Experimental Investigation of Artificial Aeration on a Smooth Spillway with a Crest Pier

Abstract

:1. Introduction

2. Materials and Methods

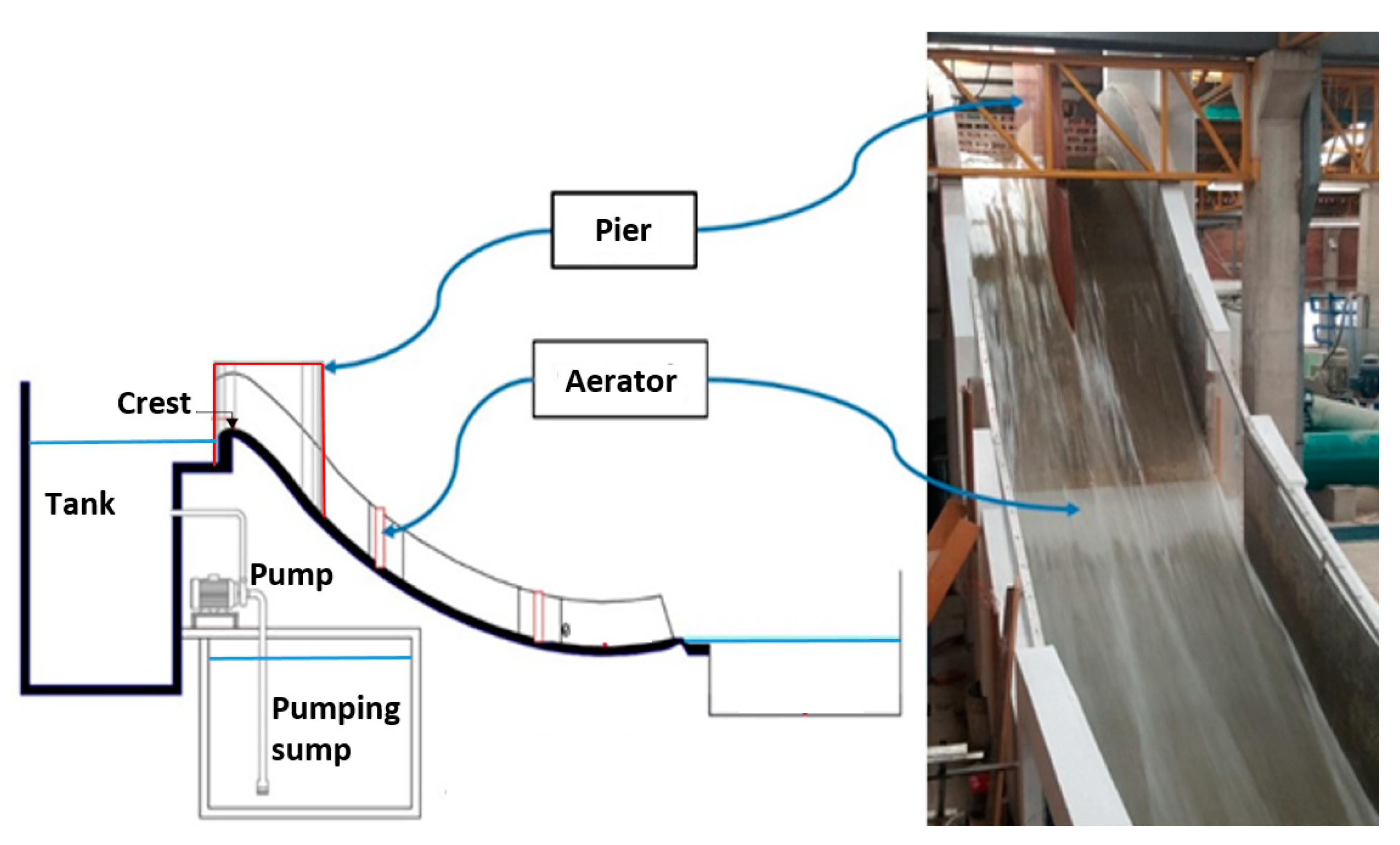

2.1. Physical Scale Spillway Model of the Huites Dam

2.2. Instrumentation

2.3. Experiments

2.4. Experimental Observations

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, S.H. Hydraulic Structures, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- May, R.W.P. Cavitation in Hydraulic Structures: Occurrence and Prevention; Report SR 79; Hydraulics Research Limited: Wallingford, UK, 1987. [Google Scholar]

