Innovative Living Mulch Management Strategies for Organic Conservation Field Vegetables: Evaluation of Continuous Mowing, Flaming, and Tillage Performances

Abstract

:1. Introduction

1.1. Organic Farming and Non-Chemical Weed Control

1.2. Living Mulch Weed Control and Management

2. Materials and Methods

2.1. Experimental Design

2.2. Crop, Living Mulch and Weed Assessments

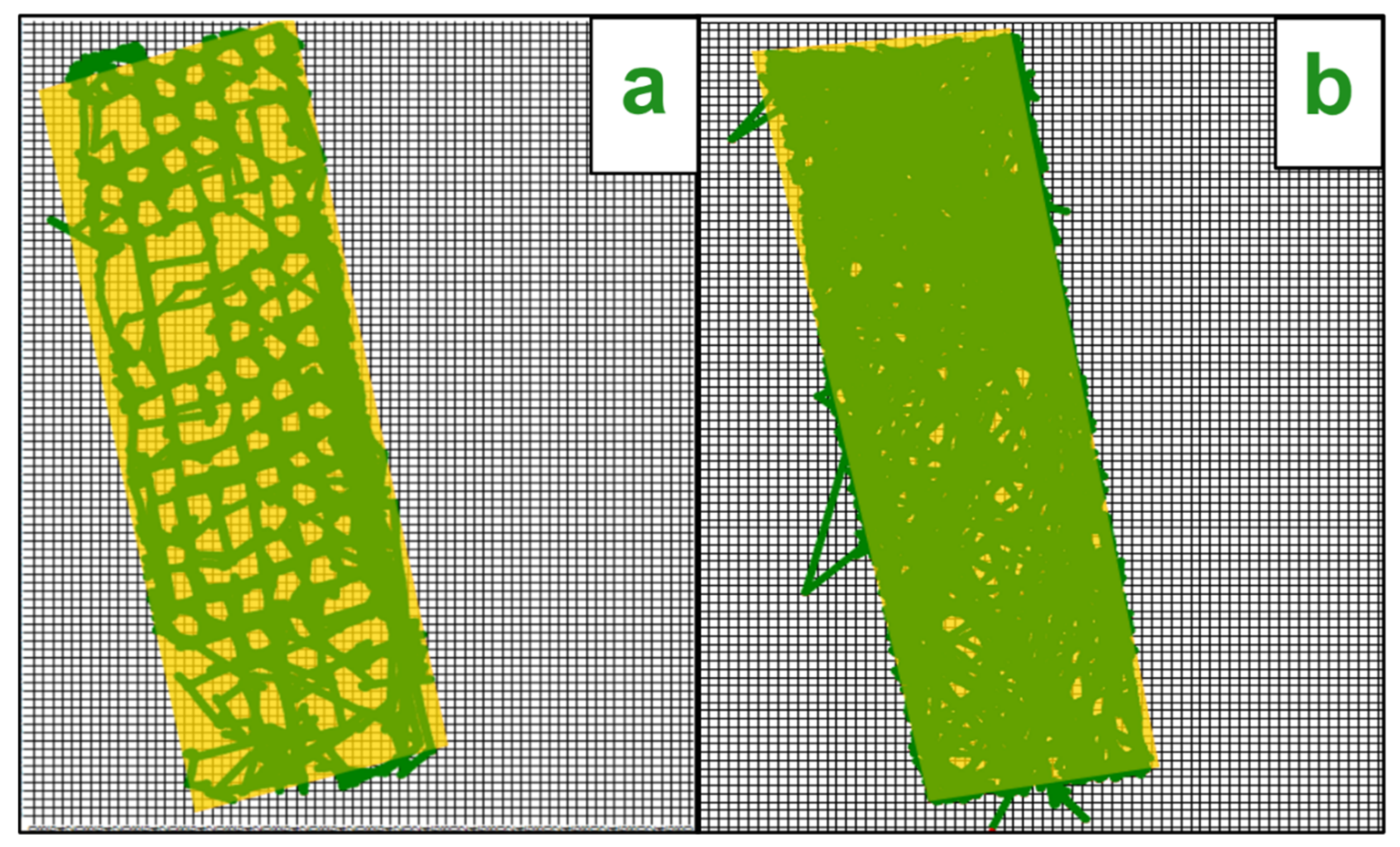

2.3. Autonomous Mower Working Data

2.4. Energy Consumption

2.5. CO2 Emission Estimation

2.6. Statistical Analysis

3. Results

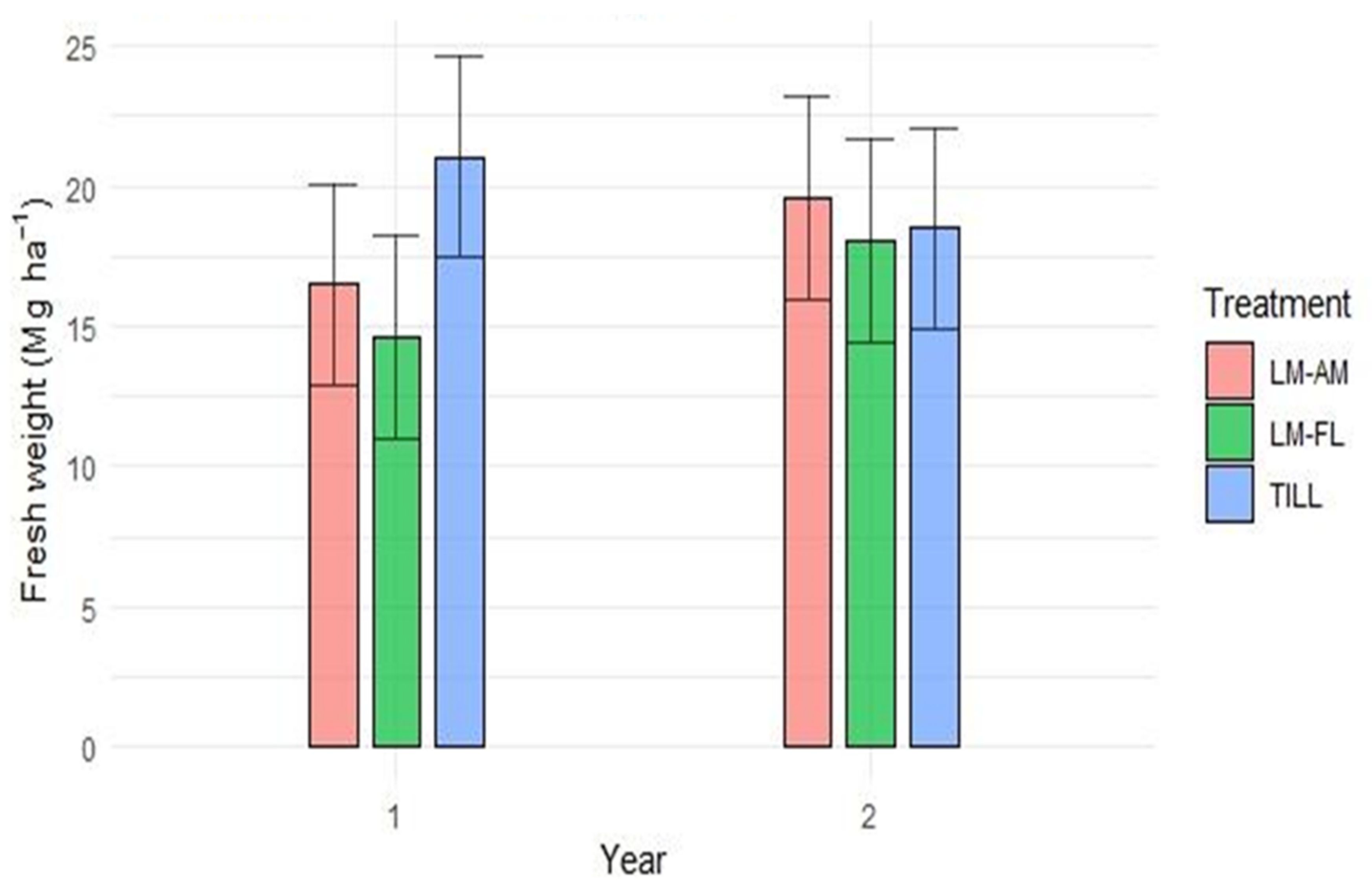

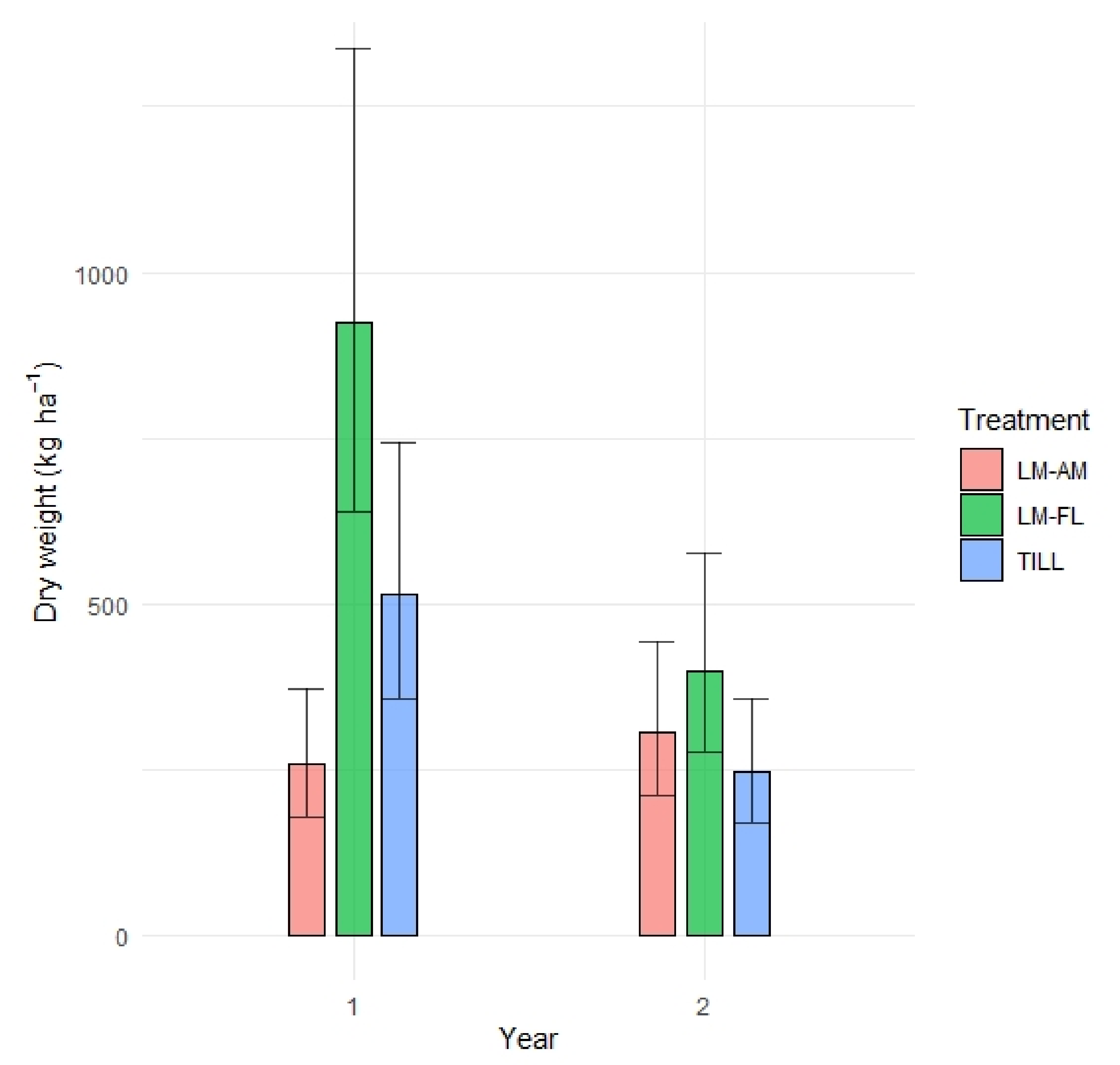

3.1. Cauliflower Data

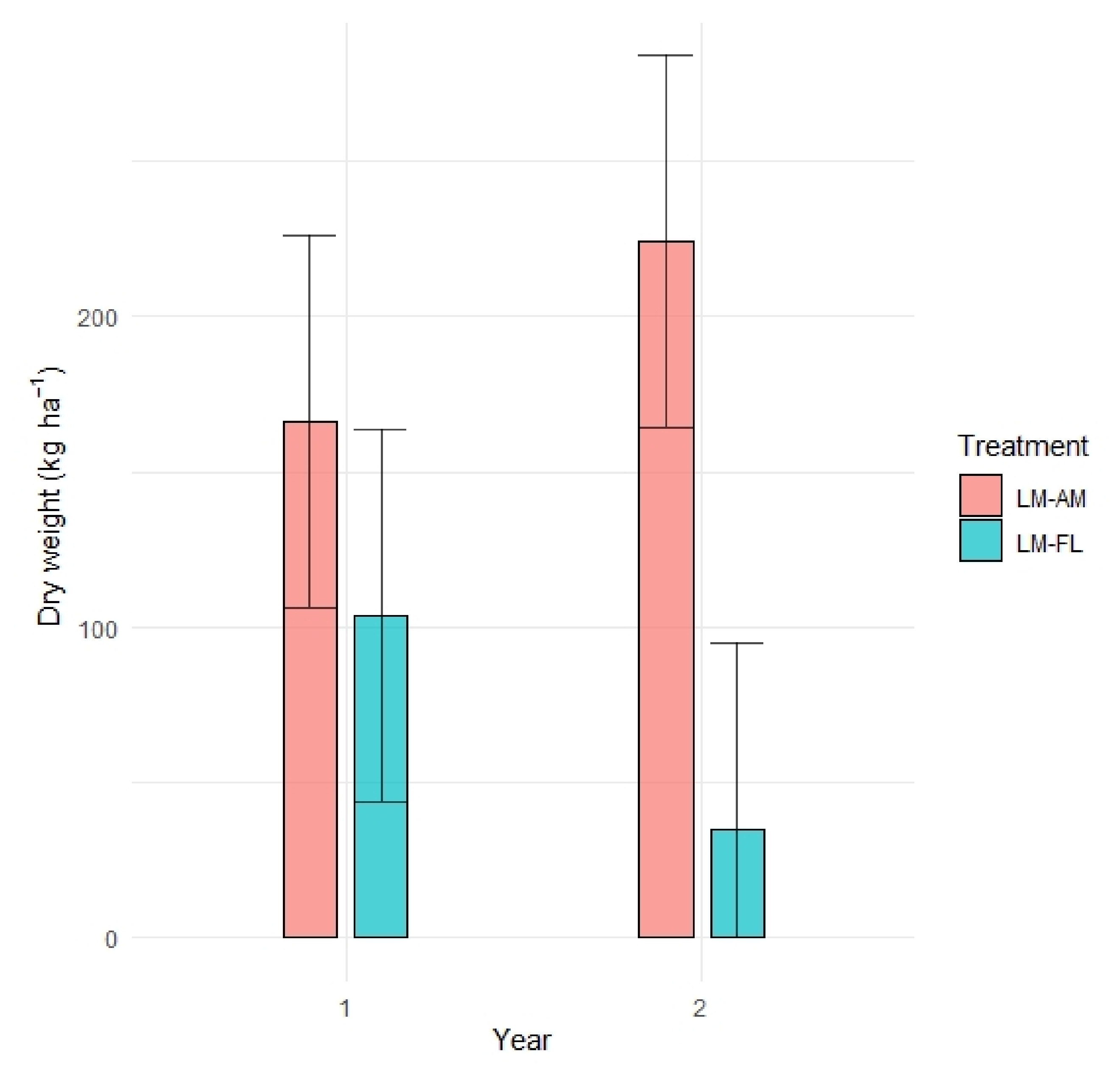

