The Design of a Vapor-Condensing Plume Abatement System and Devices for Mechanical Draft Cooling Towers

Abstract

:1. Introduction

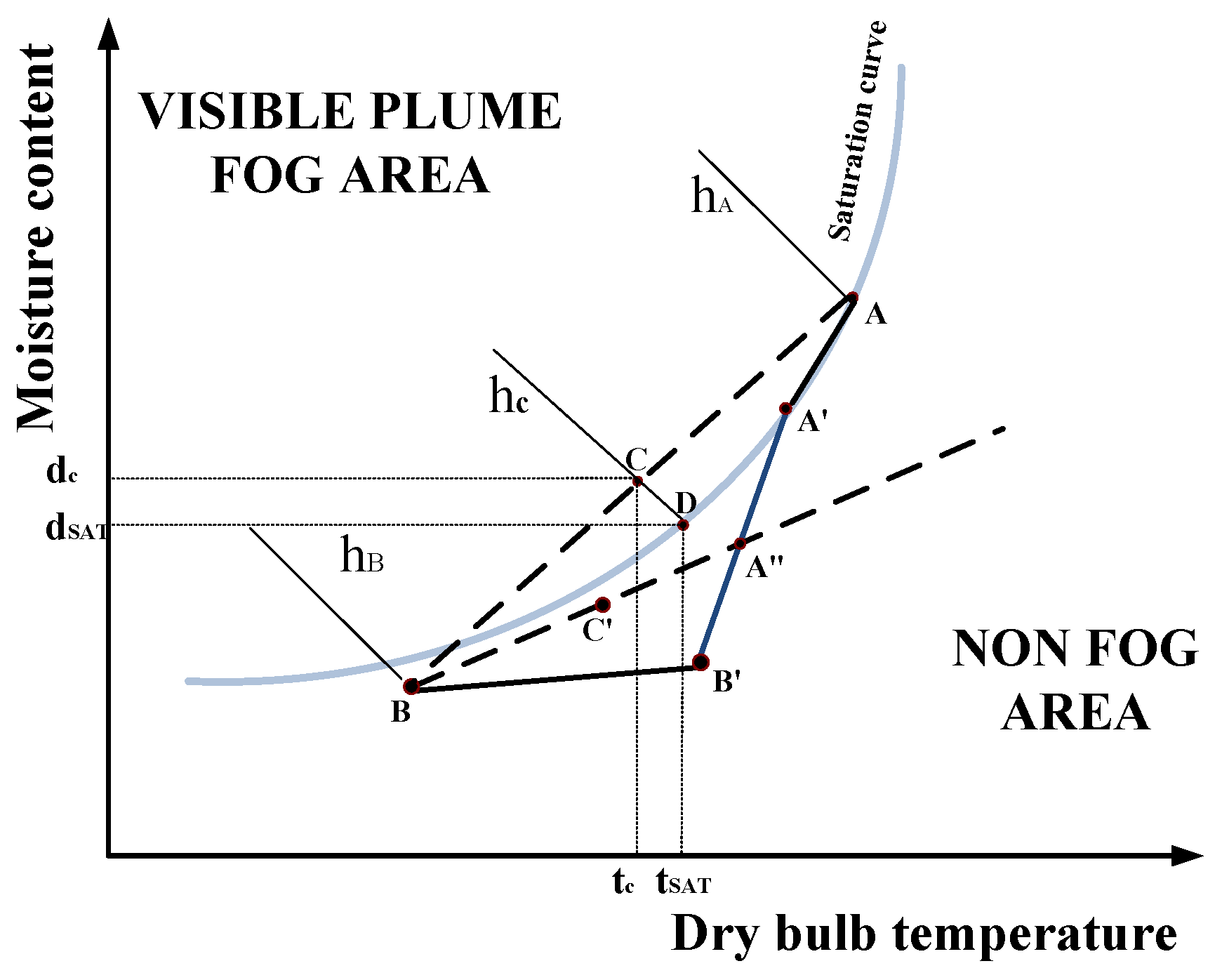

2. The Mechanism of Vapor Plume Generation in Mechanical Draft Cooling Towers

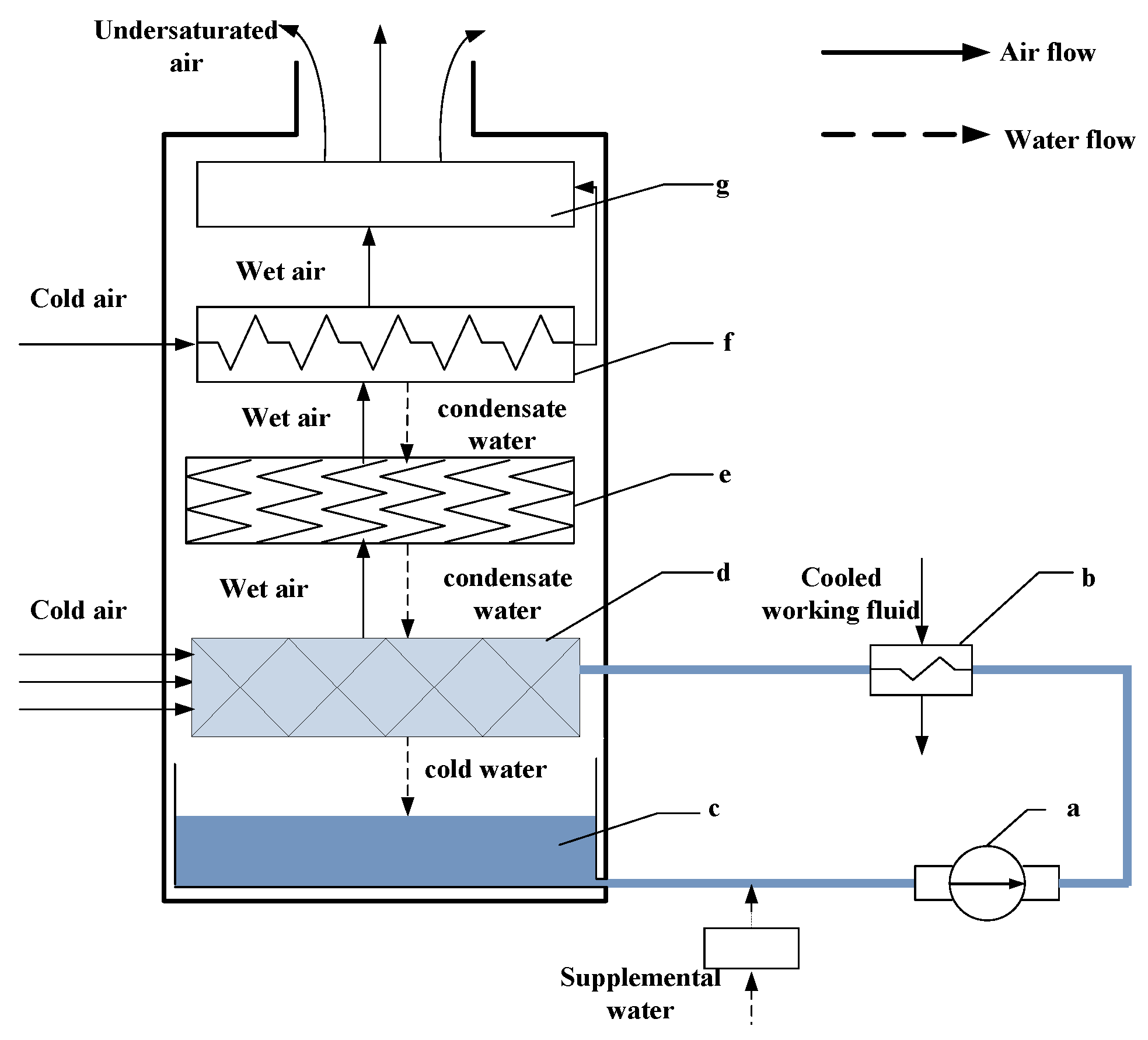

3. Vapor-Condensing Plume Abatement System

4. Vapor-Condensing Plume Abatement Devices

4.1. Design Ideas

- (1)

- Effective condensing capabilities: A sufficiently large heat exchanging surface must be available so that adequate heat exchange may occur between hot and cold air.

- (2)

- Adequate mixing between hot and cold air: The cold and hot airflows that pass through the VCPA device should mix easily.

- (3)

- Modular design: A modular design makes it easy to swap heat exchangers and install the system. Modularity also improves the generalizability of the VCPA device and makes it easier to maintain and repair.

