Figure 1.

Classification corn seed shapes. (a) Horse tooth; (b) spherical cone; (c) spherical; (d) oblate; (e) irregular.

Figure 1.

Classification corn seed shapes. (a) Horse tooth; (b) spherical cone; (c) spherical; (d) oblate; (e) irregular.

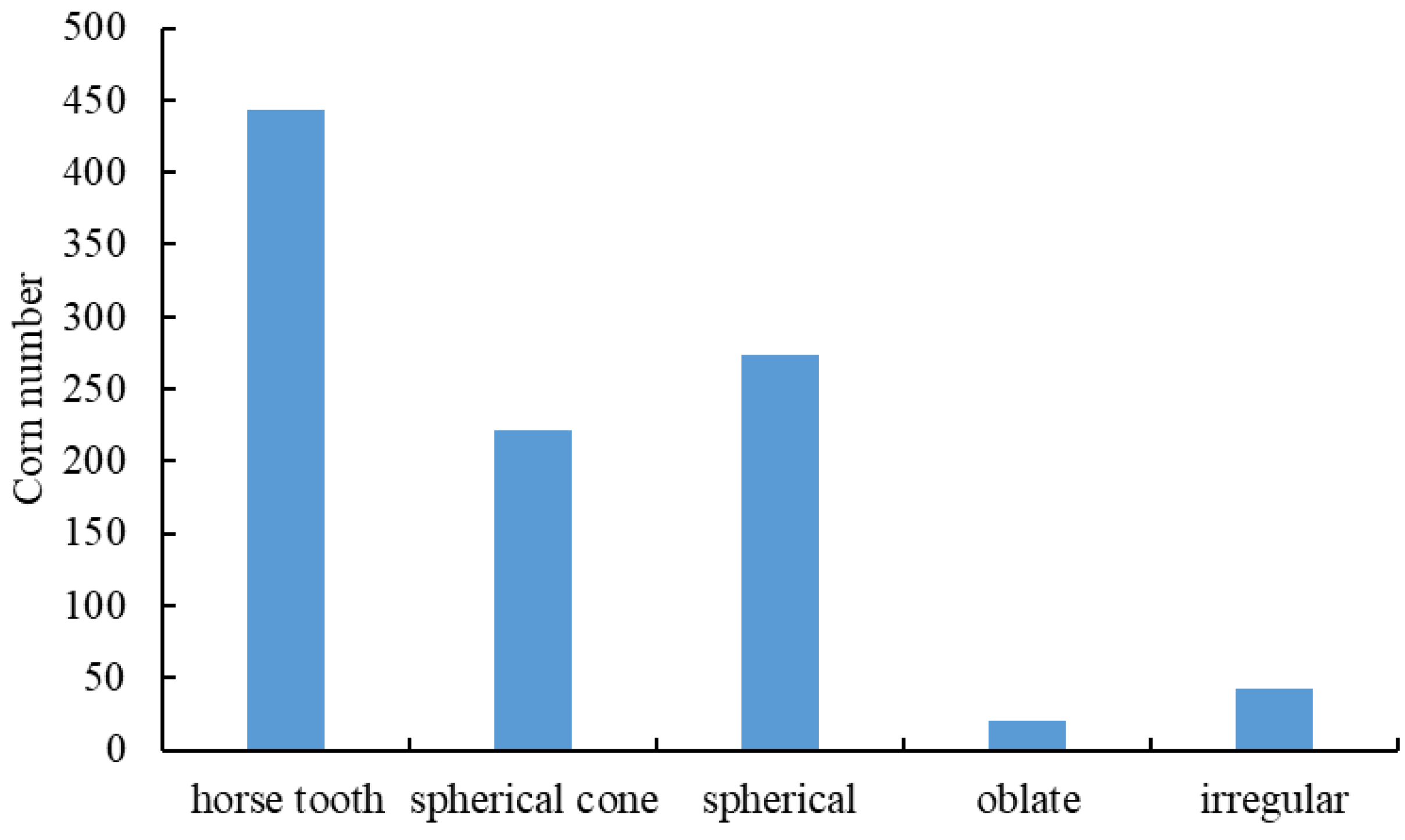

Figure 2.

Number counted for each of the five corn seed shapes.

Figure 2.

Number counted for each of the five corn seed shapes.

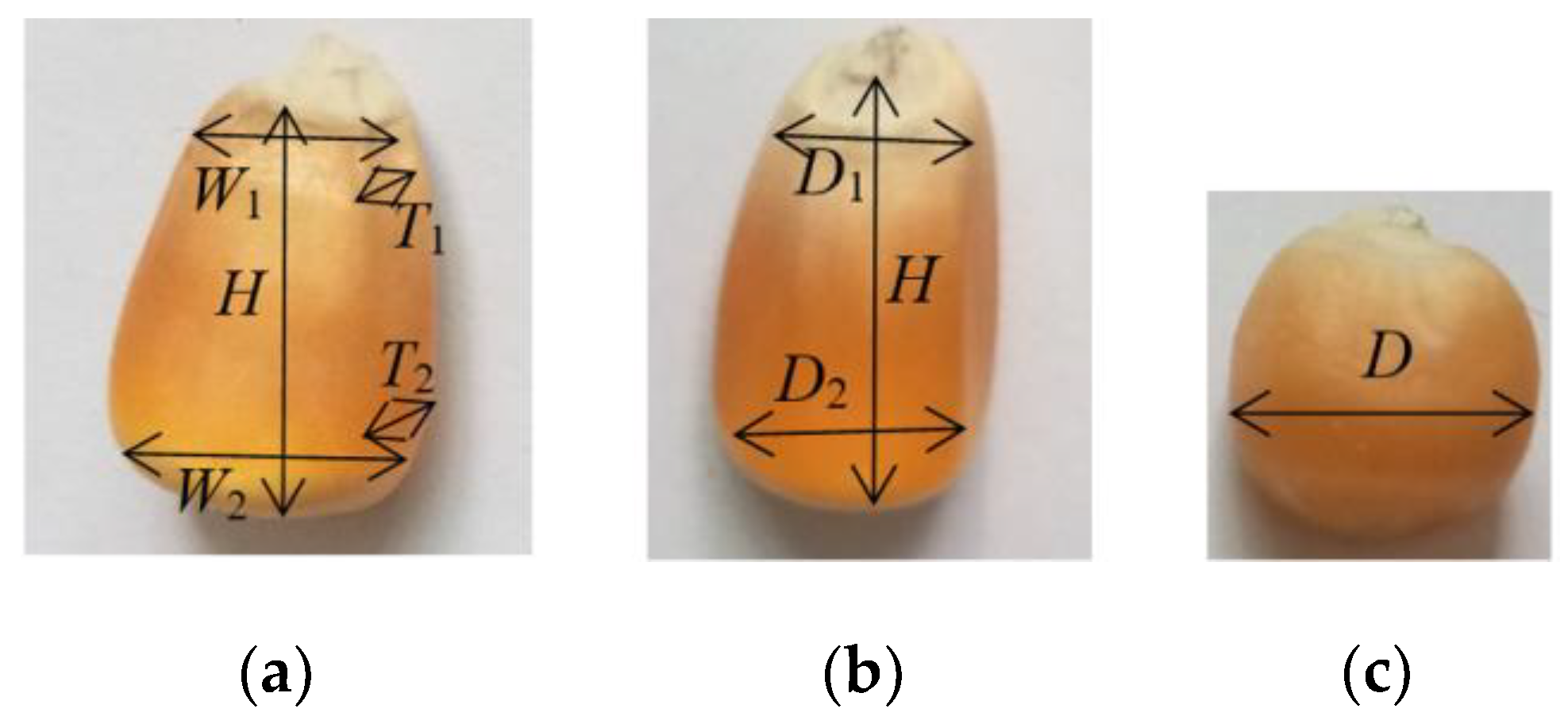

Figure 3.

Characteristic dimensions of corn seeds. (a) Horse tooth; (b) spherical cone; (c) spherical.

Figure 3.

Characteristic dimensions of corn seeds. (a) Horse tooth; (b) spherical cone; (c) spherical.

