Evaluation of Semi-Continuous Pit Manure Recharge System Performance on Mitigation of Ammonia and Hydrogen Sulfide Emissions from a Swine Finishing Barn

Abstract

1. Introduction

2. Experiments

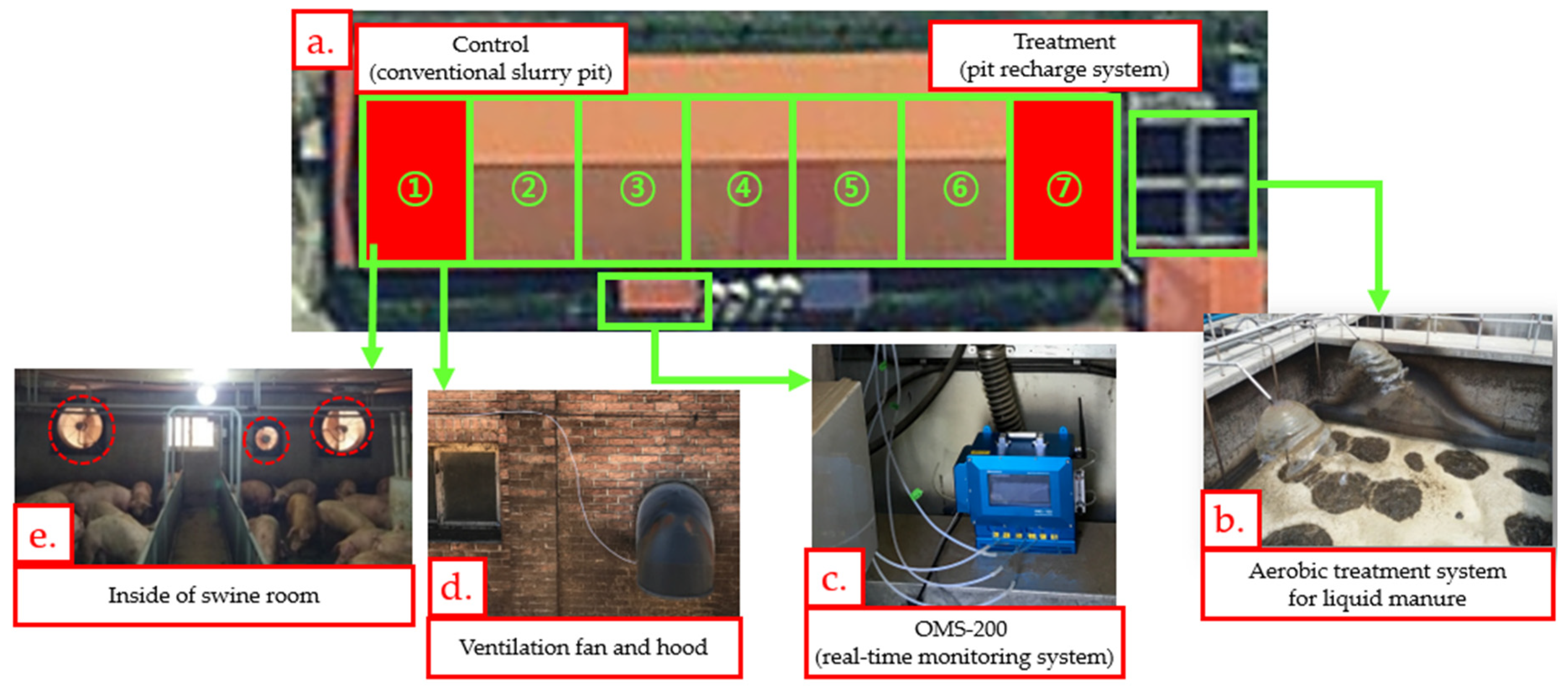

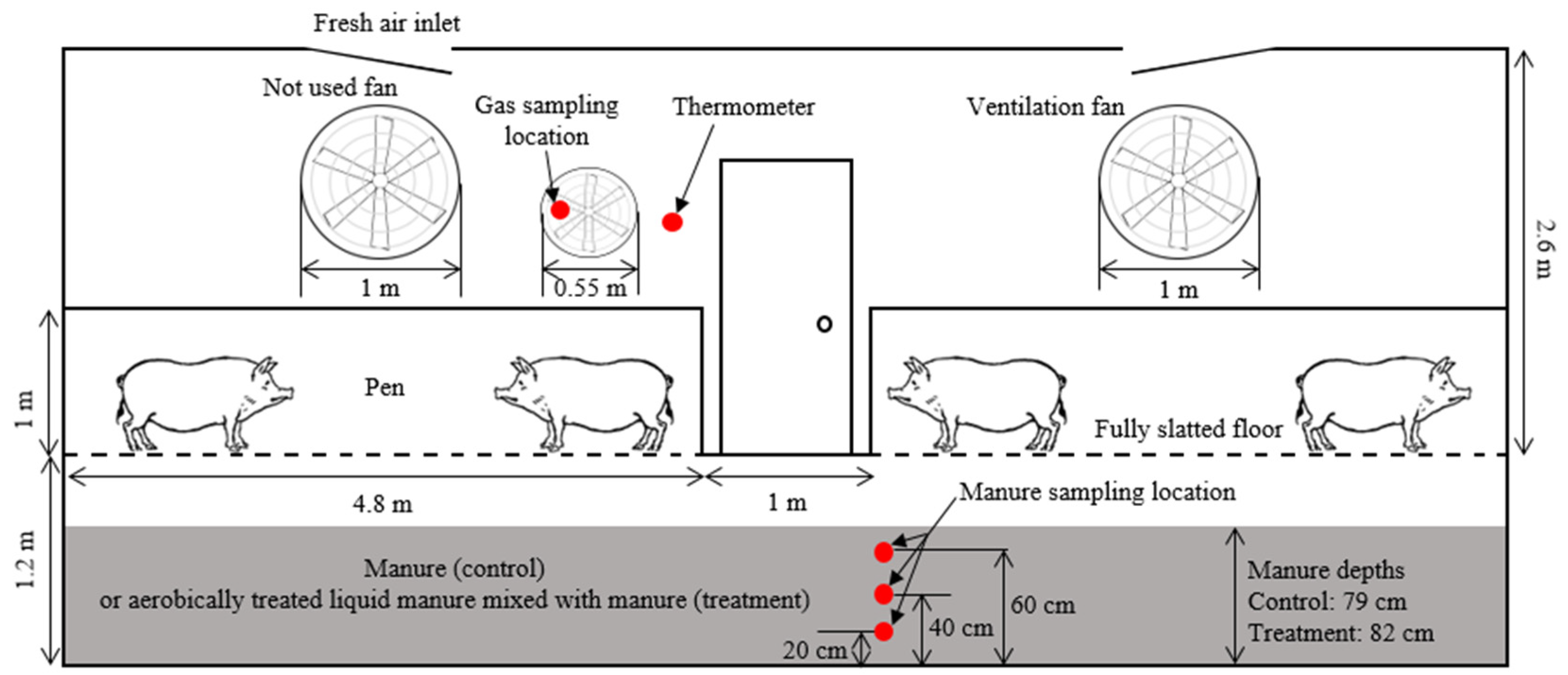

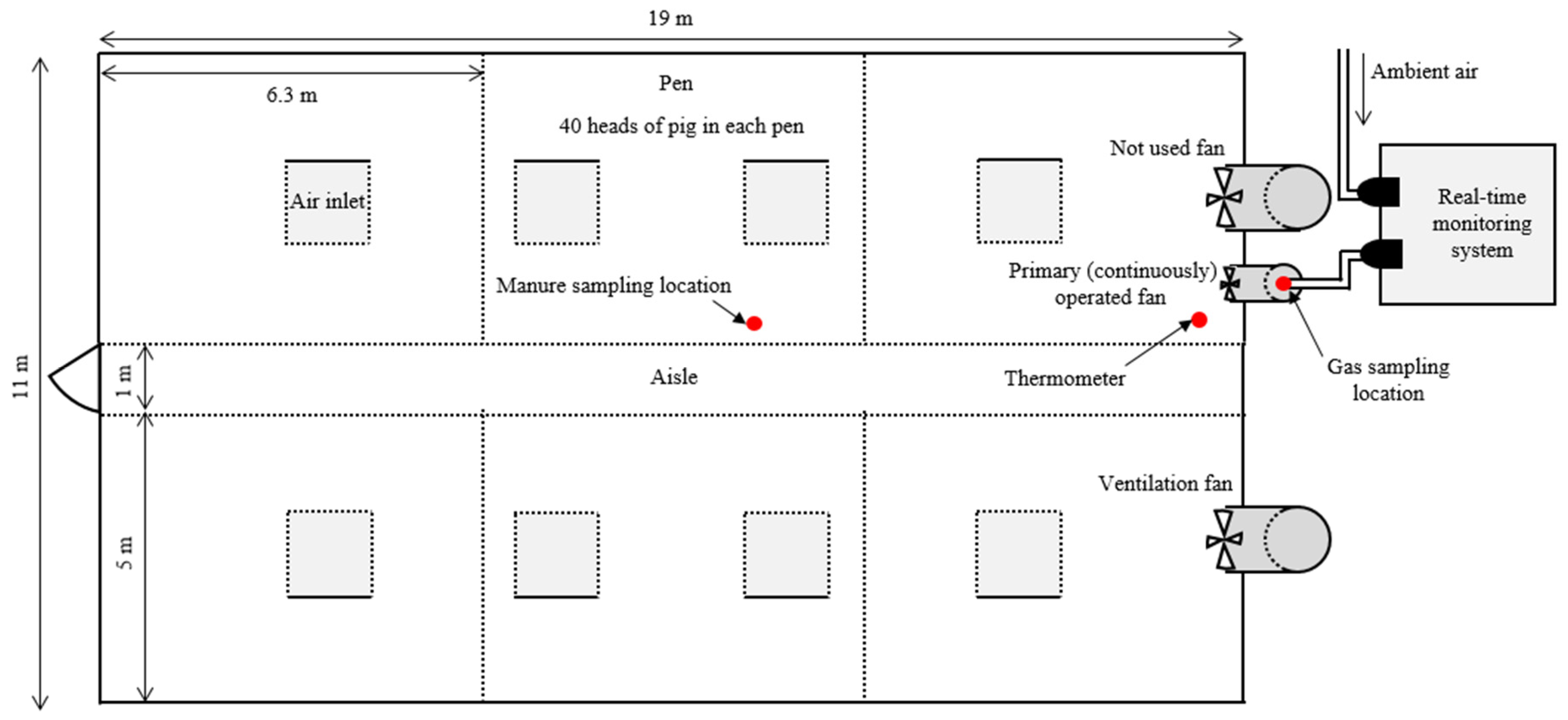

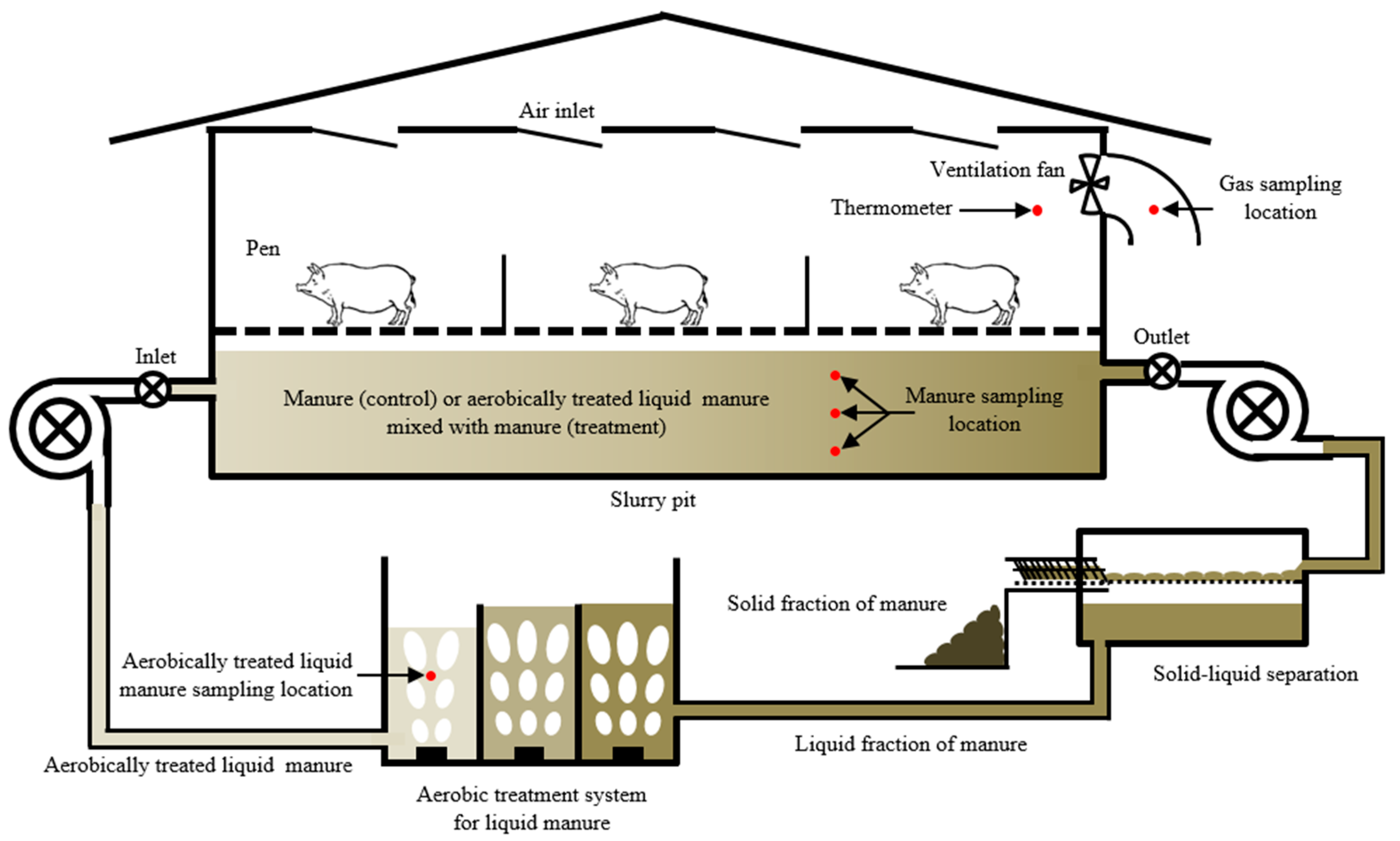

2.1. Description of Farm and Design of Experiment

2.2. Ammonia and Hydrogen Sulfide

2.3. Manure Analysis

2.4. Statistical Analysis

3. Results

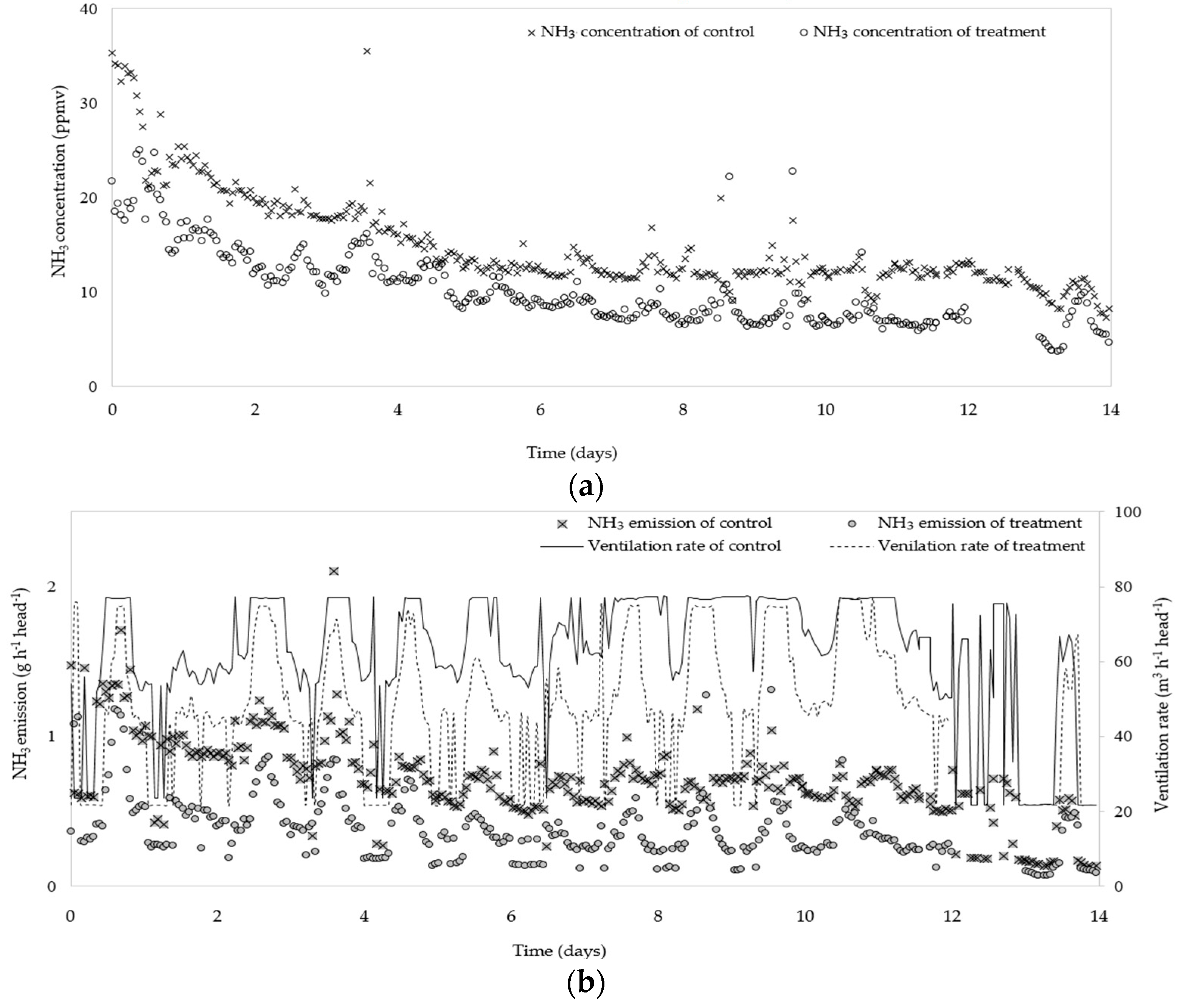

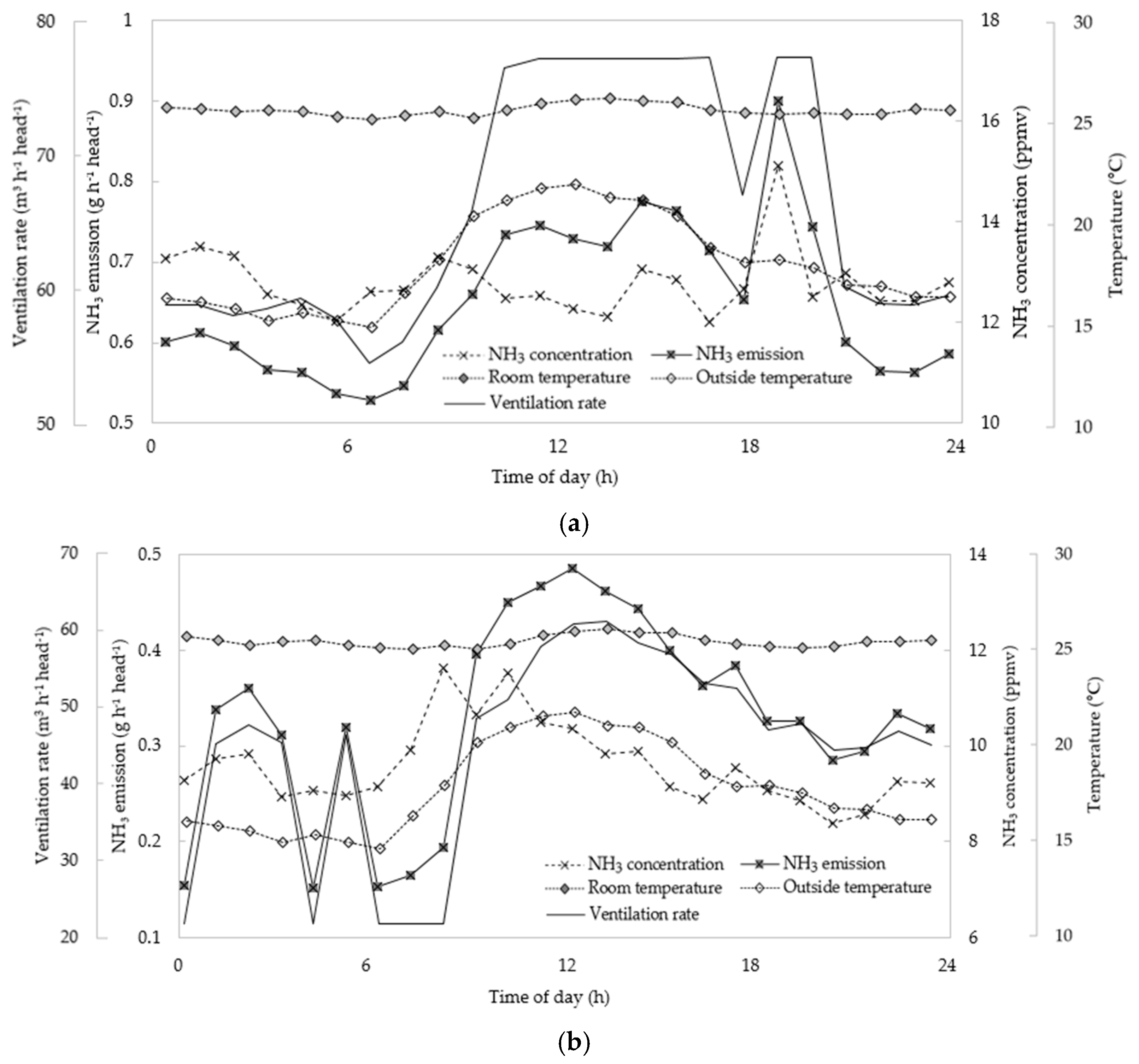

3.1. Ammonia Emissions of Each Room

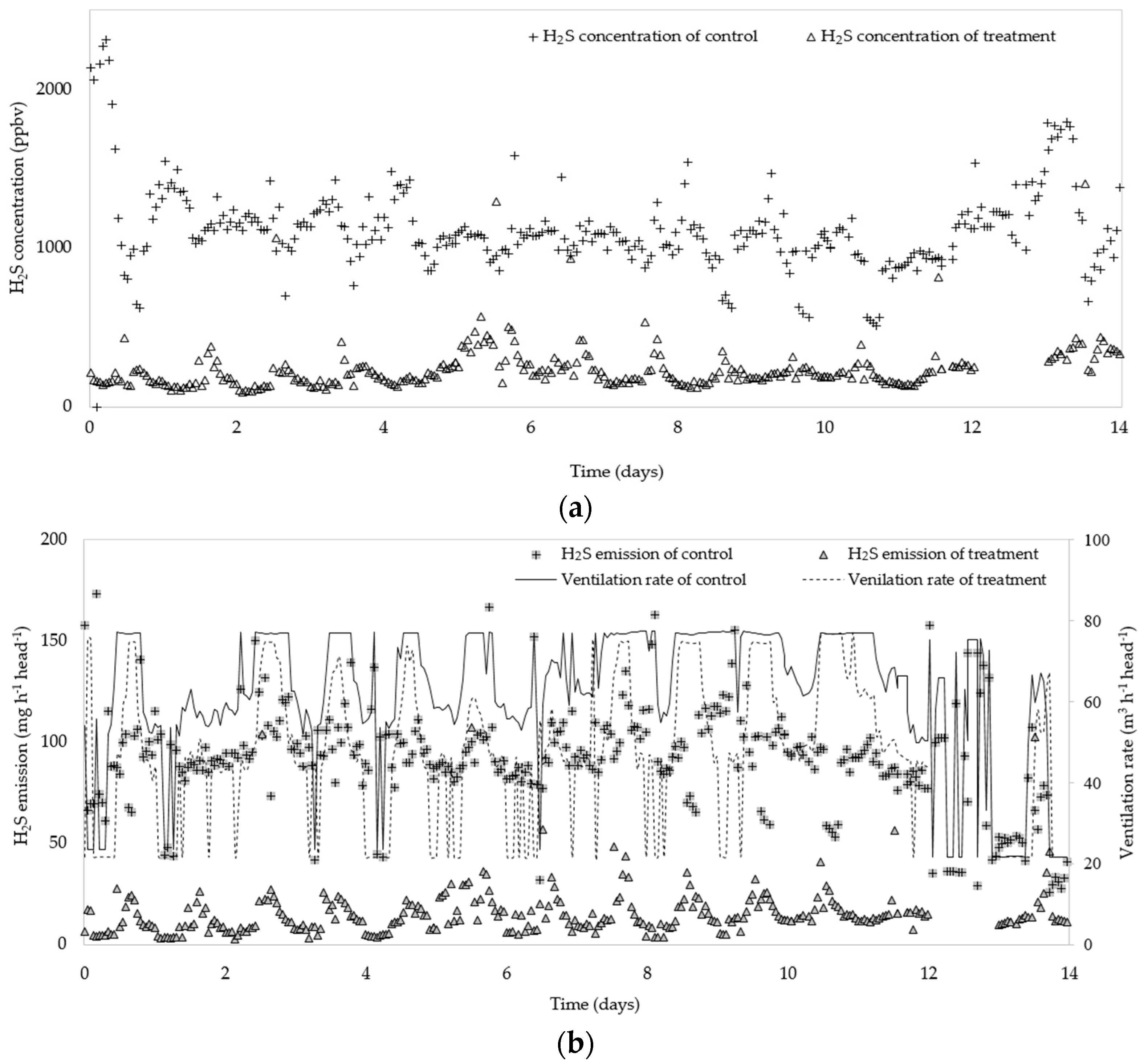

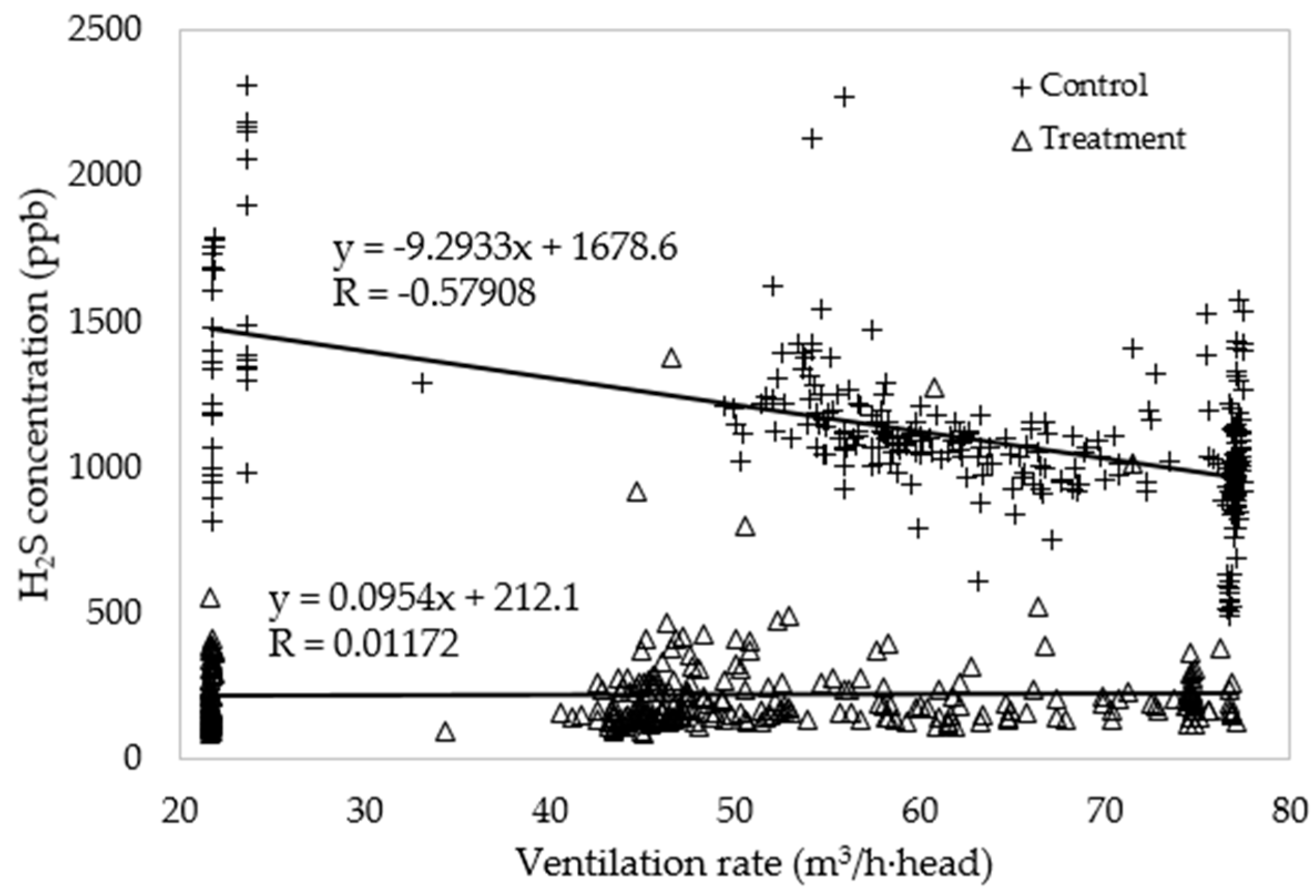

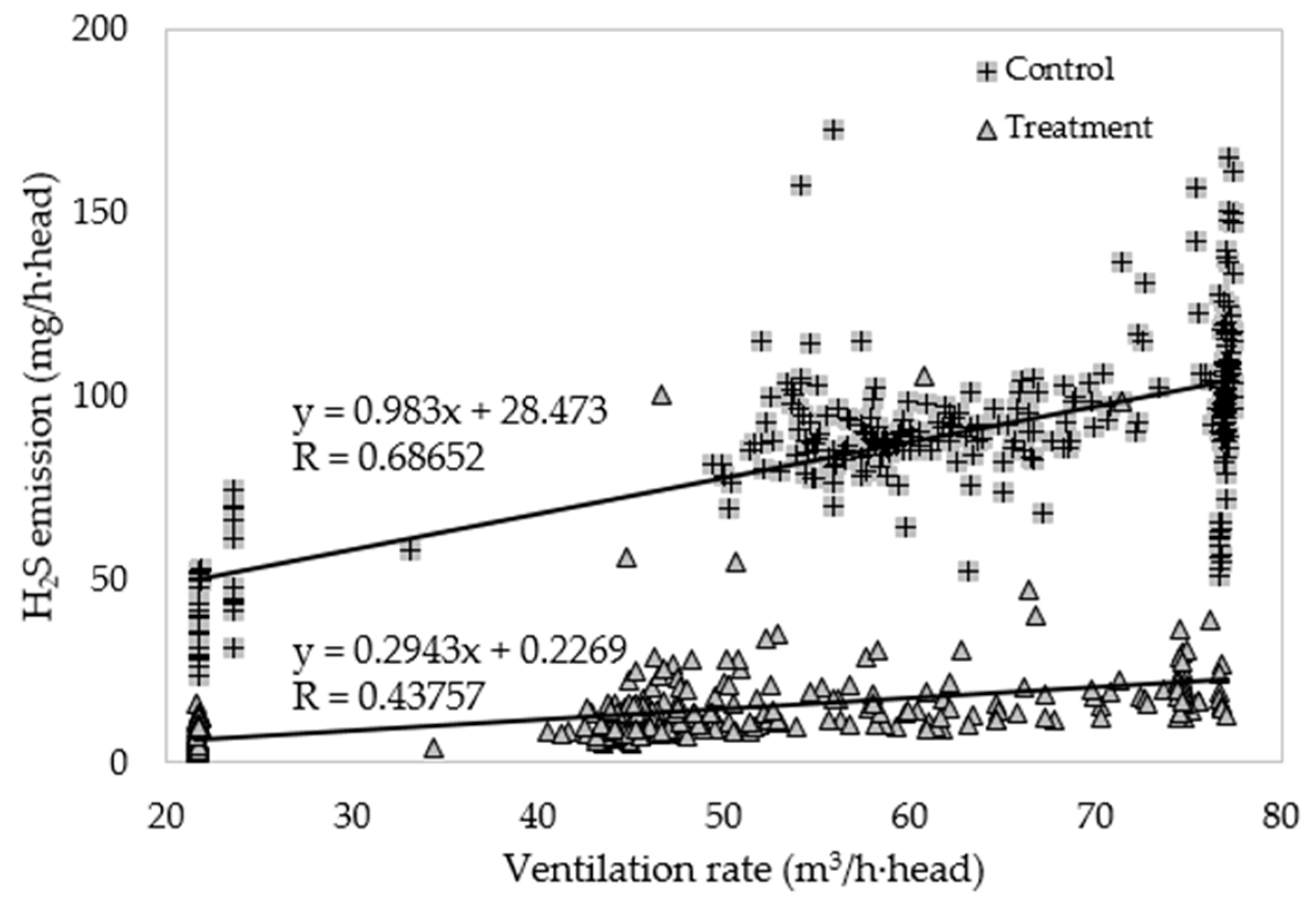

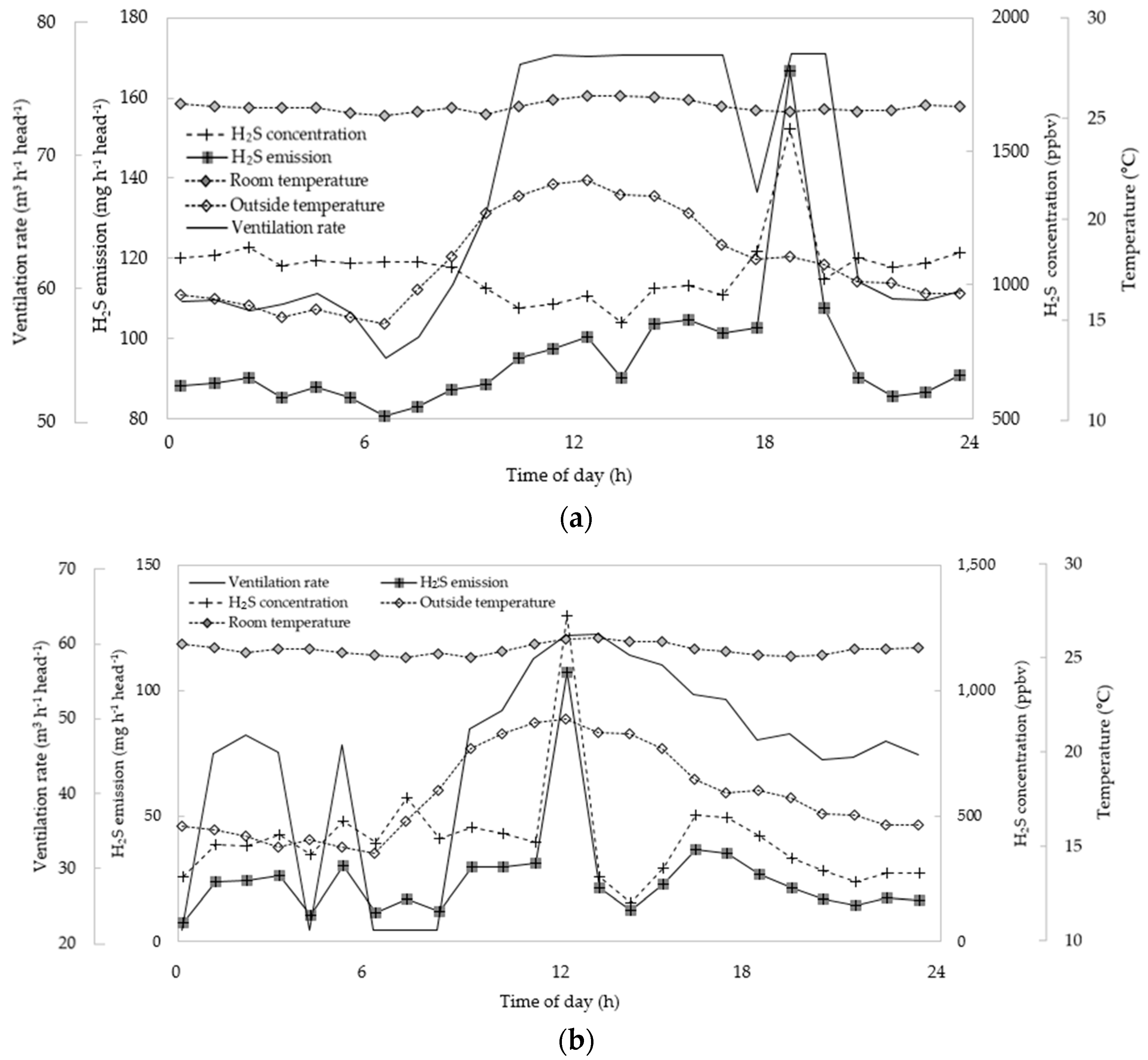

3.2. Hydrogen Sulfide Emissions

3.3. Gas Reduction Rates

3.4. Characteristics of Recharging Liquid and Manure

4. Discussion

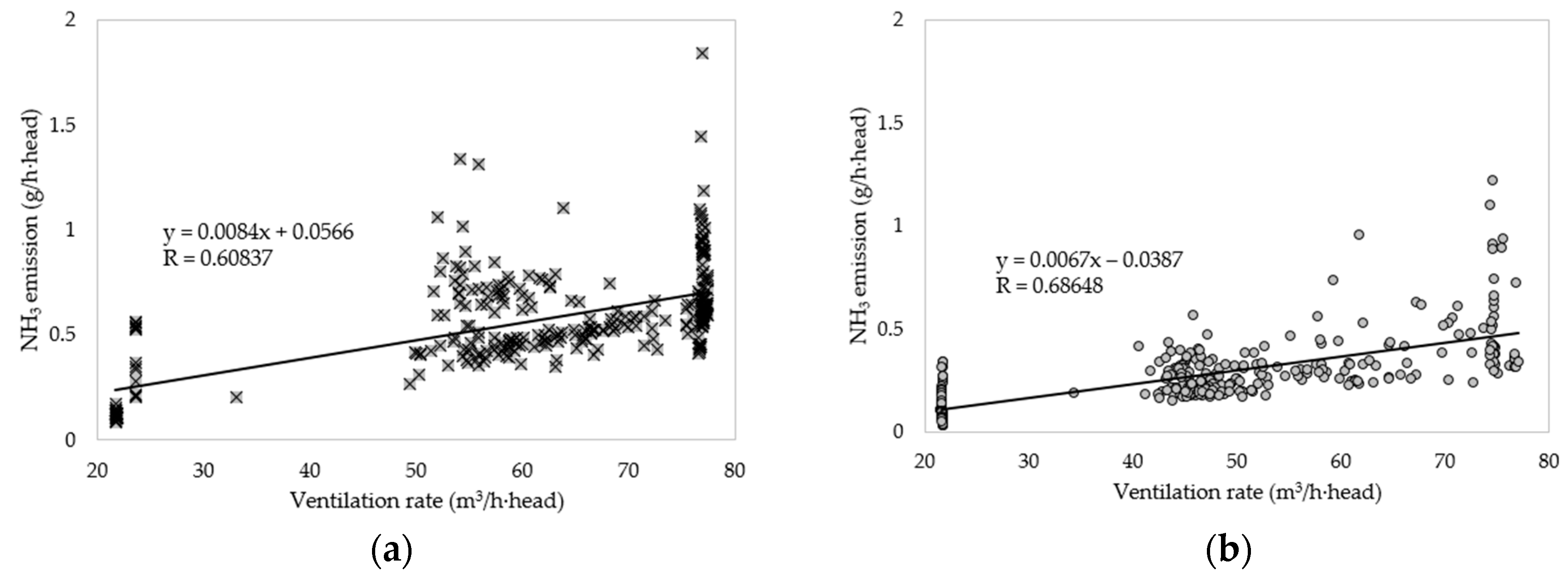