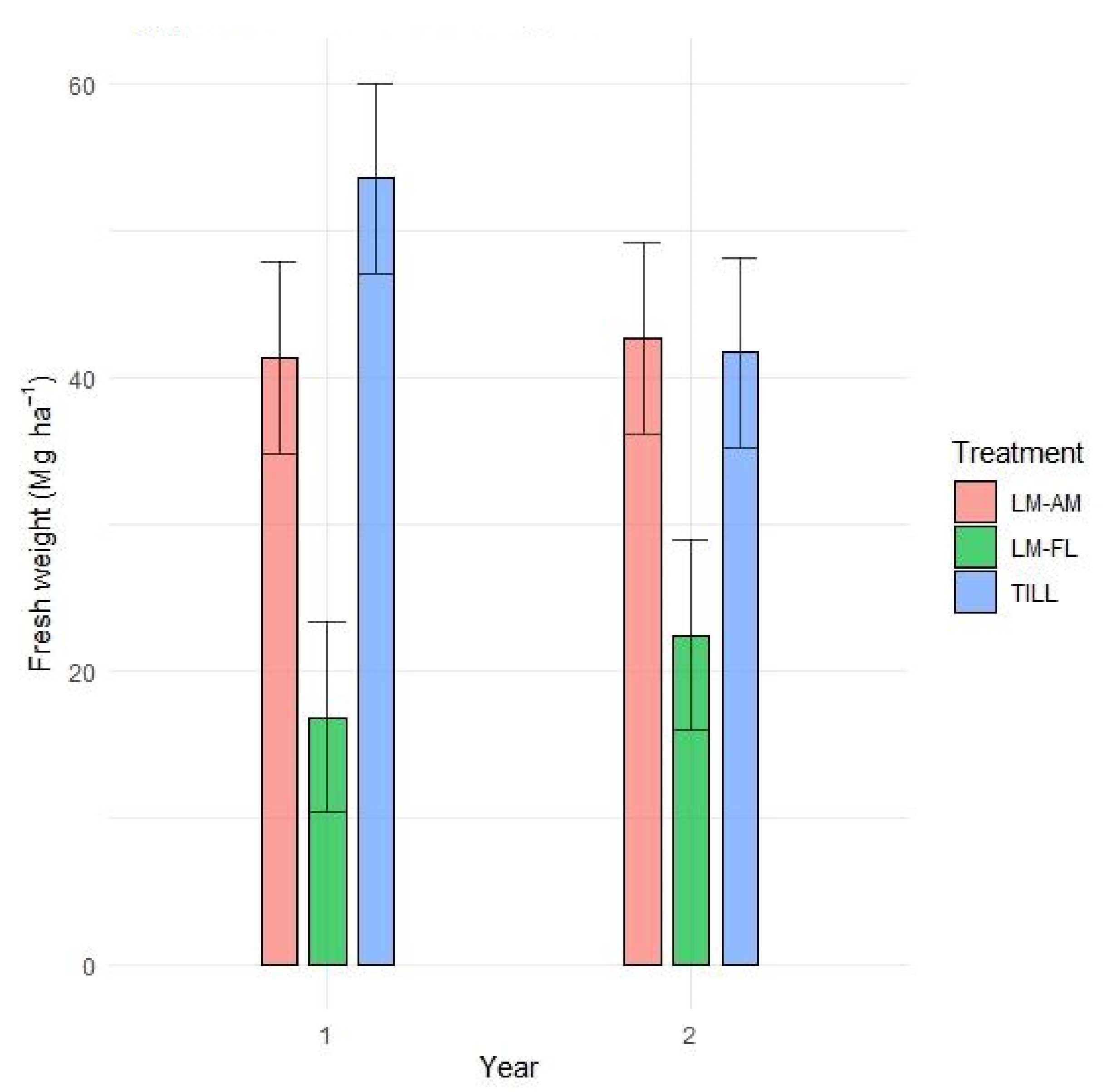

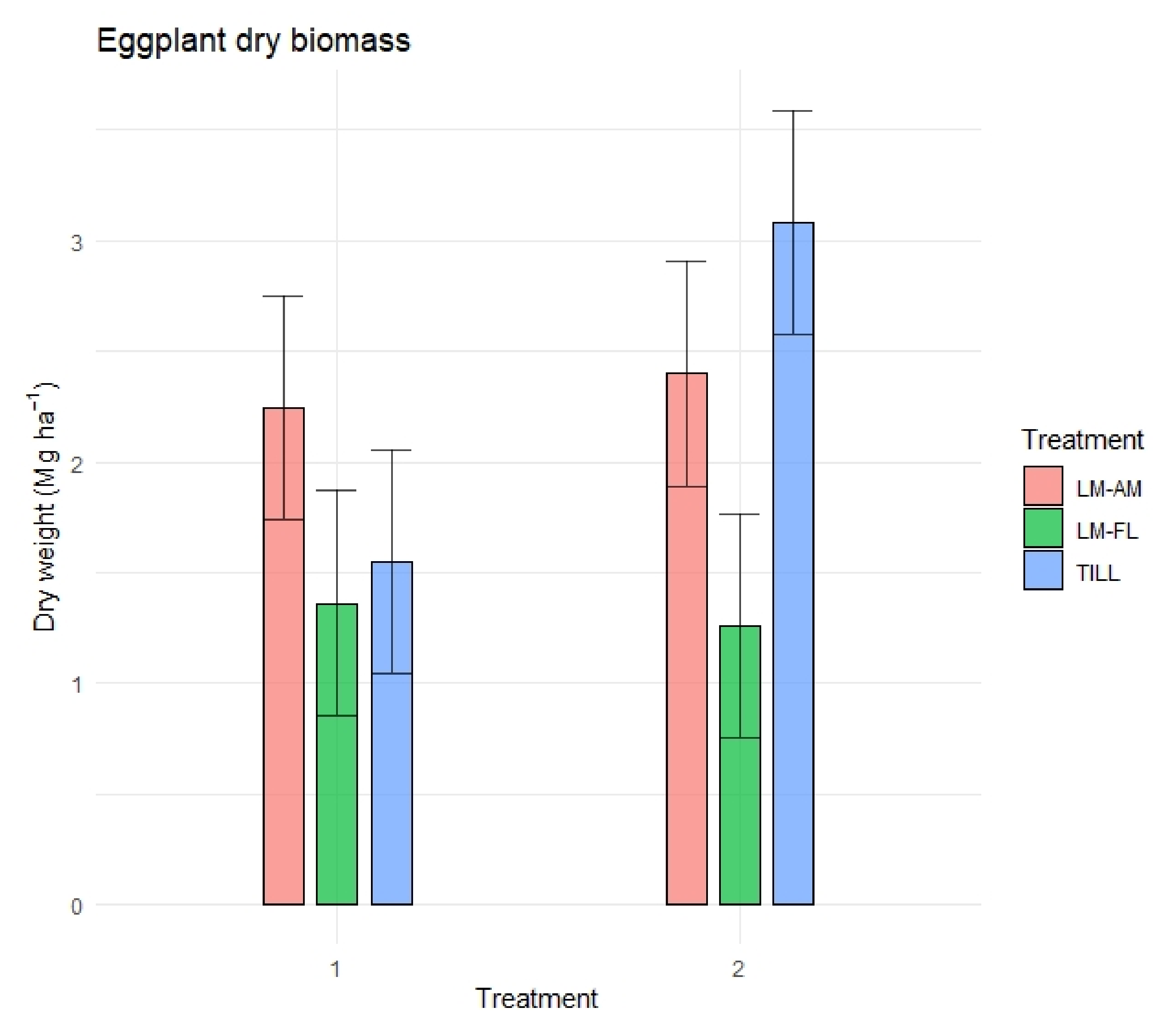

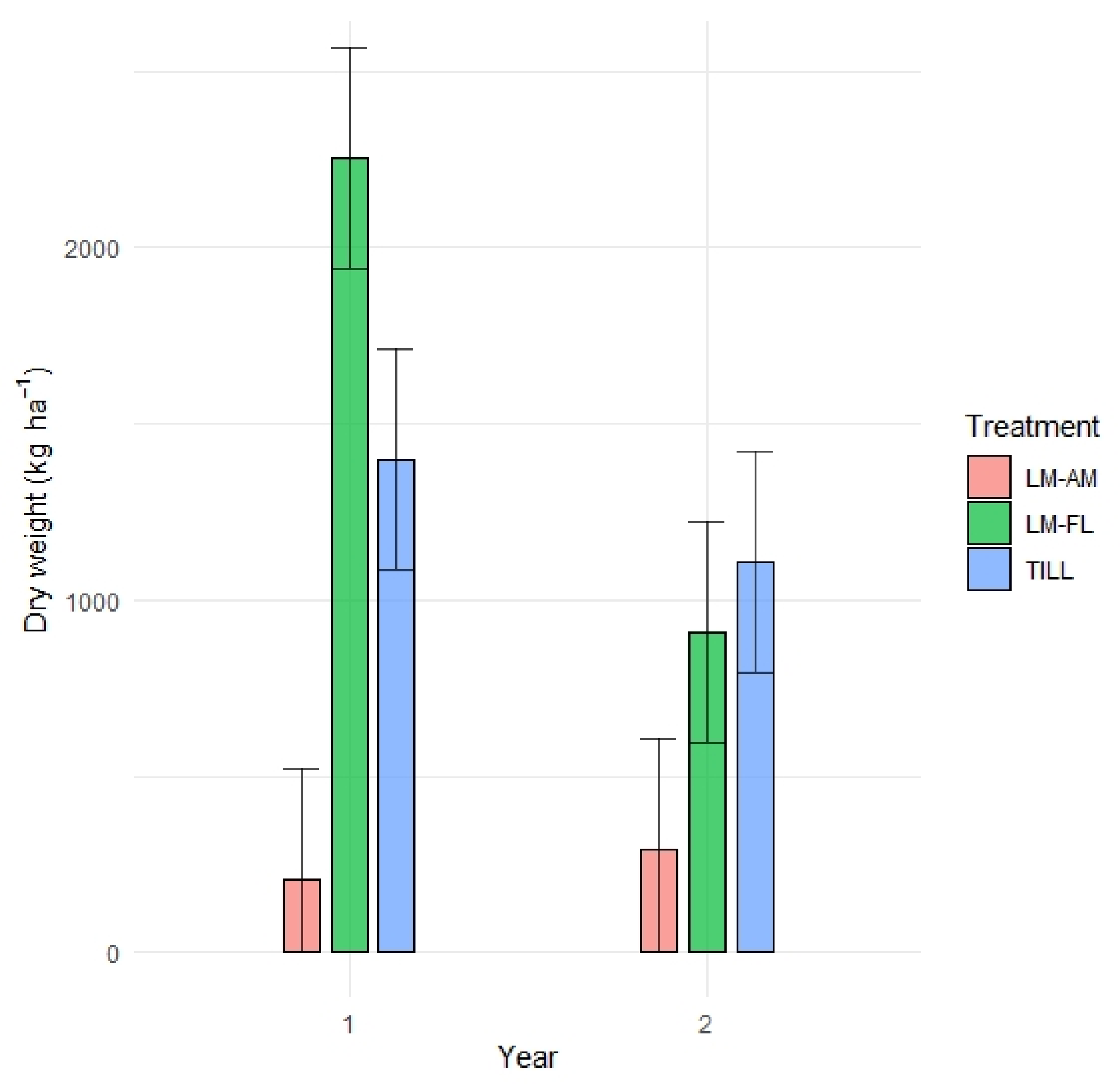

3.2. Eggplant Data

3.3. Autonomous Mower Working Data

3.4. Primary Energy Consumption and CO2 Emissions Estimation

4. Discussion

4.1. Marketable Yields and Crop Dry Biomass Production

4.2. Weed Control

4.3. LM Management System

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arunrat, N.; Sereenonchai, S.; Chaowiwat, W.; Wang, C.; Hatano, R. Carbon, Nitrogen and Water Footprints of Organic Rice and Conventional Rice Production over 4 Years of Cultivation: A Case Study in the Lower North of Thailand. Agronomy 2022, 12, 380. [Google Scholar] [CrossRef]

