Direct Membrane Filtration for Wastewater Treatment Using an Intermittent Rotating Hollow Fiber Module

Abstract

1. Introduction

2. Materials and Methods

2.1. Feedwater

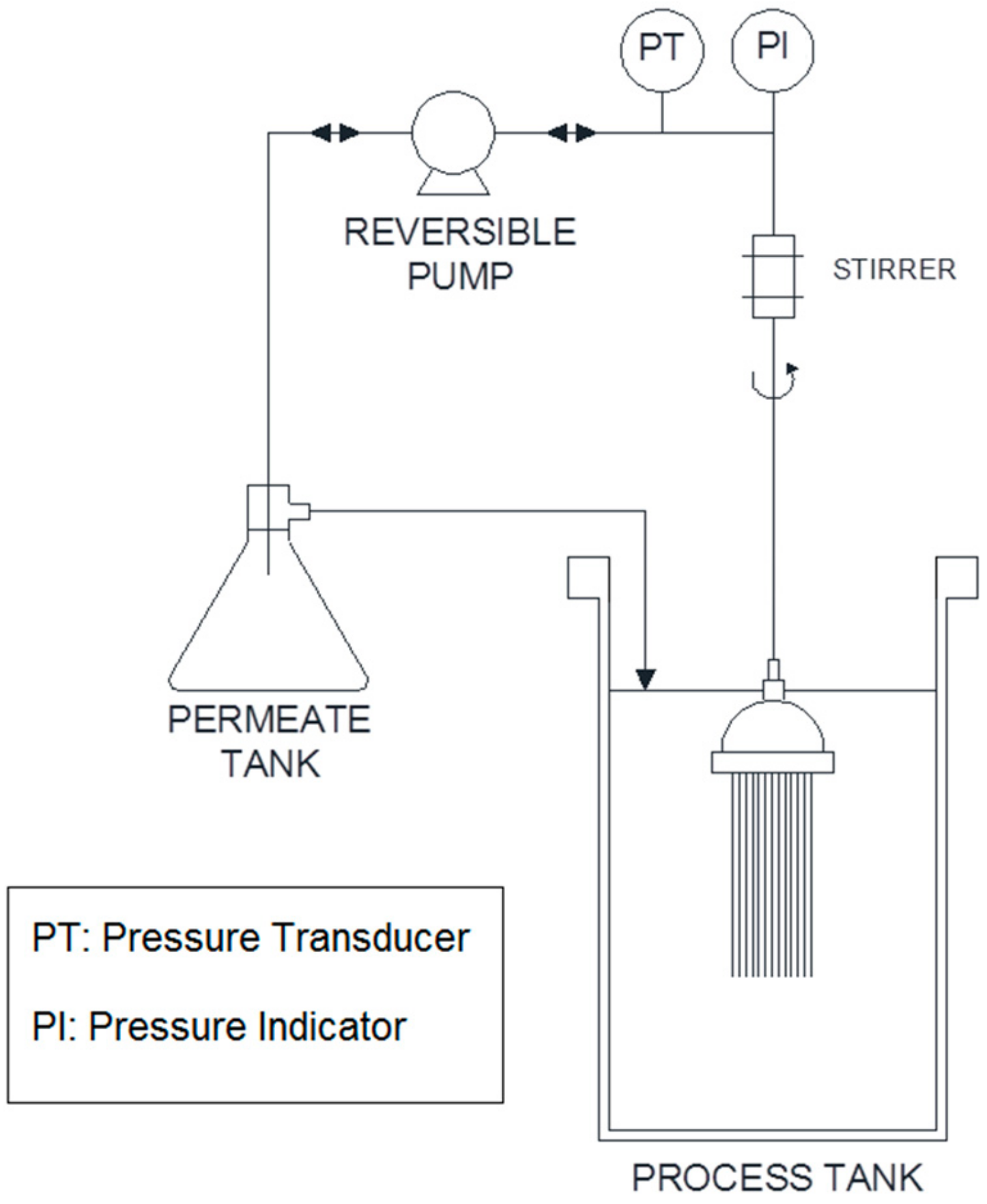

2.2. Bench Filtration Unit

