Effect of Intermittent Aeration in a Hybrid Vertical Anaerobic Biofilm Reactor (HyVAB) for Reject Water Treatment

Abstract

:1. Introduction

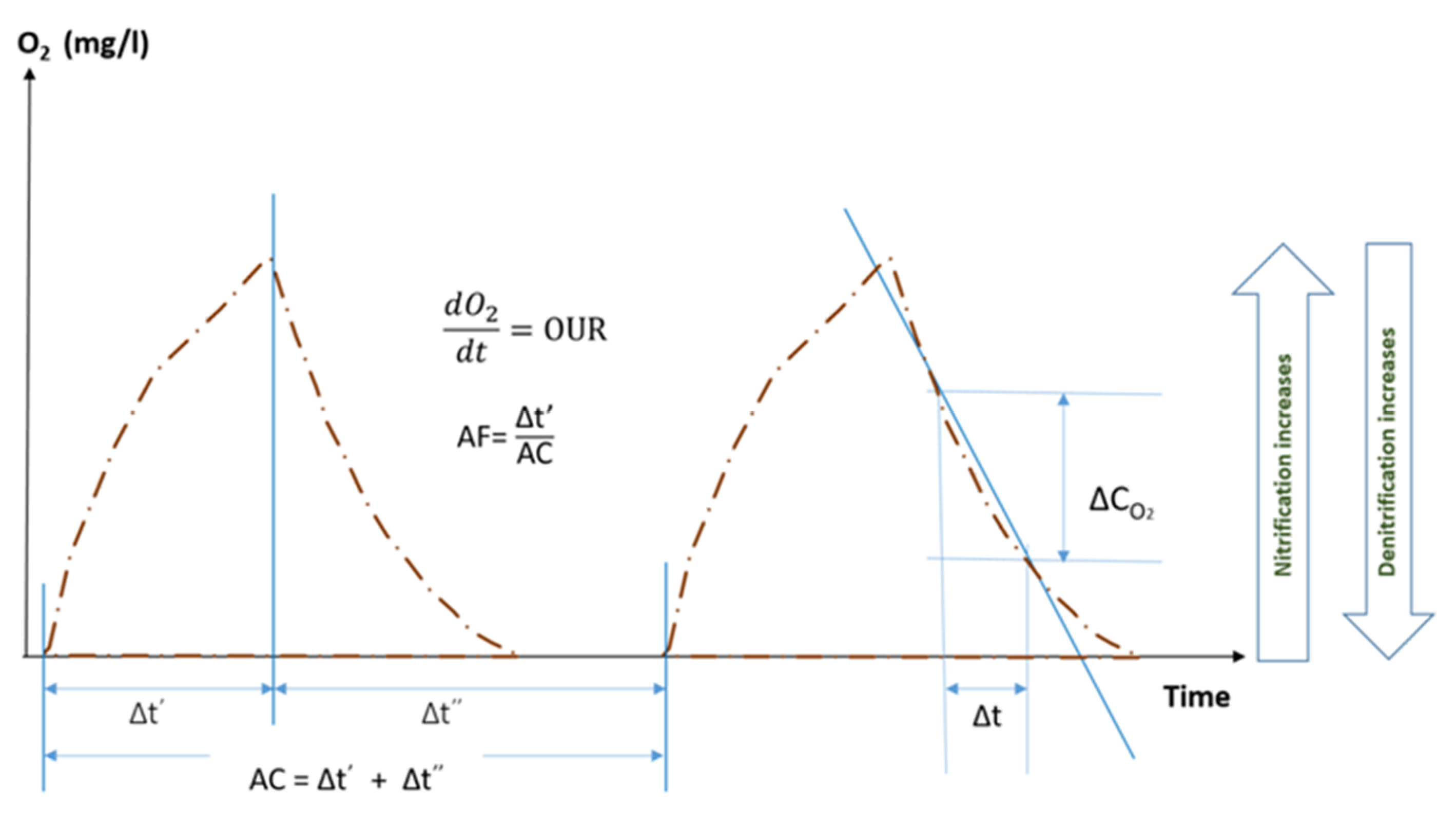

2. Theory

2.1. Traditional Nitrogen Removal

2.2. Shortcut to Traditional Biological Nitrogen Removal

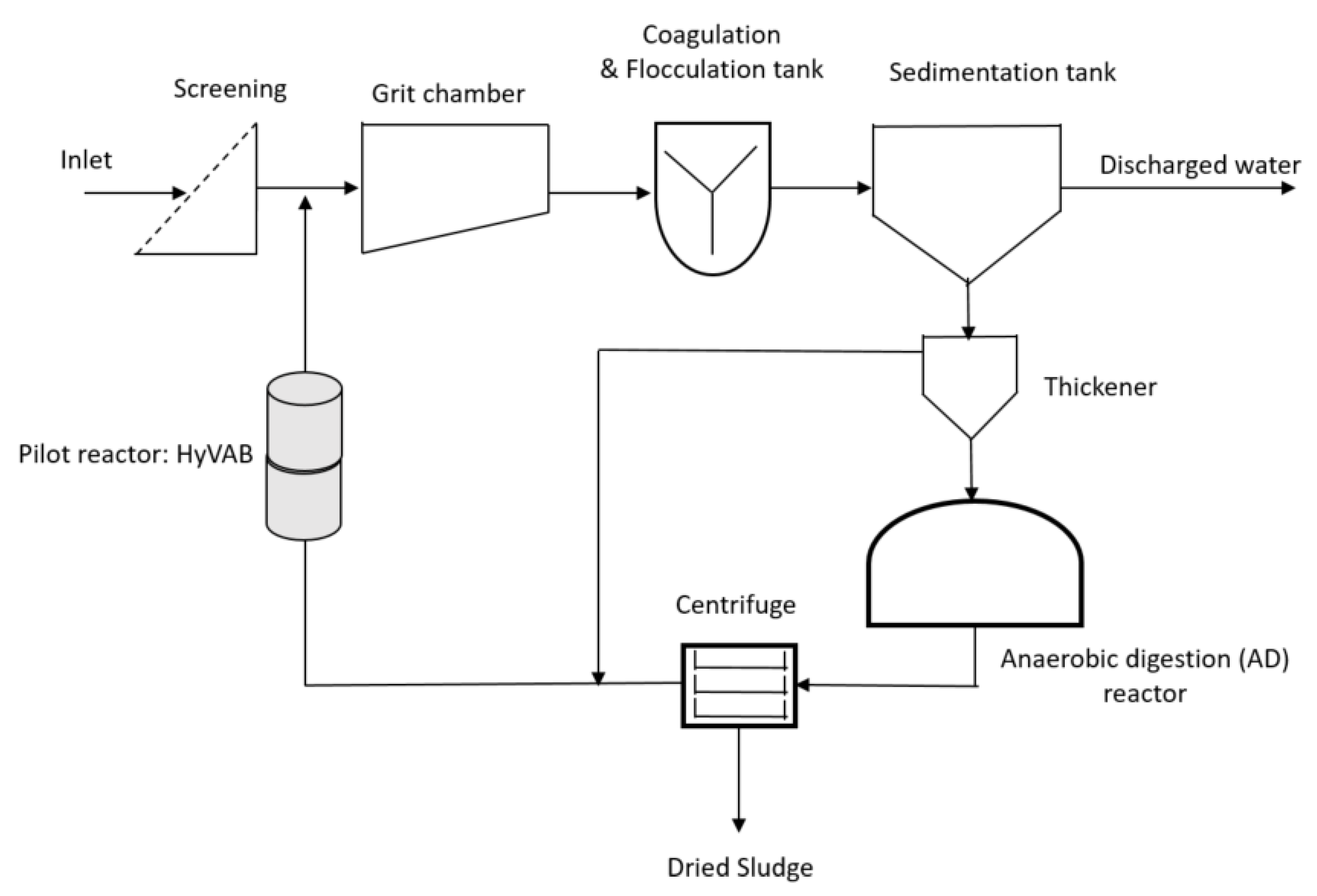

3. Materials and Methods