4.1. Correlation of NH3 & H2S Concentration with Ventilation Rate

4.2. NH3 & H2S Concentration and Emission Rates in the Pit Recharge System

4.3. Characteristics of Recharging Liquid and Manure

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| NH3 | H2S | |

|---|---|---|

| Model | NH3/CR-50 | H2S/C-50 |

| Detecting range | 0–50 ppm | 0–50 ppm |

| Resolution | 0.5 ppm | 50 ppb |

| Linearity (R2) | 0.9951 | 0.9995 |

| Study | Recharging Liquid | Recharging Frequency | Gas Emission Rate (g d−1 AU−1) |

|---|---|---|---|

| Lim et al. (2004) [35] | Lagoon effluent | 1 wk | NH3; 10 H2S; 0.16 |

| 2 wks | NH3; 12 H2S; 0.34 | ||

| 6 wks | NH3; 11 H2S; 1.42 | ||

| Kai et al. (2006) [34] | Water | 1 wk | NH3; 17~23 |

| Blunden et al. (2008) [36] | Lagoon effluent | 1 wk | NH3; 40.8 H2S; 4.2 |

| 1 wk | NH3; 37.1 H2S; 3.3 | ||

| 1 wk | NH3; 29.5 H2S; 1.2 | ||

| 1 wk | NH3; 14.3 H2S; 1.7 | ||

| This study | Aerobically treated liquid manure | 3 times d−1 | NH3; 41.5 H2S; 2.1 |

References

