Study on Chassis Leveling Control of a Three-Wheeled Agricultural Robot

Abstract

1. Introduction

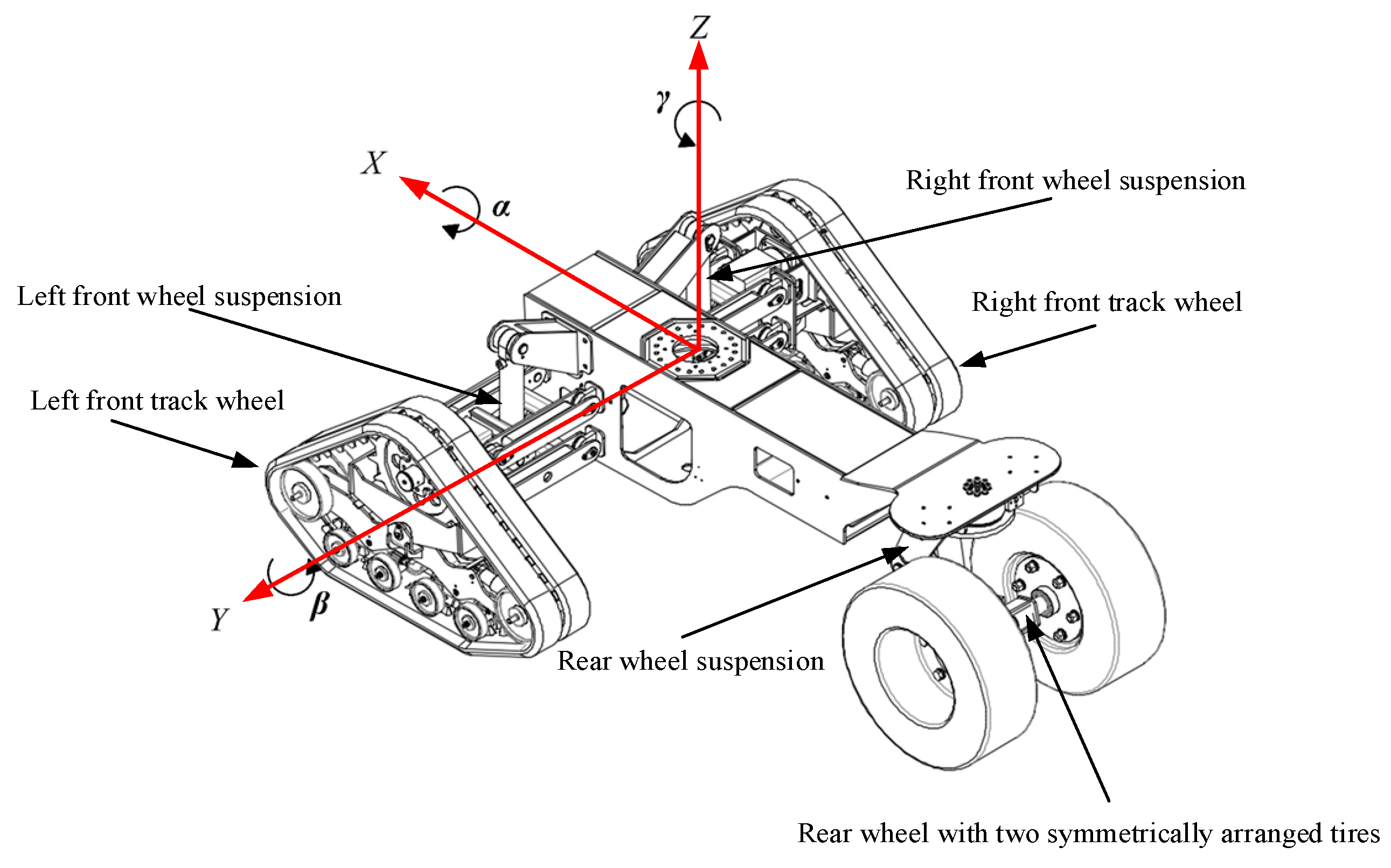

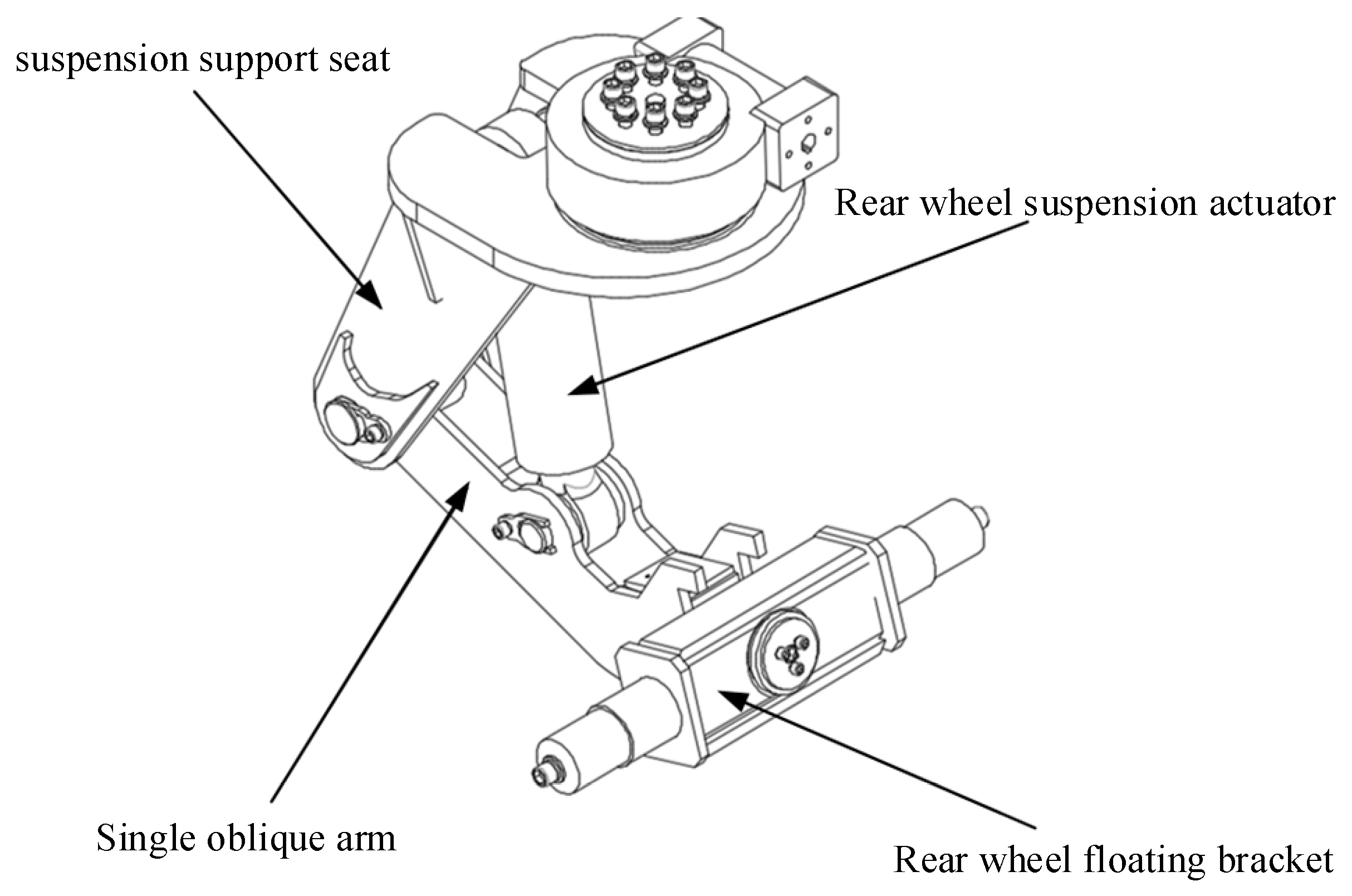

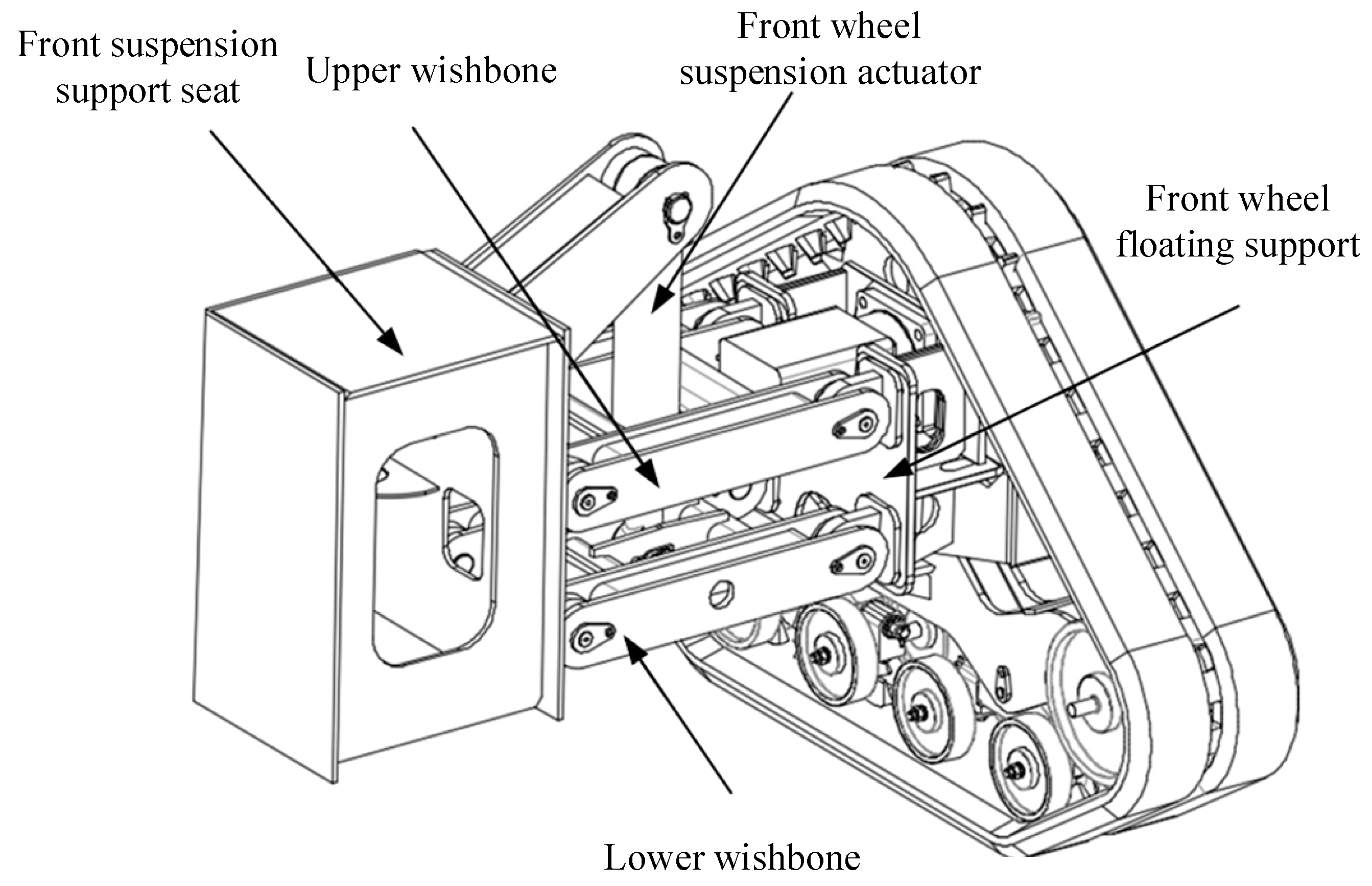

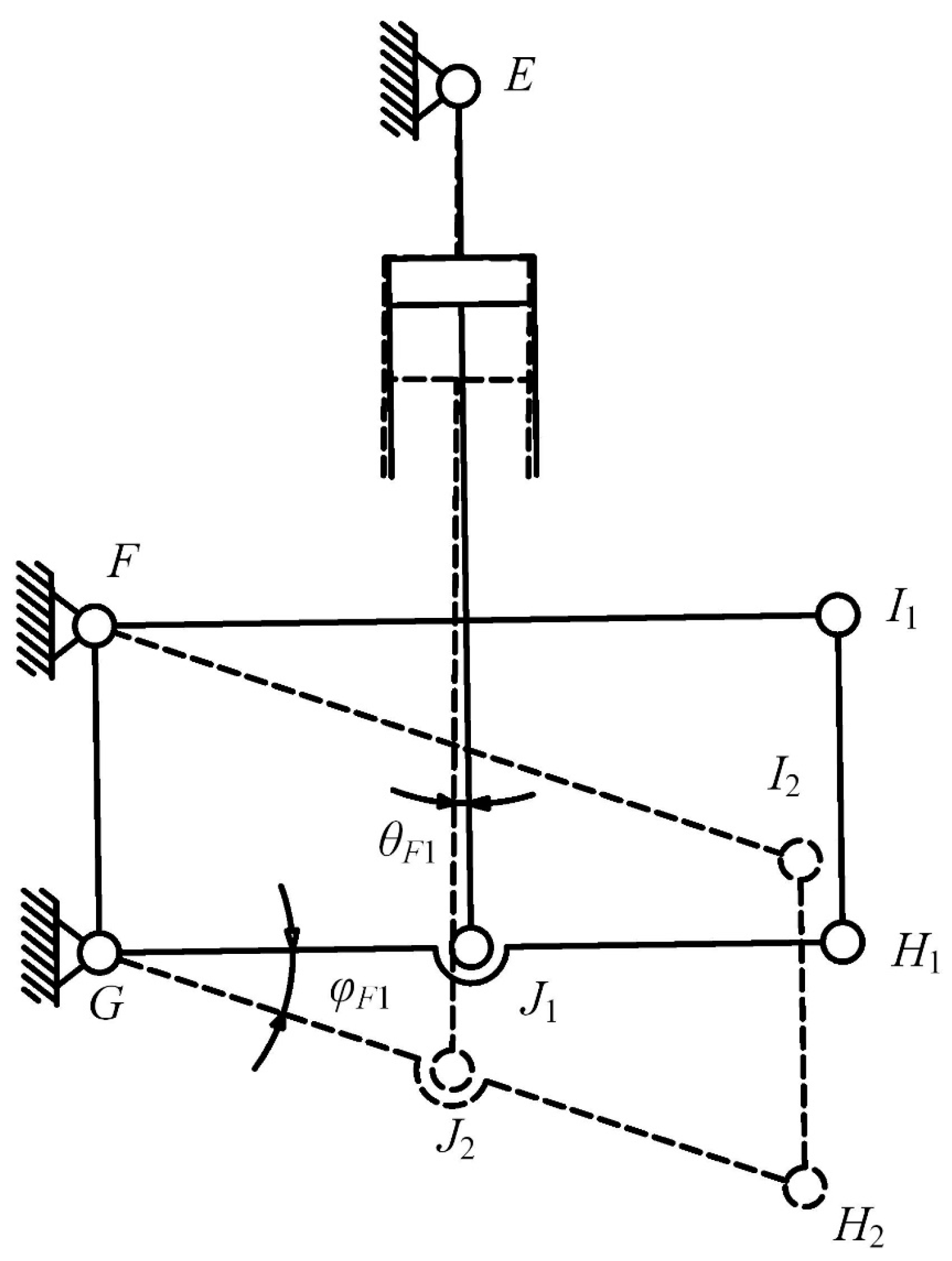

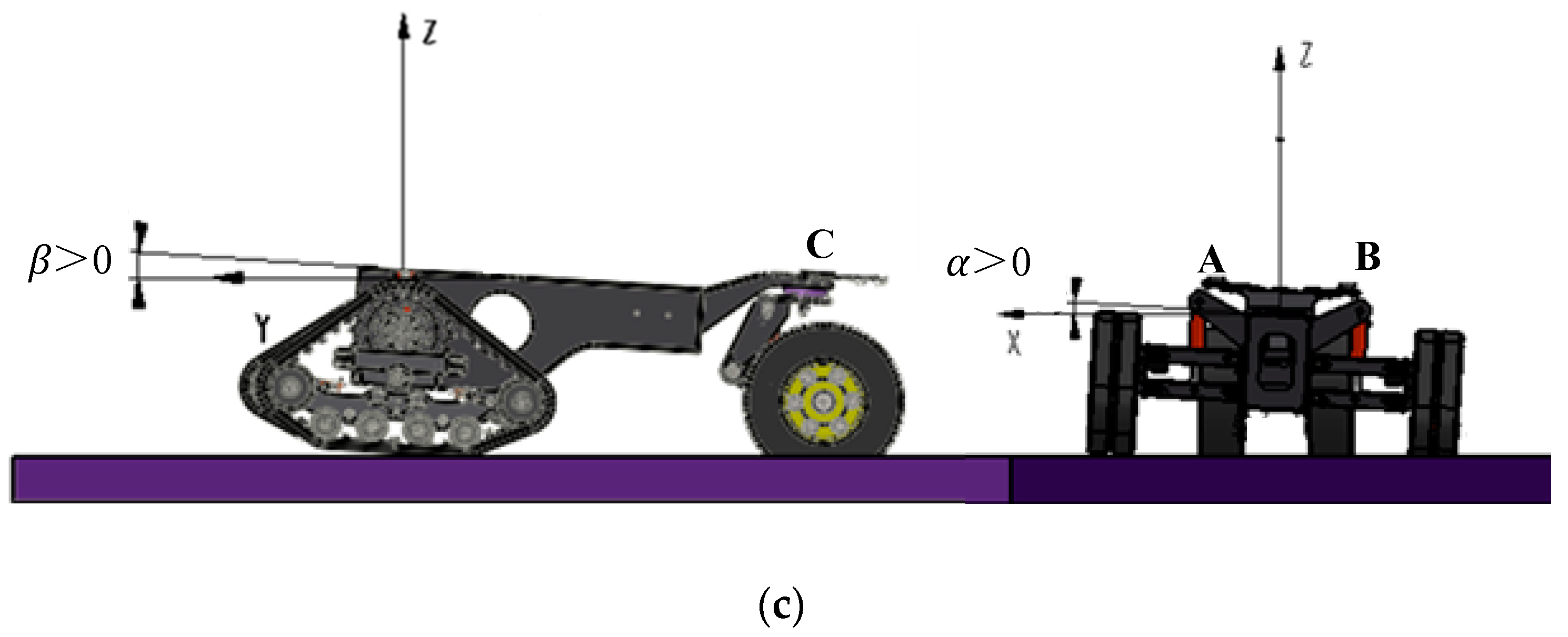

2. The Structure of the Three-Wheeled Chassis Leveling System

3. Mathematical Modelling