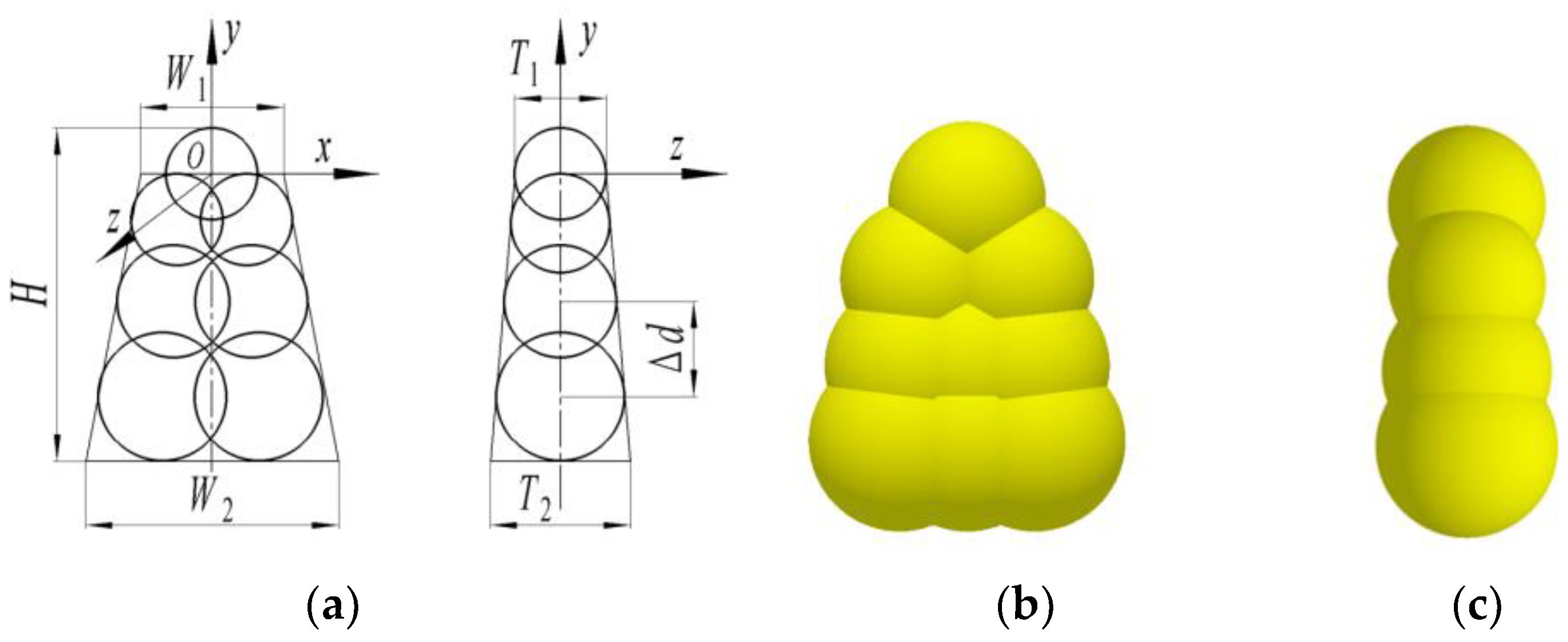

Figure 4.

Horse tooth corn seed model. (a) Feature size; (b) main view; (c) left view.

Figure 4.

Horse tooth corn seed model. (a) Feature size; (b) main view; (c) left view.

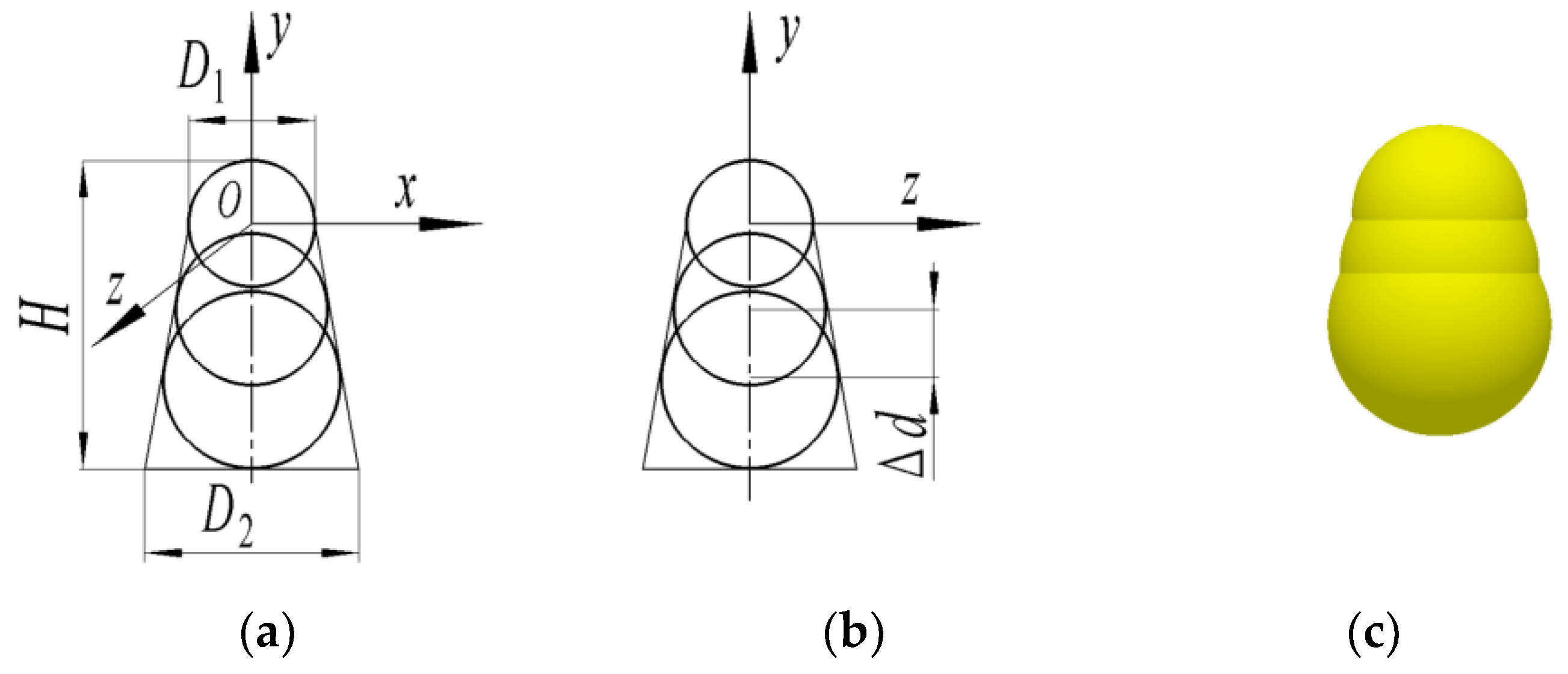

Figure 5.

Spherical cone corn seed model. (a) Feature size; (b) main view; (c) left view.

Figure 5.

Spherical cone corn seed model. (a) Feature size; (b) main view; (c) left view.

Figure 6.

Spherically shaped corn seed model.

Figure 6.

Spherically shaped corn seed model.

Figure 7.

Volume measurement of 3 shape types of corn seed. (a) Spherical (100 mm); (b) spherical cone (105 mm); (c) horse tooth (110 mm).

Figure 7.

Volume measurement of 3 shape types of corn seed. (a) Spherical (100 mm); (b) spherical cone (105 mm); (c) horse tooth (110 mm).