- Lo, Y.C.M.; Koziel, J.A.; Cai, L.; Hoff, S.J.; Jenks, W.S.; Xin, H. Simultaneous chemical and sensory characterization of volatile organic compounds and semi-volatile organic compounds emitted from swine manure using solid phase microextraction and multidimensional gas chromatography–mass spectrometry–olfactometry. J. Environ. Qual. 2008, 37, 521–534. [Google Scholar] [CrossRef]

- Buijsman, E.; Erisman, J.W. Wet deposition of ammonium in Europe. J. Atmos. Chem. 1988, 6, 265–280. [Google Scholar] [CrossRef]

- Oenema, O.; Velthof, G.; Klimont, Z.; Winiwarter, W. Emissions from Agriculture and Their Control Potentials; TSAP Report #3. IIASA; IIASA: Laxenburg, Austria, 2012; Available online: http://ec.europa.eu/environment/air/pdf/TSAP-AGRI-20121129_v21.pdf (accessed on 28 March 2019).

- Cai, L.; Koziel, J.; Lo, Y.; Hoff, S.J. Characterization of VOCs and odorants associated with swine barn particulate matter using SPME and gas chromatography–mass spectrometry-olfactometry. J. Chromatogr. A. 2006, 1102, 60–72. [Google Scholar] [CrossRef]