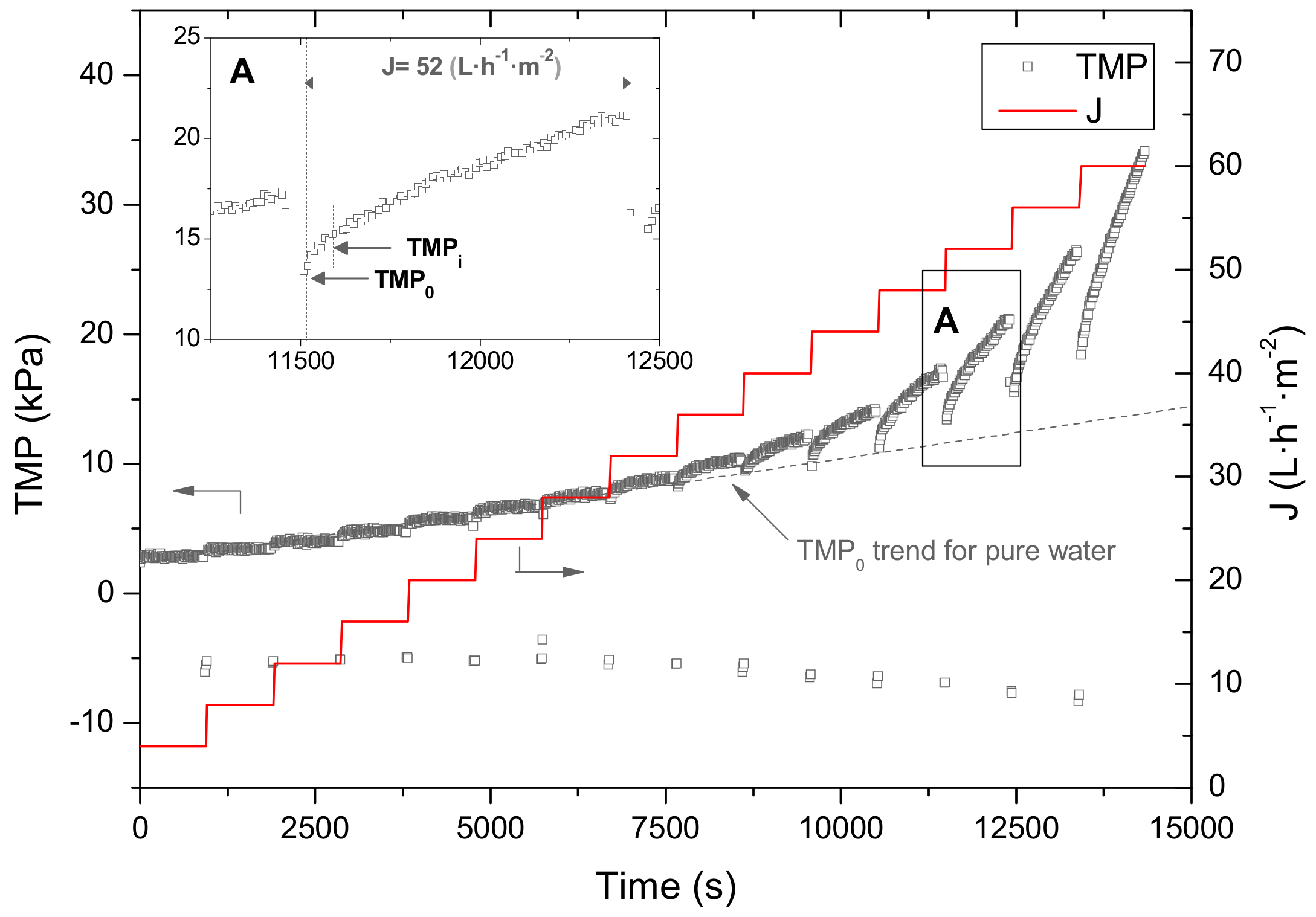

2.3. Flux-Step Assays

2.4. Filtration Tests

2.5. Membrane Fouling Characterization

2.6. Wastewater Fractionation

2.7. Analytical Methods

3. Results and Discussion

