Numerical Simulation of Free Surface Flow on Spillways and Channel Chutes with Wall and Step Abutments by Coupling Turbulence and Air Entrainment Models

Abstract

:1. Introduction

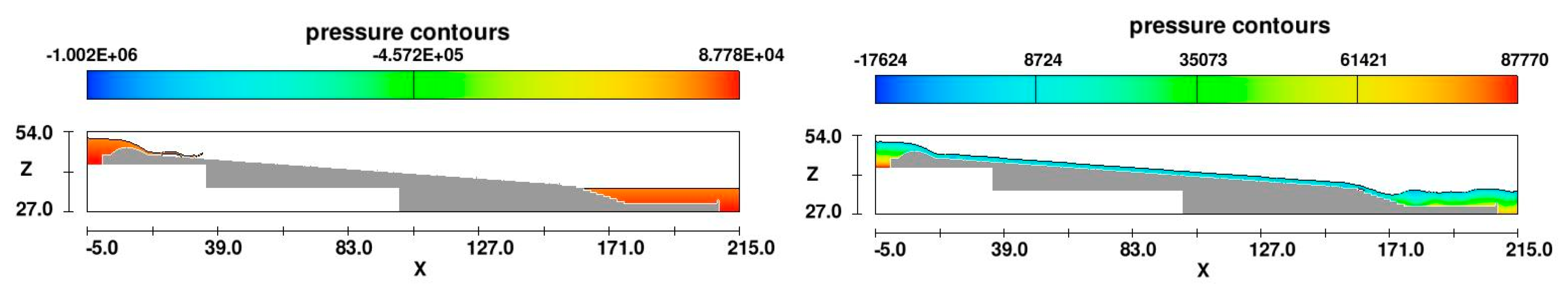

2. Materials and Methods

2.1. Air Entrainment and Turbulent Models in Flow 3D

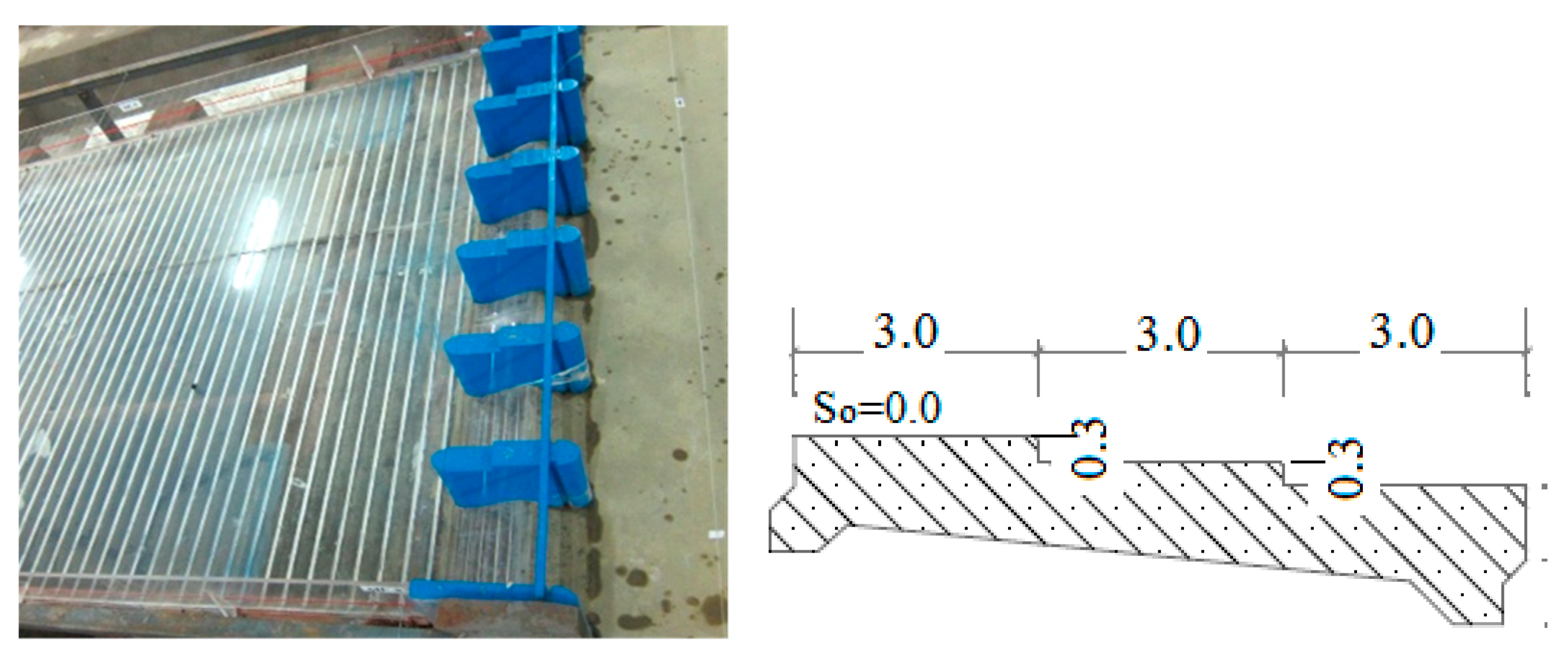

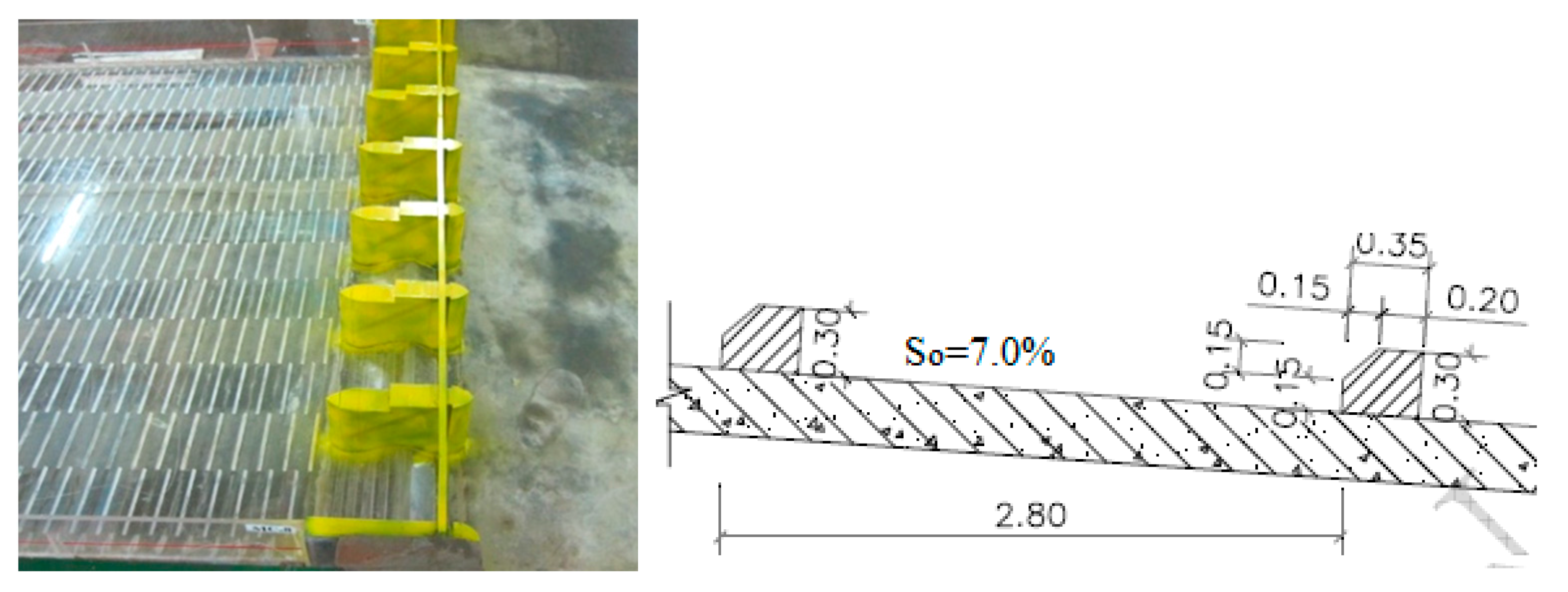

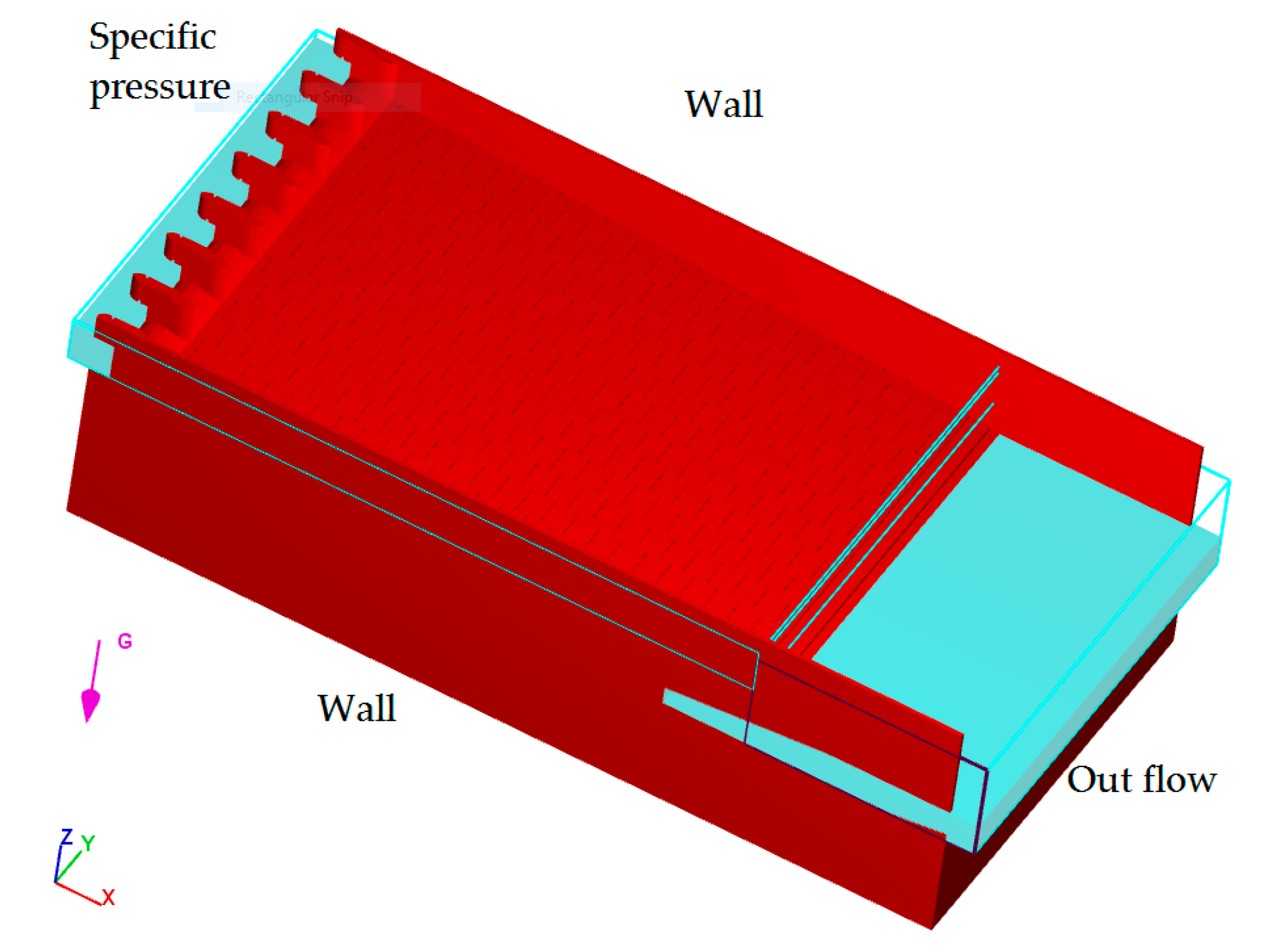

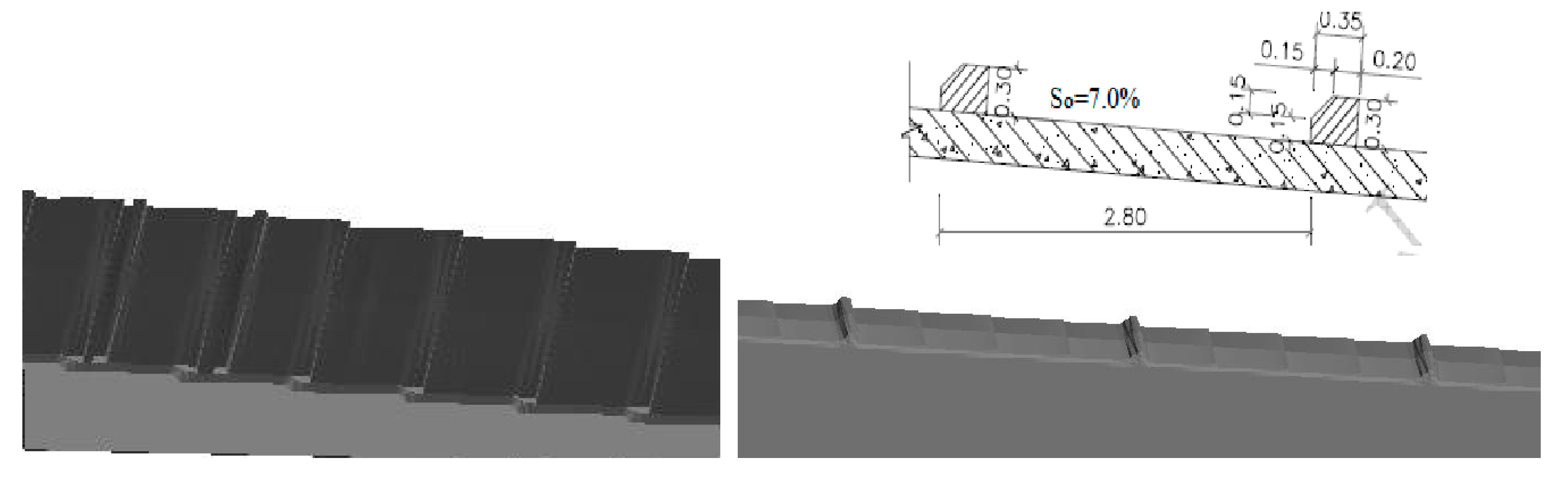

2.2. Physical Model

3. Result and Discussion

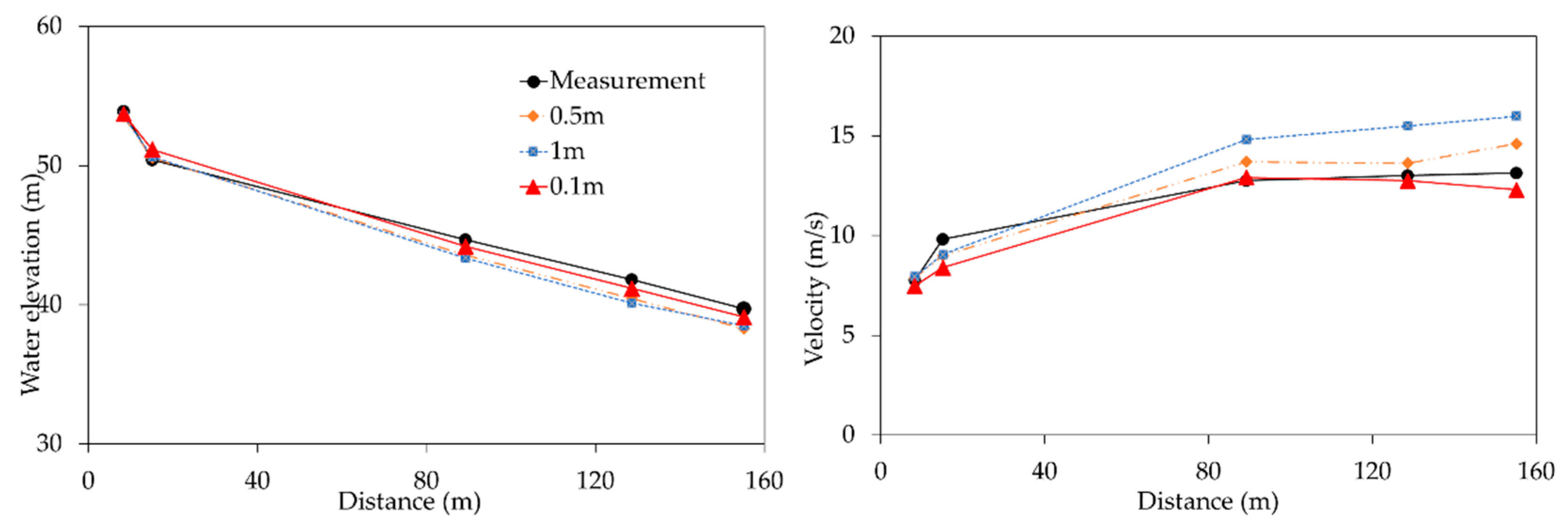

