Impact Analysis of Slope on the Head Loss of Gas-Liquid Two-Phase Flow in Siphon Pipe

Abstract

:1. Introduction

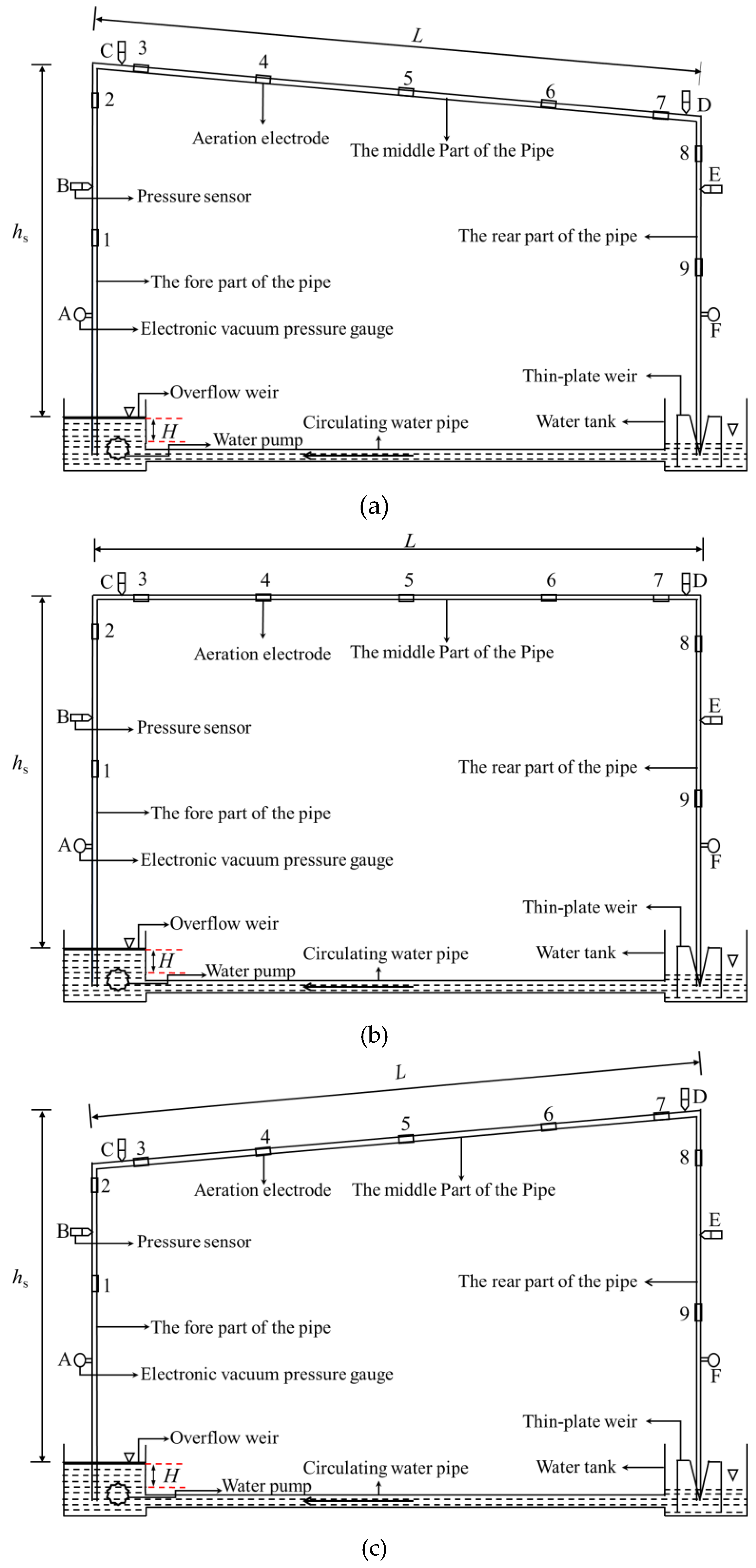

2. Materials and Methods

3. Results and Discussion

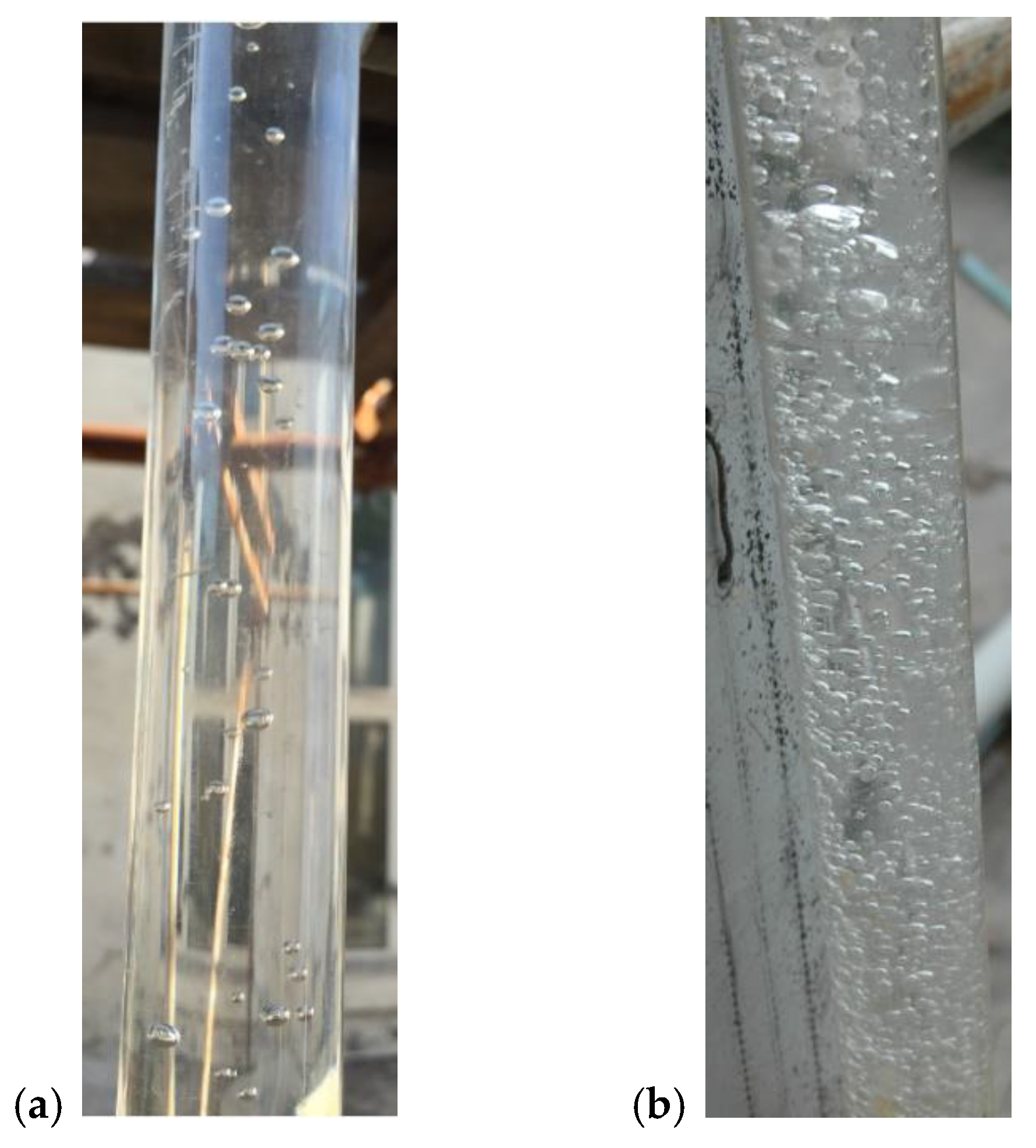

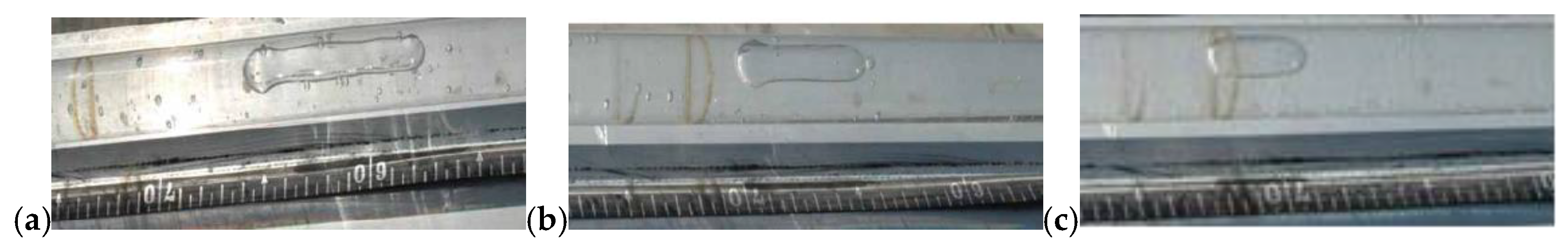

3.1. Influence of Slope on Air Mass Movement

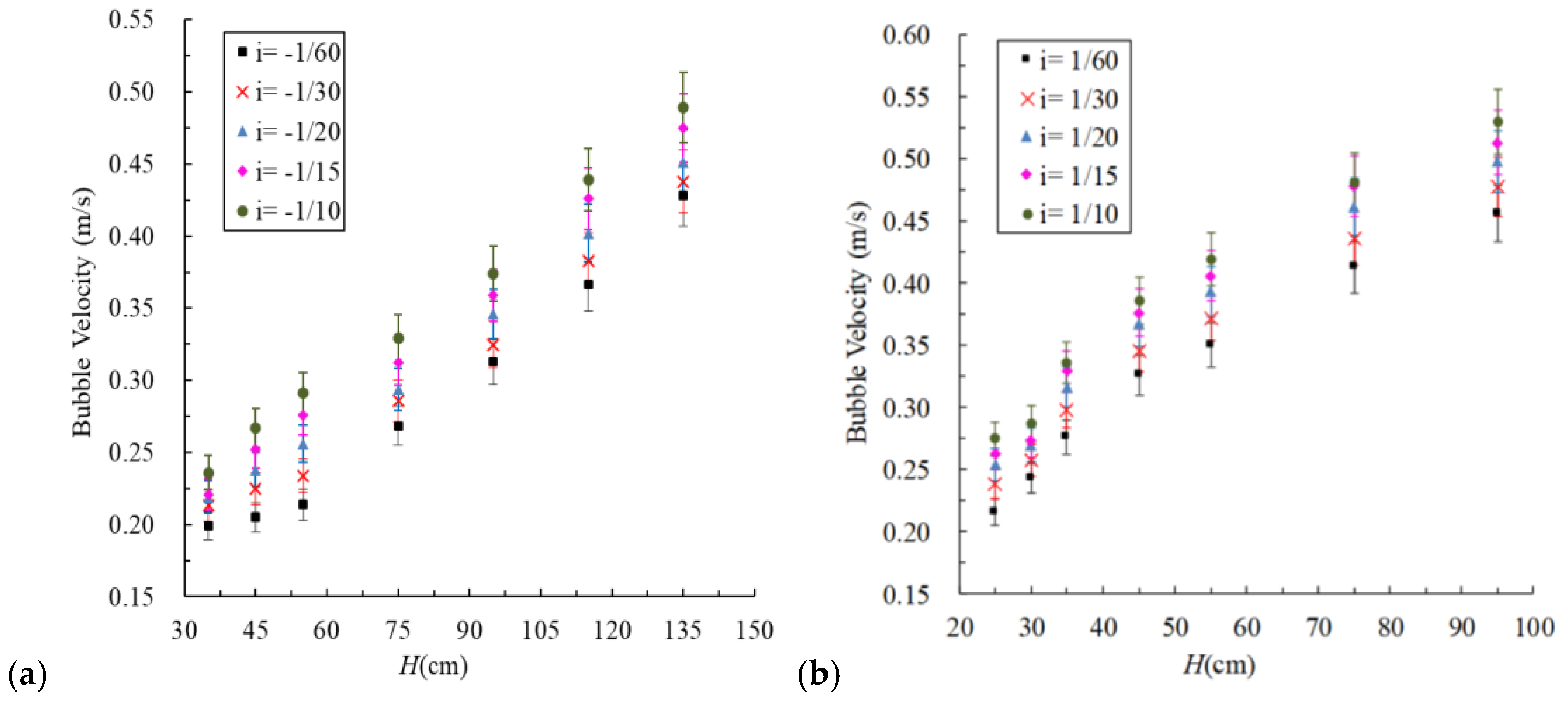

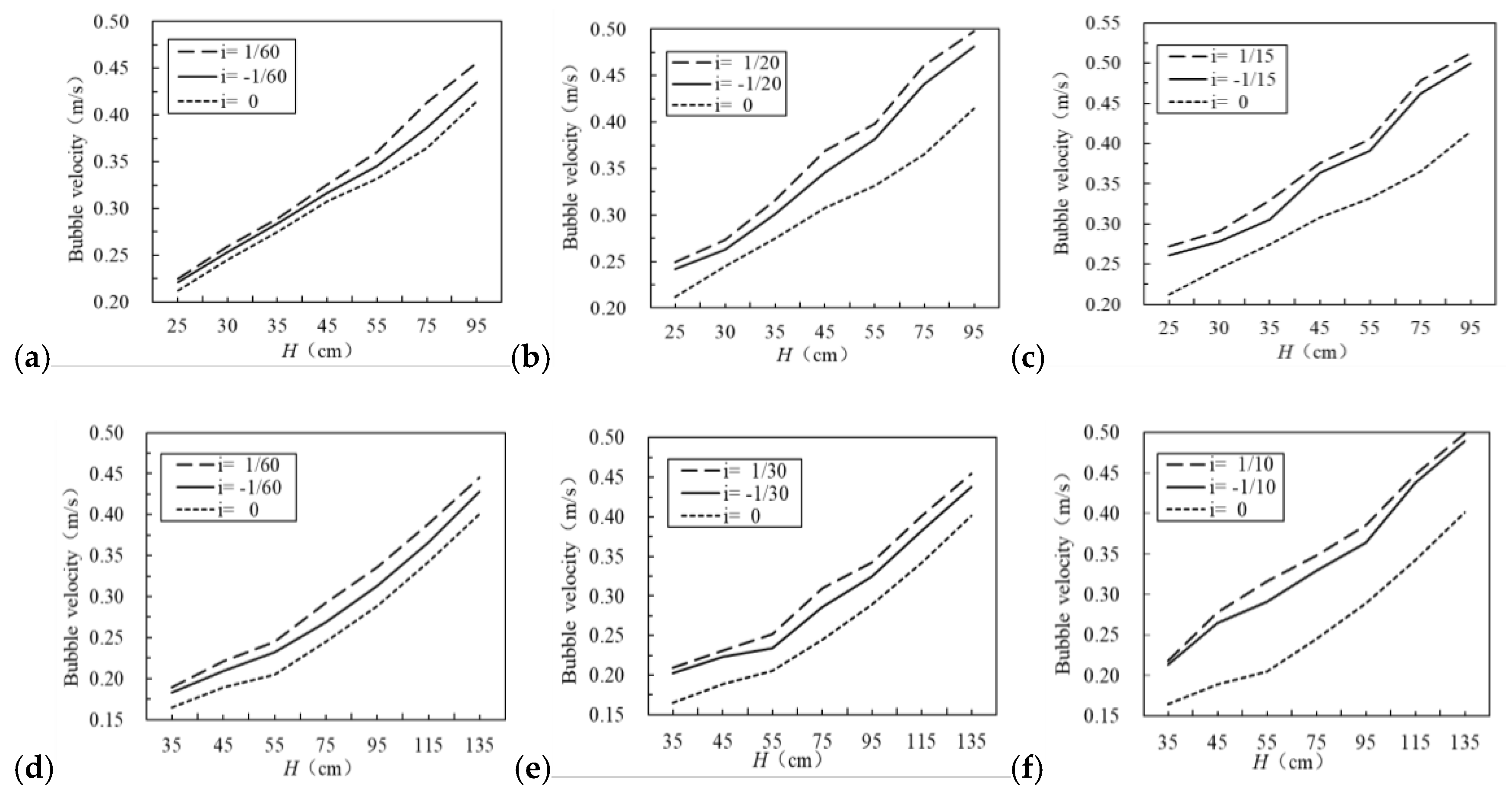

3.2. Influence of Slope on Bubble Velocity in the Pipe

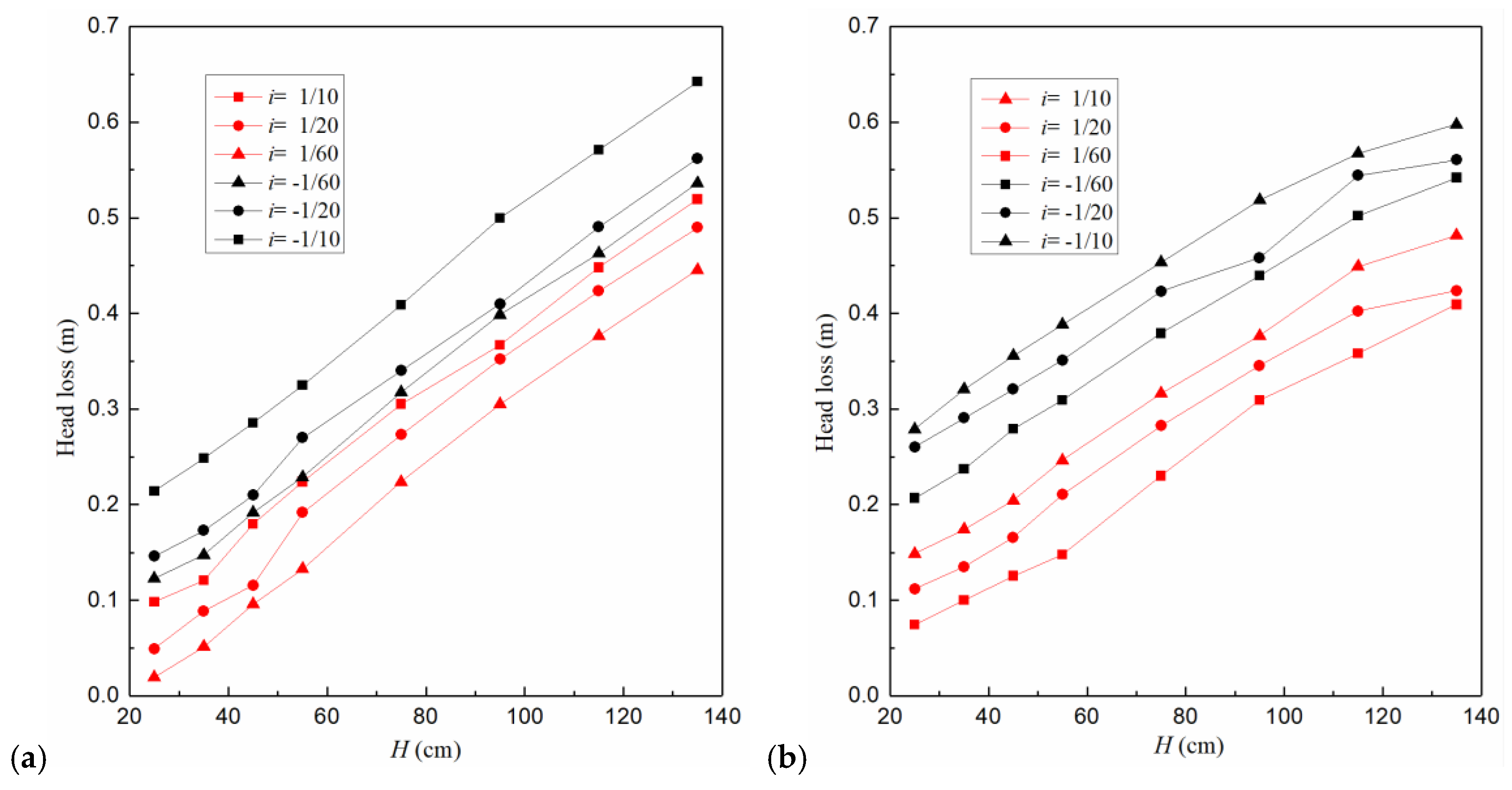

3.3. Influence of Slope on Head Loss in the Middle Part of the Pipe