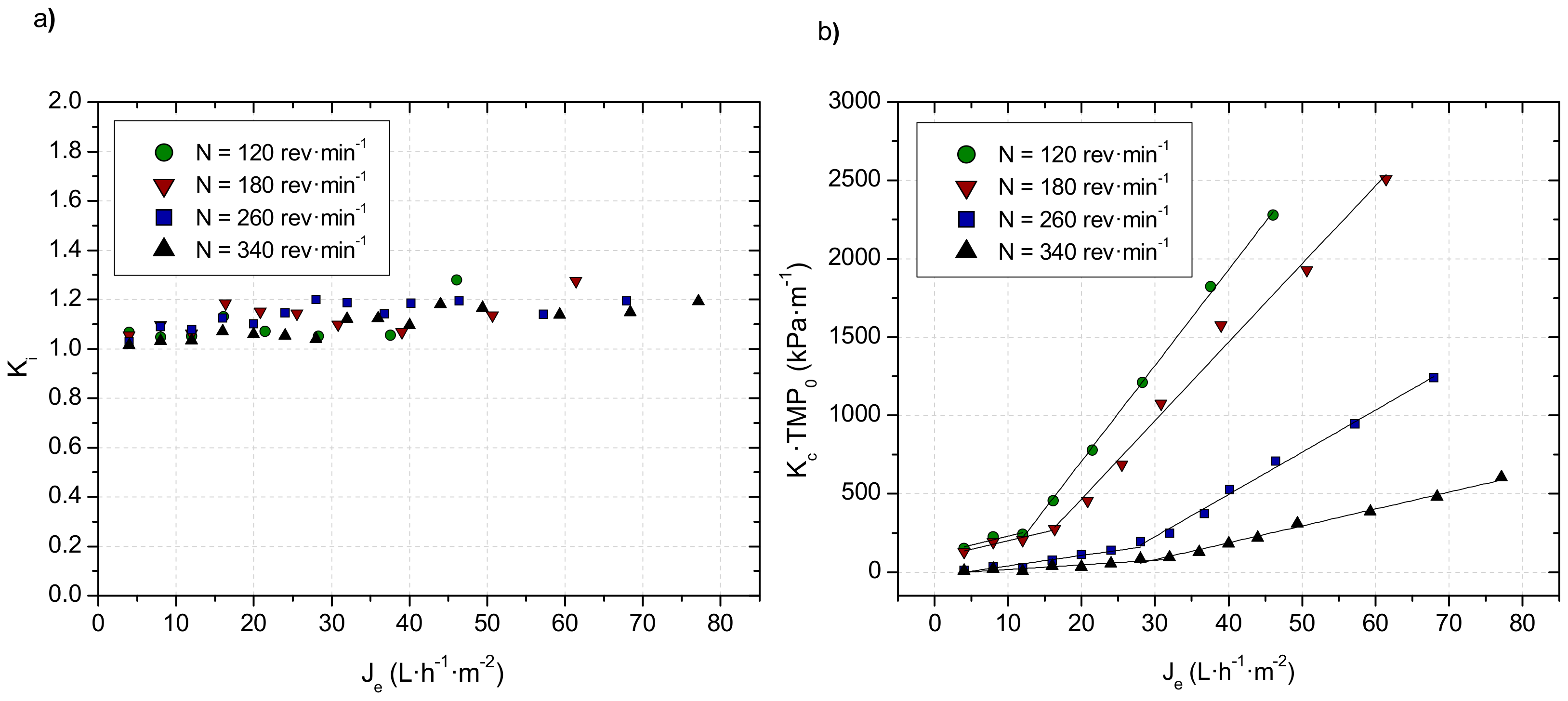

3.1. Determination of Threshold Fluxes: Effect of Rotation Speed

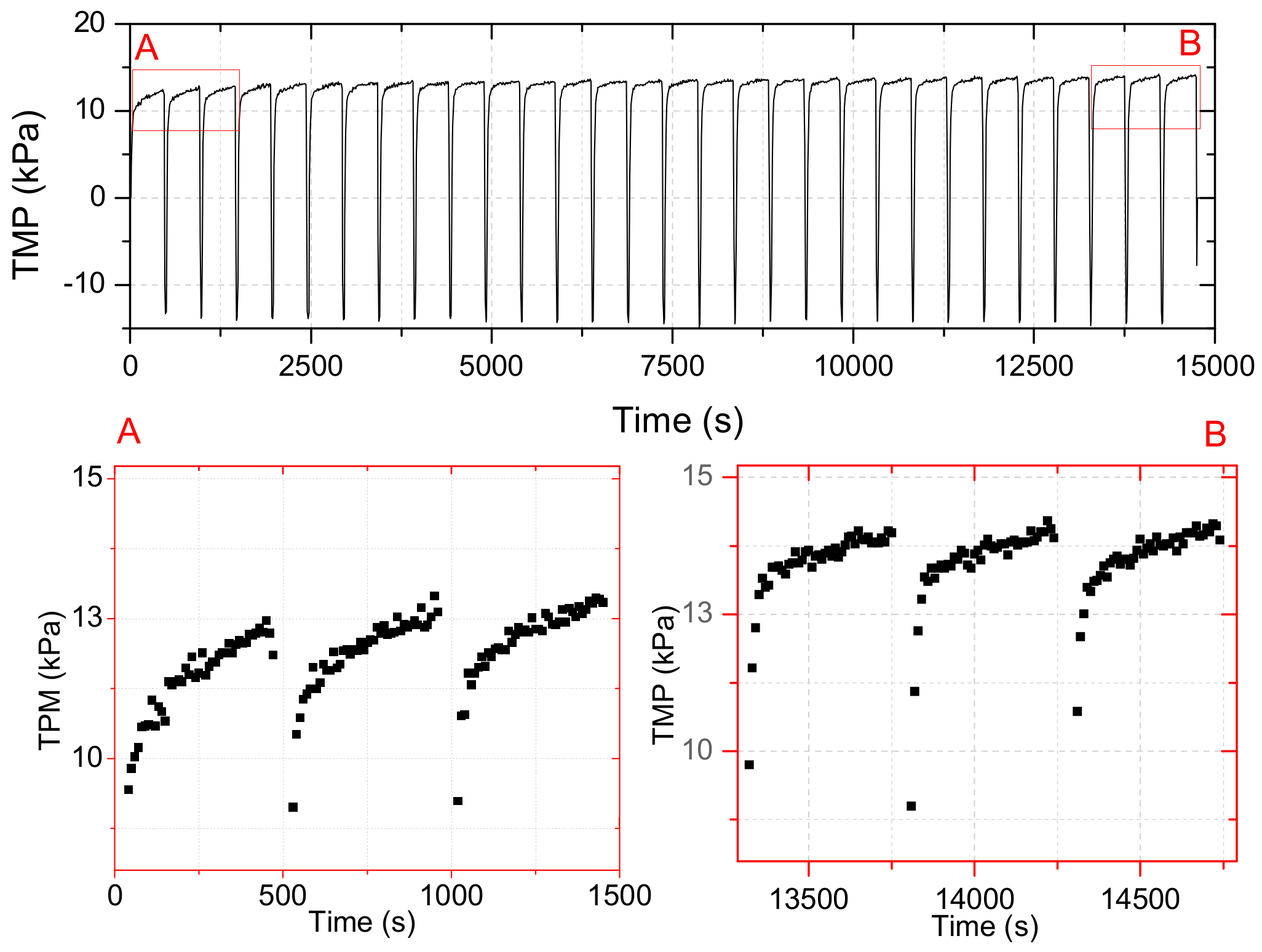

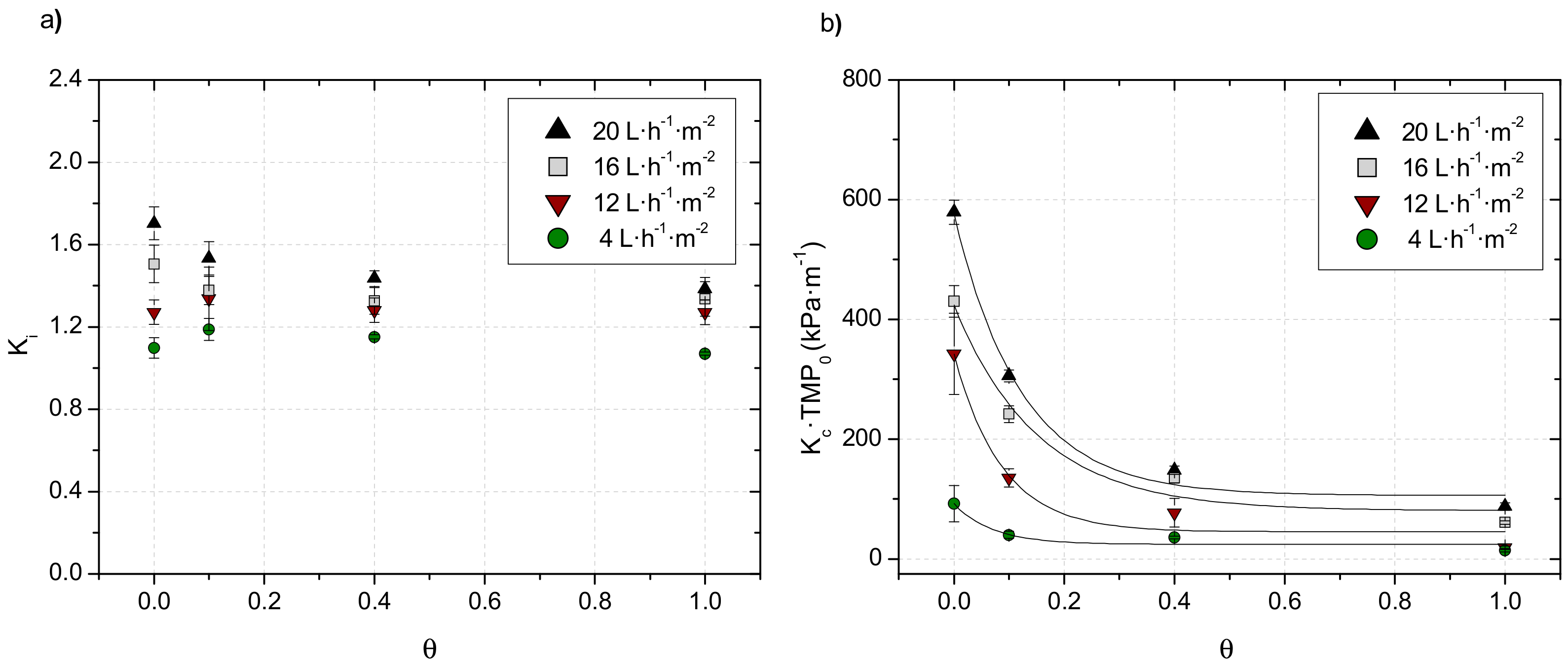

3.2. Effect of Rotation Intermittence on Filtration Performance

