Chivor’s Life Extension Project (CLEP): From Sediment Management to Development of a New Intake System

Abstract

1. Introduction

2. Materials and Methods

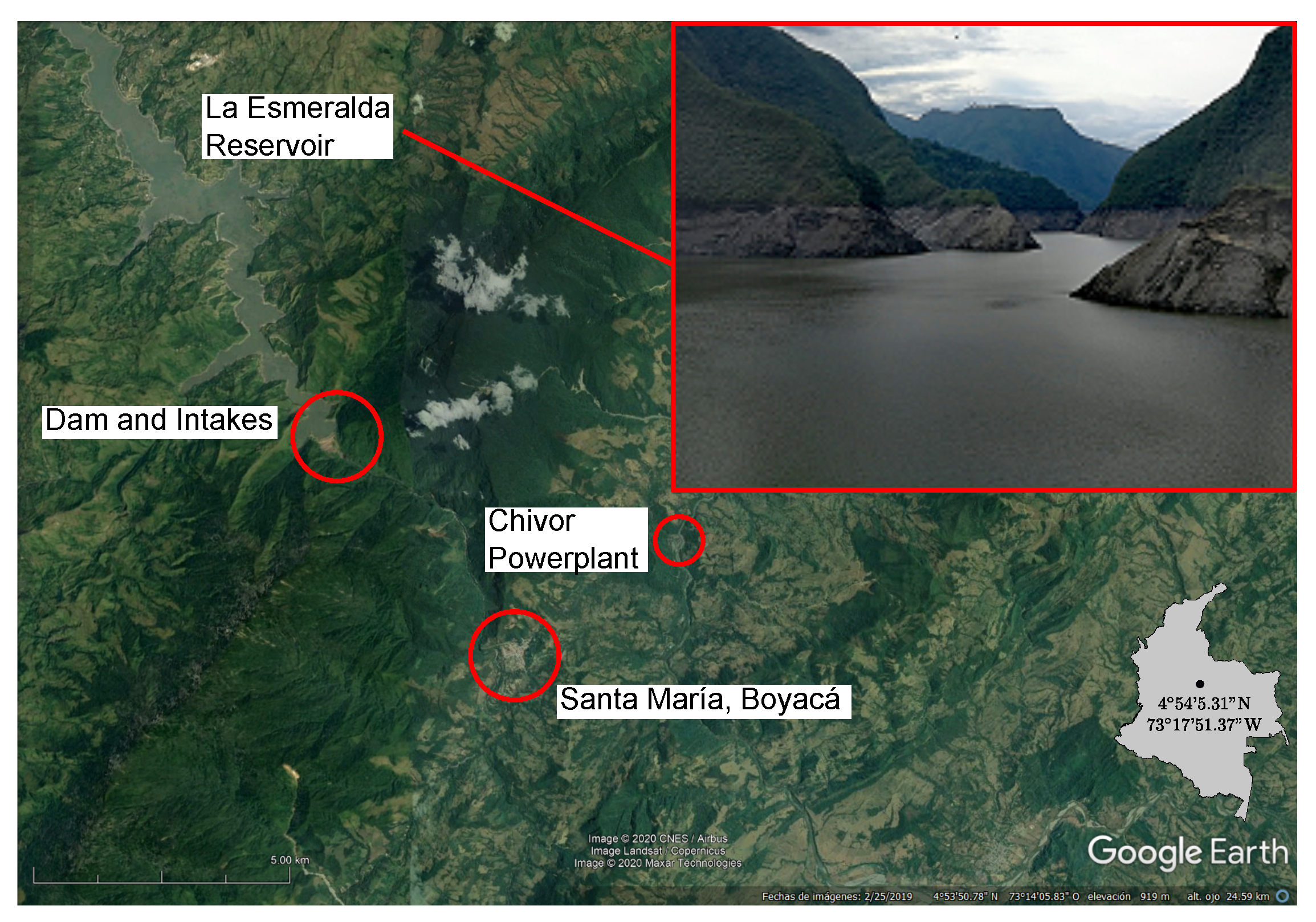

2.1. Chivor Hydropower Project