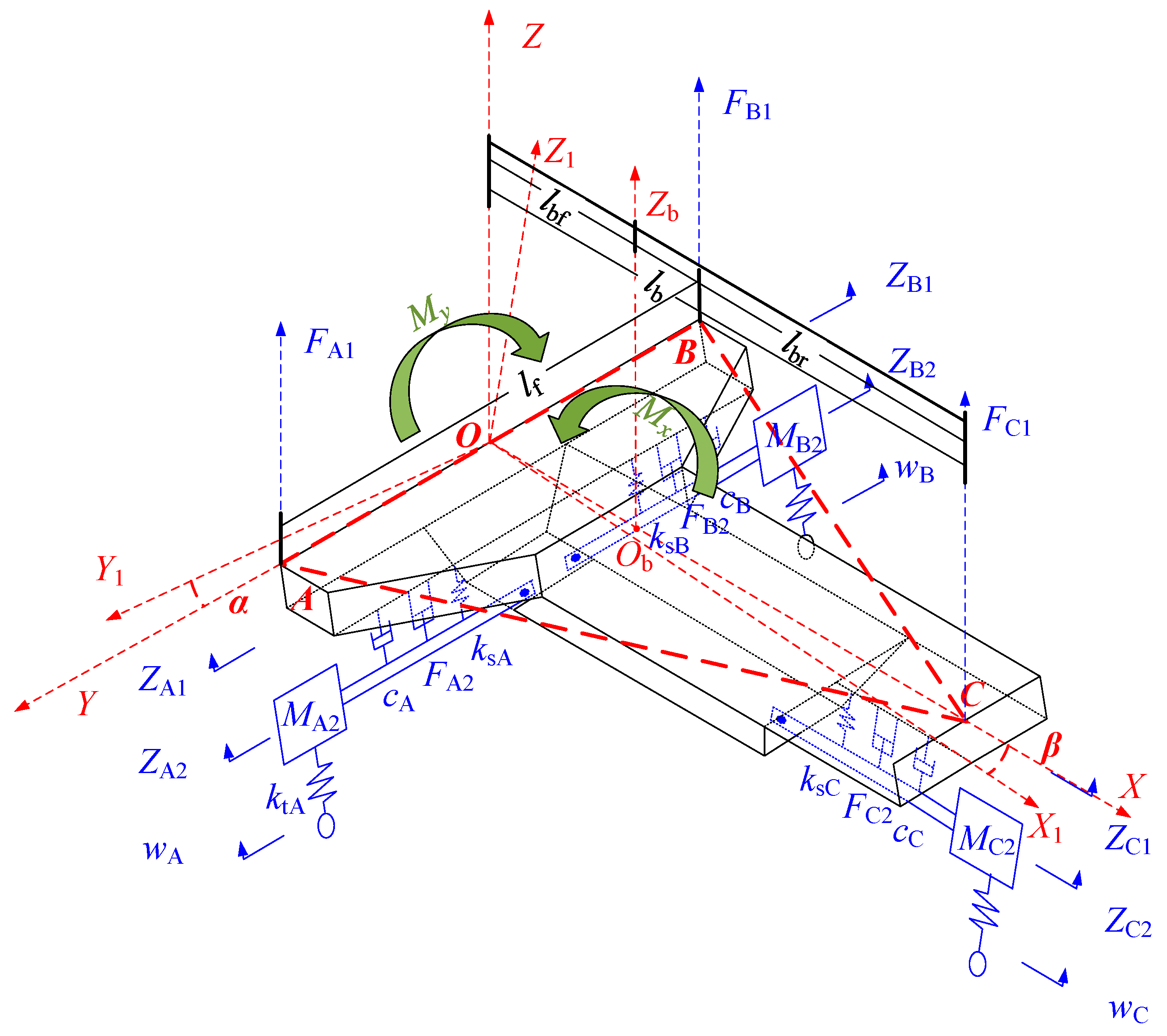

3.1. Force Model of the Three-Wheeled Chassis

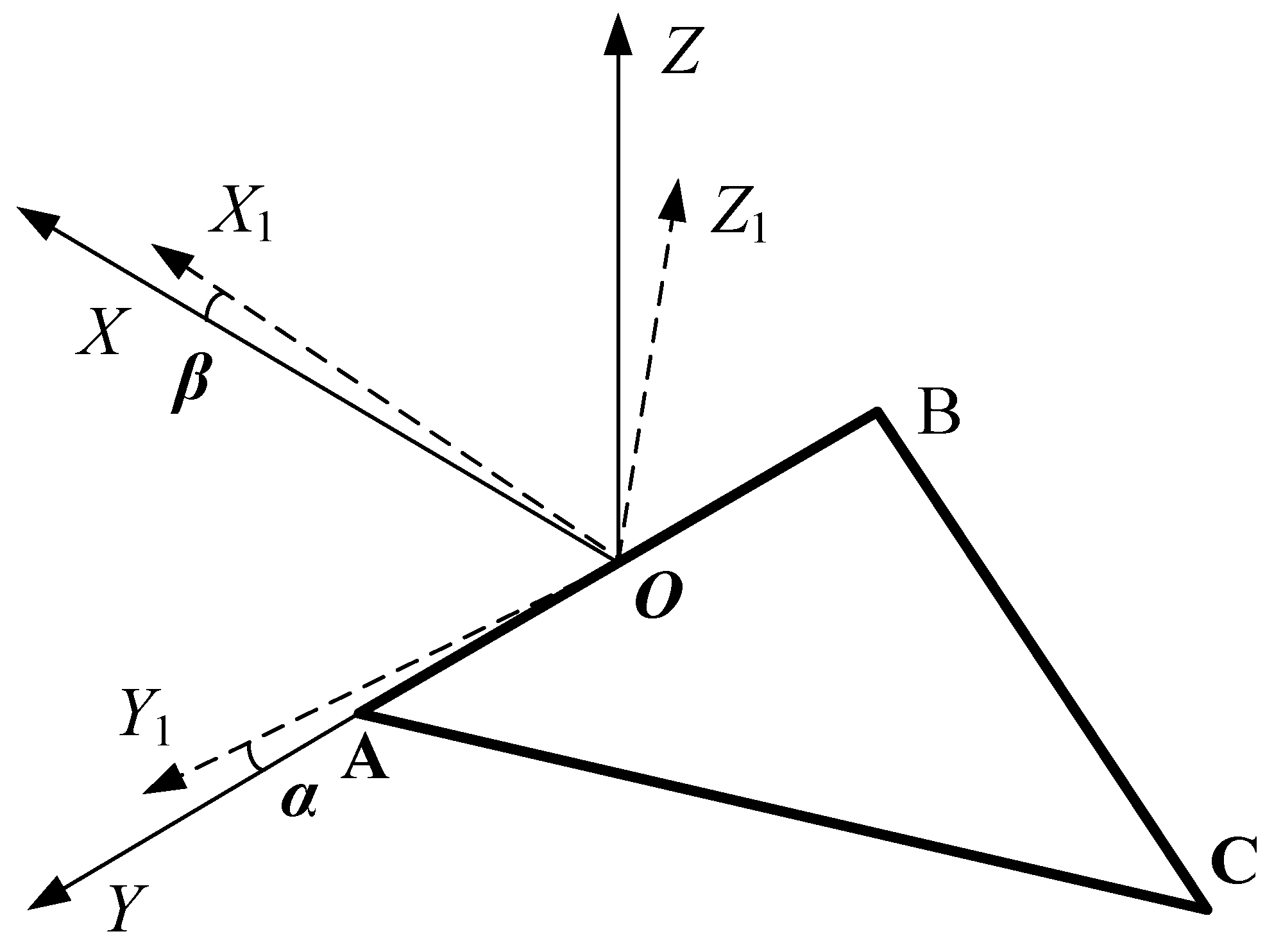

3.2. Attitude Model of the Three-Wheeled Chassis

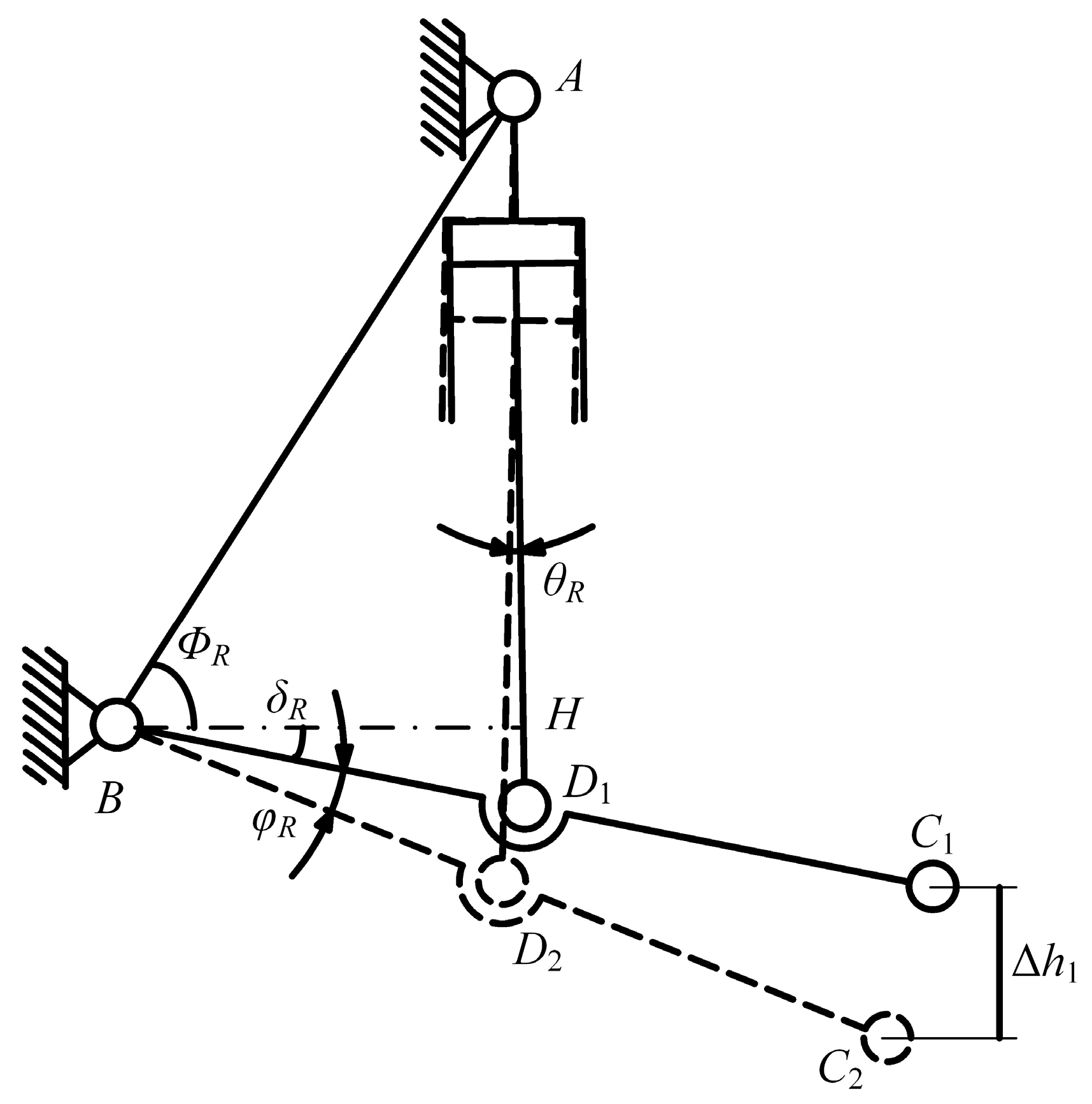

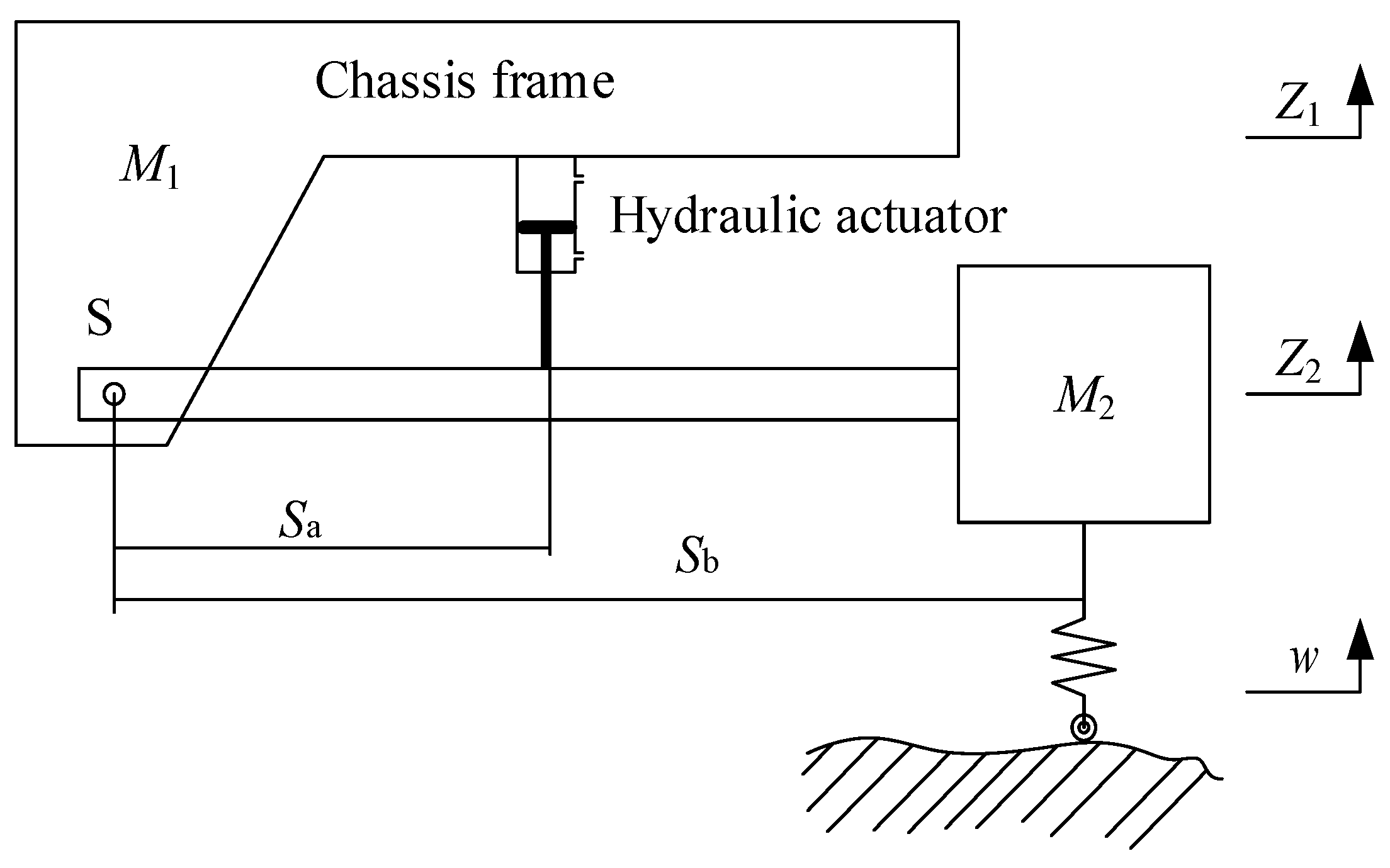

3.3. Single-Wheel Suspension System Model

3.3.1. Single-Wheel Suspension Model

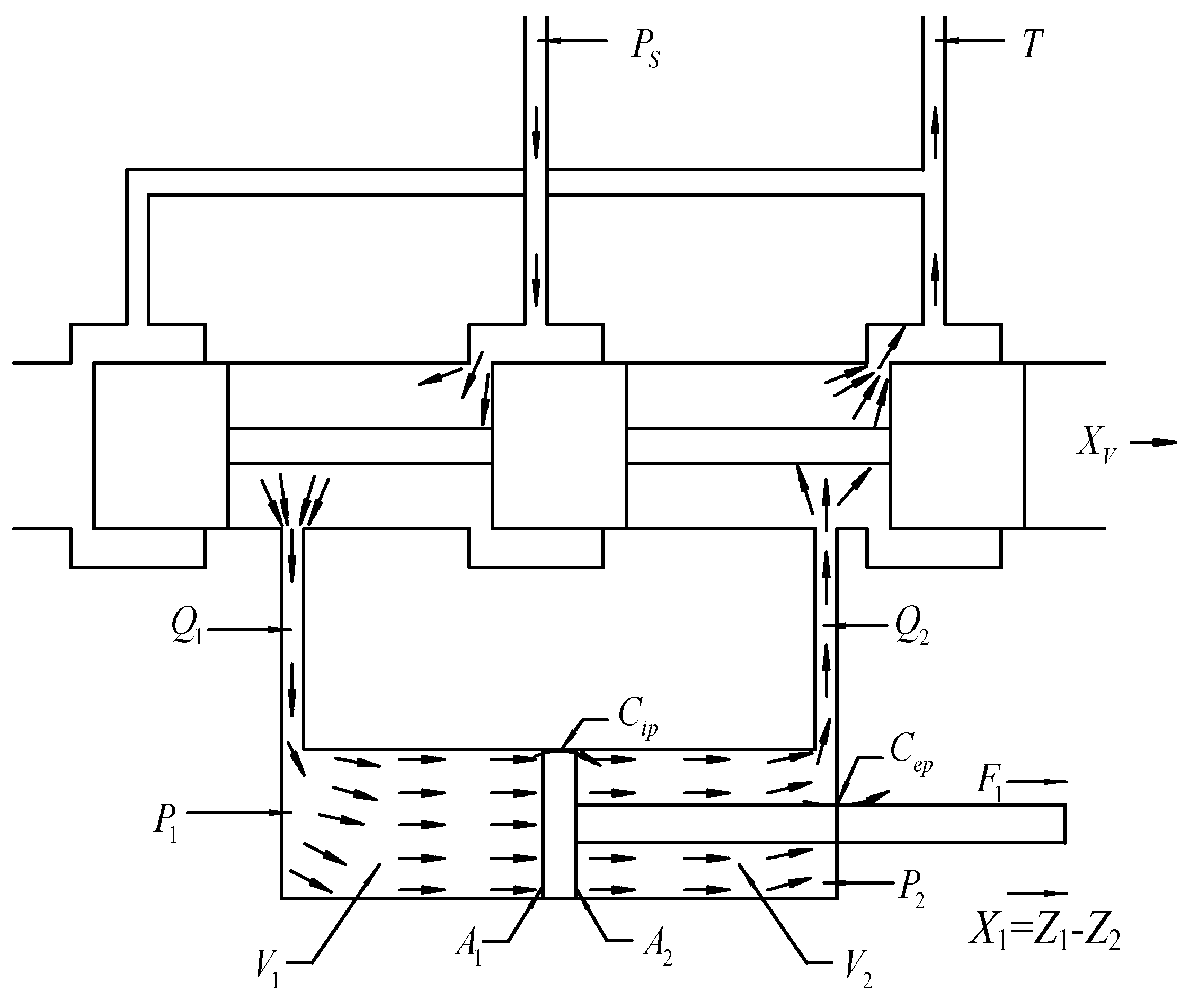

3.3.2. Hydraulic Servo System Model of the Suspension Actuator