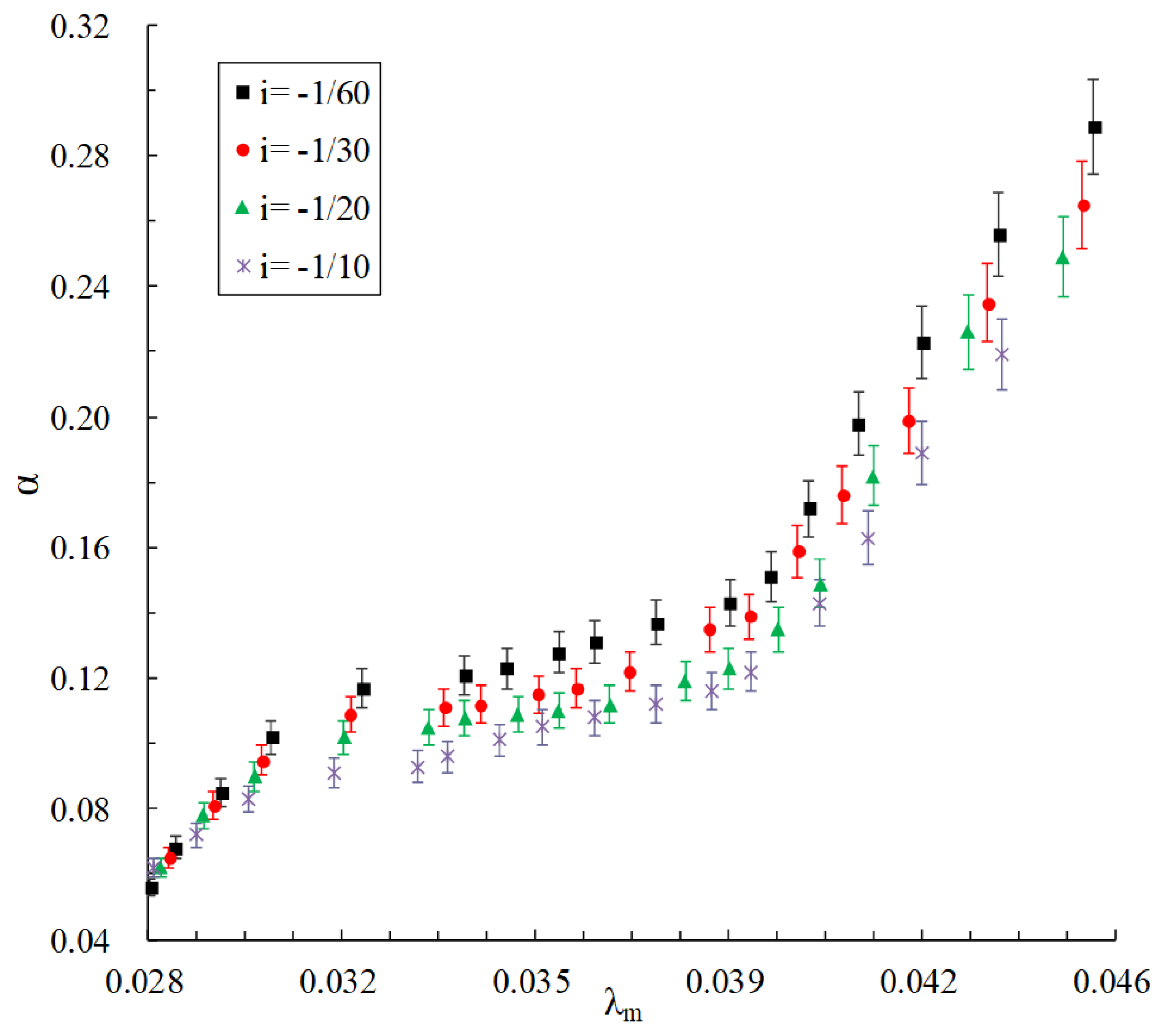

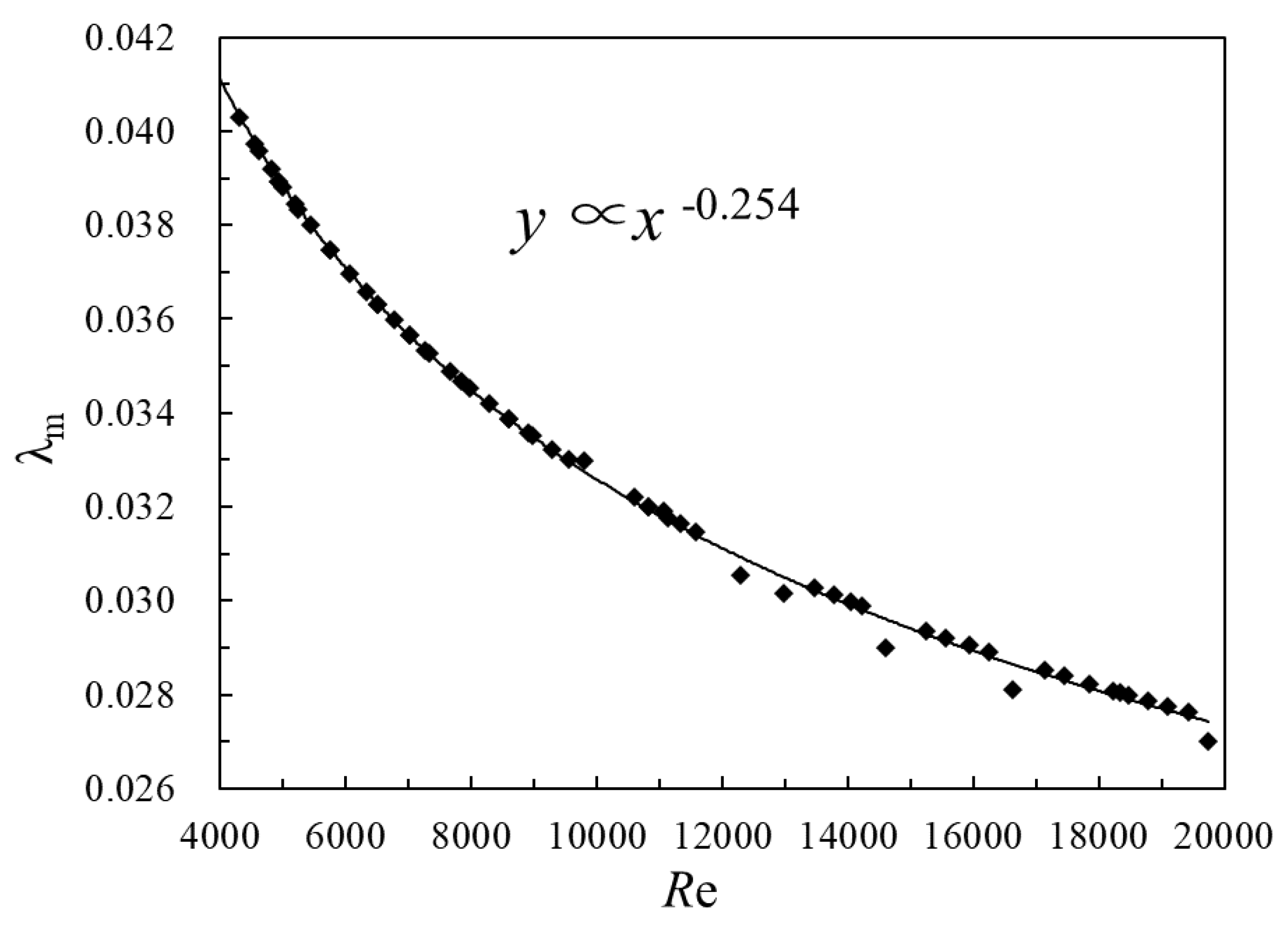

3.4. Formula Derivation and Verification of Resistance Coefficient

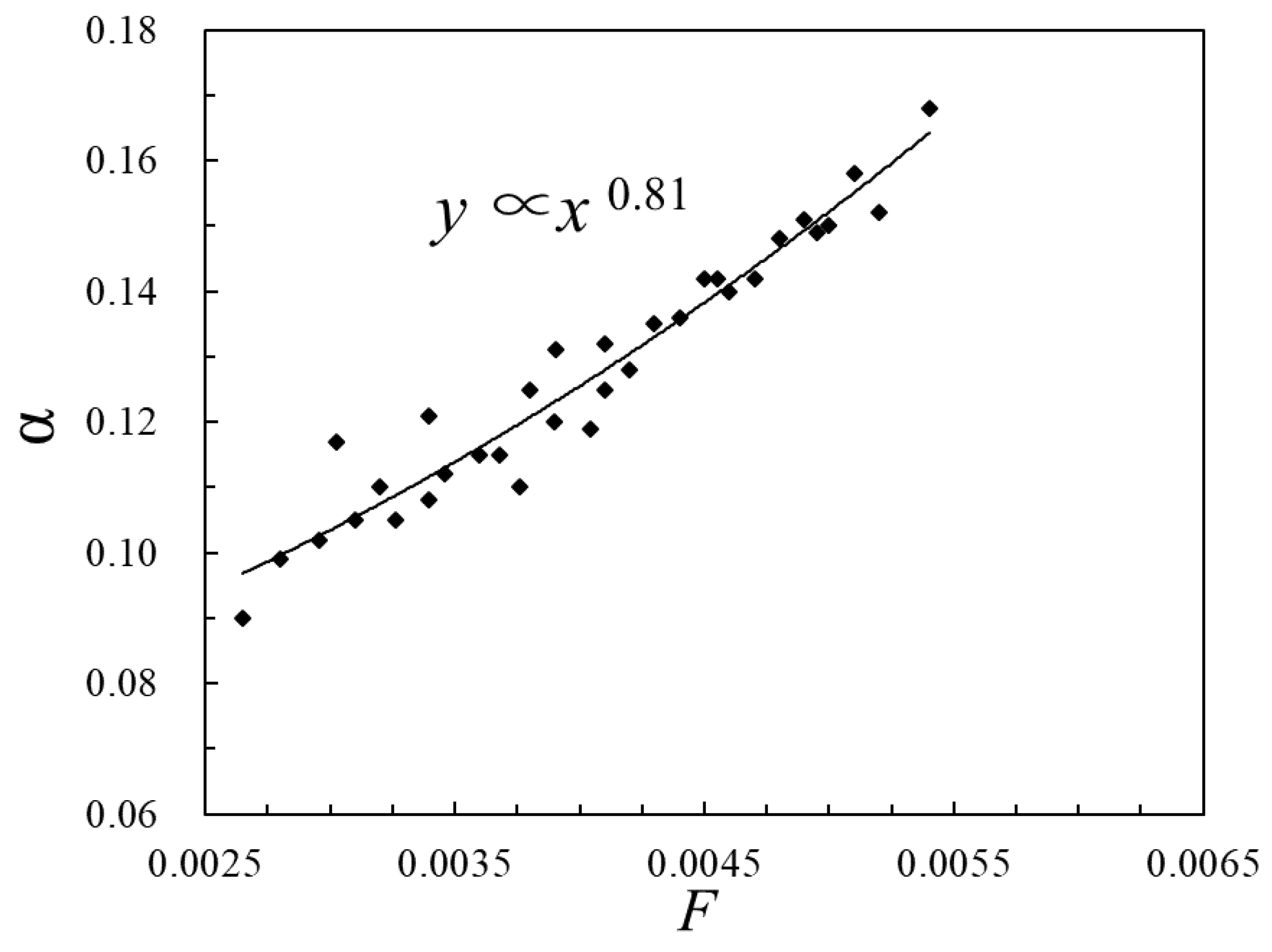

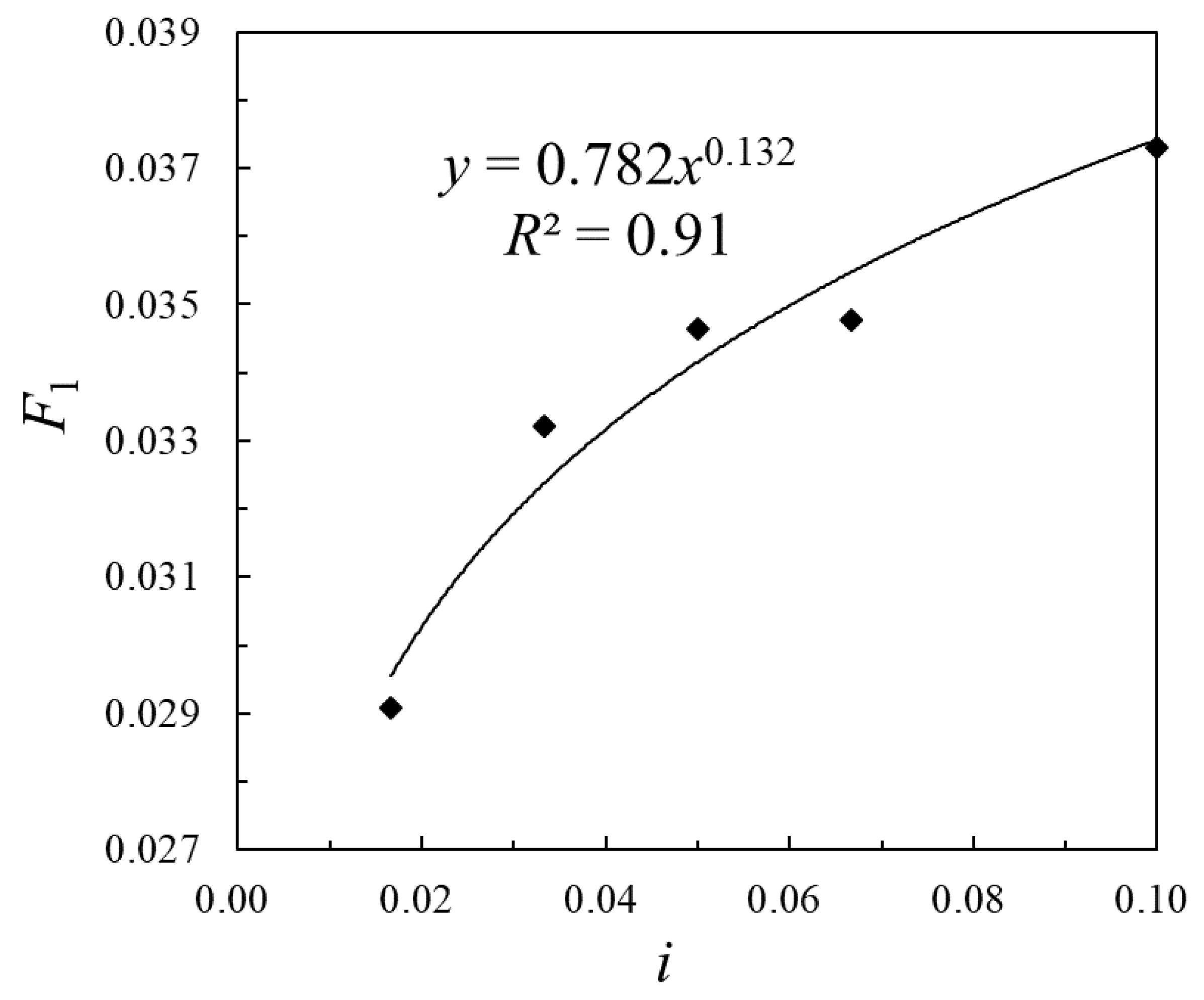

3.4.1. Formula Derivation of Resistance Coefficient

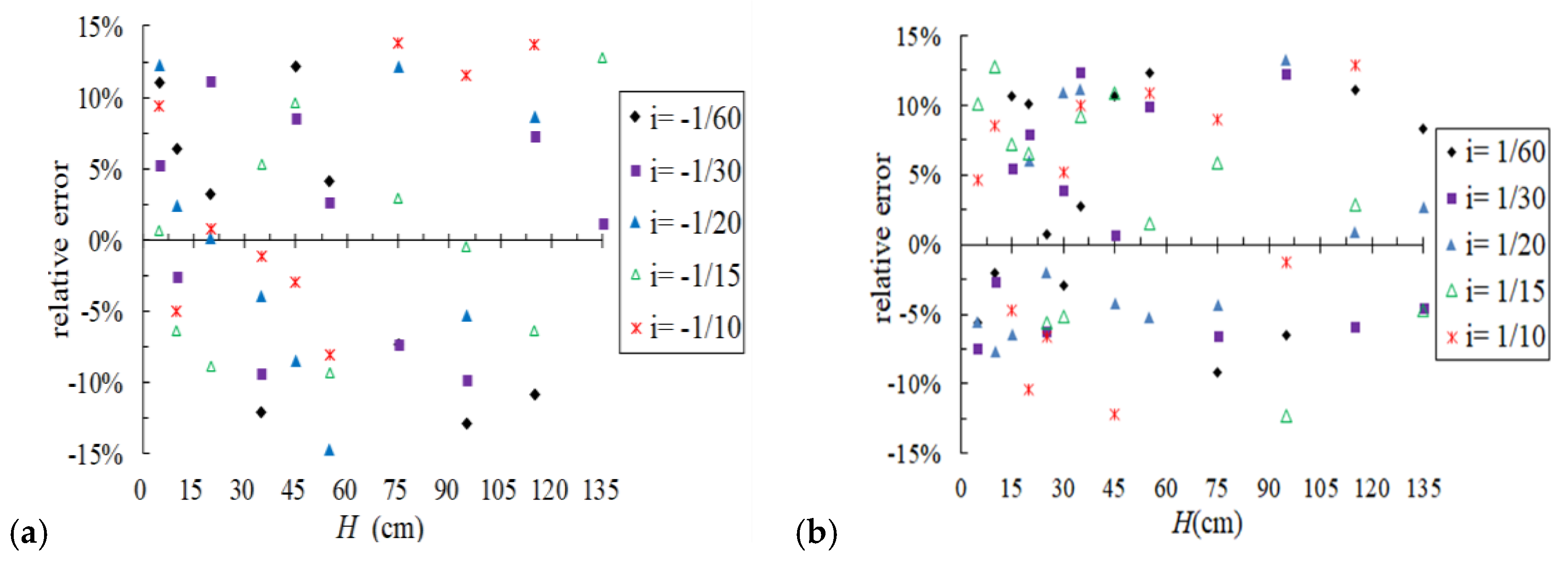

3.4.2. Verification and Error Analysis of Resistance Coefficient Formula

4. Practical Implications of this Study

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liu, C.M.; Zheng, H.X. South-to-north Water Transfer Schemes for China. Int. J. Water Resour. Dev. 2002, 18, 453–471. [Google Scholar] [CrossRef]