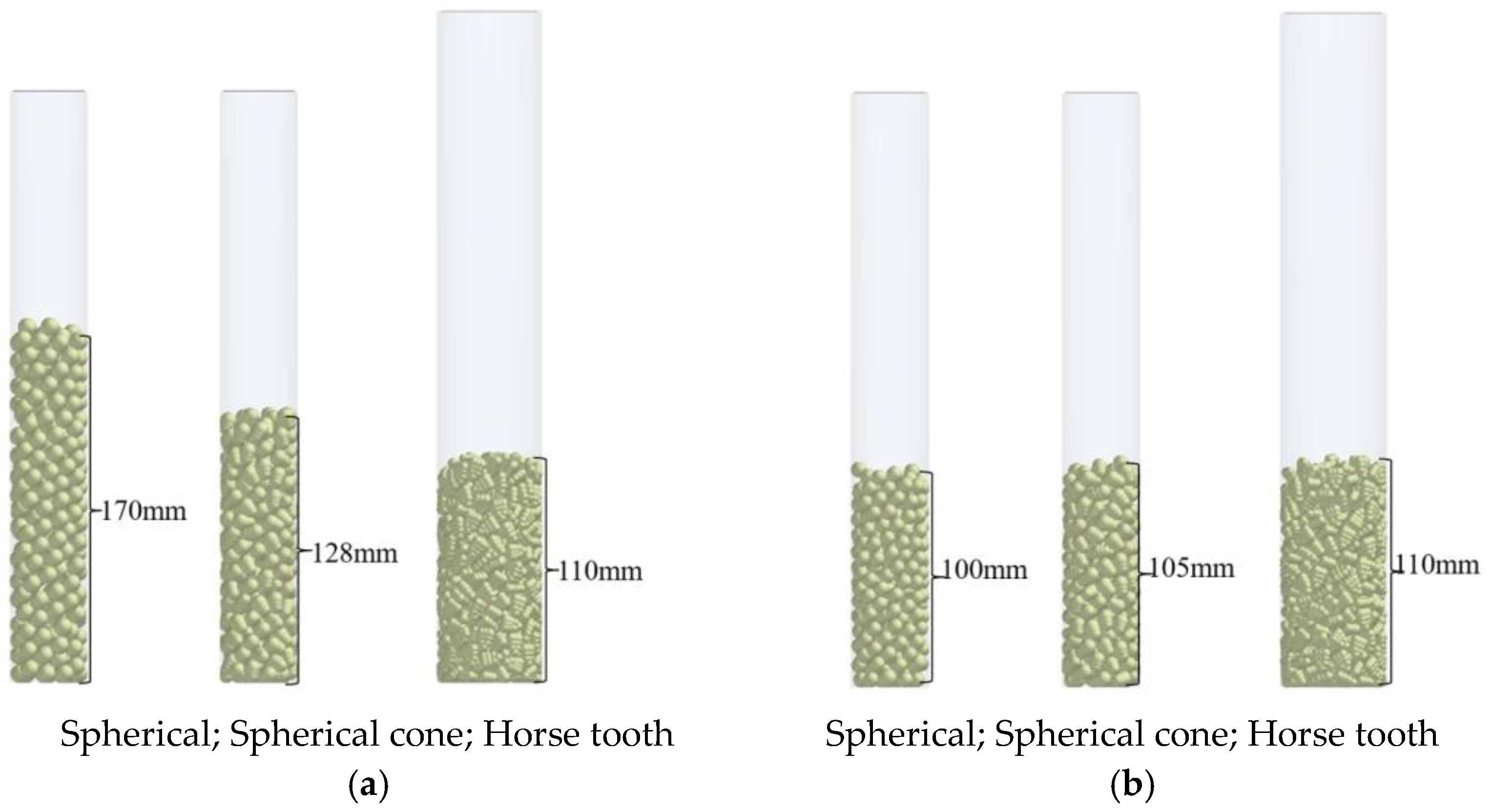

Figure 8.

Volume calibration of the model of 3 shape types of corn seed. (a) Before adjustment; (b) after adjustment.

Figure 8.

Volume calibration of the model of 3 shape types of corn seed. (a) Before adjustment; (b) after adjustment.

Figure 9.

Variation of 3 shape types of corn seed volume with normal distribution values.

Figure 9.

Variation of 3 shape types of corn seed volume with normal distribution values.

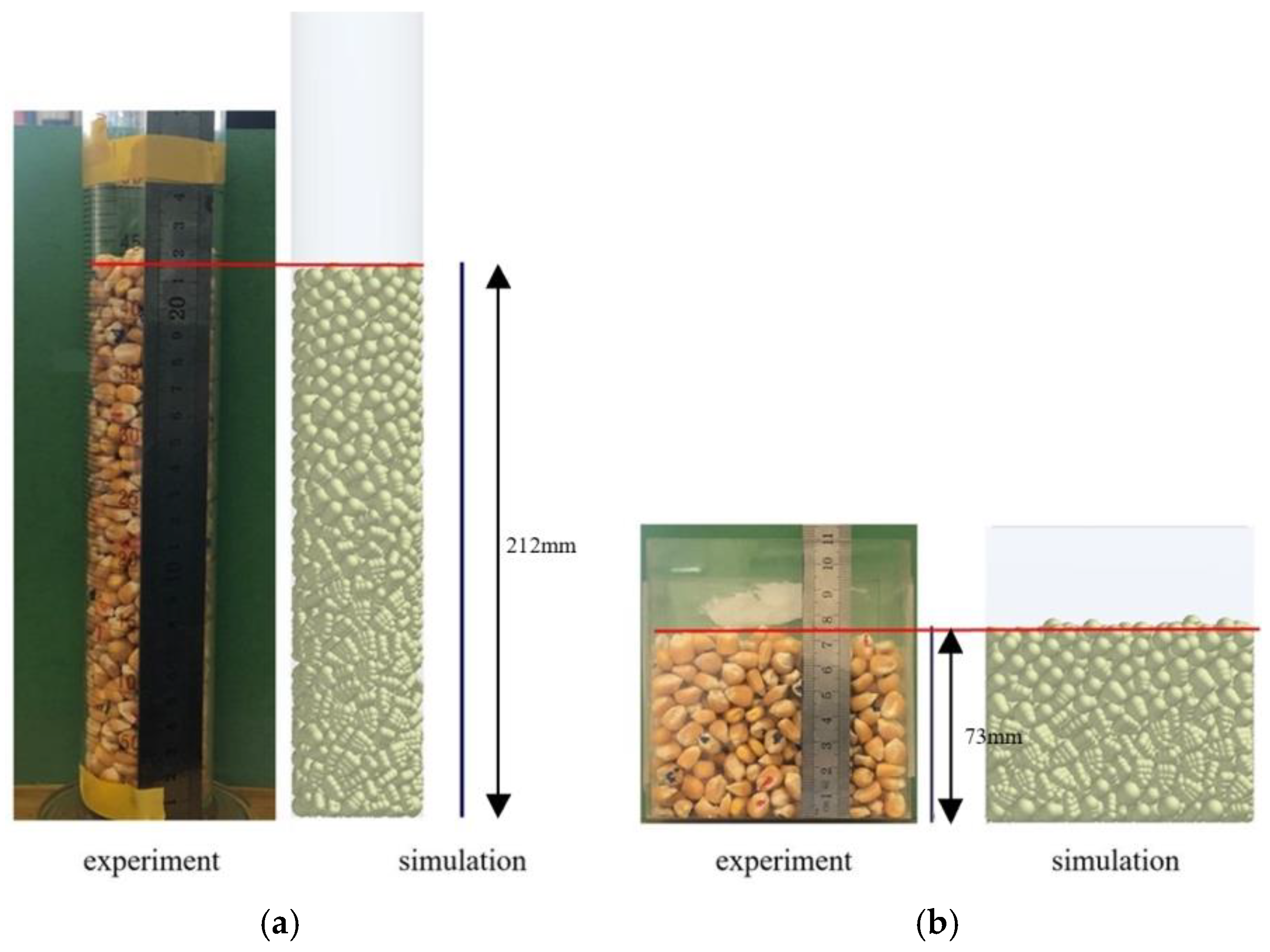

Figure 10.

Volume verification of mixed corn seeds in two types of container. (a) Measuring cylinder; (b) Plexiglas box.

Figure 10.

Volume verification of mixed corn seeds in two types of container. (a) Measuring cylinder; (b) Plexiglas box.