3.1. Analysis Methodology

3.2. Aeration Control in the HyVAB Reactor

4. Results and Discussion

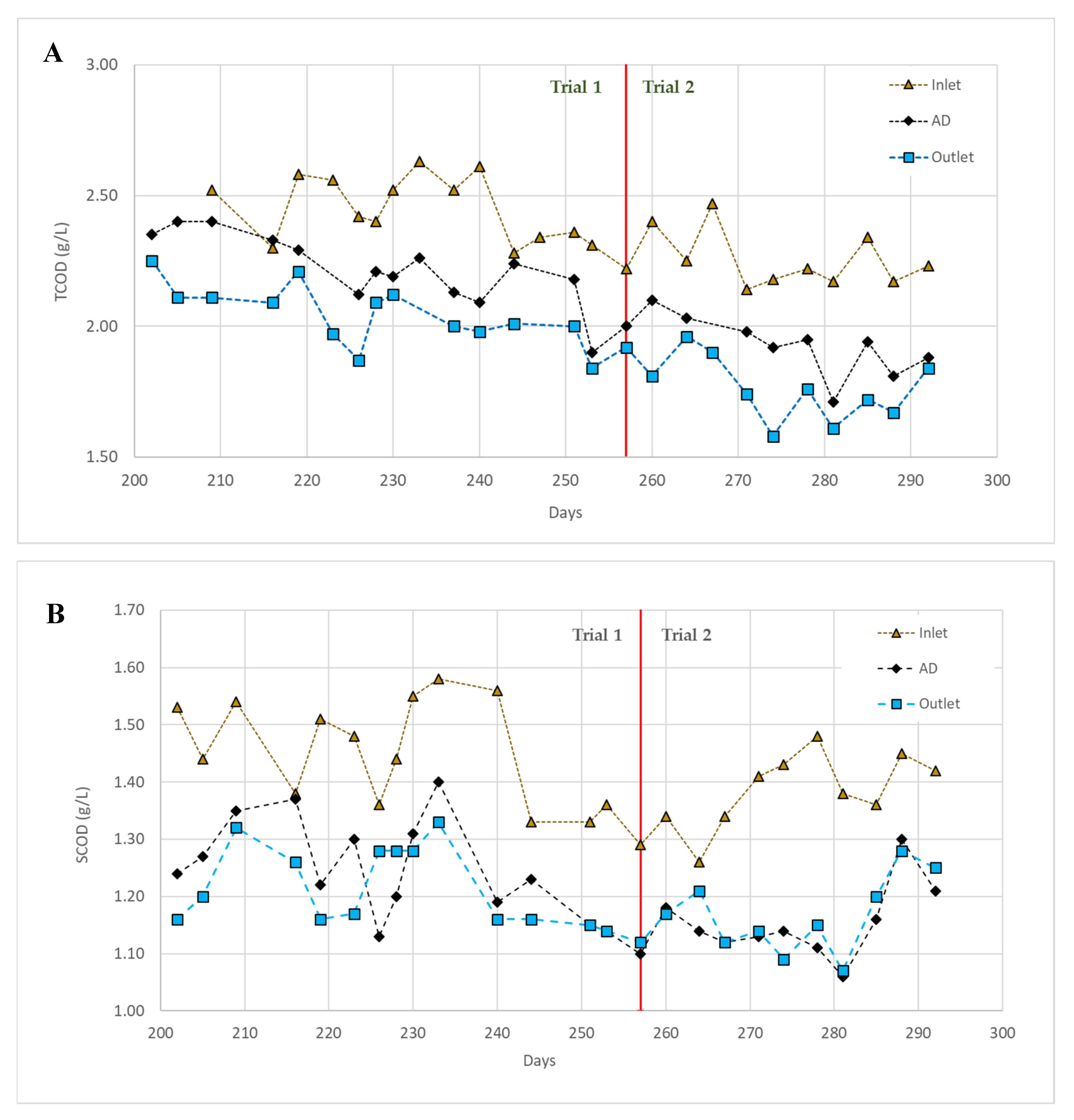

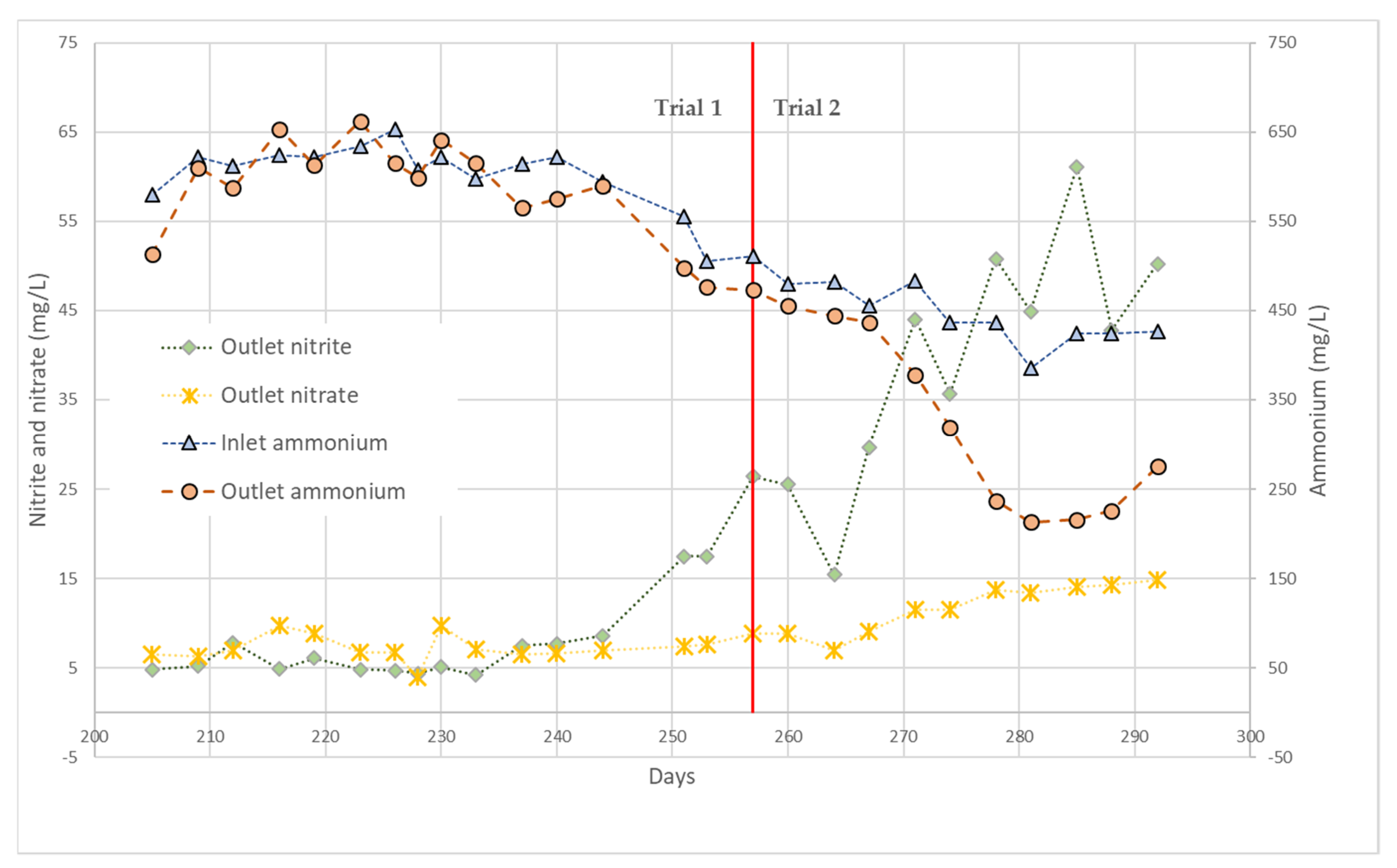

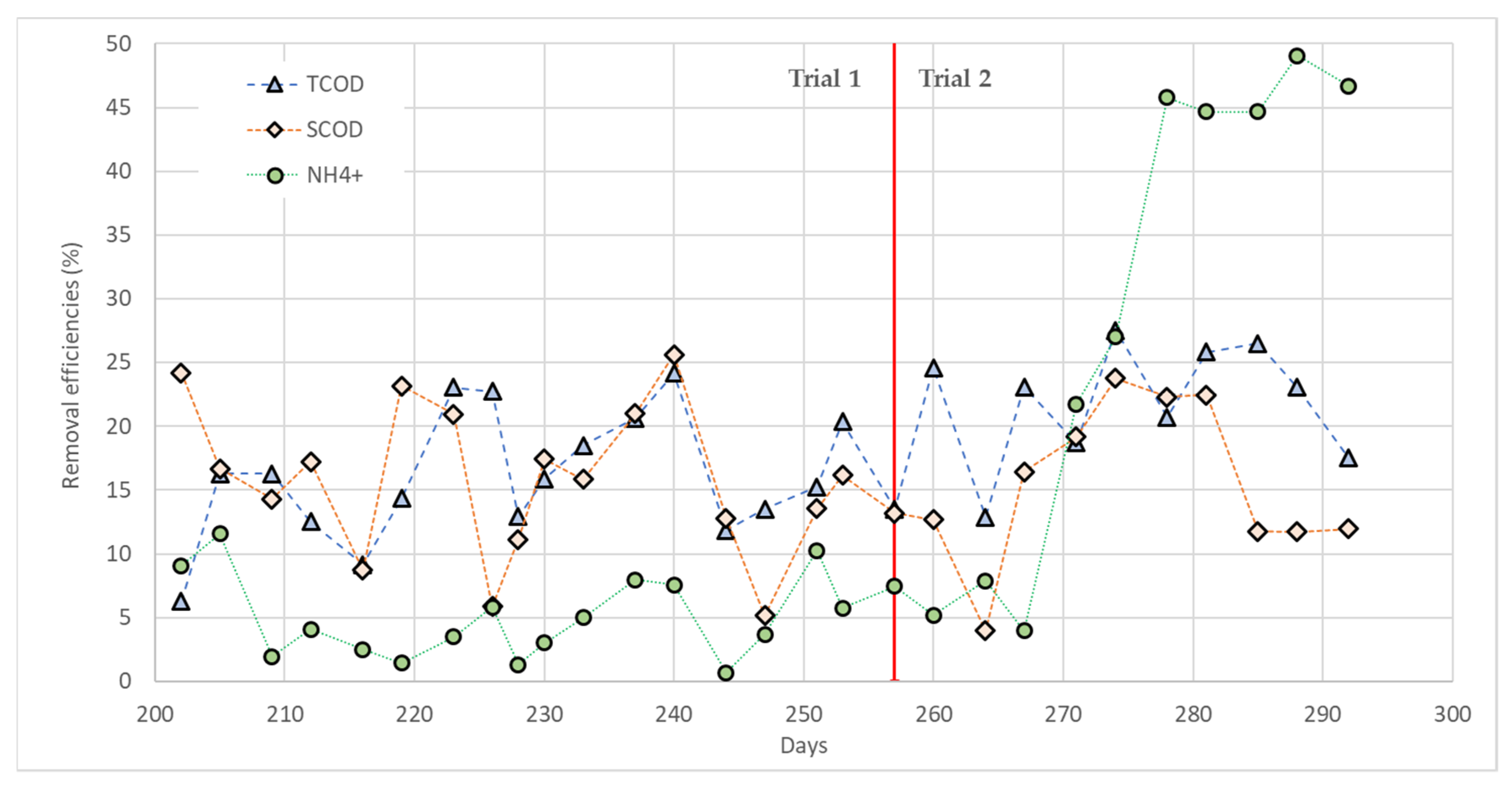

4.1. Dissolved Oxygen, Organics, and Nitrogen Species Profile

4.2. Stereo Microscopic Images

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guo, C.H.; Stabnikov, V.; Ivanov, V. The removal of nitrogen and phosphorus from reject water of municipal wastewater treatment plant using ferric and nitrate bioreductions. Bioresour. Technol. 2010, 101, 3992–3999. [Google Scholar] [CrossRef] [PubMed]

- Nyenje, P.; Foppen, J.W.; Uhlenbrook, S.; Kulabako, R.; Muwanga, A. Eutrophication and nutrient release in urban areas of sub-Saharan Africa: A review. Sci. Total Environ. 2010, 408, 447–455. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Wang, Y.; He, W.; Wu, M.; Xing, M.; Yang, J.; Gao, N.; Yin, D. Responses of biofilm characteristics to variations in temperature and NH4+-N loading in a moving-bed biofilm reactor treating micro-polluted raw water. Bioresour. Technol. 2013, 131, 365–373. [Google Scholar] [CrossRef] [PubMed]

- Jones, R.M.; Dold, P.L.; Takács, I.; Chapman, K.; Wett, B.; Murthy, S.; Shaughnessy, M. Simulation for operation and control of reject water treatment processes. Proc. Water Environ. Fed. 2007, 2007, 4357–4372. [Google Scholar] [CrossRef]