- Koutsoyiannis, D. Scale of water resources development and sustainability: Small is beautiful, large is great. Hydrol. Sci. J. 2011, 56, 553–575. [Google Scholar] [CrossRef]

- Tyralis, H.; Aristoteles, T.; Delichatsiou, A.; Mamassis, N.; Koutsoyiannis, D. A perpetually interrupted interbasin water transfer as a modern Greek drama: Assessing the Acheloos to Pinios interbasin water transfer in the context of integrated water resources management. Open Water J. 2017, 4, 11. [Google Scholar]

- Petaccia, G.; Fenocchi, A. Experimental assessment of the stage-discharge relationship of the Heyn siphons of Bric Zerbino dam. Flow Meas. Instrum. 2015, 41, 36–40. [Google Scholar] [CrossRef]

- Tajima, N.; Sadatom, M.; Kawahara, A. Dredging of sediment in dam utilizing siphon age with sliding outer tube. Jpn. J. Multiph. Flow 2010, 241, 145–148. [Google Scholar]

- Yan, T.; Chen, L.; Xu, M.; Zhou, M. Siphon pipeline resistance characteristic research. Procedia Eng. 2012, 28, 99–104. [Google Scholar]

- Seo, K.; Kang, S.H.; Kim, J.M.; Lee, K.Y.; Jeong, N.; Chi, D.Y.; Yoon, J.; Kim, M.H. Experimental and numerical study for