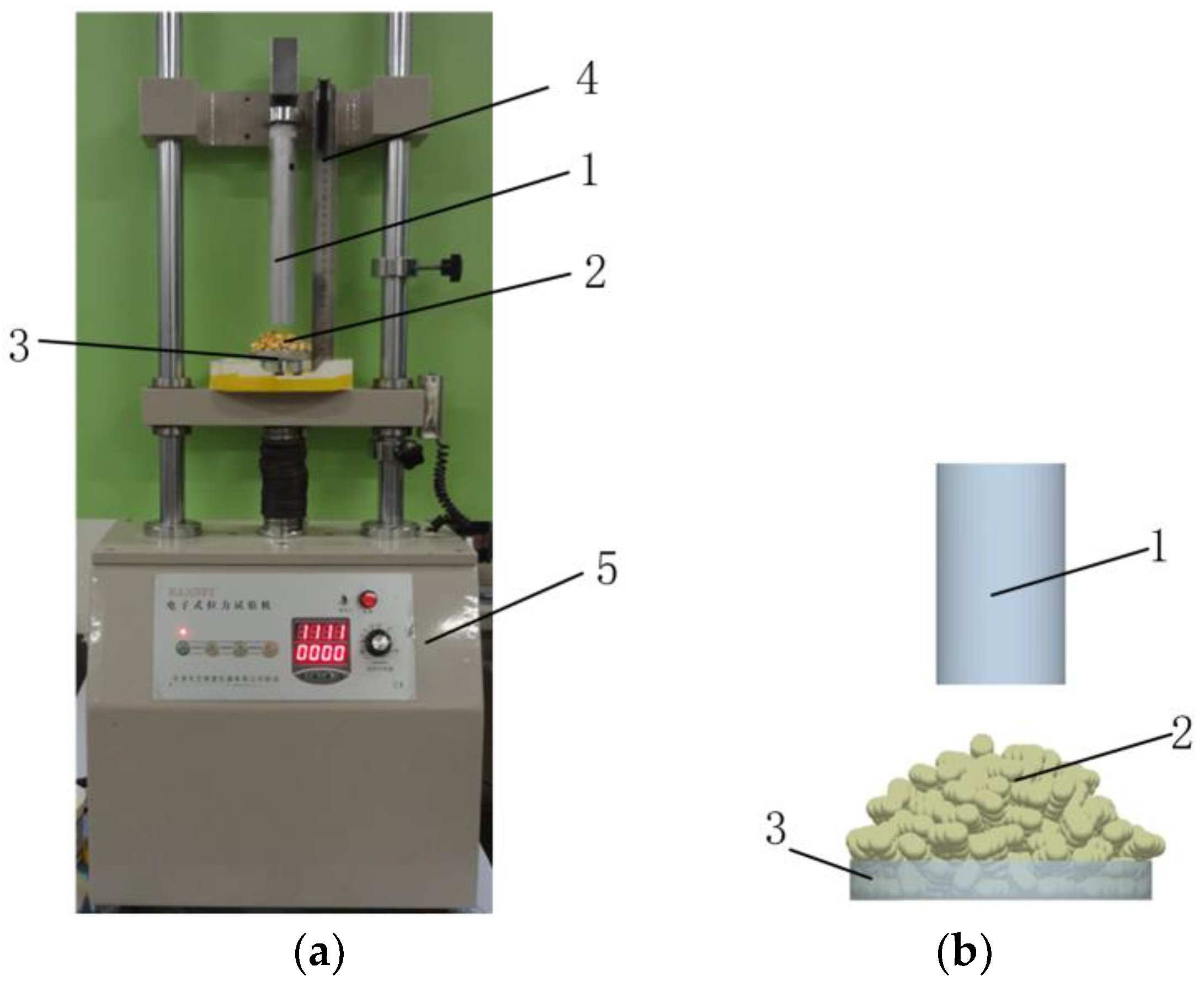

Figure 11.

Device for determining the repose angle of corn seeds. (a) Experiment; (b) simulation. 1. Aluminum cylinder; 2. corn seed model; 3. sump; 4. ruler; 5. digital display push–pull instrument.

Figure 11.

Device for determining the repose angle of corn seeds. (a) Experiment; (b) simulation. 1. Aluminum cylinder; 2. corn seed model; 3. sump; 4. ruler; 5. digital display push–pull instrument.

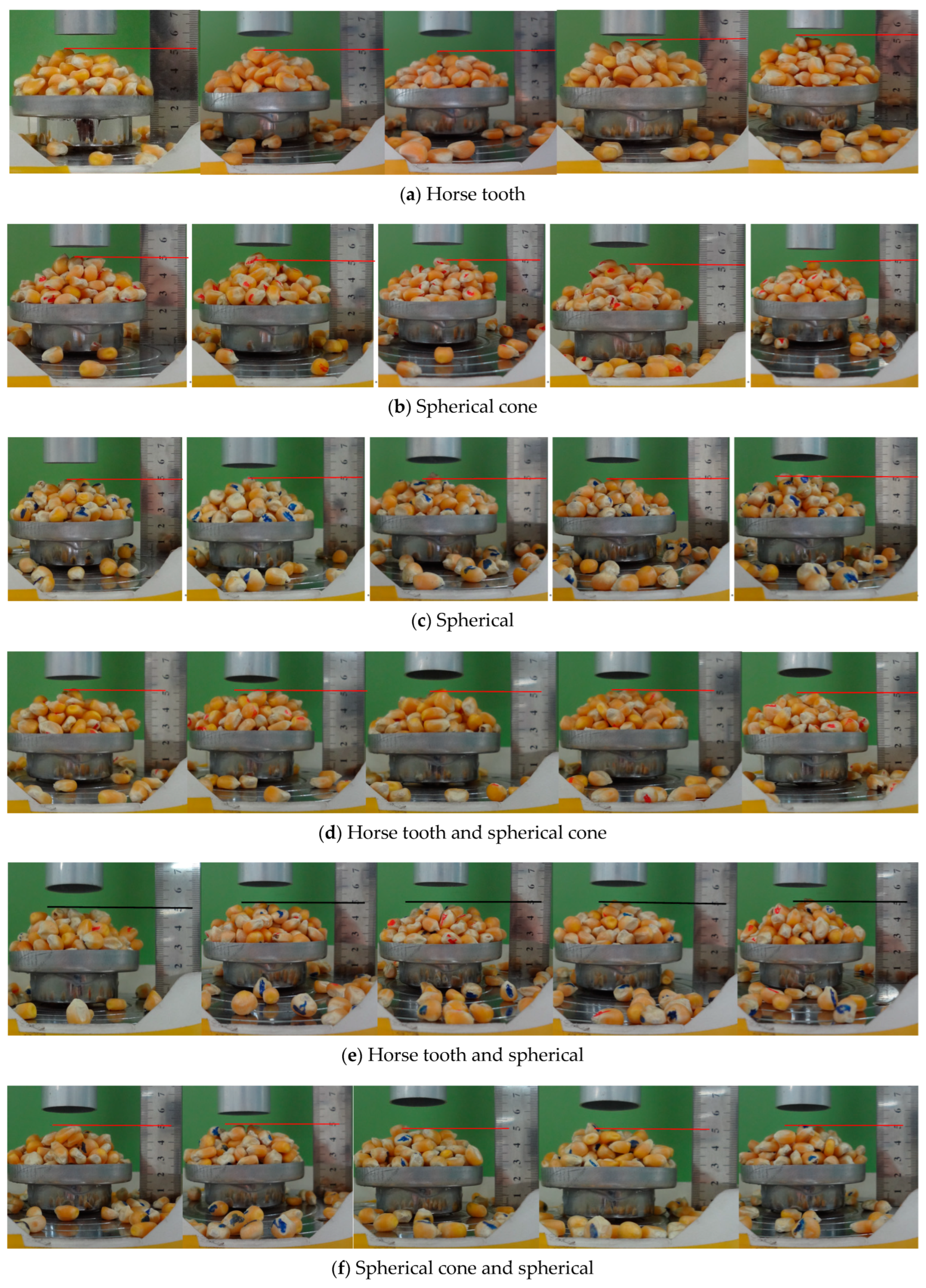

Figure 12.

The height of the repose angle of corn seeds of single shape or mixed shape. (a) Horse tooth; (b) spherical cone; (c) spherical; (d) horse tooth and spherical cone; (e) horse tooth and spherical; (f) spherical cone and spherical.

Figure 12.

The height of the repose angle of corn seeds of single shape or mixed shape. (a) Horse tooth; (b) spherical cone; (c) spherical; (d) horse tooth and spherical cone; (e) horse tooth and spherical; (f) spherical cone and spherical.

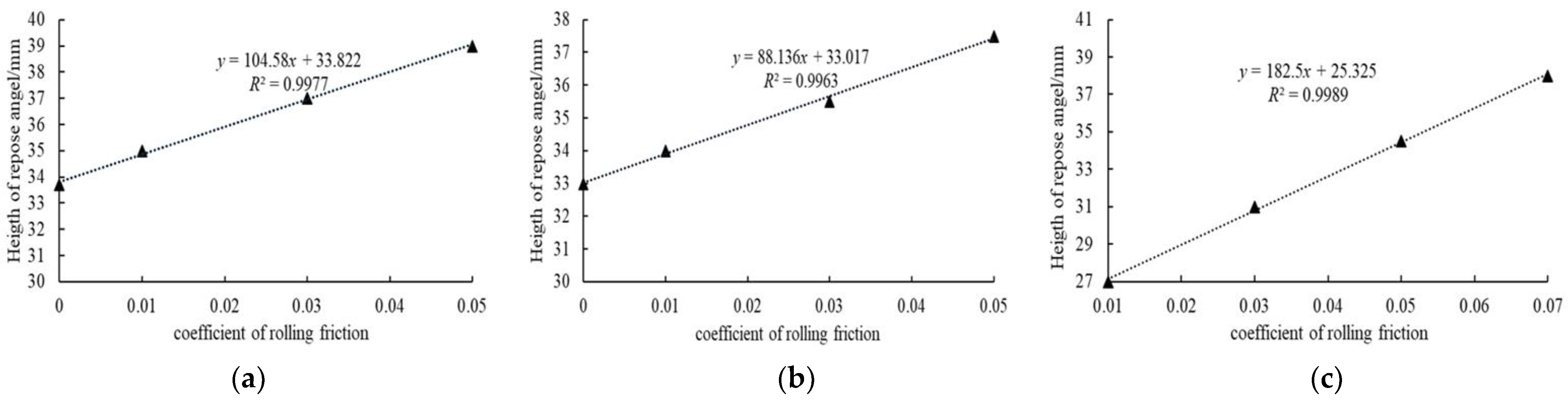

Figure 13.