- Kells, J.A.; Smith, C.D. Reduction of cavitation on spillways by induced air entrainment. Can. J. Civ. Eng. 1991, 18, 358–377. [Google Scholar] [CrossRef]

- Chanson, H. Air Bubble Entrainment in Free-Surface Turbulent Shear Flows; Academic Press: London, UK, 1996. [Google Scholar]

- Pettersson, K. Design of Aerators for Prevention of Cavitation—The Höljes Dam. Master’s Thesis, Royal Institute of Technology, Stockholm, Sweden, 2012. [Google Scholar]

- DeFazio, F.G.; Wei, C.Y. Design of aeration devices on hydraulic structures. In Frontiers in Hydraulic Engineering; Shen, H.T., Ed.; ASCE: New York, NY, USA, 1983; pp. 426–431. [Google Scholar]

- Chanson, H. Aeration and deaeration at bottom aeration devices on spillways. Can. J. Civ. Eng. 1994, 21, 404–409. [Google Scholar] [CrossRef] [Green Version]

- Bradley, J.N. Study of Air Injection into the Flow in the Boulder Dam Spillway Tunnels—Boulder Canyon Project; Report HYD-186; Bureau of Reclamation: Denver, CO, USA, 1945. [Google Scholar]

- Warnock, J.E. Cavitation in hydraulic structures: Experiences of the Bureau of Reclamation. Trans. Am. Soc. Civ. Eng. 1947, 112, 43–58. [Google Scholar]

- Peterka, A.J. The Effect of Entrained Air on Cavitation Pitting. In Proceedings Minnesota International Hydraulic Convention; ASCE: Minneapolis, MN, USA, 1953. [Google Scholar]

- Rasmussen, R.E.H. Some Experiments on Cavitation Erosion in Water Mixed with Air; Symposium on Cavitation in Hydrodynamics; National Physical Laboratory: London, UK, 1956. [Google Scholar]

- Semenkov, V.M.; Lentiaev, L.D. Spillway with Nappe Aeration. Hydrotech. Construct. 1973, 7, 436–441. [Google Scholar] [CrossRef]

- Pylaev, N.I. Investigation into the Effectiveness of Air Admission as a Means to Reduce Cavitation-Erosion. Energomasinostroenie (7); Springer: Moscow, Russia, 1973. [Google Scholar]

- Russell, S.O.; Sheehan, G.J. Effect of entrained air on cavitation damage. Can. J. Civ. Eng. 1974, 1, 97–107. [Google Scholar] [CrossRef]

- De Pinto, N.L.S.; Neidert, S.H.; Ota, J.J. Aeration at High Velocity Flows. Water Power Dam Constr. 1982, 34, 34–38. [Google Scholar]

- Chanson, H. Study of Air Entrainment and Aeration Devices on Spillway Model; Report 88-8; University of Canterbury: Christchurch, New Zealand, 1988. [Google Scholar]

- Chanson, H. Study of air entrainment and aeration devices. J. Hydraul. Res. 1989, 27, 301–319. [Google Scholar] [CrossRef] [Green Version]

- Chanson, H. Flow downstream of an aerator—Aerator spacing. J. Hydraul. Res. 1989, 27, 519–536. [Google Scholar] [CrossRef]

- Chanson, H. Study of air demand on spillway aerator. J. Fluid Eng. 1990, 112, 343–350. [Google Scholar] [CrossRef]

- Rutschmann, P.; Hager, W.H. Air entrainment by spillway aerators. J. Hydraul. Eng. 1990, 116, 765–781. [Google Scholar] [CrossRef]

- Hager, W.H. Uniform aerated chute flow. J. Hydraul. Eng. 1991, 117, 528–533. [Google Scholar] [CrossRef]

- Ervine, D.A.; Falvey, H.T.; Kahn, A.R. Turbulent Flow Structure and Air Uptake at Aerators. Hydropower Dams 1995, 2, 89–96. [Google Scholar]

- Chanson, H.; Toombes, L. Air-water flows down stepped chutes: Turbulence and flow structure observations. Int. J. Multiphase Flow 2002, 28, 1737–1761. [Google Scholar] [CrossRef]

- Oskolkov, A.G.; Semenkov, V.M. Experience in Designing and Maintenance of Spillway Structures on Large Rivers in the USSR. Presented at the 13 ICOLD Congress, New Delhi, India, 20 October 1979. [Google Scholar]