- (4)

- Effective water collecting functionality: The water collected by the condenser is valuable as it is clean and pure, and it should be collected by a water-collecting device. Therefore, the condenser should be an effective water collector.

- (5)

- Does not impede the cooling tower’s operations: The VCPA device must not hinder the ability of the cooling tower to cool circulating water, and it must allow the hot-and-wet air inside the cooling tower to flow normally.

4.2. Design Schemes

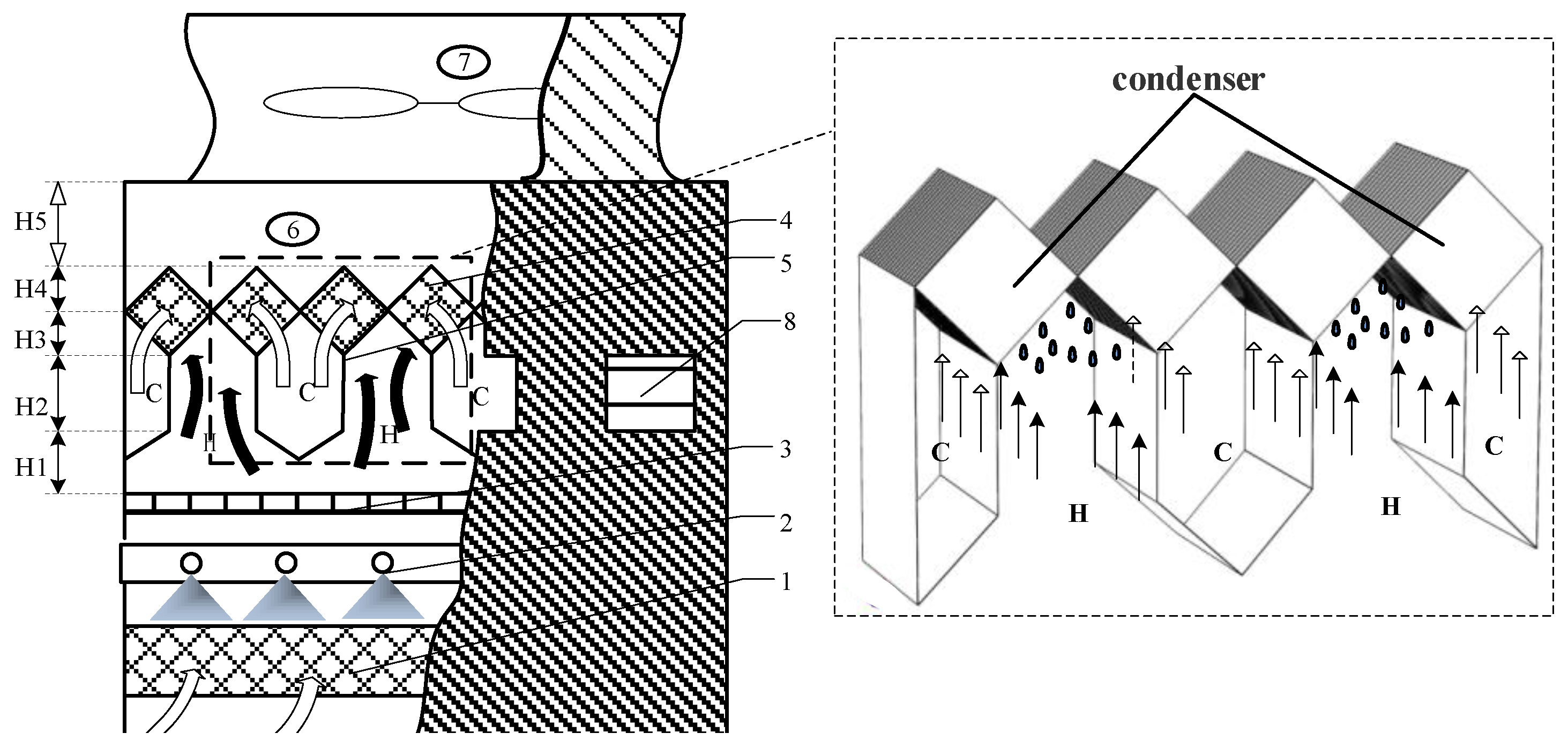

4.2.1. Vapor-Condensing Plume Abatement Device for CSCTs