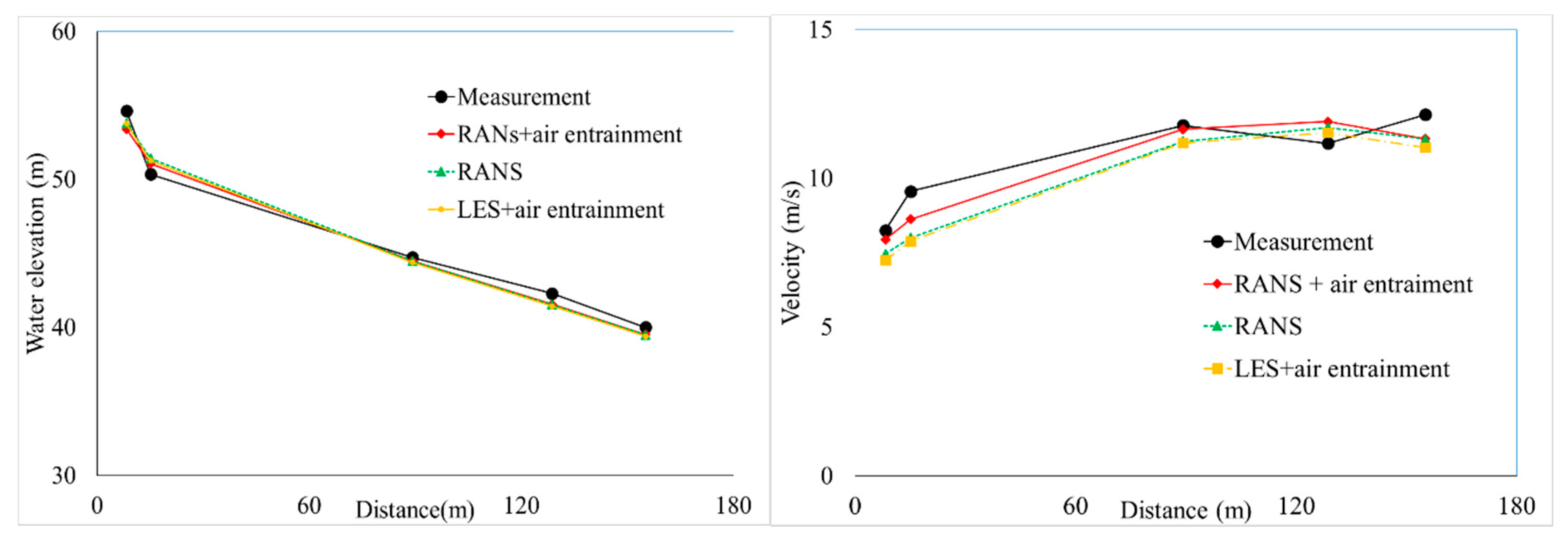

3.1. The Influence of the Turbulence Model

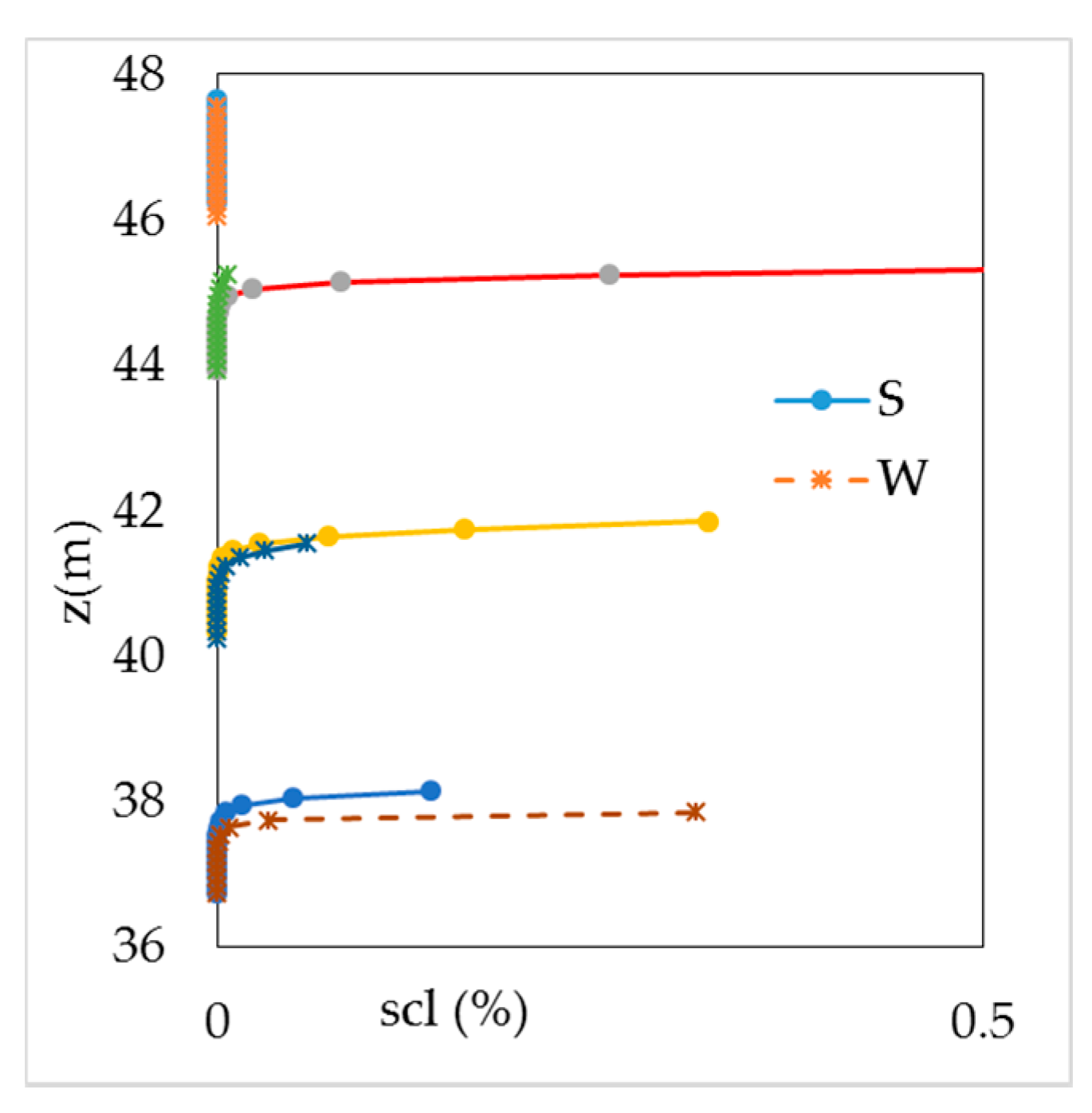

3.2. The Influence of Discretization Schemes

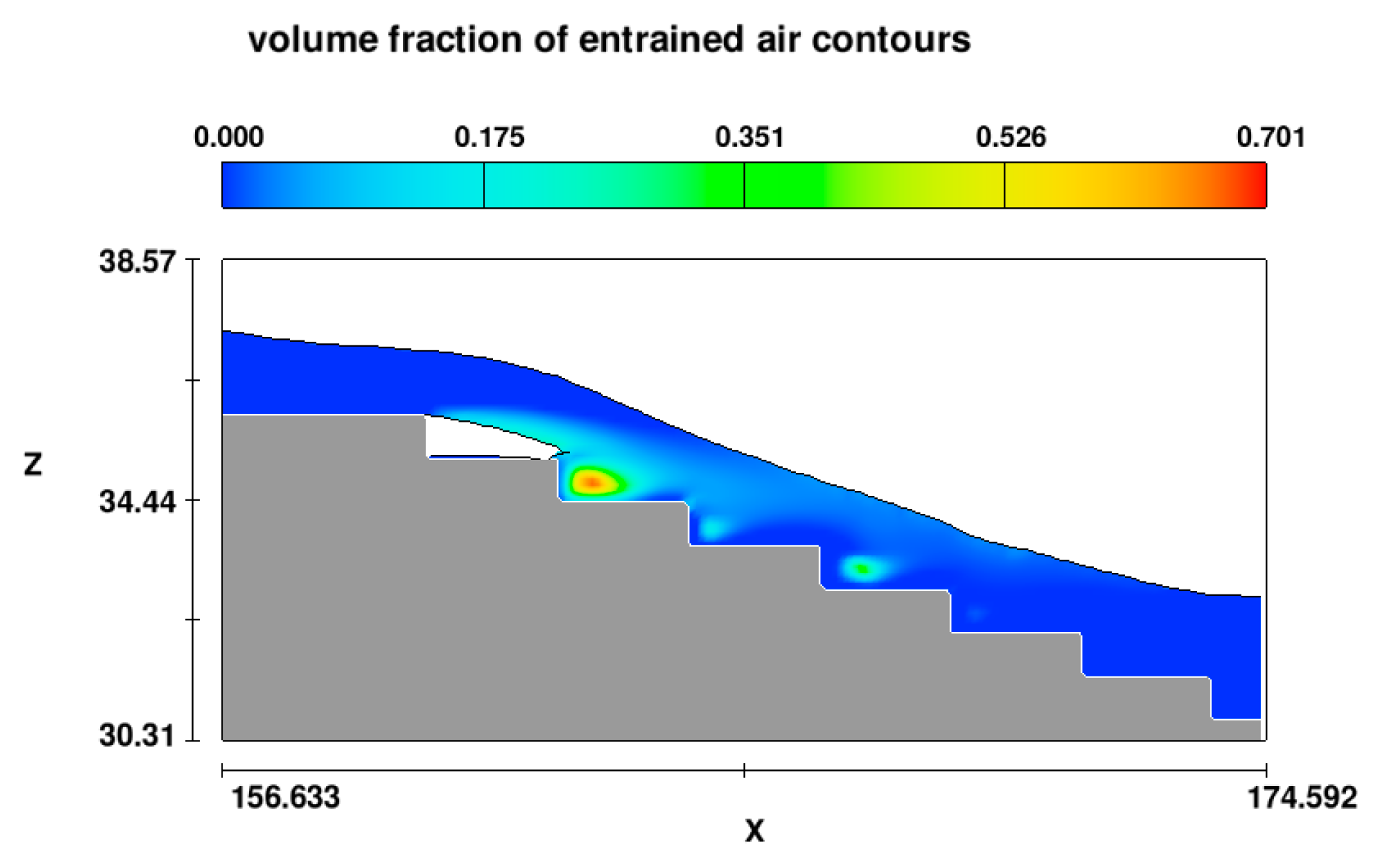

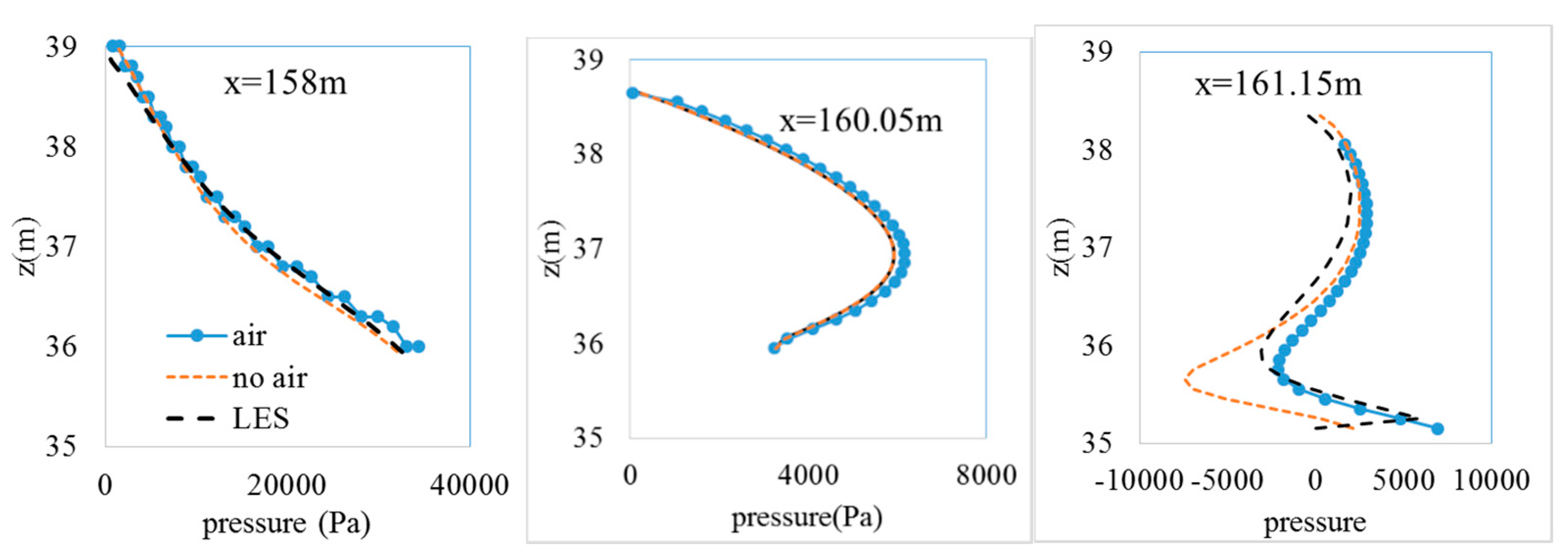

3.3. The Influnce of the Air Entrainment Model on Mathematical Results

3.4. Esimate Flow Characteristics on Stirlling Basin

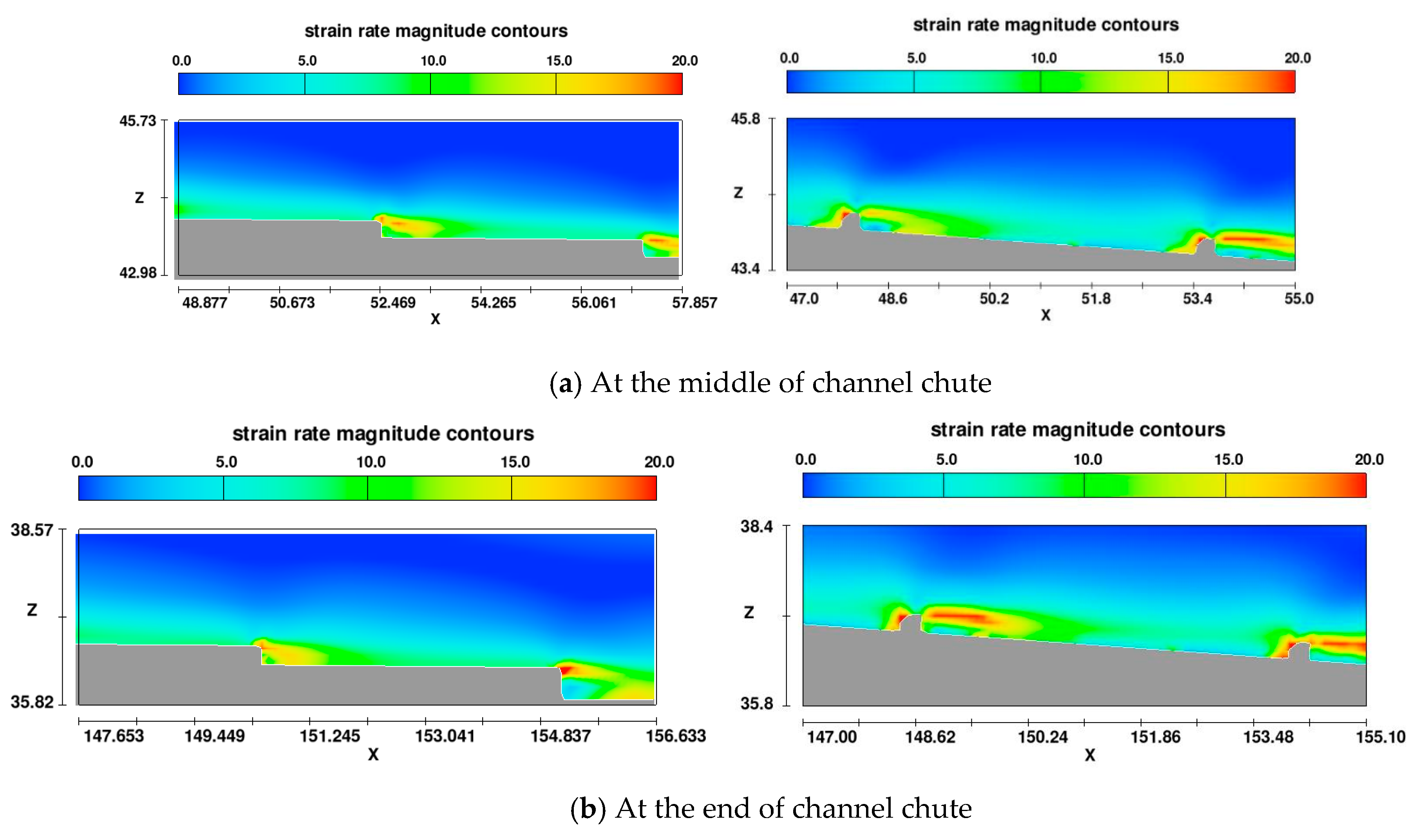

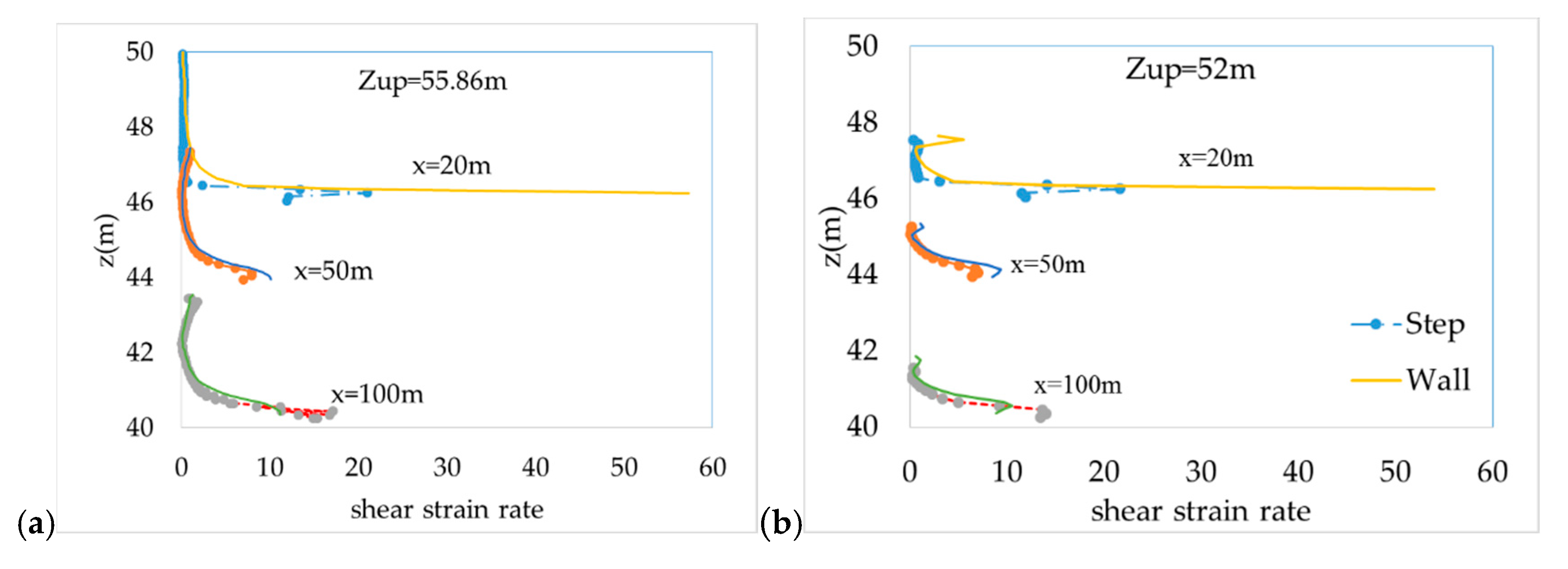

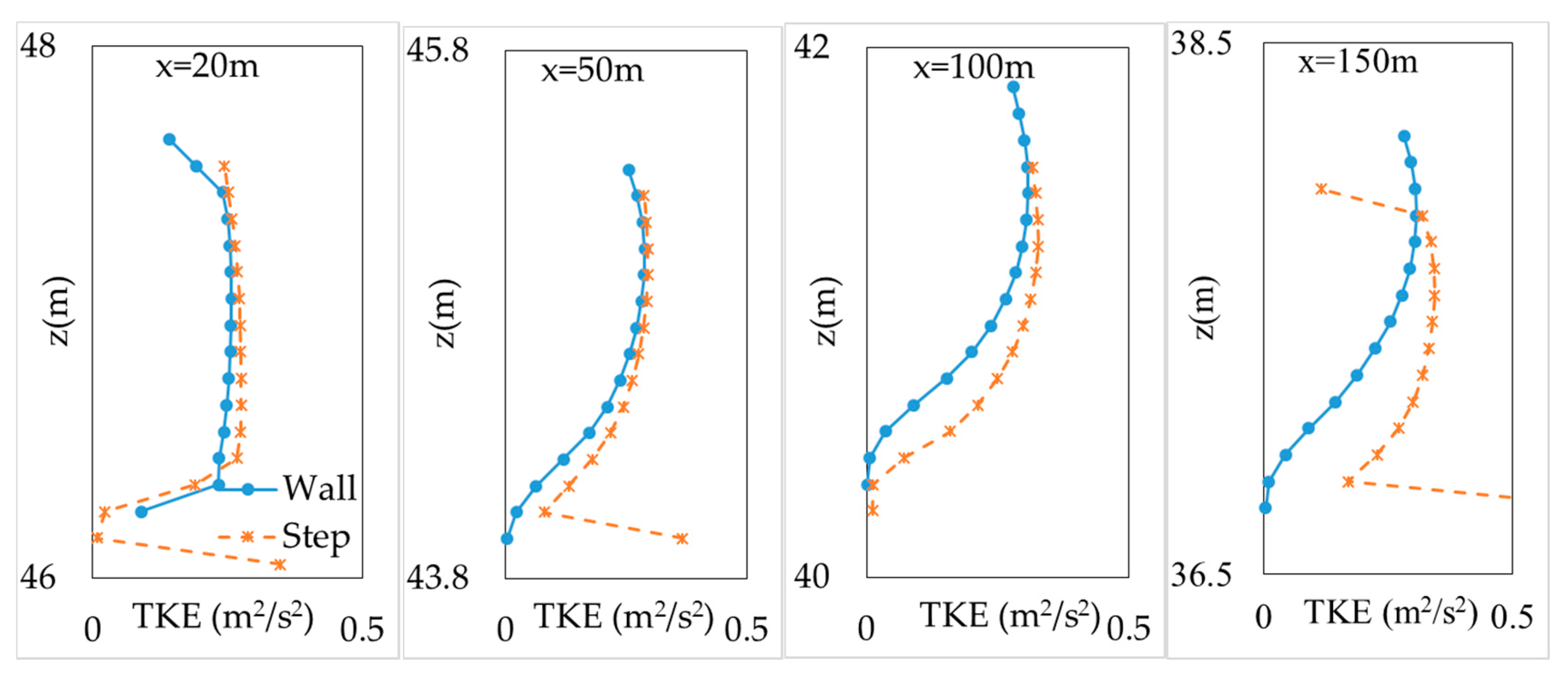