- Vischer, D.L.; Volkart, P.; Siegenthaler, A. Hydraulic Modelling of Air Slots in Open Chute Spillways. In Paper Presented at the International Conference on Hydraulic Modelling of Civil Engineering Structures, Coventry, UK, September 1982; BHRA Fluid Engineering: Reading, UK, 1982. [Google Scholar]

- Volkart, P.; Chervet, A. Air Slots for Flow Aeration; Versuchsanstalt für Wasserbau, Hydrologie und Glaziologie; ETH Zürich: Zürich, Switzerland, 1983. [Google Scholar]

- Pan, S.; Shao, Y. Scale Effects in Modelling Air Demand by a Ramp Slot. Symposium on Scale Effects in Modelling Hydraulic Structures. Presented at the IAHR Symposium on Scale Effects in Modelling Hydraulic Structures, Esslingen am Neckar, Germany, 3–6 September 1984. [Google Scholar]

- Peng, T.T.; Wood, I.R. Model Studies of Aerators on Spillways; Research Report 84-6; University of Canterbury: Christchurch, New Zealand, 1984. [Google Scholar]

- Volkart, P.; Rutschmann, P. Air Entrainment Devices (Air Slots). Mitteilung 72, Versuchsanstalt für Wasserbau, Hydrologie und Glaziologie; ETH Zürich: Zürich, Switzerland, 1984. [Google Scholar]

- Pinto, D.S.N.L. Model Evaluation of Aerators in Shooting Flow. Symposium on Scale Effects in Modelling Hydraulic Structures. Presented at the IAHR Symposium on Scale Effects in Modelling Hydraulic Structures, Esslingen am Neckar, Germany, 3–6 September 1984. [Google Scholar]

- Seng, L.H.; Wood, I.R. Model Studies of Clyde Dam Spillway Aerators; Report 86-6; University of Canterbury: Christchurch, New Zealand, 1986. [Google Scholar]

- Koschitzky, H.-P. Dimensionierungskonzept für Sohlenbelüfter in Schussrinnen zur Vermeidung von Kavitationsschäden. Mitteilung 65; Institut für Wasserbau, Technische Universität: Stuttgart, Germany, 1987. [Google Scholar]

- Frizell, K.W. Chute Spillway Aerators—McPhee Dam Model/Prototype Comparison; Model-Prototype Correlation of Hydraulic Structures, Colorado Springs: Colorado, CO, USA, 1988. [Google Scholar]

- Rutschmann, P. Belüftungseinbauten in Schussrinnen. VAW Mitteilung 97, Versuchsanstalt für Wasserbau, Hydrologie und Glaziologie; ETH: Zürich, Germany, 1988. [Google Scholar]

- Pinto, D.S.N.L. Prototype Aerator Measurements. IAHR Hydraulic Structures Design Manual 4, Air Entrainment in Free-Surface Flows 115–130; Balkema: Rotterdam, The Netherlands, 1991. [Google Scholar]

- Balaguer, G. Sohlenbelüfter in Schussrinnen Ergänzende Untersuchungen zur Bemessung. Institut für Wasserbau und Kulturtechnik; Universität Fridericiana: Karlsruhe, Germany, 1993. [Google Scholar]

- Skripalle, J. Zwangsbelüftung von Hochgeschwindigkeitsströmung an Zurückspringenden Stufen im Wasserbau, Mitteilung 124. Institut für Wasserbau und Wasserwirtschaft; Technische Universität: Berlin, Germany, 1994. [Google Scholar]

- Kökpinar, M.A. Air-Entrainment in High Speed Free Surface Flows. Ph.D. Thesis, Middle East Technical University, Ankara, Turkey, 1996. [Google Scholar]

- Gaskin, S.; Aubel, T.; Holder, G. Air Demand for a Ramp-Offset Aerator as a Function of Spillway Slope, Ramp Angle and Froude Number. Presented at the 30 IAHR Congress, Thessaloniki, Greece, 24–29 August 2003. [Google Scholar]

- Calitz, J.A. Investigation of Air Concentration and Pressures of a Stepped Spillway Equipped with a Crest Pier. Master’s Thesis, Stellenbosch University, Stellenbosch, South Africa, 2015. [Google Scholar]