4.2.2. Vapor-Condensing Plume Abatement Device for FSCTs

4.3. Design of the Condenser

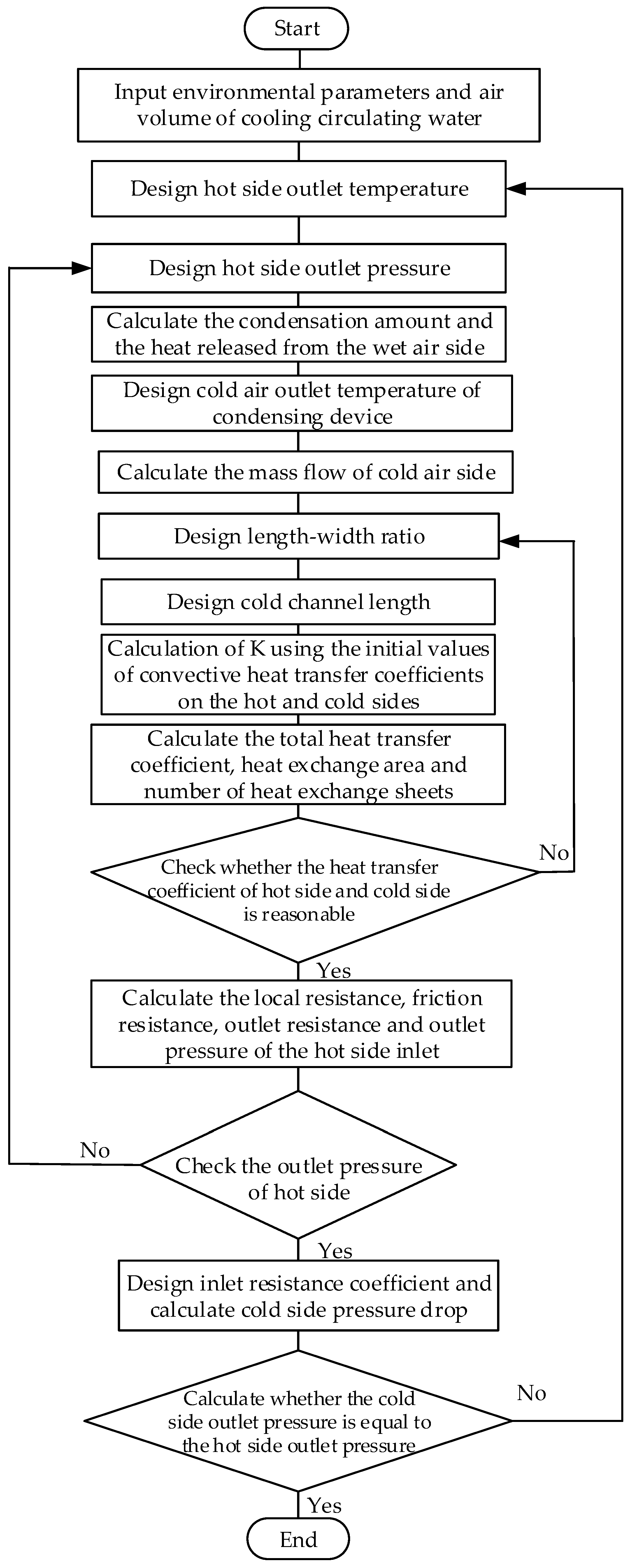

4.3.1. Mathematical Model of VCPA

4.3.2. Evaluation Index of Heat Exchanger

4.3.3. Structure of the Heat-Exchanging Channels

5. Results and Discussion

5.1. Design Example of CSCT and FSCT

5.2. Results and Validity of Design Example

5.3. Economic Analysis

6. Conclusions

- (1)

- Based on the analysis of the mechanism of vapor plume generation in mechanical draft cooling towers, a VCPA system has been designed for mechanical draft cooling towers. This forms a theoretical basis for the design of VCPA devices.