3.3.3. State Equation of the Single-Wheel Suspension

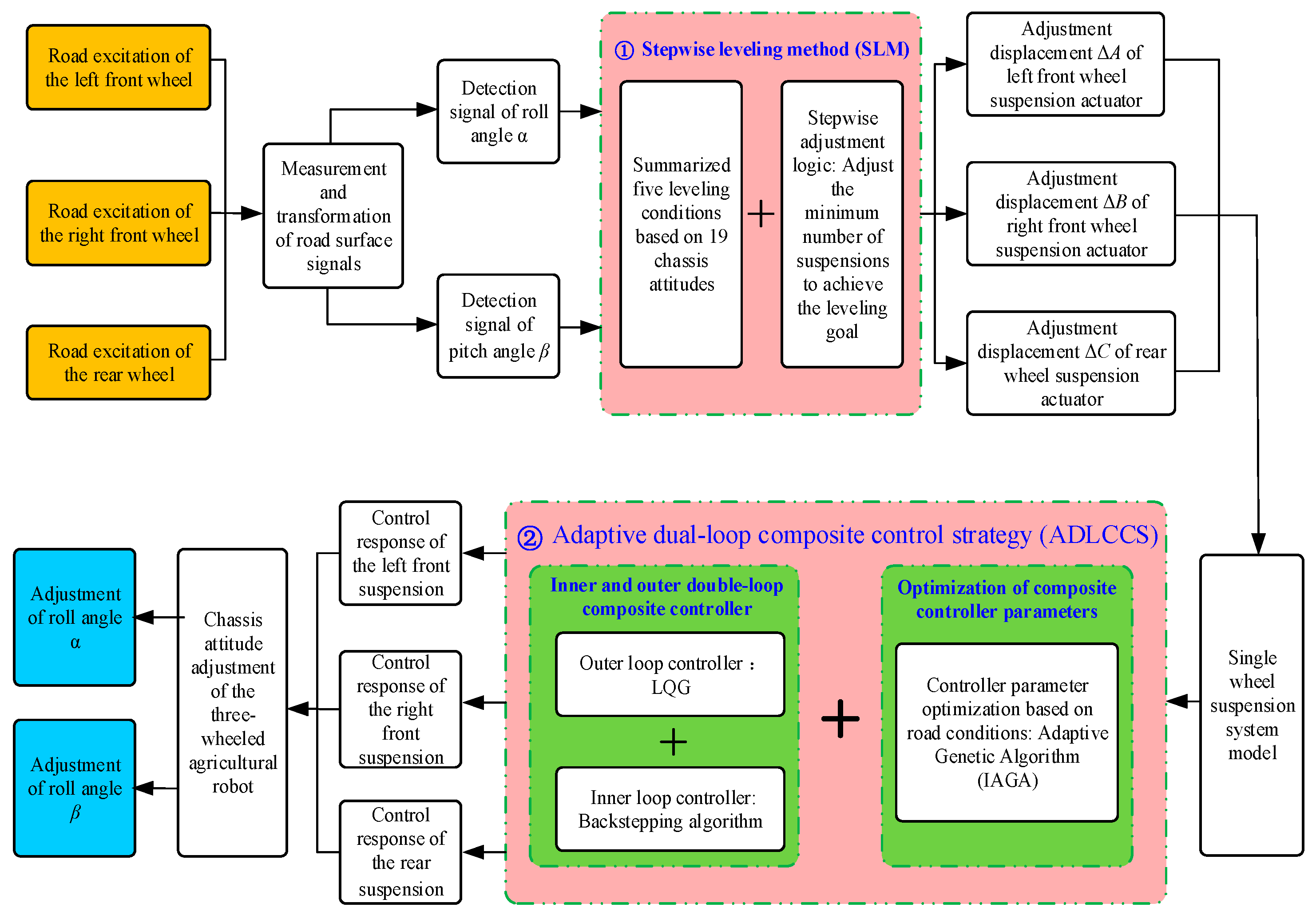

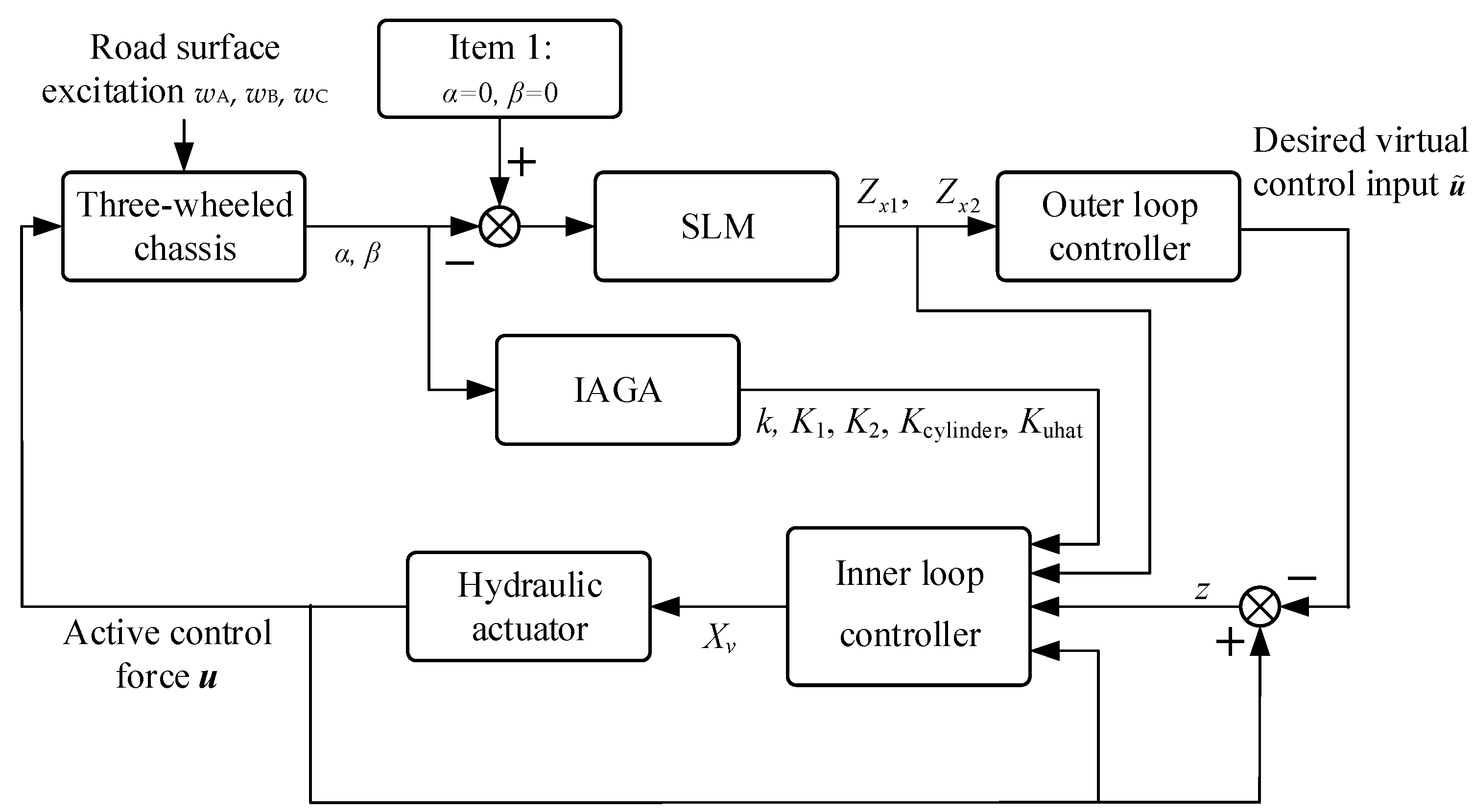

4. Chassis Leveling Control

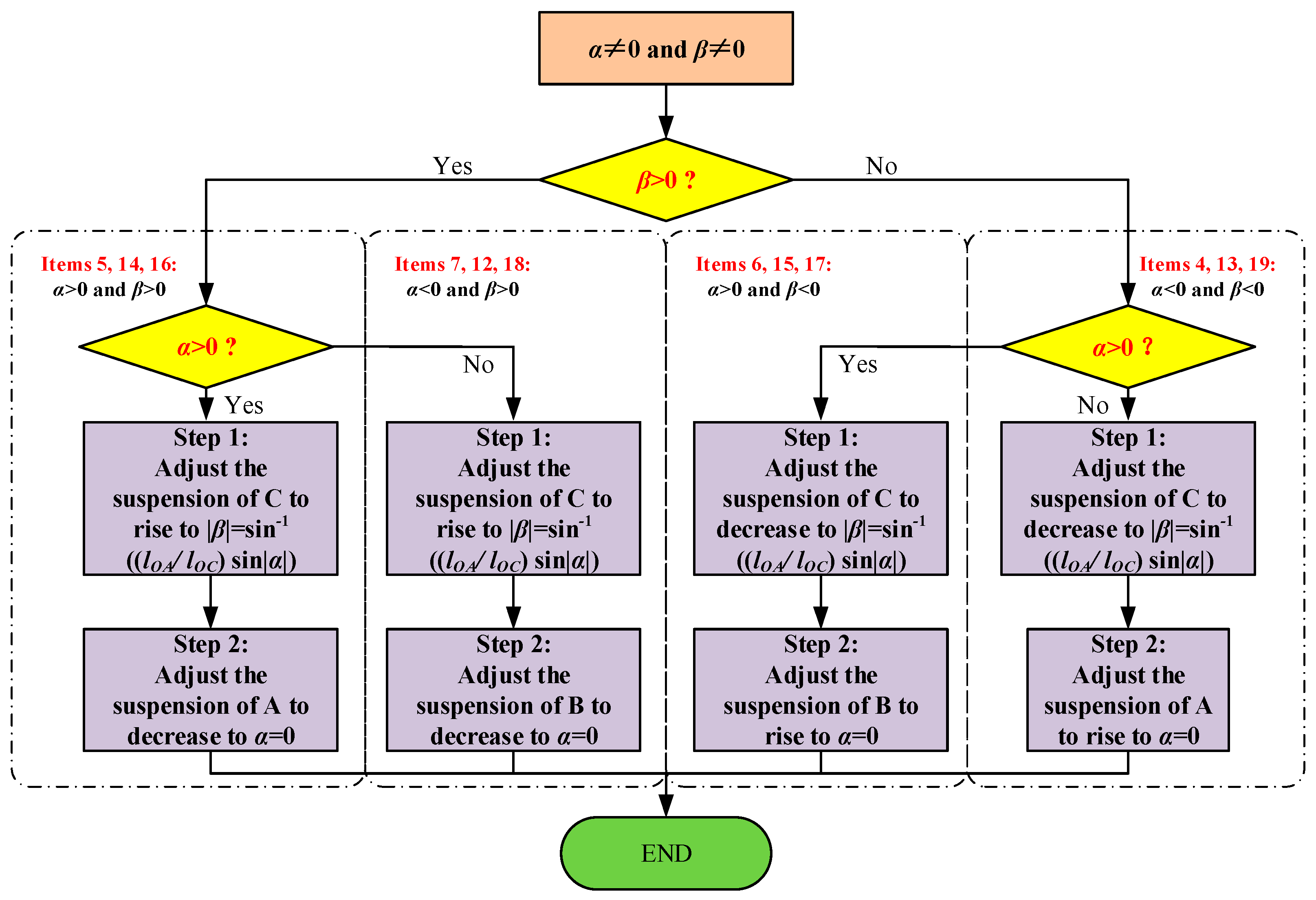

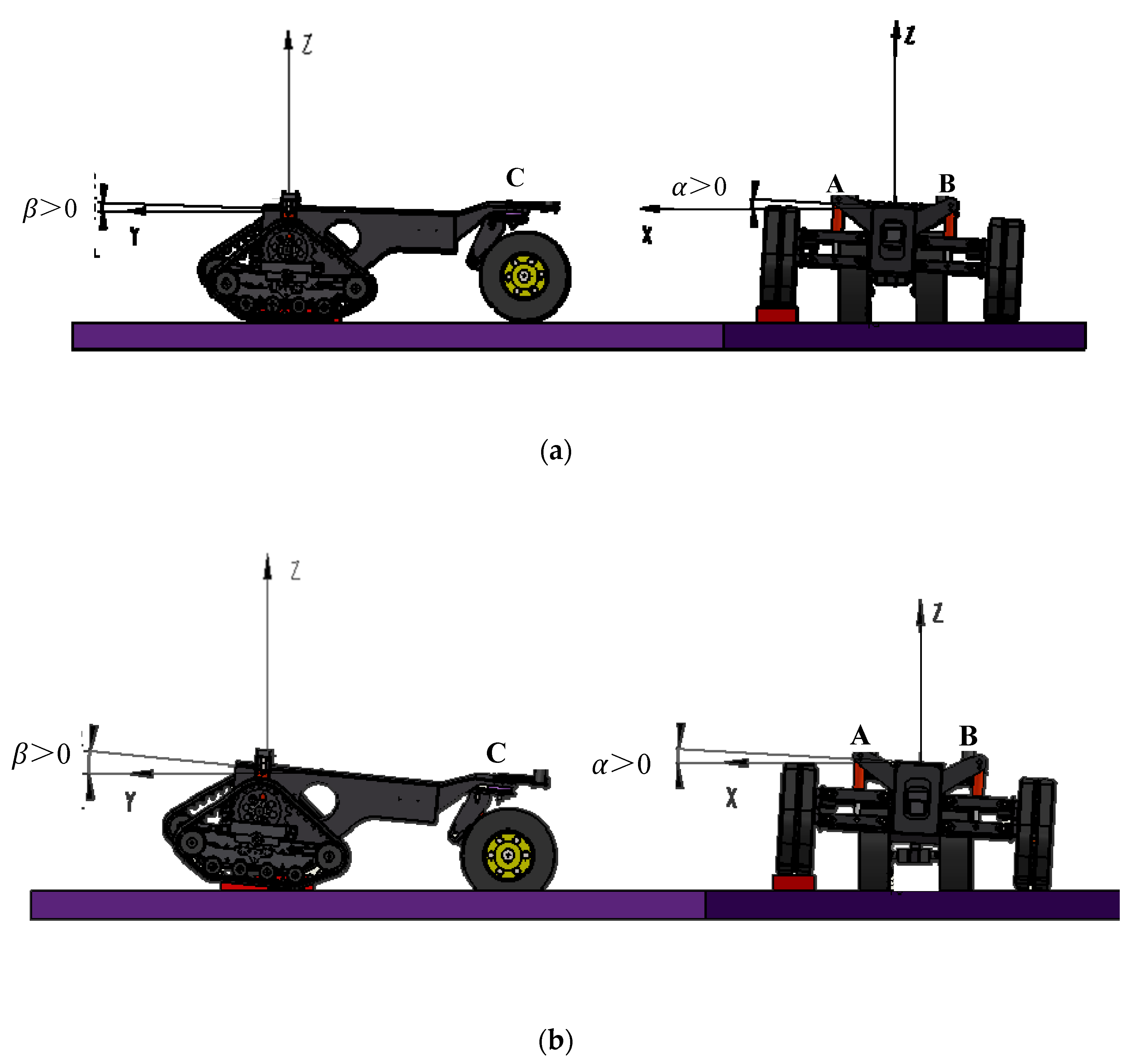

4.1. Chassis Stepwise Leveling Method

- (1)

- When the chassis maintains a level attitude while moving, α = 0 and β = 0, as shown in item 1 of the table.