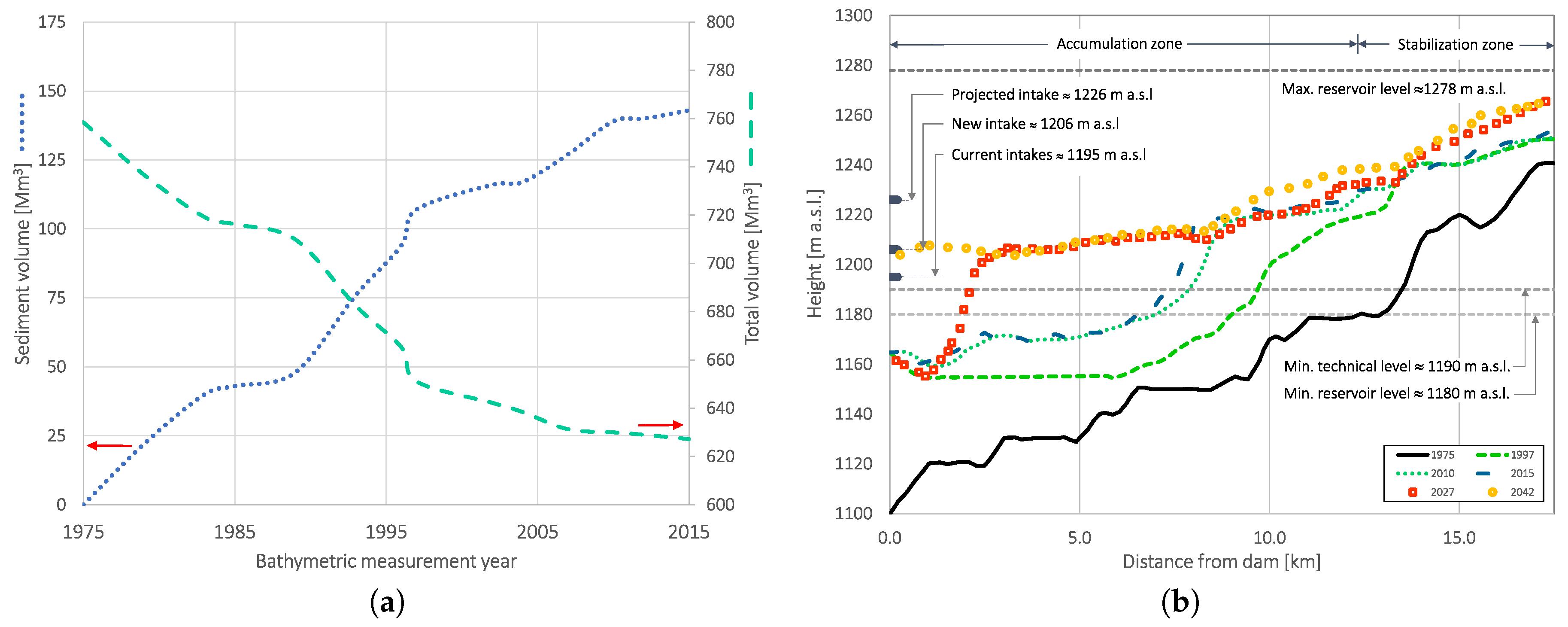

2.2. Sediment Dynamics of La Esmeralda Reservoir

2.3. Chivor’s Life Extension Project

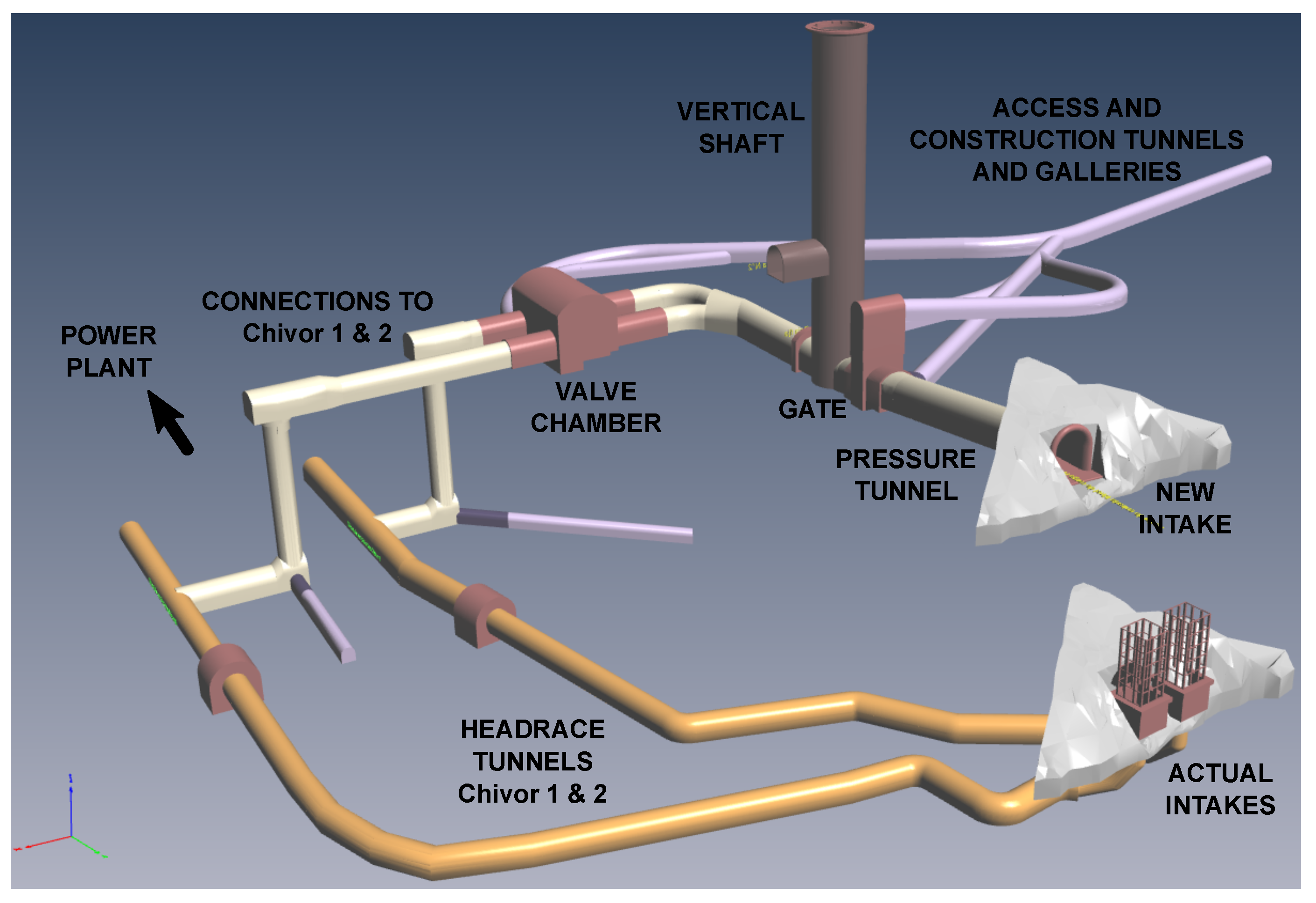

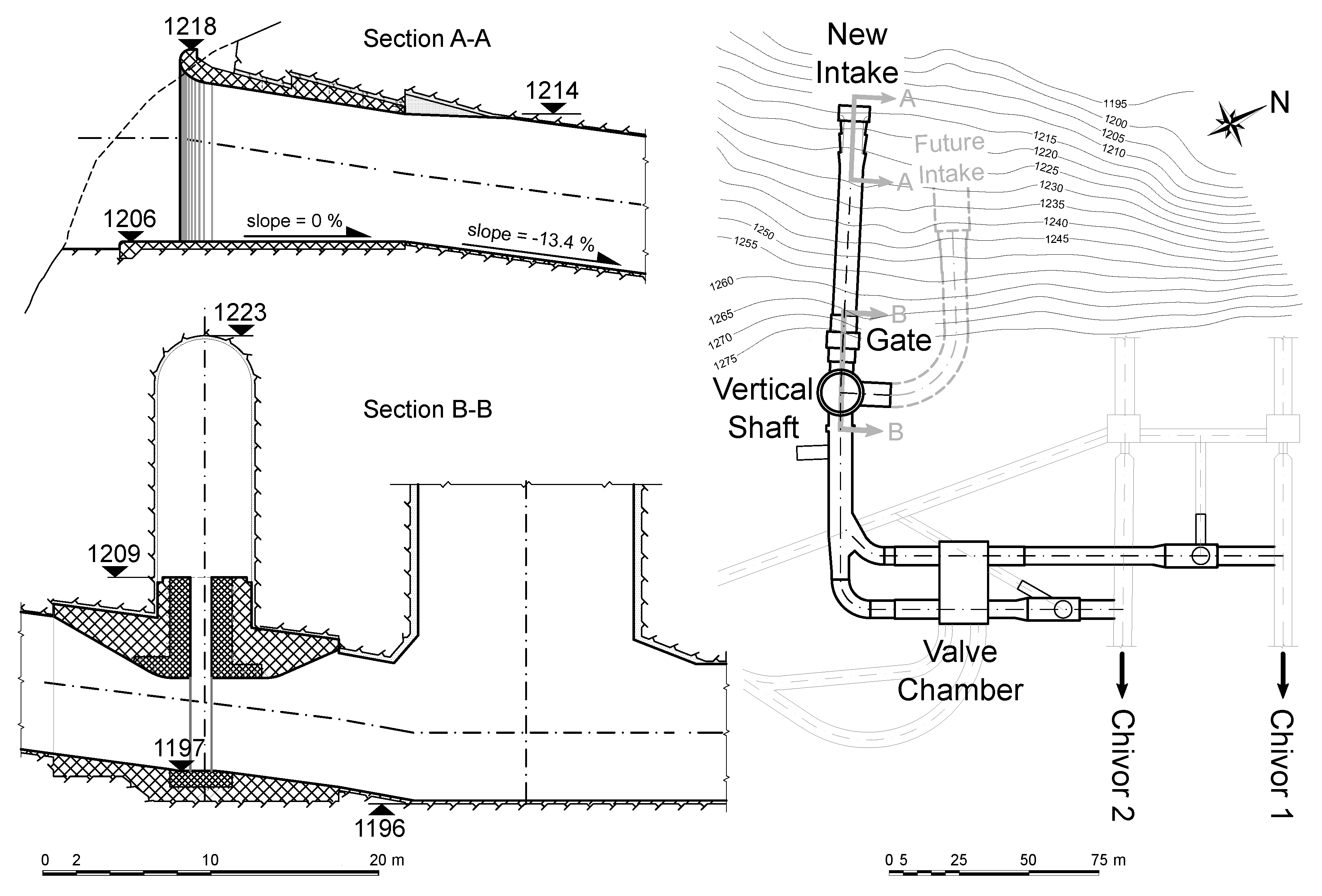

2.3.1. Chivor’s New Intake System

