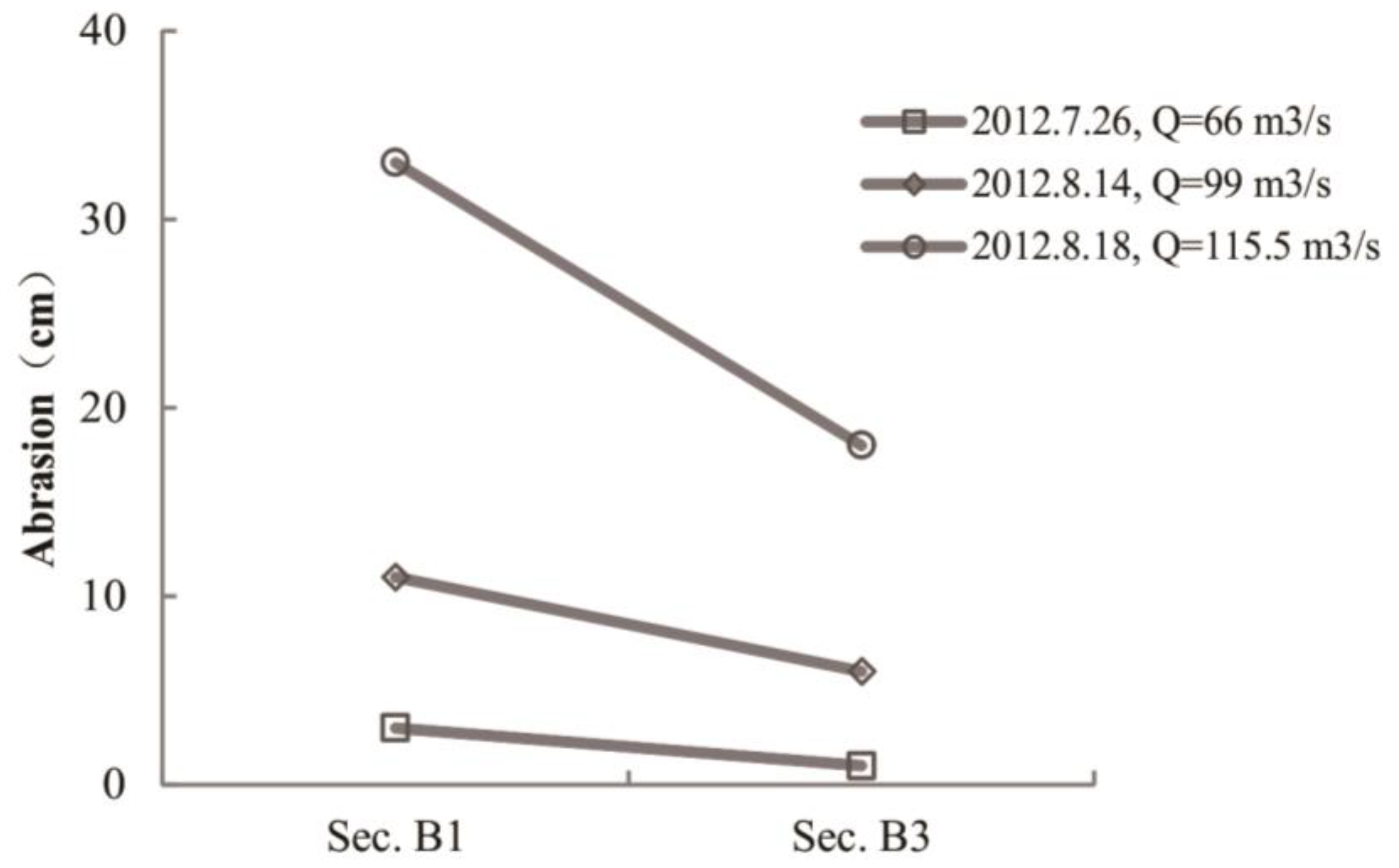

According to the field investigation after the debris flow occurred, the variation in the concrete abrasion at the bottom of the channel was measured, as shown in

Figure 12. Photos taken on site are shown in

Figure 13, which indicate that the abrasion of section B

1 (

Figure 13a) was stronger than that of section B

3 (

Figure 13b).