Relationship between the coefficient of rolling friction and the height of the repose angle of single corn shapes. (a) Horse tooth; (b) spherical cone; (c) spherical.

Figure 13.

Relationship between the coefficient of rolling friction and the height of the repose angle of single corn shapes. (a) Horse tooth; (b) spherical cone; (c) spherical.

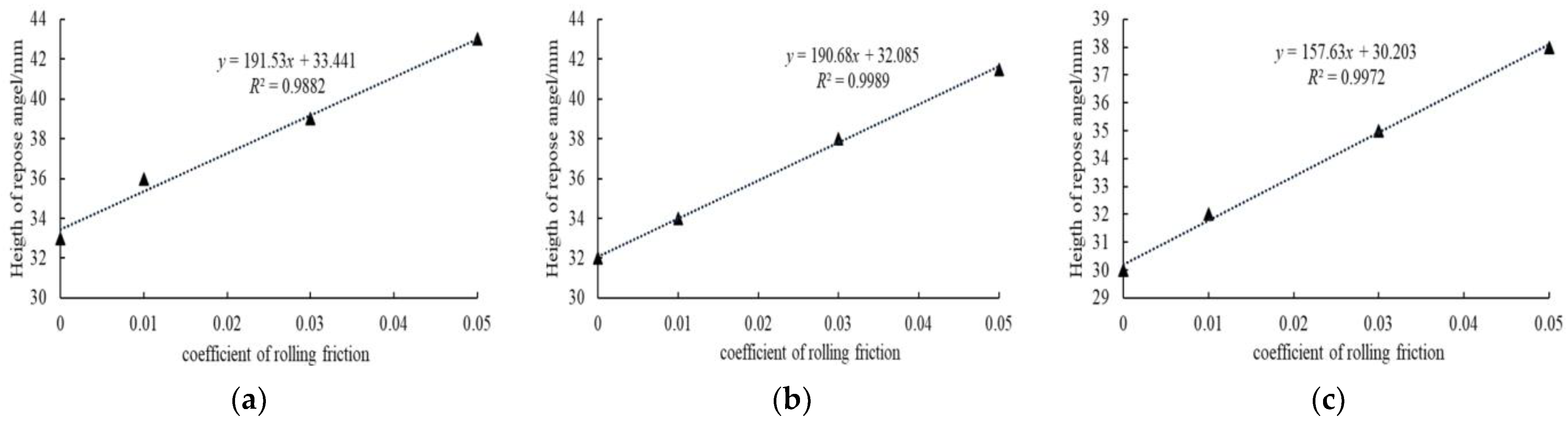

Figure 14.

Relationship between the coefficient of rolling friction and the height of repose angle for the mixed corn seeds. (a) Horse tooth and spherical cone; (b) horse tooth and spherical; (c) spherical cone and spherical.

Figure 14.

Relationship between the coefficient of rolling friction and the height of repose angle for the mixed corn seeds. (a) Horse tooth and spherical cone; (b) horse tooth and spherical; (c) spherical cone and spherical.

Figure 15.

Device with a double layer for the formation of the repose angle of corn seeds. (a) Dimensions; (b) actual device. 1. Experiment container; 2. moving plate; 3. driving motor; 4. wireless relay; 5. remote control.

Figure 15.

Device with a double layer for the formation of the repose angle of corn seeds. (a) Dimensions; (b) actual device. 1. Experiment container; 2. moving plate; 3. driving motor; 4. wireless relay; 5. remote control.