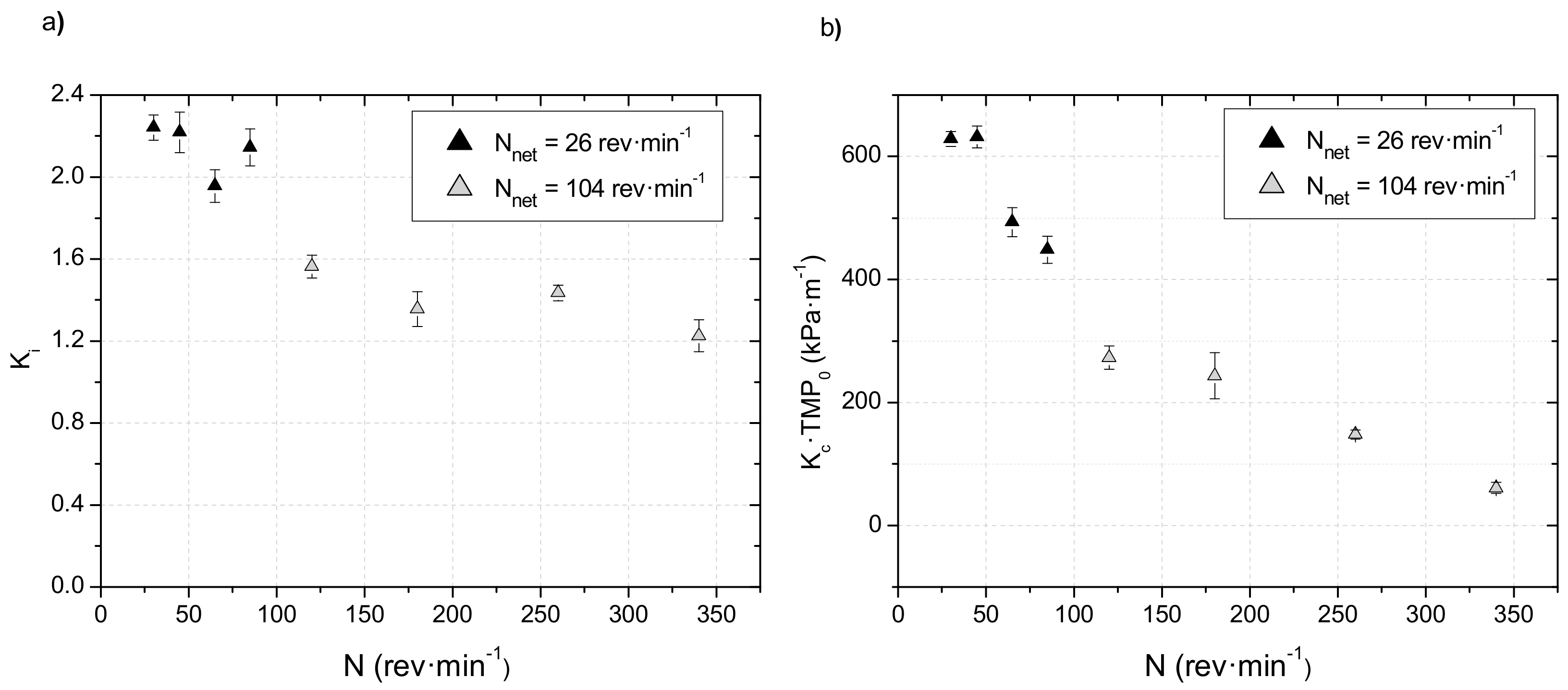

3.3. Influence of the Net Rotation Speed

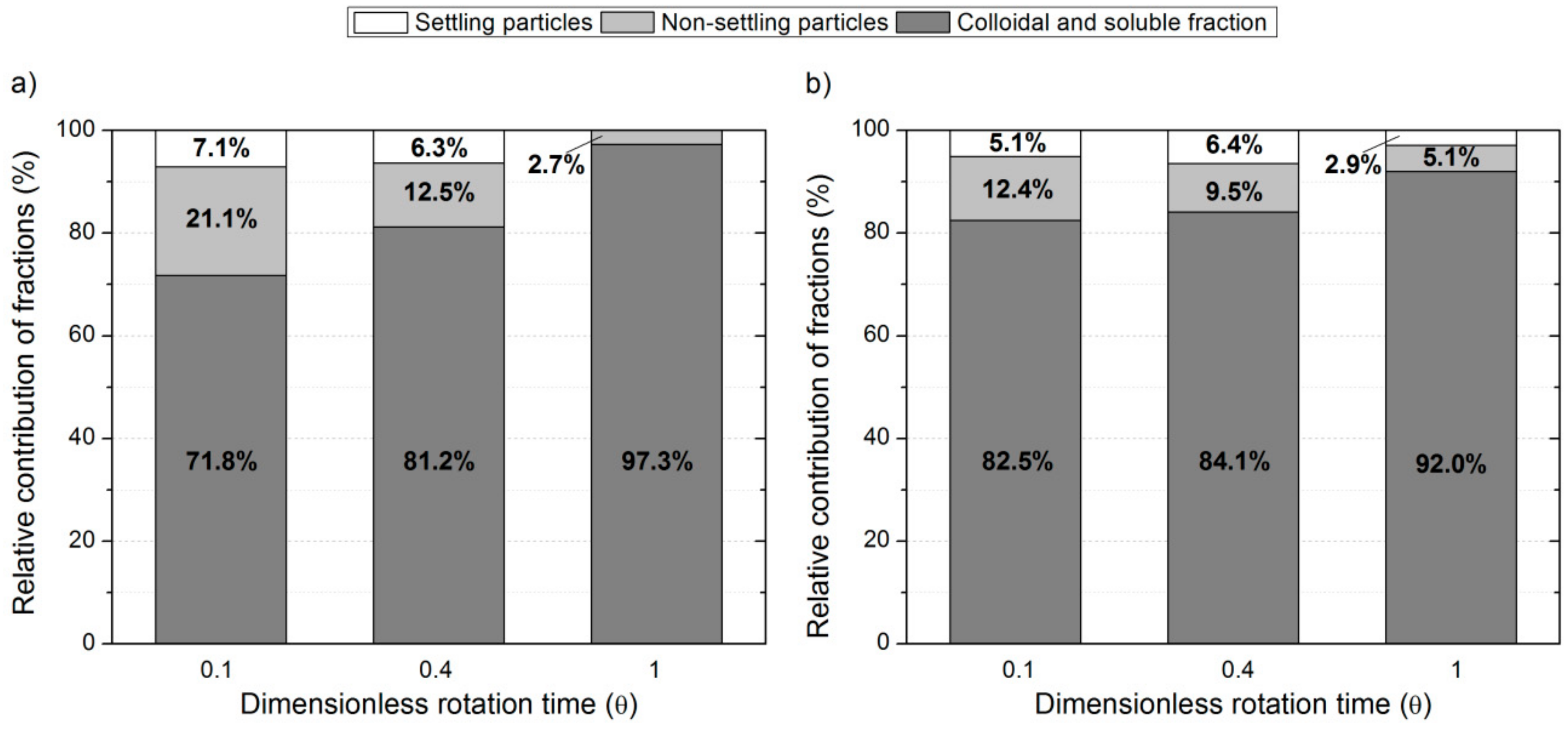

3.4. Fouling Fractions Contribution

4. Conclusions

- Membrane rotation has demonstrated a significant threshold flux improvement, where a correlation (Jth)irr ~N0.9 has been found. Fouling behavior can be well described by the combined model, where a balance between large particle deposition and cake erosion governs the threshold flux.