4.2. Observation and Analysis of Roughening Belt on the Bottom of the Channel

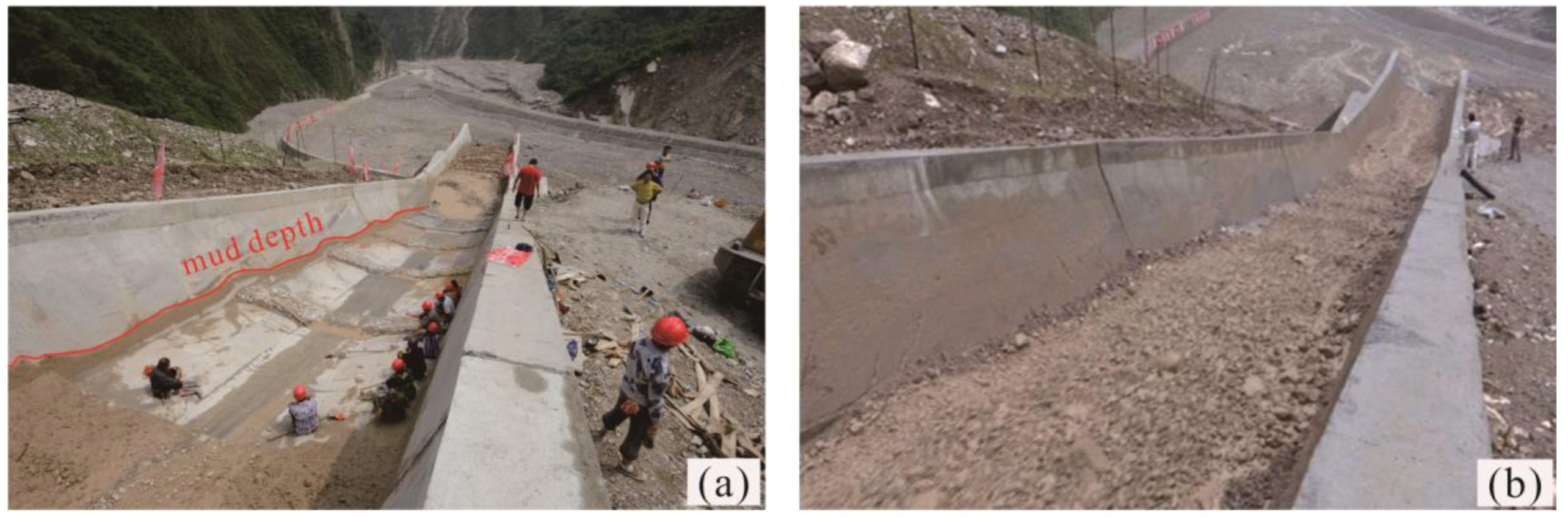

Figure 14a shows the mud depth on the side wall and the abrasion on the bottom of the roughening belt section (sec. B

3) after the debris flow of 26 July 2012, with

Figure 14b showing the flow pattern of the 14 August 2012 debris flow passing through the roughening belts.

It could be seen from the mud trace of the 7.26 debris flow that the mud depth was 20 cm~30 cm higher than that of the upstream and downstream regions when the roughening belt was laid at the bottom of the channel, indicating that the roughening belt had changed the flow pattern of the debris flow and caused a flow pattern of the ”rise up → drop“ type in the underlying fluid. Similarly, the 8.13 debris flow also showed a disturbance in the roughening belt section, forming a flow pattern of “waves moving forward”. The bumps in the roughening belts collided and rubbed with the particles in the debris flow, consuming part of the kinetic energy, thus reducing the abrasion force.

According to the investigation of the abrasion on the concrete at the bottom of the channel in the section B3, it was relatively uniform throughout the section, and abrasion at the tail end was not more serious than that at the leading end, which showed that the velocity and the abrasion force of the debris flow were not obviously increased along the section B3. That is to say, the roughening belts had restrained the development of concrete abrasion to a certain extent.