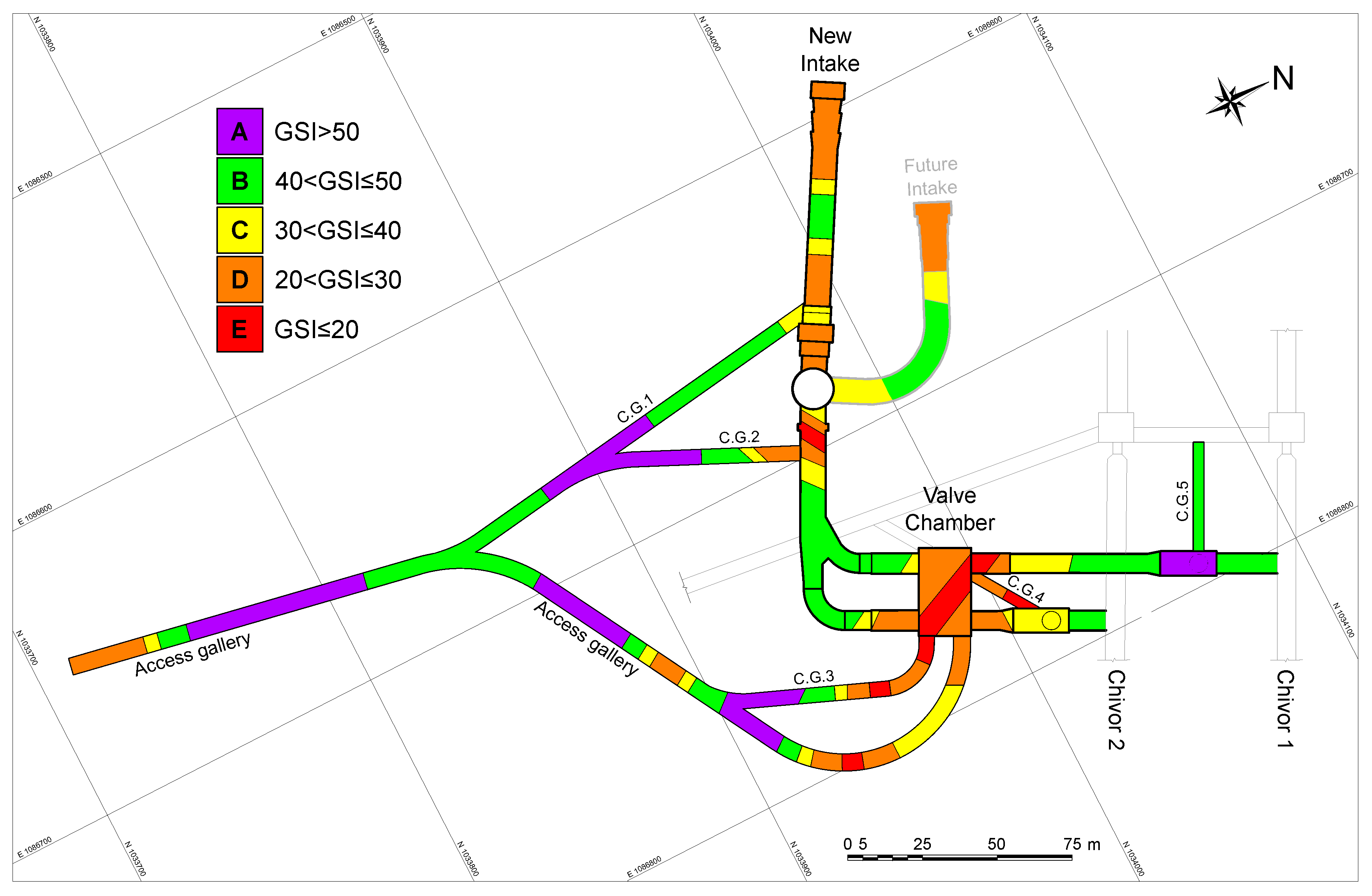

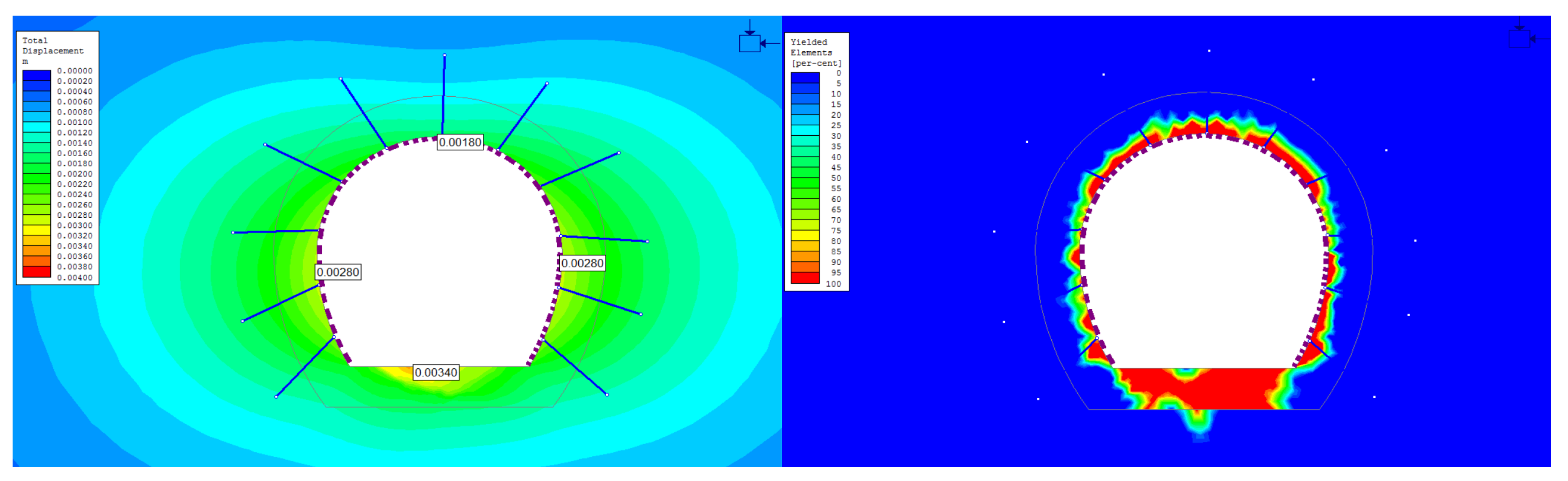

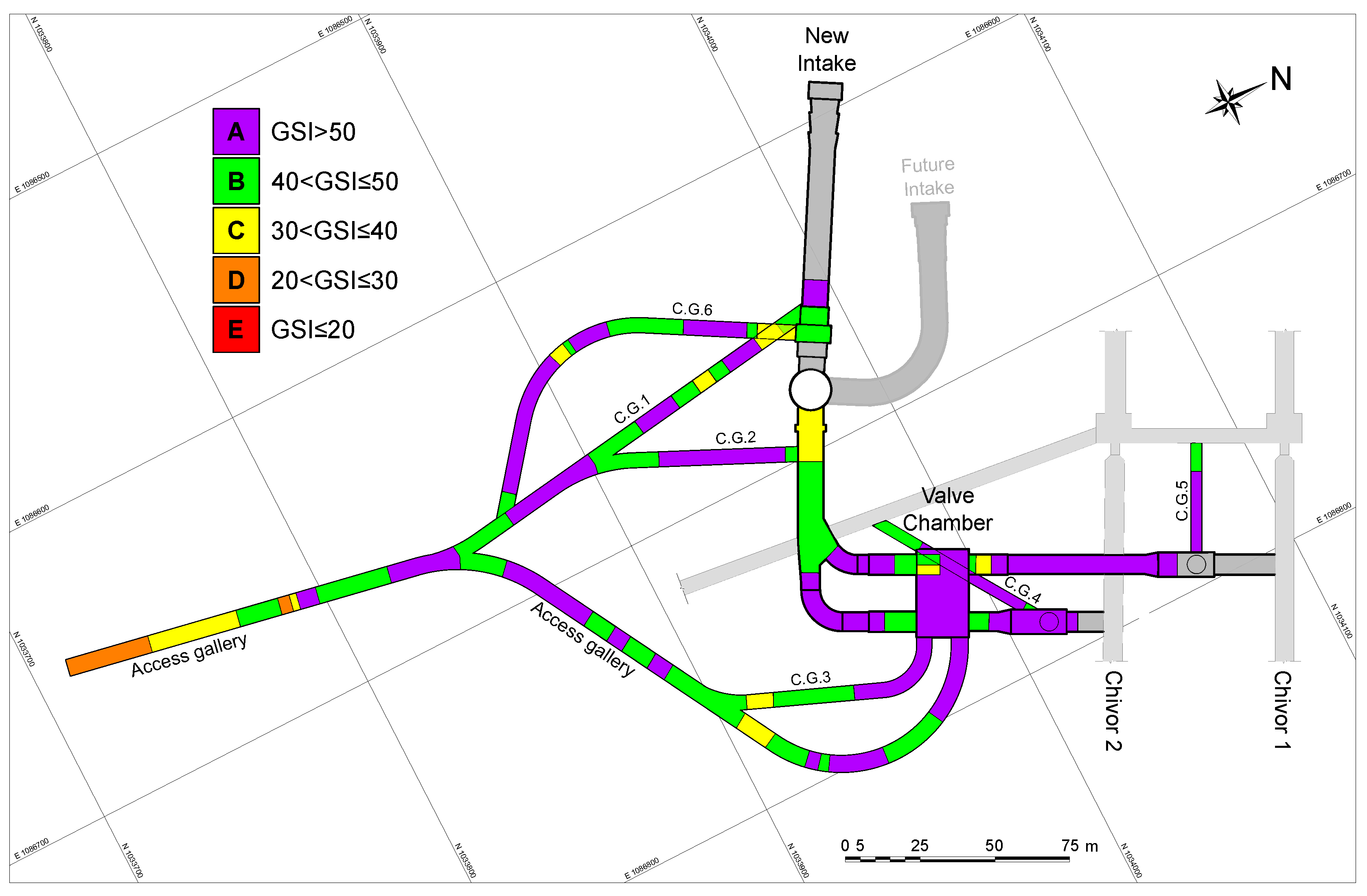

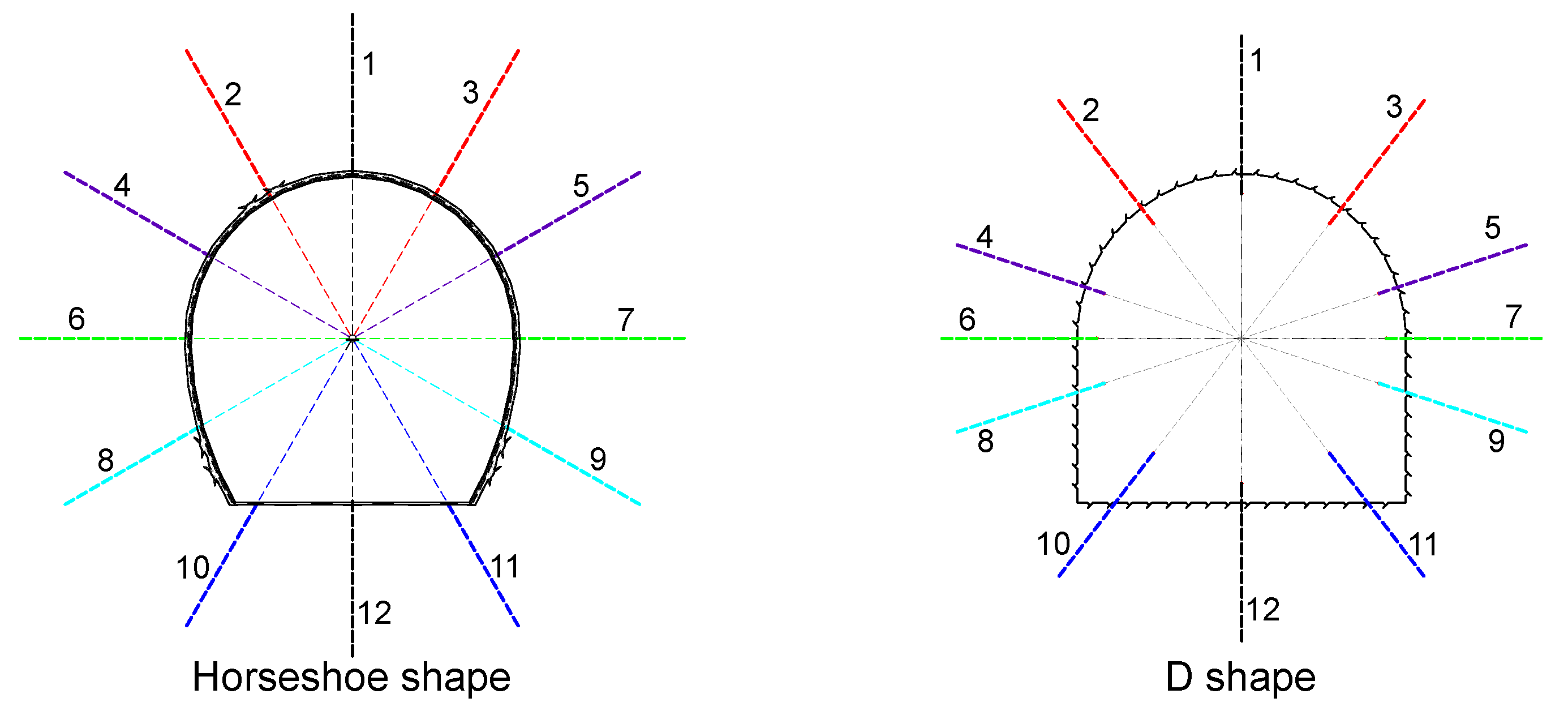

2.3.2. Geo-Technical Design

- A: GSI > 50. Healthy, massive, hard rock;

- B: 40 < GSI ≤ 50. Moderately fractured, partially deformed;

- C: 30 < GSI ≤ 40. Moderately fractured, deformed, and/or affected by localized shear zones;

- D: 20 < GSI ≤ 30. Strongly fractured, deformed, and/or affected by localized shear zones;

- E: GSI ≤ 20. Very fractured, deformed, and/or affected by fault zones.

2.3.3. Tunnel Linings

- No lining;

- Reinforced shotcrete lining;

- Cast concrete lining;

- Reinforced concrete lining, and

- Steel lining.