3.5. Estimated Energy Dissipation Capability of Two Types of Abutment

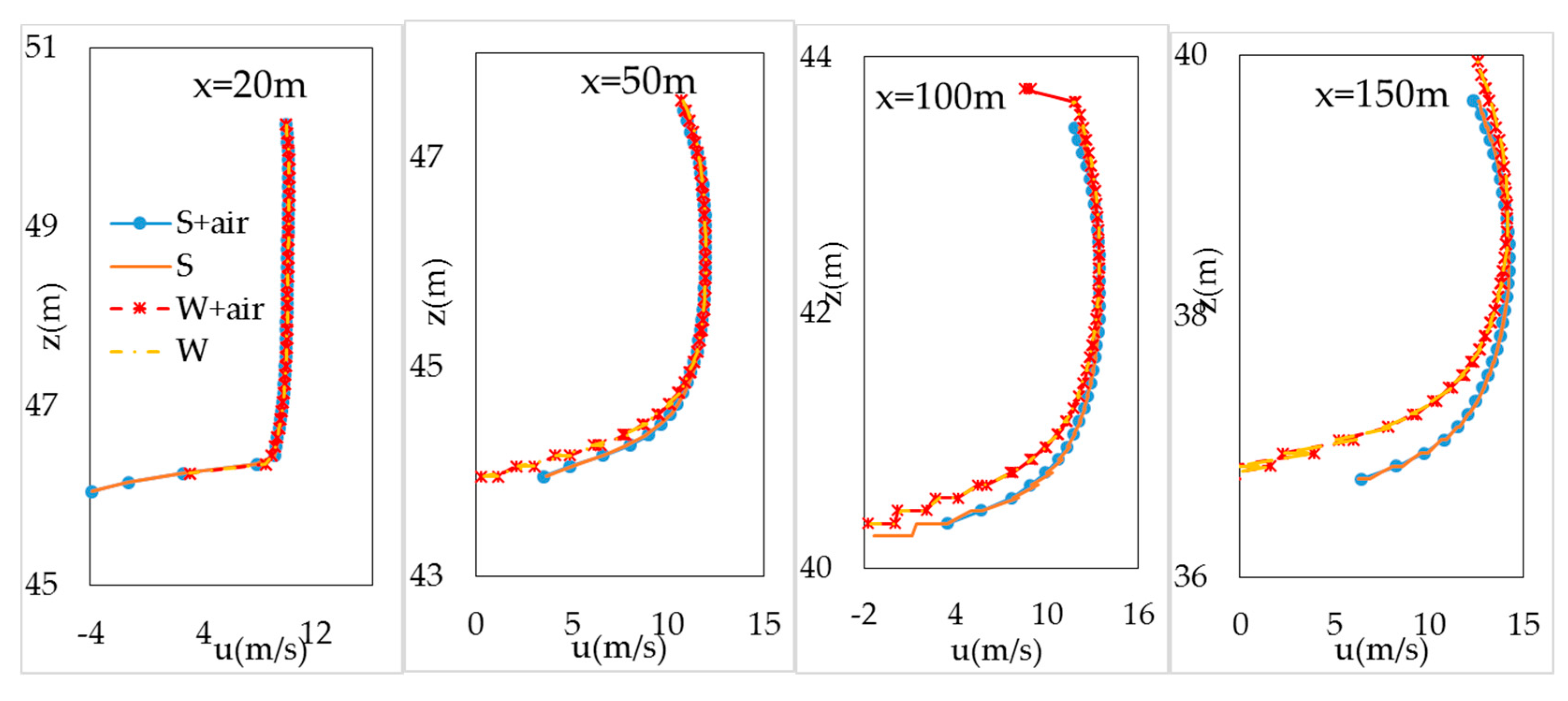

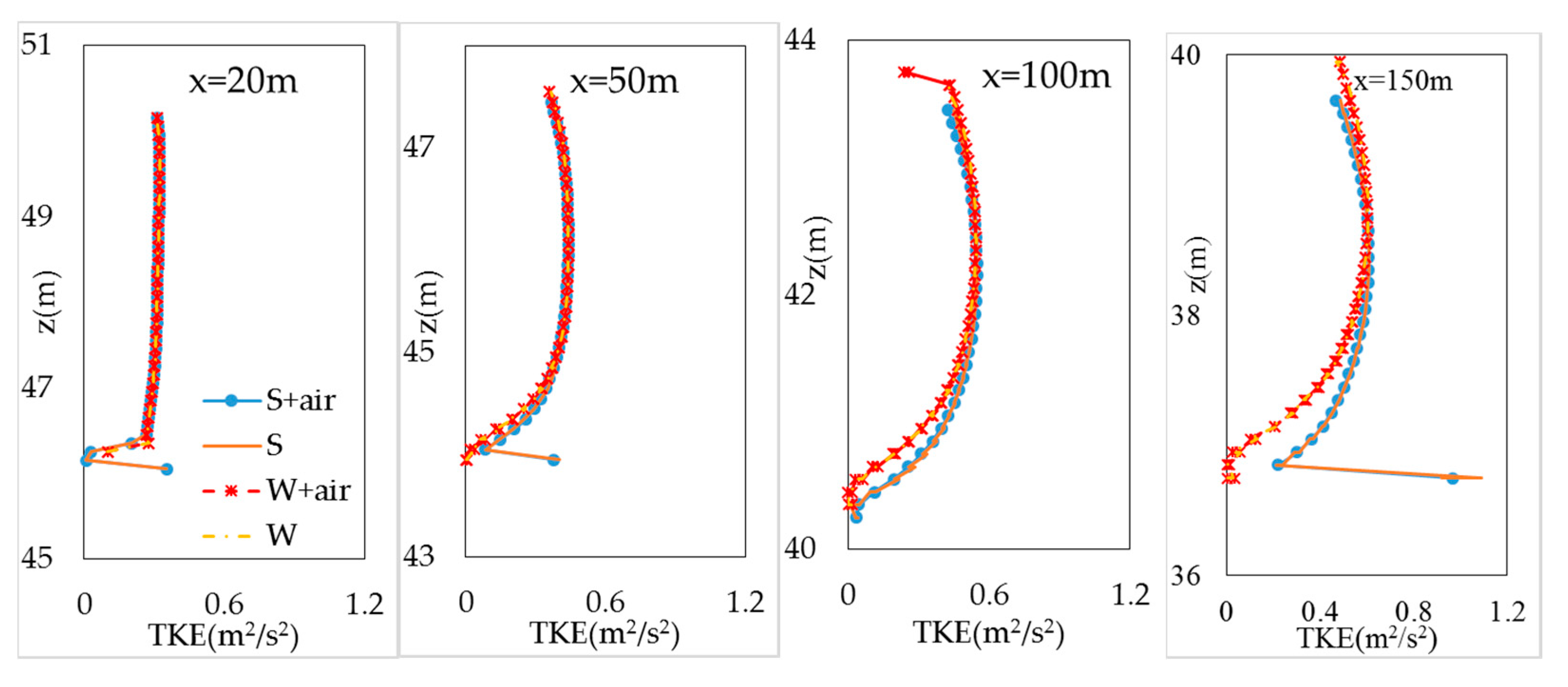

3.5.1. Hydraulic Characteristics of the Channel Chute with Wall Abutments

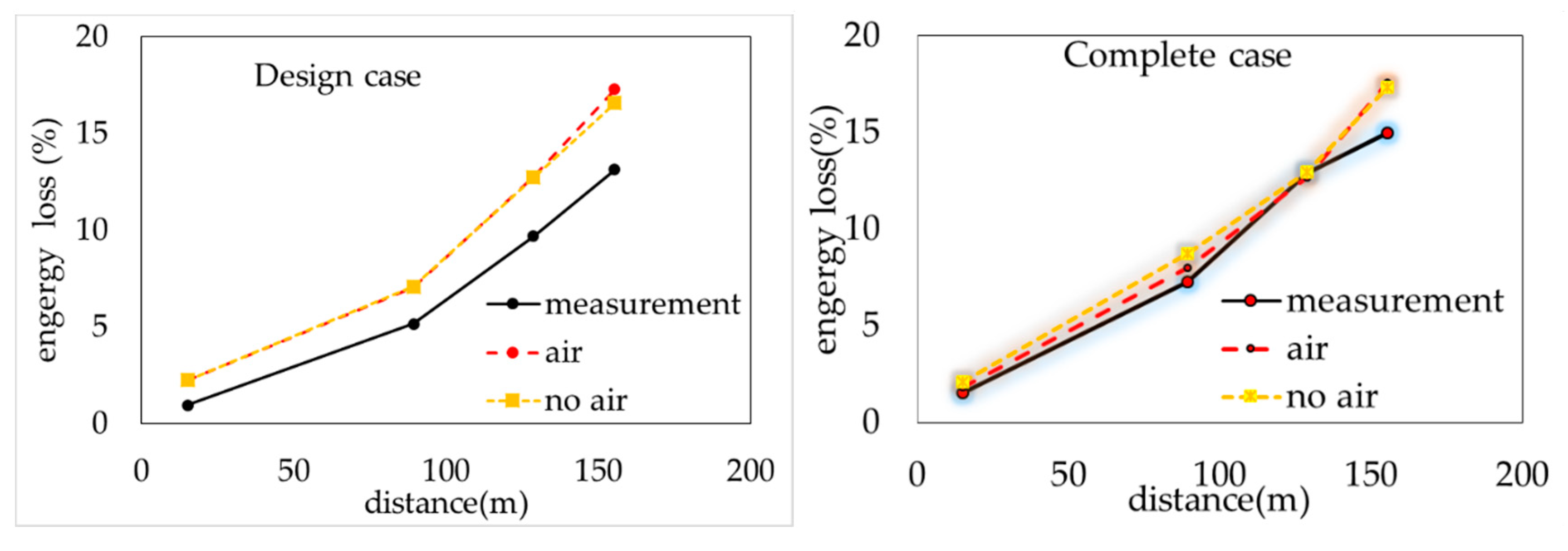

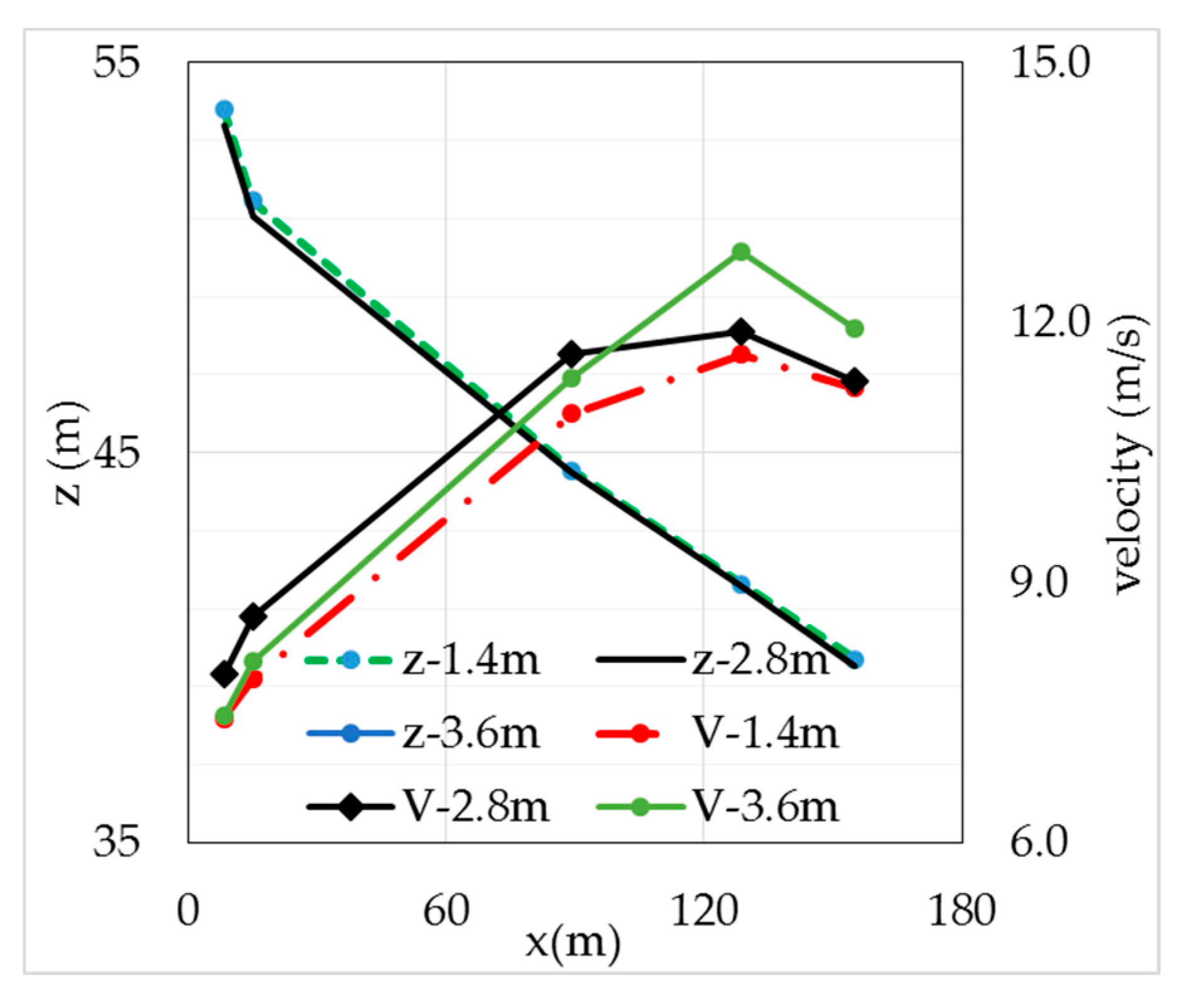

3.5.2. Optimal Distance between Two Walls

4. Conclusions

- Two turbulent models (RANS and LES) were used to calculate features. The results showed that RANS gives better solutions for the water level, velocity and pressure profiles.