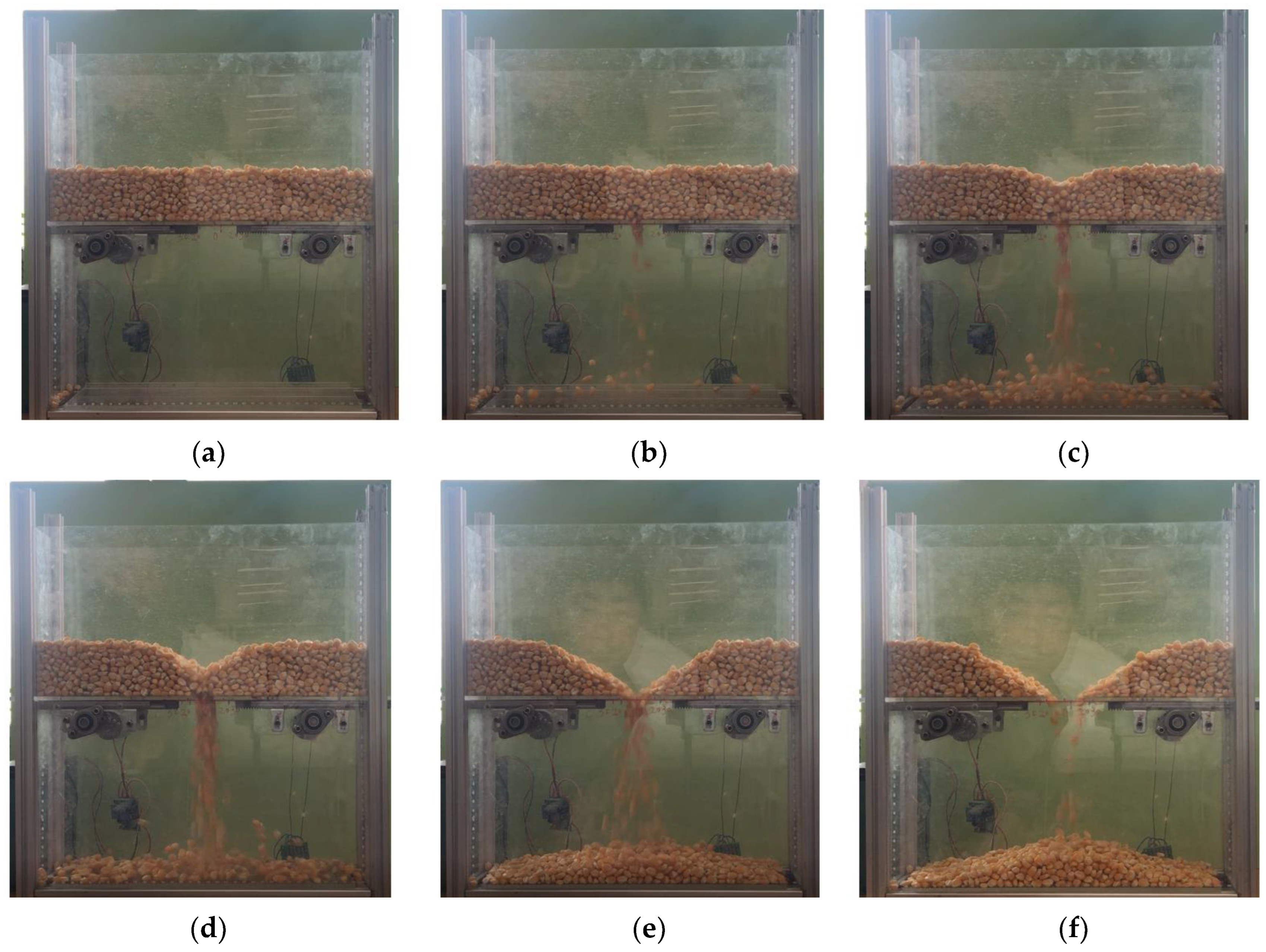

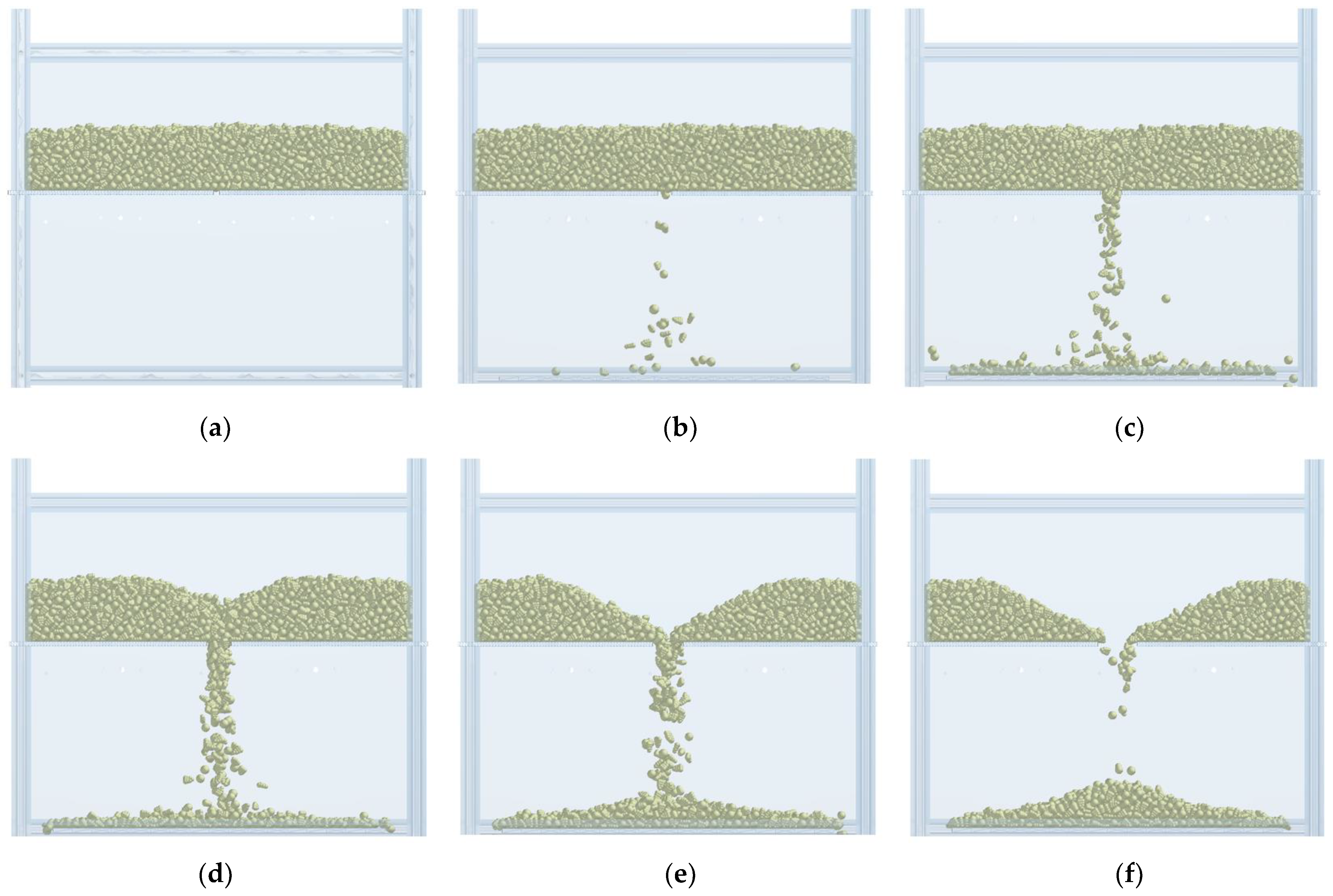

Figure 16.

Actual collapse process of mixed shape corn seeds with time. (a) 0 s; (b) 2.51 s; (c) 3.31 s; (d) 3.68 s; (e) 4.68 s; (f) 6 s.

Figure 16.

Actual collapse process of mixed shape corn seeds with time. (a) 0 s; (b) 2.51 s; (c) 3.31 s; (d) 3.68 s; (e) 4.68 s; (f) 6 s.

Figure 17.

Simulated collapse process of the corn seed model with time. (a) 0 s; (b) 2.51 s; (c) 3.31 s; (d) 3.68 s; (e) 4.68 s; (f) 6 s.

Figure 17.

Simulated collapse process of the corn seed model with time. (a) 0 s; (b) 2.51 s; (c) 3.31 s; (d) 3.68 s; (e) 4.68 s; (f) 6 s.

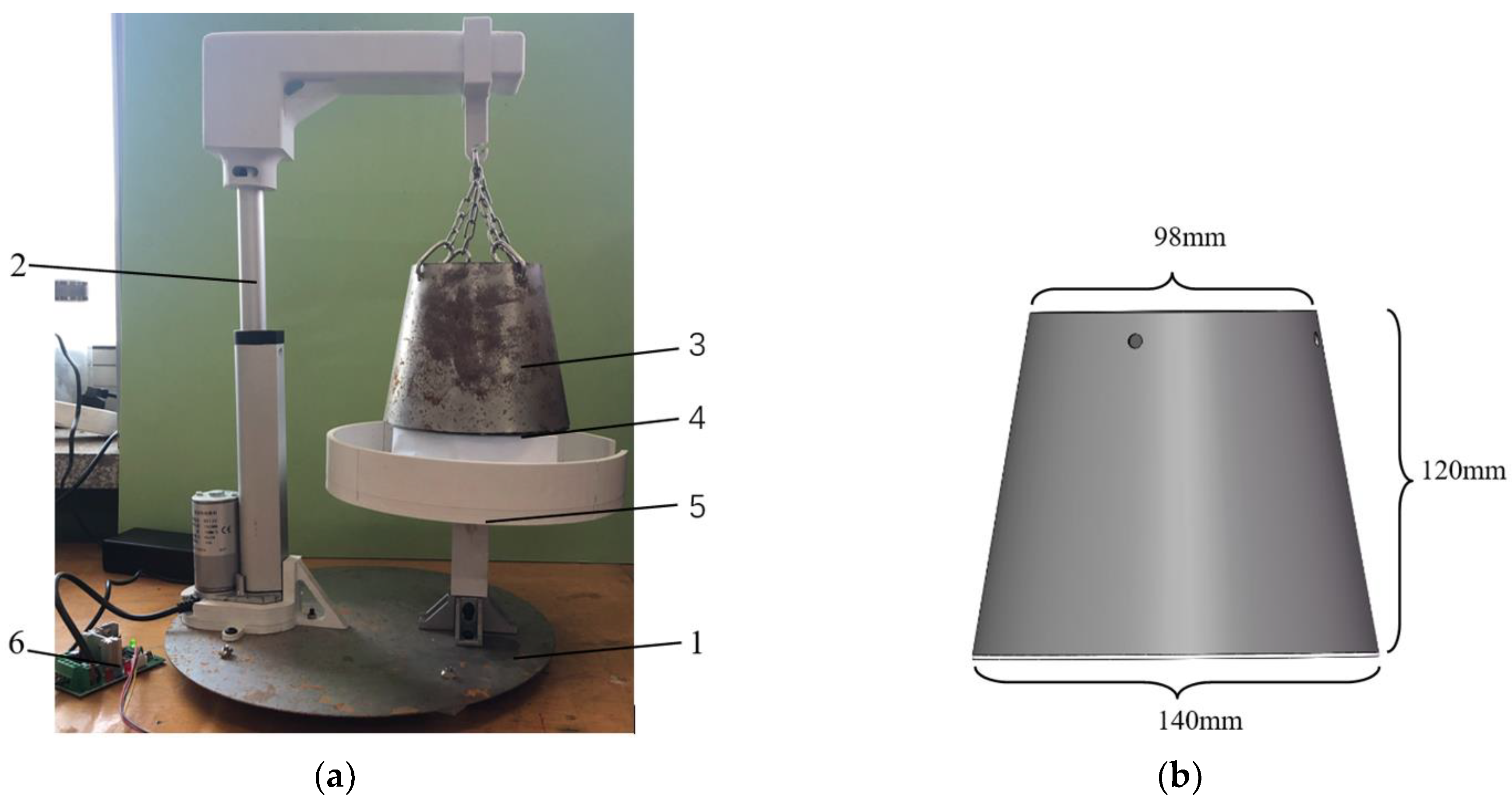

Figure 18.

Device with conical table for the formation of the repose angle of the corn seeds. (a) Component; (b) size of the cone table; 1. support; 2. linear pusher; 3. cone table; 4. stacking disk; 5. seed drops disk; 6. commutation circuit.

Figure 18.

Device with conical table for the formation of the repose angle of the corn seeds. (a) Component; (b) size of the cone table; 1. support; 2. linear pusher; 3. cone table; 4. stacking disk; 5. seed drops disk; 6. commutation circuit.