- At fluxes below the threshold, pore blocking becomes the predominant fouling mechanism at large operation times. In these conditions, proper rotation intermittence (10/15 on/off) might significantly reduce energy demand, whilst maintaining a fouling control comparable to that achieved for the continuous rotation.

- Rotation intermittence plays a significantly minor role than rotation speed on membrane fouling mitigation. Therefore, for a given energy demand, the optimal operating conditions involve high speeds with low to moderate intermittences.

- At sub-threshold fluxes, membrane rotation demonstrated its high effectiveness in preventing fouling phenomena linked to large particles (settling and non-settling ones). Therefore, colloidal and macromolecules have been found as the main contribution to membrane fouling.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- UN. Sustainable Development Goal 6 Synthesis Report 2018 on Water and Sanitation; UN: New York, NY, USA, 2018. [Google Scholar]

- Voulvoulis, N. Water reuse from a circular economy perspective and potential risks from an unregulated approach. Curr. Opin. Environ. Sci. Health 2018, 2, 32–45. [Google Scholar] [CrossRef]

- USEPA (US Environmental Protection Agency). Guidelines for Water Reuse; USEPA: Anchorage, AK, USA, 2012.

- Amec, F.W.; IEEP; ACTeon; IMDEA; NTUA. EU-Level Instruments on Water Reuse; Publications Office of the EU: Brussels, Belgium, 2016. [Google Scholar]

- WWAP (United Nations World Water Assessment Programme). The United Nations World Water Development Report 2017; Wastewater, The Untapped Resource; United Nations: Paris, France, 2017. [Google Scholar]

- Asano, T.; Burton, F.L.; Leverenz, H.L.; Tsuchihashi, R.; Tchobanoglous, G. Water Reuse, Issues, Technologies, and Applications; McGraw-Hill: New York, NY, USA, 2007. [Google Scholar]

- Hube, S.; Eskafi, M.; Hrafnkelsdóttir, K.F.; Bjarnadóttir, B.; Bjarnadóttir, M.Á.; Axelsdóttir, S.; Wu, B. Direct membrane filtration for wastewater treatment and resource recovery: A review. Sci. Total Environ. 2020, 710, 136375. [Google Scholar] [CrossRef] [PubMed]

- Nascimento, T.A.; Fdz-Polanco, F.; Peña, M. Membrane-Based Technologies for the Up-Concentration of Municipal Wastewater: A Review of Pretreatment Intensification. Sep. Purif. Rev. 2020, 49, 1–19. [Google Scholar] [CrossRef]

- Nascimento, T.A.; Mejía, F.R.; Fdz-Polanco, F.; Peña Miranda, M. Improvement of municipal wastewater pretreatment by direct membrane filtration. Environ. Technol. 2017, 38, 2562–2572. [Google Scholar] [CrossRef]

- Lateef, S.K.; Soh, B.Z.; Kimura, K. Direct membrane filtration of municipal wastewater with chemically enhanced backwash for recovery of organic matter. Bioresour. Technol. 2013, 150, 149–155. [Google Scholar] [CrossRef]

- Kramer, F.C.; Shang, R.; Heijman, S.G.J.; Scherrenberg, S.M.; Van Lier, J.B.; Rietveld, L.C. Direct water reclamation from sewage using ceramic tight ultra- and nanofiltration. Sep. Purif. Technol. 2015, 147, 329–336. [Google Scholar] [CrossRef]

- Lin, H.; Zhang, M.; Wang, F.; Meng, F.; Liao, B.Q.; Hong, H.; Chen, J.; Gao, W. A critical review of extracellular polymeric substances (EPSs) in membrane bioreactors: Characteristics, roles in membrane fouling and control strategies. J. Memb. Sci. 2014, 460, 110–125. [Google Scholar] [CrossRef]

- Wang, R.; Liang, D.; Liu, X.; Fan, W.; Meng, S.; Cai, W. Effect of magnesium ion on polysaccharide fouling. Chem. Eng. J. 2020. [Google Scholar] [CrossRef]

- Meng, S.; Meng, X.; Fan, W.; Liang, D.; Wang, L.; Zhang, W.; Liu, Y. The role of transparent exopolymer particles (TEP) in membrane fouling: A critical review. Water Res. 2020, 22, 485–497. [Google Scholar] [CrossRef]

- Yoon, S.H. Membrane Bioreactor Processes: Principles and Applications; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Diamantis, V.I.; Antoniou, I.; Athanasoulia, E.; Melidis, P.; Aivasidis, A. Recovery of reusable water from sewage using aerated flat-sheet membranes. Water Sci. Technol. 2010, 62, 2769–2775. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, P.; Li, R.; Li, X. Direct filtration for the treatment of the coagulated domestic sewage using flat-sheet ceramic membranes. Chemosphere 2019, 223, 383–390. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Wang, J.; Chen, P.; Ji, C.; Kang, Q.; Lu, B.; Li, K.; Liu, J.; Ruan, R. Bio-mitigation of carbon dioxide using microalgal systems: Advances and perspectives. Renew. Sustain. Energy Rev. 2017, 76, 1163–1175. [Google Scholar] [CrossRef]