- Šarauskis, E.; Masilionytė, L.; Juknevičius, D.; Buragienė, S.; Kriaučiūnienė, Z. Energy use efficiency, GHG emissions, and cost-effectiveness of organic and sustainable fertilization. Energy 2019, 172, 1151–1160. [Google Scholar] [CrossRef]

- Tzilivakis, J.; Warner, D.J.; May, M.; Lewis, K.A.; Jaggard, K. An assessment of the energy inputs and greenhouse gas emissions in sugar beet (Beta vulgaris) production in the UK. Agric. Syst. 2005, 85, 101–119. [Google Scholar] [CrossRef] [Green Version]

- Kirchmann, H.; Bergström, L.; Kätterer, T.; Andrén, O.; Andersson, R. Can Organic Crop Production Feed the World? In Organic Crop Production—Ambitions and Limitations; Springer: Berlin/Heidelberg, Germany, 2008; pp. 39–72. [Google Scholar] [CrossRef] [Green Version]

- Seufert, V.; Ramankutty, N.; Foley, J.A. Comparing the yields of organic and conventional agriculture. Nature 2012, 485, 229–232. [Google Scholar] [CrossRef]

- Kloen, L.; Daniels, H. Onderzoeksagenda Biologische Landbouw & Voeding 2000–2004; Biologica/Wageningen UR: Utrecht, The Netherlands, 2000. [Google Scholar]

- Zimdahl, R.L. Influence of Competition on the Plant. In Weed-Crop Competition. A Review; Blackwell Publishing Ltd.: Ames, IA, USA, 2004. [Google Scholar]

- Peruzzi, A.; Martelloni, L.; Frasconi, C.; Fontanelli, M.; Pirchio, M.; Raffaelli, M. Machines for non-chemical intra-row weed control in narrow and wide-row crops: A review. J. Agric. Eng. 2017, 48, 57–70. [Google Scholar] [CrossRef] [Green Version]

- Doohan, D.; Wilson, R.; Canales, E.; Parker, J. Investigating the Human Dimension of Weed Management: New Tools of the Trade. Weed Sci. 2010, 58, 503–510. Available online: http://www.jstor.org/stable/40891269 (accessed on 7 February 2022). [CrossRef]

- Jensen, P. Longevity of seeds of four annual grass and two dicotyledon weed species as related to placement in the soil and straw disposal technique. Weed Res. 2009, 49, 592–601. [Google Scholar] [CrossRef]

- Morris, D.R.; Gilbert, R.A.; Reicosky, D.C.; Gesch, R.W. Oxidation Potentials of Soil Organic Matter in Histosols under Different Tillage Methods. Soil Sci. Soc. Am. J. 2004, 68, 817–826. [Google Scholar] [CrossRef]

- Failla, S.; Pirchio, M.; Sportelli, M.; Frasconi, C.; Fontanelli, M.; Raffaelli, M.; Peruzzi, A. Evolution of smart strategies and machines used for conservative management of herbaceous and horticultural crops in the mediterranean basin: A review. Agronomy 2021, 11, 106. [Google Scholar] [CrossRef]

- Thomas, A.G.; Derksen, D.A.; Blackshaw, R.E.; Van Acker, R.C.; Légère, A.; Watson, P.R.; Turnbull, G.C. A multistudy approach to understanding weed population shifts in medium- to long-term tillage systems. Weed Sci. 2004, 52, 874–880. [Google Scholar] [CrossRef]

- Graziani, F.; Onofri, A.; Pannacci, E.; Tei, F.; Guiducci, M. Size and composition of weed seedbank in long-term organic and conventional low-input cropping systems. Eur. J. Agron. 2012, 39, 52–61. [Google Scholar] [CrossRef]

- Murphy, C.E.; Lemerle, D. Continuous cropping systems and weed selection. Euphytica 2006, 148, 61–73. [Google Scholar] [CrossRef]

- Bohan, D.A.; Powers, S.J.; Champion, G.; Haughton, A.J.; Hawes, C.; Squire, G.; Cussans, J.; Mertens, S.K. Modelling rotations: Can crop sequences explain arable weed seedbank abundance? Weed Res. 2011, 51, 422–432. [Google Scholar] [CrossRef]

- Campiglia, E.; Mancinelli, R.; Radicetti, E.; Caporali, F. Effect of cover crops and mulches on weed control and nitrogen fertilization in tomato (Lycopersicon esculentum Mill.). Crop Prot. 2010, 29, 354–363. [Google Scholar] [CrossRef]

- Navarro-Miró, D.; Blanco-Moreno, J.M.; Ciaccia, C.; Chamorro, L.; Testani, E.; Kristensen, H.L.; Hefner, M.; Tamm, K.; Bender, I.; Jakop, M.; et al. Agroecological service crops managed with roller crimper reduce weed density and weed species richness in organic vegetable systems across Europe. Agron. Sustain. Dev. 2019, 39, 1–13. [Google Scholar] [CrossRef]

- Peachey, R.E.; William, R.A.Y.; Mallory-Smith, C. Effect of No-Till or Conventional Planting and Cover Crops Residues on Weed Emergence in Vegetable Row Crop1. Weed Technol. 2009, 18, 1023–1030. [Google Scholar] [CrossRef]

- Teasdale, J.R.; Brandsæter, L.O.; Calegari, A.; Neto, F.S. Cover Crops and Weed Management. In Non-Chemical Weed Management: Principles, Concepts and Technology; Upadhyaya, M.K., Blackshaw, R.E., Eds.; CABI: Wallingford, UK, 2007; pp. 49–64. [Google Scholar]

- Vincent-Caboud, L.; Peigné, J.; Casagrande, M.; Silva, E.M. Overview of Organic Cover Crop-Based No-Tillage Technique in Europe: Farmers’ Practices and Research Challenges. Agriculture 2017, 7, 42. [Google Scholar] [CrossRef] [Green Version]

- Chehade, L.A.; Fontanelli, M.; Martelloni, L.; Frasconi, C.; Raffaelli, M.; Peruzzi, A. Effects of Flame Weeding on Organic Garlic Production. Horttechnology 2018, 28, 502–508. [Google Scholar] [CrossRef]

- Tei, F.; Pannacci, E. Weed Management Systems in Vegetables. In Weed Research. Expanding Horizons, 1st ed.; Hatcher, P.E., Froud-Williams, R.J., Eds.; John Wiley & Sons Ltd.: Oxford, UK, 2017; p. 367. [Google Scholar]