- Kim, K.Y.; Ko, H.J.; Kim, H.T.; Kim, Y.S.; Roh, Y.M.; Lee, C.M.; Kim, C.N. Quantification of ammonia and hydrogen sulfide emitted from pig buildings in Korea. J. Environ. Manag. 2008, 88, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Schiffman, S.S. Livestock odors: Implications for human health and well-being. J. Anim. Sci. 1998, 76, 1343–1355. [Google Scholar] [CrossRef] [PubMed]

- Ni, J.-Q.; Heber, A.J.; Diehl, C.A.; Lim, T.T. SE—Structures and environment: Ammonia, hydrogen sulphide and carbon dioxide release from pig manure in under-floor deep pits. J. Agric. Eng. Res. 2000, 77, 53–66. [Google Scholar] [CrossRef]

- Rahman, S.; Borhan, M.S. Typical odor mitigation technologies for swine production facilities: A review. J. Civ. Environ. Eng. 2012, 2, 117. [Google Scholar] [CrossRef]

- Akdeniz, N.; Jacobson, L.D.; Hetchler, B.P.; Bereznicki, S.D.; Heber, A.J.; Koziel, J.A.; Cai, L.; Zhang, S.; Parker, D.B. Odor and odorous chemical emissions from animal buildings: Part 2. Odor emissions. Trans. ASABE 2012, 55, 2335–2345. [Google Scholar] [CrossRef]

- Bereznicki, S.D.; Heber, A.J.; Akdeniz, N.; Jacobson, L.D.; Hetchler, B.P.; Heathcote, K.Y.; Hoff, S.J.; Koziel, J.A.; Cai, L.; Zhang, S. Odor and odorous chemical emissions from animal buildings: Part 1. Project overview, collection methods, and quality control. Trans. ASABE 2012, 55, 2325–2334. [Google Scholar] [CrossRef]

- Cai, L.; Koziel, J.A.; Zhang, S.; Heber, A.J.; Cortus, E.L.; Parker, D.B.; Hoff, S.J.; Sun, G.; Heathcote, K.Y.; Jacobson, L.D. Odor and odorous chemical emissions from animal buildings: Part 3. Chemical emissions. Trans. ASABE 2015, 58, 1333–1347. [Google Scholar] [CrossRef]

- Heber, A.J.; Ni, J.-Q.; Lim, T.T.; Tao, P.-C.; Schmidt, A.M.; Koziel, J.A.; Beasley, D.B.; Hoff, S.J.; Nicolai, R.E.; Jacobson, L.D. Quality assured measurements of animal building emissions: Gas concentrations. J. Air Waste Manag. Assoc. 2006, 56, 1472–1483. [Google Scholar] [CrossRef] [PubMed]

- Parker, D.B.; Perschbacher-Buser, Z.L.; Cole, N.A.; Koziel, J.A. Recovery of agricultural odors and odorous compounds from polyvinyl fluoride film bags. Sensors 2010, 10, 8536–8552. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Koziel, J.A.; Cai, L.; Hoff, S.J.; Heathcote, K.Y.; Chen, L.; Jacobson, L.D.; Akdeniz, N.; Hetchler, B.P.; Parker, D.B. Odor and odorous chemical emissions from animal buildings: Part 5. Simultaneous chemical and sensory analysis with gas chromatography-mass spectrometry-olfactometry. Trans. ASABE 2015, 58, 1349–1359. [Google Scholar] [CrossRef]

- Hoff, S.J.; Bundy, D.S.; Nelson, M.A.; Zelle, B.C.; Jacobson, L.D.; Heber, A.J.; Ni, J.; Zhang, Y.; Koziel, J.A.; Beasley, D.B. Emissions of ammonia, hydrogen sulfide, and odor before, during, and after slurry removal from a deep-pit swine finisher. J. Air Waste Manag. Assoc. 2006, 56, 581–590. [Google Scholar] [CrossRef]