- (2)

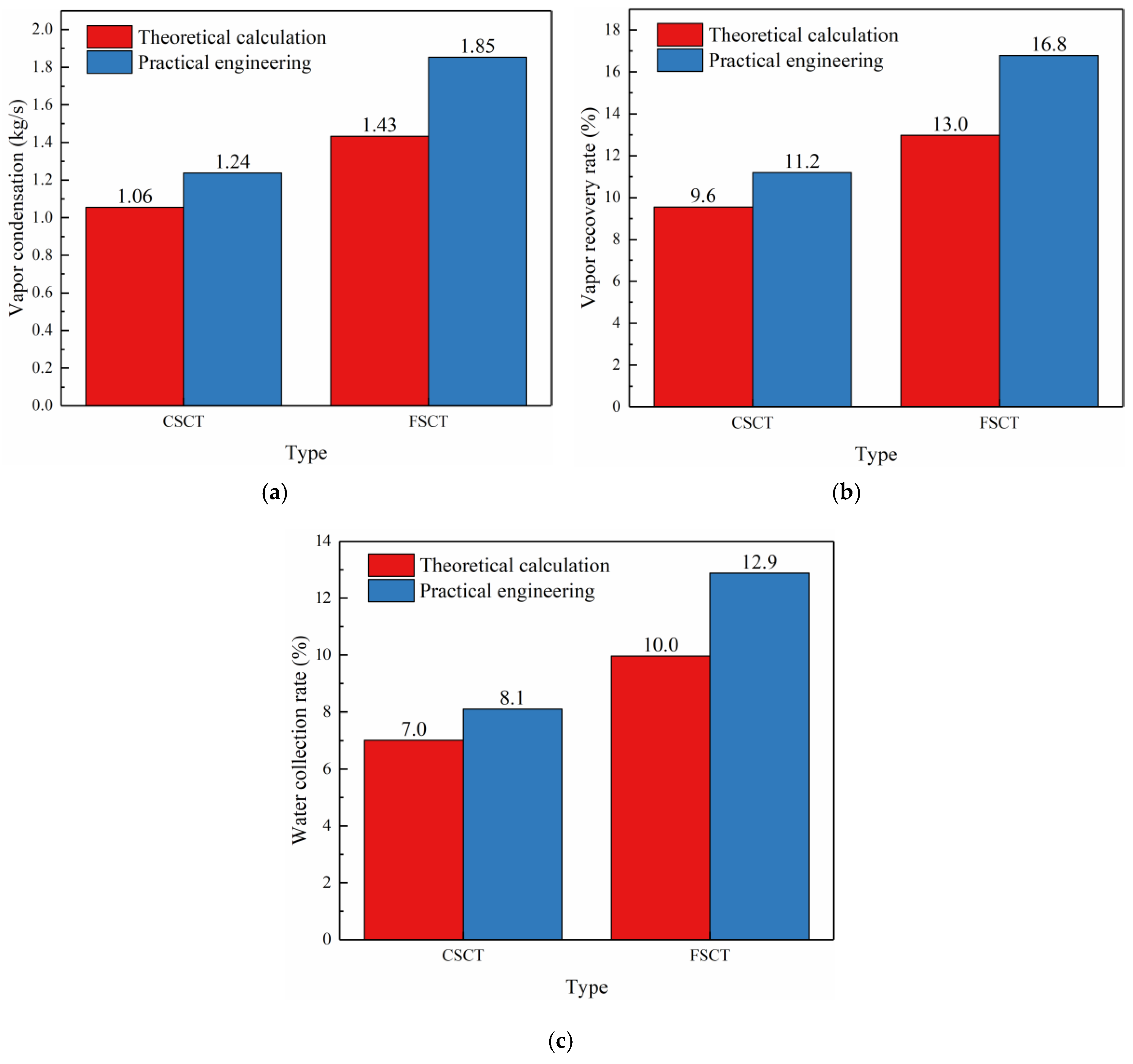

- According to the specific characteristics of CSCT and FSCT, two different VCPA devices were designed respectively. Then a basic calculation flow and method were proposed to obtain thermodynamic operating parameters. According to the theoretical calculation, some performance parameters of VCPA such as water collection rate can be obtained.

- (3)

- The condensers in the VCPAs were designed with recovery heat exchangers, and a modular design was used for the condenser’s components. The heat-exchanging plates were coupled to each other to form the condenser’s cold and hot channels, which resulted in a structure that is both simple and cheap to construct. Furthermore, this structure readily enables the collection of water (from water vapor) without invoking the need for other coolants, and it does not affect the original cooling performance of the cooling tower.

- (4)

- Due to the influence of meteorological conditions, the effect of practical engineering application is better than that of theoretical calculation.