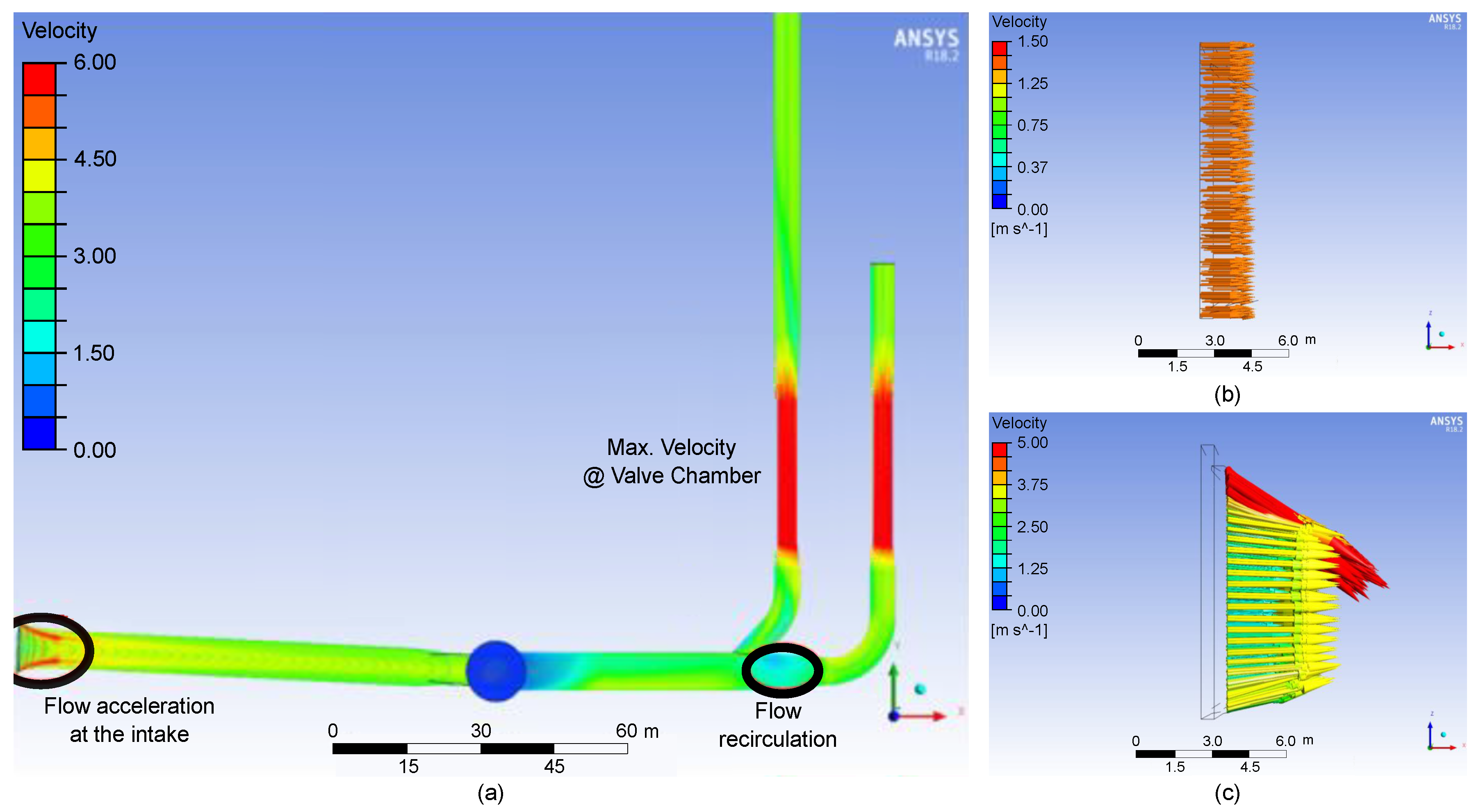

2.3.4. Hydraulic Design

- Operation conditions. Simulations only considered steady-state behavior, and internal single-phase constant flow equal to the design flow m/s; water density was assumed as 1000 kg/m and viscosity 1 × 10 Pas; and the hydrostatic input pressure was set corresponding to the minimal operation level of the reservoir at 1223.6 m.a.s.l.

- Geometry. Figure 7 shows that the simulation geometry included the intake, pressure tunnel, bifurcation, valve chamber, and connections outlets to Chivor 1 and 2.

- Discretization. The sizing method was used to generate the mesh, which is appropriated for complex geometries. In such a complex geometry, tetrahedral elements with low skewness are found; the maximum skewness was 0.88 in only 100 cells (less than 0.005% of the elements), and the average value was 0.18. The mesh comprised 1,711,774 elements and 490,139 nodes, with 0.5 m as the maximum size of the cell.

- Numerical parameters. Convergence residuals were set to 1 × 10 and a minimum 2000 iterations was chosen; the simulation was set up for turbulent flow and the RANS (Reynolds Average Navier-Stokes equations) method was used with k-epsilon-RNG for turbulence estimation. RANS models are used extensively for the study of various components in hydroelectric plants [37]. Among that, the model is robust, requires less computational resources, and has reasonable precision for a wide range of turbulent flows [38].

- Boundary conditions. The input boundary condition to the pressure tunnel was selected as “mass flow inlet” with a mass flow of 160,000 kg/s. Hydraulic losses were calibrated in order to determine the output energy and equally distribute the flow through the two branches of the valve chamber that are connected to Chivor 1 and 2. The output boundary condition (at the connection to Chivor 1 and 2) was set as “pressure outlet”. In this case the hydro-static pressure was specified, equivalent to the difference between the inlet and outlet levels, the dynamic pressure, and the hydraulic losses in the system. Frictions and geometry hydraulic energy losses were calculated between the new intake and the junction site with the existing pipelines. Minimal, maximum, and nominal values of the Manning’s roughness coefficients used to evaluate pressure losses were, respectively 0.012, 0.016, and 0.014 for the concrete lining. For the steel-lined sections, the Manning’s roughness coefficients used were 0.010, 0.014, and 0.012, respectively. Other boundaries were considered as no-slip walls.

3. Results

- Rock mass resistance: Sound rock was detected in the area of the underground works. An evidence of this favorable condition is that more than 85% of the excavation was classified as type A or B, which represents the better rock quality on a scale from A to E. No rock class D or E was encountered along the hydraulic tunnel and shaft, as it can be seen in Figure 8;

- Water table and rock mass permeability: The rock mass permeability is low in the area of the underground works and the water table is equal or slightly higher than the internal water pressure. Therefore, uncontrolled leakages can be excluded;

- Rock stability: The rock mass present in the area is not susceptible to dissolution, swelling, or karst phenomena.

4. Discussion

4.1. Design Process

4.2. Construction Process

4.3. Impact of CLEP on Colombia’s Energy Market

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- United Nations. World Population Prospects 2019: Highlights; Technical Report ST/ESA/SER.A/423; United Nations, Department of Economic and Social Affairs, Population Division: New York, NY, USA, 2019. [Google Scholar]

- IEA. World Energy Outlook 2019; Technical Report WEO-2019; International Energy Agency: Paris, France, 2019. [Google Scholar]

- United Nations. The Sustainable Development Goals Report 2020; Technical Report; United Nations Publications: New York, NY, USA, 2020. [Google Scholar]

- International Energy Agency (IEA); The World Bank. Sustainable Energy for All 2017—Progress Toward Sustainable Energy (Summary); Technical Report; License: Creative Commons Attribution CC BY 3.0 IGO; World Bank: Washington, DC, USA, 2017. [Google Scholar]

- Su, H.; Hu, J.; Yang, M.; Wen, Z. Assessment and prediction for service life of water resources and hydropower engineering. Nat. Hazards 2015, 75, 3005–3019. [Google Scholar] [CrossRef]