- (2)

- When only one wheel is subjected to road excitation, the chassis has six attitudes, which are considered the basic attitudes of the chassis, as shown in items 2 to 7.

- (3)

- By combining any two of the aforementioned six basic chassis attitudes and then excluding the combinations that result in the horizontal attitude, an additional 12 chassis attitudes can be derived, as shown in items 8 to 19.

4.2. Adaptive Dual-Loop Composite Control Strategy (ADLCCS)

4.2.1. Design of the Outer-Loop Controller

4.2.2. Design of the Inner Loop Controller

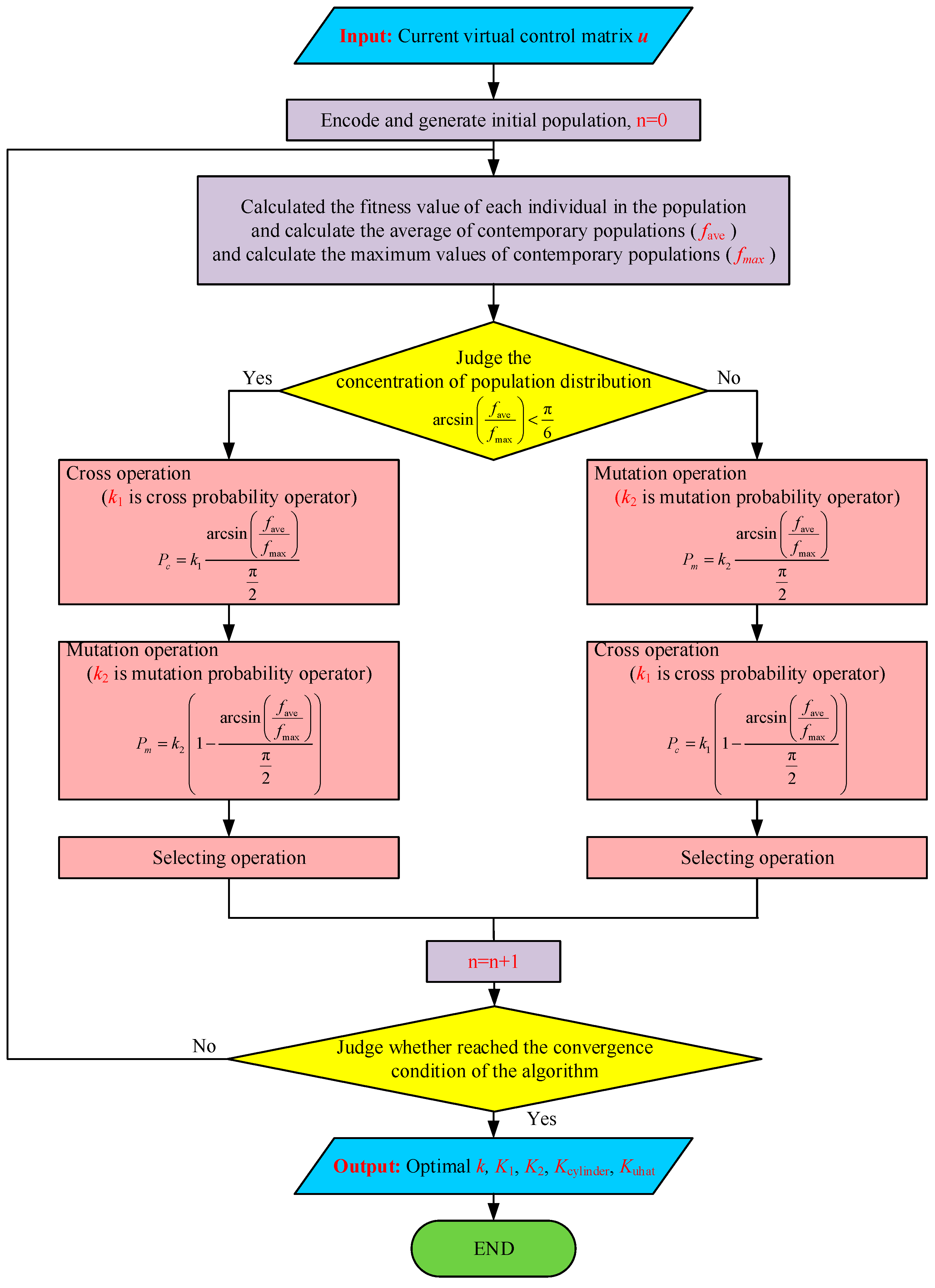

4.2.3. Adaptive Optimization of Control Parameters

- (1)

- Take the change matrix of the virtual control variable, , as the input, generate the initial optimization population, and perform encoding.