4.3. Applicability of Anti-Wear Measures

(1) Analysis on the different effects of abrasion resistance. Both the PRC box and the roughening belt are designed to reduce the flow velocity and abrasion by changing the roughness coefficient of the channel bottom [

37]. The roughness coefficient of a drainage channel with abrasion resistance structures is always larger than that of a smooth rectangular drainage channel because of the different boundary conditions at the channel baseplate. However, there are differences in the extent of the two values. The reason is that, compared with the roughened belt, the debris flow in the PRC box obtains a larger drop range and a more intensive drop frequency, resulting in a larger dissipation of kinetic energy.

(2) The design method needs to be improved and the applicability of specific structure types and sizes needs to be analyzed. Limited to the strength and impact resistance of the block stone material, the raised height of the roughening belt in the current design is not high enough. Hence, it can only affect the fluid in the bottom layer, which is more suitable for a wide-shallow type channel; for a narrow-deep channel with a high mud level, its deceleration and wear resistance effect may not be significant. In order to enhance the effectiveness of the roughening belt, high-strength and impact-resistant materials (hard sandstone, steel, etc.) should be adopted for use as a bulge. The height of the bulge should be increased and its layout optimized. In addition, the width and spacing of the roughening belt should be adjusted appropriately, taking into account the differences in longitudinal slope and the flow velocity.

(3) The performance of the ED structure could be enhanced in the next step. During the flood season of 2012, the PRC boxes in the ED structure had been filled with debris flow sediments, and they evolved into a stepped structure. In this situation, the sediments should either be delivered by follow-up torrential floods or be removed artificially. On the other hand, the side walls of the PRC boxes were not thick or strong enough to withstand the impact force of boulders in the debris flow. As a result, the tops of the boxes were partially damaged by local impact, and the height of the boxes became uneven, which partly affected the falling range of the debris flow. In the future, the structural type of the boxes, the width of the row and the height difference between different rows should be designed more rationally in order to avoid damage by the debris flow’s deposition or impact. For example, the channel bottom of the frame formed by the cast-in-place foundation beam could be adopted.

5. Conclusions

(1) Due to its high potential and kinetic energy, the DCLG experiences high velocity and strong abrasion. There are four types of abrasion morphology in regard to debris flow drainage channels: (a) uniform surface peeling (USP); (b) plowing groove along the streamline direction (PG); (c) jumping erosion pits (JEP); (d) surface wear of the ground sills (SWGS).

(2) The abrasion system of a debris flow drainage channel has the characteristics of system dependency, time dependency and multidisciplinary coupling. The main influencing factors of abrasion intensity are bulk density, velocity, grain composition, duration, mud depth, scouring angle of debris flow, section shape, material strength (shear strength, compressive strength), aggregate grading and hardness of drainage channel structure.

(3) The engineering measures to reduce debris flow abrasion include the ED structure lined with PRC boxes in the middle section, the roughening strip in the lower section of the drainage channel and the wear-resistant layer of steel fiber concrete on the surface of the channel. Among these, the ED structure lined with PRC boxes is most suitable for the DCLG. Through changing the flow pattern of the debris flow’s movement, the kinetic energy is partially dissipated and the impact force and abrasion force are weakened, which can achieve the effect of interrupting the acceleration process of the debris flow and preventing the increase in abrasion along the course. According to observational data from the flood season of 2012, the average velocity of a debris flow is reduced by 5.7%~37.1% in the ED section. The PRC box structure was shown to have the significant effect of slowing down and reducing the abrasion of the debris flow and could reduce the threat of the debris flow to the downstream section of the drainage channel.

(4) The other two structural measures also show a certain degree of abrasion reduction. According to the observations made during the flood season, the flow pattern of the debris flow in the roughening strip zone is changed and the abrasion at the bottom of the channel is relatively uniform after the overflow, which shows that the increase in flow velocity and erosion intensity along the roughened section is not significant, and the roughened zone plays a certain role in reducing abrasion. Adding high-strength fiber wear-resistant material to the concrete at the bottom of the channel is more suitable for medium and small-scale and low velocity debris flows, but the effects on high velocity and long-term debris flows are limited.