- Koziel, J.; Spinhirne, J.; Lloyd, J.; Parker, D.; Wright, D.; Kuhrt, F. Evaluation of sample recoveries of malodorous gases for odor bags, SPME, air sampling canisters, and sorbent tubes. J. Air Waste Manag. Assoc. 2005, 55, 1147–1157. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Koziel, J.A.; Cai, L.; Wright, D.; Kuhrt, F. Testing odorants recovery from a novel metallized fluorinated ethylene propylene gas sampling bag. J. Air Waste Manag. Assoc. 2015, 65, 1434–1445. [Google Scholar] [CrossRef]

- Maurer, D.L.; Bragdon, A.M.; Short, B.C.; Ahn, H.; Koziel, J.A. Improving environmental odor measurements: Comparison of lab-based standard method and portable odor measurement technology. Arch. Environ. Prot. 2018, 44. [Google Scholar] [CrossRef]

- Gay, S.; Schmidt, D.; Clanton, C.; Janni, K.; Jacobson, L.; Weisberg, S. Odor, total reduced sulfur, and ammonia emissions from animal housing facilities and manure storage units in Minnesota. Appl. Eng. Agric. 2003, 19, 347. [Google Scholar] [CrossRef]

- Maurer, D.L.; Koziel, J.A.; Harmon, J.D.; Hoff, S.J.; Rieck-Hinz, A.M.; Andersen, D.S. Summary of performance data for technologies to control gaseous, odor, and particulate emissions from livestock operations: Air management practices assessment tool (AMPAT). Data Br. 2016, 7, 1413–1429. [Google Scholar] [CrossRef]

- Van der Heyden, C.; Demeyer, P.; Volcke, E.I. Mitigating emissions from pig and poultry housing facilities through air scrubbers and biofilters: State-of-the-art and perspectives. Biosyst. Eng. 2015, 134, 74–93. [Google Scholar] [CrossRef]

- Chen, L.; Hoff, S.; Cai, L.; Koziel, J.; Zelle, B.; Association, W.M. Evaluation of wood chip-based biofilters to reduce odor, hydrogen sulfide, and ammonia from swine barn ventilation air. J. Air Waste Manag. Assoc. 2009, 59, 520–530. [Google Scholar] [CrossRef]

- Chen, L.; Hoff, S.J.; Koziel, J.A.; Cai, L.; Zelle, B.; Sun, G. Performance evaluation of a wood-chip based biofilter using solid-phase microextraction and gas chromatography–mass spectroscopy–olfactometry. Bioresour. Technol. 2008, 99, 7767–7780. [Google Scholar] [CrossRef]

- Zhu, W.; Koziel, J.A.; Maurer, D.L. Mitigation of livestock odors using black light and a new titanium dioxide-based catalyst: Proof-of-concept. Atmosphere 2017, 8, 103. [Google Scholar] [CrossRef]

- Maurer, D.; Koziel, J.A. On-farm pilot-scale testing of black ultraviolet light and photocatalytic coating for mitigation of odor, odorous VOCs, and greenhouse gases. Chemosphere 2019, 221, 778–784. [Google Scholar] [CrossRef]

- Maurer, D.L.; Koziel, J.A.; Kalus, K.; Andersen, D.S.; Opalinski, S. Pilot-scale testing of non-activated biochar for swine manure treatment and mitigation of ammonia, hydrogen sulfide, odorous volatile organic compounds (VOCs), and greenhouse gas emissions. Sustainability 2017, 9, 929. [Google Scholar] [CrossRef]

- Maurer, D.L.; Koziel, J.A.; Bruning, K.; Parker, D.B. Farm-scale testing of soybean peroxidase and calcium peroxide for surficial swine manure treatment and mitigation of odorous VOCs, ammonia and hydrogen sulfide emissions. Atmos. Environ. 2017, 166, 467–478. [Google Scholar] [CrossRef]

- Maurer, D.L.; Koziel, J.A.; Bruning, K.; Parker, D.B. Pilot-scale testing of renewable biocatalyst for swine manure treatment and mitigation of odorous VOCs, ammonia and hydrogen sulfide emissions. Atmos. Environ. 2017, 150, 313–321. [Google Scholar] [CrossRef]

- Cai, L.; Koziel, J.A.; Liang, Y.; Nguyen, A.T.; Xin, H. Evaluation of zeolite for control of odorants emissions from simulated poultry manure storage. J. Environ. Qual. 2007, 36, 184–193. [Google Scholar] [CrossRef] [PubMed]

- Kalus, K.; Opaliński, S.; Maurer, D.; Rice, S.; Koziel, J.A.; Korczyński, M.; Dobrzański, Z.; Kołacz, R.; Gutarowska, B. Odour reducing microbial-mineral additive for poultry manure treatment. Front. Environ. Sci. Eng. 2017, 11, 7. [Google Scholar] [CrossRef]

- Mackie, R.I.; Stroot, P.G.; Varel, V.H. Biochemical identification and biological origin of key odor components in livestock waste. J. Anim. Sci. 1998, 76, 1331–1342. [Google Scholar] [CrossRef]

- Arogo, J.; Westerman, P.; Heber, A.J. A review of ammonia emissions from confined swine feeding operations. Trans. ASAE 2003, 46, 805. [Google Scholar] [CrossRef]

- Maurer, D.L.; Koziel, J.A.; Bruning, K. Field scale measurement of greenhouse gas emissions from land applied swine manure. Front. Environ. Sci. Eng. 2017, 11, 1. [Google Scholar] [CrossRef]

- Kai, P.; Kaspers, B.; Van Kempen, T. Modeling sources of gaseous emissions in a pig house with recharge pit. Trans. ASABE 2006, 49, 1479–1485. [Google Scholar] [CrossRef]

- Lim, T.T.; Heber, A.J.; Ni, J.Q.; Kendall, D.C.; Richert, B.R. Effects of manure removal strategies on odor and gas emissions from swine finishing. Trans. ASAE 2004, 47, 2041–2050. [Google Scholar] [CrossRef]

- Blunden, J.; Aneja, V.P.; Westerman, P.W. Measurement and analysis of ammonia and hydrogen sulfide emissions from a mechanically ventilated swine confinement building in North Carolina. Atmos. Environ. 2008, 42, 3315–3331. [Google Scholar] [CrossRef]

- Ha, D.; Kim, D. The effect of liquid manure circulation system on the odor reduction of swine swine farm. J. Agric. Life Sci. 2015, 49, 57–64. [Google Scholar] [CrossRef]

- Strobel, B.; Oertwig, T.; Paulsen, B.; Harmon, J.D. Daily cleaning options for sloped manure pits in swine finishing. In Proceedings of the 2009 ASABE Annual Meeting, Reno, Nevada, 21–24 June 2009; p. 096307. [Google Scholar] [CrossRef]

- Ahn, H.K.; Choi, H.L. Piggery slurry composting using batch operating autothermal thermophilic aerobic digestion system. Asian-Australas. J. Anim. Sci. 2005, 19, 273–279. [Google Scholar] [CrossRef]

- Koziel, J.A.; Frana, T.S.; Ahn, H.; Glanville, T.D.; Nguyen, L.T.; van Leeuwen, J.H. Efficacy of NH3 as a secondary barrier treatment for inactivation of Salmonella Typhimurium and methicillin-resistant Staphylococcus aureus in digestate of animal carcasses: Proof-of-concept. PLoS ONE 2017, 12, e0176825. [Google Scholar] [CrossRef] [PubMed]