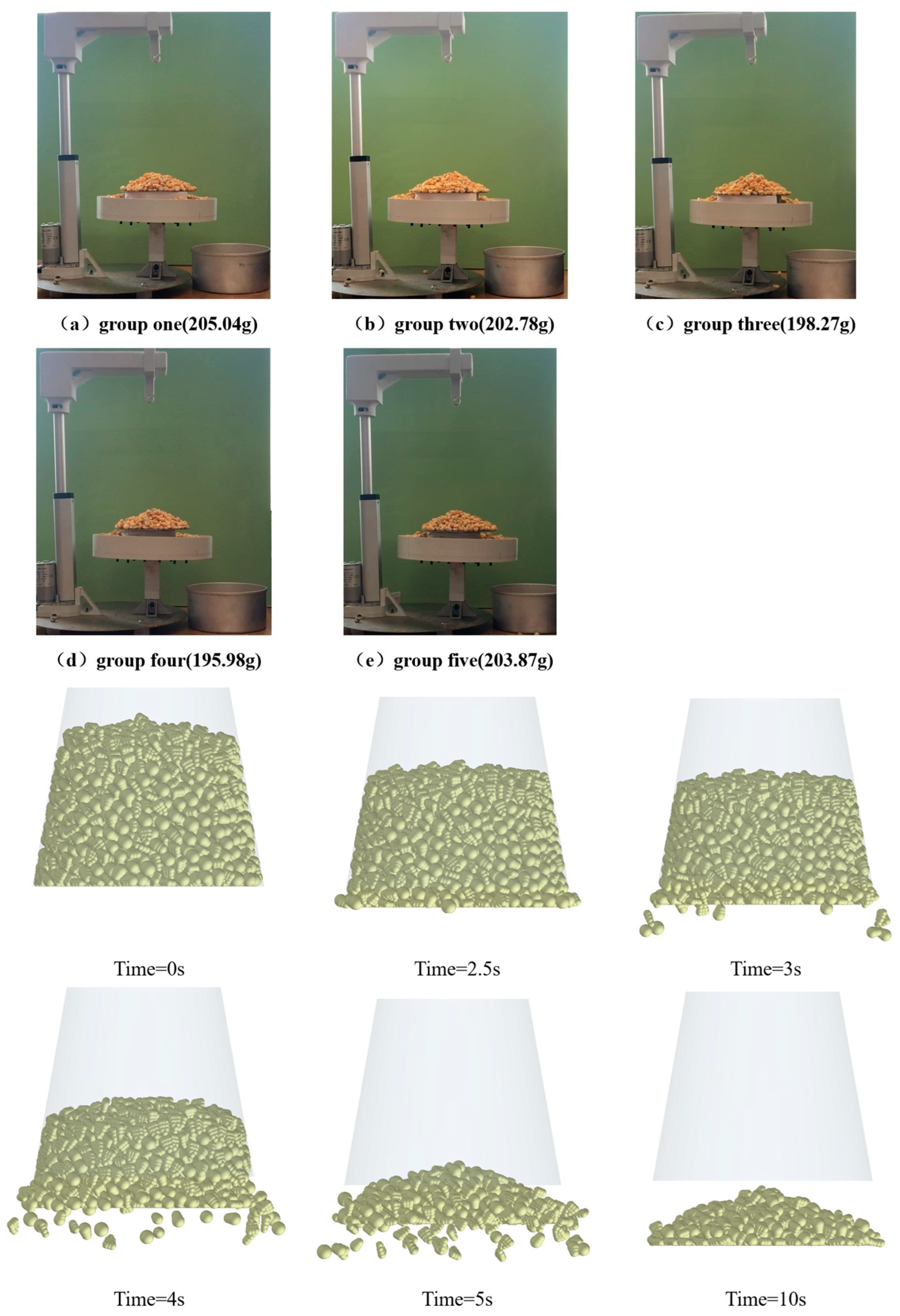

Figure 19.

Simulation process to form repose angle of corn seeds model with conical table device.

Figure 19.

Simulation process to form repose angle of corn seeds model with conical table device.

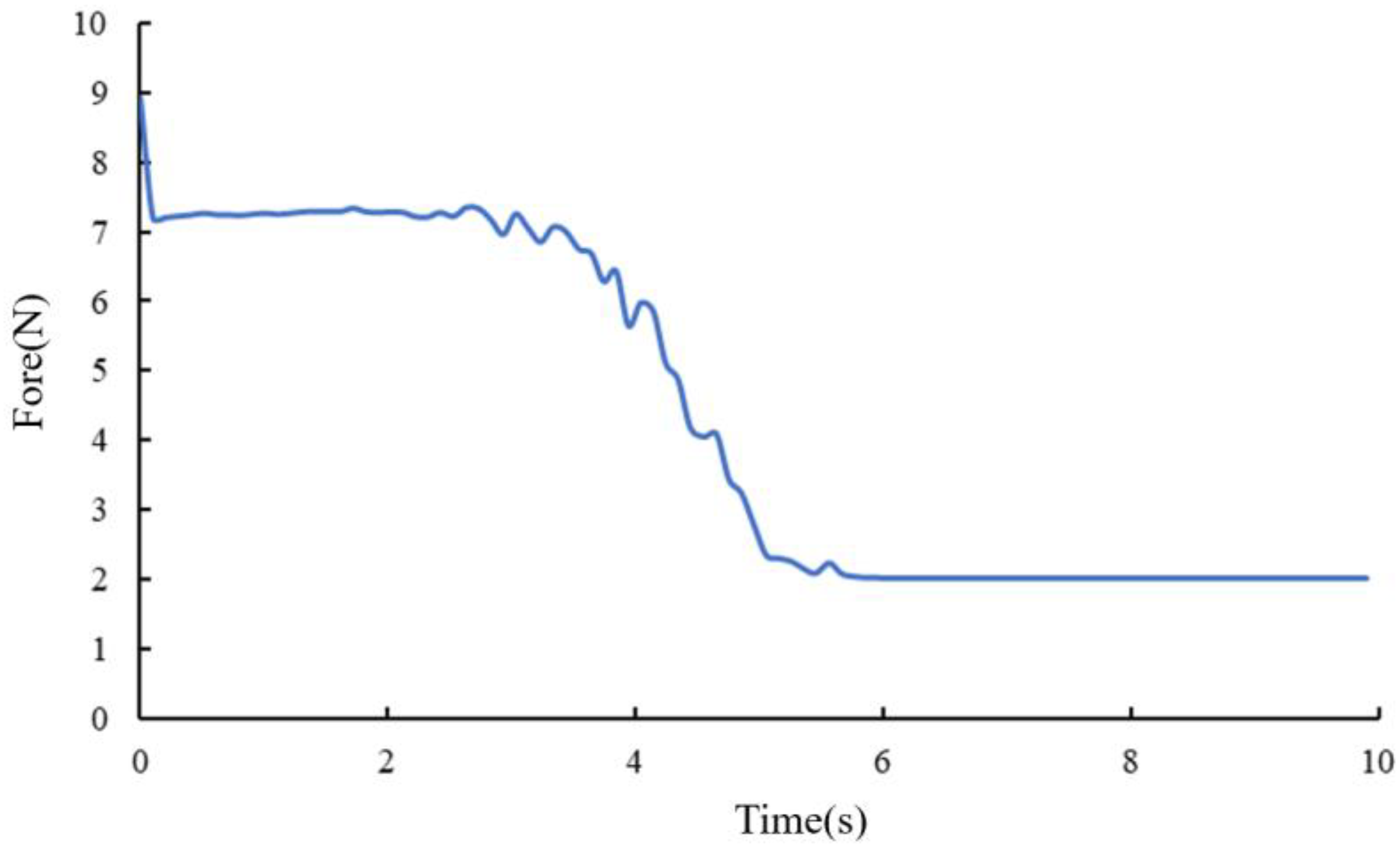

Figure 20.

Force curve on the disc during forming repose angle.

Figure 20.

Force curve on the disc during forming repose angle.

Figure 21.

Corn seed metering device. 1. Seed box; 2. seed pickup wheel; 3. right seed spacer; 4. seed cleaning plate; 5. seed brushing wheel; 6. seed disturbing wheel; 7. left seed spacer; 8. corn model; 9. seed rower; 10. seed conveyor.

Figure 21.

Corn seed metering device. 1. Seed box; 2. seed pickup wheel; 3. right seed spacer; 4. seed cleaning plate; 5. seed brushing wheel; 6. seed disturbing wheel; 7. left seed spacer; 8. corn model; 9. seed rower; 10. seed conveyor.

Figure 22.

Method of corn seeds filling hole. Note: The color of the corn changes from blue to red, indicating an increasing trend in the corn speed, with green representing values between low and high speed. The red circle represents the seed of the object under observation.

Figure 22.

Method of corn seeds filling hole. Note: The color of the corn changes from blue to red, indicating an increasing trend in the corn speed, with green representing values between low and high speed. The red circle represents the seed of the object under observation.