- Stoll, B.; Andrade, J.; Cohen, S.; Brinkman, G.; Martinez-Anido, C.B. Hydropower Modeling Challenges; Technical Report NREL/TP-5D00-68231; Prepared under Task No. WFGX.1040; National Renewable Energy Laboratory: Denver, CO, USA, 2017. [Google Scholar]

- Malovic, D.; Engelmann-Pilger, H.; Arsenijevic, N.; Gassner, K.B.; Merle-Beral, E.; Monti, G.; Pooley, J.; Inouye, L.K.; Levin, J.; Kellenberg, J. Hydroelectric Power: A Guide for Developers and Investors; Technical Report 99392; World Bank Group: Washington, DC, USA, 2015. [Google Scholar]

- Kondolf, G.M.; Gao, Y.; Annandale, G.W.; Morris, G.L.; Jiang, E.; Zhang, J.; Cao, Y.; Carling, P.; Fu, K.; Guo, Q.; et al. Sustainable sediment management in reservoirs and regulated rivers: Experiences from five continents. Earth’s Future 2014, 2, 256–280. [Google Scholar] [CrossRef]

- World Water Council. Analysis of the 3rd World Water Forum; Technical Report; World Water Council: Marseille, France, 2003. [Google Scholar]

- Morris, G.L. Modern Water Resources Engineering. In Handbook of Environmental Engineering; Chapter Sediment Management and Sustainable Use of Reservoirs; Humana Press: Totowa, NJ, USA, 2014; Volume 15, pp. 279–337. [Google Scholar] [CrossRef]

- Annandale, G.W.; Morris, G.L.; Karki, P. Extending the Life of Reservoirs: Sustainable Sediment Management for Dams and Run-of-River Hydropower; Directions in Development; License: Creative Commons Attribution CC BY 3.0 IGO; World Bank: Washington, DC, USA, 2016. [Google Scholar] [CrossRef]

- Annandale, G.W.; Dinar, A.; Palmieri, A.; Shah, F. Reservoir Conservation: Economic and Engineering Evaluation of Alternative Strategies for Managing Sedimentation in Storage Reservoirs: RESCON Approach; Technical Report 34954; World Bank: Washington, DC, USA, 2003. [Google Scholar]

- Haun, S.; Kjærås, H.; Løvfall, S.; Olsen, N.R.B. Three-dimensional measurements and numerical modelling of suspended sediments in a hydropower reservoir. J. Hydrol. 2013, 479, 180–188. [Google Scholar] [CrossRef]

- Gabbud, C.; Lane, S.N. Ecosystem impacts of Alpine water intakes for hydropower: The challenge of sediment management. WIREs Water 2016, 3, 41–61. [Google Scholar] [CrossRef]

- Schleiss, A.J.; Franca, M.J.; Juez, C.; Cesare, G.D. Reservoir sedimentation. J. Hydraul. Res. 2016, 54, 595–614. [Google Scholar] [CrossRef]

- Alighalehbabakhani, F.; Miller, C.J.; Selegean, J.P.; Barkach, J.; Abkenar, S.M.S.; Dahl, T.; Baskaran, M. Estimates of sediment trapping rates for two reservoirs in the Lake Erie watershed: Past and present scenarios. J. Hydrol. 2017, 544, 147–155. [Google Scholar] [CrossRef]

- Adeogun, A.G.; Sule, B.F.; Salami, A.W. Cost effectiveness of sediment management strategies for mitigation of sedimentation at Jebba Hydropower reservoir, Nigeria. J. King Saud Univ. Eng. Sci. 2018, 30, 141–149. [Google Scholar] [CrossRef]

- Kim, H.Y.; Fontane, D.G.; Julien, P.Y.; Lee, J.H. Multiobjective Analysis of the Sedimentation behind Sangju Weir, South Korea. J. Water Resour. Plan. Manag. 2018, 144, 05017019. [Google Scholar] [CrossRef]

- Gabl, R.; Gems, B.; Birkner, F.; Hofer, B.; Aufleger, M. Adaptation of an Existing Intake Structure Caused by Increased Sediment Level. Water 2018, 10, 1066. [Google Scholar] [CrossRef]

- Razad, A.A.; Abbas, N.; Sidek, L.M.; Alexander, J.; Jung, K. Sediment Management Strategies for Hydropower Reservoirs in Active Agricultural Area. Int. J. Eng. Technol. 2018, 7, 228–233. [Google Scholar] [CrossRef]

- Jansen, L. Sediment Management Strategies-Case Study on Hydropower Reservoirs in Malaysia. In ICDSME 2019; Springer: Singapore, 2020; pp. 417–430. [Google Scholar] [CrossRef]

- Hauer, C.; Wagner, B.; Aigner, J.; Holzapfel, P.; Flödl, P.; Liedermann, M.; Tritthart, M.; Sindelar, C.; Pulg, U.; Klösch, M.; et al. State of the art, shortcomings and future challenges for a sustainable sediment management in hydropower: A review. Renew. Sustain. Energy Rev. 2018, 98, 40–55. [Google Scholar] [CrossRef]

- Morris, G. Classification of Management Alternatives to Combat Reservoir Sedimentation. Water 2020, 12, 861. [Google Scholar] [CrossRef]

- Bermúdez, M.; Cea, L.; Puertas, J.; Conde, A.; Martín, A.; Baztán, J. Hydraulic model study of the intake-outlet of a pumped-storage hydropower plant. Eng. Appl. Comput. Fluid Mech. 2017, 11, 483–495. [Google Scholar] [CrossRef]

- González-Zeas, D.; Rosero-López, D.; Walter, T.; Flecker, A.; Lloret, P.; De Bièvre, B.; Condom, T.; Osorio, R.; Dangles, O. Designing Eco-Friendly Water Intake Portfolios in a Tropical Andean Stream Network. Water Resour. Res. 2019, 55, 6946–6967. [Google Scholar] [CrossRef]

- DNP. Energy Demand Situation in Colombia; Technical Report; Departamento Nacional de Planeación: Bogotá, Colombia, 2017. [Google Scholar]

- DNP. Energy Supply Situation in Colombia; Technical Report; Departamento Nacional de Planeación: Bogotá, Colombia, 2017. [Google Scholar]

- REN21. Renewables 2018 Global Status Report. In A Comprehensive Annual Overview of the State of Renewable Energy; Technical Report GSR2018; REN21 Secretariat: Paris, France, 2018. [Google Scholar]