- Raffaelli, M.; Frasconi, C.; Fontanelli, M.; Martelloni, L.; Peruzzi, A. LPG burners for weed control. Appl. Eng. Agric. 2015, 31, 717–731. [Google Scholar] [CrossRef]

- Martelloni, L.; Fontanelli, M.; Frasconi, C.; Raffaelli, M.; Peruzzi, A. Cross-flaming application for intra-row weed control in maize. Appl. Eng. Agric. 2016, 32, 569–578. [Google Scholar] [CrossRef]

- Martelloni, L.; Fontanelli, M.; Frasconi, C.; Raffaelli, M.; Pirchio, M.; Peruzzi, A. A combined flamer-cultivator for weed control during the harvesting season of asparagus green spears. Span. J. Agric. Res. 2017, 15, e0203. [Google Scholar] [CrossRef]

- Bhadra, T.; Paul, S. Weed management in sugar beet: A review. Fundam. Appl. Agric. 2020, 5, 1. [Google Scholar] [CrossRef]

- Garnier, E.; Navas, M.-L. A trait-based approach to comparative functional plant ecology: Concepts, methods and applications for agroecology. A review. Agron. Sustain. Dev. 2012, 32, 365–399. [Google Scholar] [CrossRef] [Green Version]

- Magni, S.; Sportelli, M.; Grossi, N.; Volterrani, M.; Minelli, A.; Pirchio, M.; Fontanelli, M.; Frasconi, C.; Gaetani, M.; Martelloni, L.; et al. Autonomous mowing and turf-type bermudagrass as innovations for an environment-friendly floor management of a vineyard in coastal tuscany. Agriculture 2020, 10, 189. [Google Scholar] [CrossRef]

- MacLaren, C.; Bennett, J.; Dehnen-Schmutz, K. Management practices influence the competitive potential of weed communities and their value to biodiversity in South African vineyards. Weed Res. 2019, 59, 93–106. [Google Scholar] [CrossRef]

- Sportelli, M.; Frasconi, C.; Fontanelli, M.; Pirchio, M.; Raffaelli, M.; Magni, S.; Caturegli, L.; Volterrani, M.; Mainardi, M.; Peruzzi, A. Autonomous mowing and complete floor cover for weed control in Vineyards. Agronomy 2021, 11, 538. [Google Scholar] [CrossRef]

- Machleb, J.; Peteinatos, G.G.; Sökefeld, M.; Gerhards, R. Sensor-Based Intrarow Mechanical Weed Control in Sugar Beets with Motorized Finger Weeders. Agronomy 2021, 11, 1517. [Google Scholar] [CrossRef]

- Slaughter, D.C.; Giles, D.K.; Downey, D. Autonomous robotic weed control systems: A review. Comput. Electron. Agric. 2008, 61, 63–78. [Google Scholar] [CrossRef]

- Hossain, M.; Takahashi, K.; Komatsuzaki, M. Robotic Lawnmower Saves Labor and Operation Costs in a Pear (Pyrus pyrifolia) Orchard. Jpn. J. Farm Work Res. 2020, 55, 143–153. [Google Scholar] [CrossRef]

- Antichi, D.; Sbrana, M.; Martelloni, L.; Abou Chehade, L.; Fontanelli, M.; Raffaelli, M.; Mazzoncini, M.; Peruzzi, A.; Frasconi, C. Agronomic performances of organic field vegetables managed with conservation agriculture techniques: A study from central Italy. Agronomy 2019, 9, 810. [Google Scholar] [CrossRef] [Green Version]

- Raffaelli, M.; Martelloni, L.; Frasconi, C.; Fontanelli, M.; Peruzzi, A. Development of machines for flaming weed control on hard surfaces. Appl. Eng. Agric. 2013, 29, 663–673. [Google Scholar] [CrossRef]

- Raffaelli, M.; Fontanelli, M.; Frasconi, C.; Sorelli, F.; Ginanni, M.; Peruzzi, A. Physical weed control in processing tomatoes in Central Italy. Renew. Agric. Food Syst. 2011, 26, 95–103. [Google Scholar] [CrossRef]

- Ciaccia, C.; Kristensen, H.L.; Campanelli, G.; Xie, Y.; Testani, E.; Leteo, F.; Canali, S. Living mulch for weed management in organic vegetable cropping systems under Mediterranean and North European conditions. Renew. Agric. Food Syst. 2017, 32, 248–262. [Google Scholar] [CrossRef]

- van der Maarel, E. Transformation of cover-abundance values for appropriate numerical treatment—Alternatives to the proposals by Podani. J. Veg. Sci. 2007, 18, 767–770. [Google Scholar] [CrossRef]

- Sportelli, M.; Pirchio, M.; Fontanelli, M.; Volterrani, M.; Frasconi, C.; Martelloni, L.; Caturegli, L.; Gaetani, M.; Grossi, N.; Magni, S.; et al. Autonomous mowers working in narrow spaces: A possible future application in agriculture? Agronomy 2020, 10, 553. [Google Scholar] [CrossRef] [Green Version]

- Pirchio, M.; Fontanelli, M.; Labanca, F.; Sportelli, M.; Frasconi, C.; Martelloni, L.; Raffaelli, M.; Peruzzi, A.; Gaetani, M.; Magni, S.; et al. Energetic Aspects of Turfgrass Mowing: Comparison of Different Rotary Mowing Systems. Agriculture 2019, 9, 178. [Google Scholar] [CrossRef] [Green Version]

- ISPRA—Istituto Superiore per la Protezione e la RicercaAmbientale. Rapporti 280/2018. Available online: https://www.isprambiente.gov.it/files2018/pubblicazioni/rapporti/R_280_18_Emissioni_Settore_Elettrico.pdf (accessed on 7 February 2022).

- Bilancio Energetico Nazionale (BEN). National Energetic Report 2017. Available online: https://dgsaie.mise.gov.it/pub/ben/BEN_2017.pdf (accessed on 7 February 2022).

- ISPRA. Italian Greenhouse Gas Inventory 1990–2015. National Inventory Report 2017. Available online: http://www.isprambiente.gov.it/files2017/pubblicazioni/rapporto/R_261_17.pdf (accessed on 7 February 2022).

- Perry’s Chemical Engineers’ Handbook. Available online: https://www.academia.edu/32945246/Perry_s_Chemical_Engineers_Handbook (accessed on 7 February 2022).

- Gerhard, D.; Ritz, C. medrc: Mixed Effect Dose-Response Curves. Available online: https://rdrr.io/github/DoseResponse/medrc/man/metadrm.html (accessed on 7 February 2022).