- Berends, D.; Salem, S.; Van Der Roest, H.; Van Loosdrecht, M. Boosting nitrification with the BABE technology. Water Sci. Technol. 2005, 52, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Niazi, S. Coagulation Effects of Biological Sludge Reject Water Treatment. Master’s Thesis, University of South-Eastern Norway, Porsgrunn, Norway, May 2018. [Google Scholar]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D. Wastewater Engineering: Treatment and Resource Recovery; McGraw-Hill Higher Education: New York, NY, USA, 2014. [Google Scholar]

- Hashemi, S. Biological Reject Water Treatment by Using Moving Bed Biofilm Reactors (MBBR). Master’s Thesis, University of South-Eastern Norway, Porsgrunn, Norway, May 2018. [Google Scholar]

- Sivalingam, V.; Ibrahim, O.; Kukankov, S.; Omodara, B.; Janka, E.; Wang, S.; Dinamarca, C.; Haugen, H.; Bakke, R. Chemical equilibrium model to investigate scaling in moving bed biofilm reactors (MBBR). In Proceedings of the 60th SIMS Conference on Simulation and Modelling SIMS 2019, Vasteras, Sweden, 12–16 August 2019; Linkoping University Electronic Press: Linkoping, Sweden, 2020; pp. 139–144. [Google Scholar]

- Barwal, A.; Chaudhary, R. To study the performance of biocarriers in moving bed biofilm reactor (MBBR) technology and kinetics of biofilm for retrofitting the existing aerobic treatment systems: A review. Rev. Environ. Sci. Bio/Technol. 2014, 13, 285–299. [Google Scholar] [CrossRef]

- Davey, M.E.; O’toole, G.A. Microbial biofilms: From ecology to molecular genetics. Microbiol. Mol. Biol. Rev. MMBR 2000, 64, 847–867. [Google Scholar] [CrossRef] [Green Version]

- Flemming, H.-C.; Wingender, J.; Szewzyk, U.; Steinberg, P.; Rice, S.A.; Kjelleberg, S. Biofilms: An emergent form of bacterial life. Nat. Rev. Microbiol. 2016, 14, 563–575. [Google Scholar] [CrossRef]

- Piculell, M. New Dimensions of Moving Bed Biofilm Carriers: Influence of Biofilm Thickness and Control Possibilities; Lund University: Lund, Sweden, 2016. [Google Scholar]

- Almstrand, R.; Persson, F.; Daims, H.; Ekenberg, M.; Christensson, M.; Wilén, B.-M.; Sorensson, F.; Hermansson, M. Three-dimensional stratification of bacterial biofilm populations in a moving bed biofilm reactor for nitritation-anammox. Int. J. Mol. Sci. 2014, 15, 2191–2206. [Google Scholar] [CrossRef] [Green Version]

- Sliekers, A.O.; Haaijer, S.C.M.; Stafsnes, M.H.; Kuenen, J.G.; Jetten, M.S.M. Competition and coexistence of aerobic ammonium- and nitrite-oxidizing bacteria at low oxygen concentrations. Appl. Microbiol. Biotechnol. 2005, 68, 808–817. [Google Scholar] [CrossRef]

- Odegaard, H. A road-map for energy-neutral wastewater treatment plants of the future based on compact technologies (including MBBR). Front. Environ. Sci. Eng. 2016, 10, 2. [Google Scholar] [CrossRef]

- Ruiz, G.; Jeison, D.; Rubilar, O.; Ciudad, G.; Chamy, R. Nitrification–denitrification via nitrite accumulation for nitrogen removal from wastewaters. Bioresour. Technol. 2006, 97, 330–335. [Google Scholar] [CrossRef]

- Yang, J.; Trela, J.; Zubrowska-Sudol, M.; Plaza, E. Intermittent aeration in one-stage partial nitritation/anammox process. Ecol. Eng. 2015, 75, 413–420. [Google Scholar] [CrossRef]

- Cowman, J.; Torres, C.I.; Rittmann, B.E. Total nitrogen removal in an aerobic/anoxic membrane biofilm reactor system. Water Sci. Technol. 2005, 52, 115–120. [Google Scholar] [CrossRef]

- Bakke, R. High Tech Process in Combination with Natural Systems. M.Sc Lecture presentation, University of South-Eastern Norway, Porsgrunn, Norway, 2018. [Google Scholar]

- HyVAB. Biowater Technology. Available online: https://www.biowatertechnology.com/en/technology/hyvab/ (accessed on 9 March 2020).