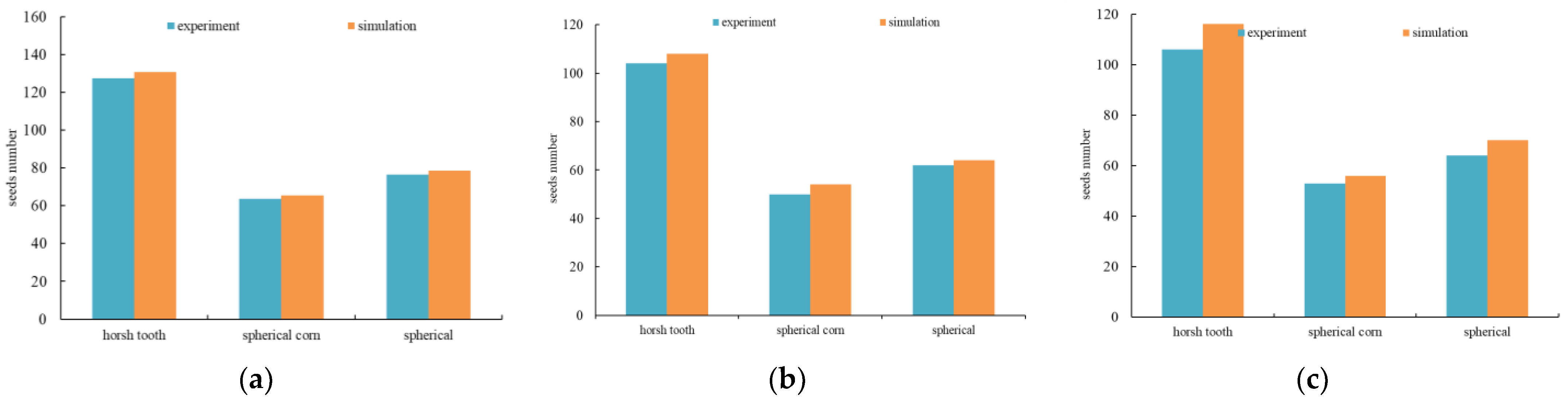

Figure 23.

Comparison of corn seed metering number between simulation and experiment condition. (a) 1.14 rad/s; (b) 3.25 rad/s; (c) 5.35 rad/s.

Figure 23.

Comparison of corn seed metering number between simulation and experiment condition. (a) 1.14 rad/s; (b) 3.25 rad/s; (c) 5.35 rad/s.

Table 1.

Equation for calculating the characteristic size of horse tooth corn seeds.

Table 1.

Equation for calculating the characteristic size of horse tooth corn seeds.

| Features | Relationship Formula | Standard Deviation | R2 | p |

|---|

| Upper width (W1) | W1/T1 = −0.3253T1 + 3.0734 | 0.70 | 0.4962 | 2.2 × 10−7 (**) |

| Lower width (W2) | W2/T2 = −0.322T2 + 3.4086 | 0.51 | 0.7282 | 0.118 |

| Height (H) | H/T1 = −0.5746T1 + 5.1881 | 0.69 | 0.7604 | 5.77 × 10−7 (**) |

| Height (H) | H/T2 = −0.4766T2 + 4.7261 | 0.69 | 0.7672 | 1.06 × 10−4 (**) |

| Lower thickness (T2) | T2/T1 = −0.1672T1 + 1.9051 | 0.53 | 0.3297 | 0.117 |

Table 2.

Calculated feature size of the horse tooth corn seed.

Table 2.

Calculated feature size of the horse tooth corn seed.

| Feature Size Average/mm |

|---|

| W1 (W1:T1) | W2 (W2:T2) | H (H:T2~H:T1) | T1 | T2 |

|---|

| 7.15 (1.63) | 8.92 (1.76) | 11.57 (2.61~2.64) | 4.43 | 5.12 |

Table 3.

Equation for calculating the characteristic size of spherical cone corn seeds.

Table 3.

Equation for calculating the characteristic size of spherical cone corn seeds.

| Features | Relationship Formula | Standard Deviation | R2 | p |

|---|

| Lower radius (D2) | D2/D1 = −0.1093D1 + 1.973 | 0.75 | 0.4477 | 0.168 |

| High (H) | H/D1 = −0.2256D1 + 3.2146 | 0.80 | 0.6778 | 0.399 |

Table 4.

Calculated feature size of the spherical cone corn seed.

Table 4.

Calculated feature size of the spherical cone corn seed.

| Feature Size Average/mm |

|---|

| H (H:D1) | D1 | D2 |

|---|

| 11.14 (1.80) | 6.27 | 8.00 |

Table 5.

DEM simulation parameters.

Table 5.

DEM simulation parameters.

| Materials | Parameters | Value | Source |

|---|

| Corn | Poisson’s ratio | 0.4 | [15] |

| Young’s modulus/MPa | 26 | [15] |

| Density of horse tooth particle/(kg/m3) | 1213 | Measurement |

| Density of spherical cone particles/(kg/m3) | 1194 | Measurement |

| Density of spherical corn/(kg/m3) | 1234 | Measurement |

| Collision recovery coefficient | 0.37 | [28] |

| Coefficient of static friction | 0.2 | [29] |

| Aluminum | Poisson’s ratio | 0.34 | [23] |

| Shear modulus/Pa | 2.5 × 1010 | [23] |

| Density/(kg/m3) | 2700 | [23] |

| Plexiglas | Poisson’s ratio | 0.35 | [10] |

| Shear modulus/Pa | 1.3 × 109 | [10] |

| Density/(kg/m3) | 1200 | [10] |

| Steel | Poisson’s ratio | 0.3 | EDEM materials |

| Shear modulus/Pa | 7.9 × 1010 | EDEM materials |

| Density/(kg/m3) | 7800 | EDEM materials |

| Corn and aluminum | Collision recovery coefficient | 0.729 | [23] |

| Coefficient of static friction | 0.342 | [23] |

| Coefficient of rolling friction | 0.052 | [23] |

| Corn and Plexiglas | Collision recovery coefficient | 0.621 | [10] |

| Coefficient of static friction | 0.459 | [10] |

| Coefficient of rolling friction | 0.093 | [10] |

| Corn and steel | Collision recovery coefficient | 0.5 | [30] |

| Coefficient of static friction | 0.408 | [30] |

| Coefficient of rolling friction | 0.01 | [30] |

Table 6.

The height of the repose angle of corn seeds of single shape or mixed shape.

Table 6.

The height of the repose angle of corn seeds of single shape or mixed shape.

| Corn Type | Height of Repose Angle (mm) | Average Value (mm) | Standard Deviation (mm) |

|---|

| Horse tooth | 34.43 | 33.93 | 32.43 | 33.93 | 35.93 | 34.13 | 1.25 |

| Spherical cone | 32.43 | 33.43 | 33.43 | 34.93 | 32.43 | 33.33 | 1.02 |

| Spherical | 31.43 | 32.43 | 31.93 | 31.43 | 33.43 | 32.13 | 0.84 |

| Horse tooth and spherical cone | 33.93 | 34.43 | 32.43 | 34.43 | 33.93 | 33.83 | 0.82 |

| Horse tooth and spherical | 32.43 | 32.43 | 32.43 | 32.93 | 33.43 | 32.73 | 0.45 |

| Spherical cone and spherical | 32.93 | 31.93 | 32.43 | 32.43 | 32.43 | 32.43 | 0.35 |

Table 7.

Comparison of the repose angles of the two methods.

Table 7.

Comparison of the repose angles of the two methods.

| | Slump Stacking Experiment | Stacking Experiment |

|---|

| Simulation repose angle/° | 26.29 ± 0.5 | 23.60 ± 0.7 |

| Experiment repose angle/° | 26.48 ± 1.5 | 23.55 ± 1.7 |

| Their relative error/% | 0.72 | 0.20 |

Table 8.

Comparison of single- and multi-seed rates between the simulated and experimental condition.

Table 8.

Comparison of single- and multi-seed rates between the simulated and experimental condition.

| Metering Wheel Angular Speed | Indicators |

|---|

| Single-Grain Rate (%) | Multi-Grain Rate (%) |

|---|

| 1.14 rad/s | Experiment | 78.54 | 21.46 |

| Simulation | 80.37 | 19.63 |

| 3.25 rad/s | Experiment | 71.88 | 28.12 |

| Simulation | 73.92 | 26.08 |

| 5.35 rad/s | Experiment | 85.22 | 14.78 |

| Simulation | 86.55 | 13.45 |