- Koen, J. Artificial Aeration on Stepped Spillways with Piers and Flares to Mitigate Cavitation Damage. Master’s Thesis, Stellenbosch University, Stellenbosch, South Africa, 2017. [Google Scholar]

- Reinauer, R.; Hager, W.H. Supercritical flow behind chute piers. J. Hydraul. Eng. 1994, 120, 1292–1308. [Google Scholar] [CrossRef]

- Khatsuria, R.M. Hydraulics of Spillways and Energy Dissipators; Marcel Dekker: New York, NY, USA, 2005. [Google Scholar]

- Koch, H.J. Schussstrahlzusammenfuehrung bei Einem Grundablass Mit Nebeneinanderliegenden Segmentschuetzen. Wasserwirtschaft; Springer: Stuttgart, Germany, 1982. [Google Scholar]

- Slopek, R.J.; Nunn, J.O.H. Freeboard Allowances for Chute Spillways; American Society of Civil Engineers: Niagara Falls, NY, USA, 1989. [Google Scholar]

- Reinauer, R.; Hager, W.H. Shockwave in air-water flows. Int. J. Multiphase Flow 1996, 22, 1255–1263. [Google Scholar] [CrossRef]

- Reinauer, R.; Hager, W.H. Pier waves in sloping chutes. Int. J. Hydropower Dams 1997, 4, 100–103. [Google Scholar]

- Vischer, D.L.; Hager, W.H. Dam Hydraulics; Wiley: Chichester, UK, 1998. [Google Scholar]

- Carnacina, I.; Mahmoudi-Kurdistani, S.; Palermo, M.; Pagliara, S. El Chaparral Dam Model: Rooster Tail Formation on High Sloped Spillway; University of Queensland: Brisbane, Australia, 2010. [Google Scholar]

- Pagliara, S.; Mahmoudi, M.S.; Roshni, T. Rooster tail wave hydraulics of chutes. J. Hydraul. Eng. 2011, 137, 1085–1088. [Google Scholar] [CrossRef]

- Pagliara, S.; Kurdistani, S.M.; Palermo, M. Effects of Vertical Deflectors on Rooster Tail Geometry. In Proceedings of the 2nd IAHR European Congress, Munich, Germany, 27–29 June 2012. [Google Scholar]

- United States Bureau of Reclamation (USBR). Design of Small Dams; U.S. Department of the Interior, Bureau of Reclamation: Denver, CO, USA, 1987.

- Falvey, H.T. Cavitation in Chutes and Spillways; U.S. Department of the Interior, Bureau of Reclamation: Denver, CO, USA, 1990.

- Pfister, M.; Hager, W.H. History and significance of the Morton number in hydraulic engineering. J. Hydraul. Eng. 2014, 140, 02514001. [Google Scholar] [CrossRef]

- Ervine, D.A.; Falvey, H.T. Behavior of turbulent water jets in the atmosphere and in plunge pools. Proc. Inst. Civ. Eng. 1987, 83, 295–314. [Google Scholar]

- Chanson, H. Turbulent air-water flows in hydraulic structures: Dynamic similarity and scale effects. Environ. Fluid Mech. 2009, 9, 125–142. [Google Scholar] [CrossRef] [Green Version]

- Pfister, M.; Chanson, H. Scale effects in physical hydraulic engineering models. Discussion. J. Hydraul. Res. 2012, 50, 244–246. [Google Scholar] [CrossRef]

- Pfister, M.; Hager, W.H. Chute aerators. I: Air transport characteristics. J. Hydraul. Eng. 2010, 136, 352–359. [Google Scholar] [CrossRef]

- Cain, P.; Wood, I.R. Instrumentation for aerated flow on spillways. J. Hydraul. Div. 1981, 107, 1407–1424. [Google Scholar]

- Chanson, H. A Study of Air Entrainment and Aeration Devices on a Spillway Model. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 1988. [Google Scholar]

- Matos, J.; Frizell, K.H.; André, S.; Frizell, K.W. On the Performance of Velocity Measurement Techniques in Air-Water Flows. Presented at the Hydraulic Measurements and Experimental Methods Specialty Conference (HMEM), Estes Park, CO, USA, 28 July–1 August 2002. [Google Scholar]

- Chanson, H. Air-water flow measurements with intrusive, phase-detection probes: Can we improve their interpretation? J. Hydraul. Eng. 2002, 128, 252–255. [Google Scholar] [CrossRef]