- (2)

- Use the objective function, Jk, to evaluate the fitness of each individual in the current population and calculate the average fitness (fave) and the maximum fitness (fmax) of the population.

- (3)

- Analyze the dispersion of the population to determine the evolutionary direction of the population: if the distribution is dispersed, proceed to step (4); if the distribution is concentrated, proceed to step (5).

- (4)

- In the case of a dispersed population distribution, generate a new generation of individuals: first perform crossover operations, then perform mutation operations, and finally complete the selection process.

- (5)

- In the case of a concentrated population distribution, generate a new generation of individuals: first perform mutation operations, then perform crossover operations, and finally complete the selection process.

- (6)

- Evaluate whether the current population meets the aggregation requirements: if it does, proceed to step (7); if not, return to step (2) for re-evaluation.

- (7)

- After optimization, output the optimal values of k, K1, K2, Kcylinder, and Kuhat corresponding to the change matrix of the current virtual control variable, .

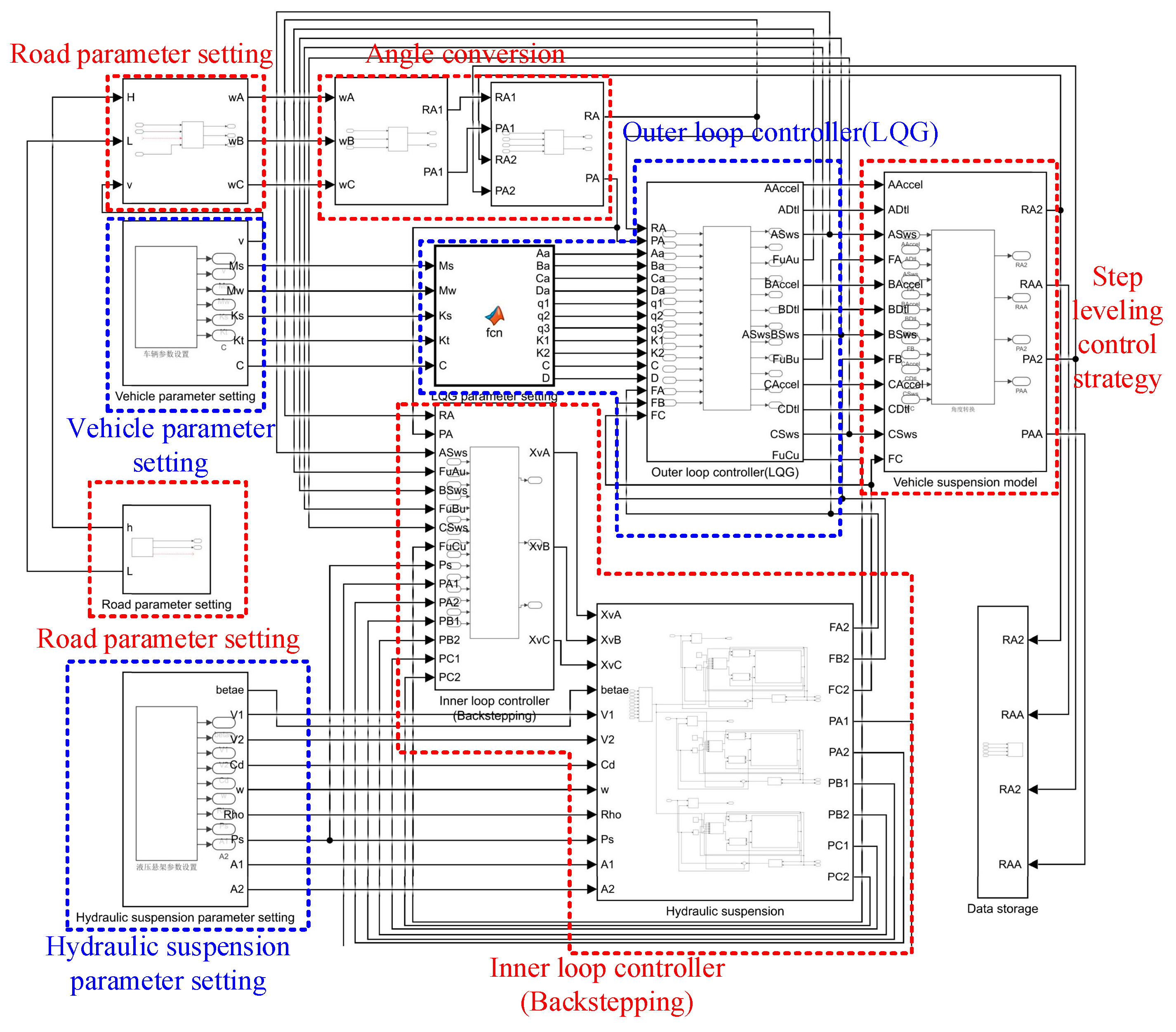