a siphon breaker design of a research reactor. Ann. Nucl. Energy 2012, 50, 94–102. [Google Scholar] [CrossRef]

- Kang, S.H.; Ahn, H.S.; Kim, J.M.; Joo, H.M.; Lee, K.Y.; Seo, K.; Chi, D.Y.; Yoon, J.; Jeun, G.D.; Kim, M.H. Experimental study of siphon breaking phenomenon in the real-scaled research reactor pool. Nucl. Eng. Des. 2013, 255, 28–37. [Google Scholar] [CrossRef]

- Kang, S.H.; Lee, K.; Lee, G.C. Investigation on effects of enlarged pipe rupture size and air penetration timing in real-scale experiment of siphon breaker. Nucl. Eng. Technol. 2014, 46, 817–824. [Google Scholar] [CrossRef]

- Matozinhos, C.F.; Santos, A.A.C. Two-phase CFD simulation of research reactor siphon breakers: A verification, validation and applicability study. Nucl. Eng. Des. 2018, 326, 7–16. [Google Scholar] [CrossRef]

- Jin, S.F.; Liu, H.X.; Ding, W.; Shang, H.; Wang, G.L. Sensitivity Analysis for the Inverted Siphon in a Long-Distance Water Transfer Project: An Integrated System Modeling Perspective. Water 2018, 10, 292. [Google Scholar] [CrossRef]

- Diogo, A.F.; Oliveira, M.C. A simplified approach for the computation of steady two-phase flow in inverted siphons. J. Environ. Manag. 2016, 166, 294–308. [Google Scholar] [CrossRef] [PubMed]

- Revellin, R.; Thome, J.R. A theoretical motel for the prediction of the critical heat flux in heated micro channels. Int. J. Heat Mass Trans. 2008, 51, 1216–1225. [Google Scholar] [CrossRef]

- Chorai, S.; Nigam, K.D.P. CFD modeling of flow profiles and interfacial phenomena in two-phase flow in pipes. Chem. Eng. Process. 2006, 45, 55–65. [Google Scholar]

- Musa, A.; Danjuma, Y.; Lao, L.Y. Interfacial friction in upward annular gas-liquid two-phase flow in pipes. Exp. Therm. Fluid Sci. 2017, 84, 90–109. [Google Scholar]