- Chanson, H.; Carosi, G. Advanced post-processing and correlation analyses in high-velocity air–water flows. Environ. Fluid Mech. 2007, 7, 495–508. [Google Scholar] [CrossRef] [Green Version]

- Chanson, H. Hydraulics of aerated flows: Qui pro quo? J. Hydraul. Res. 2013, 51, 223–243. [Google Scholar] [CrossRef]

- Yang, R.; Zheng, R.; Zhou, F.; Liu, R. Measurement of Two-Dimensional Bubble Velocity by Using Tri-Fiber-Optical Probe. In Proceedings of the 6th International Symposium on Measurement Techniques for Multiphase Flows, Okinawa, Japan, 15–17 December 2008. [Google Scholar]

- Shen, X.; Saito, Y.; Mishima, K.; Nakamura, H. Methodological improvement of an intrusive for-sensor probe for the multi-dimensional two-phase flow measurement. Int. J. Multiphase Flow 2005, 31, 593–617. [Google Scholar] [CrossRef]

- Bai, R.; Zhang, F.; Liu, S.; Wang, W. Air concentration and bubble characteristics downstream of a chute aerator. Int. J. Multiphase Flow 2016, 87, 156–166. [Google Scholar] [CrossRef]

- Wargsjö, E.; Hedehag Damberg, A. Experimental Investigation of the Air-Water Flow Properties in the Cavity Zone Downstream a Chute Aerator. Master’s Thesis, Uppsala University, Uppsala, Sweden, 2017. [Google Scholar]

- Volkart, P. Transition from aerated supercritical to subcritical flow and associated bubble de-aeration. Presented at the 21 IAHR Congress, Melbourne, Australia, 19–23 August 1985. [Google Scholar]

- Hager, W.H. Spillways-Shockwaves and Air Entrainment: Review and Recommendations. Subcommittee No. 4 of the Committee on Hydraulics for Dams; Bulletin 81; Commission Internationale des Grands Barrages: Paris, France, 1992. [Google Scholar]

- Kramer, K. Development of Aerated Chute Flow. Ph.D. Thesis, ETH Zurich, Zürich, Switzerland, 2004. [Google Scholar]

- Wu, J.H.; Cai, C.G.; Ji, W.; Ruan, S.P.; Luo, C. Experimental study on cavitation and water-wing for middle-piers of discharge tunnels. J. Hydrodyn. Ser. B 2005, 17, 429–437. [Google Scholar]

- Sheng, C.; Jian, Z.; Ming, H.; Hazrati, A. Experimental study on water wing characteristics induced by piers in flood drainage culverts. Sci. Iran. Trans. A Civ. Eng. 2013, 20, 1320–1326. [Google Scholar]

| Discharge (L/s) | ho (m) | vo (m/s) | Fo | Ro | Wo |

|---|---|---|---|---|---|

| 500 | 0.042 | 6.96 | 10.84 | 2.92 × 105 | 167.55 |

| 1000 | 0.086 | 6.80 | 7.41 | 5.85 × 105 | 234.25 |

| 1500 | 0.128 | 6.85 | 6.11 | 8.77 × 105 | 287.88 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luna-Bahena, J.C.; Pozos-Estrada, O.; Ortiz-Martínez, V.M.; Gracia-Sánchez, J. Experimental Investigation of Artificial Aeration on a Smooth Spillway with a Crest Pier. Water 2018, 10, 1383. https://doi.org/10.3390/w10101383

Luna-Bahena JC, Pozos-Estrada O, Ortiz-Martínez VM, Gracia-Sánchez J. Experimental Investigation of Artificial Aeration on a Smooth Spillway with a Crest Pier. Water. 2018; 10(10):1383. https://doi.org/10.3390/w10101383

Chicago/Turabian StyleLuna-Bahena, Juan César, Oscar Pozos-Estrada, Víctor Manuel Ortiz-Martínez, and Jesús Gracia-Sánchez. 2018. "Experimental Investigation of Artificial Aeration on a Smooth Spillway with a Crest Pier" Water 10, no. 10: 1383. https://doi.org/10.3390/w10101383

APA StyleLuna-Bahena, J. C., Pozos-Estrada, O., Ortiz-Martínez, V. M., & Gracia-Sánchez, J. (2018). Experimental Investigation of Artificial Aeration on a Smooth Spillway with a Crest Pier. Water, 10(10), 1383. https://doi.org/10.3390/w10101383