5. Simulation Study

5.1. Simulation Setup

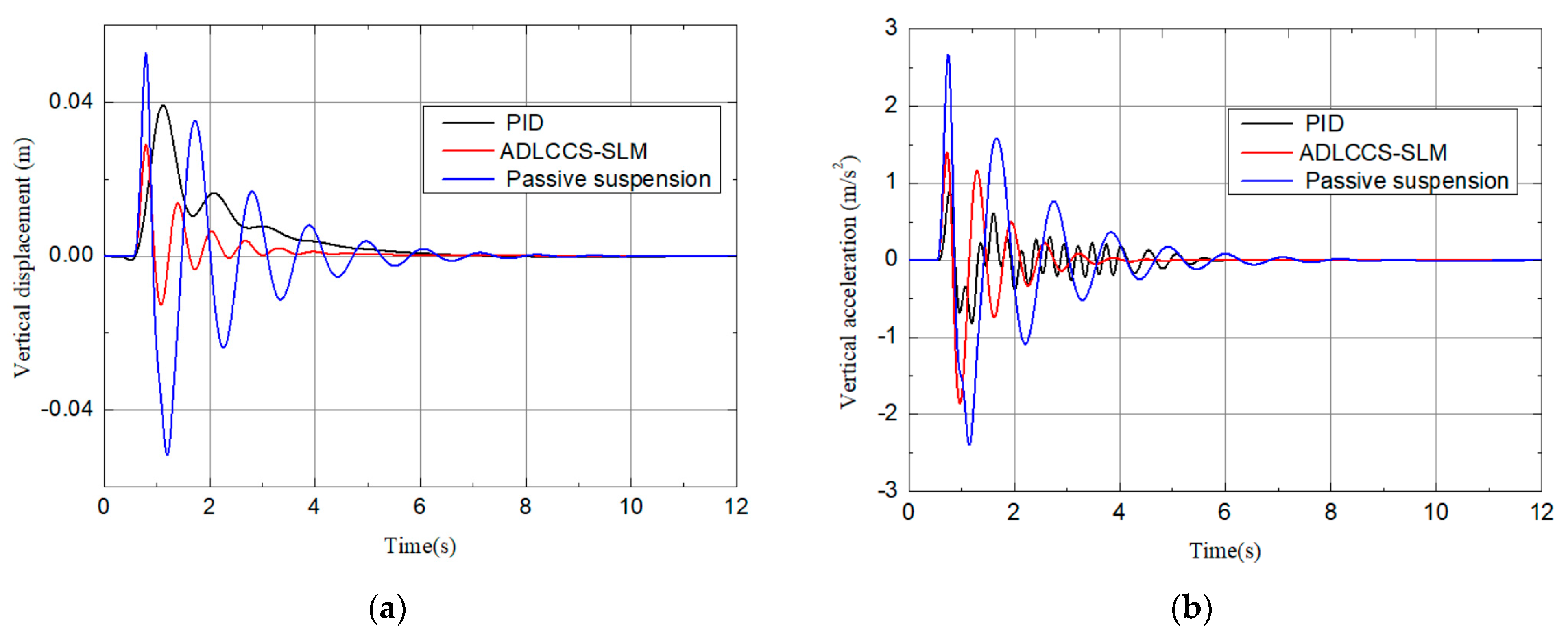

5.2. Comparison with Baseline Methods

5.3. Discussion

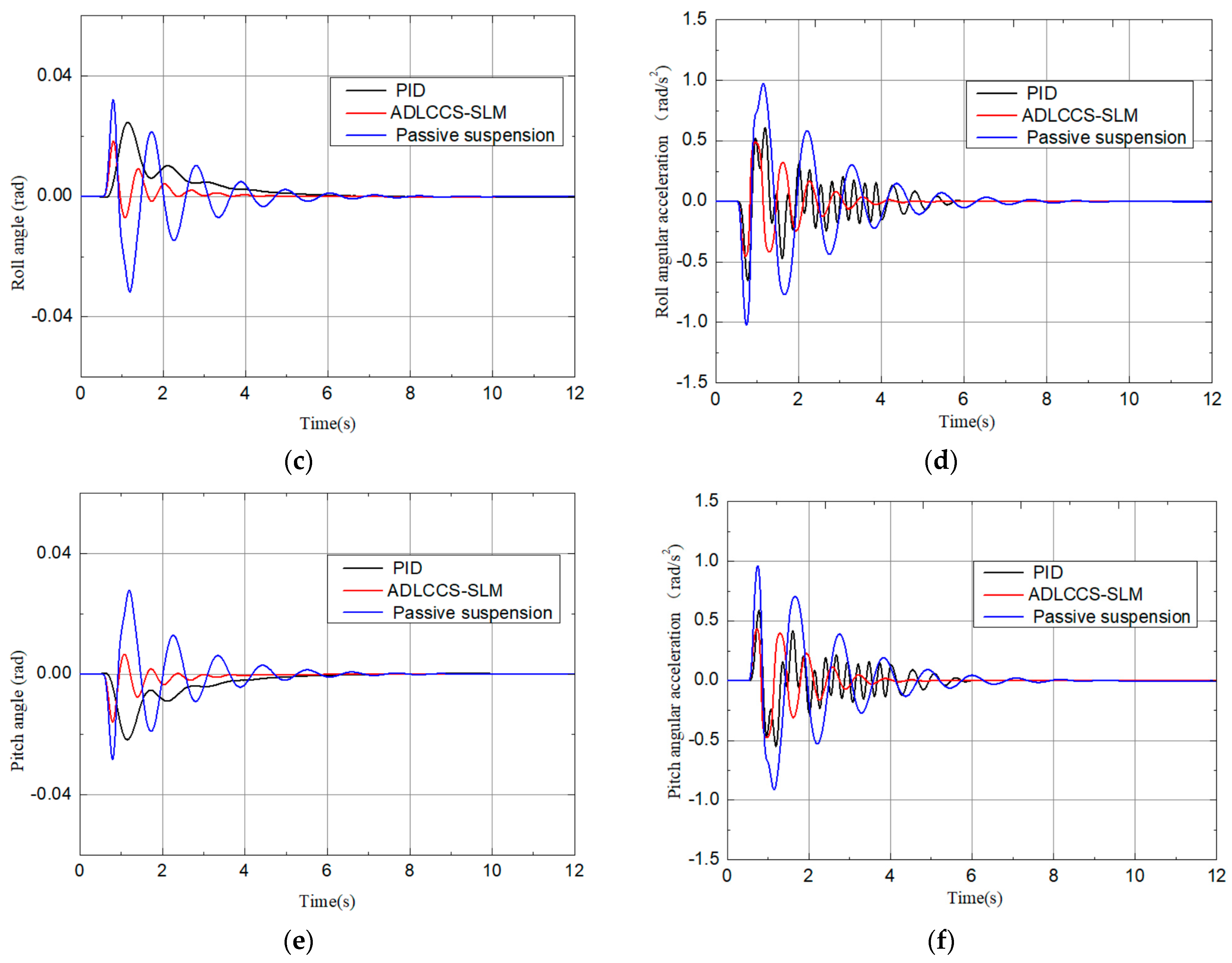

6. Test Verification

6.1. Test Setup

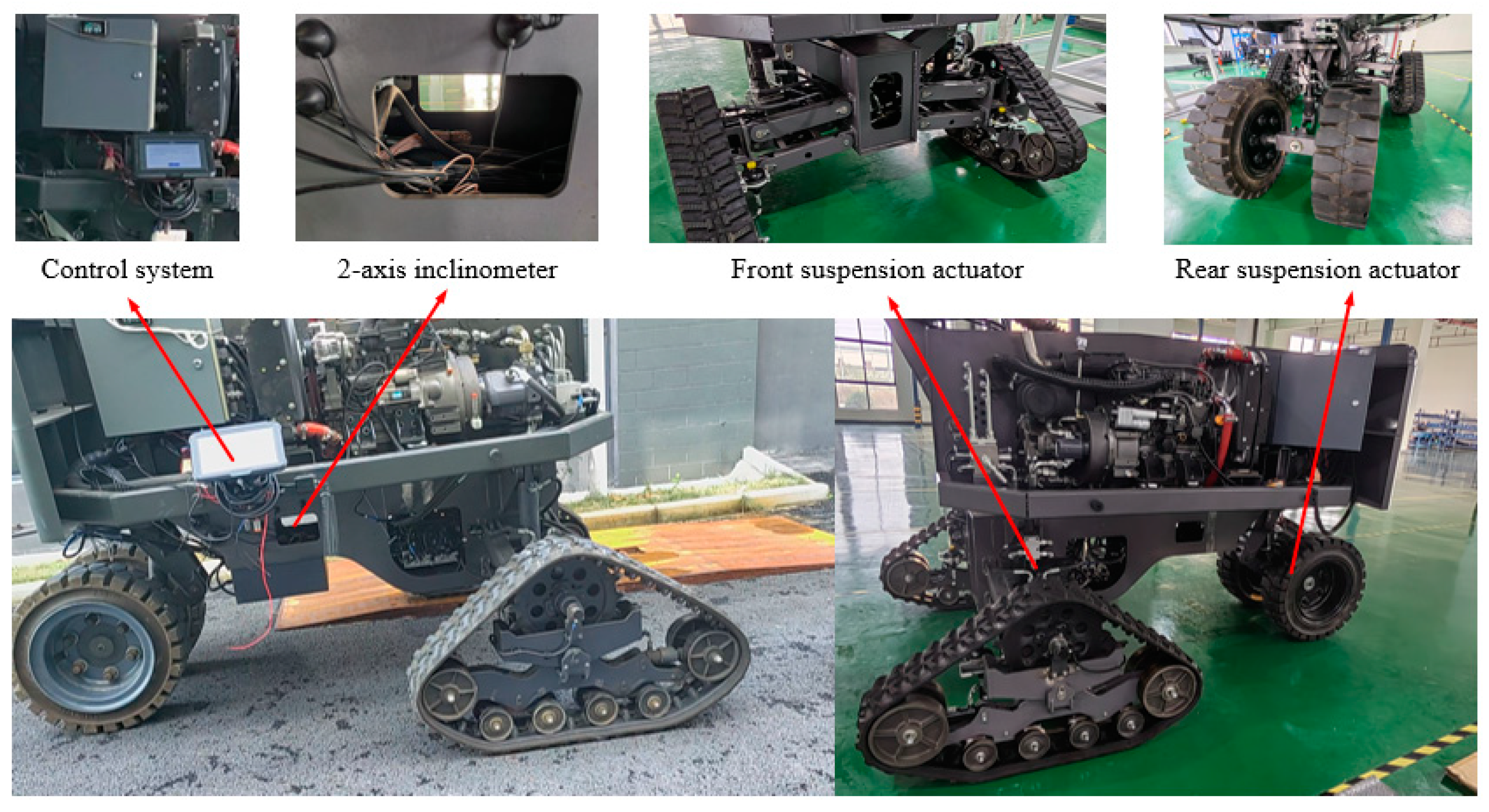

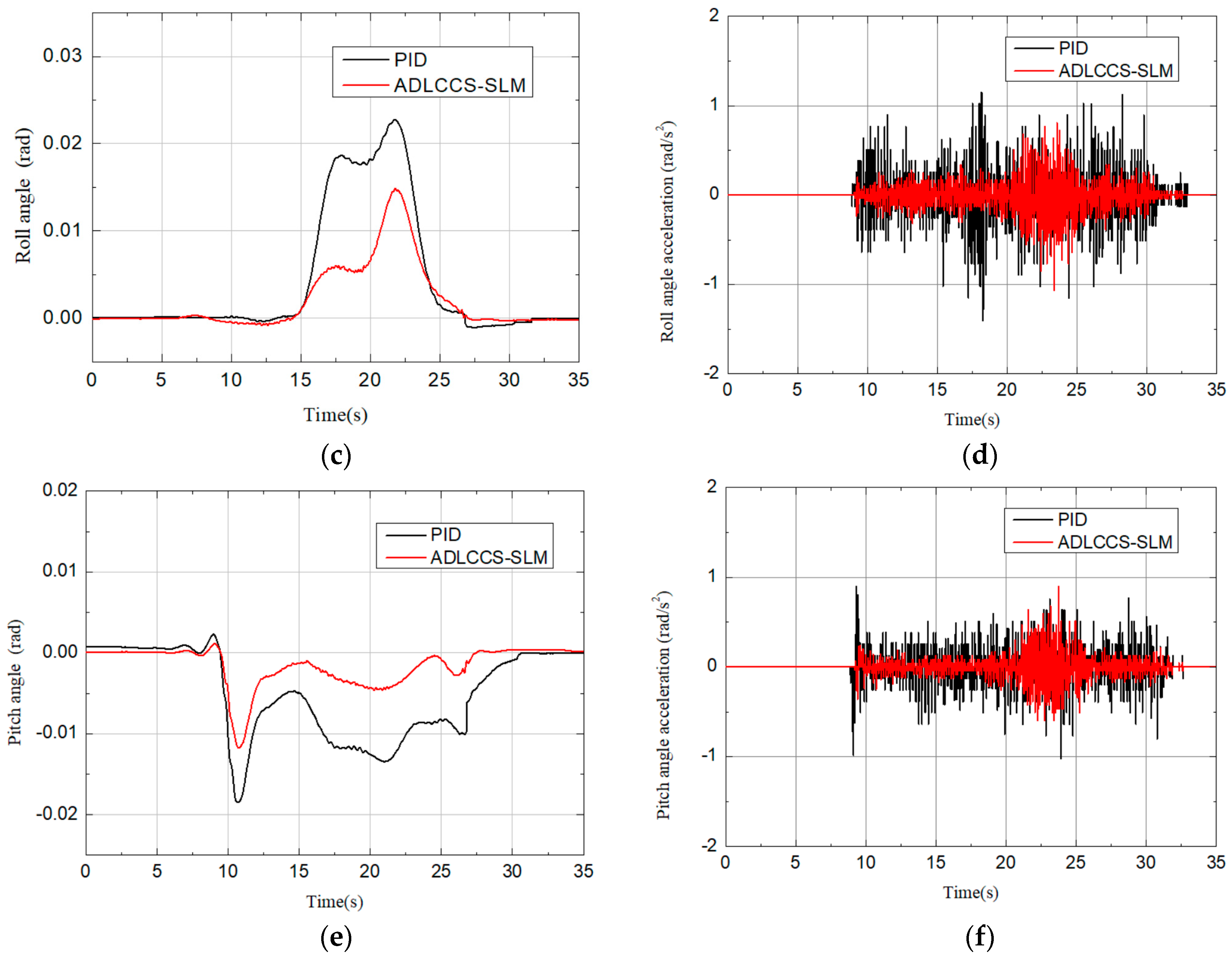

6.2. Comparison with Baseline Methods

6.3. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Derivation of the Suspension Structure Principle

Appendix B. Hydraulic Servo System Model of the Suspension Actuator

- (1)

- Valve flow equationTo simplify calculations, the following assumptions are made:

- (a)

- The supply pressure, Ps, is constant, and the return pressure, T, is zero;

- (b)

- Pressure losses in the pipes and valve chambers are neglected;

- (c)

- The flow coefficients of all throttling orifices of the servo valve are equal, denoted as Cd.

- (2)

- Hydraulic cylinder flow equationTo simplify calculations, the following assumptions are made:

- (a)

- Pressure losses and dynamic effects in the pipes are negligible;

- (b)

- The oil temperature and bulk modulus are constant;

- (c)

- Both internal and external leakage in the hydraulic cylinder are laminar.