- Shams, R.; Tavakoli, A. Experimental investigation of two-phase flow in horizontal wells: Flow regime assessment and pressure drop analysis. Exp. Therm. Fluid Sci. 2017, 88, 55–64. [Google Scholar] [CrossRef]

- Schmidt, J.; Claramunt, S. Sizing of rupture disks for two-phase gas/liquid flow according to HNE-CSE-model. J. Loss Prev. Process Ind. 2016, 41, 419–432. [Google Scholar] [CrossRef]

- Chen, F.; Sun, B.; Wang, E.P. Research on the dynamic characteristics of gas-liquid two phase flow measurement with different throttle devices. J. Exp. Fluid Mech. 2012, 26, 55–60. [Google Scholar]

- Pietrzak, M.; Placzek, M.; Witczak, S. Upward flow of air-oil-water mixture in vertical pipe. Exp. Thermal Fluid Sci. 2017, 81, 175–186. [Google Scholar] [CrossRef]

- Kjeldby, T.K.; Nydal, O.J. A Lagrangian three-phase slug tracking framework. Int. J. Multiph. Flow 2013, 56, 184–194. [Google Scholar] [CrossRef]

- Wang, Q.; Polansky, J.; Karki, B.; Wang, M.; Wei, K.; Qiu, C.; Kenbar, A.; Millington, D. Experimental tomographic methods for analyzing flow dynamics of gas-oil-water flows in horizontal pipeline. J. Hydrodyn. 2016, 28, 1018–1021. [Google Scholar] [CrossRef]

- Barnea, D.; Shoham, D. Flow pattern transitions for gas-liquid flow in horizontal and inclined pipes: Comparison of experimental data with theory. Int. J. Multiph. Flow 1980, 6, 217–225. [Google Scholar] [CrossRef]

- Wiesman, J.; Kang, S.Y. Flow pattern transition in vertical and upwardly inclined lines. Int. J. Multiph. Flow 1981, 7, 271–291. [Google Scholar] [CrossRef]

- Barnea, D.A.; Shohamo, O.; Tatel, Y. Gas-liquid flow in inclined tubes: Flow pattern transitions for upward flow. Chem. Eng. Sci. 1985, 40, 131–136. [Google Scholar] [CrossRef]

- Barnea, D. A unified model for predicting flow-pattern transition for whole ranges of pipe inclinations. Int. J. Multiph. Flow 1987, 13, 1–12. [Google Scholar] [CrossRef]

- Pansunee, S.; Somchai, W. An experimental study of two-phase air-water flow and heat transfer characteristics of segmented flow in a microchannel. Exp. Therm. Fluid Sci. 2015, 62, 29–39. [Google Scholar]

- Kawahara, A.; Mohamed, H.M.; Sadatomi, M.; Law, W.Z.; Kurihara, H.; Kusumaningsih, H. Characteristics of gas-liquid two-phase flows through a sudden contraction in rectangular microchannels. Exp. Therm. Fluid Sci. 2015, 66, 243–253. [Google Scholar] [CrossRef]

- Chiwoong, C.; Moohwan, K. Flow pattern-based correlations of two-phase pressure drop in rectangular microchannels. Int. J. Heat Fluid Flow 2011, 32, 1199–1207. [Google Scholar]

- Bhagwat, S.M.; Ghajar, A.J. Experimental Investigation of Non-Boiling Gas-Liquid Two Phase Flow in Downward Inclined Pipes. Exp. Therm. Fluid Sci. 2017, 89, 219–237. [Google Scholar] [CrossRef]

- Schubert, D.; Costello, P.; Heintzman, T.; Lohr, E. Vacuum sewer design construction and operation in rural Alaska. In On-Site Wastewater Treatment, Proceedings of the Ninth National Symposium on Individual and Small Community Sewage Systems, Fort Worth, TX, USA, 11–14 March 2001; ASAE: Washington, DC, USA, 2001; pp. 369–376. [Google Scholar]

- Anonymous. Vacuum Sewers Help Clean Up Michigan Lakes. Water Environ. Technol. 2004, 16, 102. [Google Scholar]

- Anonymous. High water table/flat terrain a climate for vacuum sewer system. Public Works 2002, 133, 36–38. [Google Scholar]

- Mandal, A.; Kundu, G.; Mukherjee, D. Studies on frictional pressure drop of gas-non-Newtonian two-phase flow in a cocurrent downflow bubble column. Chem. Eng. Sci. 2004, 59, 3807–3815. [Google Scholar] [CrossRef]

- Donald, D.; Gray, P.E. Design Programs for Vacuum Sewer System. Ph.D. Thesis, Department of Civil. Engineering West. Virginia University, Charlottesville, VA, USA, 1990; pp. 182–189. [Google Scholar]

- U.S. Environmental Protection Agency. Manual Alternative Wastewater Collection Systems; EPA: Washington, DC, USA, 1991; pp. 35–93.

- Duan, J.M.; Zhou, J.X. Studies on Frictional Pressure Drop of Gas-non-Newtonian Fluid Two-phase Flow in the Vacuum Sewers. Civ. Eng. Environ. Syst. 2006, 23, 1–10. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, L.; Jin, S.; Tan, Y.; Wu, Y. Impact Analysis of Slope on the Head Loss of Gas-Liquid Two-Phase Flow in Siphon Pipe. Water 2019, 11, 1095. https://doi.org/10.3390/w11051095

Zhang X, Li L, Jin S, Tan Y, Wu Y. Impact Analysis of Slope on the Head Loss of Gas-Liquid Two-Phase Flow in Siphon Pipe. Water. 2019; 11(5):1095. https://doi.org/10.3390/w11051095

Chicago/Turabian StyleZhang, Xiaoying, Lin Li, Sheng Jin, Yihai Tan, and Yangfeng Wu. 2019. "Impact Analysis of Slope on the Head Loss of Gas-Liquid Two-Phase Flow in Siphon Pipe" Water 11, no. 5: 1095. https://doi.org/10.3390/w11051095

APA StyleZhang, X., Li, L., Jin, S., Tan, Y., & Wu, Y. (2019). Impact Analysis of Slope on the Head Loss of Gas-Liquid Two-Phase Flow in Siphon Pipe. Water, 11(5), 1095. https://doi.org/10.3390/w11051095