- Four discretization types (1 m, 0.75 m, 0.5 m and 0.1 m) were used. The finest mesh cell of 0.1 m yeilded the best match between numerical model results and the physical measurements.

- An air entrainment model was included to simulate rapid flow over a complex structure. The predictions for the water level, velocity in the spillway chute, pressure distribution, and the location of the hydraulic jump in the stilling basin all closely agreed with measured data. The study also indicates that, without the air entrainment model, air–water flow cannot be simulated well if the water input is low and a napped flow occurs.

- The estimation of engergy dissipation also indicates that wall abutments provide better energy dissipation. The maximum strain rate after steps was smaller than after walls. Three spacing distances between abutments were tested on the spillway chute to study energy dissipation along the chute. Our results showed that the distance of 2.8 m dissipated energy better than other spacings.

Author Contributions

Funding

Conflicts of Interest

References

- Demeke, G.K.; Asfaw, D.H.; Shiferaw, Y.S. 3D Hydrodynamic Modelling Enhances the Design of Tendaho Dam Spillway, Ethiopia. Water 2019, 11, 82. [Google Scholar] [CrossRef] [Green Version]

- Salmasi, F.; Samadi, A. Experimental and numerical simulation of flow over stepped spillways. Appl. Water Sci. 2018. [Google Scholar] [CrossRef] [Green Version]

- Amador, A.; Juny, M.S.; Dolz, J. Developing flow region and pressure fluctuations on steeply sloping stepped spillways. J. Hydraul. Eng. 2009, 135, 1092–1100. [Google Scholar] [CrossRef]

- Bayon, A.; Toro, J.P.; Bombardelli, F.A.; Matos, J.; Lospez-Jiménez, P.A. Influence of VOF technique, turbulence model and discretization scheme on the numerical simulation of the non-aerated, skimming flow in stepped spillways. J. Hydro Environ. Res. 2018, 19, 137–149. [Google Scholar] [CrossRef] [Green Version]

- Dong, Z.; Wang, J.; Vetsch, D.F.; Boes, R.M.; Tan, G. Numerical simulation of air water two phase flow on stepped spillway behind X shaped flaring gate piers under very high unit discharge. Water 2019, 11, 1956. [Google Scholar] [CrossRef] [Green Version]