- (5)

- According to the comparison between the results of theoretical calculation and practical engineering application, it was demonstrated that the VCPA devices are capable of yielding considerable water-saving and societal benefits. The findings of this work will serve as a reference for the development of water-saving plume abated cooling towers and the augmentation of cooling towers that are currently in service with VCPA technology.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wu, P.; Feng, H.; Niu, W.; Gao, J.; Jiang, D.; Wang, Y.; Fan, X.; Qi, P. Analysis of developmental tendency of water distribution and water-saving strategies. Trans. Chin. Soc. Agric. Eng. 2003, 19, 1–6. (In Chinese) [Google Scholar]

- Consuegro, A.J.; Kaiser, A.S.; Zamora, B.; Sánchez, F.; Lucas, M.; Hernández, M. Numerical modeling of the drift and deposition of droplets emitted by mechanical cooling towers on buildings and its experimental validation. Build. Environ. 2014, 78, 53–67. [Google Scholar] [CrossRef]

- Bentham, R.H.; Broadbent, C.R. A model autumn outbreaks of Legionnaries disease associate with cooling towers, linked to system operation and size. Epidemiol. Infect. 1993, 111, 287–295. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Isozumi, R.; Ito, Y.; Ito, I.; Osawa, M.; Hirai, T.; Takakura, S. An outbreak of Legionella pneumonia originating from a cooling tower. Scand J. Infect Dis. 2005, 37, 709–711. [Google Scholar] [CrossRef]

- Chang, T.; Lin, T. Water and energy conservation for a counterflow cooling tower using UV light disinfection and variable speed fan. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2016, 230, 235–243. [Google Scholar] [CrossRef]

- Hafez, O.M.; Shoeib, M.A.; EI-Khateeb, M.A.; Abdel-Shafy, H.I.; Youssef, A.O. Removal of scale forming species from cooling tower blowdown water by electrocoagulation using different electrodes. Chem. Eng. Res. Des. 2018, 136, 347–357. [Google Scholar] [CrossRef]

- Thorp, J.M.; Orgill, M.M. Cooling tower visible plume rise analyses by time integrated photographs. Atmos. Environ. 1984, 18, 675–683. [Google Scholar] [CrossRef]

- Bernier, M.A. Cooling tower performance—Theory and experiments. ASHRAE Trans. 1994, 100, 114–121. [Google Scholar]

- Bornoff, R.B.; Mokhtarzadeh-Dehghan, M.R. A numerical study of interacting buoyant cooling-tower plumes. Atmos. Environ. 2001, 35, 589–598. [Google Scholar] [CrossRef]

- Wang, S.W.; Tyagi, S.K.; Sharma, A.; Kaushik, S.C. Application of solar collectors to control the visible plume from wet cooling towers of a commercial building in Hong Kong: A case study. Appl. Therm. Eng. 2007, 27, 1394–1404. [Google Scholar] [CrossRef]

- Tyagi, S.K.; Wang, S.W.; Ma, Z.J. Prediction, potential and control of plume from wet cooling tower of commercial buildings in Hong Kong: A case study. Int. J. Energy Res. 2007, 31, 778–795. [Google Scholar] [CrossRef]

- Wang, S.W.; Xu, X.H. Effects of alternative control strategies of water-evaporative cooling systems on energy efficiency and plume control: A case study. Build Environ. 2008, 43, 1973–1989. [Google Scholar] [CrossRef]

- Xu, X.H.; Wang, S.W.; Ma, Z.J. Evaluation of plume potential and plume abatement of evaporative cooling towers in a subtropical region. Appl. Therm. Eng. 2008, 28, 1471–1484. [Google Scholar] [CrossRef]

- Ding, F.; Xing, K.J.; Li, S.B.; Bai, J.H. Sensitivity analysis of plume rising height from cooling tower. Procedia Environ. Sci. 2010, 2, 1374–1379. [Google Scholar]

- Sánchez, F.; Kaiser, A.S.; Zamora, B.; Ruiz, J.; Lucas, M. Prediction of the lifetime of droplets emitted from mechanical cooling towers by numerical investigation. Int. J. Heat Mass Transf. 2015, 89, 1190–1206. [Google Scholar] [CrossRef] [Green Version]

- Meroney, R.N. CFD prediction of cooling tower drift. J. Wind Eng. Ind. Aerodyn. 2006, 94, 463–490. [Google Scholar] [CrossRef]

- Takata, K.; Michioka, T.; Kurose, R. Prediction of a visible plume from a dry and wet combined cooling tower and its mechanism of abatement. Atmosphere 2016, 7, 59. [Google Scholar] [CrossRef] [Green Version]