- Huang, B.C.; Guan, Y.F.; Chen, W.; Yu, H.Q. Membrane fouling characteristics and mitigation in a coagulation-assisted microfiltration process for municipal wastewater pretreatment. Water Res. 2017, 123, 216–223. [Google Scholar] [CrossRef]

- Jin, Z.; Meng, F.; Gong, H.; Wang, C.; Wang, K. Improved low-carbon-consuming fouling control in long-term membrane-based sewage pre-concentration: The role of enhanced coagulation process and air backflushing in sustainable sewage treatment. J. Memb. Sci. 2017, 529, 252–262. [Google Scholar] [CrossRef]

- Choo, K.H.; Choi, S.J.; Hwang, E.D. Effect of coagulant types on textile wastewater reclamation in a combined coagulation/ultrafiltration system. Desalination 2007, 202, 262–270. [Google Scholar] [CrossRef]

- Cui, X.; Zhou, D.; Fan, W.; Huo, M.; Crittenden, J.C.; Yu, Z.; Ju, P.; Wang, Y. The effectiveness of coagulation for water reclamation from a wastewater treatment plant that has a long hydraulic and sludge retention times: A case study. Chemosphere 2016, 157, 224–231. [Google Scholar] [CrossRef]

- Zsirai, T.; Qiblawey, H.; A-Marri, M.J.; Judd, S. The impact of mechanical shear on membrane flux and energy demand. J. Memb. Sci. 2016, 516, 56–63. [Google Scholar] [CrossRef]

- Jaffrin, M.Y. Dynamic filtration with rotating disks, and rotating and vibrating membranes: An update. Curr. Opin. Chem. Eng. 2012, 1, 171–177. [Google Scholar] [CrossRef]

- Kimura, K.; Honoki, D.; Sato, T. Effective physical cleaning and adequate membrane flux for direct membrane filtration (DMF) of municipal wastewater: Up-concentration of organic matter for efficient energy recovery. Sep. Purif. Technol. 2017, 181, 37–43. [Google Scholar] [CrossRef]

- Mezohegyi, G.; Bilad, M.R.; Vankelecom, I.F.J. Direct sewage up-concentration by submerged aerated and vibrated membranes. Bioresour. Technol. 2012, 118, 1–7. [Google Scholar] [CrossRef]

- Ruigómez, I.; González, E.; Galán, P.; Rodríguez-Sevilla, J.; Vera, L. A Rotating Hollow Fiber Module for Fouling Control in Direct Membrane Filtration of Primary Settled Wastewater. Ind. Eng. Chem. Res. 2019, 58, 16901–16910. [Google Scholar] [CrossRef]

- Le Clech, P.; Jefferson, B.; Chang, I.S.; Judd, S.J. Critical flux determination by the flux-step method in a submerged membrane bioreactor. J. Memb. Sci. 2003, 227, 81–93. [Google Scholar] [CrossRef]

- Rector, T.J.; Garland, J.L.; Starr, S.O. Dispersion characteristics of a rotating hollow fiber membrane bioreactor: Effects of module packing density and rotational frequency. J. Memb. Sci. 2006, 278, 144–150. [Google Scholar] [CrossRef]

- Kirschner, A.Y.; Cheng, Y.H.; Paul, D.R.; Field, R.W.; Freeman, B.D. Fouling mechanisms in constant flux crossflow ultrafiltration. J. Memb. Sci. 2019. [Google Scholar] [CrossRef]

- Ognier, S.; Wisniewski, C.; Grasmick, a. Membrane bioreactor fouling in sub-critical filtration conditions: A local critical flux concept. J. Memb. Sci. 2004, 229, 171–177. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Li, P.; Li, R.H.; Li, X.Y. Characterization and mitigation of the fouling of flat-sheet ceramic membranes for direct filtration of the coagulated domestic wastewater. J. Hazard. Mater. 2020, 385, 121557. [Google Scholar] [CrossRef]

- Lodge, B.; Judd, S.J.; Smith, A.J. Characterisation of dead-end ultrafiltration of biotreated domestic wastewater. J. Memb. Sci. 2004, 231, 91–98. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Martí-Calatayud, M.C.; Schneider, S.; Yüce, S.; Wessling, M. Interplay between physical cleaning, membrane pore size and fluid rheology during the evolution of fouling in membrane bioreactors. Water Res. 2018, 147, 393–402. [Google Scholar] [CrossRef]

- Diez, V.; Ezquerra, D.; Cabezas, J.L.; García, A.; Ramos, C. A modified method for evaluation of critical flux, fouling rate and in situ determination of resistance and compressibility in MBR under different fouling conditions. J. Memb. Sci. 2014, 453, 1–11. [Google Scholar] [CrossRef]

- Van der Marel, P.; Zwijnenburg, A.; Kemperman, A.; Wessling, M.; Temmink, H.; van der Meer, W. An improved flux-step method to determine the critical flux and the critical flux for irreversibility in a membrane bioreactor. J. Memb. Sci. 2009, 332, 24–29. [Google Scholar] [CrossRef]

- Bacchin, P.; Aimar, P.; Field, R.W. Critical and sustainable fluxes: Theory, experiments and applications. J. Memb. Sci. 2006, 281, 42–69. [Google Scholar] [CrossRef]