- Canali, S.; Diacono, M.; Campanelli, G.; Montemurro, F. Organic No-Till with Roller Crimpers: Agro-ecosystem Services and Applications in Organic Mediterranean Vegetable Productions. Sustain. Agric. Res. 2015, 4, 70. [Google Scholar] [CrossRef]

- Moncada, A.; Miceli, A.; Vetrano, F.; Mineo, V.; Planeta, D.; D’Anna, F. Effect of grafting on yield and quality of eggplant (Solanum melongena L.). Sci. Hortic. 2013, 149, 108–114. [Google Scholar] [CrossRef]

- Peigné, J.; Ball, B.C.; Roger-Estrade, J.; David, C. Is conservation tillage suitable for organic farming? A review. Soil Use Manag. 2007, 23, 129–144. [Google Scholar] [CrossRef]

- Blanco-Canqui, H.; Ruis, S.J. No-tillage and soil physical environment. Geoderma 2018, 326, 164–200. [Google Scholar] [CrossRef]

- Pittelkow, C.M.; Linquist, B.A.; Lundy, M.E.; Liang, X.; Van Groenigen, K.J.; Lee, J.; Van Gestel, N.; Six, J.; Venterea, R.T.; Van Kessel, C. When does no-till yield more? A global meta-analysis. Field Crop. Res. 2015, 183, 156–168. [Google Scholar] [CrossRef] [Green Version]

- Oorts, K.; Nicolardot, B.; Merckx, R.; Richard, G.; Boizard, H. C and N mineralization of undisrupted and disrupted soil from different structural zones of conventional tillage and no-tillage systems in northern France. Soil Biol. Biochem. 2006, 38, 2576–2586. [Google Scholar] [CrossRef]

- Marques, L.; Bianco, S.; Filho, A.; Bianco, M.; Lopes, G. Weed interference in eggplant crops. Rev. Caatinga 2017, 30, 866–875. [Google Scholar] [CrossRef] [Green Version]

- Sen, S.; Sharma, R.; Kushwah, S.; Dubey, R. Effect of different weed management practices on growth and yield of cauliflower (Brassica oleracea var. botrytis L.). Ann. Plant Soil Res. 2018, 20, 63–68. [Google Scholar]

- Mainardis, M.; Boscutti, F.; Cebolla, M.d.R.; Pergher, G. Comparison between flaming, mowing and tillage weed control in the vineyard: Effects on plant community, diversity and abundance. PLoS ONE 2020, 15, e0238396. [Google Scholar] [CrossRef]

- Abou Chehade, L.; Antichi, D.; Martelloni, L.; Frasconi, C.; Sbrana, M.; Mazzoncini, M.; Peruzzi, A. Evaluation of the Agronomic Performance of Organic Processing Tomato as Affected by Different Cover Crop Residues Management. Agronomy 2019, 9, 504. [Google Scholar] [CrossRef] [Green Version]

- Melander, B.; Liebman, M.; Davis, A.S.; Gallandt, E.R.; Bàrberi, P.; Moonen, A.C.; Rasmussen, J.; van der Weide, R.; Vidotto, F. Non-Chemical Weed Management. Thermal Weed Control. In Weed Research. Expanding Horizons, 1st ed.; Hatcher, P.E., Froud-Williams, R.J., Eds.; John Wiley & Sons Ltd.: Oxford, UK, 2017; pp. 259–264. [Google Scholar]

- Martelloni, L.; Frasconi, C.; Sportelli, M.; Fontanelli, M.; Raffaelli, M.; Peruzzi, A. Flaming, glyphosate, hot foam and nonanoic acid for weed control: A comparison. Agronomy 2020, 10, 128. [Google Scholar] [CrossRef] [Green Version]

- Lai, R. Managing Soils for Food Security and Climate Change. J. Crop Improv. 2007, 19, 49–71. [Google Scholar] [CrossRef]

- Diacono, M.; Ciaccia, C.; Canali, S.; Fiore, A.; Montemurro, F. Assessment of agro-ecological service crop managements combined with organic fertilisation strategies in organic melon crop. Ital. J. Agron. 2018, 13, 172–182. [Google Scholar] [CrossRef] [Green Version]

- Sportelli, M.; Fontanelli, M.; Pirchio, M.; Frasconi, C.; Raffaelli, M.; Caturegli, L.; Magni, S.; Volterrani, M.; Peruzzi, A. Robotic Mowing of Tall Fescue at 90 mm Cutting Height: Random Trajectories vs. Systematic Trajectories. Agronomy 2021, 11, 2567. [Google Scholar] [CrossRef]

- Bergtold, J.S.; Ramsey, S.; Maddy, L.; Williams, J.R. A review of economic considerations for cover crops as a conservation practice. Renew. Agric. Food Syst. 2019, 34, 62–76. [Google Scholar] [CrossRef]

- Gagliardi, L.; Sportelli, M.; Frasconi, C.; Pirchio, M.; Peruzzi, A.; Raffaelli, M.; Fontanelli, M. Evaluation of Autonomous Mowers Weed Control Effect in Globe Artichoke Field. Appl. Sci. 2021, 11, 11658. [Google Scholar] [CrossRef]

| Operation | Number of Operations | Plots | ||||

|---|---|---|---|---|---|---|

| Year 1 * | Year 2 ** | TILL | LM-FL | LM-AM | ||

| Seed-bed preparation and cover crop establishment | Tillage 25 cm (combined cultivator) | 1 | 1 | ✓ | ✓ | ✓ |

| Tillage 15 cm (rotary hoe) | 1 | 1 | ✓ | ✓ | ✓ | |

| Cover crop hand seeding | 1 | 1 | - | ✓ | ✓ | |

| rolling (compacting roller) | 1 | 1 | - | ✓ | ✓ | |

| Weed control treatments | Autonomous mower installation | 1 | 1 | - | - | ✓ |

| Weed control (backpack flaming machine) | 4 | 4 | - | ✓ | - | |

| Weed control (cultivation at 4–5 cm of depth) | 4 | 4 | ✓ | - | - | |

| Crop transplantation and harvest | Vegetable transplantation | 2 | 2 | ✓ | ✓ | ✓ |

| Cauliflower harvesting | 1 | 1 | ✓ | ✓ | ✓ | |

| Eggplant harvesting | 5 | 5 | ✓ | ✓ | ✓ | |

| Species | Botanical Family | BG 1 | Life Cycle | Cauliflower | Eggplant | ||||

|---|---|---|---|---|---|---|---|---|---|

| LM-AM | LM-FL | TILL | LM-AM | LM-FL | TILL | ||||

| Chenopodium album L. | Chenopodiaceae | T | annual | 0.08 | 0.07 | 0.13 | 0.19 | 0.04 | 0.16 |

| Amaranthus retroflexus L. * | Amaranthaceae | T | annual | 0.02 | 0.17 | 0.14 | 0.04 | 0.24 | 0.10 |

| Digitaria sanguinalis (L.) Scop. | Poaceae | T | annual | 0.16 | 0.11 | 0.07 | 0.17 | 0.12 | 0.10 |

| Echinochloa crus-galli (L.) P. Beauv | Poaceae | T | annual | 0.06 | 0.10 | 0.13 | 0.01 | 0.03 | 0.09 |