- Powers, W.; Zamzow, S.; Kerr, B.J. Reduced crude protein effects on aerial emissions from swine. Appl. Eng. Agric. 2007, 23, 539–546. [Google Scholar] [CrossRef]

| Study | Experimental Scale & Location | Growth Stage & Size | Description of Barn | Recharged Liquid & Volume | Recharging Frequency | Experimental Period and Season | Gas & Odor; Emission Rate (g d−1AU−1) 1 | Measured Gas Emissions Reduction Rate (%) |

|---|---|---|---|---|---|---|---|---|

| Lim et al. (2004) [35] | Research barn Indiana, US | 78–97 kg finisher, 75 pigs | Shallow pit (1.1 m deep), Fully slatted | Anaerobic treated lagoon effluent, 72 L head−1 | 1 wk, Batch mode | May–July (3 wks) | NH3; 10 H2S; 0.16 Odor; 2.6 OUE s−1 | 63 41 |

| 2 wks, Batch mode | May–July (6 wks) | NH3; 12 H2S; 0.34 | 52 17 | |||||

| 6 wks, Batch mode | March–May (7 wks) | NH3; 11 H2S; 1.42 Odor; 25 OUE s−1 | Not reported 2 | |||||

| Kai et al. (2006) [34] | Research barn Denmark | 25–45 kg grower 20 pigs | Shallow pit (0.3 m deep), Fully slatted | Fresh water, 6 L head−1 | 1 wk, Batch mode | 1 wk | NH3; 17–23 Odor; 6.0 OU s−1 | Not reported |

| Blunden et al. (2008) [36] | Commercial barn North Carolina, US | 38–88 kg finisher 842–896 pigs | Shallow pit, Fully slatted | Anaerobic treated Lagoon fluid (No information about volume) | 1 wk, Batch mode | February (6 days) | NH3; 40.8, H2S; 4.2 | Not reported |

| April (8 days) | NH3; 37.1, H2S; 3.3 | |||||||

| June (6 days) | NH3; 29.5, H2S; 1.2 | |||||||

| October (6 days) | NH3; 14.3, H2S; 1.7 | |||||||

| Ha and Kim (2015) 3 [37] | Commercial barn Republic of Korea | Not reported | Not reported | Aerobically treated liquid manure | Not reported | Not reported | Not reported | Not reported |

| Item | Contents (%, d.b. 1) |

|---|---|

| Crude protein | 17.48 |

| Crude fiber | 5.16 |

| Fat | 2.91 |

| Control | Treatment | p-Value | Reduction Rate (%) | |

|---|---|---|---|---|

| n | 14 | 13 | - | |

| Room temperature (°C) | 25.0 ± 0.7 a | 25.1 ± 0.6 a | 0.7125 | - |

| Ventilation rate (m3 h−1 head−1) | 62.0 ± 11.7 | 47.0 ± 9.0 | - | - |

| Gas concentration | ||||

| NH3 (ppmv) | 14.9 ± 5.0 | 10.3 ± 3.8 | - | 32.6 ± 5.3 |

| H2S (ppbv) | 1,122 ± 137 | 239 ± 75 | - | 78.3 ± 6.8 |

| Gas emission rate | ||||

| NH3 (g d−1 head−1) | 13.8 ± 4.5 a | 6.6 ± 2.4 b | 0.0000 | 53.3 ± 6.6 |

| H2S (mg d−1 head−1) | 2,146 ± 311 a | 338 ± 92 b | 0.0000 | 83.7 ± 6.8 |

| Ventilation Rate Range (m3 h−1 head−1) | NH3 Concentration (ppmv) | NH3 Emission (g h−1 head−1) | ||||

|---|---|---|---|---|---|---|

| Control (n) | Treatment (n) | Reduction Rate (%) | Control | Treatment | Reduction Rate (%) | |

| 20~25 | 12.2 ± 8.4 a (40) | 7.6 ± 4.7 b (75) | 37.3 | 0.21 ± 0.16 a | 0.13 ± 0.08 b | 40.0 |

| 50~55 | 15.4 ± 5.8 a (33) | 6.6 ± 1.7 b (25) | 57.1 | 0.63 ± 0.24 a | 0.27 ± 0.07 b | 58.0 |

| 70~78 | 11.8 ± 3.4 a (138) | 8.8 ± 4.0 b (46) | 24.9 | 0.69 ± 0.20 a | 0.51 ± 0.23 b | 26.9 |

| Ventilation Rate Range (m3 h−1 head−1) | Aerobically Treated Liquid Manure | Manure Sample from the Pit in Day 13 | |||

|---|---|---|---|---|---|

| Day 0 | Day 13 | Control 1 | Treatment 2 | p-Value | |

| Moisture content (%, w.b. 3) | 98.7 | 98.7 | 93.9 ± 2.8 a | 95.6 ± 4.0 a | 0.0532 |

| Volatile solids (%, d. b. 4) | 40.4 | 39.8 | 68.8 ± 3.5 a | 38.9 ± 6.5 b | 0.0000 |

| pH | 8.6 | 8.2 | 7.7 ± 0.1 a | 8.0 ± 0.4 a | 0.3475 |

| EC 5 (μS cm−1) | 14.2 | 11.6 | 30.7 ± 4.0 a | 12.7 ± 0.2 b | 0.0159 |

| Total N (mg L−1) | 1175.8 | 1199.9 | 6037 ± 829 | 2207 ± 1173 b | 0.0135 |

| NH4-N (mg L−1) | 918.2 | 216.3 | 3806 ± 17 a | 801 ± 304 b | 0.0002 |

| Control 1 | Treatment 2 | |||||||

|---|---|---|---|---|---|---|---|---|

| Mean | Shallow 3 | Middle 4 | Deep 5 | Mean | Shallow 3 | Middle 4 | Deep 5 | |

| Moisture content (%, w.b. 6) | 93.9 | 96.3 | 95.2 | 90.1 | 98.5 | 98.6 | 98.3 | 89.9 |

| Volatile solids (%, d. b. 7) | 68.8 | 66.5 | 66.2 | 73.8 | 43.2 | 40.8 | 45.7 | 30.2 |

| pH | 7.7 | 7.7 | 7.7 | 7.6 | 8.0 | 8.3 | 8.2 | 7.5 |

| EC 8 (μS cm−1) | 30.7 | 33.2 | 32.8 | 26.1 | 12.7 | 12.9 | 12.7 | 12.6 |

| Total N (mg L−1) | 6037 | 5414 | 5,488 | 7209 | 2,207 | 2,044 | 1125 | 3453 |

| NH4-N (mg L−1) | 3806 | 3827 | 3,785 | 3807 | 801 | 619 | 633 | 1153 |

| pH | Fraction Present (%) | |

|---|---|---|

| H2S | HS- | |

| 7.7 (Control) | 17.95 | 82.05 |

| 8.3 (Treatment) | 5.21 | 94.79 |

| Crude Protein in the Feed (%, d.b. 1) | |

|---|---|

| JRC (2005) 1 | 13.0 |

| SCA (1987) 2 | 15.0 |

| Lim et al. (2004) [35] | 11.5~13.1 |

| Kai et al. (2006) [34] | 16.0 |

| This study | 17.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wi, J.; Lee, S.; Kim, E.; Lee, M.; Koziel, J.A.; Ahn, H. Evaluation of Semi-Continuous Pit Manure Recharge System Performance on Mitigation of Ammonia and Hydrogen Sulfide Emissions from a Swine Finishing Barn. Atmosphere 2019, 10, 170. https://doi.org/10.3390/atmos10040170

Wi J, Lee S, Kim E, Lee M, Koziel JA, Ahn H. Evaluation of Semi-Continuous Pit Manure Recharge System Performance on Mitigation of Ammonia and Hydrogen Sulfide Emissions from a Swine Finishing Barn. Atmosphere. 2019; 10(4):170. https://doi.org/10.3390/atmos10040170

Chicago/Turabian StyleWi, Jisoo, Seunghun Lee, Eunjong Kim, Myeongseong Lee, Jacek A. Koziel, and Heekwon Ahn. 2019. "Evaluation of Semi-Continuous Pit Manure Recharge System Performance on Mitigation of Ammonia and Hydrogen Sulfide Emissions from a Swine Finishing Barn" Atmosphere 10, no. 4: 170. https://doi.org/10.3390/atmos10040170

APA StyleWi, J., Lee, S., Kim, E., Lee, M., Koziel, J. A., & Ahn, H. (2019). Evaluation of Semi-Continuous Pit Manure Recharge System Performance on Mitigation of Ammonia and Hydrogen Sulfide Emissions from a Swine Finishing Barn. Atmosphere, 10(4), 170. https://doi.org/10.3390/atmos10040170