- Ye, Y.; Chen, V.; Le-Clech, P. Evolution of fouling deposition and removal on hollow fibre membrane during filtration with periodical backwash. Desalination 2011, 283, 198–205. [Google Scholar] [CrossRef]

- Jaffrin, M.Y. Dynamic shear-enhanced membrane filtration: A review of rotating disks, rotating membranes and vibrating systems. J. Memb. Sci. 2008, 324, 7–25. [Google Scholar] [CrossRef]

- Sánchez Pérez, J.A.; Rodríguez Porcel, E.M.; Casas López, J.L.; Fernández Sevilla, J.M.; Chisti, Y. Shear rate in stirred tank and bubble column bioreactors. Chem. Eng. J. 2006, 124, 1–5. [Google Scholar] [CrossRef]

- Hughes, D.; Field, R.W. Crossflow filtration of washed and unwashed yeast suspensions at constant shear under nominally sub-critical conditions. J. Memb. Sci. 2006, 280, 89–98. [Google Scholar] [CrossRef]

- Field, R.W.; Pearce, G.K. Critical, sustainable and threshold fluxes for membrane filtration with water industry applications. Adv. Colloid Interface Sci. 2011, 164, 38–44. [Google Scholar] [CrossRef]

- Ji, P.; Motin, A.; Shan, W.; Bénard, A.; Bruening, M.L.; Tarabara, V.V. Dynamic crossflow filtration with a rotating tubular membrane: Using centripetal force to decrease fouling by buoyant particles. Chem. Eng. Res. Des. 2016, 106, 101–114. [Google Scholar] [CrossRef]

- Chew, J.W.; Kilduff, J.; Belfort, G. The behavior of suspensions and macromolecular solutions in crossflow microfiltration: An update. J. Memb. Sci. 2020, 601, 117865. [Google Scholar] [CrossRef]

- Delgado, S.; Vera, L.; González, E.; Martínez, M.; Vera, L.M.; Bravo, L.R. Effect of previous coagulation in direct ultrafiltration of primary settled municipal wastewater. Desalination 2012, 304, 41–48. [Google Scholar] [CrossRef]

- Christensen, M.L.; Niessen, W.; Sørensen, N.B.; Hansen, S.H.; Jørgensen, M.K.; Nielsen, P.H. Sludge fractionation as a method to study and predict fouling in MBR systems. Sep. Purif. Technol. 2018, 194, 329–337. [Google Scholar] [CrossRef]

| Parameter | Units | Mean | Standard Deviation |

|---|---|---|---|

| COD | mg·L−1 | 1073 | 160.3 |

| DOC | mg·L−1 | 62.5 | 36.0 |

| TSS | mg·L−1 | 569.8 | 231.8 |

| Turbidity | NTU | 543.8 | 230.5 |

| Nnet rev·min−1 | N rev·min−1 | θ |

|---|---|---|

| 26 | 30 | 0.867 |

| 26 | 45 | 0.578 |

| 26 | 65 | 0.400 |

| 26 | 85 | 0.306 |

| 104 | 120 | 0.867 |

| 104 | 180 | 0.578 |

| 104 | 260 | 0.400 |

| 104 | 340 | 0.306 |

| Parameter | Units | Feedwater | Supernatant | Filtrate (<1–3 µm) |

|---|---|---|---|---|

| COD | mg·L−1 | 1176 | 663 | 368 |

| DOC | mg·L−1 | 114 | 133 | 120 |

| TSS | mg·L−1 | 457 | 145 | n.d. |

| Turbidity | NTU | 411 | 153 | 37 |

| N | Jth, irr | Jth | αc·ωc | αss·ωss | αss·S |

|---|---|---|---|---|---|

| rev·min−1 | L·h−1·m−2 | L·h−1·m−2 | m−2 | m−2 | m−1·s−1 |

| 120 | 20 | 12 | 8.6 × 1013 | 2.2 × 1014 | 8.2 × 108 |

| 180 | 24 | 16 | 6.6 × 1013 | 1.8 × 1014 | 8.3 × 108 |

| 260 | 40 | 28 | 1.8 × 1013 | 9.7 × 1013 | 7.2 × 108 |

| 340 | 48 | 32 | 8.3 × 1012 | 4.0 × 1013 | 3.4 × 108 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruigómez, I.; González, E.; Rodríguez-Gómez, L.; Vera, L. Direct Membrane Filtration for Wastewater Treatment Using an Intermittent Rotating Hollow Fiber Module. Water 2020, 12, 1836. https://doi.org/10.3390/w12061836

Ruigómez I, González E, Rodríguez-Gómez L, Vera L. Direct Membrane Filtration for Wastewater Treatment Using an Intermittent Rotating Hollow Fiber Module. Water. 2020; 12(6):1836. https://doi.org/10.3390/w12061836

Chicago/Turabian StyleRuigómez, Ignacio, Enrique González, Luis Rodríguez-Gómez, and Luisa Vera. 2020. "Direct Membrane Filtration for Wastewater Treatment Using an Intermittent Rotating Hollow Fiber Module" Water 12, no. 6: 1836. https://doi.org/10.3390/w12061836

APA StyleRuigómez, I., González, E., Rodríguez-Gómez, L., & Vera, L. (2020). Direct Membrane Filtration for Wastewater Treatment Using an Intermittent Rotating Hollow Fiber Module. Water, 12(6), 1836. https://doi.org/10.3390/w12061836