| Cyperus spp. * | Cyperaceae | G | perennial | 0.02 | 0.02 | 0.11 | 0.02 | 0.02 | 0.04 |

| Cynodon dactylon (L.) Pers. | Poaceae | G | perennial | 0.17 | 0.03 | 0.06 | 0.01 | 0.01 | 0.19 |

| Lysimachia arvensis (L.) U. Manns and Anderb. | Primulaceae | T | annual | - | - | - | - | 0.01 | 0.01 |

| Schedonorus arundinaceus (Schreb.) Dumort | Poaceae | H | perennial | - | - | - | - | 0.01 | 0.01 |

| Veronica persica Poir * | Plantaginaceae | T | annual | - | 0.02 | 0.02 | - | - | - |

| Paspalum spp. * | Poaceae | G | perennial | 0.17 | 0.05 | 0.01 | 0.34 | 0.12 | 0.04 |

| Fumaria officinalis L. | Papaveraceae | T | annual | - | 0.01 | 0.01 | - | 0.03 | 0.01 |

| Setaria italica subsp. viridis (L.) Thell. | Poaceae | T | annual | 0.02 | 0.15 | - | 0.09 | 0.04 | - |

| Verbena officinalis L. | Verbenaceae | H | perennial | 0.04 | 0.01 | - | - | - | - |

| Portulaca oleracea L. s.l. | Portulacaceae | T | annual | - | 0.02 | 0.11 | - | 0.01 | 0.03 |

| Poa annua L. | Poaceae | T | annual | 0.26 | 0.05 | 0.06 | 0.09 | 0.01 | 0.03 |

| Solanum nigrum L. | Solanaceae | T | annual | - | 0.04 | 0.05 | - | 0.07 | - |

| Rumex spp. | Polygonaceae | H | perennial | - | 0.05 | 0.02 | - | 0.11 | 0.02 |

| Stellaria media (L.) Vill. | Caryophyllaceae | T | annual | - | - | 0.01 | - | - | 0.01 |

| Geranium molle L. | Geraniaceae | T | annual | - | - | - | - | - | 0.01 |

| Ranunculus repens L. | Ranunculaceae | H | perennial | - | - | 0.03 | - | - | 0.05 |

| Erigeron canadensis L. * | Asteraceae | T | annual | - | - | - | - | 0.01 | - |

| Symphyotrichum squamatum (Spreng.) G.L. Nesom * | Asteraceae | T | annual | - | - | - | 0.02 | 0.01 | - |

| Senecio vulgaris L. | Asteraceae | T | annual | - | - | 0.03 | - | - | 0.06 |

| Cardamine hirsuta L. | Brassicaceae | T | annual | - | - | - | - | 0.02 | 0.01 |

| Artemisia vulgaris L. | Asteraceae | H | perennial | - | - | - | 0.02 | - | - |

| Hypochaeris radicata L. | Asteraceae | H | perennial | - | - | - | - | - | 0.01 |

| Plantago lanceolata L. | Plantaginaceae | H | perennial | - | 0.07 | - | - | 0.06 | - |

| Plantago major L. | Plantaginaceae | H | perennial | - | 0.03 | 0.01 | - | 0.03 | 0.01 |

| Subtotals | LM-AM | LM-FL | TILL | LM-AM | LM-FL | TILL | |||

| Percentage of therophytes (%) | 0.60 | 0.74 | 0.76 | 0.60 | 0.64 | 0.62 | |||

| Percentage of hemicryptophytes (%) | 0.04 | 0.16 | 0.06 | 0.02 | 0.21 | 0.10 | |||

| Percentage of geophytes (%) | 0.36 | 0.10 | 0.18 | 0.37 | 0.15 | 0.27 | |||

| Percentage of annual (%) | 0.60 | 0.74 | 0.76 | 0.60 | 0.64 | 0.62 | |||

| Percentage of perennial (%) | 0.40 | 0.26 | 0.24 | 0.39 | 0.36 | 0.37 | |||

| Field | d | e | Effective Time (h) | ||

|---|---|---|---|---|---|

| ET30 | ET60 | ET90 | |||

| obstacles * | 108.59 (9.73) | 222.42 (29.76) | 1.32 (0.18) | 3.40 (0.46) | 8.54 (1.14) |

| obstacle-free ** | 99.43 (0.92) | 56.59 (1.79) | 0.34 (0.01) | 0.86 (0.03) | 2.17 (0.07) |

| Parameter | Operation | TILL | LM-FL | LM-AM |

|---|---|---|---|---|

| Primary energy consumption (kWh ha−1) | Seed-bed preparation and CC establishment | 1222.79 (±37.16) | 770.64 (±20.18) | 771.11 (±25.52) |

| Weed control treatments | 1975.57 (±95.44) | 7353.32 (±124.71) | 97.47 (±0.40) | |

| Total | 3198.37 (±132.60) | 8123.96 (±144.89) | 868.58 (±25.92) | |

| CO2 emission equivalents (kg ha−1) | Seed-bed preparation and CC establishment | 324.04 (±9.85) | 204.22 (±5.35) | 204.34 (±6.76) |

| Weed control treatments | 523.53 (±25.29) | 22,133.49 (±375.38) | 32.36 (±0.13) | |

| Total | 847.57 (±35.14) | 22,337.71 (±380.70) | 236.70 (±6.90) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sportelli, M.; Frasconi, C.; Fontanelli, M.; Pirchio, M.; Gagliardi, L.; Raffaelli, M.; Peruzzi, A.; Antichi, D. Innovative Living Mulch Management Strategies for Organic Conservation Field Vegetables: Evaluation of Continuous Mowing, Flaming, and Tillage Performances. Agronomy 2022, 12, 622. https://doi.org/10.3390/agronomy12030622

Sportelli M, Frasconi C, Fontanelli M, Pirchio M, Gagliardi L, Raffaelli M, Peruzzi A, Antichi D. Innovative Living Mulch Management Strategies for Organic Conservation Field Vegetables: Evaluation of Continuous Mowing, Flaming, and Tillage Performances. Agronomy. 2022; 12(3):622. https://doi.org/10.3390/agronomy12030622

Chicago/Turabian StyleSportelli, Mino, Christian Frasconi, Marco Fontanelli, Michel Pirchio, Lorenzo Gagliardi, Michele Raffaelli, Andrea Peruzzi, and Daniele Antichi. 2022. "Innovative Living Mulch Management Strategies for Organic Conservation Field Vegetables: Evaluation of Continuous Mowing, Flaming, and Tillage Performances" Agronomy 12, no. 3: 622. https://doi.org/10.3390/agronomy12030622

APA StyleSportelli, M., Frasconi, C., Fontanelli, M., Pirchio, M., Gagliardi, L., Raffaelli, M., Peruzzi, A., & Antichi, D. (2022). Innovative Living Mulch Management Strategies for Organic Conservation Field Vegetables: Evaluation of Continuous Mowing, Flaming, and Tillage Performances. Agronomy, 12(3), 622. https://doi.org/10.3390/agronomy12030622