- Paredes, J.R.; Ramírez, J.J. Variable Renewable Energies and Their Contribution to Energy Security: Complementarity in Colombia; Technical Report IDB-MG-497; Iteramerican Development Bank, Energy Division: Washington, DC, USA, 2017. [Google Scholar]

- Montoya-Ramírez, R.D.; Cuervo, F.I.; Rico, C.A.M. Technical and financial valuation of hydrokinetic power in the discharge channels of large hydropower plants in Colombia: A case study. Renew. Energy 2016, 99, 136–147. [Google Scholar] [CrossRef]

- Arango-Aramburo, S.; Turner, S.W.; Daenzer, K.; Ríos-Ocampo, J.P.; Hejazi, M.I.; Kober, T.; Álvarez-Espinosa, A.C.; Romero-Otalora, G.D.; van der Zwaan, B. Climate impacts on hydropower in Colombia: A multi-model assessment of power sector adaptation pathways. Energy Policy 2019, 128, 179–188. [Google Scholar] [CrossRef]

- Del Río, D.; Moffett, H.; Nieto-Londoño, C.; Vásquez, R.E.; Escudero-Atehortua, A. Extending life expectancy of La Esmeralda reservoir: A bet to support Colombia’s future energy demand. In Proceedings of the ASME 2020 28th International Conference on Nuclear Engineering Joint with the ASME 2020 Power Conference ICONE28-POWER2020, Anaheim, CA, USA, 2–6 August 2020; American Society of Mechanical Engineers ASME: New York, NY, USA, 2020; p. 6, in press. [Google Scholar]

- Horton, B.K. Sedimentary record of Andean mountain building. Earth-Sci. Rev. 2018, 178, 279–309. [Google Scholar] [CrossRef]

- Horton, B.K.; Parra, M.; Mora, A. The Geology of Colombia; Servicio Geológico, Colombiano; Paleogene-Neogene, Chapter Construction of the Eastern Cordillera of Colombia: Insights from the Sedimentary Record; Publicaciones Geológicas Especiales: Bogota, Colombia, 2020; Volume 3, pp. 1–22. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E. The Hoek-Brown failure criterion and GSI—2018 edition. J. Rock Mech. Geotech. Eng. 2019, 11, 445–463. [Google Scholar] [CrossRef]

- U.S. Army Corps of Engineers. Engineering and Design of Tunnels and Shafts in Rock; Technical Report EM1110-2901; Department of the Army—U.S. Army Corps of Engineers: Washington, DC, USA, 1997.

- Yaseen, Z.M.; Ameen, A.M.S.; Aldlemy, M.S.; Ali, M.; Abdulmohsin Afan, H.; Zhu, S.; Sami Al-Janabi, A.M.; Al-Ansari, N.; Tiyasha, T.; Tao, H. State-of-the Art-Powerhouse, Dam Structure, and Turbine Operation and Vibrations. Sustainability 2020, 12, 1676. [Google Scholar] [CrossRef]

- Velísková, Y.; Chára, Z.; Schügerl, R.; Dulovičová, R. CFD simulation of flow behind overflooded obstacle. J. Hydrol. Hydromech. 2018, 66, 6. [Google Scholar] [CrossRef]

- Brown, G.O. The History of the Darcy-Weisbach Equation for Pipe Flow Resistance, In Environmental and Water Resources History; American Society of Civil Engineers ASCE: Washington, DC, USA, 2002; pp. 34–43. [Google Scholar] [CrossRef]

- Bishwakarma, M.B. Computation of Head Losses in Hydro Power Tunnels. Dam Eng. 2012, 23, 71. [Google Scholar]

- Nieves, M.T.; Hernández, A. Colombia Energy Investment Report; Technical Report; Energy Charter Secretariat: Brussels, Belgium, 2016. [Google Scholar]

- UPME. Plan Energético Nacional 2020–2050; Technical Report PEN50; Unidad de Planeación Minero Energética, Ministerio de Minas y Energía: Bogotá, DC, USA, 2019. [Google Scholar]

| Part of the Intake System | Hydraulic Section [m] | Speed [m/s] | Lining Type | Max. Speed [m/s] |

|---|---|---|---|---|

| Intake | 48.6 | 3.29 | Casted concrete | 6.0 |

| Pressure tunnel | 57.5 | 2.78 | Shotcrete | 3.0 |

| Gate | 41.2 | 3.88 | Casted concrete | 6.0 |

| Vertical shaft | 120 | 1.32 | Shotcrete | 3.0 |

| Main tunnel | 57.5 | 2.78 | Shotcrete | 3.0 |

| Connection branches | 30.3 | 2.64 | Shotcrete | 3.0 |

| Shielded branches (valve chamber) | 12.6 | 6.37 | Steel | ≥6 |

| Connection tunnels | 26.4 | 3.00 | Shotcrete | 3.0 |

| Part of the System | Loss [m] | % |

|---|---|---|

| Losses due to components (local) | 3.34 | 81% |

| Losses due to friction in tunnels | 0.76 | 19% |

| Total | 4.11 | 100% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

del Río, D.A.; Moffett, H.; Nieto-Londoño, C.; Vásquez, R.E.; Escudero-Atehortúa, A. Chivor’s Life Extension Project (CLEP): From Sediment Management to Development of a New Intake System. Water 2020, 12, 2743. https://doi.org/10.3390/w12102743

del Río DA, Moffett H, Nieto-Londoño C, Vásquez RE, Escudero-Atehortúa A. Chivor’s Life Extension Project (CLEP): From Sediment Management to Development of a New Intake System. Water. 2020; 12(10):2743. https://doi.org/10.3390/w12102743

Chicago/Turabian Styledel Río, David A., Hugo Moffett, César Nieto-Londoño, Rafael E. Vásquez, and Ana Escudero-Atehortúa. 2020. "Chivor’s Life Extension Project (CLEP): From Sediment Management to Development of a New Intake System" Water 12, no. 10: 2743. https://doi.org/10.3390/w12102743

APA Styledel Río, D. A., Moffett, H., Nieto-Londoño, C., Vásquez, R. E., & Escudero-Atehortúa, A. (2020). Chivor’s Life Extension Project (CLEP): From Sediment Management to Development of a New Intake System. Water, 12(10), 2743. https://doi.org/10.3390/w12102743