- Wang, S.; Savva, I.; Bakke, R. A full-scale hybrid vertical anaerobic and aerobic biofilm wastewater treatment system: case study. Water Pract. Technol. 2019, 14, 189–197. [Google Scholar] [CrossRef]

- Janka, E.; Carvajal, D.; Wang, S.; Bakke, R.; Dinamarca, C. Treatment of Metformin-Containing Wastewater by a Hybrid Vertical Anaerobic Biofilm-Reactor (HyVAB). Int. J. Environ. Res. Public Health 2019, 16, 4125. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- APHA. Standard Methods for the Examination of Water and Wastewater; American Public Health Association, American Water Works Association and Water Environment Federation: Washington, DC, USA, 1995. [Google Scholar]

- Tassew, F.A.; Bergland, W.H.; Dinamarca, C.; Kommedal, R.; Bakke, R. Granular Sludge Bed Processes in Anaerobic Digestion of Particle-Rich Substrates. Energies 2019, 12, 2940. [Google Scholar] [CrossRef] [Green Version]

- Mota, C.; Head, M.A.; Ridenoure, J.A.; Cheng, J.J.; Reyes, F.L. Effects of Aeration Cycles on Nitrifying Bacterial Populations and Nitrogen Removal in Intermittently Aerated Reactors. Appl. Environ. Microbiol. 2005, 71, 8565–8572. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J.; Li, J.; Gao, R.; Wang, M.; Yang, L.; Wang, X.; Zhang, L.; Peng, Y. A critical review of one-stage anammox processes for treating industrial wastewater: optimization strategies based on key functional microorganisms. Bioresour. Technol. 2018, 265, 498–505. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Unit | Value | Parameter | Unit | Value |

|---|---|---|---|---|---|

| Anaerobic section | Aerobic section | ||||

| Total volume | L | 21.6 | Total volume | L | 21.6 |

| Temperature | °C | 35 ± 2 | Temperature | °C | 30 ± 2 |

| Granular sludge bed volume | L | 18.7 | Cross-sectional area | m2 | 0.018 |

| Water depth | m | 1.0 | Type of media | BWT15® | |

| Cross-sectional area | m2 | 0.016 | Carriers filled | L | 16.3 |

| Upflow velocity | m/h | 0.675 | Number of carriers filled | No | 1332 |

| Internal diameter | cm | 14.2 | Total protected surface area | m2 | 10.5 |

| Gas baffle diameter | mm | 82 | |||

| Trial No. | Aeration Cycle (min) | Aeration Fraction | Duration (Days) |

|---|---|---|---|

| 1 | 20 | 0.75 | 48 |

| 2 | 7 | 0.43 | 35 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sivalingam, V.; Dinamarca, C.; Janka, E.; Kukankov, S.; Wang, S.; Bakke, R. Effect of Intermittent Aeration in a Hybrid Vertical Anaerobic Biofilm Reactor (HyVAB) for Reject Water Treatment. Water 2020, 12, 1151. https://doi.org/10.3390/w12041151

Sivalingam V, Dinamarca C, Janka E, Kukankov S, Wang S, Bakke R. Effect of Intermittent Aeration in a Hybrid Vertical Anaerobic Biofilm Reactor (HyVAB) for Reject Water Treatment. Water. 2020; 12(4):1151. https://doi.org/10.3390/w12041151

Chicago/Turabian StyleSivalingam, Vasan, Carlos Dinamarca, Eshetu Janka, Sergey Kukankov, Shuai Wang, and Rune Bakke. 2020. "Effect of Intermittent Aeration in a Hybrid Vertical Anaerobic Biofilm Reactor (HyVAB) for Reject Water Treatment" Water 12, no. 4: 1151. https://doi.org/10.3390/w12041151

APA StyleSivalingam, V., Dinamarca, C., Janka, E., Kukankov, S., Wang, S., & Bakke, R. (2020). Effect of Intermittent Aeration in a Hybrid Vertical Anaerobic Biofilm Reactor (HyVAB) for Reject Water Treatment. Water, 12(4), 1151. https://doi.org/10.3390/w12041151