- Bombardelli, F.A.; Meireles, I.; Matos, J. Laboratory measurements and multi-block numerical simulations of the mean flow and turbulence in the non-aerated skimming flow region of steep stepped spillways. Environ. Fluid Mech. 2011, 11, 263–288. [Google Scholar] [CrossRef] [Green Version]

- Morovati, K.; Eghbalzadeh, A. Study of inception point, void fraction and pressure over pooled stepped spillways using Flow-3D. Int. J. Numer. Methods Heat Fluid Flow 2018, 28, 982–998. [Google Scholar] [CrossRef]

- Kermani, E.F.; Barani, G.A. Numerical simulation of flow over spillway based on CFD method. Sci. Iran. A 2014, 21, 91–97. [Google Scholar]

- Kumcu, S.Y. Investigation of flow over spillway modeling and comparison between experimental data and CFD analysis. KSCE J. Civ. Eng. 2017, 21, 994–1003. [Google Scholar] [CrossRef]

- Valero, D.; Rafael, G.B. Calibration of an Air Entrainment Model for CFD Spillway Applications. Adv. Hydroinform. 2016, 38, 571–582. [Google Scholar] [CrossRef]

- Arnau, B.; Daniel, V.; Rafael, G.B.; Francisco, J.V.M.; Amparo, L.J. Performance assessment of OpenFOAM and FLOW-3D in the numerical modeling of a low Reynolds number hydraulic jump. Env. Model. Softw. 2016, 80, 322–335. [Google Scholar]

- Valerio, D. On the Fluid Mechanics of Self-Areation in Open Channel Flow. Ph.D. Thesis, Liege University, Liege, Belgium, November 2018. [Google Scholar]

- Bore, R.M. Guidelined on the design and hydraulic characteristics on stepped spillways. In Proceedings of the 24th ICOLD Congress, Kyoto, Japan, 6–8 June 2012; pp. 203–220. [Google Scholar]

- Felder, S.; Chanson, H. Energy dissipation, flow resistance and gas-liquid interfacial area in skimming flows on moderate-slope stepped spillways. Environ. Fluid Mech. 2009, 9, 427–441. [Google Scholar] [CrossRef]

- Chanson, H. Comparison of energy dissipation between nappe and skimming flow regimes on stepped chutes. J. Hydraul. Res. 1994, 32, 213–219. [Google Scholar] [CrossRef]

- Key Laboratory of River and Coastal Engineering. Báo cáo kết quả thí Nghiệm mô hình Thủy Lực—Tràn xả lũ Ngàn Trươi PA6B; Key Laboratory of River and Coastal Engineering: Hanoi, Vietnam, 2008. (In Vietnamese) [Google Scholar]

- Flow Science Inc. Flow-3D, Version 12.0; User Mannual; Flow Science Inc.: Santa Fe, NM, USA, 2020. [Google Scholar]

- Hint, C.W. Modeling Turbulent Entrainment of Air at a Free Surface; Technical Note FSI-01-12; Flow Science, Inc.: Santa Fe, NM, USA, 2003. [Google Scholar]

- Lubin, P.; Vincent, S.; Abadie, S.; Caltagirone, J.P. Three dimensional large eddy simulation of air entrainment under plunging breaking waves. Coast. Eng. 2006, 53, 631–655. [Google Scholar] [CrossRef] [Green Version]

- Morris, H.M. Hydraulics of Energy Dissipation in Steep, Rough Channels; Technical Report; Civil Engineering Department, Virginia Polytechnic Institute: Blacksburg, VA, USA, 1968. [Google Scholar]

| No | Flow Rate Q (m3/s) | Upstream Water Level Zup (m) | Downstream Water Level Zdown (m) |

|---|---|---|---|

| 1 | 3319 | 55.86 | 39.54 |

| 2 | 1061 | 52.00 | 35.11 |

| No | X (m) | Zbed (m) | Water Level | Velocity | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Zmeas (m) | ZRANs (m) | RZ,RAN (%) | ZLES (m) | RZ,LESs (%) | Vmeas (m/s) | VRANs (m/s) | RV,RAN (%) | VLES (m/s) | RV,LES (%) | |||

| 7 | 8.30 | 48.60 | 54.62 | 53.40 | 2.23 | 53.76 | 1.57 | 8.25 | 7.94 | 3.74 | 7.24 | 12.74 |

| 8 | 15.13 | 46.40 | 50.35 | 51.07 | −1.42 | 51.27 | −1.83 | 9.56 | 8.62 | 9.82 | 7.89 | 19.42 |

| 9 | 89.23 | 41.10 | 44.73 | 44.49 | 0.54 | 44.38 | 0.79 | 11.77 | 11.65 | 1.05 | 11.19 | 4.97 |

| 10 | 128.63 | 38.30 | 42.30 | 41.57 | 1.71 | 41.43 | 2.06 | 11.17 | 11.90 | −6.55 | 11.53 | −3.05 |

| 11 | 155.13 | 36.40 | 40.00 | 39.51 | 1.21 | 39.40 | 1.50 | 12.14 | 11.33 | 6.69 | 11.03 | 9.77 |

| Zup (m) | Grid Size (m) | |||||||

|---|---|---|---|---|---|---|---|---|

| 1.00 | 0.75 | 0.50 | 0.10 | |||||

| Design | Complete | Design | Complete | Design | Complete | Design | Complete | |

| 55.86 | 0.95 | 0.93 | 0.96 | 0.93 | 0.96 | 0.93 | 0.98 | 0.98 |

| 52.00 | 0.97 | 0.96 | 0.96 | 0.97 | 0.99 | |||

| Zup (m) | Grid Size (m) | |||||||

|---|---|---|---|---|---|---|---|---|

| 1.00 | 0.75 | 0.50 | 0.10 | |||||

| Design | Complete | Design | Complete | Design | Complete | Design | Complete | |

| 55.86 | 0.17 | 0.22 | 0.79 | 0.68 | 0.82 | 0.71 | 0.85 | 0.79 |

| 52.00 | 0.75 | 0.65 | 0.66 | 0.81 | 0.71 | |||

| No | Zup (m) | Max Pvac (Pa) - Design Case | Max Pvac (Pa) - Complete Case |

|---|---|---|---|

| 1 | 55.86 | 23,561.5 | 9027.2 |

| 2 | 52.00 | 4549.5 (2nd step); 6242.8 (3rd step) | 894.9 (2nd step); 981.2 (3rd step) |

| Zup (m) | Design Project | Complete Project | ||

|---|---|---|---|---|

| Physical | Mathematical | Physical | Mathematical | |

| 55.86 | Middle of 4th step | End of 4th step | Begin of 4th step | End of 4th step |

| 52.00 | End of 5th step | Begin of 6th step | Begin of 6th step | Middle of 6th step |

| l (m) | 1.4 | 2.8 | 3.6 |

| ΔE/E(%) | 17.36 | 17.55 | 16.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hien, L.T.T.; Duc, D.H. Numerical Simulation of Free Surface Flow on Spillways and Channel Chutes with Wall and Step Abutments by Coupling Turbulence and Air Entrainment Models. Water 2020, 12, 3036. https://doi.org/10.3390/w12113036

Hien LTT, Duc DH. Numerical Simulation of Free Surface Flow on Spillways and Channel Chutes with Wall and Step Abutments by Coupling Turbulence and Air Entrainment Models. Water. 2020; 12(11):3036. https://doi.org/10.3390/w12113036

Chicago/Turabian StyleHien, Le Thi Thu, and Duong Hoai Duc. 2020. "Numerical Simulation of Free Surface Flow on Spillways and Channel Chutes with Wall and Step Abutments by Coupling Turbulence and Air Entrainment Models" Water 12, no. 11: 3036. https://doi.org/10.3390/w12113036

APA StyleHien, L. T. T., & Duc, D. H. (2020). Numerical Simulation of Free Surface Flow on Spillways and Channel Chutes with Wall and Step Abutments by Coupling Turbulence and Air Entrainment Models. Water, 12(11), 3036. https://doi.org/10.3390/w12113036