- (3)

- Hydraulic cylinder force balance equation

References

- Dettù, F.; Corno, M.; D’Ambrosio, D.; Acquistapace, A.; Taroni, F.; Savaresi, S.M. Modeling, control design and experimental automatic calibration of a leveling system for combine harvesters. Control. Eng. Pract. 2023, 132, 105411. [Google Scholar] [CrossRef]

- Hu, J.; Pan, J.; Dai, B.; Chai, X.; Sun, Y.; Xu, L. Development of an attitude adjustment crawler chassis for combine harvester and Experiment of adaptive leveling system. Agronomy 2022, 12, 717. [Google Scholar] [CrossRef]

- Peng, H.; Ma, W.; Wang, Z.; Yuan, Z. Leveling Control of Hillside Tractor Body Based on Fuzzy Sliding Mode Variable Structure. Appl. Sci. 2023, 13, 6066. [Google Scholar] [CrossRef]

- Lü, X.; Liu, Z.; Lü, X.; Wang, X. Design and study on the leveling mechanism of the tractor body in hilly and mountainous areas. J. Eng. Des. Technol. 2024, 22, 679–689. [Google Scholar] [CrossRef]

- Jin, X.; Wang, J.; Yan, Z.; Xu, L.; Yin, G.; Chen, N. Robust vibration control for active suspension system of in-wheel-motor-driven electric vehicle via μ-synthesis methodology. J. Dyn. Syst. Meas. Control. 2022, 144, 051007. [Google Scholar] [CrossRef]

- Liu, S.; Zheng, T.; Zhao, D.; Hao, R.; Yang, M. Strongly perturbed sliding mode adaptive control of vehicle active suspension system considering actuator nonlinearity. Veh. Syst. Dyn. 2022, 60, 597–616. [Google Scholar] [CrossRef]

- Han, S.-Y.; Dong, J.-F.; Zhou, J.; Chen, Y.-H. Adaptive fuzzy PID control strategy for vehicle active suspension based on road evaluation. Electronics 2022, 11, 921. [Google Scholar] [CrossRef]

- Jayaraman, T.; Thangaraj, M. Standalone and interconnected analysis of an independent accumulator pressure compressibility hydro-pneumatic suspension for the Four-Axle Heavy Truck. Actuators 2023, 12, 347. [Google Scholar] [CrossRef]

- Chen, H.; Gong, M.; Zhao, D.; Zhu, J. Body attitude control strategy based on road level for heavy rescue vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 1351–1363. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, L.; Chen, M.; Yang, C.; Zhang, J.; Wang, J. Multiple Suspensions Coordinated Control for Corner Module Architecture Intelligent Electric Vehicles on Stepped Roads. IEEE Trans. Intell. Veh. 2024. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, S.; Wu, G.; Ding, H.; Zhang, Z.; Guo, K. Fast distributed model predictive control method for active suspension systems. Sensors 2023, 23, 3357. [Google Scholar] [CrossRef] [PubMed]

- Hamza, A.; Ben Yahia, N. Artificial neural networks controller of active suspension for ambulance based on ISO standards. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 34–47. [Google Scholar] [CrossRef]

- Fu, B.; Liu, B.; Di Gialleonardo, E.; Bruni, S. Semi-active control of primary suspensions to improve ride quality in a high-speed railway vehicle. Veh. Syst. Dyn. 2023, 61, 2664–2688. [Google Scholar] [CrossRef]

- Li, J.; Wang, J.; Chen, Y.; Si, E. Optimization of Suspension Active Control System Based on Improved Genetic Algorithm. In Proceedings of the 2023 7th International Conference on Electrical, Mechanical and Computer Engineering (ICEMCE), Xi’an, China, 25–27 October 2024; pp. 737–740. [Google Scholar]

- Jin, X.; Wang, J.; He, X.; Yan, Z.; Xu, L.; Wei, C.; Yin, G. Improving vibration performance of electric vehicles based on in-wheel motor-active suspension system via robust finite frequency control. IEEE Trans. Intell. Transp. Syst. 2023, 24, 1631–1643. [Google Scholar] [CrossRef]

- Ding, R.; Wang, R.; Meng, X.; Chen, L. Research on time-delay-dependent H∞/H2 optimal control of magnetorheological semi-active suspension with response delay. J. Vib. Control. 2023, 29, 1447–1458. [Google Scholar] [CrossRef]

- Maciejewski, I.; Blazejewski, A.; Pecolt, S.; Krzyzynski, T. A sliding mode control strategy for active horizontal seat suspension under realistic input vibration. J. Vib. Control. 2023, 29, 2539–2551. [Google Scholar] [CrossRef]

- Chen, G.; Jiang, Y.; Tang, Y.; Xu, X. Revised adaptive active disturbance rejection sliding mode control strategy for vertical stability of active hydro-pneumatic suspension. ISA Trans. 2023, 132, 490–507. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.A. A novel approach with a fuzzy sliding mode proportional integral control algorithm tuned by fuzzy method (FSMPIF). Sci. Rep. 2023, 13, 7327. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Zhao, D.; Zhao, X.; Qin, Y. Nonlinear adaptive back-stepping optimization control of the hydraulic active suspension actuator. Processes 2023, 11, 2020. [Google Scholar] [CrossRef]

- Nguyen, H.L.T. Lyapunov-based Design of a Model Reference Adaptive Control for Half-Car Active Suspension Systems. Meas. Control. Autom. 2024, 5, 22–29. [Google Scholar]

| Symbol | Description |

|---|---|

| Zb | Vehicle body centroid vertical displacement |

| α | Roll angle of the three-wheeled agricultural robot |

| β | Pitch angle of the three-wheeled agricultural robot |

| ZA1 | Sprung mass displacement at the left front wheel |

| ZB1 | Sprung mass displacement at the right front wheel |

| ZC1 | Sprung mass displacement at the rear wheel |

| ZA2 | Wheel displacement of the left front wheel |

| ZB2 | Wheel displacement of the right front wheel |

| ZC2 | Wheel displacement of the rear wheel |

| wA | Road excitation of the left front wheel |

| wB | Road excitation of the right front wheel |

| wC | Road excitation of the rear wheel |

| FA1 | Force of the left front wheel suspension on the chassis |

| FB1 | Force of the right front wheel suspension on the chassis |

| FC1 | Force of the rear wheel suspension on the chassis |

| FA2 | Controllable forces provided by the left front wheel suspension hydraulic actuators |

| FB2 | Controllable forces provided by the right front wheel suspension hydraulic actuators |

| FC2 | Controllable forces provided by the rear wheel suspension hydraulic actuators |

| cA | Left front wheel suspension damping coefficients |

| cB | Right front wheel suspension damping coefficients |

| cC | Rear wheel suspension damping coefficients |

| ksA | Left front wheel suspension spring stiffness |

| ksB | Right front wheel suspension spring stiffness |

| ksC | Rear wheel suspension spring stiffness |

| ktA | Left front wheel tire stiffness |

| ktB | Right front wheel tire stiffness |

| ktC | Rear wheel tire stiffness |

| Ms | Sprung mass of the three-wheeled chassis |

| Mw | Unsprung mass of the three-wheeled chassis |

| MA1 | Sprung mass at the left front wheel |

| MB1 | Sprung mass at the right front wheel |

| MC1 | Sprung mass at the rear wheel |

| MA2 | Unsprung mass at the left front wheel |

| MB2 | Unsprung mass at the right front wheel |

| MC2 | Unsprung mass at the rear wheel |

| lf | Distance between the two front wheel suspensions |

| lb | Distance between the center of the two front wheel suspensions and the rear wheel suspension |

| lbf | Distance between the vehicle body centroid and the center of the two front wheel suspensions |

| lbr | Distance between the vehicle body centroid and the rear wheel suspension |

| Ix | Pitch moment of inertia |

| Iy | Roll moment of inertia |

| Mx | Pitch moment of the vehicle body |

| My | Roll moment of the vehicle body |

| Xv | Valve spool displacement |

| Ps | Supply pressure |

| P1 | Pressure in the rodless chamber |

| P2 | Pressure in the rod chamber |

| ρ | Fluid density |

| ω | Valve port area gradient |

| Cd | Flow coefficient of the throttling orifice |

| V1 | Volume of the rodless chamber of the hydraulic cylinder |

| V2 | Volume of the rod chamber of the hydraulic cylinder |

| A1 | Effective piston area of the rodless chamber |

| A2 | Effective piston area of the rod chamber |

| βe | Effective bulk modulus |

| Item | ∆A | ∆B | ∆C | α | β | Chassis Attitude Classification Based on Angles α and β |

|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 0 | 0 | α = 0, β = 0 |

| 2 | 0 | 0 | −1 | 0 | + | α = 0, β > 0 |

| 3 | 0 | 0 | 1 | 0 | − | α = 0, β < 0 |

| 4 | −1 | 0 | 0 | − | − | α < 0, β < 0 |

| 5 | 1 | 0 | 0 | + | + | α > 0, β > 0 |

| 6 | 0 | −1 | 0 | + | − | α > 0, β < 0 |

| 7 | 0 | 1 | 0 | − | + | α < 0, β > 0 |

| 8 | −1 | −1 | 0 | 0 | − | α = 0, β < 0 |

| 9 | 1 | 1 | 0 | 0 | + | α = 0, β > 0 |

| 10 | 1 | −1 | 0 | + | 0 | α > 0, β = 0 |

| 11 | −1 | 1 | 0 | − | 0 | α < 0, β = 0 |

| 12 | −1 | 0 | −1 | − | + | α < 0, β > 0 |

| 13 | −1 | 0 | 1 | − | − | α < 0, β < 0 |

| 14 | 1 | 0 | −1 | + | + | α > 0, β > 0 |

| 15 | 1 | 0 | 1 | + | − | α > 0, β < 0 |

| 16 | 0 | −1 | −1 | + | + | α > 0, β > 0 |

| 17 | 0 | −1 | 1 | + | − | α > 0, β < 0 |

| 18 | 0 | 1 | −1 | − | + | α < 0, β > 0 |

| 19 | 0 | 1 | 1 | − | − | α < 0, β < 0 |

| Variables | Values | Units | Variables | Values | Units | Variables | Values | Units |

|---|---|---|---|---|---|---|---|---|

| Ms | 1250 | kg | Mw | 400 | kg | 0.00098 | m3 | |

| ks | 20,000 | N/m | c | 1000 | N·s·m⁻¹ | 0.00035 | m3 | |

| kt | 2 × 105 | N/m | h | 0.1 | m | 7 × 108 | Pa | |

| 1.6 × 107 | Pa | 0.6 | — | L | 2 | m | ||

| Ix | 525.5 | kg·m2 | Iy | 625.5 | kg·m2 | 900 | kg/m3 | |

| 0.00196 | m2 | Lb | 1.84 | m | lbf | 0.55 | m | |

| 0.0007 | m2 | Lf | 1.62 | m | lbr | 1.29 | m | |

| 1 | m/s | 0.0015 | m |

| Leveling Method | Vertical Displacement (m) | Roll Angle (rad) | Pitch Angle (rad) |

|---|---|---|---|

| Passive suspension | 0.052 | 0.032 | 0.028 |

| PID | 0.041 | 0.025 | 0.022 |

| ADLCCS-SLM | 0.029 | 0.018 | 0.016 |

| Leveling Method | Vertical Displacement (m) | Roll Angle (rad) | Pitch Angle (rad) |

|---|---|---|---|

| PID | 0.035 | 0.022 | 0.018 |

| ADLCCS-SLM | 0.020 | 0.015 | 0.012 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Yang, J.; Zhong, Y.; Zhang, C.; Gao, Y. Study on Chassis Leveling Control of a Three-Wheeled Agricultural Robot. Agronomy 2024, 14, 1765. https://doi.org/10.3390/agronomy14081765

Zhao X, Yang J, Zhong Y, Zhang C, Gao Y. Study on Chassis Leveling Control of a Three-Wheeled Agricultural Robot. Agronomy. 2024; 14(8):1765. https://doi.org/10.3390/agronomy14081765

Chicago/Turabian StyleZhao, Xiaolong, Jing Yang, Yuhang Zhong, Chengfei Zhang, and Yingjie Gao. 2024. "Study on Chassis Leveling Control of a Three-Wheeled Agricultural Robot" Agronomy 14, no. 8: 1765. https://doi.org/10.3390/agronomy14081765

APA StyleZhao, X., Yang, J., Zhong, Y., Zhang, C., & Gao, Y. (2024). Study on Chassis Leveling Control of a Three-Wheeled Agricultural Robot. Agronomy, 14(8), 1765. https://doi.org/10.3390/agronomy14081765