- Mantelli, M.H.B. Development of porous media thermosyphon technology for vapor recovering in cross-current cooling towers. Appl. Therm. Eng. 2016, 108, 398–413. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, M. CFD-based turbulent reactive flow simulations of power plant plumes. Atmos. Environ. 2017, 150, 77–86. [Google Scholar] [CrossRef]

- Li, S.; Moradi, A.; Vickers, B.; Flynn, M.R. Cooling tower plume abatement using a coaxial plume structure. Int. J. Heat Mass Transf. 2018, 120, 178–193. [Google Scholar] [CrossRef]

- The Ministry of Housing and Urban-Rural Development of the People’s Republic of China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Code for Design of Cooling Tower for Mechanical Ventilation; China Planning Press: Beijing, China, 2016.

- Hu, L.; Wang, J.; Zhao, X. Analysis and design of the fluid state of the section of duct pervasion in the mechanical ventilation cooling tower. Ind. Water Treatment 2009, 29, 76–79. (In Chinese) [Google Scholar]

| Parameter | Unit | Value |

|---|---|---|

| Thermal conductivity of the heat-exchanging plate, λ | W/(m·k) | 0.17 |

| Plate thickness, δ | m | 4 × 10−4 |

| Length of hot channel, lh | m | 0.75 |

| Width of a hot channel, x | m | 0.026 |

| Length of each side of the cold channels, lc | m | 6.8 |

| Width of a cold channel, y | m | 0.049 |

| Total length of a cold channel | m | 15 |

| Number of heat-exchange fins in each element, N | - | 488 |

| Total heat exchanger surface area, A | m2 | 4758 |

| Parameter | Unit | Value |

|---|---|---|

| Thermal conductivity of the heat-exchanging plate, λ | W/(m·k) | 0.17 |

| Plate thickness, δ | m | 4 × 10−4 |

| Length of hot channel, lh | m | 1.45 |

| Width of a hot channel, x | m | 0.051 |

| Length of cold channel, lc | m | 1.45 |

| Width of a cold channel, y | m | 0.017 |

| Number of heat exchanger unit | - | 8 |

| Number of heat-exchange fins in each element, N | - | 600 |

| Total heat exchanger surface area, A | m2 | 10,092 |

| Type | P (kPa) | RH (%) | tdb (°C) | tin (°C) | tout (°C) |

|---|---|---|---|---|---|

| CSCT | 101.02kPa | 47.8% | 8.4 | 38.0 | 28.0 |

| FSCT | 103kPa | 54.3% | 5.2 | 36.8 | 27.0 |

| Parameter | CSCT | FSCT |

|---|---|---|

| Vapor condensation, kg/s | 1.06 | 1.43 |

| Vapor recovery rate, % | 9.6 | 13.0 |

| Water collection rate, % | 7.0 | 10.0 |

| Parameter | CSCT | FSCT |

|---|---|---|

| Vapor condensation, kg/s | 1.24 | 1.85 |

| Vapor recovery rate, % | 11.2 | 16.8 |

| Water collection rate, % | 8.1 | 12.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Xu, W.; Wang, W.; Shi, X.; Chen, G.; Zhao, S. The Design of a Vapor-Condensing Plume Abatement System and Devices for Mechanical Draft Cooling Towers. Water 2020, 12, 1013. https://doi.org/10.3390/w12041013

Zhu X, Xu W, Wang W, Shi X, Chen G, Zhao S. The Design of a Vapor-Condensing Plume Abatement System and Devices for Mechanical Draft Cooling Towers. Water. 2020; 12(4):1013. https://doi.org/10.3390/w12041013

Chicago/Turabian StyleZhu, Xiaojing, Weihui Xu, Weishu Wang, Xu Shi, Gang Chen, and Shifei Zhao. 2020. "The Design of a Vapor-Condensing Plume Abatement System and Devices for Mechanical Draft Cooling Towers" Water 12, no. 4: 1013. https://doi.org/10.3390/w12041013

APA StyleZhu, X., Xu, W., Wang, W., Shi, X., Chen, G., & Zhao, S. (2020). The Design of a Vapor-Condensing Plume Abatement System and Devices for Mechanical Draft Cooling Towers. Water, 12(4), 1013. https://doi.org/10.3390/w12041013